Nylon 66 alloy and preparation method thereof

A nylon and alloy technology, applied in the field of polymer composite materials, can solve the problems of increased material density and poor mechanical properties of materials, and achieve the effects of low density, excellent performance and excellent electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

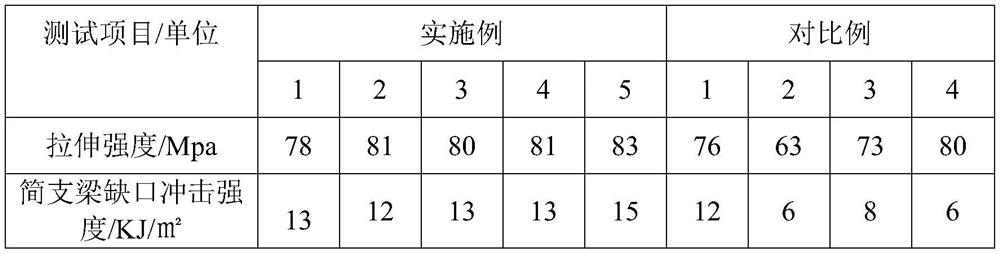

Examples

Embodiment 1

[0026] (1) The polyaniline is soaked in 3 times the weight of tetrahydrofuran solvent for 5 minutes, filtered, and dried to obtain pretreated polyaniline for use.

[0027] (2) Dissolving nylon 66 salt in water to obtain a nylon 66 salt solution with a mass fraction of 55%; adding 100 parts of nylon 66 salt solution to the reaction kettle, then adding 0.5 parts of adipic acid and 10 parts of pretreated polyaniline. The temperature of the reaction kettle is set at 220°C, the pressure is 1.5MPA, and the pressure is maintained for 1 hour. After opening the exhaust valve to exhaust to normal pressure, add 0.5 parts of antioxidant 1098 and 0.5 parts of antioxidant 168, the vacuum pressure gauge is negative 0.1MPA, the temperature is set at 260 °C, maintain for 30 minutes, discharge and pelletize, That is, the final product is obtained.

Embodiment 2

[0029] (1) The polyaniline was soaked in 3 times the weight of tetrahydrofuran solvent for 10 minutes, filtered, and dried to obtain pretreated polyaniline for use.

[0030] (2) Dissolving nylon 66 salt in water to obtain a nylon 66 salt solution with a mass fraction of 65%; adding 100 parts of nylon 66 salt solution to the reactor, adding 1 part of adipic acid and 15 parts of pretreated polyaniline. The temperature of the reaction kettle is set at 240°C, the pressure is 2MPA, and the pressure is maintained for 2 hours. After opening the exhaust valve to exhaust to normal pressure, add 1 part of antioxidant 1098 and 1 part of antioxidant 168, the vacuum pressure gauge is minus 0.2MPA, the temperature is set at 270°C, maintain for 60 minutes, discharge and pelletize, That is, the final product is obtained.

Embodiment 3

[0032] (1) The polyaniline was soaked in 3 times the weight of tetrahydrofuran solvent for 8 minutes, filtered, and dried to obtain pretreated polyaniline for use.

[0033] (2) Nylon 66 salt was dissolved in water to obtain a nylon 66 salt solution with a mass fraction of 62%; 100 parts of nylon 66 salt solution was added to the reactor, and then 0.8 parts of adipic acid and 12 parts of pretreated polyaniline were added. The temperature of the reaction kettle was set at 230°C, the pressure was 1.8MPA, and the pressure was maintained for 1.5 hours. After opening the exhaust valve to exhaust to normal pressure, add 0.8 parts of antioxidant 1098 and 0.8 parts of antioxidant 168, the vacuum pressure gauge is negative 0.15MPA, the temperature is set at 265°C, maintain for 45 minutes, discharge and pelletize, That is, the final product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com