Recovery treatment method for waste power battery powder

A technology for recycling and processing power batteries, which is applied in the field of recycling and processing waste power battery powder, can solve the problems of low lithium yield and high cost, and achieve the effects of high lithium leaching rate, low recycling cost, and easy acid leaching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

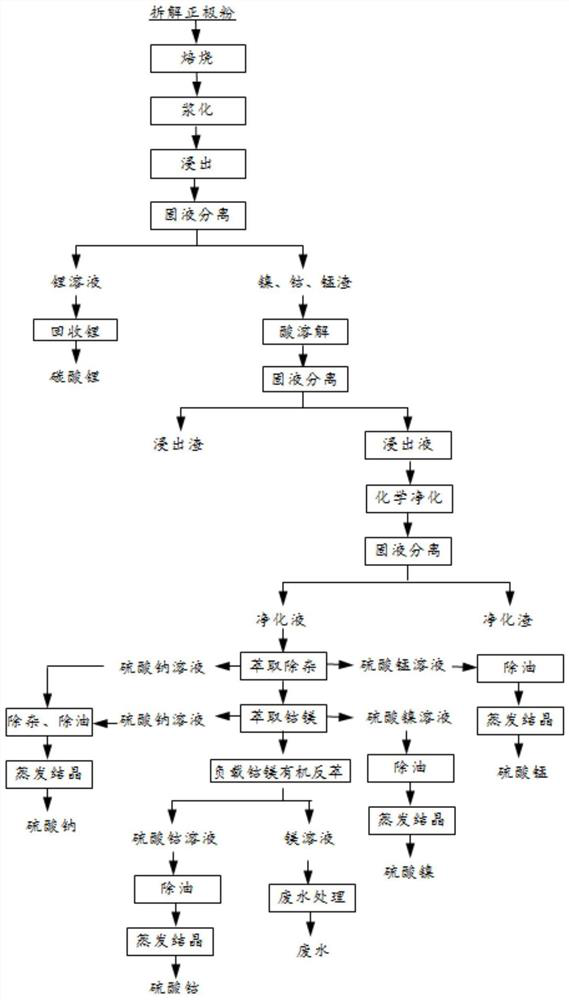

[0046] The recycling method of waste power battery powder, the process is as follows figure 1 shown, including the following steps:

[0047] S1: reducing and roasting the waste power battery powder to obtain reduced and roasted battery powder;

[0048] S2: Dissolving and filtering the battery powder treated in step S1 to obtain a filtrate and a filter residue, passing carbon dioxide into the filtrate, separating the formed precipitate from solid and liquid, and drying to obtain lithium carbonate;

[0049]S3: adding sulfuric acid to the filter residue in step S2, and leaching to obtain a solution containing nickel, cobalt and manganese;

[0050] S4: Extract the solution containing nickel, cobalt and manganese obtained in step S3 with P204 to obtain a sodium-containing stripping solution, a manganese-containing stripping solution, a zinc-aluminum-containing stripping solution, and a cobalt-containing magnesium-nickel stripping solution;

[0051] S5: Extract the manganese-conta...

Embodiment 2

[0058] This example adopts the method of embodiment 1 to the waste power battery powder, and the subdivision particle size 180 order passing rate is greater than 95%, the waste and old ternary power battery of dismantling, as the nickel-containing, the nickel that the battery of electric vehicle, the battery of electric tool etc. are produced Both cobalt and manganese waste power battery powder can be recycled by this method, the process is as follows figure 1 As shown, the specific situation is

[0059] 1. Production of lithium carbonate

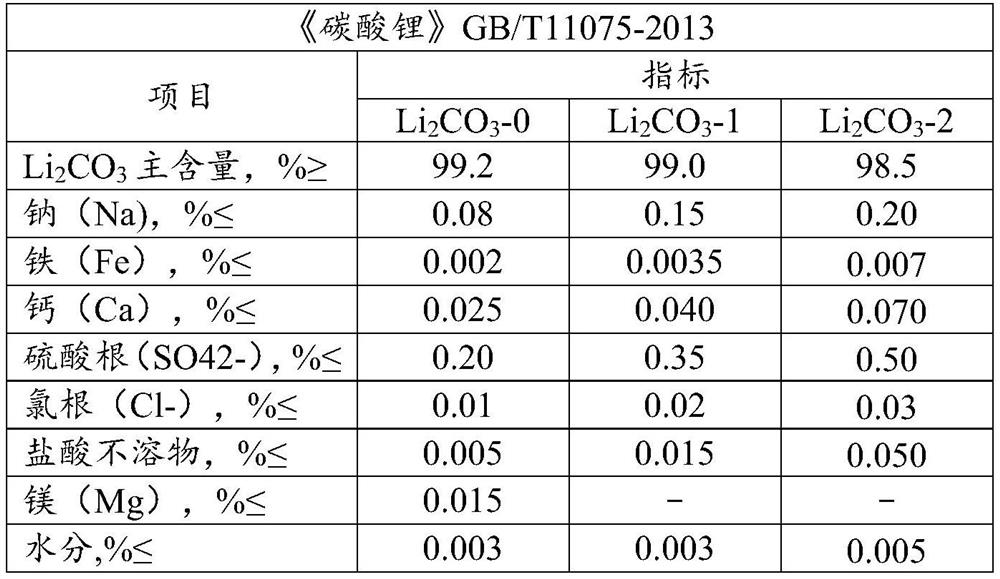

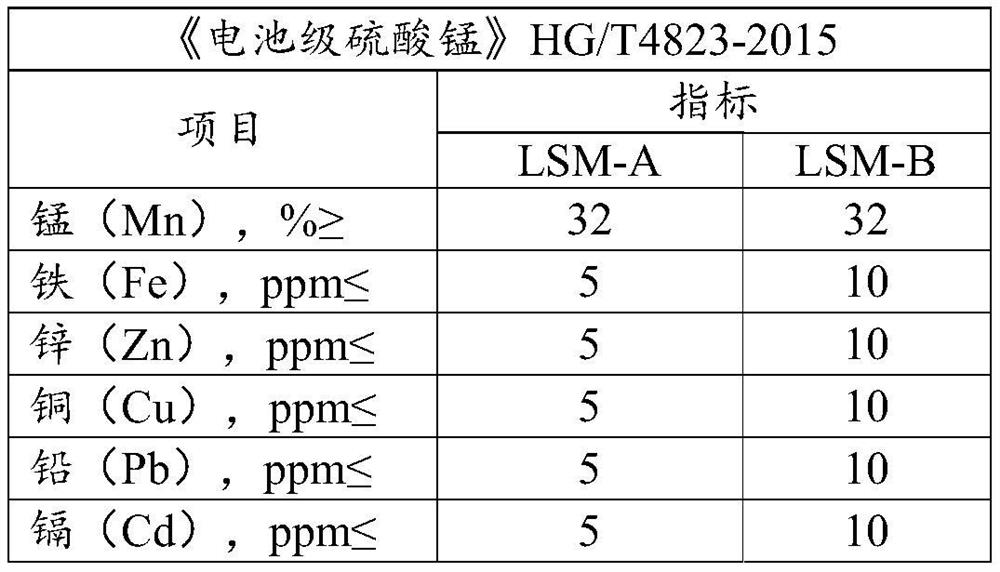

[0060] The reduced battery powder is leached, and the Li in the leaching solution reaches about 20-30g / L. It can be cyclically leached, and the concentration of the leachate can be increased to Li: 50g / L. After the solution is purified, lithium carbonate is synthesized, and solid lithium carbonate is obtained after solid-liquid separation of lithium carbonate. Lithium carbonate is obtained through drying, metering and packaging. The quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com