Method for controlling deviation of intermediate billet of coil box

A hot coil box and deviation technology, applied in the field of hot rolled steel, can solve the problems of coiling tower shape and uncoil deviation of the hot coil box, achieve stable production improvement, strong applicability, and solve the failure of intermediate coil coiling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

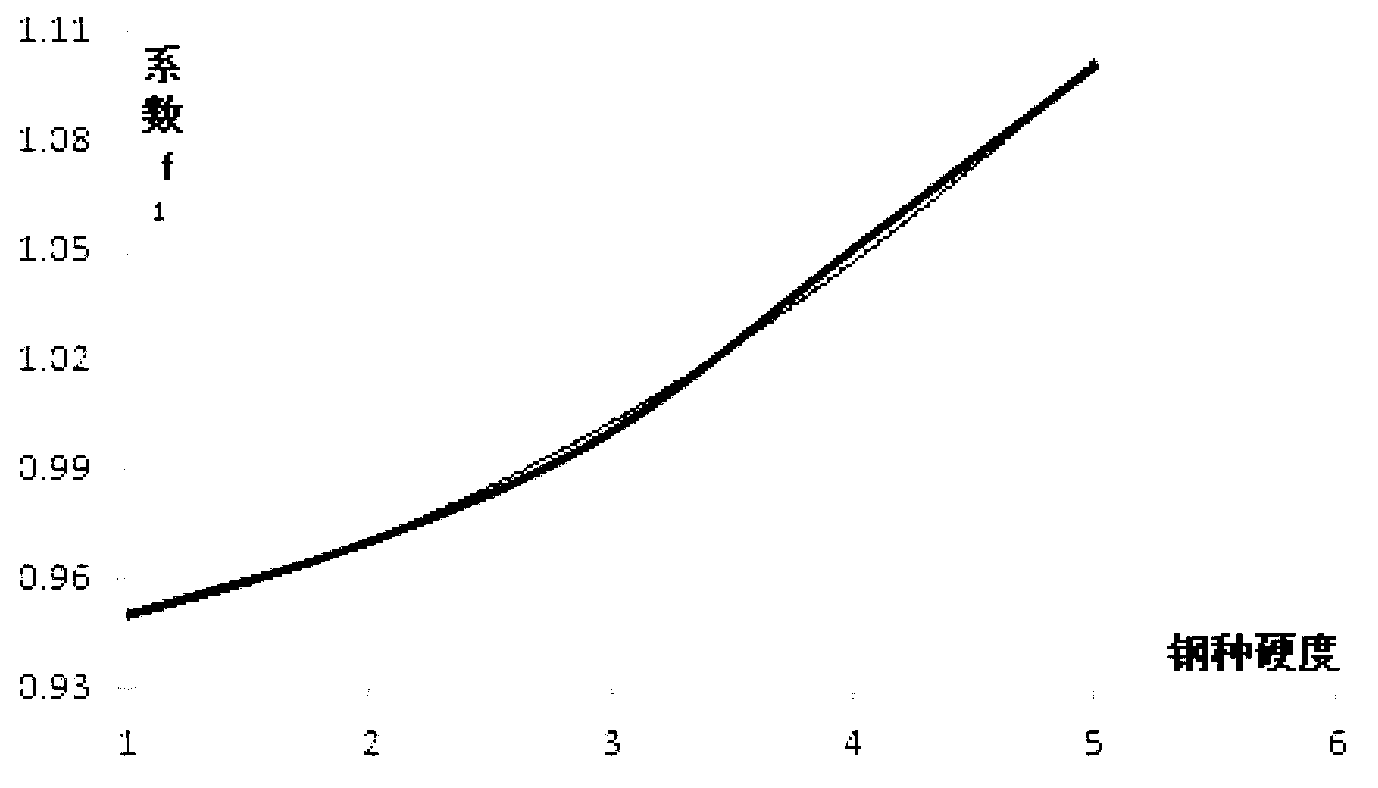

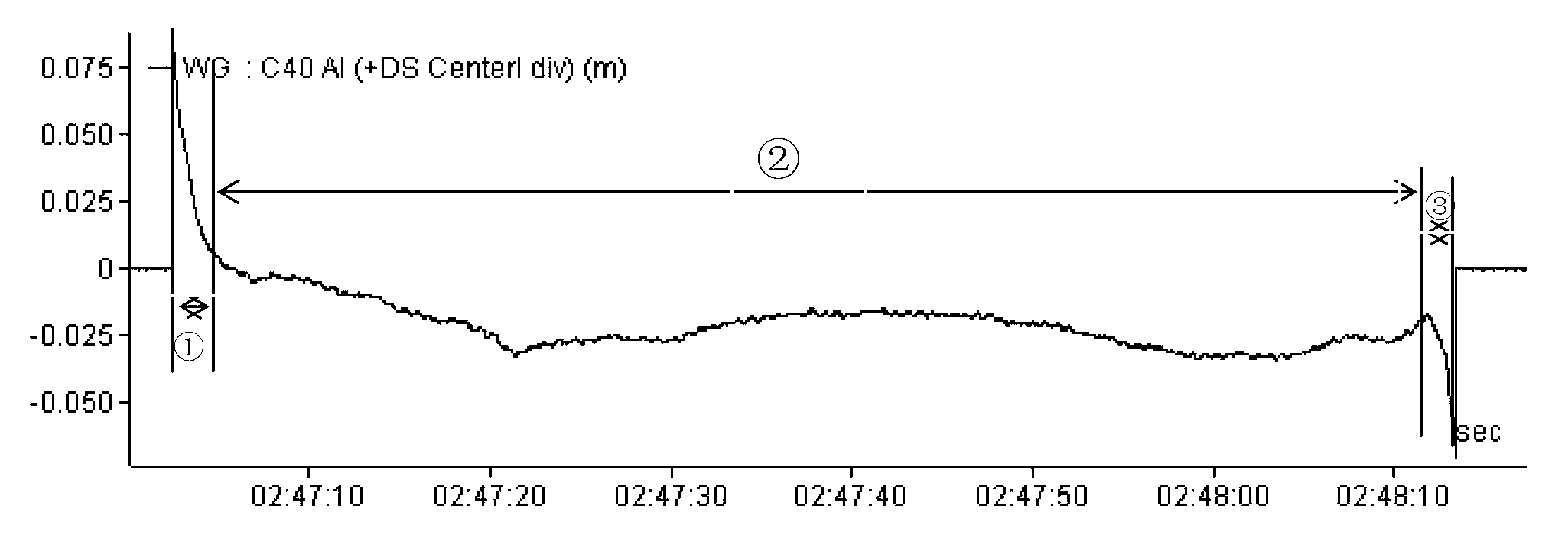

[0027] see figure 1 , a method for controlling the deviation of the middle billet of the hot coil box provided by the embodiment of the present invention. The specific implementation time is April 25, 2012. The middle billet enters the bending roller unit from the entrance side guide plate and the entrance roller unit in turn, and the middle billet The billet is bent to form a strip blank, and the strip blank passes through the forming roller of the coiling station and the first roller in turn, so that the strip blank is rolled into a coil, and the coil is uncoiled by the uncoiling station and transferred to the coil. After the straight rolls are leveled by pinch straightening rolls, they are sent to the finishing rolling unit through the front side guide plate of the flying shear for rolling.

[0028] The three-roll bending roll unit of the coiling station bends the intermediate billet to a certain curvature, and forms a three-roll coiling with the forming roll and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com