Variable water ratio control method of secondary cooling of billet caster

A technology of secondary cooling and control method, which is applied in the control field of continuous casting cooling of slabs, can solve problems such as the influence of production equipment, steel breakout, restrictions, etc., so as to reduce the internal crack rate of slabs, simple and convenient operation, and improve enterprise economy. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

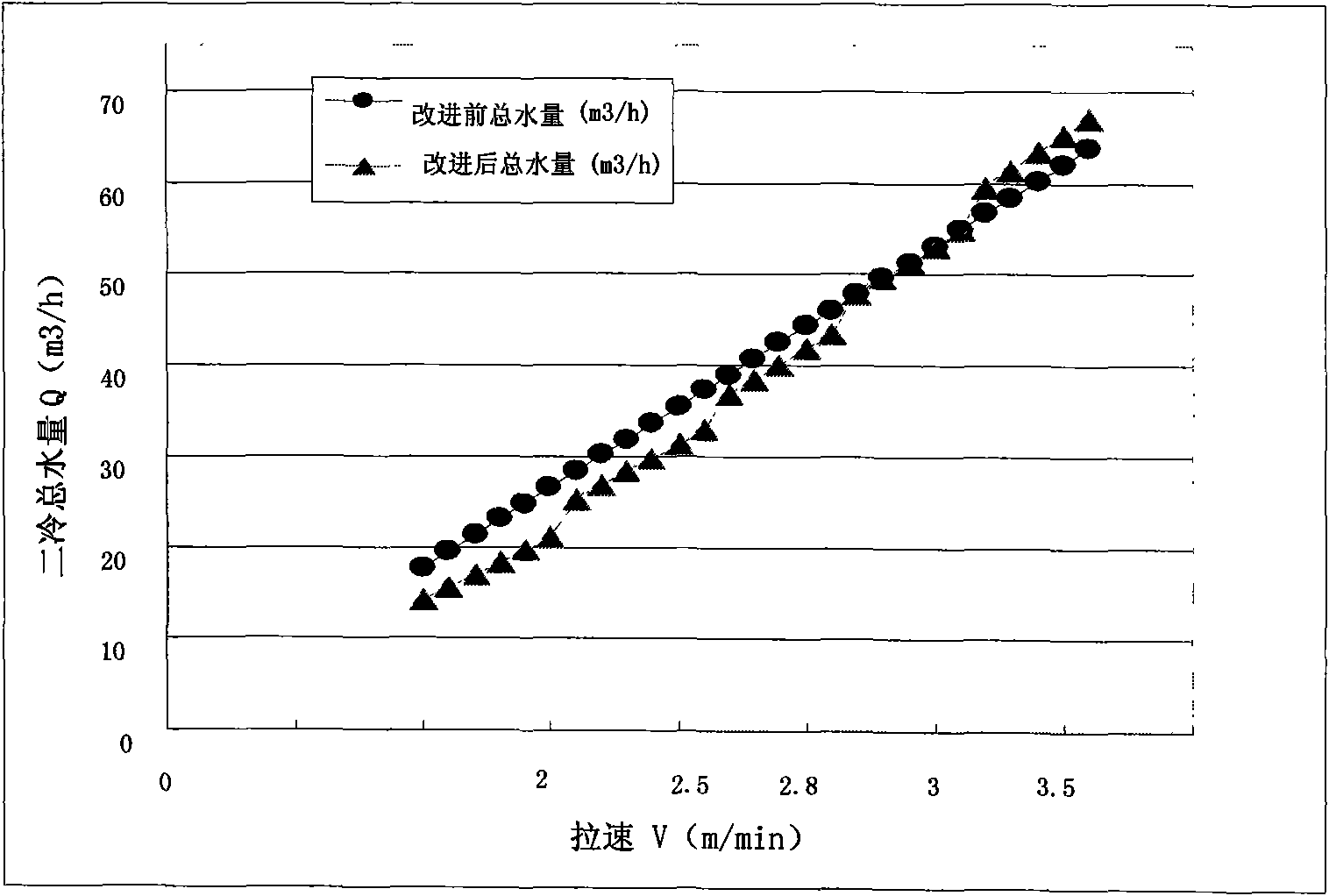

[0041] A variable-ratio water control method for secondary cooling of a billet continuous caster. Taking the production of HPB235 steel slabs by this method as an example, the control method is to make the specific water δ and the total water Q increase with the increase of the slab casting speed V And correspondingly increase in segments; that is,

[0042] When the billet casting speed V=1m / min, the specific water quantity δ is 1.37L / kg, and the functional relationship between the total secondary cooling water quantity Q and the billet casting speed V is: Q=14.1V=14.1m 3 / h;

[0043] When the billet casting speed is between V=2m / min, the specific water amount δ is 1.63L / kg, and the functional relationship between the total secondary cooling water Q and the billet casting speed V is: Q=16.7V=33.4m 3 / h;

[0044]When the billet casting speed is between V=2.4m / min, the specific water amount δ is 1.69L / kg, and the functional relationship between the total secondary cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com