Patents

Literature

39results about How to "Reduce cracking rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

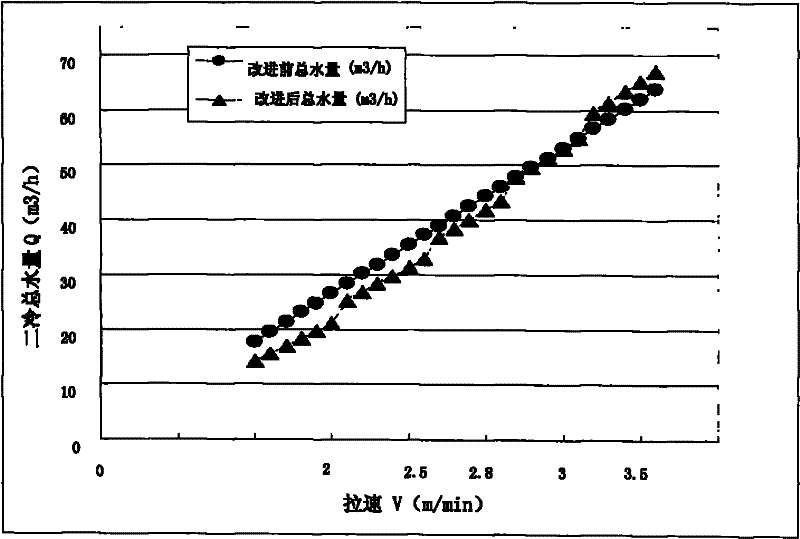

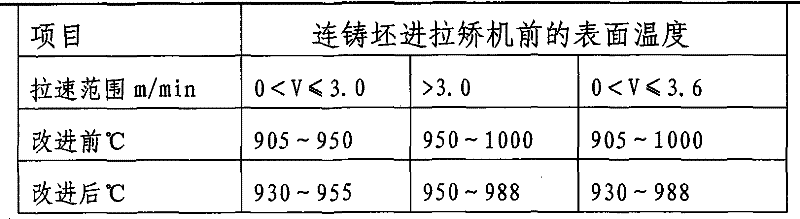

Variable water ratio control method of secondary cooling of billet caster

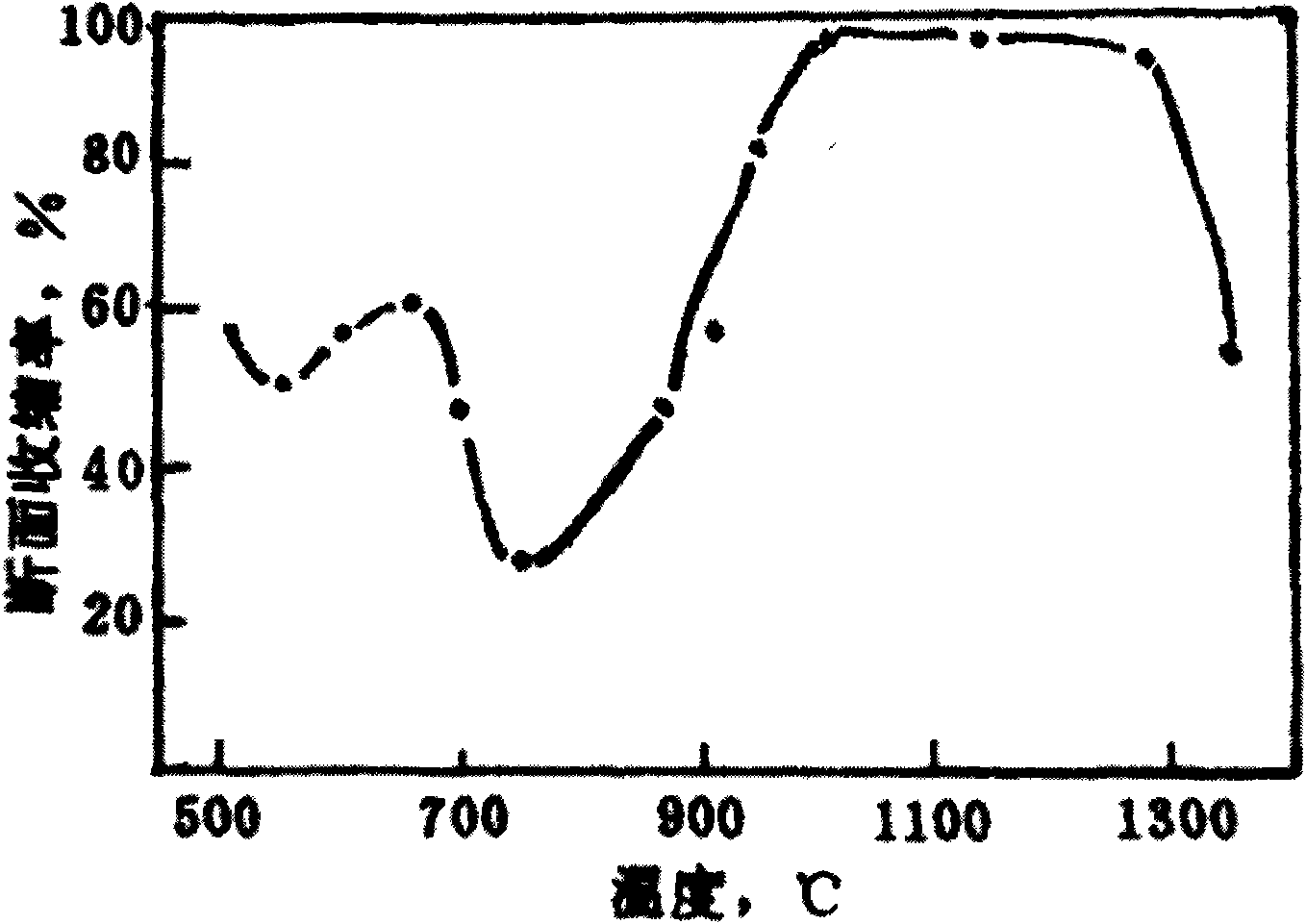

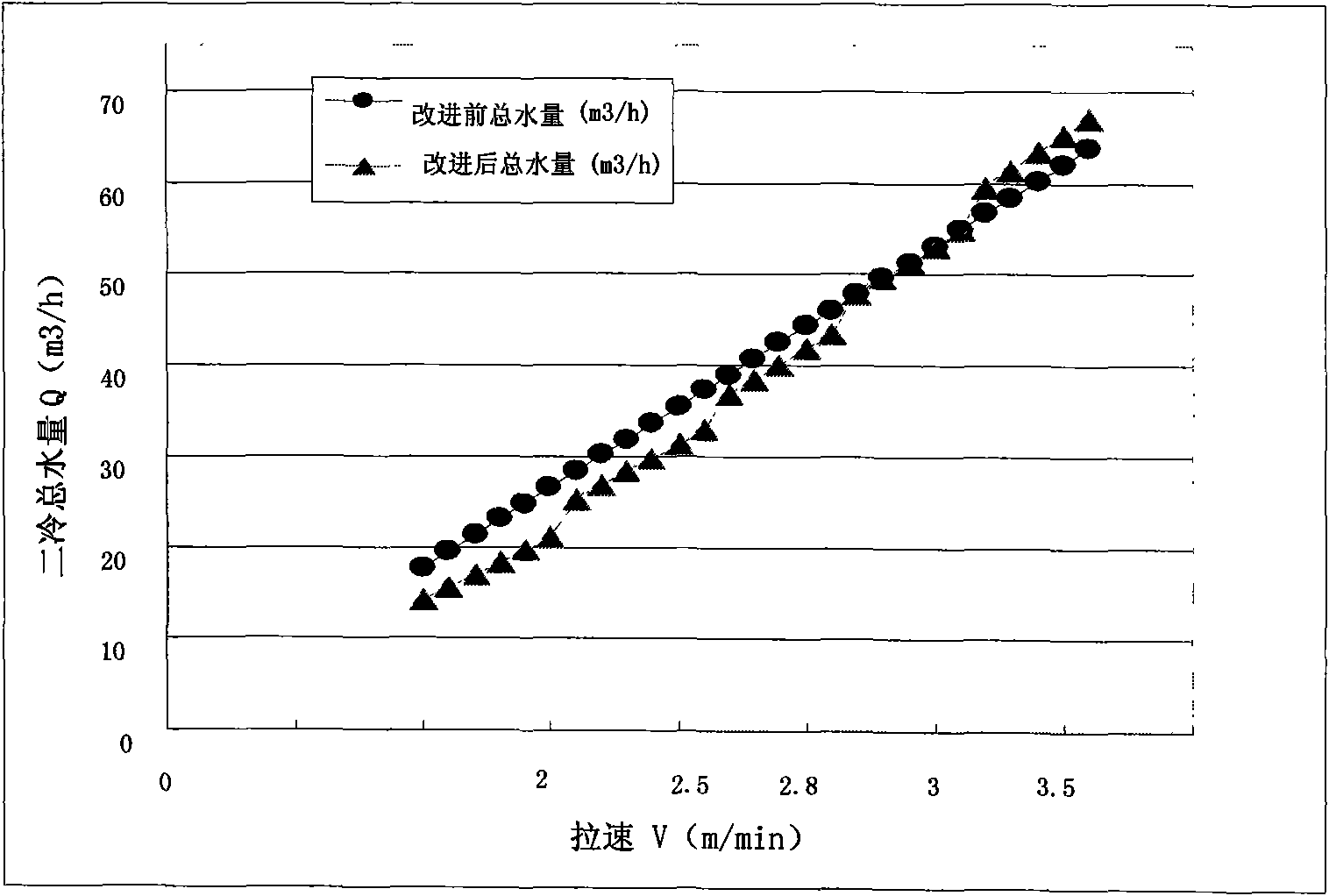

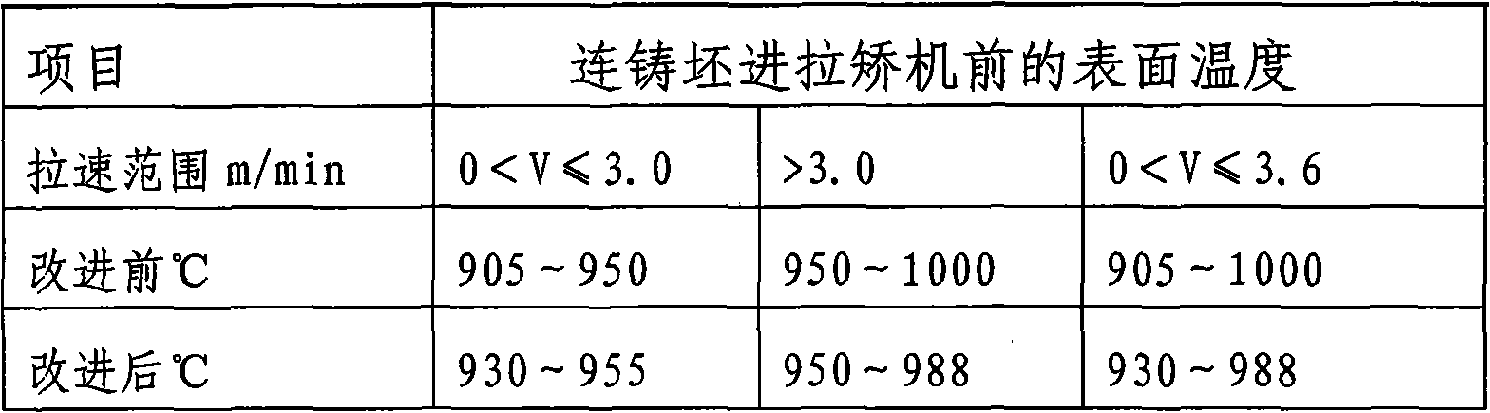

The invention discloses a variable water ratio control method of the secondary cooling of a billet caster which can reduce the inner crack rate of casting blanks. The control method can realize that the water flow rate delta and the total amount of water Q increase by stages with the increasing of the casting speed V of casting blanks, namely when the casting speed V of casting blanks is 0-2m / min,the water flow rate delta is 1.35-1.39L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 13.8-14.3V; when the casting speed V of casting blanks is 2-2.4m / min, the water flow rate delta is 1.58-1.64L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 16.2-16.8V; when the casting speed V of casting blanks is 2.4-2.8m / min, the water flow rate delta is 1.67-1.71L / kg, the functional relationship between the secondary cooling totalamount of water Q and the casting speed V of casting blanks is Q = 17.1-17.5V; when the casting speed V of casting blanks is 2.8-3.0m / min, the water flow rate delta is 1.73-1.76L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 17.7-18.1V; and when the casting speed V of casting blanks is 3.0-3.6m / min, the waterflow rate delta is 1.8-1.86L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 18.5-19.1V.

Owner:XINJIANG BAYI IRON & STEEL

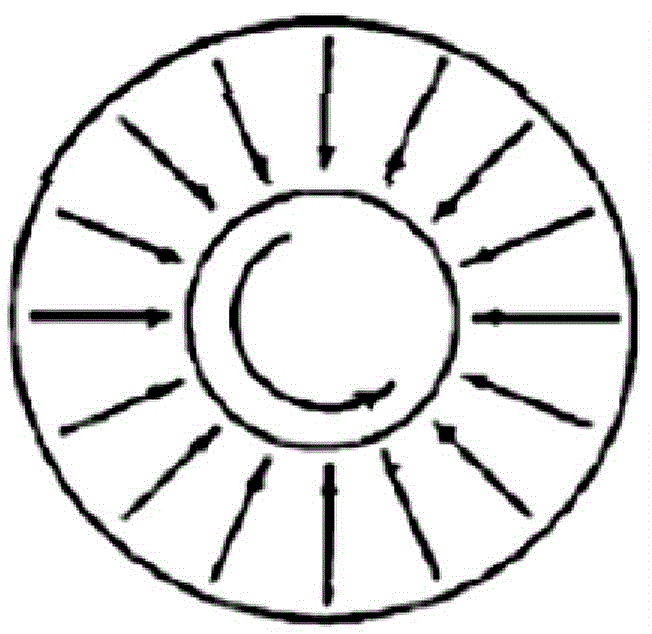

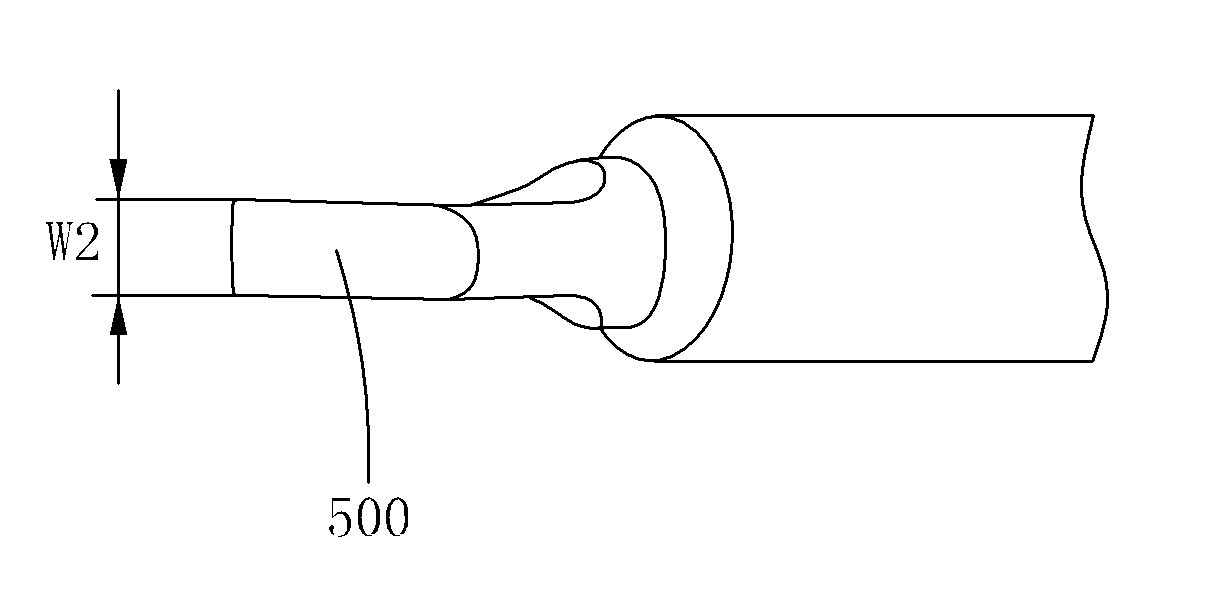

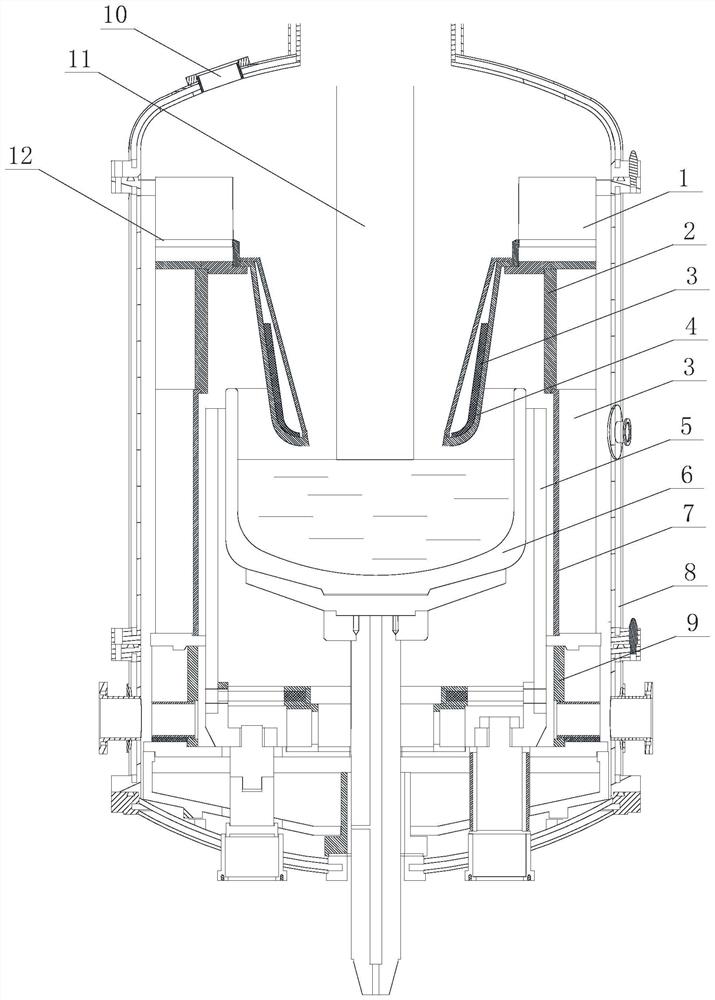

Rotating shoulder-expanding stable pulling-up method for large-kilogram sapphire crystals

ActiveCN104099660AImprove thermal field unevennessImprove the shortcomings of unstable molten soup streamlinePolycrystalline material growthBy pulling from meltSeed crystalSapphire

The invention discloses a rotating shoulder-expanding stable pulling-up method for large-kilogram sapphire crystals. The method comprises the steps as follows: heating for material melting to enable the raw materials to be just melted and enable the temperature of the melted material to be close to a melting point; lowering a crystalline style, and preheating a seed crystal mounted below the crystalline style; measuring temperature to adjust and control the temperature of the melted material to a crystal growth temperature; seeding, to be specific, placing the clean seed crystal above liquid level in a standing manner to enable the surface of the seed crystal to melt, rotating the crystalline style, and actuating the seeding process after an artificial cold-core is formed; actuating an automatic shoulder-expanding procedure, lifting the crystalline style at uniform speed, adjusting the power of a heater to lower the temperature gradually, at the same time, keeping the rotation of the crystalline style, stopping rotation when the weight of the crystal reaches 5 kg, enabling the rotating speed of the crystalline style to gradually decrease by stages when the weight of the crystal is 0-5 kg; actuating an automatic growing procedure when the weight of the crystal reaches 10 kg, lifting the crystalline style at uniform speed, adjusting the power of the heater to lower the temperature gradually; finally, separating, cooling, and taking out the crystal, so that the whole crystal growing process is completed. Through the method provided by the invention, the seeding and shoulder-expanding method in the prior art are improved, and the finished product rate as well as the yield are improved.

Owner:SUNPHIRE OPT TRONIC

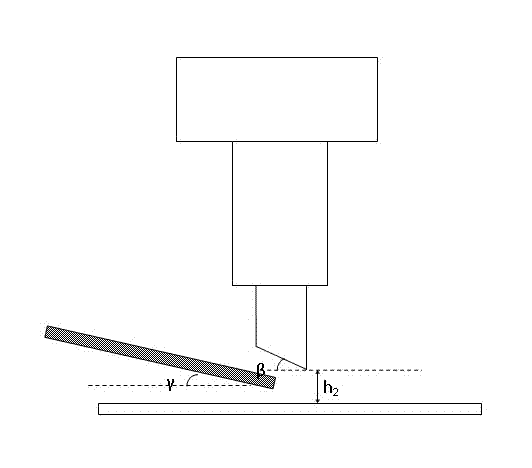

Preparation method for back electrode of solar battery

ActiveCN104752554ALow costAvoid Ultrasonic Vibration DevicesFinal product manufacturePhotovoltaic energy generationElectrical batteryPhotoelectric efficiency

The invention discloses a preparation method for a back electrode of a solar battery. The preparation method includes that using soldering flux to form a soldering flux belt at the surface of an aluminum back field, forming a non-silver metal solder belt at the surface of the soldering flux belt, wherein the soldering flux belt can break an alumina film at the surface of the aluminum back field to expose fresh aluminum from the surface of the aluminum back field, the subsequently fed non-silver metal wires (solder) are melted by the heat effect of a soldering head, the molten liquid fuses with the aluminum, the molten solder is well bonded at the surface of the aluminum back field, the silver use is avoided, the cost is lowered, an ultrasonic vibration device is not used, the intensity of a finished product is obviously improved, fragment and crack are obviously reduced, and the quality of the back electrode of the solar battery is greatly improved. The back electrode of the solar battery prepared by the preparation method is low in fragment and crack rate, the adhesion between the back electrode and aluminum back field is strong, the welding with a photovoltaic soldering belt is good, the average photoelectric efficiency conforms to requirement, and the manufacturing cost is low.

Owner:BYD CO LTD

Preparation method of earthen ink-stone tea tray

The invention discloses a preparation method of an earthen ink-stone tea tray. The method comprises the following steps: stirring glue mud, kaolin and clay in water according to a certain mass part ratio to form slurry, filtering the slurry, and kneading and flapping the filtered slurry to prepare mud pie; putting the mud pie into an ink-stone tea tray mould to prepare a blank, and evaporating and airing the blank in the mould in the shade; and coarsely engraving, sintering by adopting a special process, and discharging from a kiln to obtain the earthen ink-stone tea tray. The preparation method has the beneficial effects that the prepared earthen ink-stone tea tray is not deformed, the cracking rate is low after the sintering process, the yield is more than 95%, and the purpose of making mud ink-stone into the tea tray is achieved; and the prepared earthen ink-stone tea tray has various advantages of clear mud ink-stone materials.

Owner:闫吉平

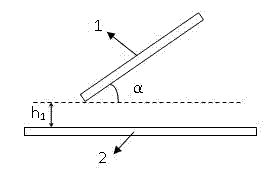

Method for cutting silicon wafer through low-particle electroplating gold wire

ActiveCN104441282AImprove cutting effectImprove pass rateFine working devicesVibration amplitudeEconomic benefits

The invention discloses a method for cutting a silicon wafer through a low-particle electroplating gold wire. The method includes the first step of bar adhesion, the second step of wire cutting, the third step of glue disengaging, the fourth step of wafer inserting, the fifth step of cleaning and the sixth step of verifying. According to the method, the silicon wafer is cut through the low-particle electroplating gold wire with a particle height of 6 microns to 12 microns; meanwhile, an existing production process is improved, the linear speed in the wire cutting step is increased, the steel wire feed and return distance is increased, the cooling temperature of cooling liquid is lowered; by means of the method, the abnormity, caused by the particle vibration amplitude generated by electroplating gold wire swinging, of the surface of the silicon wafer can be reduced, the cutting capacity of the low-particle electroplating gold wire can be reduced, it is ensured that the yield of the silicon wafer cut by the low-particle electroplating gold wire and the yield of the silicon wafer cut by an intermediate-particle electroplating gold wire are located at the same level, and the aims of increasing the silicon wafer yield, ensuring the high production efficiency and increasing the economic benefits are achieved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Watermelon plastic film full-mulching cultivation method

InactiveCN103329724AChange permeabilityChange physical and chemical propertiesClimate change adaptationPlant protective coveringsDiseaseCaladium

The invention discloses a watermelon plastic film full-mulching cultivation method. The watermelon plastic film full-mulching cultivation method comprises a first step of preparing a land and sowing laguminosae, a second step of evening the laguminosae, a third step of conducting irrigation and covering plastic film, and a fourth step of growing watermelon seedlings and conducting filed management. According to the watermelon plastic film full-mulching cultivation method, due to the fact that the land is fully covered by the two-color plastic film, the two-color plastic film has the effects of restraining weeds and avoiding aphids, the aphids and other insects are effectively prevented from spreading diseases, the land temperature inside a ridge is rapidly improved, and effective degradation of green manure plants is improved. Due to the fact that quick lime is applied, soil acidification can be effectively relieved, the calcium content of soil can be increased, and the rate of watermelon cracking in the watermelon mature period is reduced. Due to the fact that a layer of dry straw covers the plastic film arranged between every two ridges, moistures is absorbed, the dryness degree inside a green house is improved, fixation of watermelon vines is facilitated, and watermelon growth is facilitated. The incidence of fusarium wilt is reduced by 96% compared with that of the prior art. The quality of watermelons is remarkably improved. The sugar degree of each watermelon is increased by 1%-3%. The yield is increased by 200%-600% compared with that of the prior art.

Owner:ZHENJIANG SUIHAN AGRI

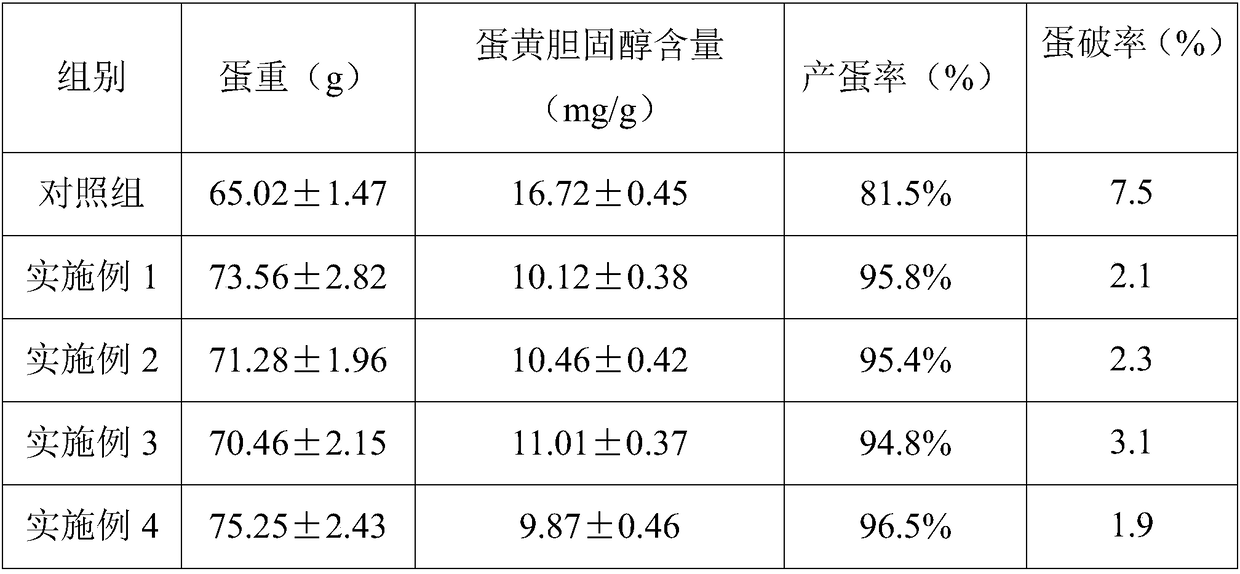

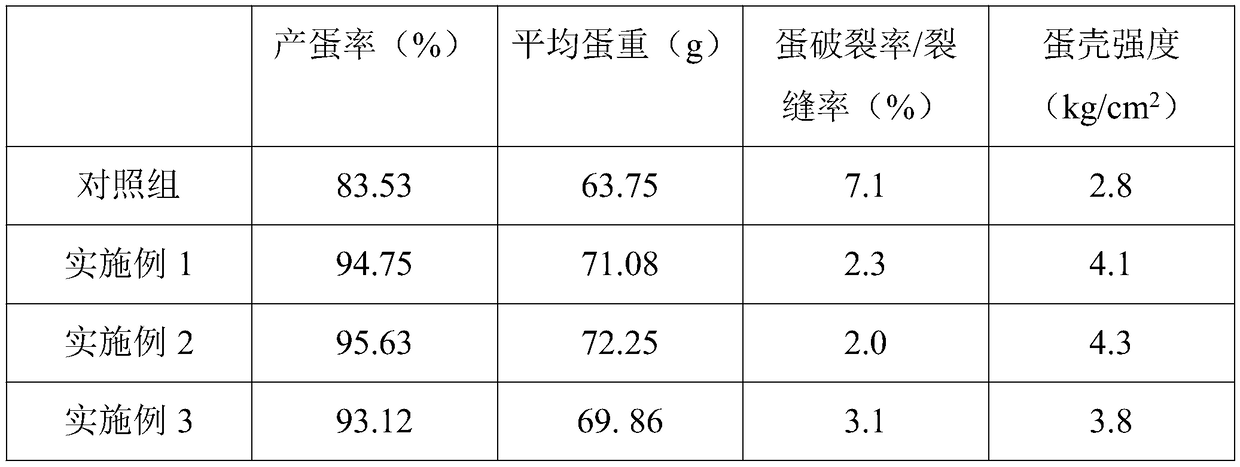

Monascorubrin pigment traditional Chinese medicine mixed protein ferment containing functional premix for laying chickens

The present invention discloses a monascorubrin pigment traditional Chinese medicine mixed protein ferment containing functional premix for laying chicken. The technological points are that based on 1000 parts as a total amount, the premix consists of 3-5 parts of laying chicken vitamin core materials, 40-60 parts of bile acids, 1 part of D-pantothenic acids, 1-3 parts of choline chloride, 130-170 parts of calcium hydrophosphate, 5-15 parts of methionine, 4-8 parts of lysine, 250-350 parts of corn fibers, 1-3 parts of phytase, 1-2 parts of copper sulfate pentahydrate, 13-17 parts of ferrous sulfate monohydrate, 13-14 parts of zinc sulfate monohydrate, 16-17 parts of manganese sulfate monohydrate, 3-5 parts of sodium sulfite, 1 part of potassium iodide, 1 part of an antioxidant, 70-80 parts of zeolite powder, and the balanced being monascorubrin pigment traditional Chinese medicine mixed protein ferment and rice chaffs. The monascorubrin pigment traditional Chinese medicine mixed protein ferment containing functional premix for the laying chickens which can increase the egg production rates of cage rearing chickens and domestic chickens, can enable the egg yolk to have natural pigments similar to free-range native chickens, can improve the egg shell hardness and chroma, and can improve egg quality are provided.

Owner:HANGZHOU BAOJI BIO TECH

Watermelon plastic film full coverage cultivation method

InactiveCN103329724BChange permeabilityChange physical and chemical propertiesClimate change adaptationPlant protective coveringsDiseasePlastic mulch

The invention discloses a watermelon plastic film full-mulching cultivation method. The watermelon plastic film full-mulching cultivation method comprises a first step of preparing a land and sowing laguminosae, a second step of evening the laguminosae, a third step of conducting irrigation and covering plastic film, and a fourth step of growing watermelon seedlings and conducting filed management. According to the watermelon plastic film full-mulching cultivation method, due to the fact that the land is fully covered by the two-color plastic film, the two-color plastic film has the effects of restraining weeds and avoiding aphids, the aphids and other insects are effectively prevented from spreading diseases, the land temperature inside a ridge is rapidly improved, and effective degradation of green manure plants is improved. Due to the fact that quick lime is applied, soil acidification can be effectively relieved, the calcium content of soil can be increased, and the rate of watermelon cracking in the watermelon mature period is reduced. Due to the fact that a layer of dry straw covers the plastic film arranged between every two ridges, moistures is absorbed, the dryness degree inside a green house is improved, fixation of watermelon vines is facilitated, and watermelon growth is facilitated. The incidence of fusarium wilt is reduced by 96% compared with that of the prior art. The quality of watermelons is remarkably improved. The sugar degree of each watermelon is increased by 1%-3%. The yield is increased by 200%-600% compared with that of the prior art.

Owner:ZHENJIANG SUIHAN AGRI

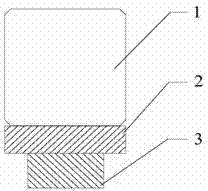

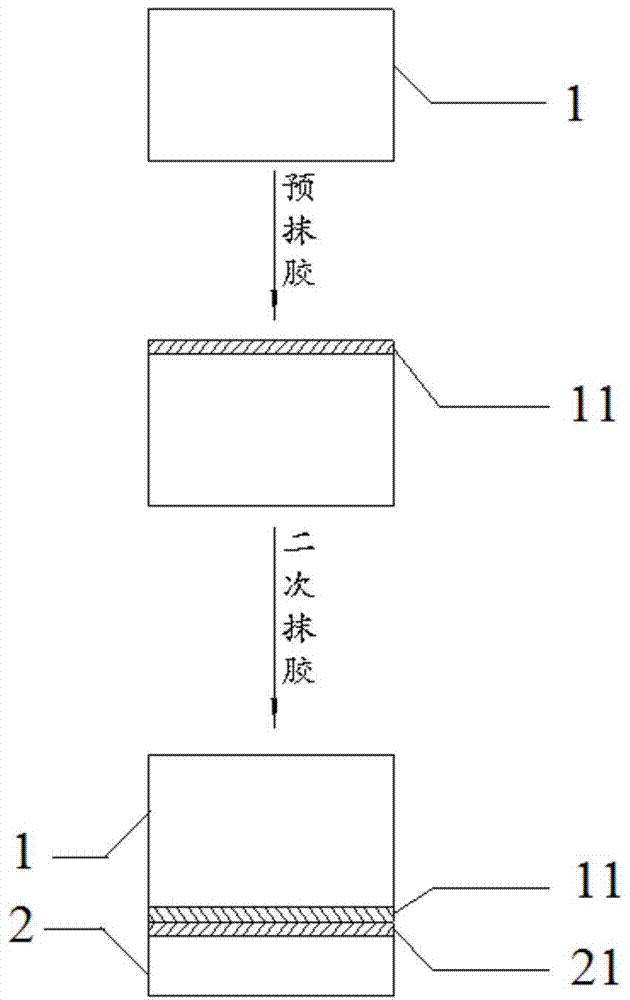

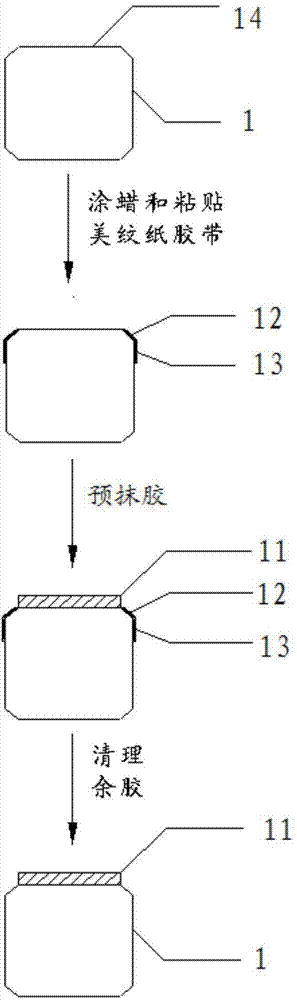

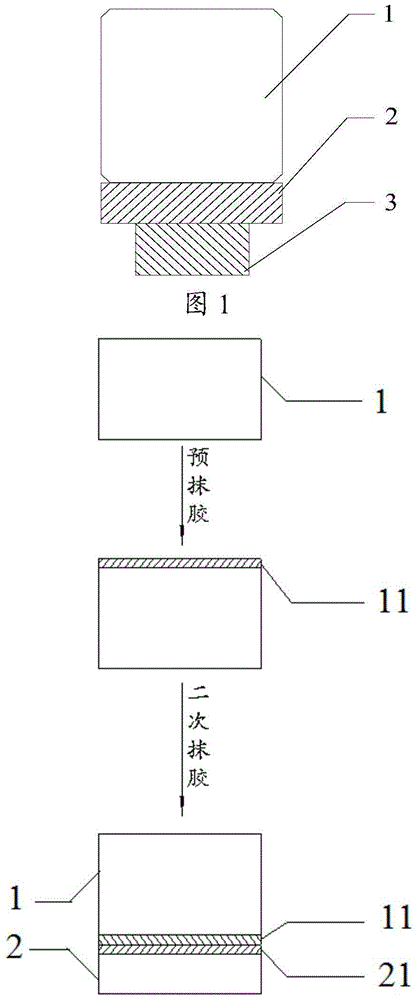

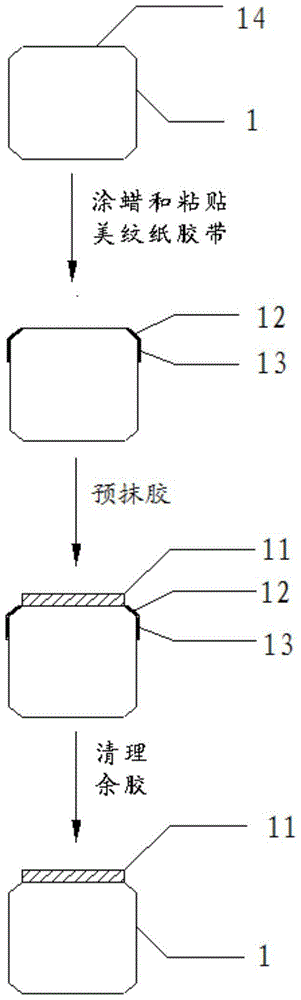

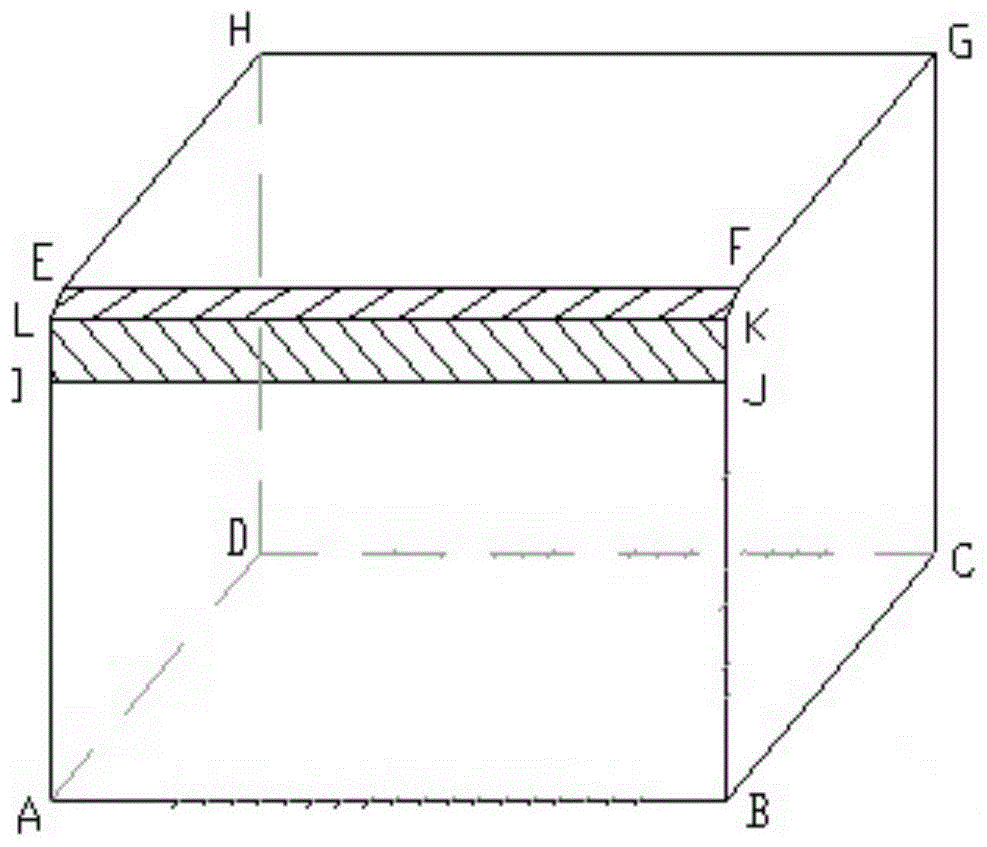

Adhesion method for crystal bar

The invention provides an adhesion method for a crystal bar. The method comprises the steps that before the adhesion of the crystal bar and a bearing plate, adhesives are applied on the crystal bar in advance to form an adhesive layer, and after the adhesive is solidified, adhesion is conducted on the crystal bar with the adhesive layer and the bearing plate by applying the adhesive for a second time. The adhesion method for the crystal bar is simple and efficient, cracks on the adhesive surface of the crystal bar can be reduced, adverse effects caused by the empty adhesive phenomenon are eliminated, the breakage and hidden crack rate in silicon wafer cutting process is further reduced, and the yield of silicon wafers is improved.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

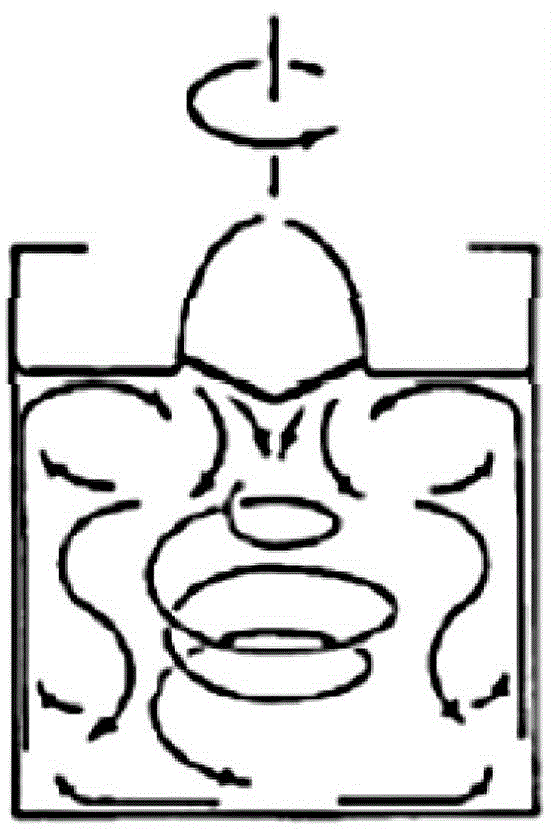

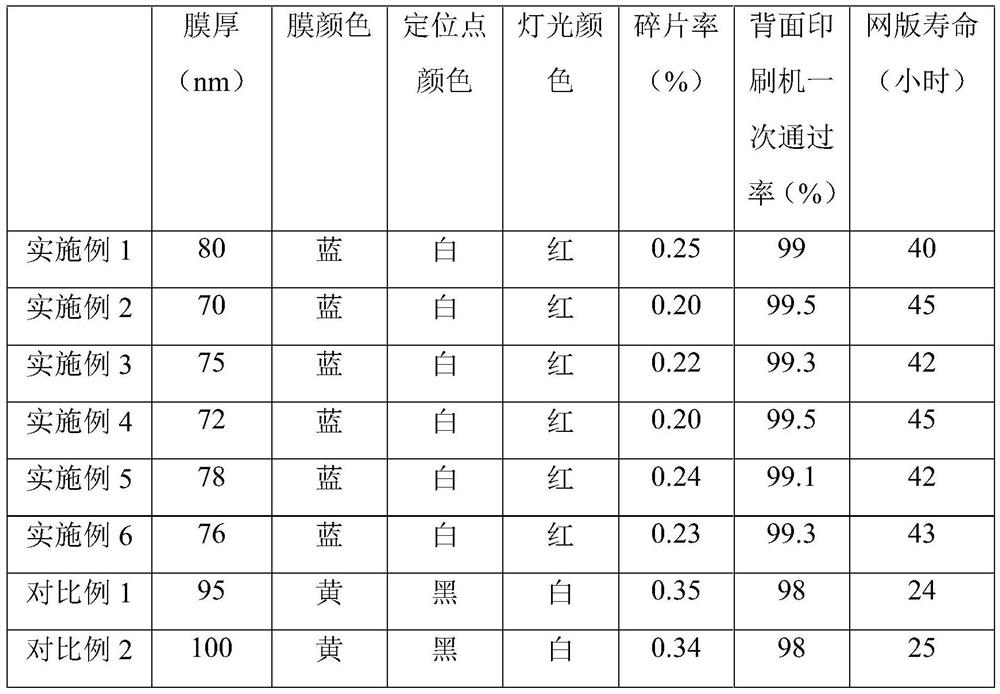

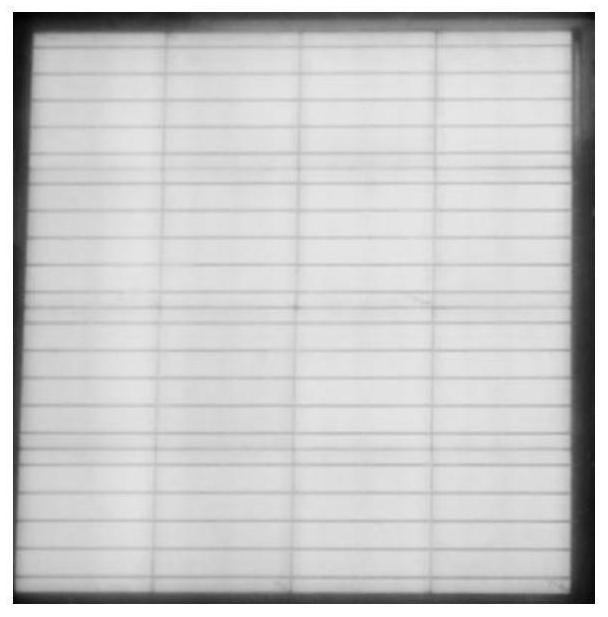

Solar cell electrode printing method

PendingCN112397610AReduce cracking rateAvoid damageFinal product manufacturePhotovoltaic energy generationSolar cellMaterials science

The invention discloses a solar cell electrode printing method. The method comprises the following steps of cleaning and texturing, diffusion, laser doping, oxidation, back oxide layer removal, alkalipolishing, film coating, laser grooving and printing, a silicon nitride film is plated on the surface of a silicon wafer during film coating, and the thickness of the back silicon nitride film is 70-80 nm; laser grooving is carried out on the back face of the silicon wafer to obtain a positioning point, the vertical distance between the highest point of a fusion protrusion of the positioning point and the back face of the silicon wafer is not larger than 10 [mu]m, and a red light lamp is adopted in a printing machine for printing back face electric field slurry. When the method is used in laser grooving, local ablation and the protruding degree caused by positioning point punching are reduced by setting relevant technological parameters of the positioning points on the back face of the silicon wafer, so that the subfissure probability of a battery piece is reduced, and damage of the positioning points to a screen printing plate of a printing machine is reduced.

Owner:JA SOLAR

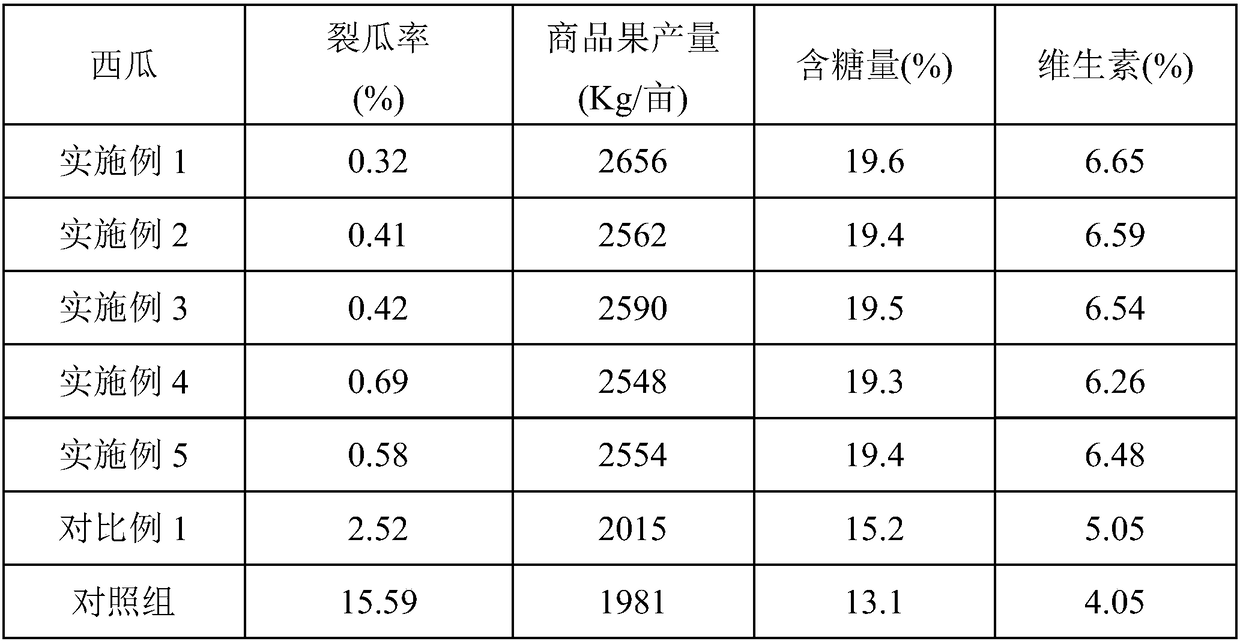

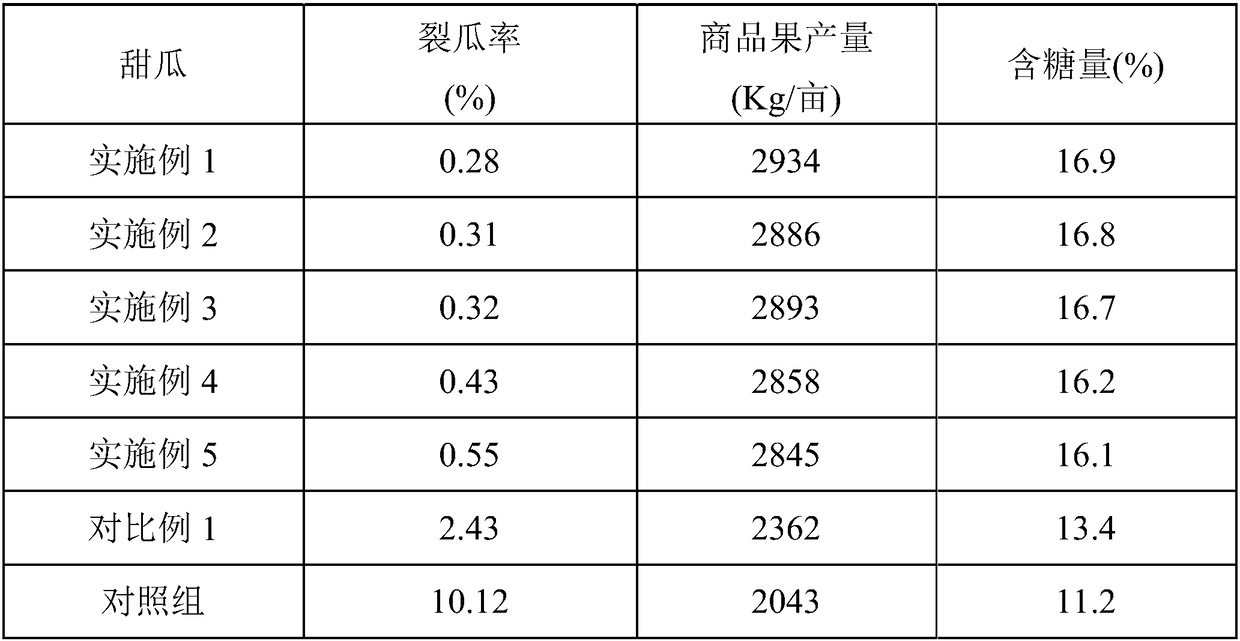

Nutrient solution for preventing watermelon and muskmelon rind from cracking and preparation method and application thereof

InactiveCN108586099AAvoid crackingReduce cracking rateCalcareous fertilisersMagnesium fertilisersCalcium nitrate tetrahydrateNutrient solution

The invention provides a nutrient solution for preventing watermelon and muskmelon rind from cracking and a preparation method and application thereof. The nutrient solution is prepared from calcium nitrate terahydrate, edathamil monosodium ferric salt, potassium nitrate, magnesium sulfate heptahydrate, monopotassium phosphate, potassium sulphate, manganese sulfate monohydrate, boric acid, zinc sulphate, copper sulfate pentahydrate, ammonium molybdate, calcium chloride, sodium metasilicate nonahydrate and balance water, matching is scientific, the synergistic effect is stronger, and the effectof the melon cracking prevention is significant. The nutrient solution for preventing the watermelon and muskmelon rind from cracking has the advantages that not only is the melon cracking rate reduced, the yield is improved, but also the sugar content and the vitamin content are both significantly improved.

Owner:HAINAN RUNDA MODERN AGRI CO LTD

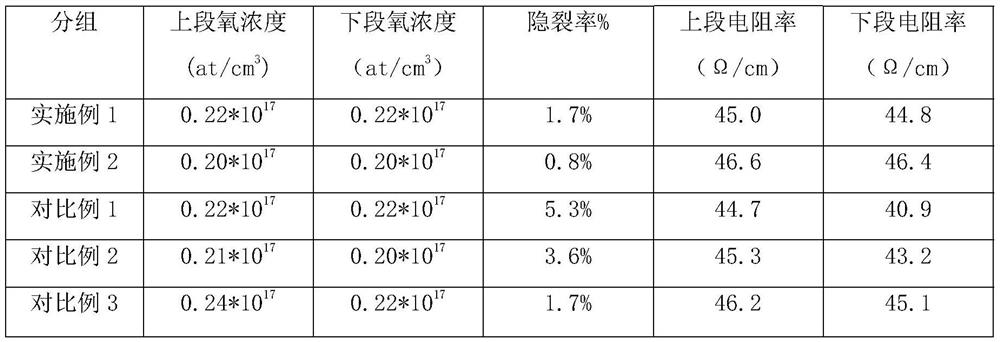

Preparation method of square silicon core

ActiveCN113355737ALow oxygenHigh resistivityPolycrystalline material growthFinal product manufactureSingle crystalElectric resistivity

The invention relates to the technical field of silicon core processes, in particular to a preparation method of a square silicon core. The preparation method comprises the following steps: (1) feeding; (2) melting the polycrystalline silicon raw material; (3) seeding; (4) shouldering; (5) shoulder turning; (6) performing equal-diameter growth; (7) ending; and (8) blowing out, blowing in, cutting and pickling to obtain a square silicon core; wherein in the shouldering step, the diameter of a fine grain is shouldered to be more than 200mm by adjusting the electrifying power of a single crystal furnace and the shaft lifting speed of a flexible shaft; and the crystal bar with more uniform crystal pulling resistivity distribution by adjusting the electric power, the rising speed of the flexible shaft and the crucible is grown in an equal-diameter manner. According to the invention, by controlling key process parameters, the crystal pulling time is shortened, the contact time of the crucible and the molten silicon liquid is reduced, the content of impurities in the silicon crystal liquid is effectively reduced, and the resistivity of a silicon core is favorably controlled.

Owner:内蒙古和光新能源有限公司

Feed additive for improving egg quality of laying hens

InactiveCN108576474AImprove utilizationReduce egg cracking rateAnimal feeding stuffAnimal scienceCoryphaena

The invention provides a feed additive for improving the egg quality of laying hens. The additive is characterized by comprising the following raw materials in parts by weight: 24-45 parts of gynostemma pentaphyllum, 24-45 parts of pomegranate rind, 20-40 parts of Symphytum officinale, 20-40 parts of tartary buckwheat, 10-20 parts of hawthorn fruits, 10-20 parts of dodder seeds, 5-10 parts of Chinese yams and 12-24 parts of fish scale enzymolysis extract. The feed additive can reduce the cholesterol of eggs of laying hens, improve the laying rate, and reduce the cracking rate of eggs.

Owner:安徽华龙生物工程股份有限公司

Method for improving mark point hidden crack

InactiveCN110465755AGuaranteed not to overlapAvoid cracking defectsLaser beam welding apparatusLaser scanningEngineering

The invention discloses a method for improving a mark point hidden crack. The method comprises the following steps that parameters of a laser device are adjusted, wherein the power factor of the laserdevice is set to 50, and the PRF is set to 0; the parameters of the laser device are set to be controlled from external control to internal control, so that the problems that double superposition iscaused on the parameters of the laser device and internal parameters of a graph, and laser energy is aggravated and struck on a silicon wafer to cause the hidden crack are avoided; four mark points are prepared by laser scanning, wherein the mark points are composed of a transverse line and two vertical lines, the two vertical lines are located on the two sides of the transverse line correspondingly, the vertical lines are perpendicular to the transverse line and located on the central line of the transverse line, and the vertical distances from the end points, close to the transverse line, ofthe two vertical lines to the transverse line are equal and greater than zero; and the mark points are transversely punched once, the vertical lines are divided into two sections which are not overlapped with the transverse line and are respectively punched once. The defect of hidden cracks at overlapped positions caused by repeated punching is effectively avoided, the hidden crack ratio is reduced, and meanwhile the printing grab points are not influenced.

Owner:阜宁苏民绿色能源科技有限公司

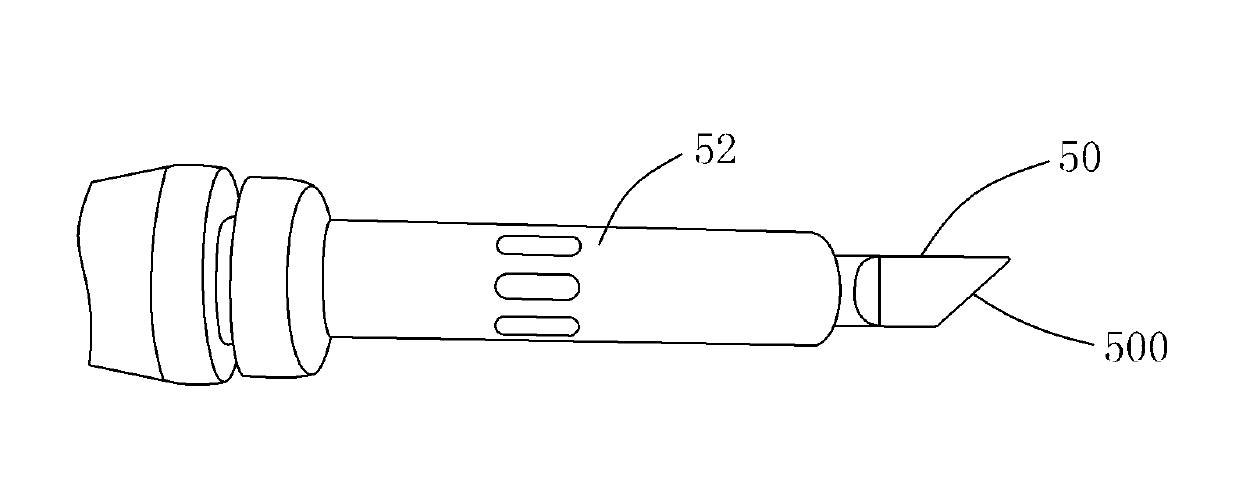

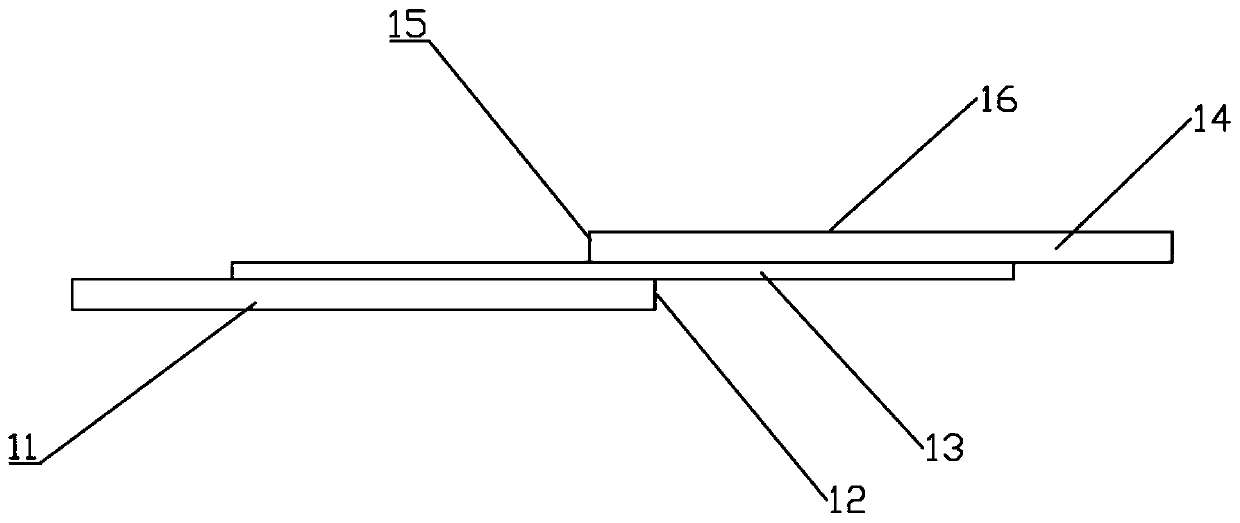

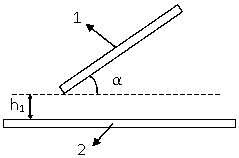

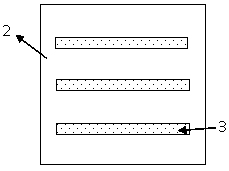

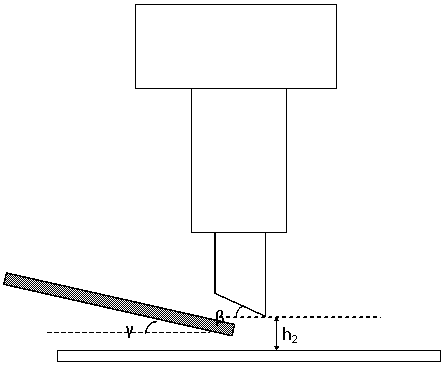

Welding method for connecting solar cells to form solar cell module and soldering iron

The invention provides a welding method for connecting solar cells to form a solar cell module. The welding method includes that interconnectors are placed on the solar cells along a direction roughly perpendicular to electrodes of the solar cells, a first end of each interconnector is arranged at a first distance position of a first edge of the each solar cell, and a second end of the interconnector extends out of the solar cell; and from a second distance position of a second edge of the solar cell and along the interconnector, the first edge of the solar cell is welded to the first end of the interconnector. The invention further provides a corresponding soldering iron. By the aid of the method, breakage rate and hidden crack rate of the solar cells can be effectively lowered.

Owner:WUXI SUNTECH POWER CO LTD

Egg-laying hen feed capable of improving egg productivity

The invention provides an egg-laying hen feed capable of improving egg productivity. The egg-laying hen feed is prepared from the following raw material in percentage by weight of 40-60% of corn, 10-15% of soybean meal, 6-12% of rice bran meal, 1-3% of corn protein powder, 0.1-0.6% of a fish scale enzymolysis extract, 0.02-0.04% of bacillus subtilis, 5-10% of cottonseed meal, 5-10% of peanut meal,0.1-0.3% of composite amino acids, 0.15-0.45% of a complex enzyme, 0.1-0.15% of trace elements and 0.04-0.08% of a traditional Chinese medicine additive, wherein the traditional Chinese medicine additive comprises the following raw materials in parts by weight of 24-45 parts of fiveleaf gynostemma herb, 24-45 parts of pomegranate rinds, 20-40 parts of giant knotweed rhizomes, 20-40 parts of treepeony barks, 10-20 parts of haws, 10-20 parts of cuscutae semen, and 5-10 parts of poria cocos. The feed realizes the purposes of improving the egg producing performance of egg-laying hens and improving egg quality, besides, the cholesterol level of eggs produced by the egg-laying hens is reduced, and the eggshell hardness is reinforced.

Owner:安徽华龙生物工程股份有限公司

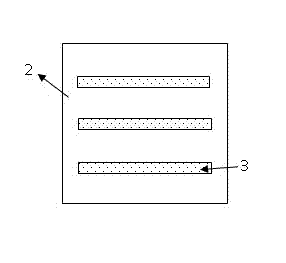

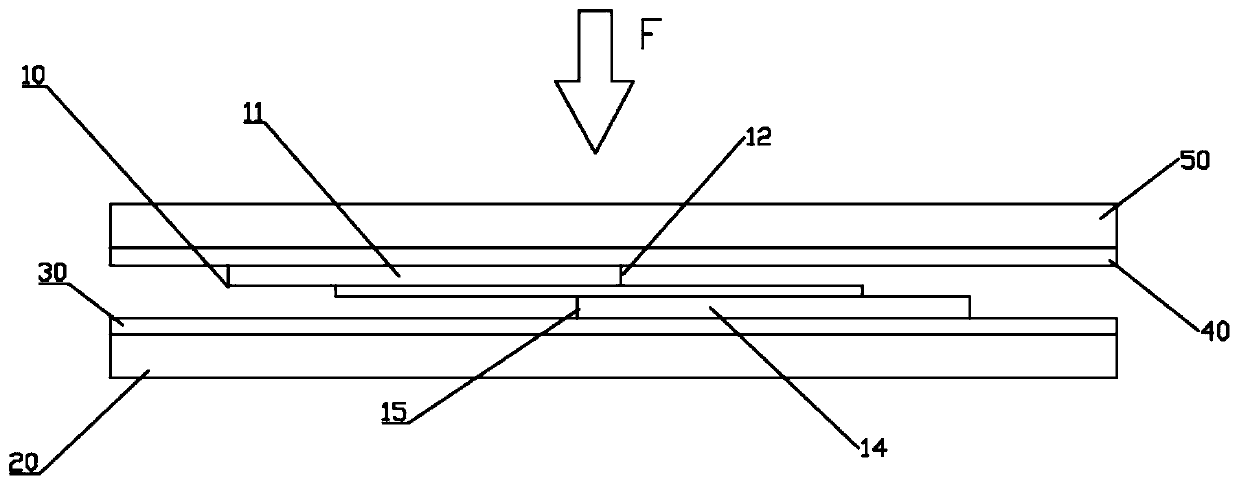

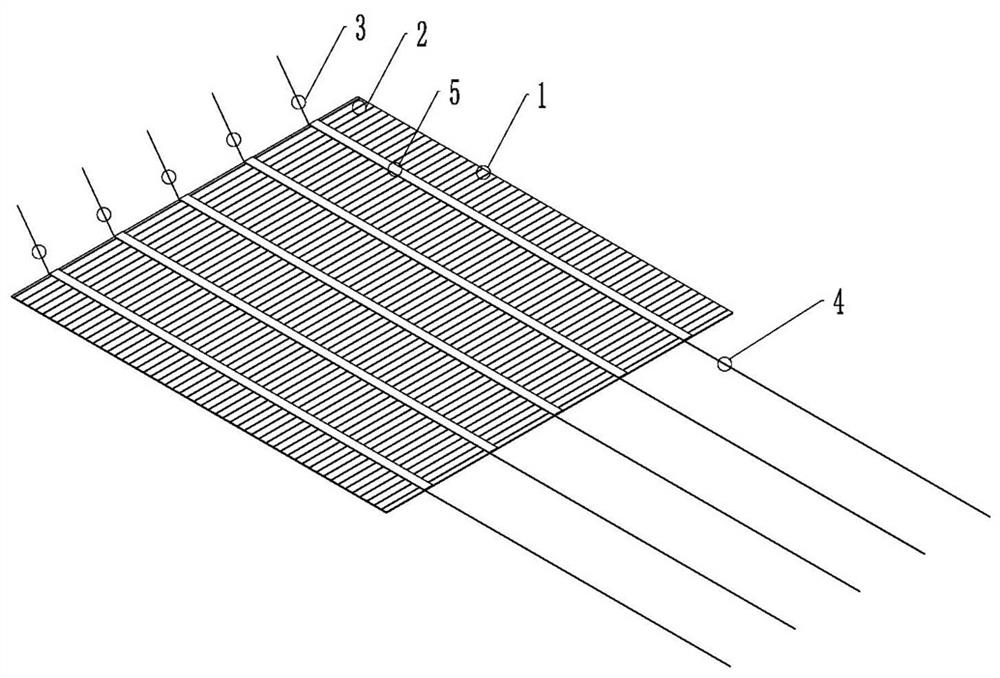

Method for overlapping sliced battery slices

ActiveCN110137303AReduce distortionReduces the possibility of crackingFinal product manufacturePhotovoltaic energy generationEngineeringElectrical and Electronics engineering

The application discloses a method for overlapping sliced battery slices, comprising the step of successively stacking a solder strip and a second sliced battery slice on a first sliced battery slicesuch that the orthographic projection the first sliced battery slice and the orthographic projection of the second sliced battery slice on a plane where the solder strip is located have an overlappingarea, wherein the solder strip is located between the first sliced battery slice and the second sliced battery slice, the non-cut surface of the first sliced battery slice and the cut surface of thesecond sliced battery slice are located in the overlapping area, and the negative electrode of the first sliced battery slice and the negative electrode of the second sliced battery slice are facing upward. The method can reduce the possibility of deformation and cracking of the sliced battery slices during a lamination process, and reduce the cracking rate of the sliced battery slices.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

A kind of preparation method of back electrode of solar cell

ActiveCN104752554BReduce usageReduce breakageFinal product manufacturePhotovoltaic energy generationUltrasonic vibrationSoldering

The invention discloses a preparation method for a back electrode of a solar battery. The preparation method includes that using soldering flux to form a soldering flux belt at the surface of an aluminum back field, forming a non-silver metal solder belt at the surface of the soldering flux belt, wherein the soldering flux belt can break an alumina film at the surface of the aluminum back field to expose fresh aluminum from the surface of the aluminum back field, the subsequently fed non-silver metal wires (solder) are melted by the heat effect of a soldering head, the molten liquid fuses with the aluminum, the molten solder is well bonded at the surface of the aluminum back field, the silver use is avoided, the cost is lowered, an ultrasonic vibration device is not used, the intensity of a finished product is obviously improved, fragment and crack are obviously reduced, and the quality of the back electrode of the solar battery is greatly improved. The back electrode of the solar battery prepared by the preparation method is low in fragment and crack rate, the adhesion between the back electrode and aluminum back field is strong, the welding with a photovoltaic soldering belt is good, the average photoelectric efficiency conforms to requirement, and the manufacturing cost is low.

Owner:BYD CO LTD

Variable water ratio control method of secondary cooling of billet caster

InactiveCN101658913BMeet the requirements of high pulling speedReduce cracking rateMetallurgyWater flow

The invention discloses a variable water ratio control method of the secondary cooling of a billet caster which can reduce the inner crack rate of casting blanks. The control method can realize that the water flow rate delta and the total amount of water Q increase by stages with the increasing of the casting speed V of casting blanks, namely when the casting speed V of casting blanks is 0-2m / min, the water flow rate delta is 1.35-1.39L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 13.8-14.3V; when the casting speed V of casting blanks is 2-2.4m / min, the water flow rate delta is 1.58-1.64L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 16.2-16.8V; when the casting speed V of casting blanks is 2.4-2.8m / min, the water flow rate delta is 1.67-1.71L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 17.1-17.5V; when the casting speed V of casting blanks is 2.8-3.0m / min, the water flow rate delta is 1.73-1.76L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 17.7-18.1V; and when the casting speed V of casting blanks is 3.0-3.6m / min, the water flow rate delta is 1.8-1.86L / kg, the functional relationship between the secondary cooling total amount of water Q and the casting speed V of casting blanks is Q = 18.5-19.1V.

Owner:XINJIANG BAYI IRON & STEEL

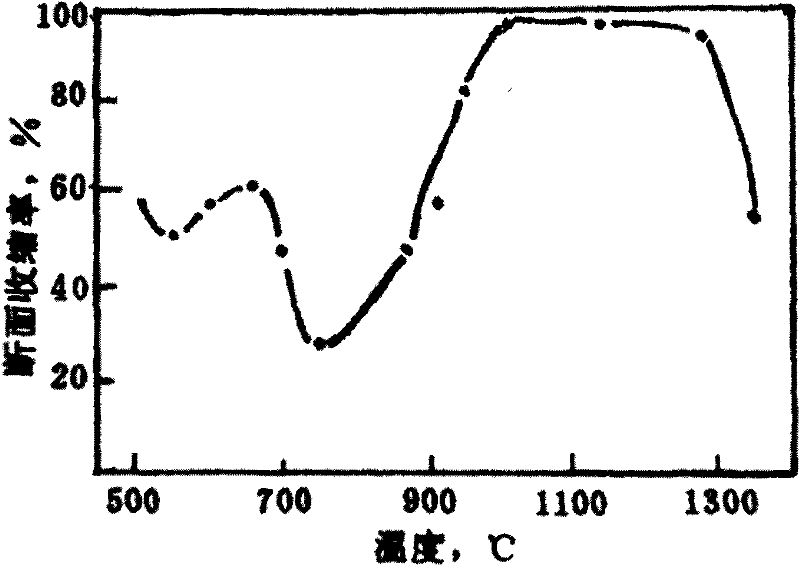

Heat treatment technology for increasing hardness of eccentric body of pressing machine

InactiveCN104630438AReduce the rate of crackingMeet the use requirementsFurnace typesHeat treatment furnacesMachine pressEngineering

The invention provides a heat treatment technology for increasing the hardness of the eccentric body of a pressing machine. The technology can reduce the chance of cracking of eccentric body of a pressing machine so as to make the eccentric body meet the usage requirements of pressing machine. The heat treatment technology comprises the following steps: (1) placing an eccentric body of a pressing machine in a heating furnace, heating to a temperature of 550 to 650 DEG C, and then maintaining the temperature for 3 to 5 hours; (2) then placing the eccentric body after the temperature maintaining step into a heating furnace, heating to a temperature of 850 to 900 DEG C, maintaining the temperature for 5 to 6 hours, then taking out the eccentric body out of the heating furnace, and cooling in the air to the room temperature; (3) heating the eccentric body with a room temperature in a heating furnace, heating to a temperature of 650 DEG C, and maintaining the temperature for 3 to 5 hours; (4) going on heating the eccentric body to a temperature of 850 DEG C or more, maintaining the temperature for 5 to 6 hours, then cooling in the air to a temperature of 840 to 860 DEG C, and then cooling in oil with a temperature of 30 to 50 DEG C for 50 to 60 minutes; (5) maintaining the temperature in a tempering furnace with a temperature of 350 to 400 DEG C for 5 to 8 hours, taking out the eccentric body out of the tempering furnace, and finally cooling in the air naturally.

Owner:李清扬

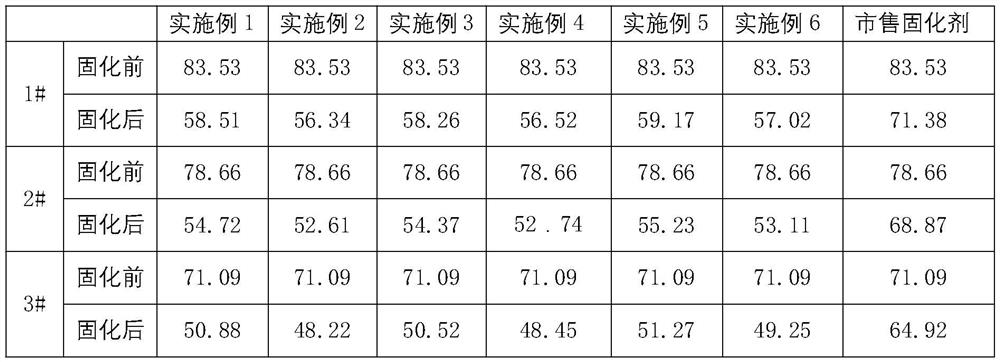

A curing agent for making bricks after water-based drilling cuttings are cured and its preparation method and application

The invention provides a curing agent for making bricks after curing water-based drilling cuttings as well as a preparation method and application of curing agent. The invention relates to the technical field of environment-friendly treating of oil field water-based drilling cuttings. The curing agent comprises 2%-5% of a solid surfactant, 30%-50% of industrial waste residues, 30%-50% of cement, 5%-10% of plant shell and 3%-5% of inorganic salt. According to the curing agent, the industrial waste residues such as coal gangue and the like are used, waste is treated with waste, the plant shell and the solid surfactant are introduced, the problems that the sintered brick prepared from the cured water-based drilling cuttings is prone to crisping, high in moisture content, adhesive and the likeare solved, the cured water-based drilling cuttings can be recycled to be used for preparing the sintered brick, and the practical value and the popularization prospect are achieved.

Owner:四川颐千石油工程有限公司

Rotating Shoulder Expansion Stable Lifting Method for Large Kilo Sapphire Crystals

ActiveCN104099660BReduce cracking rateImprove yieldPolycrystalline material growthBy pulling from meltPhacusCrystal growth

The invention discloses a rotating shoulder-expanding stable pulling-up method for large-kilogram sapphire crystals. The method comprises the steps as follows: heating for material melting to enable the raw materials to be just melted and enable the temperature of the melted material to be close to a melting point; lowering a crystalline style, and preheating a seed crystal mounted below the crystalline style; measuring temperature to adjust and control the temperature of the melted material to a crystal growth temperature; seeding, to be specific, placing the clean seed crystal above liquid level in a standing manner to enable the surface of the seed crystal to melt, rotating the crystalline style, and actuating the seeding process after an artificial cold-core is formed; actuating an automatic shoulder-expanding procedure, lifting the crystalline style at uniform speed, adjusting the power of a heater to lower the temperature gradually, at the same time, keeping the rotation of the crystalline style, stopping rotation when the weight of the crystal reaches 5 kg, enabling the rotating speed of the crystalline style to gradually decrease by stages when the weight of the crystal is 0-5 kg; actuating an automatic growing procedure when the weight of the crystal reaches 10 kg, lifting the crystalline style at uniform speed, adjusting the power of the heater to lower the temperature gradually; finally, separating, cooling, and taking out the crystal, so that the whole crystal growing process is completed. Through the method provided by the invention, the seeding and shoulder-expanding method in the prior art are improved, and the finished product rate as well as the yield are improved.

Owner:SUNPHIRE OPT TRONIC

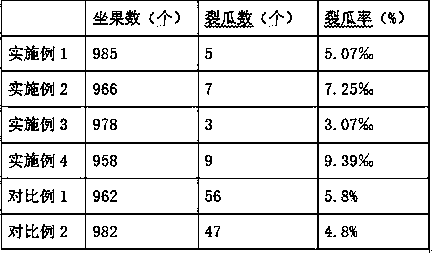

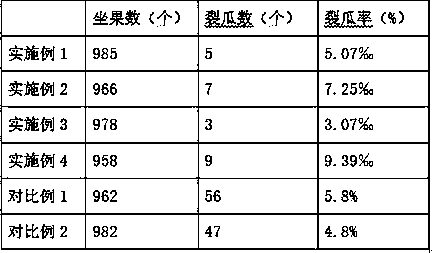

A kind of anti-cracking method of seedless watermelon

ActiveCN107646394BReduce cracking rateAvoid crackingBiocidePlant growth regulatorsAstragalus polysaccharideXylanase

The invention provides a seedless watermelon anti-dehiscence method. According to the anti-dehiscence method, after a seedless watermelon grows to a fruit swelling period, a seedless watermelon anti-dehiscence agent is sprayed. The anti-dehiscence agent is prepared from ammonium molybdate, pectin, xylanase, calcium superphosphate, serine protease, astragalus polysaccharide and water. By the adoption of the seedless watermelon anti-dehiscence method, the fruit dehiscence rate of the planted seedless watermelon is lowered to 3.07-9.39%o.

Owner:潍坊郭牌农业科技有限公司

Seedless watermelon anti-dehiscence method

ActiveCN107646394AReduce cracking rateAvoid crackingBiocidePlant growth regulatorsAstragalus polysaccharideXylanase

The invention provides a seedless watermelon anti-dehiscence method. According to the anti-dehiscence method, after a seedless watermelon grows to a fruit swelling period, a seedless watermelon anti-dehiscence agent is sprayed. The anti-dehiscence agent is prepared from ammonium molybdate, pectin, xylanase, calcium superphosphate, serine protease, astragalus polysaccharide and water. By the adoption of the seedless watermelon anti-dehiscence method, the fruit dehiscence rate of the planted seedless watermelon is lowered to 3.07-9.39%o.

Owner:潍坊郭牌农业科技有限公司

A method for bonding crystal rods

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

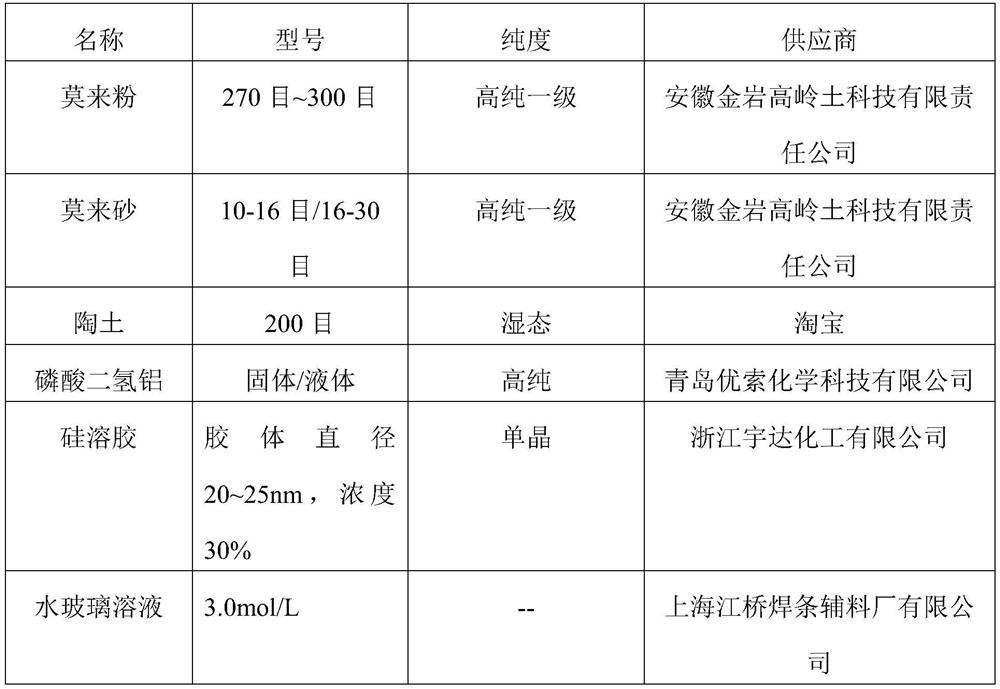

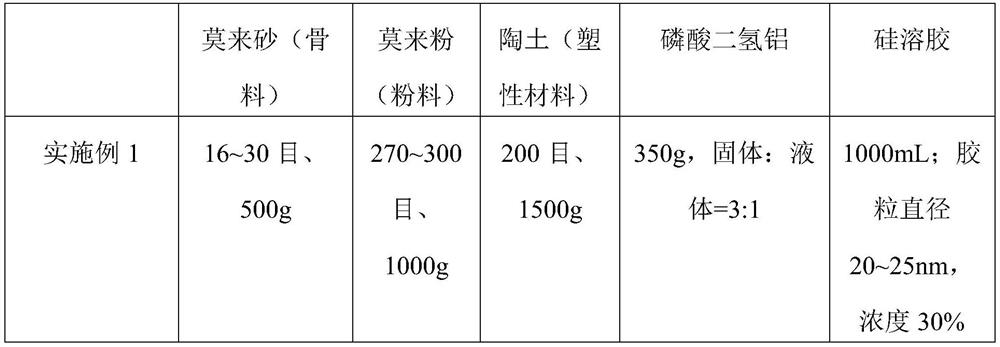

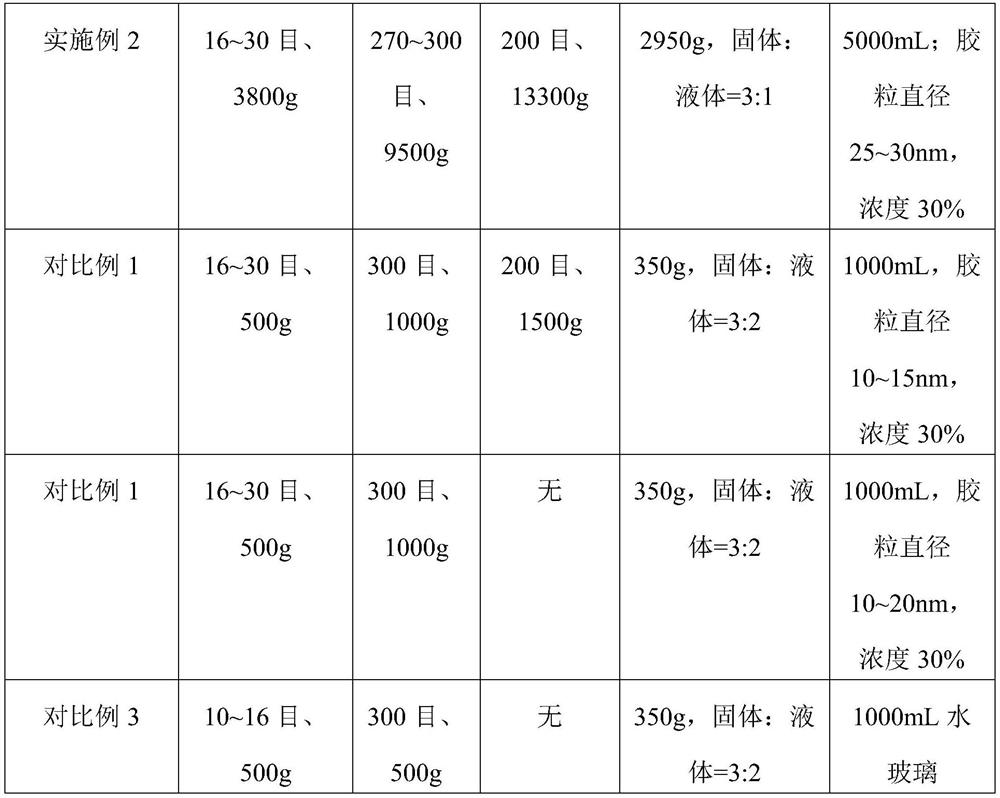

Coating and raw material composition, investment casting mold shell and preparation method and application of investment casting mold shell

ActiveCN114558982AHigh temperature strengthReduce cracking rateFoundry mouldsFoundry coresPlastic materialsInvestment casting

The invention discloses a coating, a raw material composition, an investment casting mold shell and a preparation method and application of the investment casting mold shell. The raw material composition of the coating comprises the following components in parts by weight: 100 parts of silica sol, 200-500 parts of solid particles and 20-70 parts of aluminum dihydrogen phosphate, wherein the solid particles comprise a silicon-aluminum refractory material and a plastic material, the silicon-aluminum refractory material comprises a powder material of 200-400 meshes and an aggregate of 10-60 meshes, and the weight ratio of the aggregate to the powder material to the plastic material is 1: (1.5-3): (2.5-4); the particle size of silicon dioxide in the silica sol is 20-40nm. The coating is used for reinforcing the shell of the large precision casting, so that the strength of the shell is greatly improved under the condition of conventional shell layers, the shell explosion rate is reduced, and the coating is particularly suitable for casting of the large precision casting.

Owner:SHANGHAI ZHONGZHOU SPECIAL ALLOY MATERIALS

Thermal treatment method for multi-link lever press off-centering body

ActiveCN101509059BHigh strengthHigh hardnessFurnace typesHeat treatment furnacesFurnace temperatureFree cooling

The invention discloses a method for heat-treating eccentric bodies of a multi-link press. The method comprises the following steps: placing the eccentric bodies of the multi-link press in a heating furnace; heating to 550 to 570 DEG C, and holding for 4 to 6 hours; then, placing the eccentric bodies in a heating furnace where the furnace temperature is lower than 400 DEG C, and holding for 2 hours; heating to 600 to 650 DEG C and holding for 2 hours; further heating to 880 to 900 DEG C, holding for 5 to 7 hours, discharging and cooling to the room temperature with compressed gas; and finally, placing the eccentric bodies in the heating furnace where the furnace temperature is lower than 400 DEG C, holding for 2 hours, heating to the tempering temperature of 550 to 570 DEG C, holding for 5 to 7 hours, then, discharging and naturally cooling. The invention has the following beneficial effects: (1) the cracking rate of the eccentric bodies of the multi-link press is reduced and the qualification rate is improved; and (2) the strength and the hardness of the eccentric bodies thereof are increased, thereby meeting the actual requirements for production.

Owner:JIER MACHINE TOOL GROUP

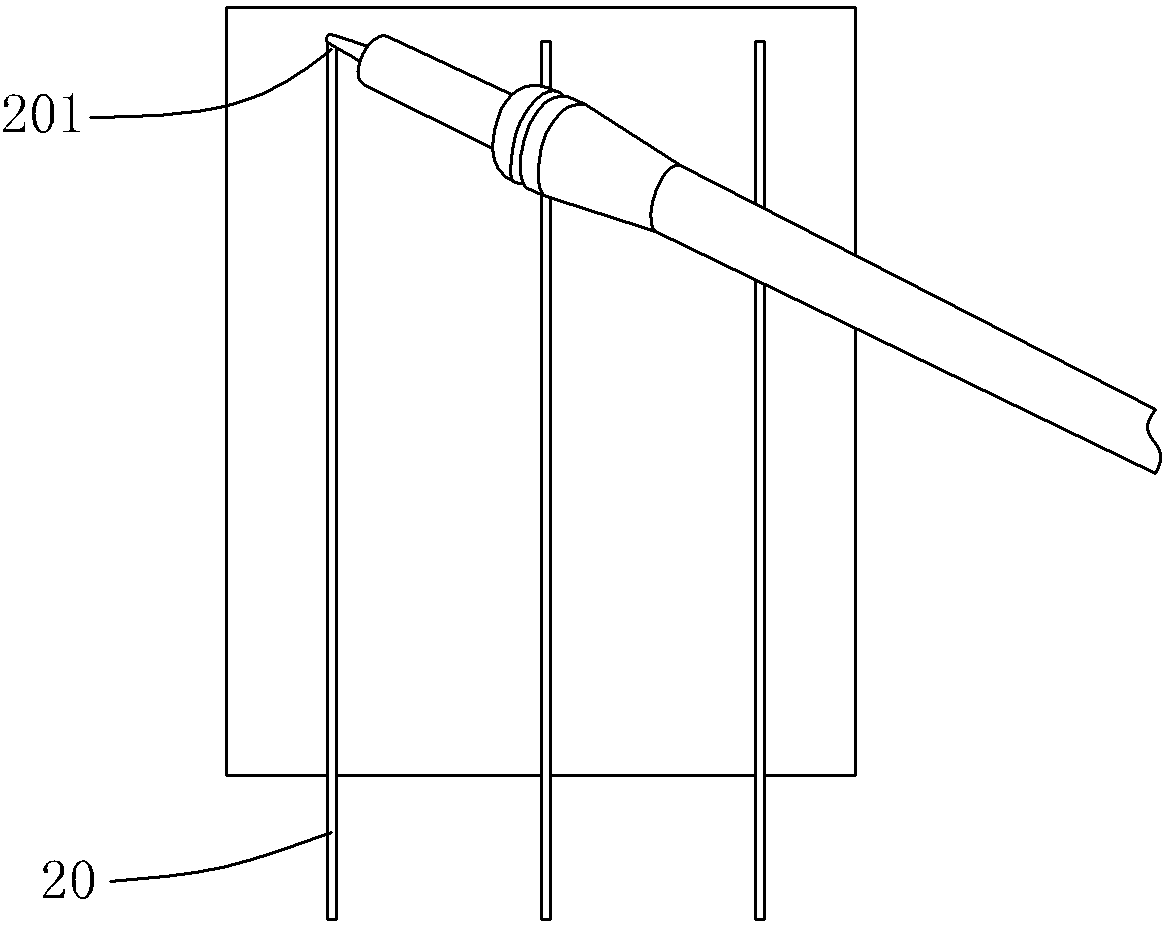

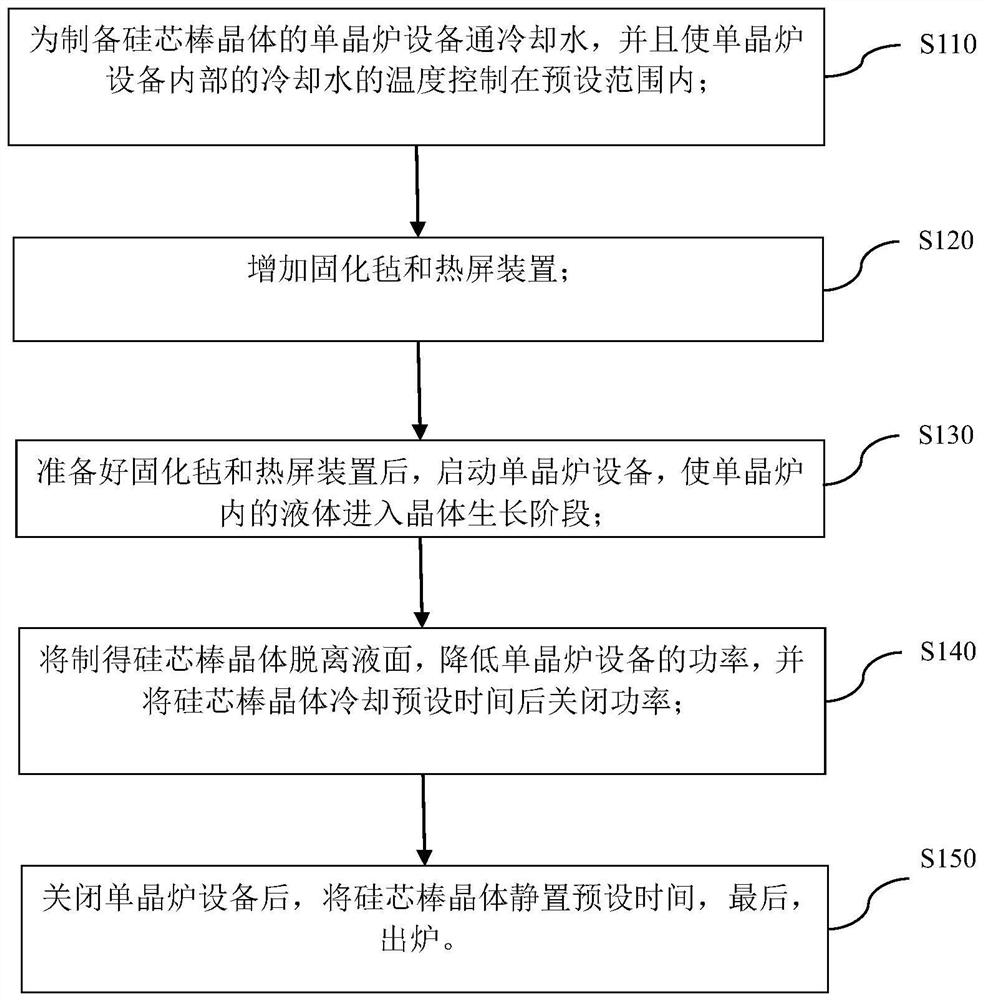

Method and device for reducing crystal subfissure of straightened silicon core rod

PendingCN114752994AReduce cracking rateReduce the difficulty of productionPolycrystalline material growthBy pulling from meltPhysical chemistryEngineering

The invention provides a method and device for reducing subfissure of a straightened silicon core rod crystal, and the method comprises the following steps: introducing cooling water into single crystal furnace equipment for preparing the silicon core rod crystal, so that the temperature of the single crystal furnace equipment is controlled within a preset range; a curing felt and a heat shield device are arranged at the upper part of a guide cylinder of the single crystal furnace equipment; starting the single crystal furnace equipment to enter a crystal growth stage; after the crystal growth stage is completed, the prepared silicon core rod crystal is separated from the liquid level to a preset height, meanwhile, the power of the single crystal furnace equipment is reduced, and after the silicon core rod crystal is cooled for a preset time, the power is turned off; the silicon core rod crystal needs to stand within a preset time and is discharged out of the furnace. By means of the method for reducing the subfissure of the straightened silicon core rod crystal and the device for executing the method, the defects of subfissure, cracks and the like in the straightening process of the silicon core rod crystal are effectively reduced, the prefabrication process of the silicon core rod crystal is not limited to single crystals, and therefore the difficulty of preparing the silicon core rod crystal is reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

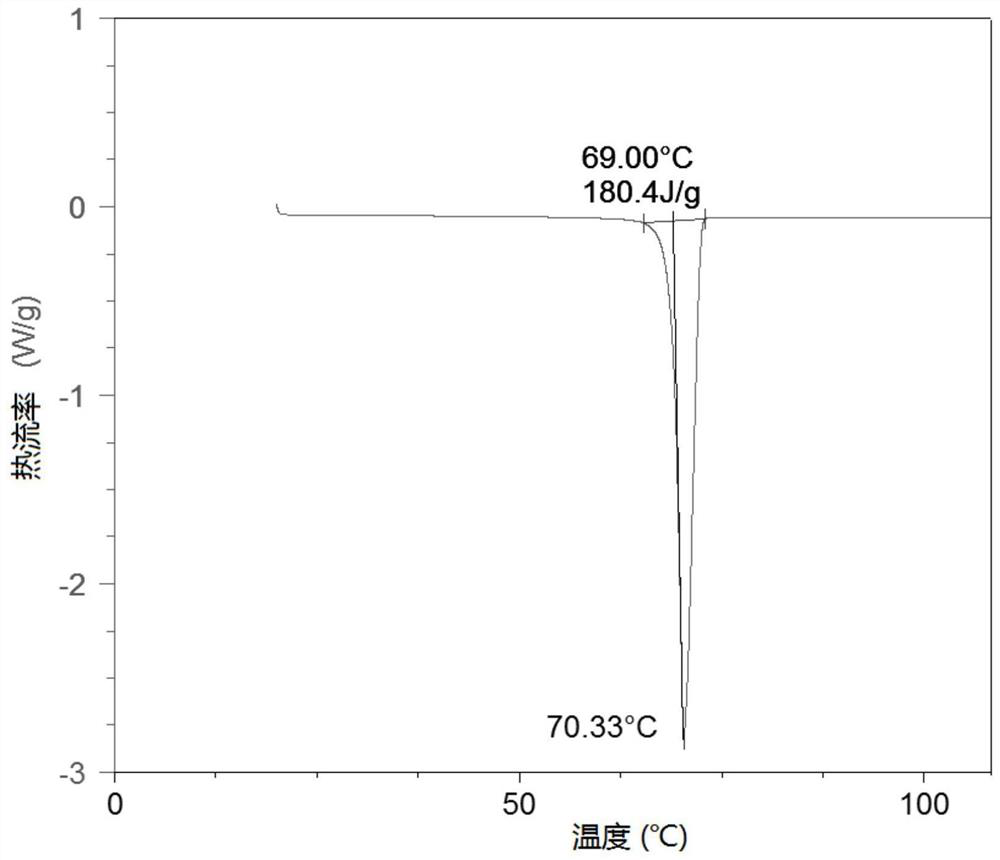

Heat-dissipating packaging adhesive film and preparation method thereof

ActiveCN112409942BAvoid issues such as package performance degradationReduce the temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesElectrical batteryPhysical chemistry

The invention provides a heat-dissipating packaging adhesive film and a preparation method thereof. The heat-dissipating encapsulation adhesive film includes a base resin, a phase-change material / heat-conducting filler compound, an initiator and a cross-linking agent dispersed in the base resin. The invention effectively solves the problem that the heat dissipation packaging method of solar photovoltaic modules in the prior art cannot simultaneously take into account heat dissipation, cell cracks, photoelectric conversion efficiency, electrical conductivity safety, anti-PID performance and other aspects. Good, good packaging performance after being applied to solar photovoltaic modules, high conductive safety, high photoelectric conversion rate, good anti-PID performance, low cost, and broad application prospects.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

A kind of photovoltaic cell module and its production method

ActiveCN111063748BAvoid thermal stress damageImprove reliabilityFinal product manufacturePhotovoltaic energy generationPhysical chemistryEngineering

A photovoltaic cell component and a production method thereof belong to the field of crystalline silicon solar cells, and in particular relate to a novel photovoltaic cell and component electrical connection method. The invention provides a photovoltaic battery module with low cost, low debris rate in the production process, improved power generation efficiency and product quality and a production method thereof. The photovoltaic cell assembly of the present invention includes a battery sheet, and is characterized in that: the battery sheet is only provided with auxiliary grid lines, and no main grid lines are provided; the battery sheet is provided with filamentary conductive materials perpendicular to the auxiliary grid lines.

Owner:YINGKOU JINCHEN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com