Rotating shoulder-expanding stable pulling-up method for large-kilogram sapphire crystals

A sapphire crystal, stable technology, applied in crystal growth, self-molten liquid pulling method, single crystal growth and other directions, can solve the problems of difficult growth rate control, inversion of solid-liquid interface, low crystal yield and yield, etc. Achieve the effect of improving the instability of the molten soup flow line, reducing the crystal cracking ratio, and improving the yield and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

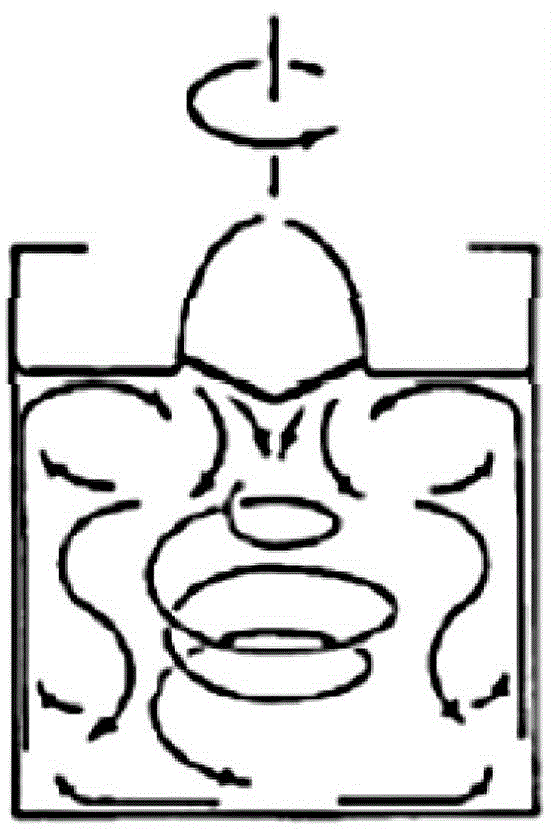

[0028] The invention discloses a method for stably pulling up a sapphire crystal with a large number of kilograms by rotation and shoulder expansion, and the specific steps are as follows to complete the crystal growth.

[0029] The first step is to heat up the material: raise the temperature of the raw material to above the melting point (2050°C), and after the raw material is completely melted, start to adjust the temperature so that the temperature of the molten soup is close to the melting point. During the whole process, the temperature is first raised and then lowered to above the melting point. In this way, the material can be melted at a faster speed.

[0030] The second step, lowering the crystal rod: after temperature adjustment, start to lower the crystal rod slowly by dropping 5 mm every 5-10 minutes, and install the seed crystal under the crystal rod to preheat the seed crystal.

[0031] The third step, temperature measurement: When the crystal rod is lowered to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com