Feed additive for improving egg quality of laying hens

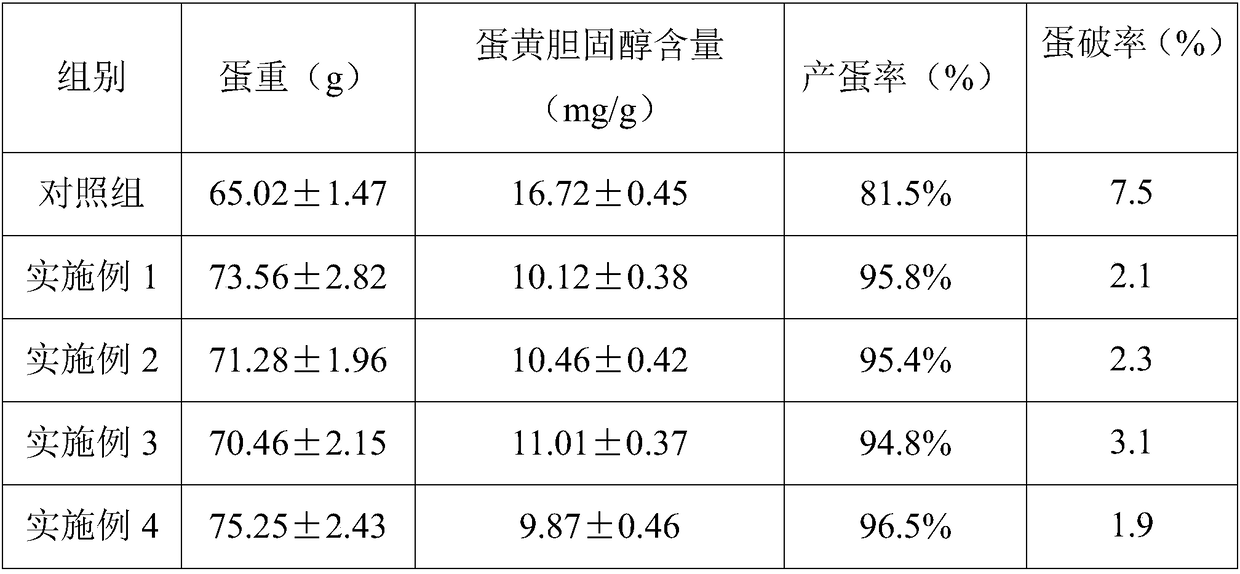

A feed additive and egg technology, applied in animal feed, animal feed, applications, etc., can solve the problems of low production level of laying hens, short laying cycle of laying hens, low egg production, etc., and reduce the cracking rate of eggs , reduce cholesterol content, increase the effect of egg production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A feed additive for improving egg quality of laying hens, calculated in parts by weight, comprising the following raw materials:

[0028] 38 parts of gynostemma, 35 parts of pomegranate peel, 31 parts of comfrey, 28 parts of tartary buckwheat, 15 parts of hawthorn, 16 parts of silkworm, 8 parts of yam and 19 parts of fish scale enzymatic hydrolysis extract.

[0029] The preparation method of fish scale enzymolysis extract comprises the following steps:

[0030] 1) Weigh fish scales and crush them to obtain fish scale powder, then soak them in an acid solution for 2.5 hours, and use an ultrasonic instrument to perform ultrasonic vibration treatment during the soaking; the acid solution consists of: 10g / L of H 3 BO 3 , 16g / L lactic acid, the balance is deionized water.

[0031] 2) Centrifuge the acid solution in step 1) to obtain acid-treated fish scale powder, then clean it with water, add an appropriate amount of water to adjust the pH to 7, and add pepsin (the amount...

Embodiment 2

[0033] A feed additive for improving egg quality of laying hens, calculated in parts by weight, comprising the following raw materials:

[0034] 42 parts of gynostemma, 24 parts of pomegranate peel, 32 parts of comfrey, 30 parts of tartary buckwheat, 12 parts of hawthorn, 15 parts of silkworm, 10 parts of yam and 12 parts of fish scale enzymatic hydrolysis extract.

[0035] The preparation method of fish scale enzymolysis extract comprises the following steps:

[0036] 1) Weigh fish scales and crush them to obtain fish scale powder, then soak them in an acid solution for 2 hours, and use an ultrasonic instrument to perform ultrasonic vibration treatment during the soaking; the acid solution consists of: 8g / L H 3 BO 3 , 20g / L lactic acid, and the balance is deionized water.

[0037] 2) Centrifuge the acid solution in step 1) to obtain acid-treated fish scale powder, then clean it with water, add an appropriate amount of water to adjust the pH to 6.5, and add pepsin (the amoun...

Embodiment 3

[0039] A feed additive for improving egg quality of laying hens, calculated in parts by weight, comprising the following raw materials:

[0040] 24 parts of gynostemma, 30 parts of pomegranate peel, 40 parts of comfrey, 20 parts of tartary buckwheat, 20 parts of hawthorn, 18 parts of silkworm, 6 parts of yam and 15 parts of fish scale enzymatic hydrolysis extract.

[0041] The preparation method of fish scale enzymolysis extract comprises the following steps:

[0042] 1) Weigh fish scales and crush them to obtain fish scale powder, then soak them in an acid solution for 3 hours, and use an ultrasonic instrument to perform ultrasonic vibration treatment during the soaking; the acid solution consists of: 12g / L of H 3 BO 3 , 12g / L lactic acid, the balance is deionized water.

[0043] 2) Centrifuge the acid solution in step 1) to obtain acid-treated fish scale powder, then clean it with clean water, add an appropriate amount of water to adjust the pH to 7.5, and add pepsin (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com