Preparation method of square silicon core

A silicon core, square technology, applied in the direction of chemical instruments and methods, final product manufacturing, self-melt pulling method, etc., can solve the problems of low production efficiency and the uniformity of the resistivity distribution of the silicon core to be further improved, to achieve The effect of reducing the content of impurities, shortening the crystal pulling time, and reducing the crack rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

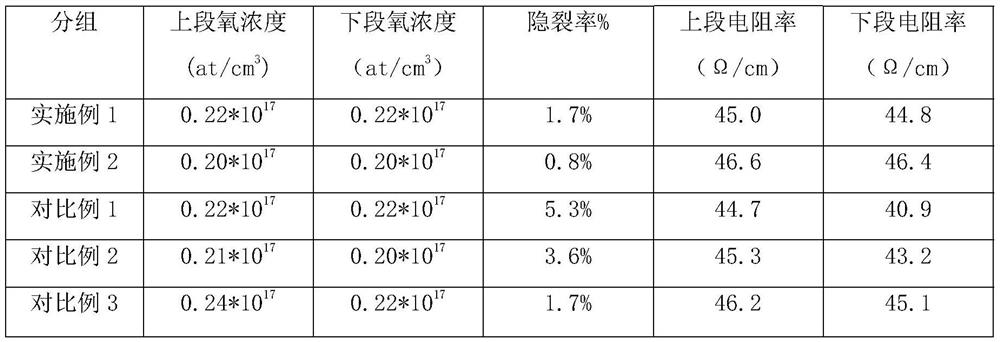

Examples

Embodiment 1

[0035] The preparation method of the silicon core of the present embodiment is as follows:

[0036] (1) Take 100 parts of 1mm-3mm polysilicon scrap and 0.01 part of boron-doped master alloy and put them into the quartz crucible at the bottom of the single crystal furnace, vacuumize, and then pass in protective gas, wherein the protective gas is argon, and the gas flow rate is 50slpm ;

[0037] (2) Heating: Power on the single crystal furnace at 30KW for half an hour, then raise it to 60KW at a speed of 1KW / min, and then increase it to 100KW at a speed of 1.5KW / min, keep it for 2 hours to obtain a completely melted silicon liquid, and then increase it at a speed of 2KW / min Reduce to 50KW, and at the same time lower the seed crystal suspended by a flexible shaft on the top of the closed single crystal furnace, 100mm away from the silicon liquid level, and keep it for 0.2 hours.

[0038] (3) Seeding: Lower the seed crystal to 5 mm below the silicon liquid level to melt the 5 mm ...

Embodiment 2

[0049] The preparation method of the silicon core of the present embodiment is as follows:

[0050] (1) Take 100 parts of 0.5mm-1mm polysilicon scrap and 0.01 part and put it in the quartz crucible at the bottom of the single crystal furnace, vacuumize it, and then feed a protective gas, wherein the protective gas is argon gas, and the gas flow rate is 75slpm;

[0051] (2) Heating: Power on the single crystal furnace at 30KW for half an hour, then raise it to 60KW at a speed of 1.5KW / min, and then increase it to 105KW at a speed of 2.0KW / min, and keep it for 2 hours; to obtain a completely melted silicon liquid, and then increase it to 5KW / min The speed is reduced to 50KW, and the seed crystal suspended by a flexible shaft on the top of the closed single crystal furnace is lowered, 120mm away from the silicon liquid surface, and kept for 0.5 hours.

[0052] (3) Seeding: Lower the seed crystal to 10 mm below the silicon liquid level to melt the 10 mm seed crystal. Then pull ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com