Heat-dissipating packaging adhesive film and preparation method thereof

An encapsulation film, heat dissipation technology, applied in the direction of adhesives, films/sheets without carriers, film/sheet adhesives, etc. Cracks and other problems, to avoid rapid temperature drop of components, low cost and good fluidity

Active Publication Date: 2022-05-31

HANGZHOU FIRST APPLIED MATERIAL CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The main purpose of the present invention is to provide a heat-dissipating encapsulation adhesive film and its preparation method, so as to solve the problem of heat dissipation, cell cracks, photoelectric conversion efficiency, and electrical safety in the heat dissipation packaging of solar photovoltaic modules in the prior art. Sexuality, anti-PID performance and other issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0057]

[0058] In formula I, n is 0 to 2, m is 10 to 250, and R is H, methyl or ethyl.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

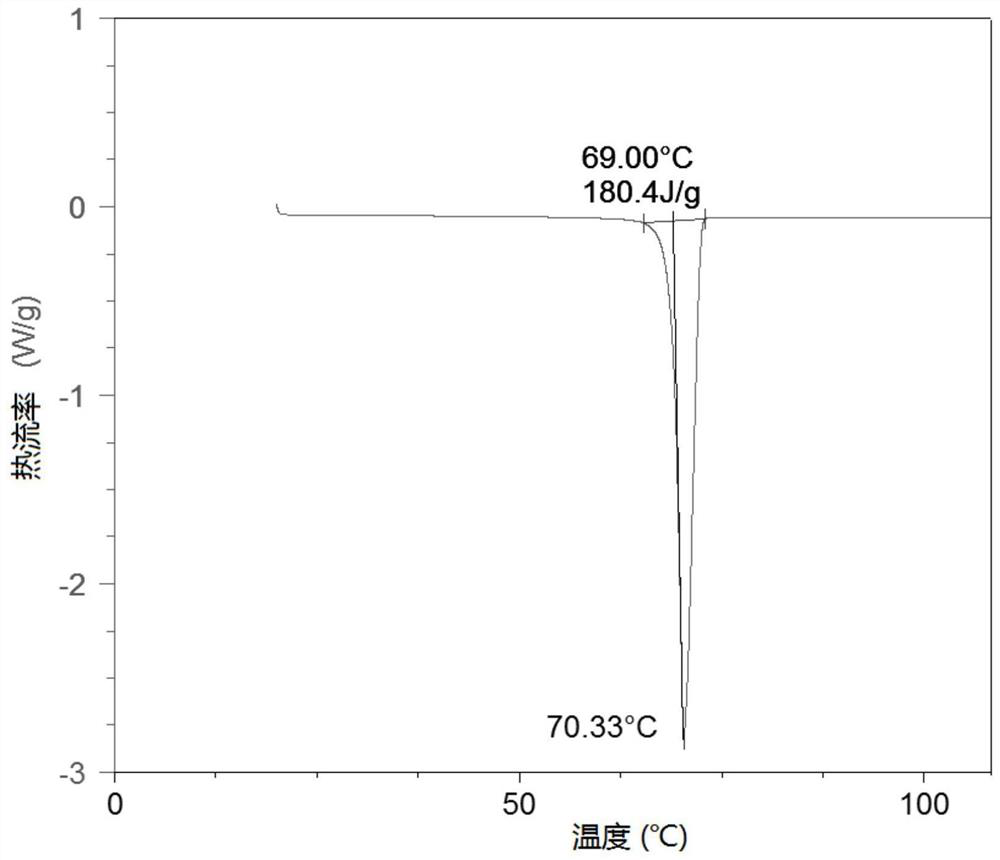

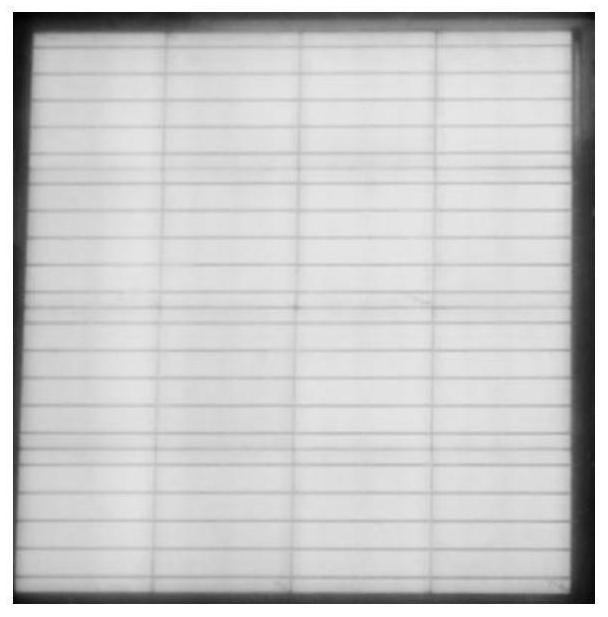

The invention provides a heat-dissipating packaging adhesive film and a preparation method thereof. The heat-dissipating encapsulation adhesive film includes a base resin, a phase-change material / heat-conducting filler compound, an initiator and a cross-linking agent dispersed in the base resin. The invention effectively solves the problem that the heat dissipation packaging method of solar photovoltaic modules in the prior art cannot simultaneously take into account heat dissipation, cell cracks, photoelectric conversion efficiency, electrical conductivity safety, anti-PID performance and other aspects. Good, good packaging performance after being applied to solar photovoltaic modules, high conductive safety, high photoelectric conversion rate, good anti-PID performance, low cost, and broad application prospects.

Description

Heat dissipation type encapsulation film and preparation method thereof technical field [0001] The present invention relates to the field of photovoltaic technology, in particular, to a heat dissipation type encapsulation film and a preparation method thereof. Background technique Due to the large-scale use of non-renewable energy such as petroleum, the renewable energy will be more and more in the energy ratio. higher. Photovoltaic solar energy is an important part of renewable energy. In the past ten years, the photovoltaic industry has developed faster and faster. The development direction of volt modules is mainly to develop towards the characteristics of high power, high reliability, low energy consumption and low cost. using the same battery In the case of wafers, how to obtain high power of components through packaging materials is the key research direction of the industry. The temperature is inversely linear, that is, the peak power of the solar cell decre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J7/30C09J7/10C09J123/08C09J11/04C09J11/08

CPCC09J7/30C09J7/10C09J123/0815C09J123/0853C09J11/04C09J11/08C08K2003/2296C08K2003/222C08K2003/2227C08L2203/206C09J2203/326C09J2423/04C09J2471/00C08L71/02C08K13/02C08K3/22C08K5/5435C08K5/13C08K3/34C08K5/5425C08K5/526Y02E60/10

Inventor 盘龚健侯宏兵唐国栋王龙

Owner HANGZHOU FIRST APPLIED MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com