Coating and raw material composition, investment casting mold shell and preparation method and application of investment casting mold shell

A raw material composition and coating technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of increased pores on the surface of castings, easy cracking of mold shells, and increased casting costs, so as to reduce the cost of mold shells, Low cost, the effect of improving high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

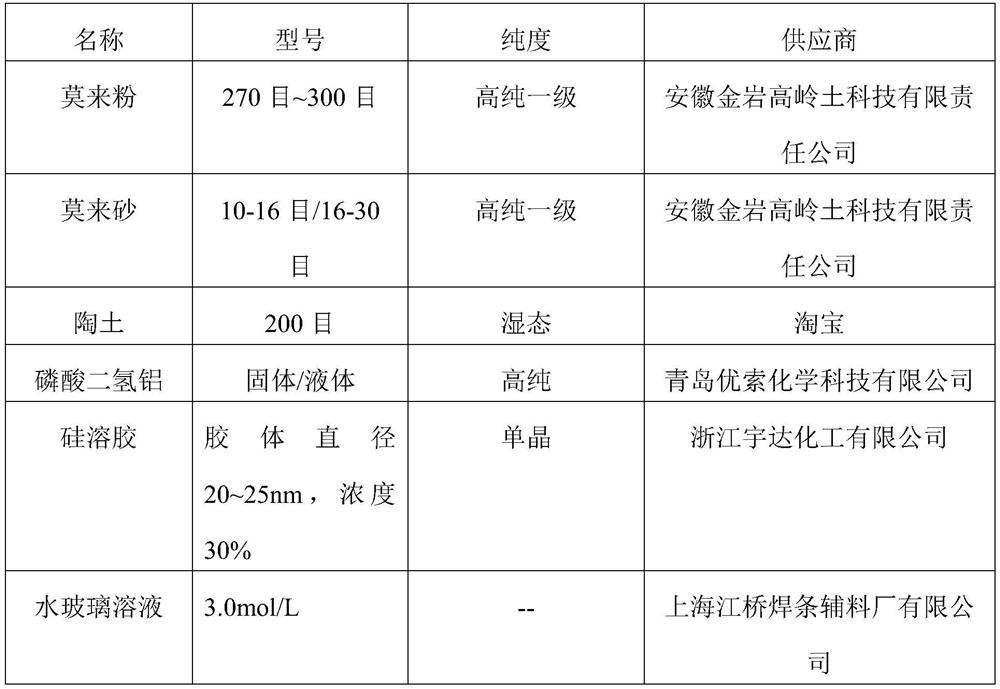

Method used

Image

Examples

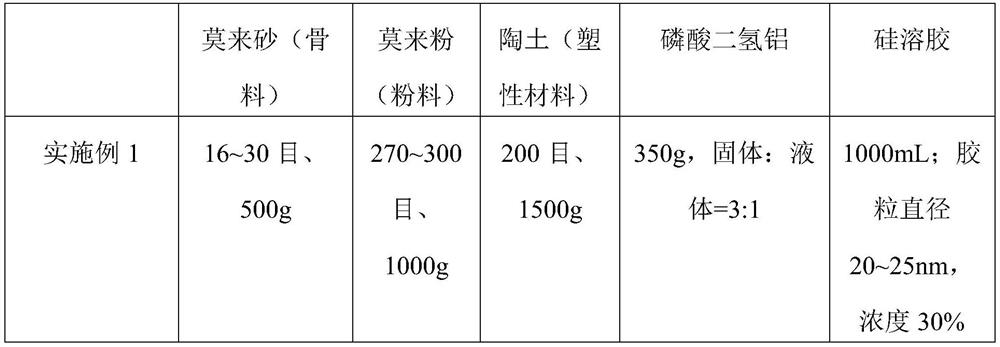

Embodiment 1

[0071] The liquid aluminum dihydrogen phosphate of embodiment 1 shown in table 2 is mixed with silica sol (density 1.18g / mL) to obtain a wet binder, and the solid aluminum dihydrogen phosphate is mixed with mullite and mullite powder to obtain a solid adhesive. The binder, the wet binder, the solid binder and the pottery clay are mixed, stepped on and beaten, and placed with a plastic wrap at 25° C. for 24 hours to ferment to obtain a coating. Among them, the weight ratio of aggregate, powder and plastic material is 1:2:3; the weight ratio of silica sol and solid particles is 1:2.54; the weight ratio of silica sol and aluminum dihydrogen phosphate is 1:0.3.

[0072] The paint is applied to the outer surface of the mold shell with a coating thickness of 5mm, baked at 200°C, and then fired at 1000-1100°C to obtain the investment casting mold shell.

[0073] The preparation method of the shell is as follows: apply the slurry of each layer shown in Table 3 in sequence, and the thi...

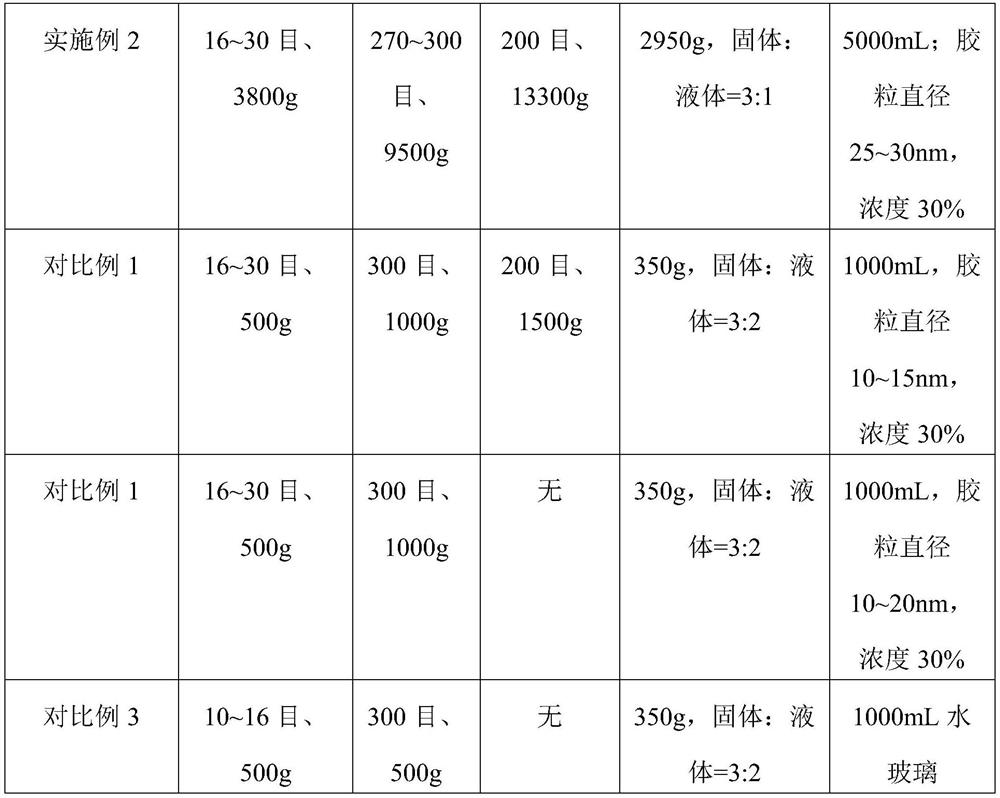

Embodiment 2

[0078] The raw materials are as shown in Example 2 of Table 2, and the others are the same as in Example 1 to obtain a coating and an investment casting mold shell. Among them, the weight ratio of aggregate, powder and plastic material is 1:2.5:3.5; the weight ratio of silica sol and solid particles is 1:2.54; the weight ratio of silica sol and aluminum dihydrogen phosphate is 1:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com