A kind of photovoltaic cell module and its production method

A technology of photovoltaic cells and production methods, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of small thin cells and large cells fragments and cracks, deformation of crystalline silicon cells, power loss of packaging components, etc. Achieve the effect of eliminating the release of harmful gases, reducing power loss and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

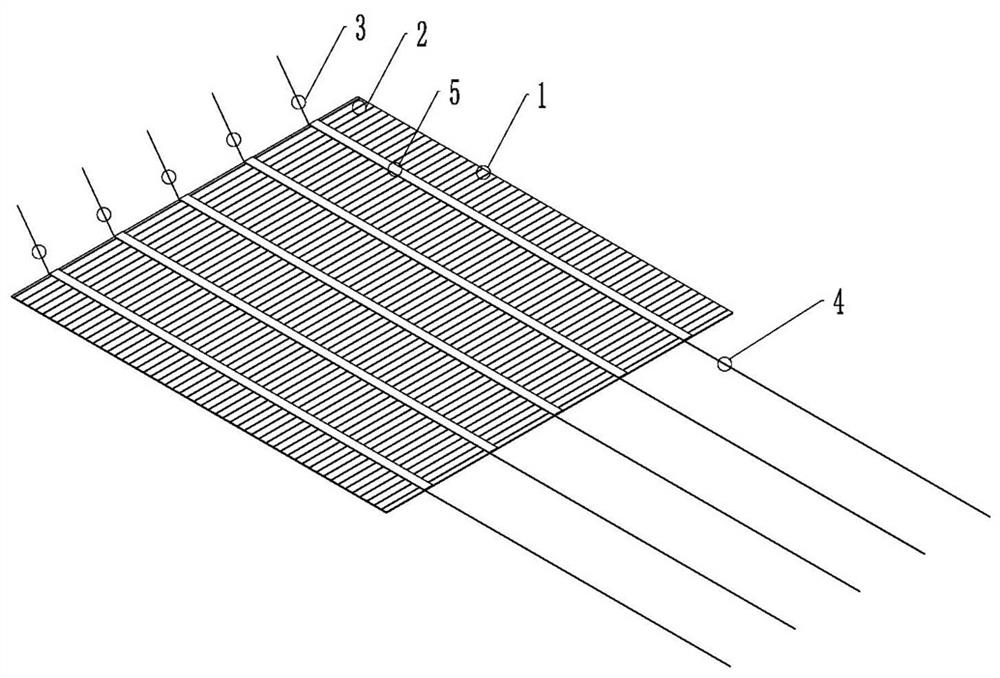

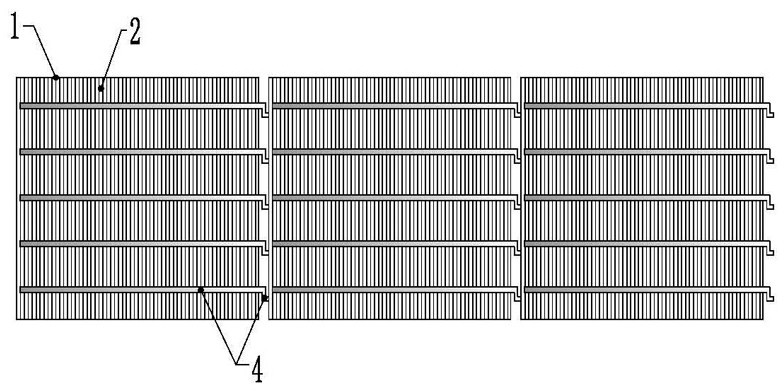

[0086] Embodiment 1: In the direction perpendicular to the front of the battery sheet without the main grid and the auxiliary grid line, the conductive adhesive 3 is used to print the bonding channel at one time. The coating thickness of the conductive adhesive 3 is uniform, and all the bonding channels are straight and are parallel to each other and perpendicular to the auxiliary grid lines. After the conductive adhesive 3 is printed on the feeder, the filamentary conductors 4 are respectively dissolved into the bonding feeder, and after being laminated and cured, the electrical connection between the battery sheet and the module is formed.

Embodiment 2

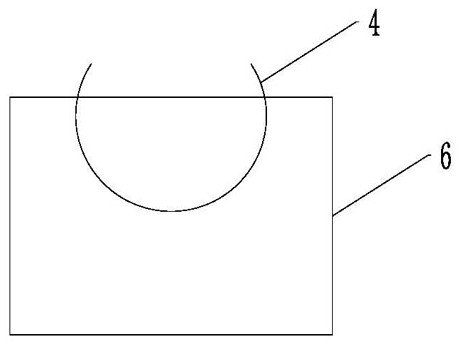

[0087] Embodiment 2: At the position where the battery sheet without main grid is laid, the filamentary conductive material 4 is pulled through the conductive glue 3 in the conductive glue 3 container (see figure 2 ), so that the conductive adhesive 3 is attached to the filamentary conductor 4, and then the auxiliary grid line on the battery sheet without the main grid is vertically corresponding to the filamentary conductor 4, so that the conductive adhesive 3 is adhered to the filamentary conductor 4. The surface of the cell without busbar is laminated and cured to form the electrical connection between the cell and the module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com