Turbine experiment device capable of quickly replacing test and measurement blade grids

An experimental device and cascade technology, which is applied in the direction of measuring device, gas turbine engine test, engine test, etc., can solve the problem that the flow and heat transfer characteristics of the gas turbine hot end parts cannot be systematically carried out, and the guide vane and moving part cannot be satisfied at the same time. Requirements for leaf test cascades, complex replacement of test cascades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

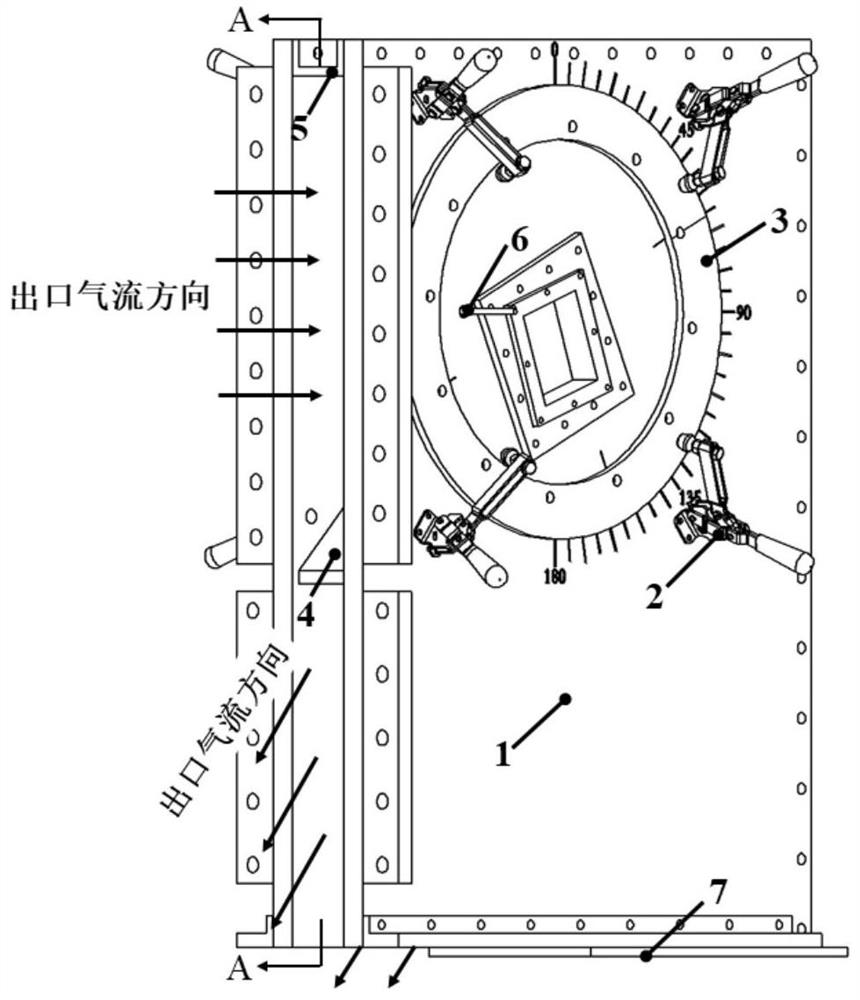

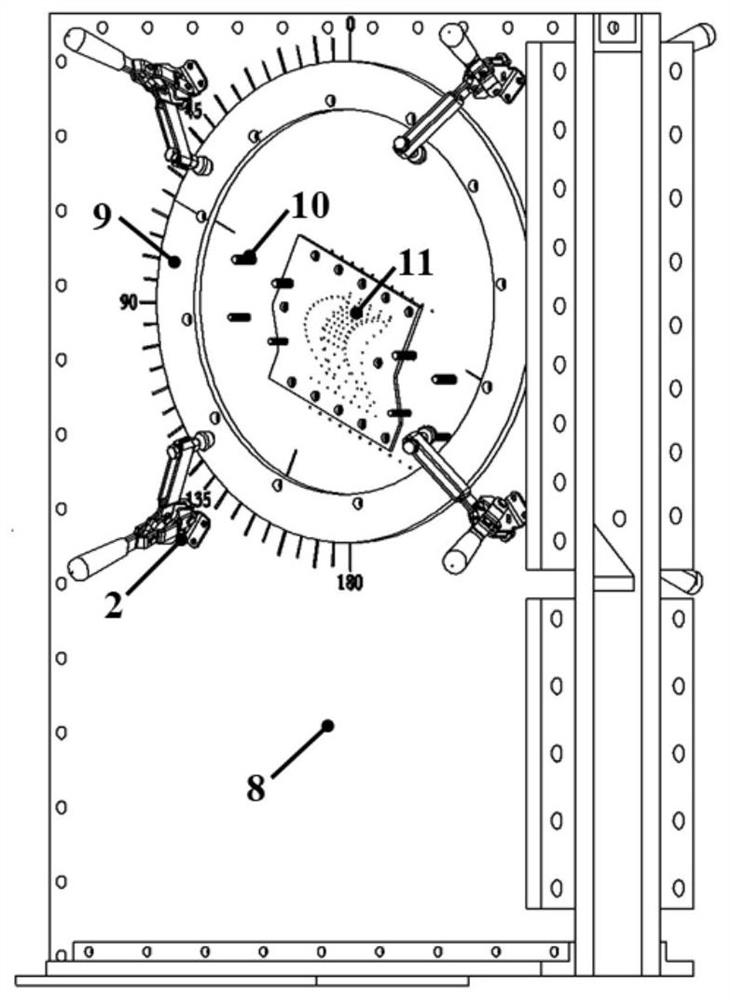

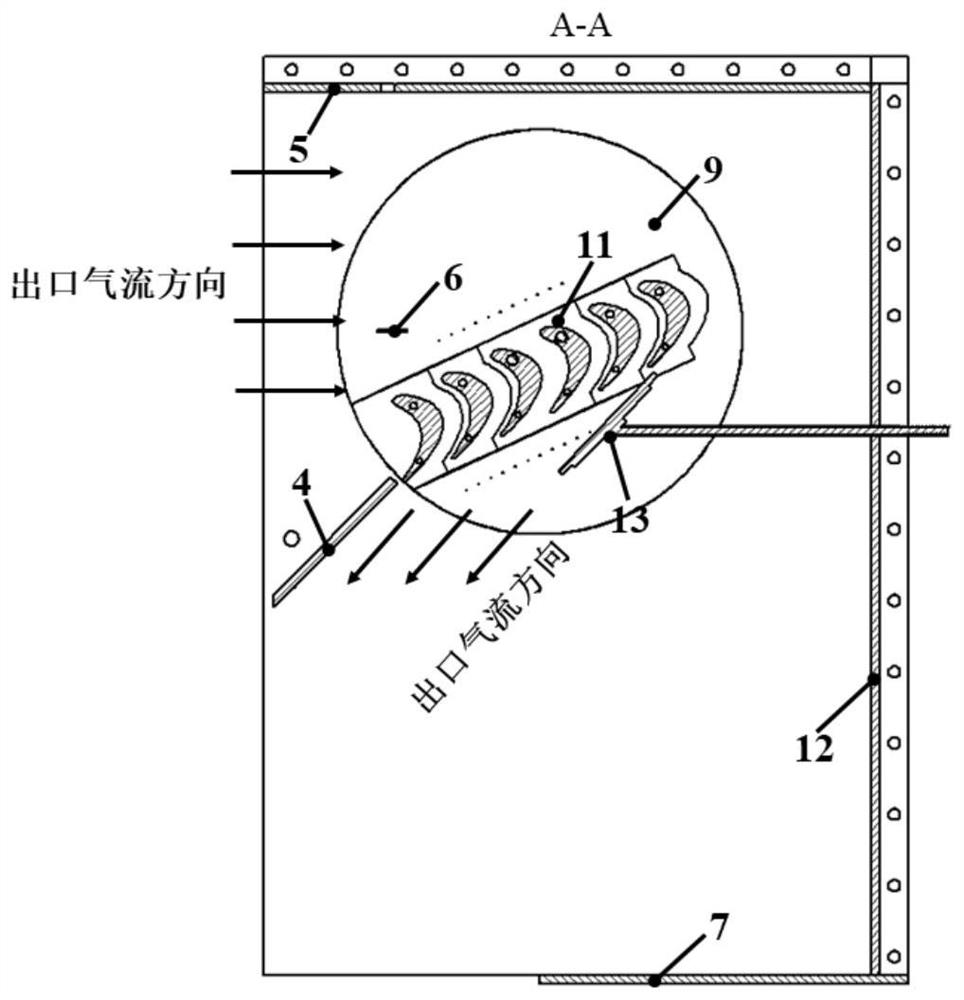

[0026] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0027] The invention is a turbine experimental device capable of quickly replacing test and measurement cascades, which can economically and quickly replace the test cascades, measure the cascades, adjust the inlet airflow angle of the test cascades, and adjust the measurement and observation range of the measurement cascades. The purpose is to conveniently carry out test measurements of different types of test cascades (guide vanes and moving vanes), test cascades with different cooling structures, and cascades with different inlet airflow angles, in order to improve the cooling effect of the hot end components of the gas turbine and to prevent hot end Provides support for thermal stress failure of components.

[0028] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes two parallel side plates with a certain d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com