Panel structure

A technology of inserts and inserts, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as the trouble of replacing inserts, and achieve the effects of short processing cycle, reduced cost and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

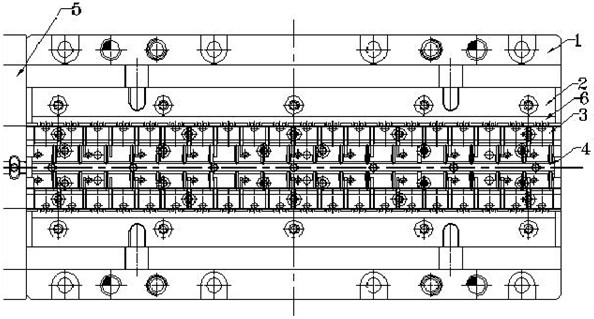

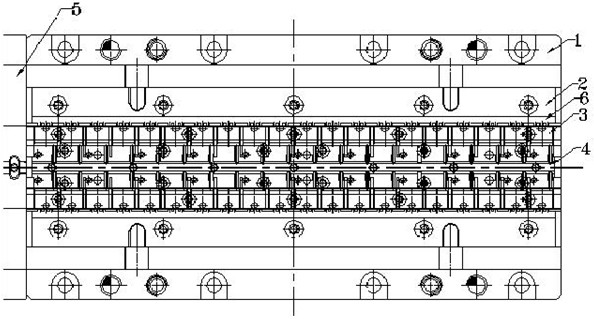

[0009] As shown in Figure 2, a molding structure provided by the present invention includes a lower mold assembly 1. In the lower mold assembly 1, a lower edge molding bar 2, a lower molding bar 3, and a runner bar 4 are sequentially provided. The plate 5 is connected to the lower mold assembly 1, and an insert 6 is assembled at the two ends of the lower insert 2 where the plastic molding compound is easily abraded.

[0010] The molding compound is injected into the cavity of the lower molding bar 3 through the sprue on the runner bar 4 through the gate. The inserts 6 at both ends of the pipe are easily worn by the molding compound and often need to be replaced. However, it is more economical to replace only one small insert 6. When replacing, just remove the lower mold closing baffle 5, and knock off the insert 6 from the side to replace it, without disassembling the entire mold. Such a mosaic method not only reduces the production cost, but is also very convenient to replace....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com