A method for bonding crystal rods

A bonding method and crystal rod technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problem of damage to the bonding surface of crystal rods, impact on the bonding surface of silicon rods, uneven force on steel wires, etc. Problems, achieve the effect of reducing damage, ensuring bonding strength, and simple bonding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

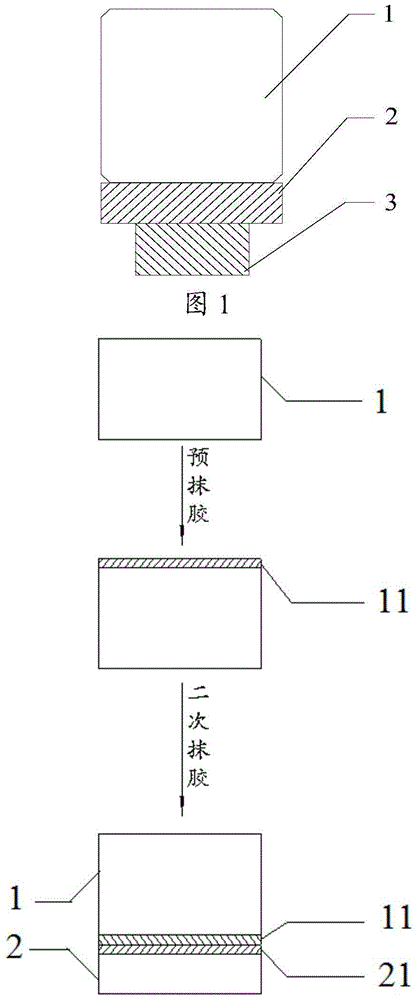

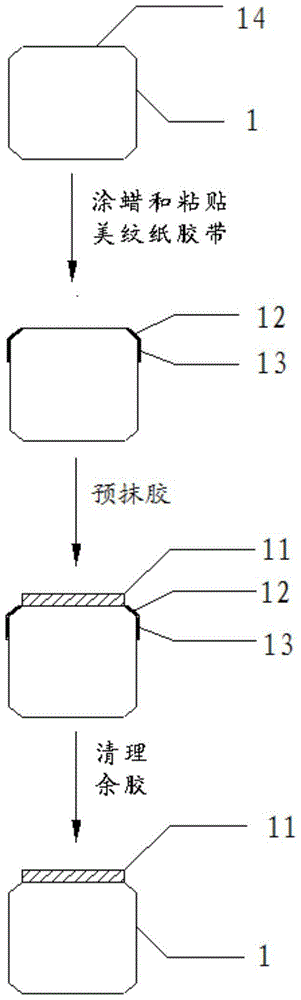

[0044] See attached figure 2 , a method for bonding crystal rods, comprising the following steps:

[0045] (1) Take the polycrystalline silicon rod as the crystal rod to be glued, clean the surface of the crystal rod to be bonded, and then apply glue for pre-applying glue, and form a uniform pre-applying glue layer after the glue is completely cured for 40 minutes. The thickness of the adhesive layer is 100 μm; then the pre-applied adhesive layer is roughened, and the roughened treatment is to use manual sandpaper to polish the pre-applied adhesive layer;

[0046](2) Take the carrier board, apply Wanda wd3640 two-component AB glue on the surface of the carrier board to be bonded, and bond the ingot with the pre-applied glue layer described in step (1) to the carrier board, and wait for the glue to cure After 4 hours, a secondary glue layer is formed to complete the bonding of the ingot.

[0047] Among them, the structure of the polycrystalline rod to be glued is as follows: ...

Embodiment 2

[0056] The technical scheme by embodiment 1 is basically the same, and the difference is that the thickness of the pre-applied adhesive layer is 120 μm, and in step (1), the curing time of glue is 45min, and in step (2), the curing time of glue is 6h, the total thickness of the pre-smear layer and the second-smear layer is 250 μm.

[0057] Cutting the bonded ingot obtained in Example 2, the chipping rate of the obtained silicon wafer was 4.9%, and the hidden cracking rate was 0.5%.

Embodiment 3

[0059] Get the monocrystalline silicon rod as the crystal rod to be glued, and glue the crystal rod according to the technical scheme of Example 1, the difference is that the thickness of the pre-applied glue layer is 80 μm, and in step (1), the glue The curing time is 30 minutes, and in step (2), the curing time of the glue is 6 hours, and the total thickness of the pre-applied glue layer and the second applied glue layer is 200 μm.

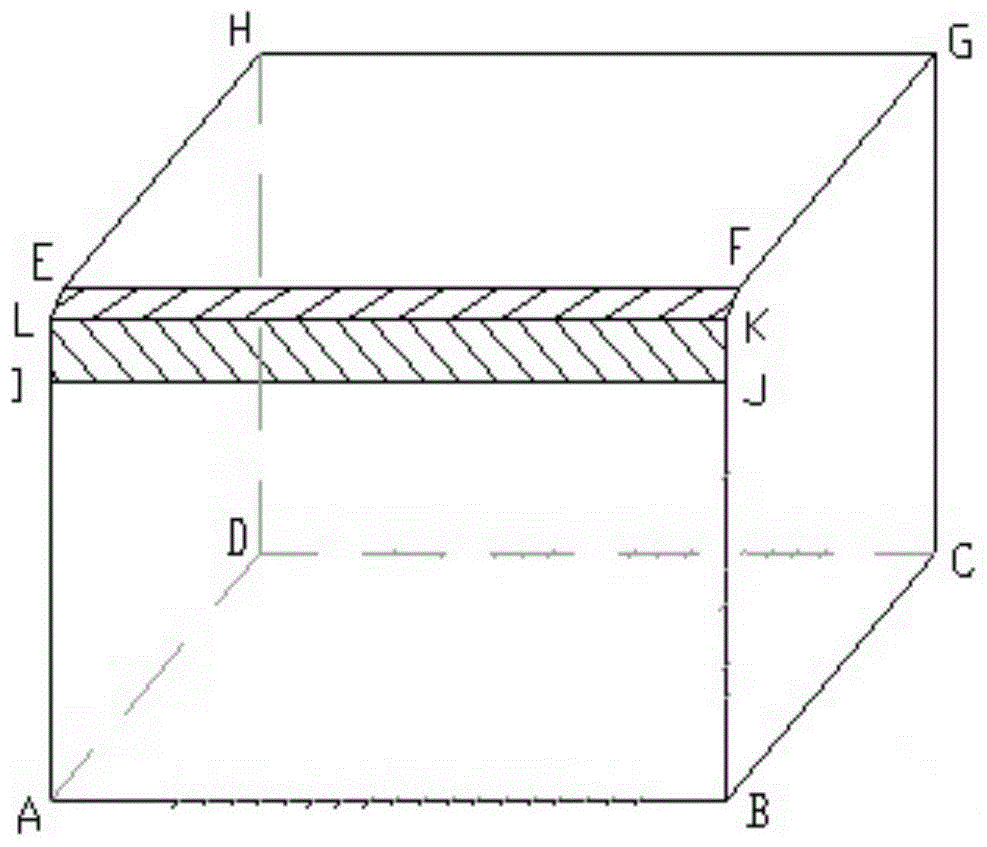

[0060] Among them, the structure of the single crystal ingot to be glued is as follows Figure 5 As shown, the planes ADHE and BCGF are the two end faces of the ingot, the AB direction is the length direction of the ingot, and the BK or AL direction is the direction in which the steel wire cuts the ingot. The plane EFGH is the surface to be bonded between the crystal ingot and the carrier plate, and the plane EFKL is a circular arc chamfering surface, which is parallel to the length direction AB of the crystal ingot. The arc diameter of the circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com