Patents

Literature

31results about How to "Low solderability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

ActiveCN102994874APromote productionIncrease the lengthHeat treatment process controlReduction rateChemical composition

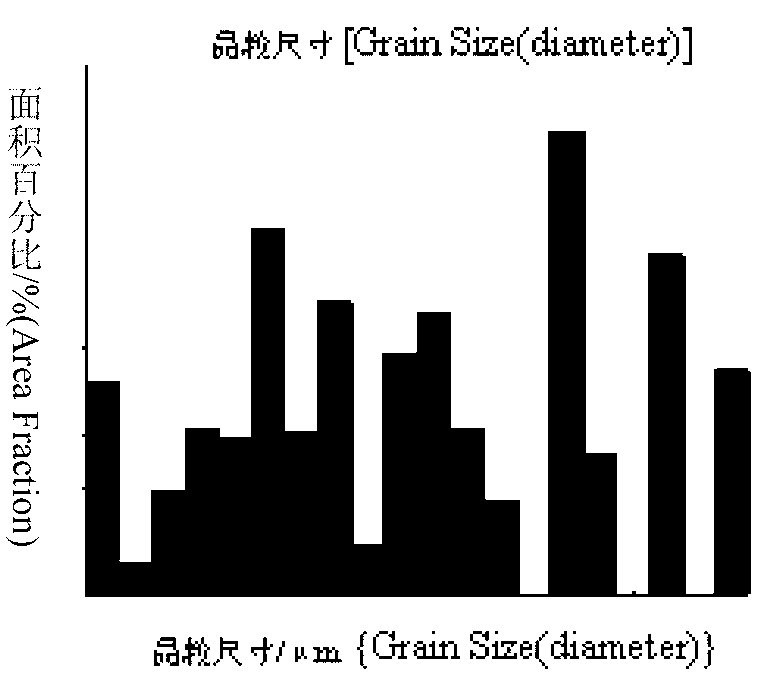

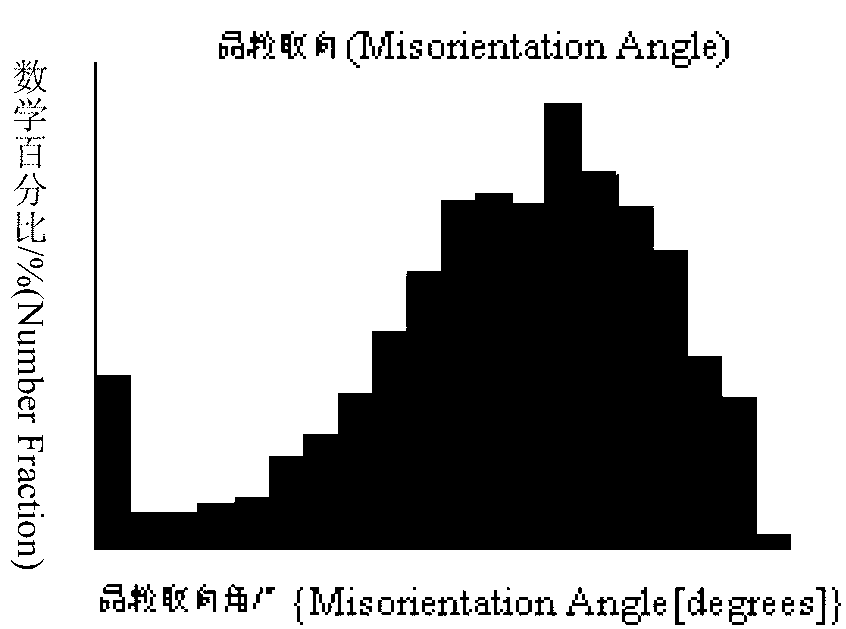

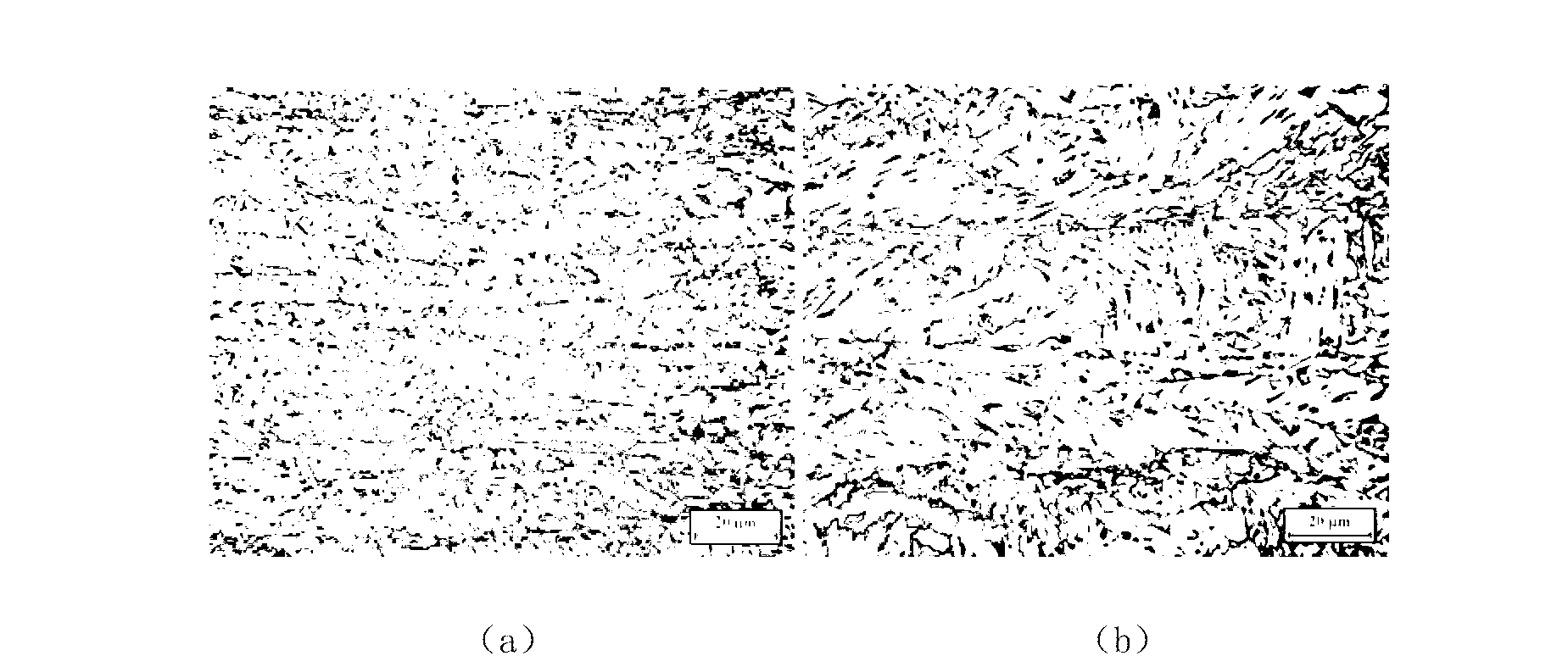

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

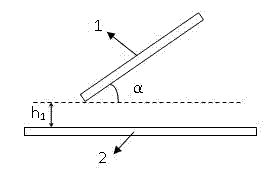

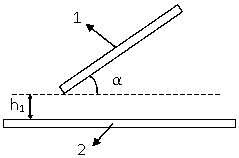

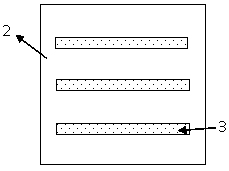

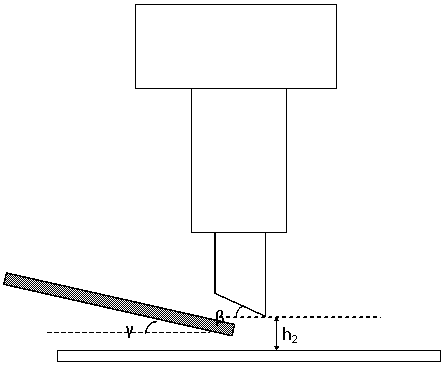

Preparation method for back electrode of solar battery

ActiveCN104752554ALow costAvoid Ultrasonic Vibration DevicesFinal product manufacturePhotovoltaic energy generationElectrical batteryPhotoelectric efficiency

The invention discloses a preparation method for a back electrode of a solar battery. The preparation method includes that using soldering flux to form a soldering flux belt at the surface of an aluminum back field, forming a non-silver metal solder belt at the surface of the soldering flux belt, wherein the soldering flux belt can break an alumina film at the surface of the aluminum back field to expose fresh aluminum from the surface of the aluminum back field, the subsequently fed non-silver metal wires (solder) are melted by the heat effect of a soldering head, the molten liquid fuses with the aluminum, the molten solder is well bonded at the surface of the aluminum back field, the silver use is avoided, the cost is lowered, an ultrasonic vibration device is not used, the intensity of a finished product is obviously improved, fragment and crack are obviously reduced, and the quality of the back electrode of the solar battery is greatly improved. The back electrode of the solar battery prepared by the preparation method is low in fragment and crack rate, the adhesion between the back electrode and aluminum back field is strong, the welding with a photovoltaic soldering belt is good, the average photoelectric efficiency conforms to requirement, and the manufacturing cost is low.

Owner:BYD CO LTD

Titanium-reinforced low-cost Q390 grade hot rolled plate and production method thereof

The invention discloses a titanium-reinforced low-cost Q390 grade hot rolled plate and a production method thereof. The chemical component percentages of the hot rolled plate are, by mass, 0.15%-0.18%of C, less than or equal to 0.10% of Si, 0.45%-0.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.06% of S, 0.015%-0.060% of Als, 0.040%-0.055% of Ti, less than or equal to 0.0050% of N, and the balance Fe and inevitable impurities; and the method includes steps of smelting, refining, continuous casting, heating a plate blank, controlling rolling, controlling cooling and rolling. By adopting a low-manganese and titanium micro-alloy strengthening design, the hot rolled plate has a yield strength greater than or equal to 390 MPa, a strength of extension greater than or equal to 490 MPa, an elongation greater than or equal to 20%, and a Ceq from 0.23 to 0.28, so that the hot rolled plate and the production method thereof have the advantages such as good welding performance, low content of alloy, good effect of galvanization and low cost.

Owner:HEBEI IRON AND STEEL

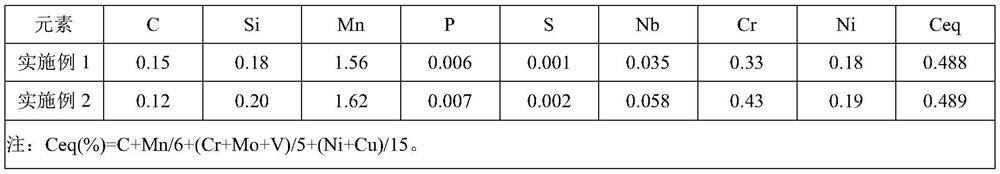

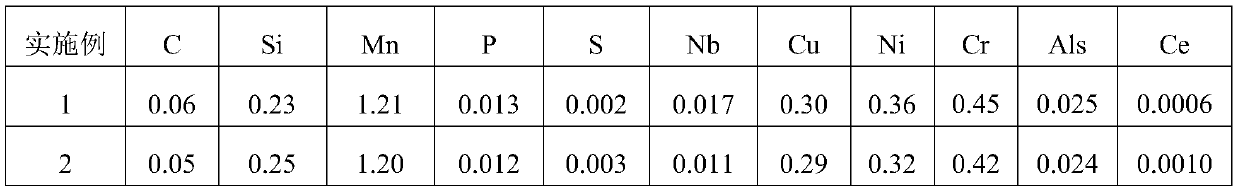

8-25mm thickness type low-yield-ratio and high-strength steel sheet for tank truck and manufacturing method thereof

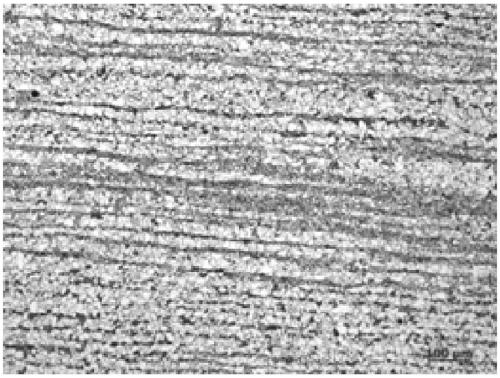

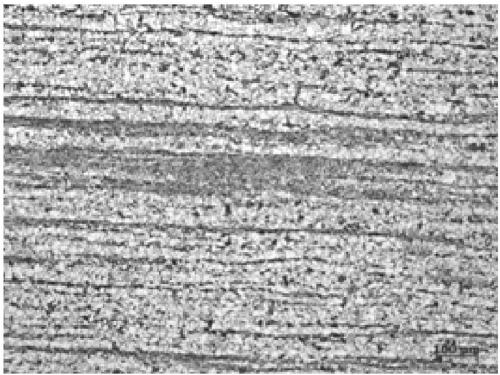

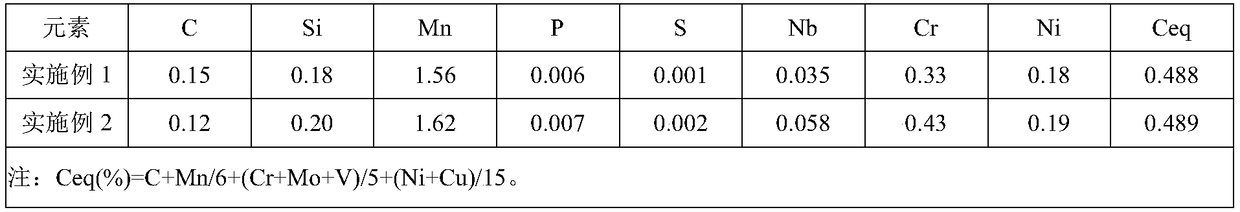

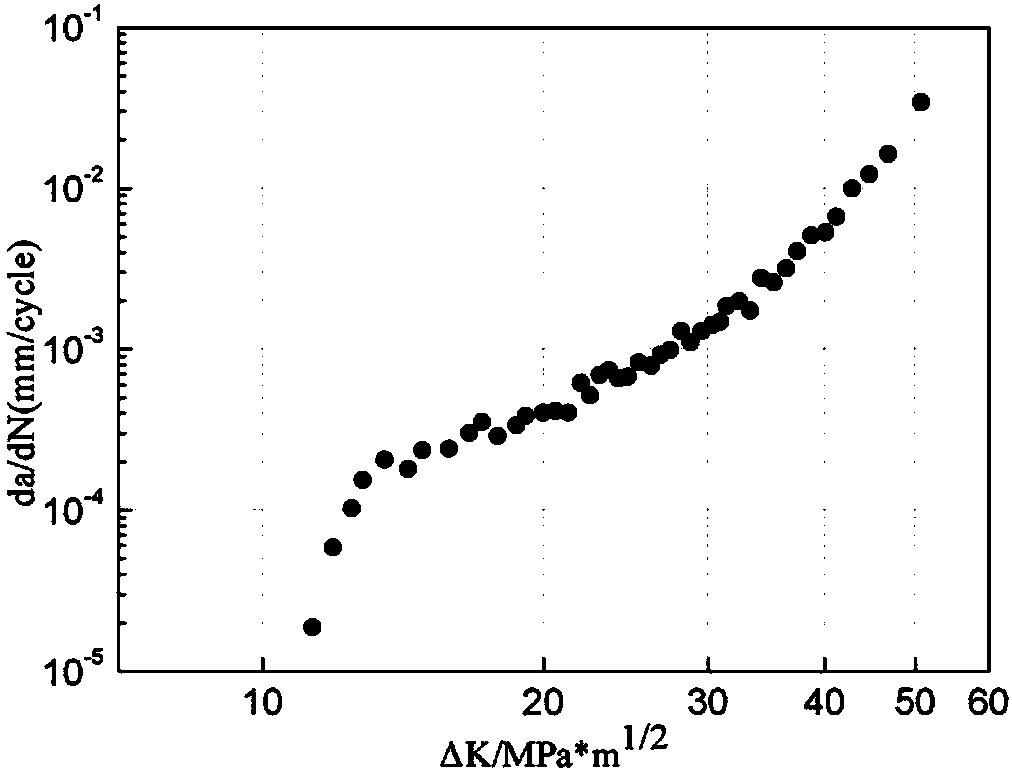

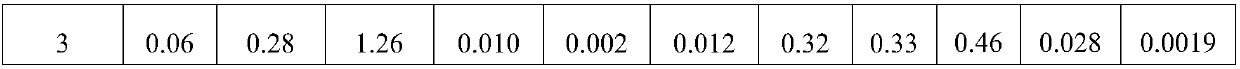

The invention relates to an 8-25mm thickness type low-yield-ratio and high-strength steel sheet for a tank truck. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck solves the shortages such as high yield ratio, low welding performance and high production cost of a current steel sheet. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck is characterized in that a C+Mn+Cr and Nb and Ni microalloying system is adopted; the steel comprises the following chemical components in percentage by weight: 0.08-0.15% of C, 0.05-0.20% of Si, 1.50-2.00% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.32-0.45% of Cr, 0.10-0.20% of Ni, 0.02-0.07% of Nb, and the balance Fe and inevitable impurity elements; and the formula (seeing the description) is met. A normalizing technology is carried out for production; the mechanical performance meets the condition that the yield strength is not less than 400MPa;the tensile strength Rm is not less than 600MPa; the ductility A50 is not less than 32%; the yield ratio is not greater than 0.75; the transverse impact energy KV2 at below 50 DEG C is not less than 47J; the technical processes include preparing molten iron through a blast furnace, performing KR treatment on the molten iron, performing smelting in a 120-160t oxygen converter, performing refining in an LF (ladle furnace), performing treatment (refining) in an RH vacuum furnace, performing continuous casting, heating a casting blank, performing controlled rolling, performing normalizing, detecting cracks, and inspecting. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck has the characteristics of being low in yield ratio, high in strength, outstandingin low-temperature toughness and plasticity, and high in welding performance; and in addition, the production cost is low; and the operability is high.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

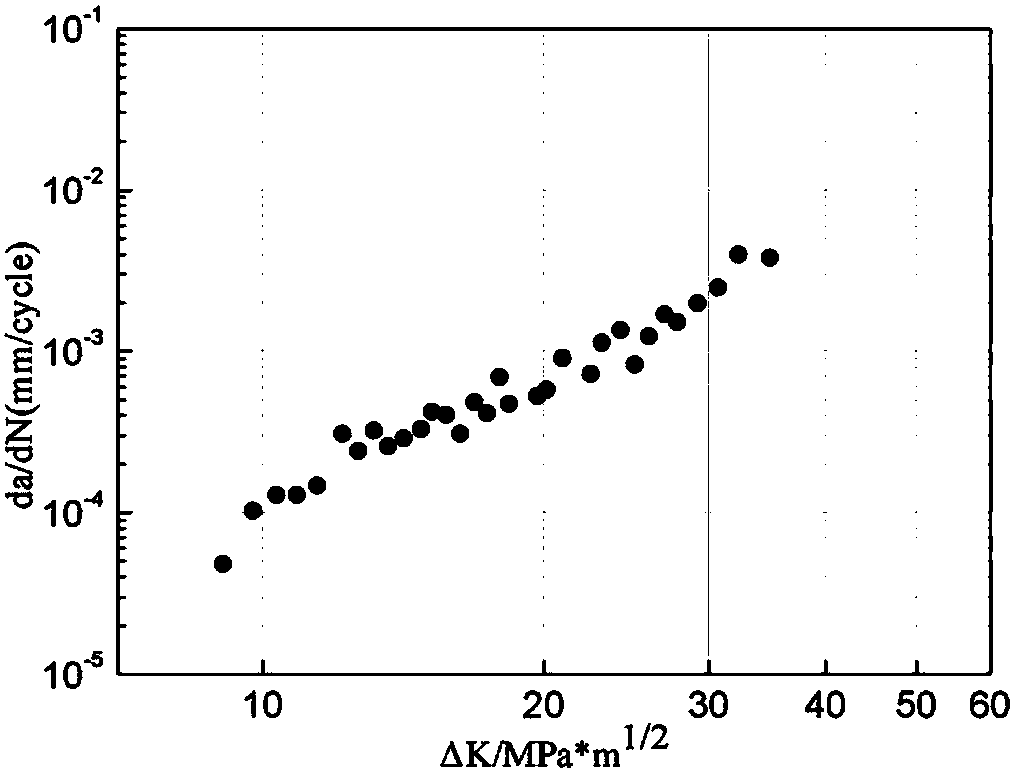

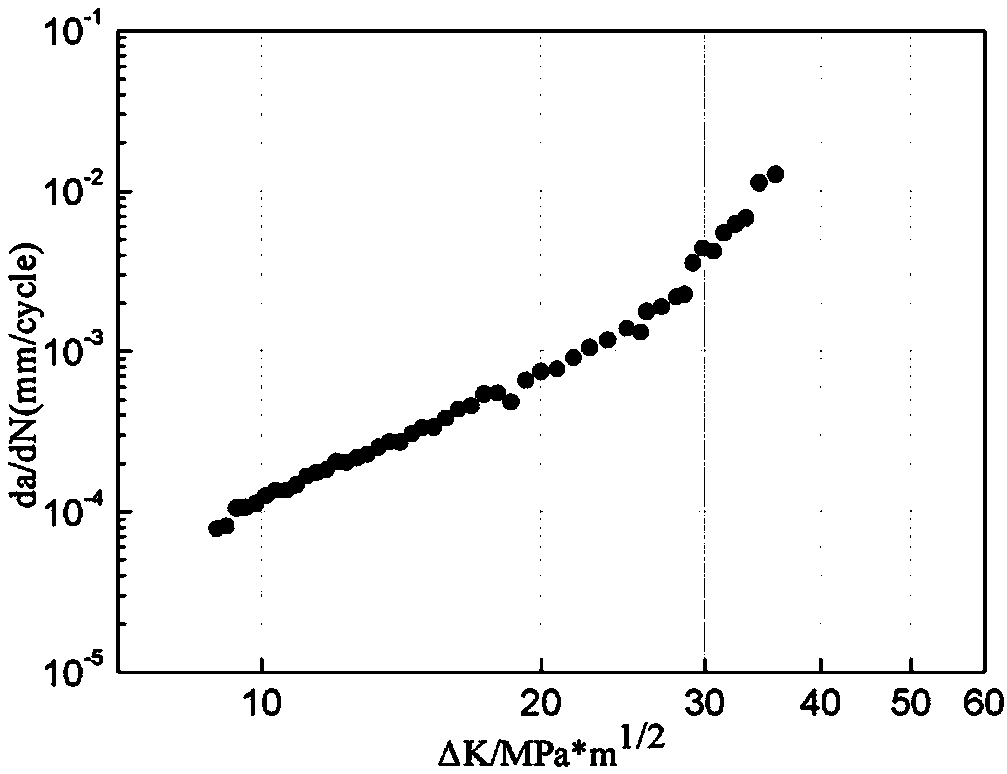

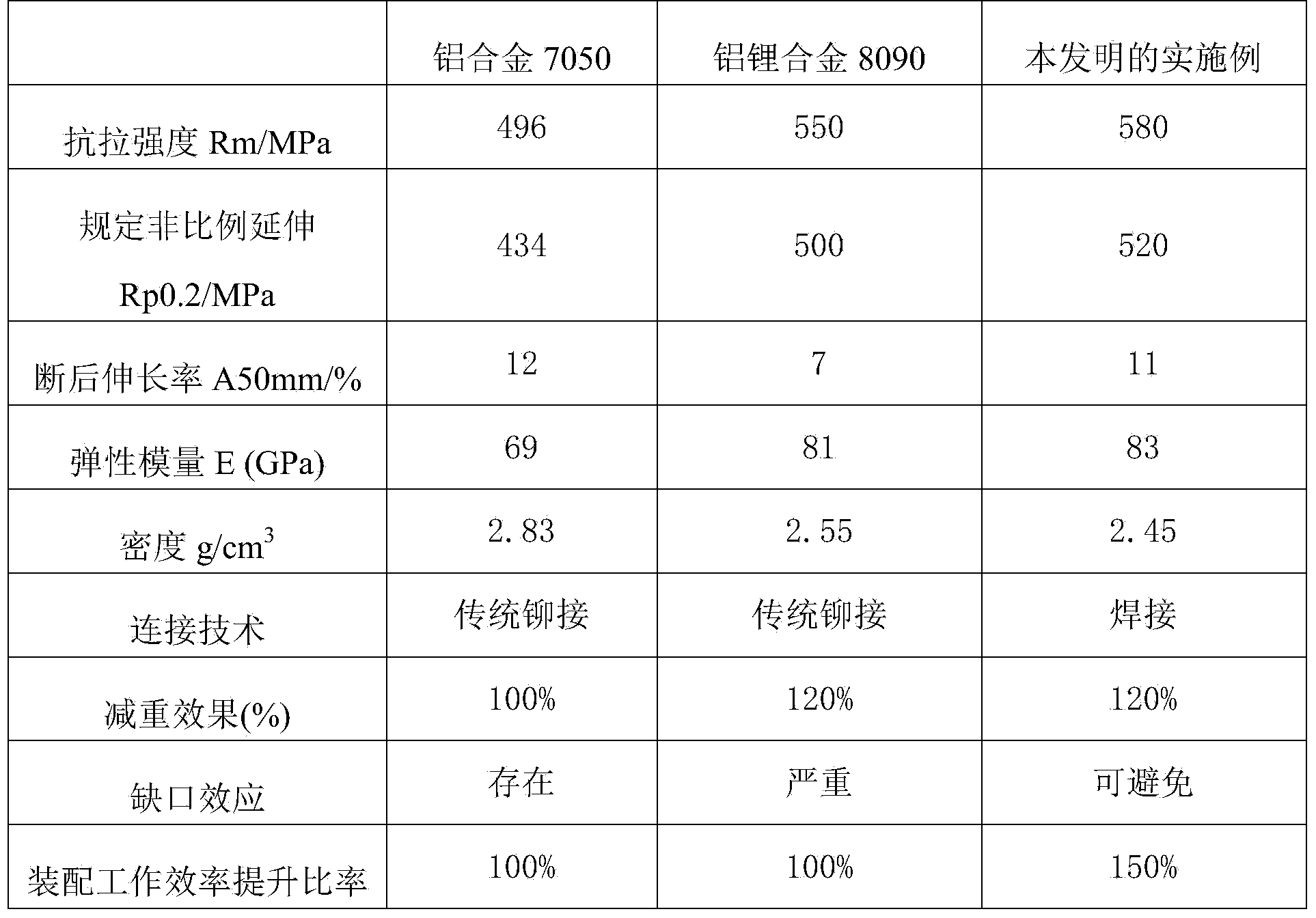

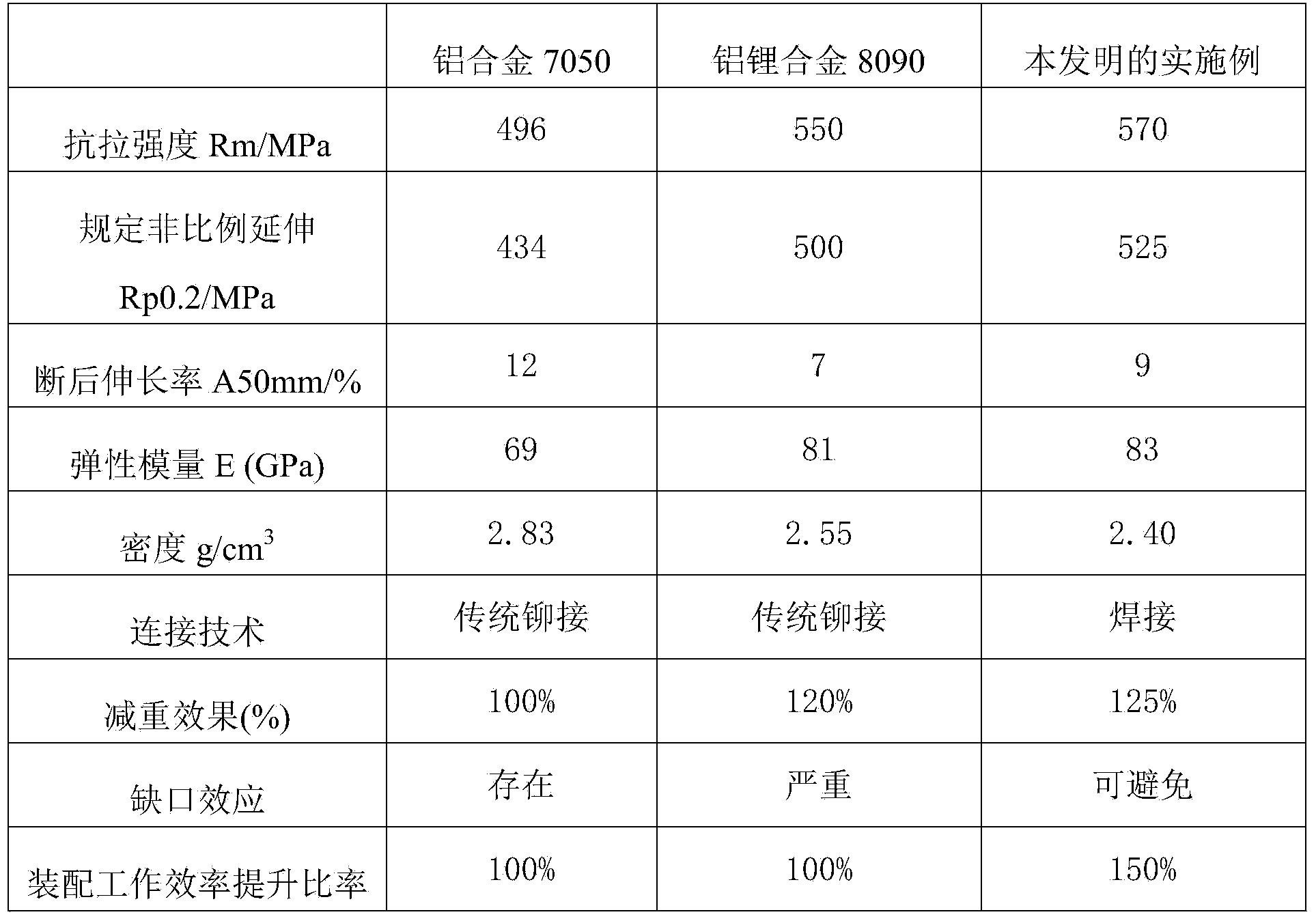

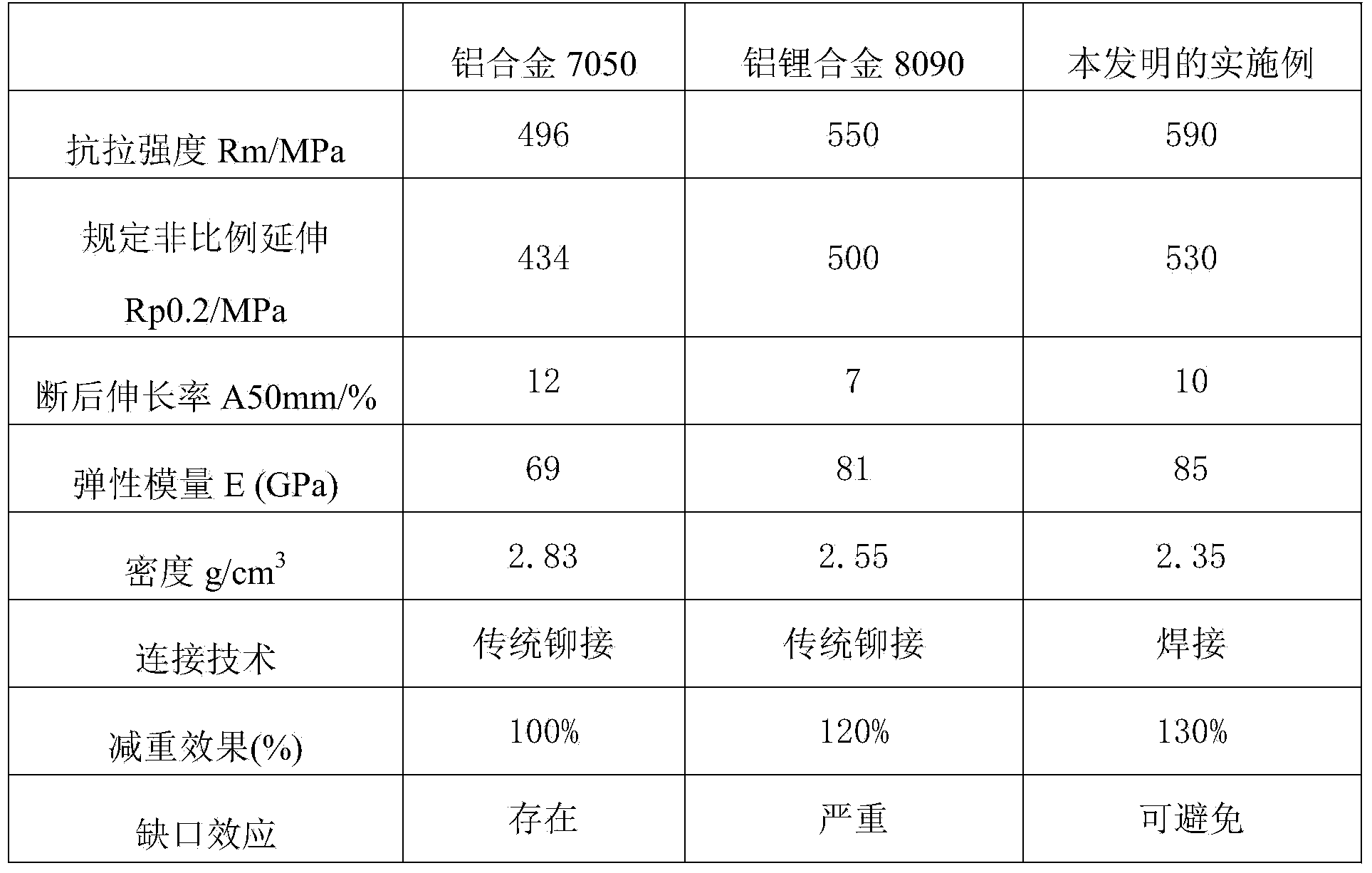

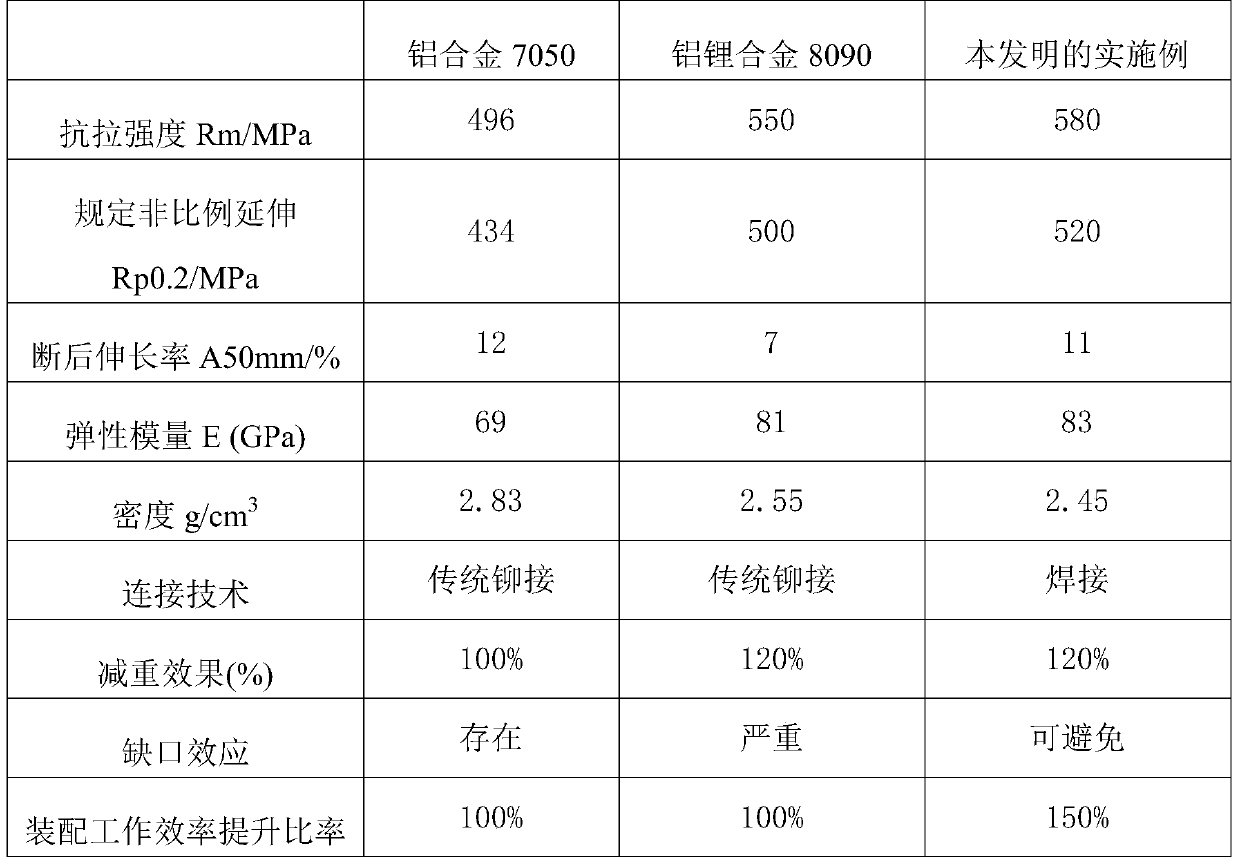

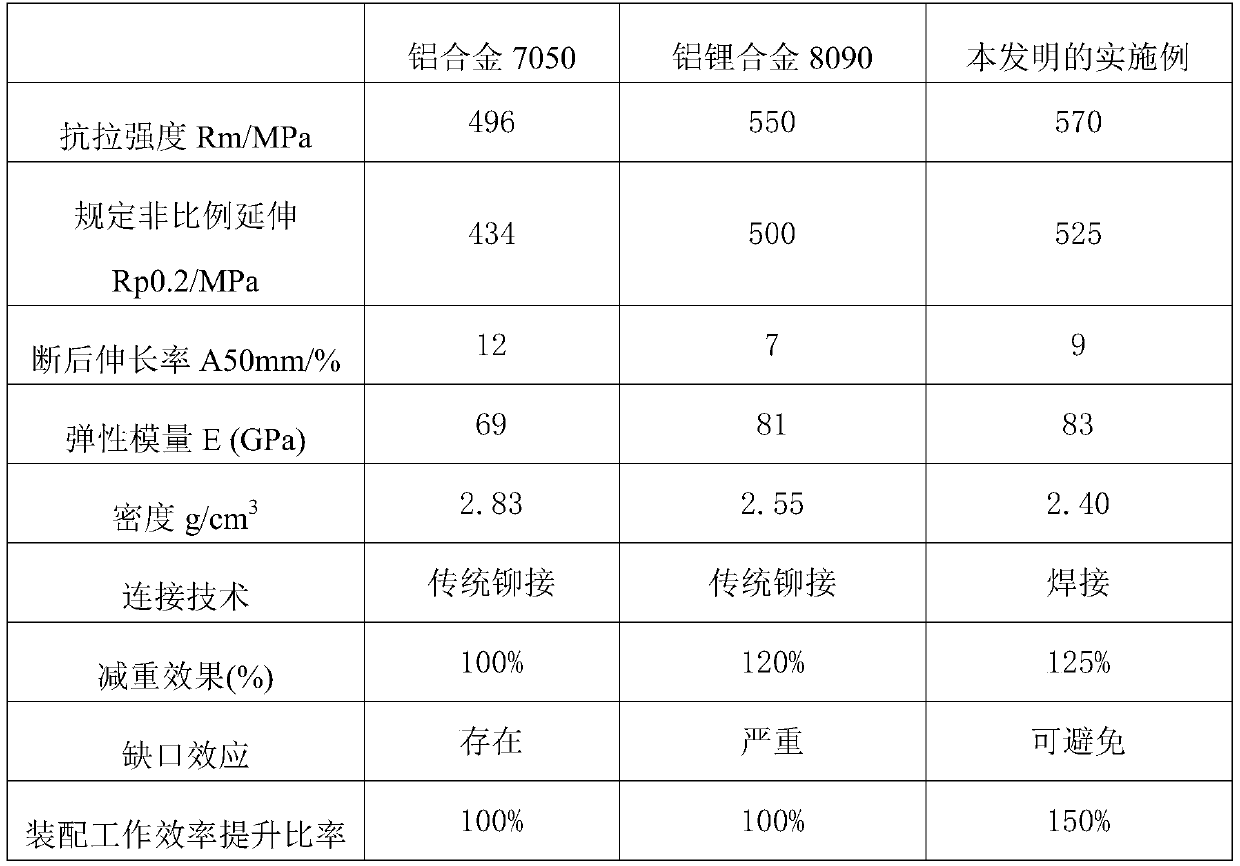

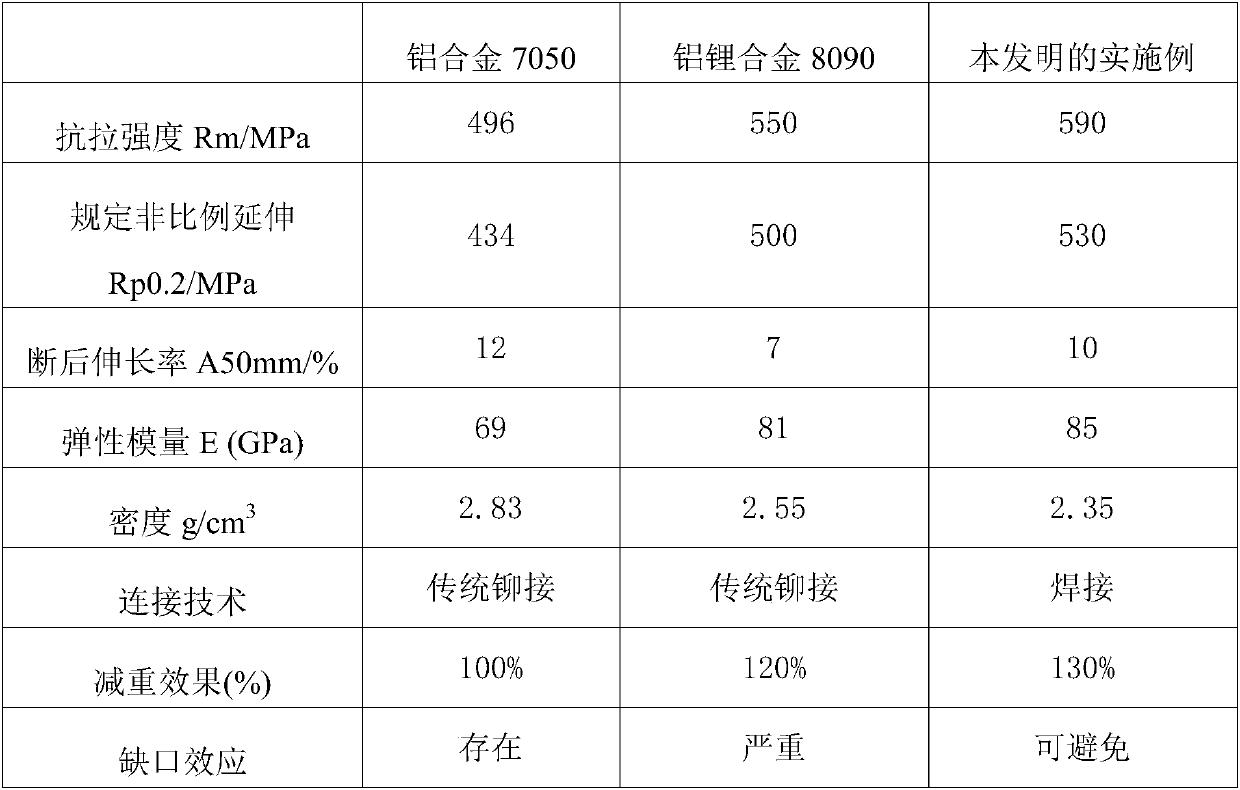

Medium and high strength damage resistant aluminum lithium alloy material and preparation method and application thereof

The invention discloses a medium and high strength damage resistant aluminum lithium alloy material and a preparation method of the medium and high strength damage resistant aluminum lithium alloy material. The medium and high strength damage resistant aluminum lithium alloy material is prepared from, by mass, 0.5-2% of lithium, 2-5% of copper, 0.2-0.7% of magnesium, 0.1-0.5% of silver, 0.1-0.6% of manganese, 0.01-0.15% of titanium, 0.08-0.15% of zirconium, 0.05-0.6% of ruthenium, 0-0.15% of erbium and the balance aluminum. Since a small amount of rare and precious metal element ruthenium withthe higher melt purifying ability is added into the alloy, the prepared aluminum lithium alloy has the high specific strength, high molding performance, high tenacity and excellent corrosion resistance, and the comprehensive mechanical properties of the alloy are greatly improved.

Owner:CENT SOUTH UNIV

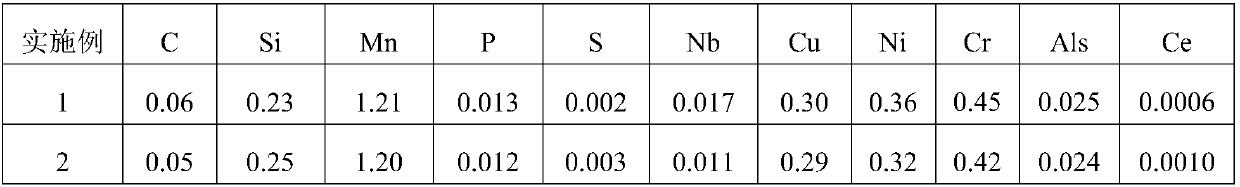

Rare earth weather-resistant bridge steel plate with yield strength being 370 MPa grade and preparation method thereof

The invention relates to a rare earth weather-resistant bridge steel plate with the yield strength being 370 MPa grade and a preparation method thereof. The preparation method comprises the steps thatsmelting and casting are conducted; heating and rolling are conducted, specifically, the heating temperature is 1200-1220 DEG C, the total in-furnace time is larger than or equal to 240 min, during rolling, rolling of the first stage is conducted in an austenite recrystallization zone, the rolling starting temperature is 1130-1180 DEG C, the reduction quantity from the first pass to the second pass is larger than 10%, and the reduction rate of at least 1-2 of the rest passes is controlled to be 25% or above, rolling of the second stage is conducted in an austenite non-recrystallization zone,the rolling starting temperature is smaller than or equal to 930 DEG C, the thickness of an intermediate blank is 2.0-3.5 times of the thickness of a finished product, and the finished rolling temperature is 830-850 DEG C; and cooling is conducted. The yield strength of the steel plate is larger than 370 MPa, the steel plate has the advantages of being low in yield ratio, good corrosion resistantperformance, low-temperature toughness, cold-forming performance and welding performance and capable of being used without coating, the production technological process is simple, the production period is short, and the cost is low.

Owner:BAOTOU IRON & STEEL GRP

Ultralow-hydrogen and high-tenacity metal powder core type seamless flux-cored welding wire for all-position welding

ActiveCN106891104ALow solderabilityReduced crack resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconMachinability

The invention provides an ultralow-hydrogen and high-tenacity metal powder core type seamless flux-cored welding wire for all-position welding. The seamless flux-cored welding wire comprises outer skin and flux core powder, wherein the inner part of the outer skin is filled with the flux core powder, and the outer skin is a low-carbon steel band. The seamless flux-cored welding wire is characterized in that the flux core powder comprises the following components in a percent by weight: 10-15% of low-carbon ferromanganese, 15-20% of atomized ferrosilicon, 2-5% of rutile, 1-5% of cryolite, 1-3% of atomized nickel powder, 1-2% of quartz, 0.5-2% of feldspar and the balance of iron powder. The seamless flux-cored welding wire is suitable for the all-position welding of carbon steel and low-alloy steel which are welded under the protection of mixed gas containing 75-85% of Ar and 15-25% of CO2. The seamless flux-cored welding wire is great in welding machinability, stable in mechanical properties, great in crack resistance, low in hydrogen dispersion and high in moisture absorbability and can be used for all-position welding.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Thermal treatment technology for special-shaped steel tube

InactiveCN104032311AHigh yield strengthLow solderabilitySolid state diffusion coatingFurnace typesWear resistantThermal expansion

The invention relates to the technical field of special-shaped steel tubes, and particularly relates to a thermal treatment technology for a special-shaped steel tube. The thermal treatment technology comprises the following steps: (1) carrying out high-temperature tempering treatment before quenched-tempered thermal treatment; (2) after the tempering treatment is completed, treating the steel tubes by adopting a method of combining chemical ferrite treatment and chemical austenite treatment; and (3) finally, conducting quenching and tempering, cooling the treated steel tubes into the range of 180-230DEG C, vacuumizing, conducting secondary quenching treatment, and insulating for 2.5-3h; heating again to 580-630DEG C, maintaining a vacuum state, conducting high-temperature tempering, insulating for 7-8h, then cooling to room temperature, thus completing the whole thermal treatment process. For the special-shaped steel tubes treated by the thermal treatment technology, the yielding strength is improved to 1100-1250MPa, the tensile strength is improved to 1200-1350MPa; the special-shaped steel tubes are long in anti-fatigue service life, wear-resistant, corrosion-resistant, low in thermal expansion coefficient, good in weldability, better in the whole straightness of the steel tubes, and low in residual stress; and the thermal treatment technology provided by the invention is green and environmentally friendly and low in cost.

Owner:张家港市华尊宝特种材料科技有限公司

Ultra-high molecular weight polyethylene thermoelectric conduction material

The invention relates to an ultra-high molecular weight polyethylene thermoelectric conduction material. The ultra-high molecular weight polyethylene thermoelectric conduction material specifically comprises the following components in parts by mass: 58-62 parts of ultra-high molecular weight polyethylene, 24-28 parts of nano aluminum powder, 12-16 parts of polysiloxane-G-polycarbonate PC resin and 0.5-2.5 parts of an anti-aging agent, namely ascorbic acid. The ultra-high molecular weight polyethylene thermoelectric conduction material disclosed by the invention has good heat-conducting and conductive functions, low filling property, good welding performance and high dispersity.

Owner:王晓伟

Anti-rust heat-resistant special-shaped steel tube and preparation method thereof

The invention relates to the technical field of special-shaped steel tubes and particularly relates to an anti-rust heat-resistant special-shaped steel tube and a preparation method thereof. The anti-rust heat-resistant special-shaped steel tube is prepared from the following components in parts by mass: 0.8-7 parts of carbon, 2-5 parts of silicon, 10-20 parts of manganese, 20-30 parts of nickel, 30-40 parts of chromium, 2-4 parts of copper, 0.1-0.4 part of sulfur, 0.3-0.8 part of phosphorus, 5-10 parts of nitrogen, 0.3-2 parts of vanadium, 0.03-0.2 part of boron, 10-20 parts of lanthanum, 80-100 parts of iron and 3-6 parts of an additive. The anti-rust heat-resistant special-shaped steel tube provided by the invention is low in cost, good in structure stability and cold and hot machinability, long in anti-fatigue service life, wear-resistant, corrosion-resistant, high in precision, good in weldability, good in overall straightness and low in residual stress. The anti-rust heat-resistant special-shaped steel tube provided by the invention can resist temperature reaching 1800 DEG C. The preparation method provided by the invention is simple in production process and low in cost, has a good economic benefit and is suitable for industrialized production on a large scale.

Owner:BEIJING JINYU SHUNDA TECH CO LTD

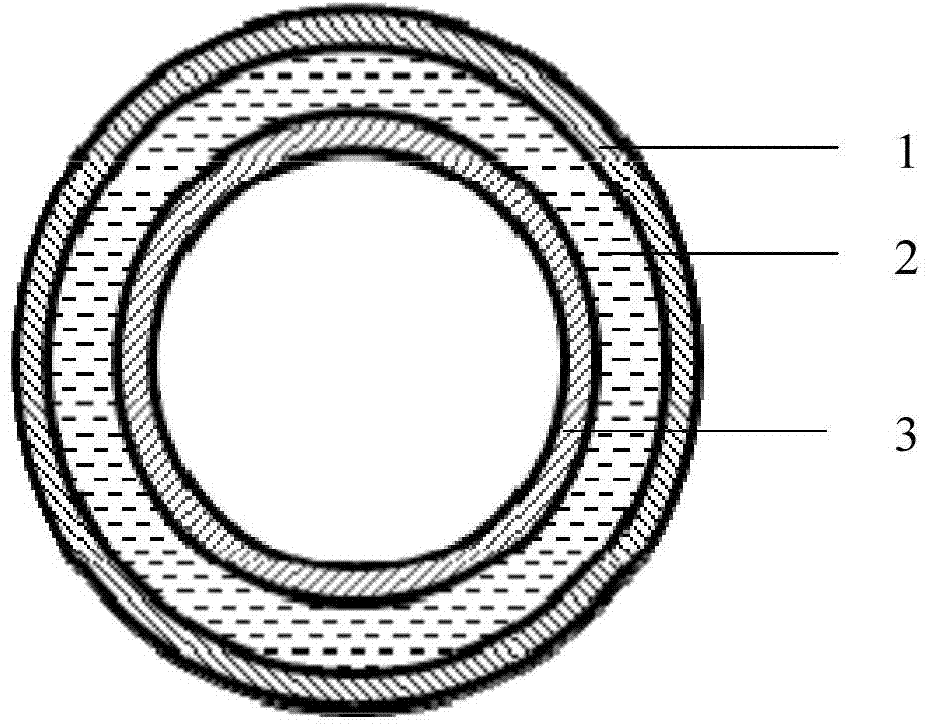

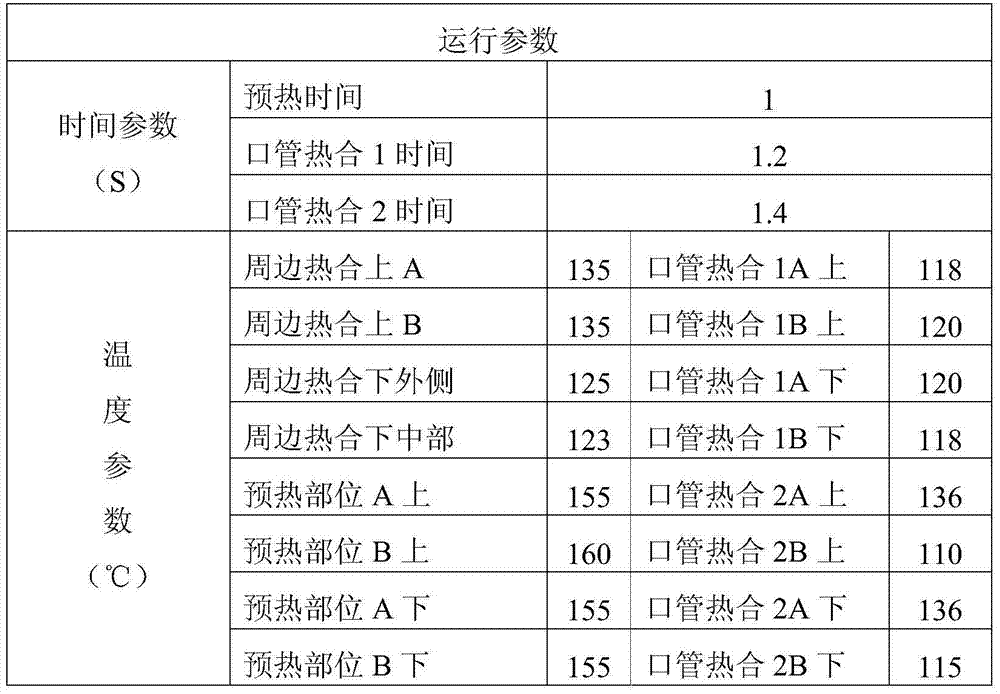

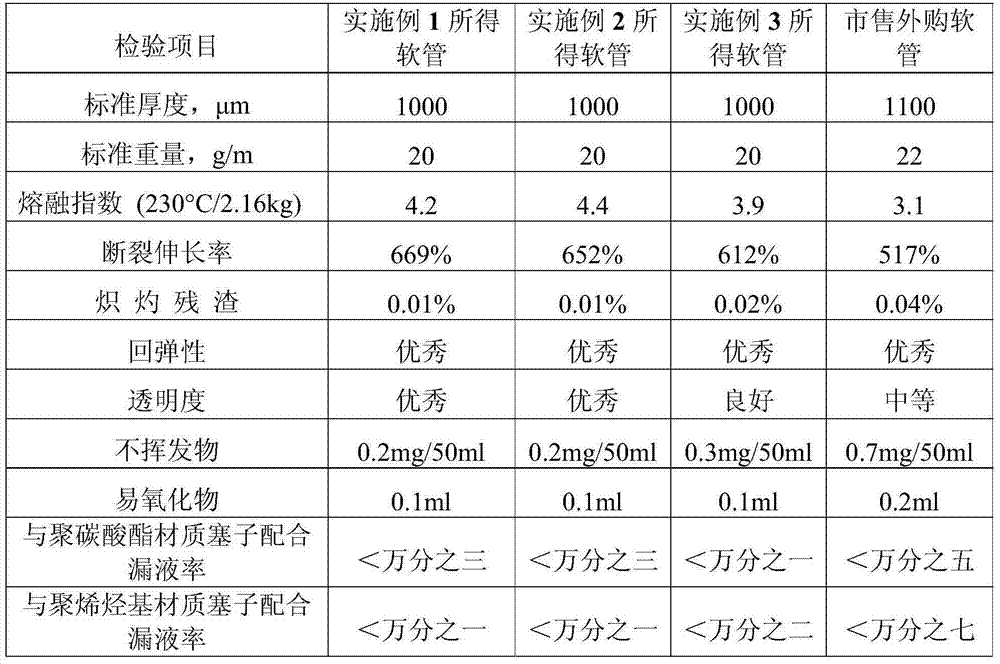

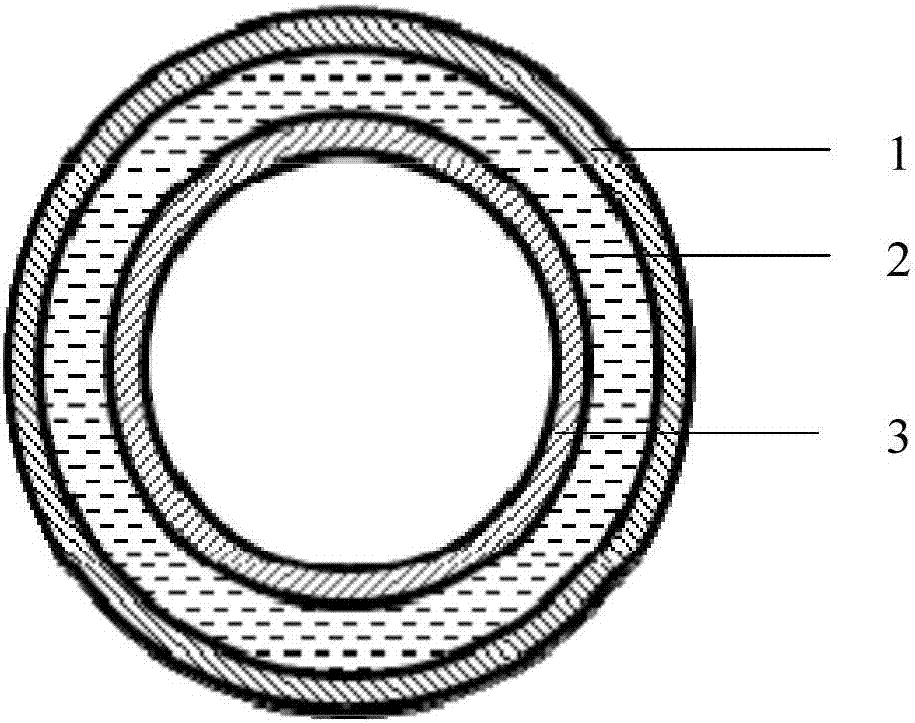

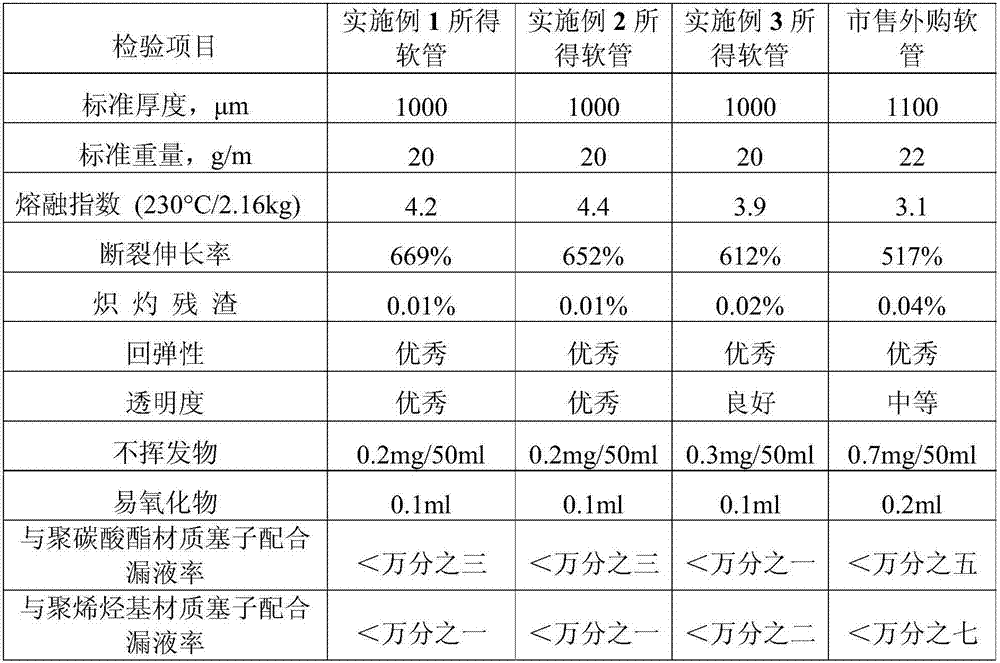

Material for transfusion hose and application of material

ActiveCN104772934AGood welding performanceReduce leak rateSynthetic resin layered productsCatheterComposite materialWeldability

The invention provides a material for a transfusion hose and an application of the material. The material is obtained by coextruding at least one outer layer material, a middle layer material and an inner layer material, wherein the outer layer material is prepared from the following components in percentage by weight: 50-99 percent of PP and 1-50 percent of SEBS, totally 100 percent; the middle layer material is prepared from the following components in percentage by weight: 30-70 percent of PP and 30-70 percent of SEBS, totally 100 percent; the inner layer material is prepared from the following components in percentage by weight: 10-45 percent of PP and 55-90 percent of SEBS, totally 100 percent. The material is high in weldability, soft, high in transparency, high in elasticity and suitable for coextrusion.

Owner:LANGHUO MEDICAL MATERIAL BEIJING

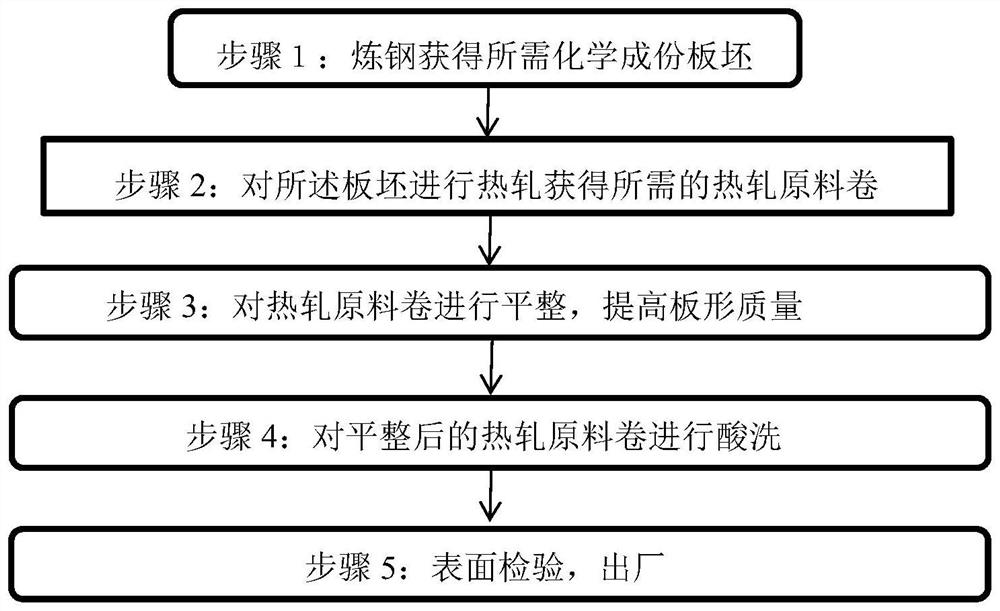

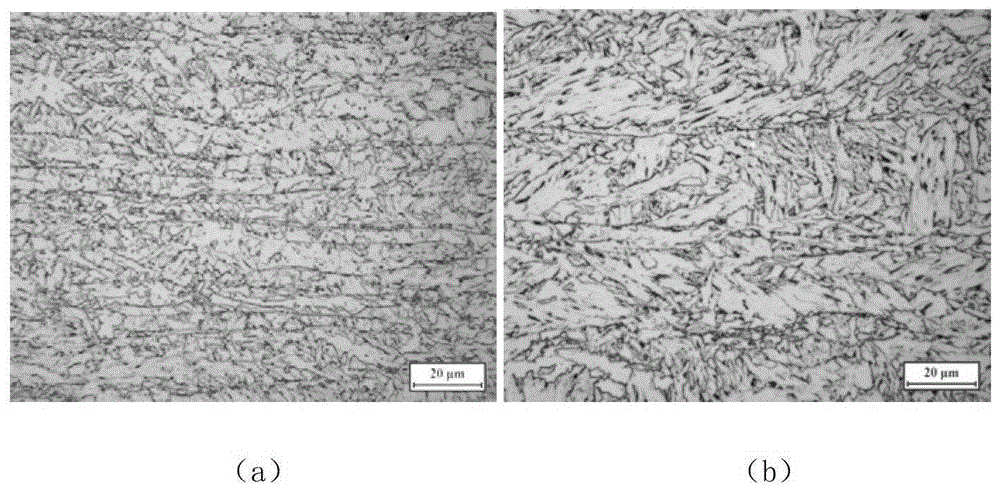

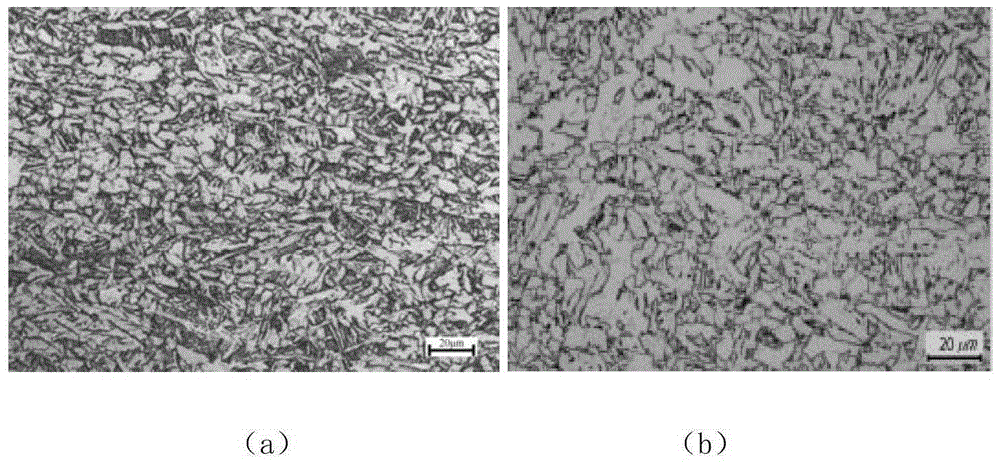

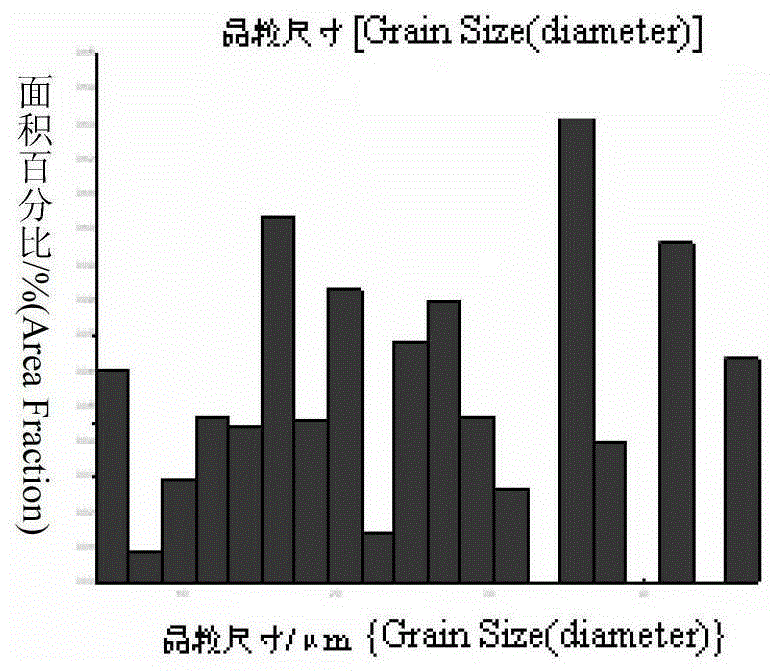

Preparation method of low-cost high-weldability hot-rolled pickled plate for 440MPa-grade automobile structure

PendingCN114774783AReduce manufacturing costGood weldability and formabilityTemperature control deviceMetal rolling arrangementsFerrite pearliteDuctility

The invention relates to a low-cost high-weldability 440MPa-grade hot-rolled pickled plate for an automobile structure and a preparation method of the low-cost high-weldability 440MPa-grade hot-rolled pickled plate. The low-cost high-weldability 440MPa-grade hot-rolled pickled plate comprises the following alloy components: 0.06-0.08% of C, 0.08-0.20% of Si, 1.20-1.40% of Mn, 0.02-0.06% of Alt, less than or equal to 0.015% of P, less than or equal to 0.006% of S, less than or equal to 0.006% of O, less than or equal to 0.005% of N and the balance of Fe and inevitable impurities. The preparation process mainly comprises the steps of blank casting, hot rolling, flattening, acid pickling and the like. According to the method, on the basis of common C and Mn steel, a low-C and low-Mn content design is adopted, a required ferrite pearlite structure is obtained through a hot rolling, controlled rolling and controlled cooling process, grains are refined, the strength is improved, the yield strength of a product is 305-400 MPa, the tensile strength is 440-560 MPa, the ductility is larger than or equal to 33%, the plasticity index and the welding performance are good, and the production cost is lower than that of a common product with the same strength level.

Owner:BENGANG STEEL PLATES

A kind of low-carbon equivalent high-strength wear-resistant steel plate and its production method

InactiveCN101748333BHigh strengthHigh hardnessTemperature control deviceElectric furnaceBrinellingHardness

The invention discloses a low-carbon-equivalent high-strength wear-resistant steel plate, which is prepared from the following components in percentage by weight: 0.15 to 0.18 percent of C, 0.20 to 0.40 percent of Si, 1.30 to 1.40 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.040 to 0.050 percent of V, 0.017 to 0.030 percent of Nb, 0.020 to 0.040 percent of Al, 0.15 to 0.25 percent of Cr, 0.18 to 0.28 percent of Mo, 0.017 to 0.026 percent of Ti, 0.0015 to 0.0030 percent of B, and the balance of Fe and inevitable impurities. The thickness of the steel plate is 8 to 60mm. The high-strength wear-resistant steel plate has the yield strength over 1,000MPa, the Brinell hardness between 380 and 430HBW, the carbon equivalent between 0.41 and 0.49 percent, the maximum tensile strength of 1,280MPa, good low temperature toughness, and the maximum thickness of 60mm.

Owner:WUYANG IRON & STEEL +1

Yield strength 500mpa grade high crack arrest toughness steel plate and production method thereof

ActiveCN102994874BPromote productionIncrease the lengthHeat treatment process controlReduction rateWater cooling

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

Two-phase composite material and preparation method thereof

The invention relates to the technical field of composite materials, and in particular relates to a preparation method of a two-phase composite material, and the two-phase composite material prepared by the preparation method. According to the method provided by the invention, firstly a silicon carbide ceramic biscuit M5 is prepared by using powder formed by silicon carbide powder with different particle sizes and wax slurry, the silicon carbide ceramic biscuit M5 is used as a part of a mold, a silicon ceramic biscuit M6 is prepared by means of hot press casting, the two biscuits are combined in the form of wax diffusion, demolding is performed, sintering is performed to obtain a ceramic substrate M7, and finally an aluminum alloy melt is infiltrated into the ceramic substrate M7 to form the two-phase composite material; and the two-phase composite material combines the advantages of aluminum silicon carbide and aluminum silicon in one, and has high thermal conductivity, an adjustable expansion coefficient, a low density, good strength and good weldability, the airtightness of the product after welding is less than 10<-10>Pa*m<3> / s, and the composite material is the best choice of a high-power package type tube shell.

Owner:西安明科微电子材料有限公司

Low-cost and high-weldability Q390 medium-thick plate and short-procedure production method thereof

InactiveCN107287518AReduce the amount addedGuaranteed carbon equivalentChemical compositionThick plate

The invention discloses a low-cost and high-weldability Q390 medium-thick plate and a short-procedure production method thereof. The low-cost and high-weldability Q390 medium-thick plate comprises chemical components, by mass percent, 0.12%-0.16% of C, 1.00%-1.20% of Mn, 0.15%-0.25% of Si, 0.005% or less of S, 0.018% or less of P, 0.020%-0.040% of Als, 0.015%-0.022% of Nb, 0.012%-0.020% of Ti, and the balance Fe and unavoidable impurities. The protection method comprises smelting, continuous casting, heating, rolling and cooling working procedures. The low-cost and high-weldability Q390 medium-thick plate is designed by adopting a C-Mn-Nb-Ti component system, the addition amount of Mn and Nb is reduced, the carbon equivalent is controlled to be 0.36% or less, the mechanical performance of the steel plate is guaranteed through ultrafast cooling, the production cost is remarkably reduced, and meanwhile welding use of a client is facilitated; and by means of removing of the stack cooling working procedure, the logistics pressure is relieved, and the economic benefits are indirectly improved.

Owner:TANGSHAN IRON & STEEL GROUP +1

A kind of preparation method of back electrode of solar cell

ActiveCN104752554BReduce usageReduce breakageFinal product manufacturePhotovoltaic energy generationUltrasonic vibrationSoldering

The invention discloses a preparation method for a back electrode of a solar battery. The preparation method includes that using soldering flux to form a soldering flux belt at the surface of an aluminum back field, forming a non-silver metal solder belt at the surface of the soldering flux belt, wherein the soldering flux belt can break an alumina film at the surface of the aluminum back field to expose fresh aluminum from the surface of the aluminum back field, the subsequently fed non-silver metal wires (solder) are melted by the heat effect of a soldering head, the molten liquid fuses with the aluminum, the molten solder is well bonded at the surface of the aluminum back field, the silver use is avoided, the cost is lowered, an ultrasonic vibration device is not used, the intensity of a finished product is obviously improved, fragment and crack are obviously reduced, and the quality of the back electrode of the solar battery is greatly improved. The back electrode of the solar battery prepared by the preparation method is low in fragment and crack rate, the adhesion between the back electrode and aluminum back field is strong, the welding with a photovoltaic soldering belt is good, the average photoelectric efficiency conforms to requirement, and the manufacturing cost is low.

Owner:BYD CO LTD

A kind of material for transfusion hose and its application

ActiveCN104772934BAvoid pollutionReduce drug riskSynthetic resin layered productsCatheterComposite materialWeldability

Owner:LANGHUO MEDICAL MATERIAL BEIJING

An ultra-low-hydrogen high-toughness metal powder-cored seamless flux-cored wire for all-position welding

ActiveCN106891104BLow solderabilityReduced crack resistanceWelding/cutting media/materialsSoldering mediaCrack resistanceFerrosilicon

The invention provides an ultralow-hydrogen and high-tenacity metal powder core type seamless flux-cored welding wire for all-position welding. The seamless flux-cored welding wire comprises outer skin and flux core powder, wherein the inner part of the outer skin is filled with the flux core powder, and the outer skin is a low-carbon steel band. The seamless flux-cored welding wire is characterized in that the flux core powder comprises the following components in a percent by weight: 10-15% of low-carbon ferromanganese, 15-20% of atomized ferrosilicon, 2-5% of rutile, 1-5% of cryolite, 1-3% of atomized nickel powder, 1-2% of quartz, 0.5-2% of feldspar and the balance of iron powder. The seamless flux-cored welding wire is suitable for the all-position welding of carbon steel and low-alloy steel which are welded under the protection of mixed gas containing 75-85% of Ar and 15-25% of CO2. The seamless flux-cored welding wire is great in welding machinability, stable in mechanical properties, great in crack resistance, low in hydrogen dispersion and high in moisture absorbability and can be used for all-position welding.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

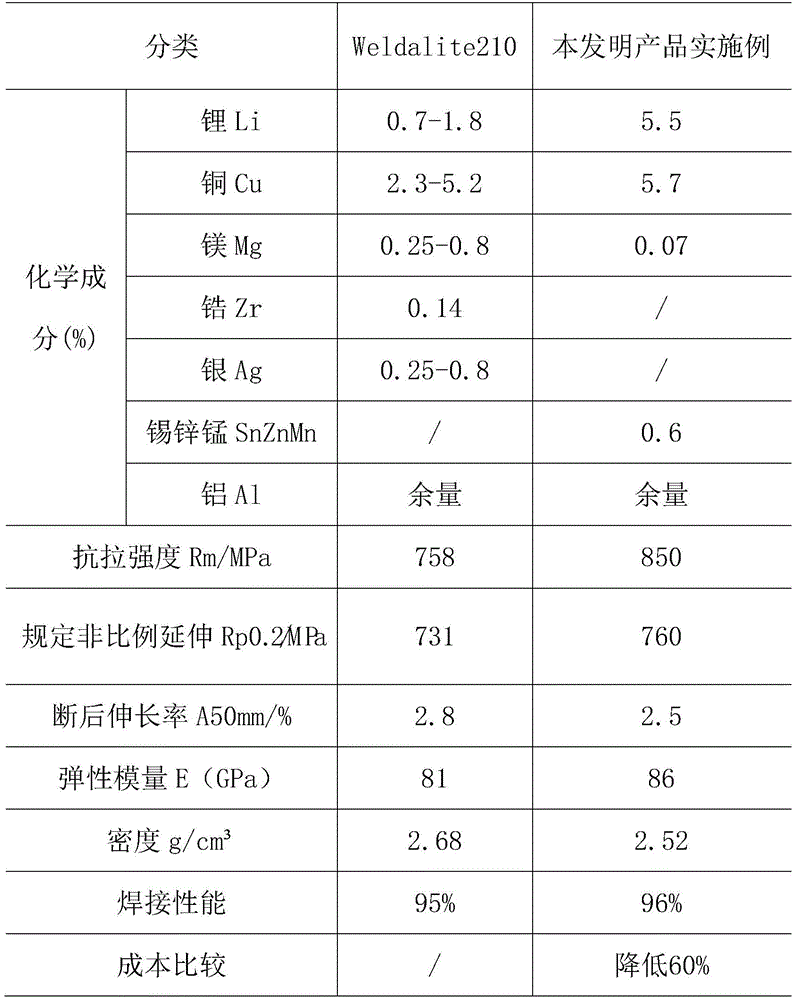

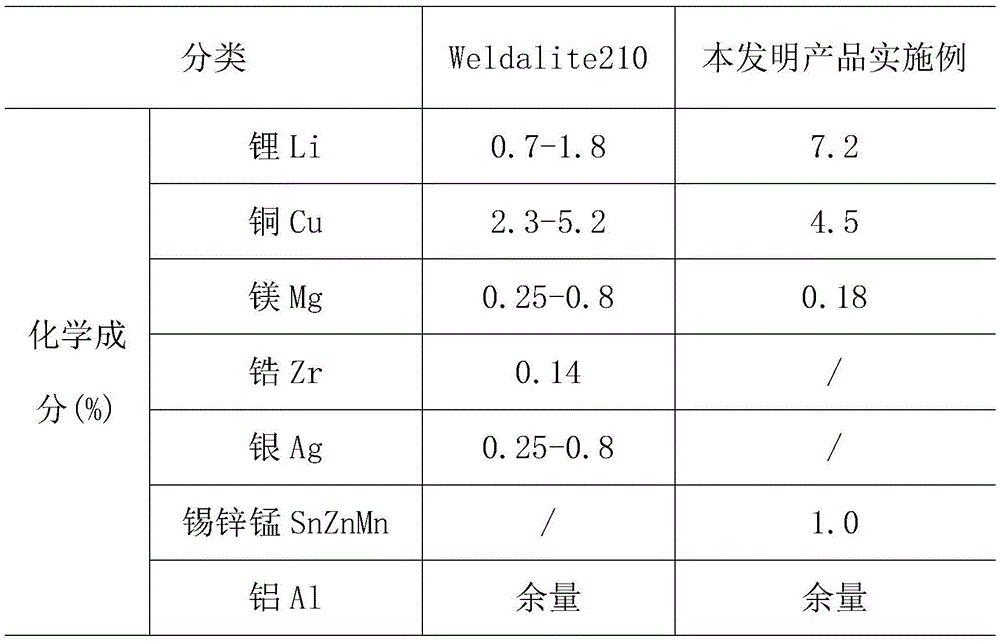

Lightweight aluminum-lithium alloy material and production method thereof.

The invention relates to a lightweight aluminum-lithium alloy material and a production method thereof. The aluminum-lithium alloy material disclosed by the invention comprises the following components in percentage by weight: 4-6.5wt% of lithium, 0.5-3wt% of copper, 0.1-0.5wt% of tin, 0.8-1.5wt% of zinc, 0.05- 0.1wt% of lead and less than or equal to 0.2wt% of inevitable impurities and the balance of aluminum. The aluminum-lithium alloy material disclosed by the invention has the advantages of lower density, light weight, low anisotropy, high weldability, high strength and significantly reduced manufacturing cost. The aluminum-lithium alloy material disclosed by the invention can be widely used in aircraft connectors, machinery manufacturing, transportation machinery, power machinery and other aviation industry.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

A high-strength steel plate with a thickness of 8-25mm and a low yield ratio tank car and its manufacturing method

ActiveCN109338215BHigh strengthExcellent low temperature toughness at -50℃Tank truckWater processing

The invention relates to an 8-25mm thickness type low-yield-ratio and high-strength steel sheet for a tank truck. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck solves the shortages such as high yield ratio, low welding performance and high production cost of a current steel sheet. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck is characterized in that a C+Mn+Cr and Nb and Ni microalloying system is adopted; the steel comprises the following chemical components in percentage by weight: 0.08-0.15% of C, 0.05-0.20% of Si, 1.50-2.00% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.32-0.45% of Cr, 0.10-0.20% of Ni, 0.02-0.07% of Nb, and the balance Fe and inevitable impurity elements; and the formula (seeing the description) is met. A normalizing technology is carried out for production; the mechanical performance meets the condition that the yield strength is not less than 400MPa;the tensile strength Rm is not less than 600MPa; the ductility A50 is not less than 32%; the yield ratio is not greater than 0.75; the transverse impact energy KV2 at below 50 DEG C is not less than 47J; the technical processes include preparing molten iron through a blast furnace, performing KR treatment on the molten iron, performing smelting in a 120-160t oxygen converter, performing refining in an LF (ladle furnace), performing treatment (refining) in an RH vacuum furnace, performing continuous casting, heating a casting blank, performing controlled rolling, performing normalizing, detecting cracks, and inspecting. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck has the characteristics of being low in yield ratio, high in strength, outstandingin low-temperature toughness and plasticity, and high in welding performance; and in addition, the production cost is low; and the operability is high.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A kind of anti-rust and heat-resistant special-shaped steel pipe and its preparation method

The invention relates to the technical field of special-shaped steel tubes and particularly relates to an anti-rust heat-resistant special-shaped steel tube and a preparation method thereof. The anti-rust heat-resistant special-shaped steel tube is prepared from the following components in parts by mass: 0.8-7 parts of carbon, 2-5 parts of silicon, 10-20 parts of manganese, 20-30 parts of nickel, 30-40 parts of chromium, 2-4 parts of copper, 0.1-0.4 part of sulfur, 0.3-0.8 part of phosphorus, 5-10 parts of nitrogen, 0.3-2 parts of vanadium, 0.03-0.2 part of boron, 10-20 parts of lanthanum, 80-100 parts of iron and 3-6 parts of an additive. The anti-rust heat-resistant special-shaped steel tube provided by the invention is low in cost, good in structure stability and cold and hot machinability, long in anti-fatigue service life, wear-resistant, corrosion-resistant, high in precision, good in weldability, good in overall straightness and low in residual stress. The anti-rust heat-resistant special-shaped steel tube provided by the invention can resist temperature reaching 1800 DEG C. The preparation method provided by the invention is simple in production process and low in cost, has a good economic benefit and is suitable for industrialized production on a large scale.

Owner:BEIJING JINYU SHUNDA TECH CO LTD

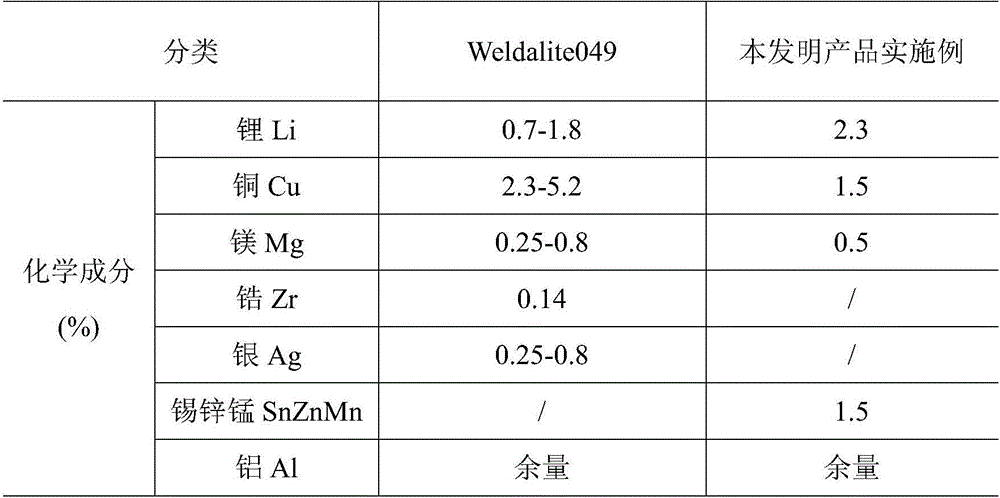

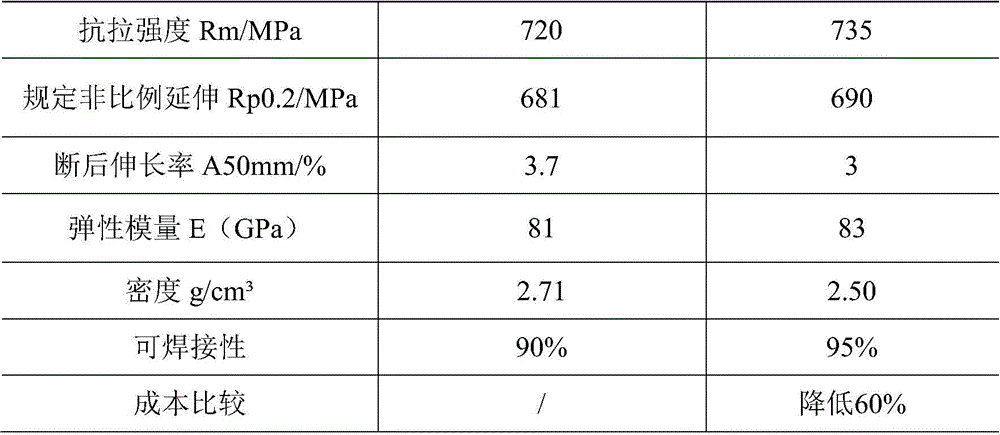

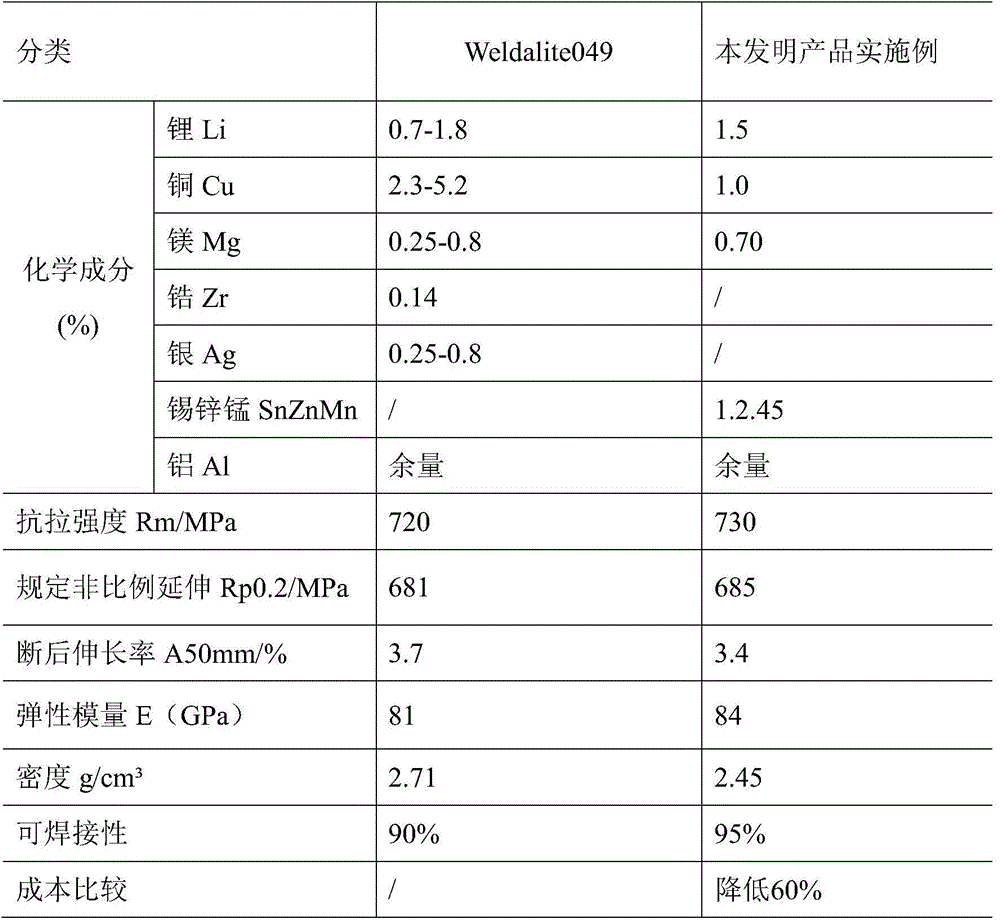

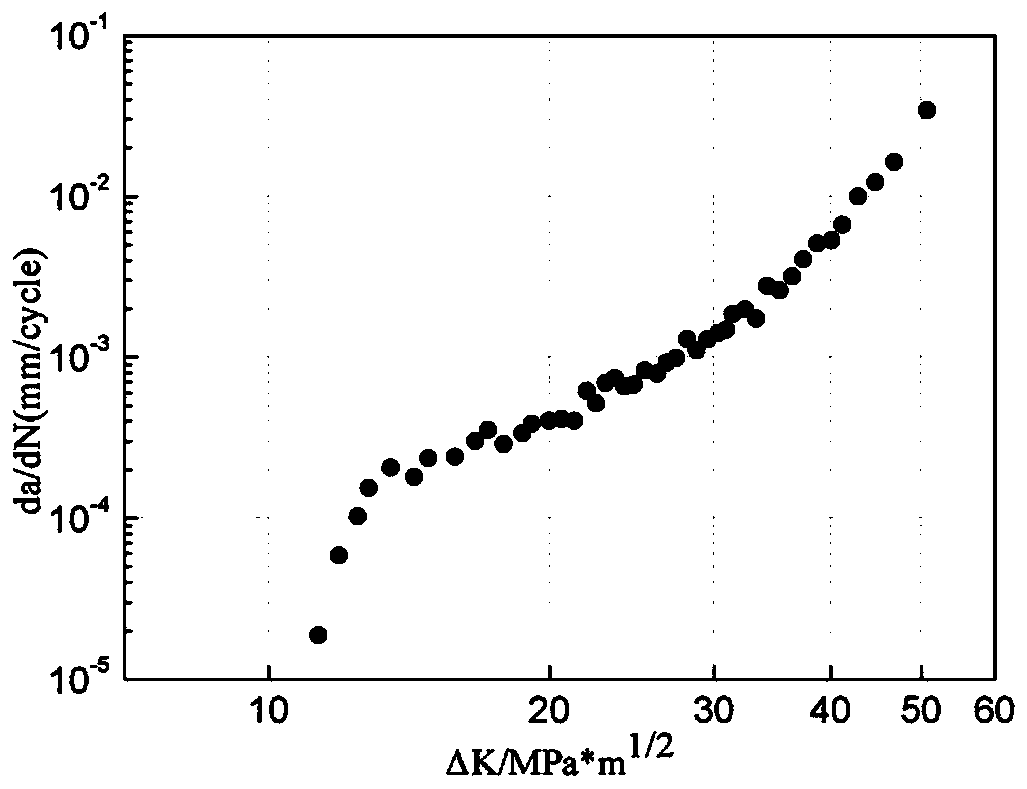

A kind of aluminum-lithium alloy material with added tin, zinc and manganese and production method thereof

The invention relates to an aluminum-lithium alloy material added with tin, zinc and manganese and a production method thereof. The aluminum-lithium alloy material of the present invention is composed of the following components by weight percentage: tin-zinc-manganese alloy particles: 1.5-2.5wt%, lithium: 1.5-2.5wt%, copper: 1-2wt%, magnesium: 0.05-0.2wt%, Balance: Aluminum. The aluminum-lithium alloy material of the present invention reduces the cost of the alloy material by replacing the expensive silver element with cheap tin, zinc and manganese elements. The particle powder made of intereutectic tin, zinc and manganese three-element material is dispersed in the alloy of lithium and aluminum, which improves the strength and welding performance of the alloy material. The production process is preferably improved, and the vacuum smelting process is used to effectively remove impurities such as hydrogen, sodium, and potassium while reducing a large amount of volatile alloying elements such as lithium and magnesium in the melt. Loss, avoiding material composition deviations. The aluminum-lithium alloy material of the invention can be widely used in machinery manufacturing, transportation machinery, power machinery, aviation industry and the like.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

A medium-high-strength damage-resistant aluminum-lithium alloy material and its preparation method and application

The invention discloses a medium and high strength damage resistant aluminum lithium alloy material and a preparation method of the medium and high strength damage resistant aluminum lithium alloy material. The medium and high strength damage resistant aluminum lithium alloy material is prepared from, by mass, 0.5-2% of lithium, 2-5% of copper, 0.2-0.7% of magnesium, 0.1-0.5% of silver, 0.1-0.6% of manganese, 0.01-0.15% of titanium, 0.08-0.15% of zirconium, 0.05-0.6% of ruthenium, 0-0.15% of erbium and the balance aluminum. Since a small amount of rare and precious metal element ruthenium withthe higher melt purifying ability is added into the alloy, the prepared aluminum lithium alloy has the high specific strength, high molding performance, high tenacity and excellent corrosion resistance, and the comprehensive mechanical properties of the alloy are greatly improved.

Owner:CENT SOUTH UNIV

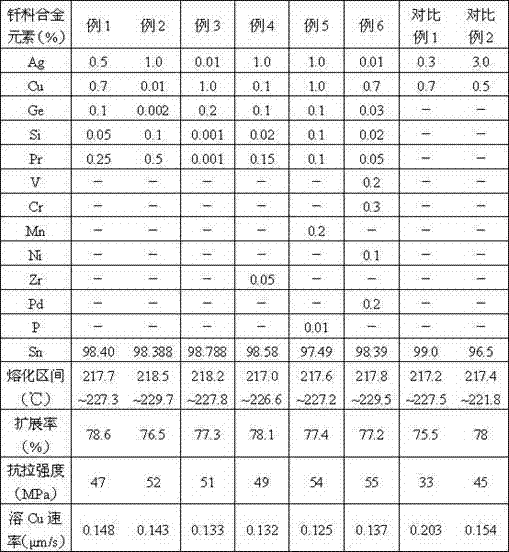

A series of low-silver lead-free solder for electronic package soldering and preparation method thereof

ActiveCN103243234BLow tensile strengthLow Cu dissolution rateWelding/cutting media/materialsSoldering mediaSolderabilityElectronic packaging

The invention relates to serial low-silver and lead-free solder for electronic packaging soft soldering and a preparation method thereof. The solder comprises Ag, Cu, Si, Pr, Ge and Sn, wherein the Ag content is only 0.01-1.0%. The preparation method of the solder comprises the following steps of: firstly, preparing an Sn-Pr intermediate alloy and an Sn-Si intermediate alloy; after heating and melting mixed salt of KCl and LiCl, covering the mixed salt of the KCl and the LiCl on the liquid surface of rest tin in a smelting furnace, and preserving the temperature; raising the temperature of the fused solder to 600-700 DEG C, adding the Sn-Si intermediate alloy, stirring, and preserving the temperature; lowering the temperature of the fused solder to 500-600 DEG C, and adding the Sn-Pr intermediate alloy; lowering the fused solder to 400-500 DEG C, adding the Ag, the Cu and the Ge, uniformly stirring, and preserving the temperature; and finally, pouring the fused solder into fixed molds, and carrying out cooling forming to prepare the solder. The serial low-silver and lead-free solder and the preparation method have the advantages and effects of low cost, good wettability, good weldability, high tensile strength, low Cu dissolving speed and the like.

Owner:深圳市同方电子新材料有限公司 +1

A kind of lightweight aluminum-lithium alloy material and production method thereof

The invention relates to a lightweight aluminum-lithium alloy material and a production method thereof. The aluminum-lithium alloy material disclosed by the invention comprises the following components in percentage by weight: 4-6.5wt% of lithium, 0.5-3wt% of copper, 0.1-0.5wt% of tin, 0.8-1.5wt% of zinc, 0.05- 0.1wt% of lead and less than or equal to 0.2wt% of inevitable impurities and the balance of aluminum. The aluminum-lithium alloy material disclosed by the invention has the advantages of lower density, light weight, low anisotropy, high weldability, high strength and significantly reduced manufacturing cost. The aluminum-lithium alloy material disclosed by the invention can be widely used in aircraft connectors, machinery manufacturing, transportation machinery, power machinery and other aviation industry.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

A rare earth weather-resistant bridge steel plate with a yield strength of 370mpa and its preparation method

The invention relates to a rare earth weather-resistant bridge steel plate with the yield strength being 370 MPa grade and a preparation method thereof. The preparation method comprises the steps thatsmelting and casting are conducted; heating and rolling are conducted, specifically, the heating temperature is 1200-1220 DEG C, the total in-furnace time is larger than or equal to 240 min, during rolling, rolling of the first stage is conducted in an austenite recrystallization zone, the rolling starting temperature is 1130-1180 DEG C, the reduction quantity from the first pass to the second pass is larger than 10%, and the reduction rate of at least 1-2 of the rest passes is controlled to be 25% or above, rolling of the second stage is conducted in an austenite non-recrystallization zone,the rolling starting temperature is smaller than or equal to 930 DEG C, the thickness of an intermediate blank is 2.0-3.5 times of the thickness of a finished product, and the finished rolling temperature is 830-850 DEG C; and cooling is conducted. The yield strength of the steel plate is larger than 370 MPa, the steel plate has the advantages of being low in yield ratio, good corrosion resistantperformance, low-temperature toughness, cold-forming performance and welding performance and capable of being used without coating, the production technological process is simple, the production period is short, and the cost is low.

Owner:BAOTOU IRON & STEEL GRP

A kind of nanoparticle modified aluminum-lithium alloy material and preparation method thereof

The invention relates to a nano-particle modified aluminum lithium alloy material and a manufacturing method of the nano-particle modified aluminum lithium alloy material. The nano-particle modified aluminum lithium alloy bar comprises 2.0-3.5 wt% of lithium, 0.05-0.5 wt% of copper, 0.05-0.5 wt% of nanometer silicon carbide particles, and the balance aluminum. As the nanometer silicon carbide (SiC) particles are added into raw materials, the anisotropy of alloy can be reduced from a molecular perspective without corresponding aging treatment. Meanwhile, by the addition of the nanometer silicon carbide particles, the toughness and superplasticity of the alloy material are further improved. The vacuum melting process is improved preferably, aluminum lithium alloy melt is effectively prevented from absorbing hydrogen, impurities such as hydrogen, sodium and potassium are removed, at the same time, lithium, magnesium and other volatile alloying elements in the melt are prevented from being largely burnt, and component deviation of the material is avoided. The nano-particle modified aluminum lithium alloy bar can be widely used for the aspects of aviation, aerospace, automobiles, mechanical manufacturing, the shipping industry and the like.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Process method for preparing silver solder

ActiveCN103192203BThe process is simple and easy to controlNo lossWelding/cutting media/materialsSoldering mediaVolumetric Mass DensityBiological activation

The invention relates to a method for preparing silver solder. The method comprises the following specific steps: applying pressure to raw material particles arranged in a graphite crucible by upper and lower graphite press heads in a spark plasma sintering system (SPS) under the vacuum condition; directly heating the raw material particles by using pulse current; and breaking through an oxidation film of each particle of metal powder at instant high temperature and enabling the oxidation film to be subjected to surface activation and quick liquefaction. The reaction speed of particles and the reaction speed among the particles are increased, the diffusion speed of alloy element atoms is increased and the aims of quickly alloying and densifying a sintering body are achieved. Compared with a traditional smelting method, the method disclosed by the invention has the advantages of simple and easily-controlled process, no loss of alloy elements, accurate components of silver-based solder components, low oxygen content, short sintering time, low energy consumption, safety, no pollution and favorable reproducibility. The ingot products prepared by the method are high in density; crystal particles are fine and are uniform in size; and the method is an economic and efficient green preparation process.

Owner:昆明铂生金属材料加工有限公司

A low-anisotropy aluminum-lithium alloy rod and production method thereof

The invention relates to a low-anisotropy high-weldability high-strength aluminum-lithium alloy bar and a production method thereof. The aluminum-lithium alloy bar is composed of the following components in percentage by weight: 6-7.5 wt% of lithium, 4-6 wt% of copper, 0.1-0.3 wt% of magnesium, 0.4-0.8 wt% of tin, 0.2-0.4 wt% of zinc, 0.05-0.3 wt% of manganese, 0.2-0.4 wt% of lanthanum and cerium and the balance of aluminum. By enhancing the content of the metallic lithium in the alloy and preferably adding the metallic copper, magnesium, tin, zinc, manganese, lanthanum and cerium, the aluminum-lithium alloy bar has the advantages of low anisotropy, high weldability, high strength and greatly lower manufacturing cost. The aluminum-lithium alloy bar can be widely used in the aspects of machine manufacturing, conveying machinery, power machinery, aviation industry and the like.

Owner:SUZHOU RICHMOND ADVANCED MATERIAL TECH TRANSFER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com