Patents

Literature

64results about How to "Reduced crack resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Piston ring for internal combustion engines

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

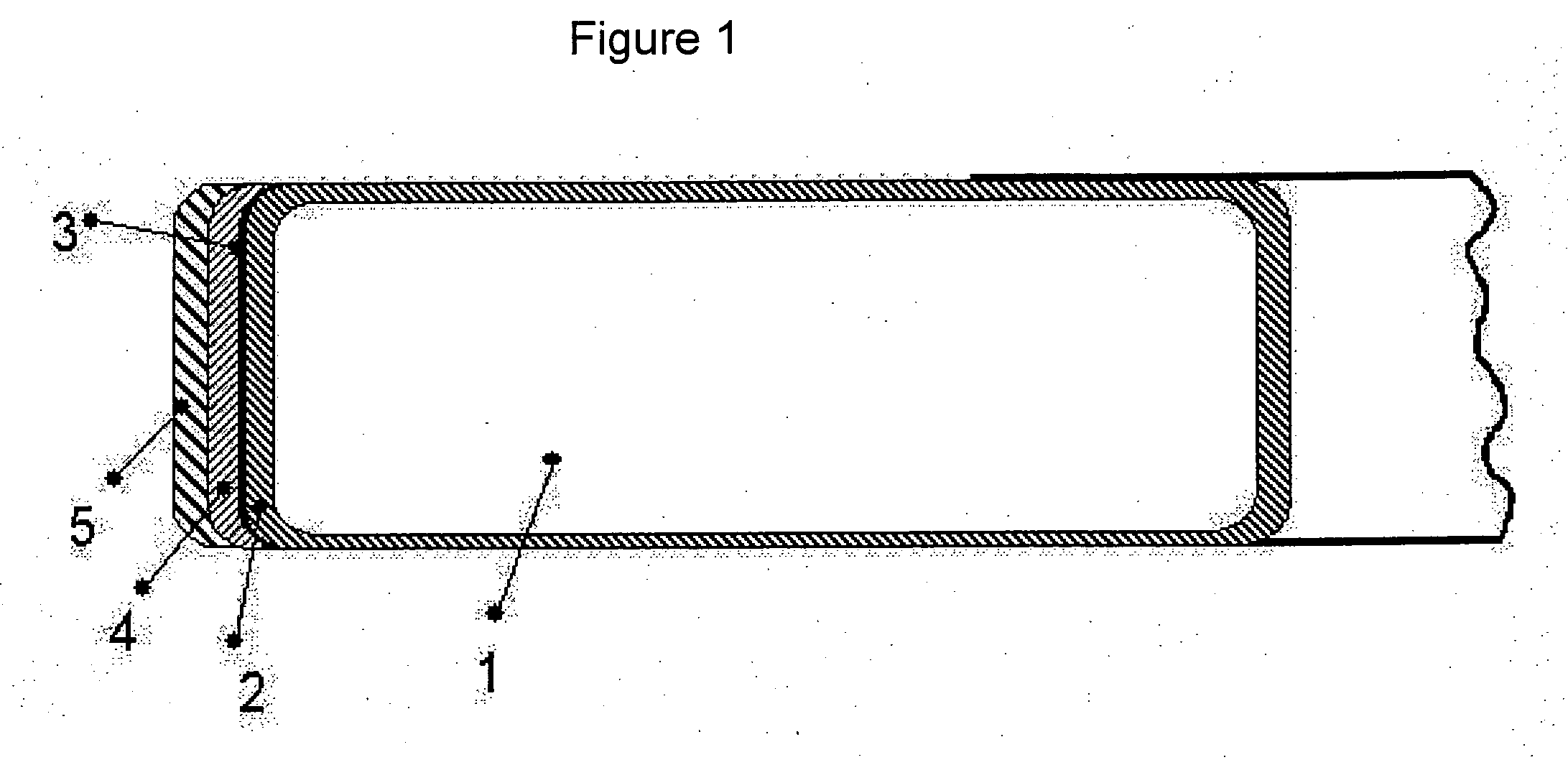

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

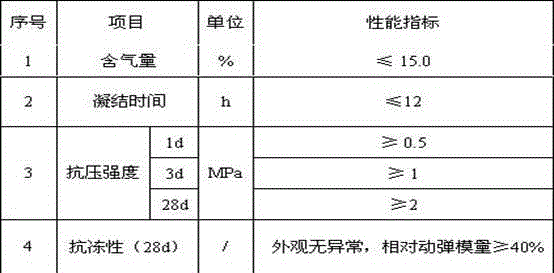

Road slope silt curing agent and preparation method thereof

The invention relates to a road slope silt curing agent and a preparation method thereof. The road slope silt is prepared from the following components in percentage by weight: 50-90% of silt and 10-50% of a curing agent, wherein the curing agent is prepared from the following components in percentage by weight: 40-70% of cement, 10-30% of coal ash, 5-10% of an expanding agent, 0.5-4% of a high polymer, 0.1-2% of a super plasticizer, 1-3% of an early strength agent, 0.001-0.1% of a retarder, 0.01-1% of a thickener, 0.1-3% of fibers and the balance of grass seeds. According to the curing agent provided by the invention, the expanding agent and fibers are introduced. Compared with a curing agent in the prior art, the road slope silt curing agent has the advantages that the shrinkage rate of cured sandy soil is reduced by 40%, so that the crack resistance of a curing body is improved. A pore structure can be controlled, so as to provide a growing space for plants. By adopting low-grade coal ash, turning waste into wealth and environmental friendliness are facilitated.

Owner:JIANGSU DINGTAI ENG MATERIAL

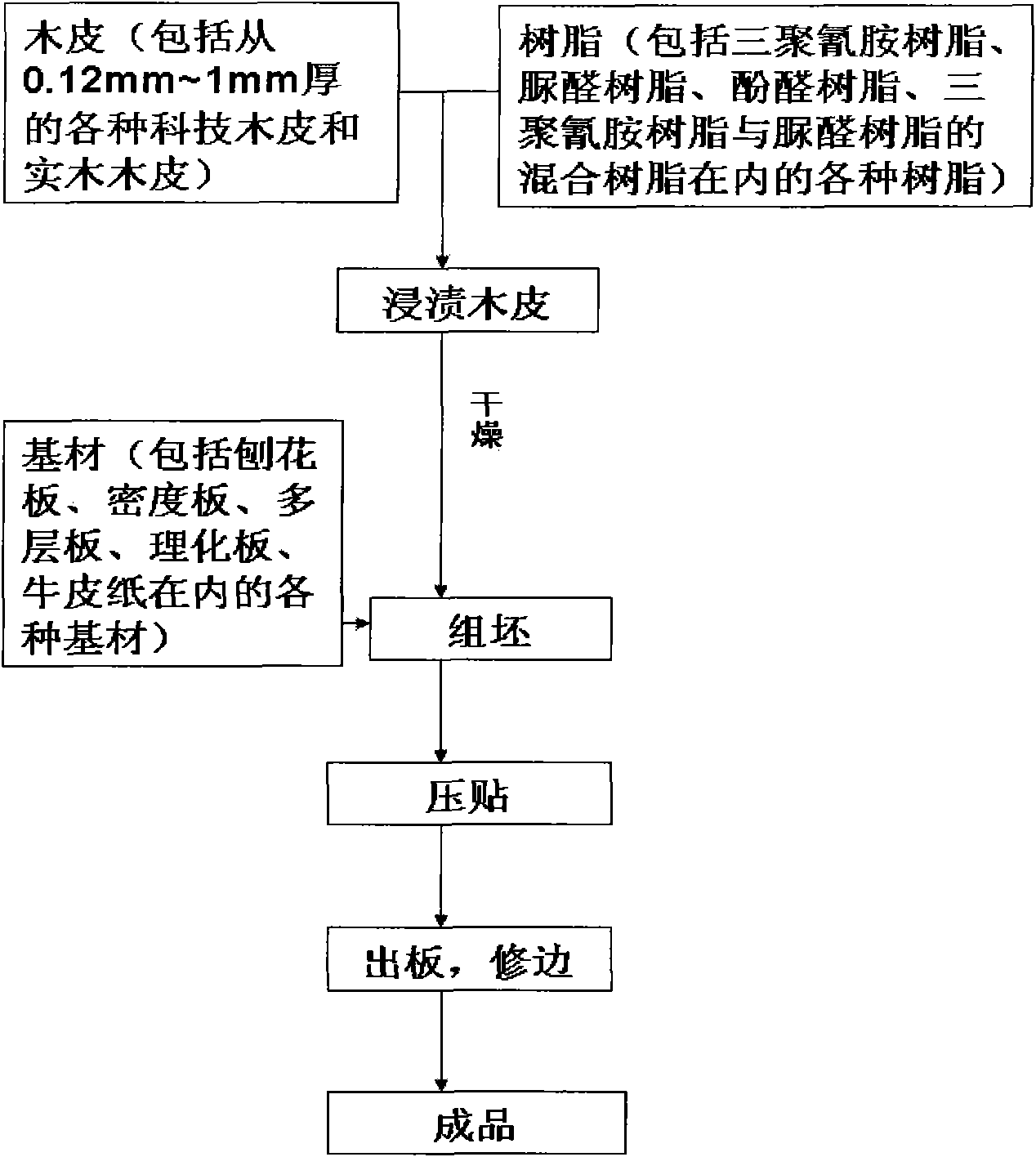

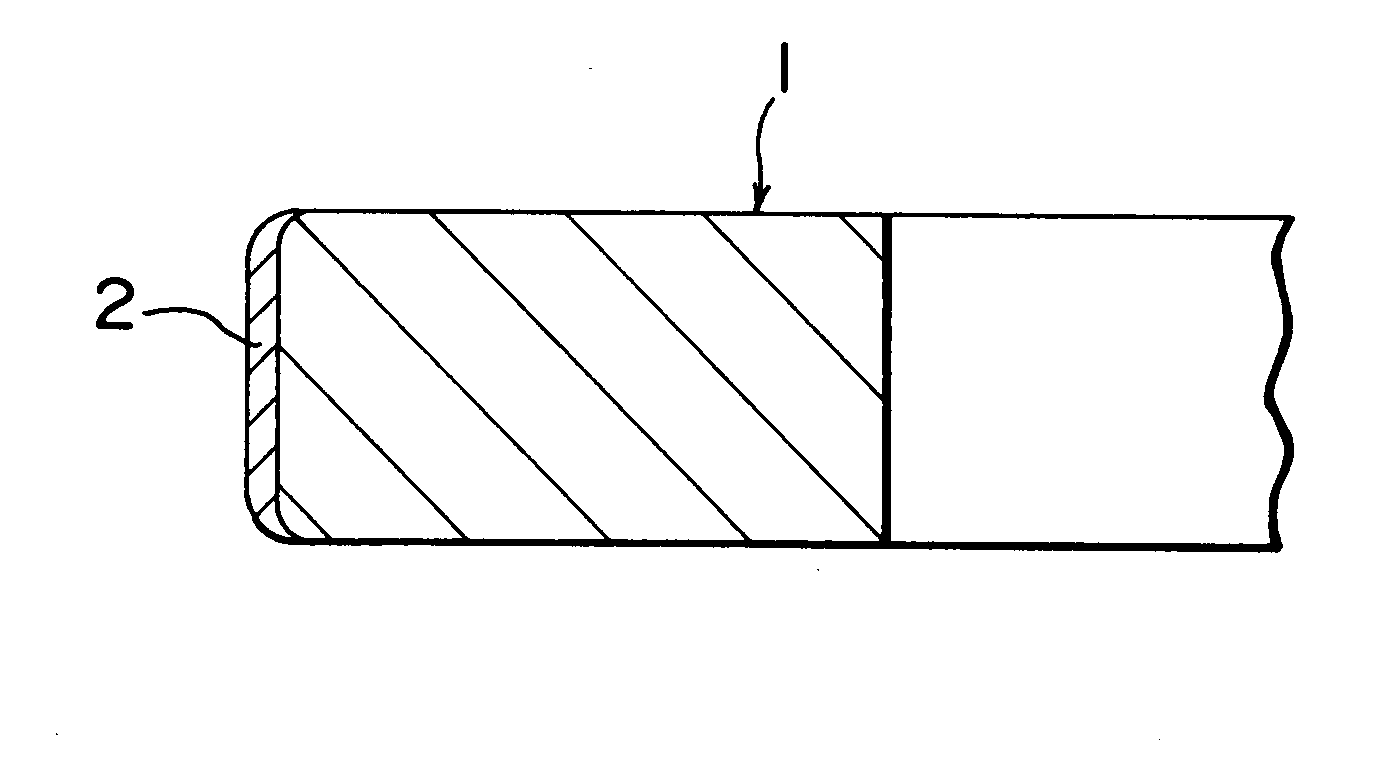

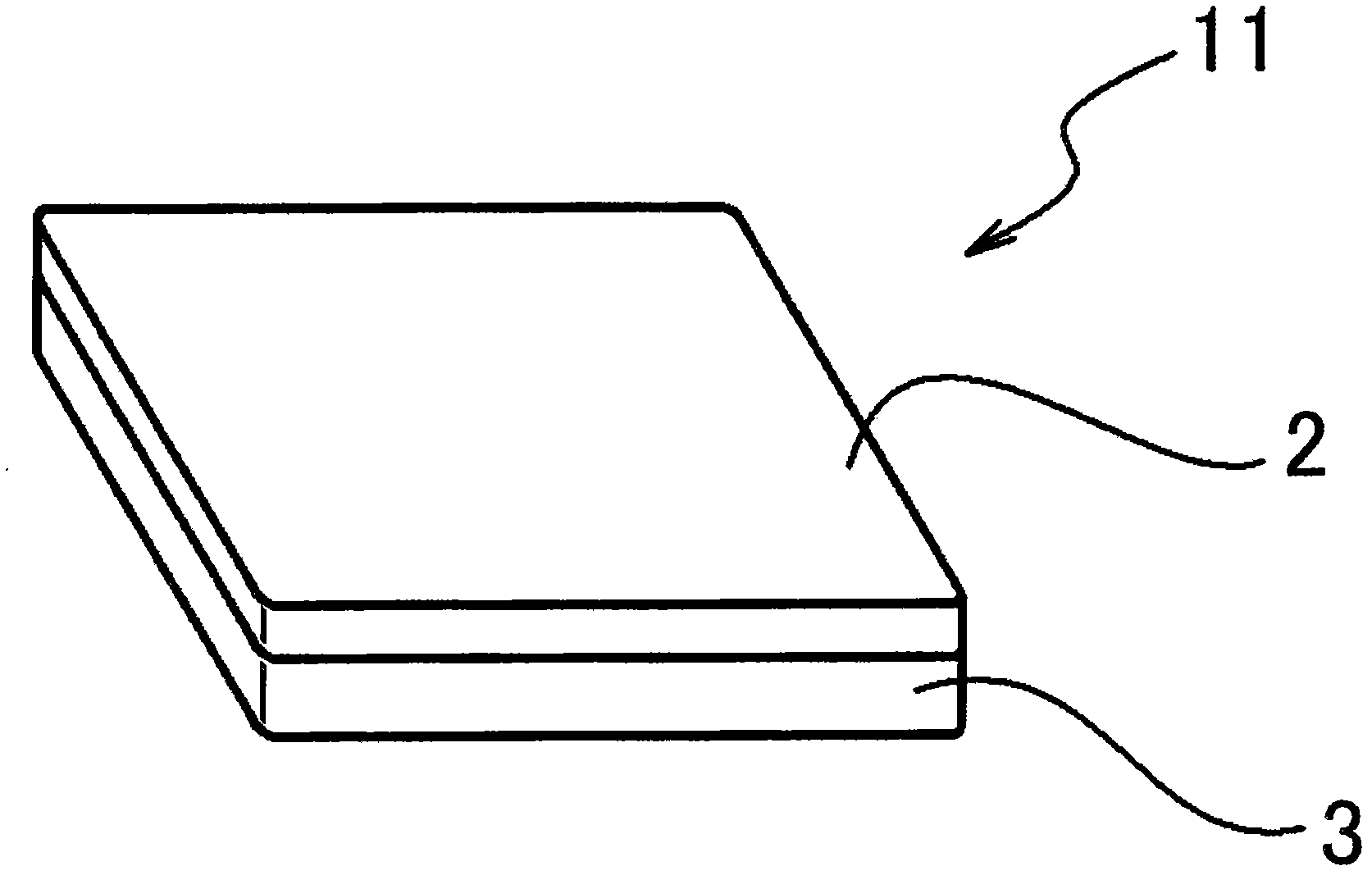

Resin impregnated wood skin veneer and manufacturing process thereof

InactiveCN102049801AEnhance the sense of real woodSimple processWood veneer joiningWood layered productsCrack resistanceDry heat

The invention relates to a resin impregnated wood skin veneer and a manufacturing process thereof. The resin impregnated wood skin veneer comprises a base material. The resin impregnated wood skin veneer is characterized in that: impregnated wood skin is pressed on the base material; the impregnated wood skin is impregnated by using melamine resin, or urea resin, or melamine resin and urea resin; and the wood skin is technological wood skin or solid wood skin. The manufacturing process comprises the following steps of: selecting the proper wood skin, and impregnating and gluing the wood skin by adopting various modes to obtain the impregnated wood skin; then covering the impregnated wood skin on the base material, and conveying the base material into a multilayer laminating machine, wherein the laminating time is 10 seconds to 60 minutes, the hot pressing temperature is 100 to 200 DEG C and the weight of the load is 300 to 2,000 tons; and finally, obtaining the resin impregnated wood skin veneer. Therefore, the surface of the veneer has the characteristics of dry heat resistance, cauterization resistance, cracking resistance, light resistance, corrosion resistance and the like. The surface does not need paint any more, the utilization rate of boards is improved, and the production cost is remarkably reduced.

Owner:吴根水

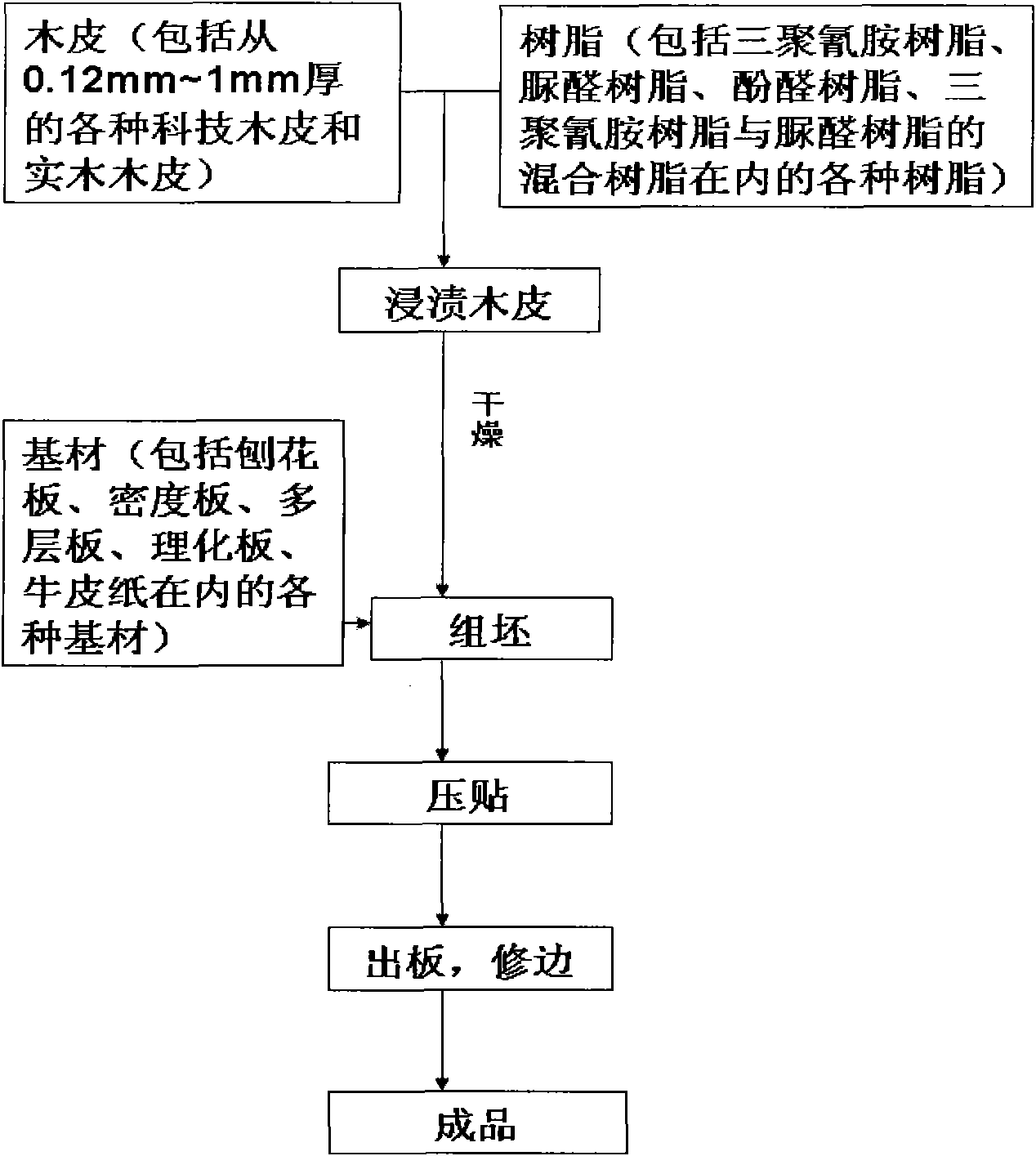

High-toughness low-alloy solid welding wire

ActiveCN101905392AQuality improvementReduced crack susceptibilityWelding/cutting media/materialsSoldering mediaSheet steelChemical composition

The invention relates to a high-toughness low-alloy solid welding wire which comprises the following chemical components in percentage by weight: not more than 0.10 percent of C, 0.4 to 0.8 percent of Si, 1.2 to 1.9 percent of Mn, 1.0 to 2.5 percent of Ni, 0.25 to 0.55 percent of Mo, 0.18 to 0.35 percent of Cr, 0.05 to 0.20 percent of Ti, 0.0005 to 0.005 percent of B, not more than 0.015 percent of S, not more than 0.015 percent of P and the balance of Fe and other inevitable impurities. The high-toughness low-alloy solid welding wire has the tensile strength of deposited metal more than 830MPa, the yield strength of the deposited metal more than 730MPa, and the reduced alloy content by near 50 percent compared with the welding wire ER83-1 on the premises of ensuring the strength and the impact toughness, can satisfy the welding of 830MPa-grade and 900MPa-grade steel plates and greatly reduce the cost and is suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

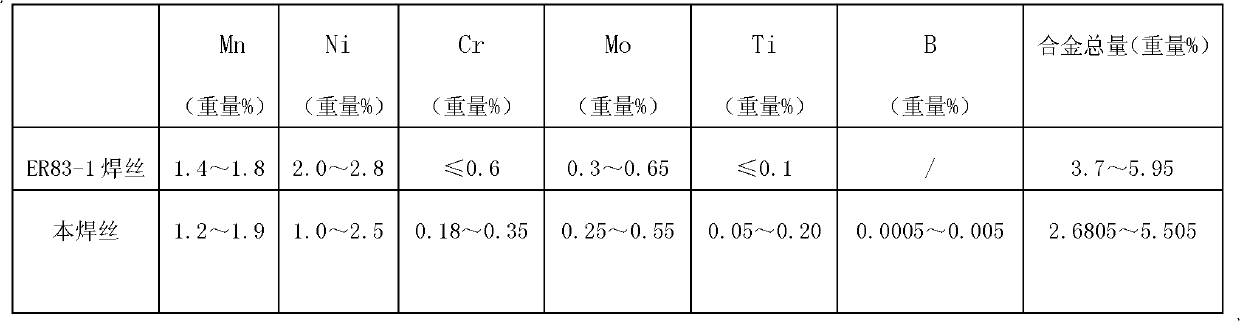

Piston ring for internal combustion engines

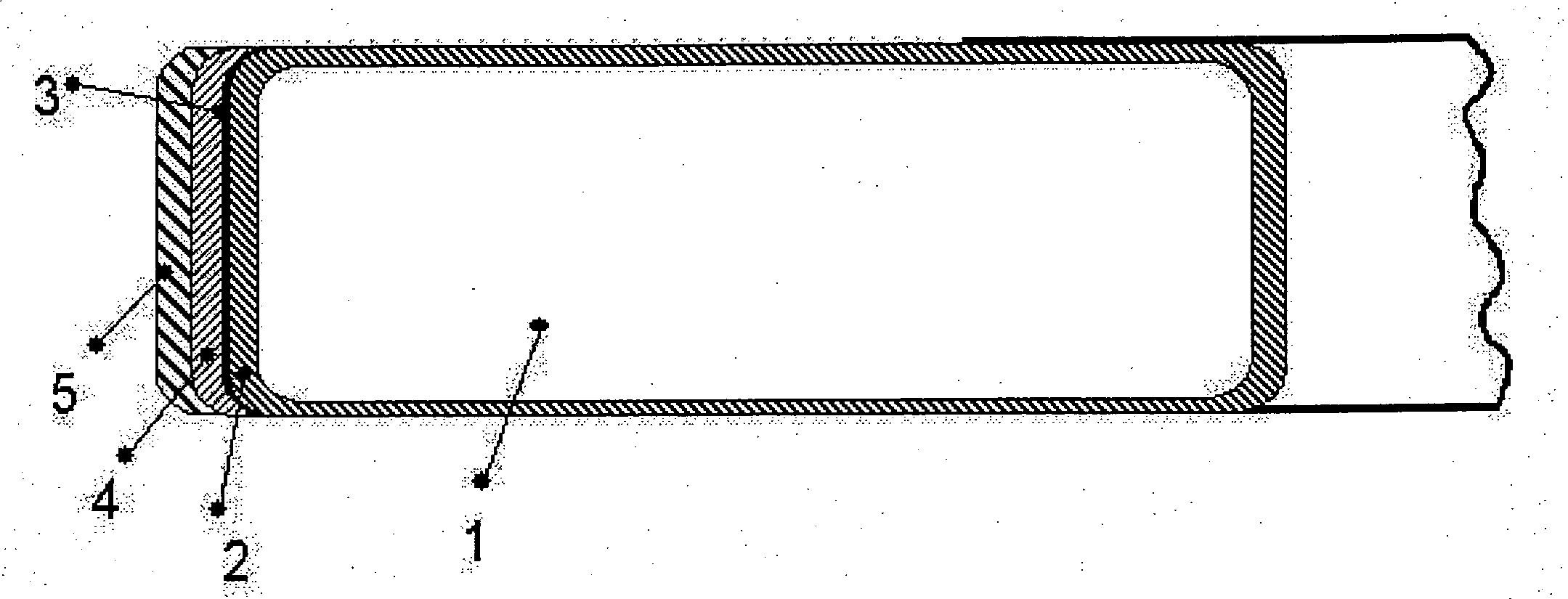

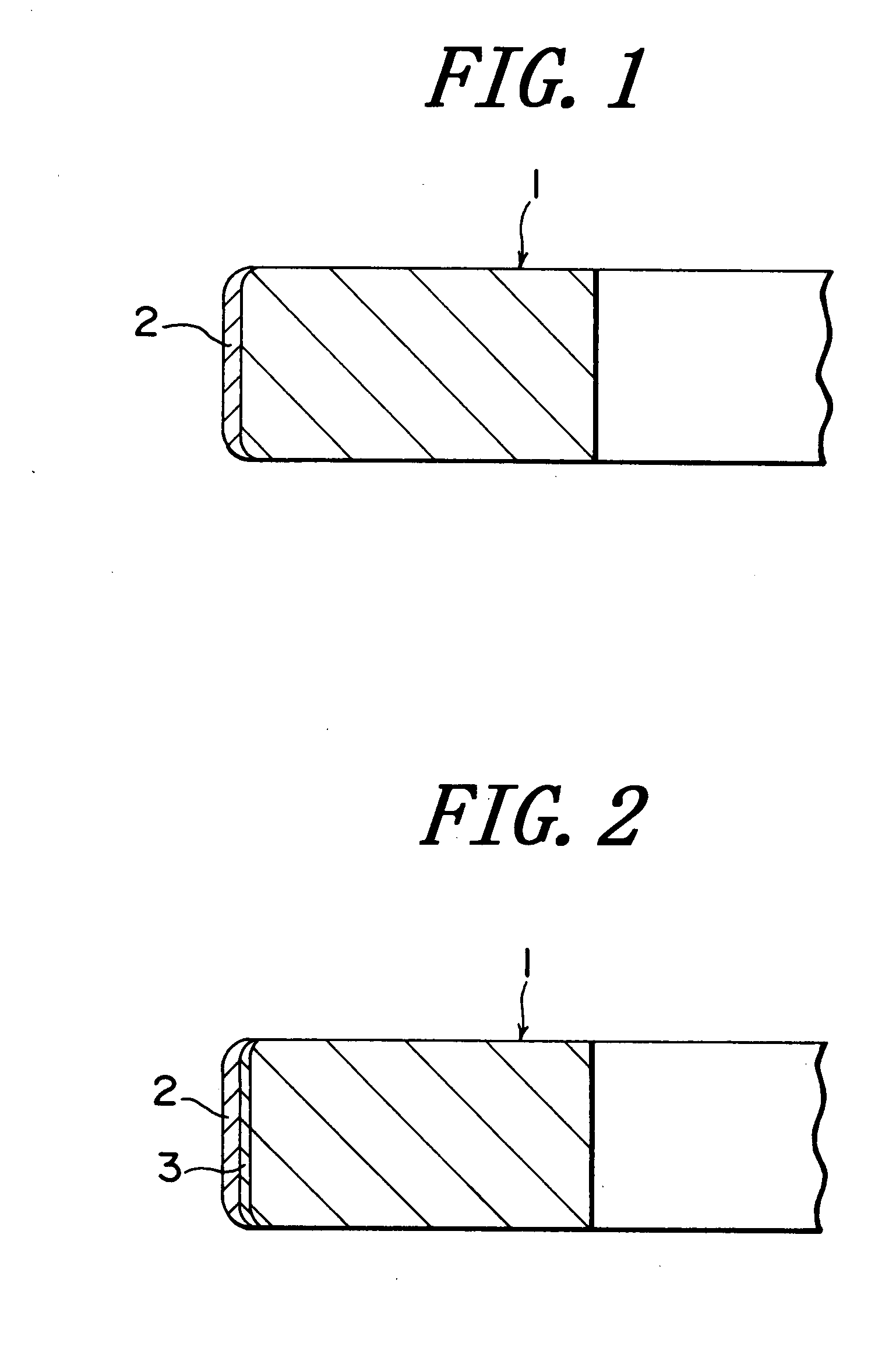

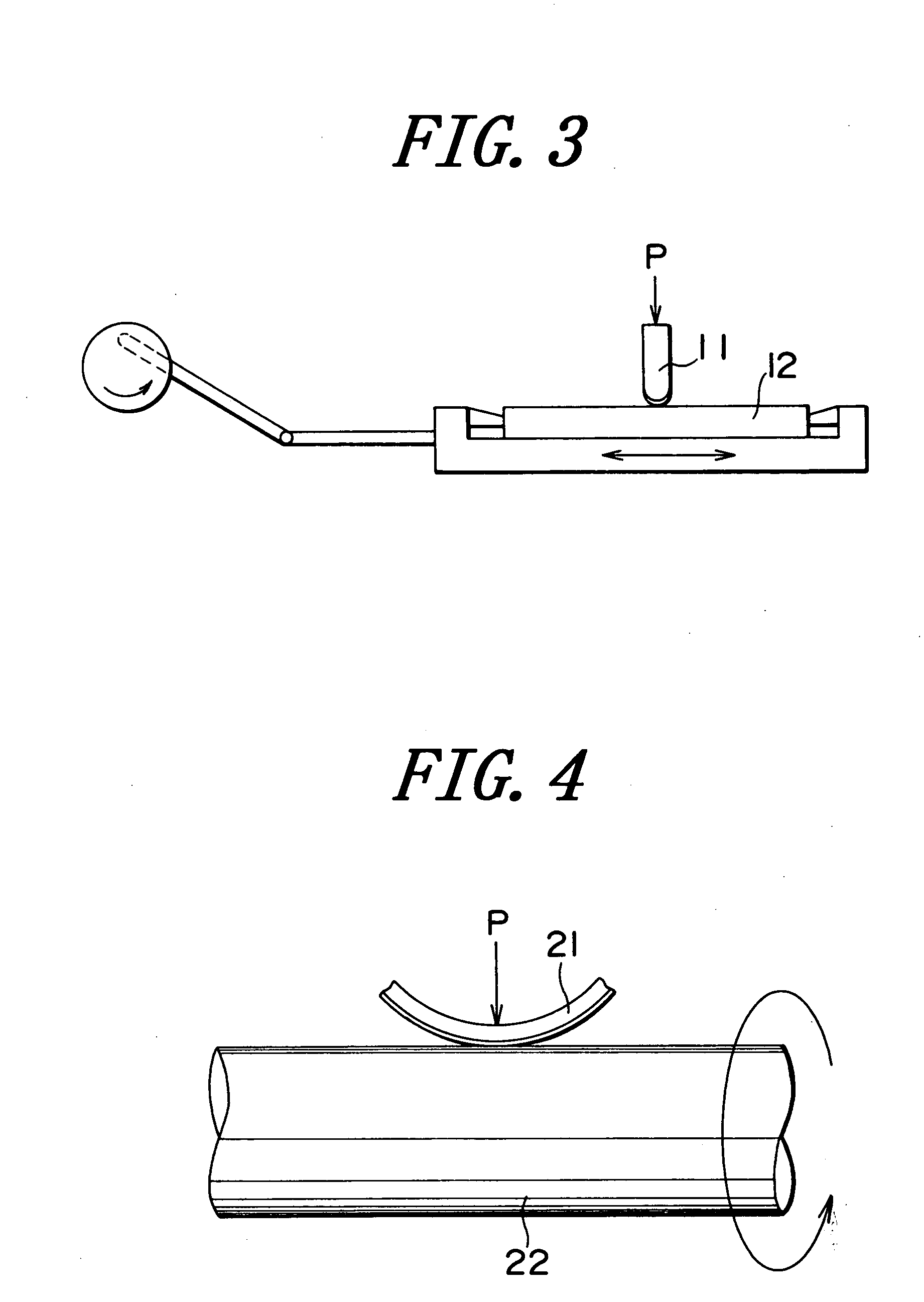

InactiveUS20080007006A1Reduced wear resistance requirementsReduced crack resistancePiston ringsVacuum evaporation coatingEngineeringOxygen

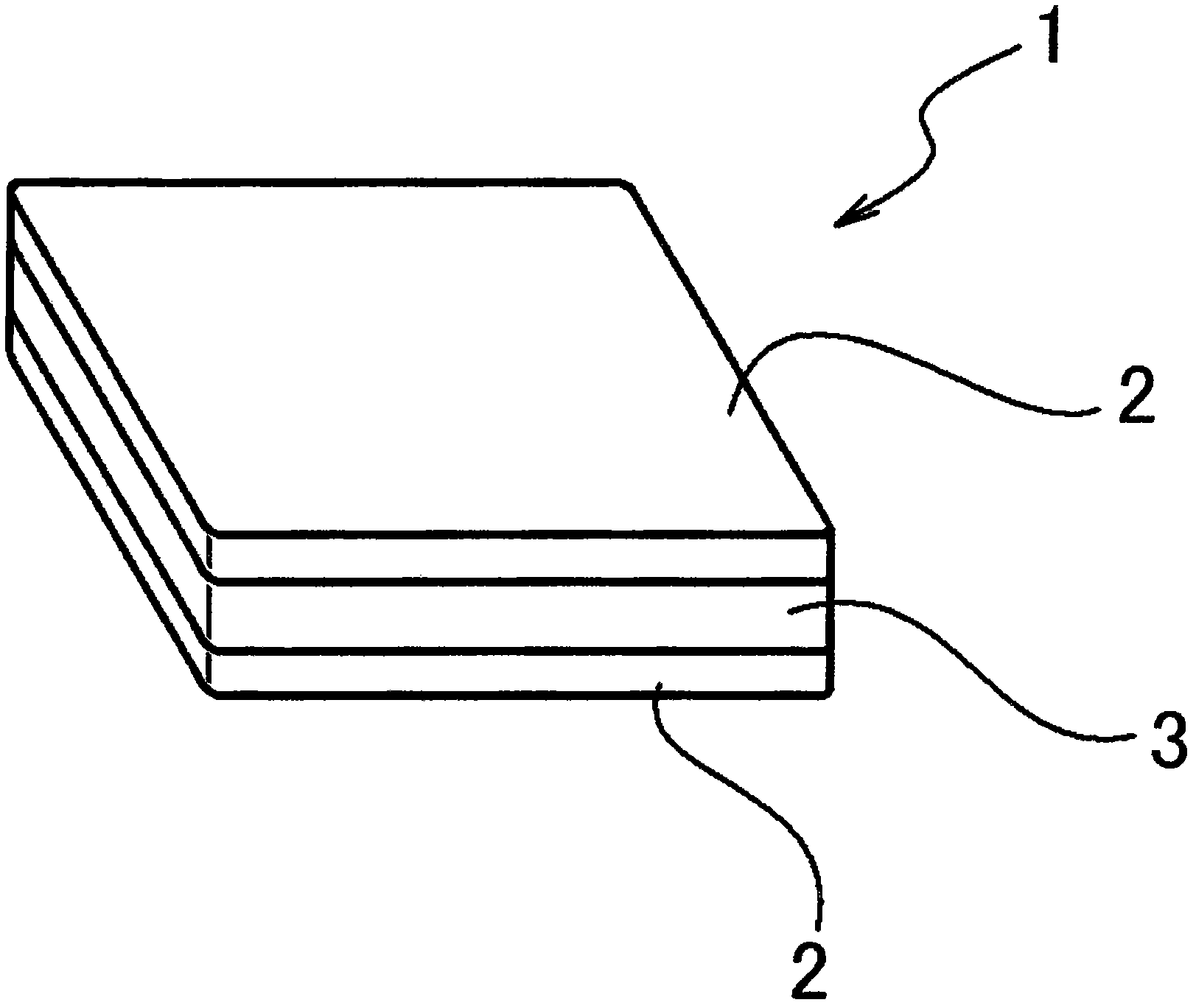

A piston ring 1 for internal combustion engines comprises a hard film 2 formed on at least an outer circumferential sliding surface of the piston ring 1. The hard film 2 includes chromium, nitrogen and silicon as structural elements and the same crystal structure as CrN, and is composed of a crystal phase where silicon is contained in a solid solution state in a crystal lattice at an atomic ratio between 1 and 9.5 percent. The hard film may be the following film. Namely, a hard film is composed of a mixed phase of a crystal phase and an amorphous phase; the crystal phase includes chromium, nitrogen and silicon as structural elements and the same crystal structure as CrN and moreover includes silicon contained in a solid solution state in a crystal lattice; the amorphous phase includes silicon, nitrogen and chromium as structural elements; the ratio of the amorphous phase in the hard film is 4.5 percent or less; and the silicon content in the hard film is between 1 and 9.5 percent at an atomic ratio. The hard film may include aluminum, vanadium, titanium, zirconium, boron, carbon, oxygen or fluorine.

Owner:TEIKOKU PISTON RING CO LTD

Inorganic board and method for manufacturing thereof

ActiveUS20060075931A1Reduce the amount requiredHardening reactionCeilingsCovering/liningsWater solubleSynthetic resin

Owner:NICHIHA CORP

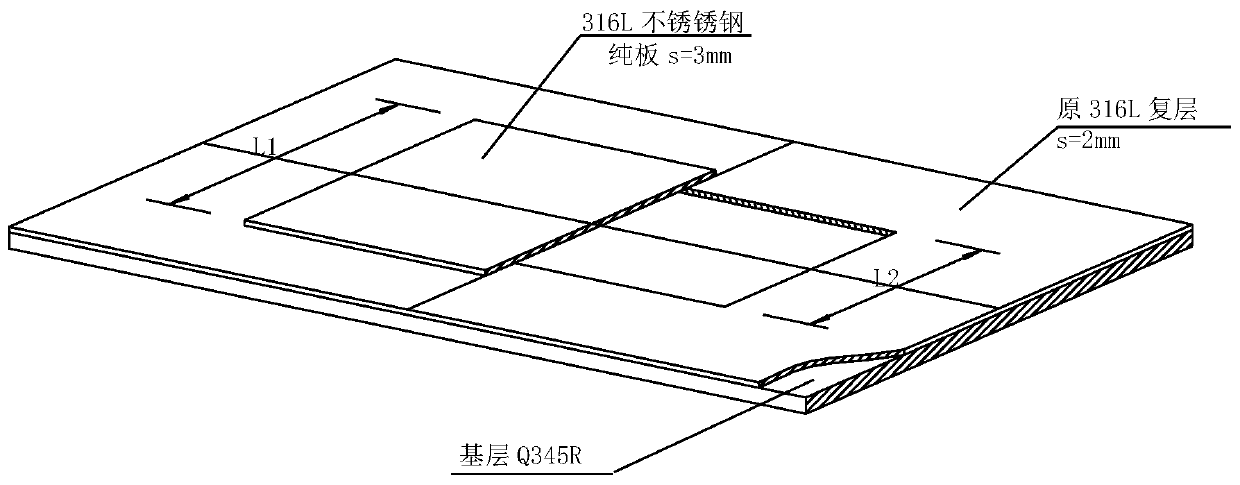

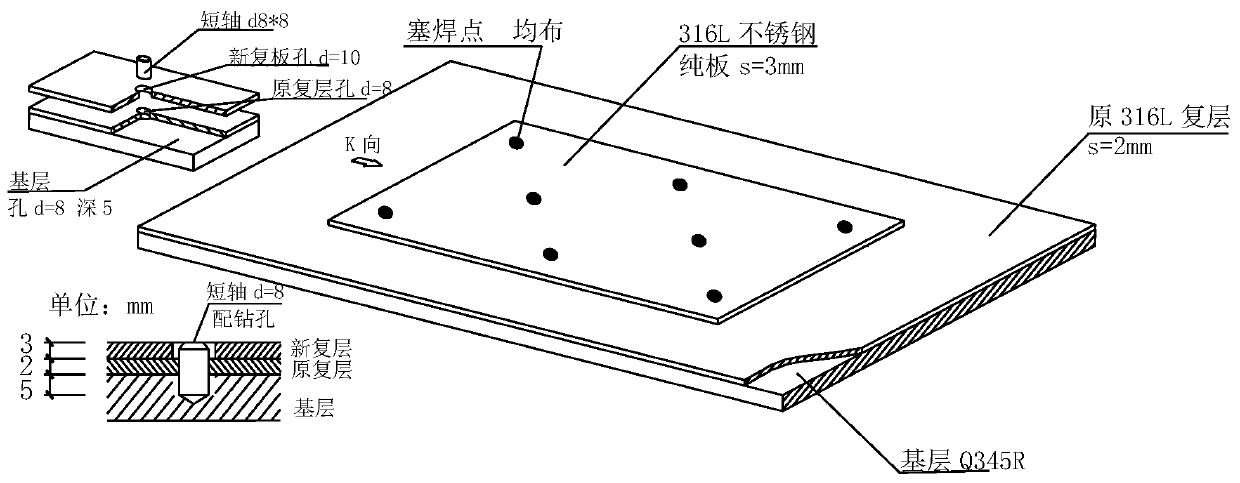

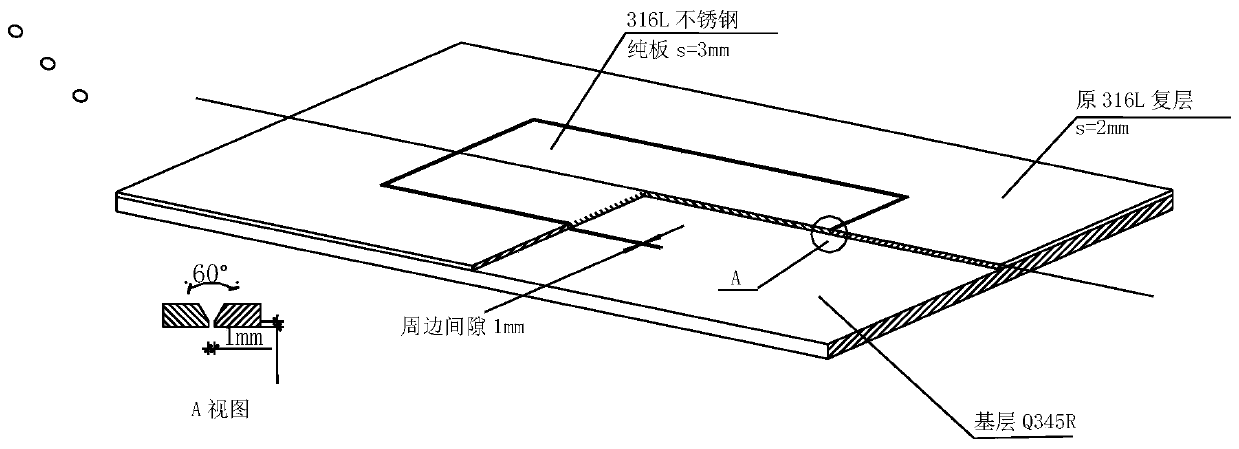

Repairing processing method of corrosion parts of original tank composite layer

InactiveCN109702427ALess welding rodReduced corrosion resistanceArc welding apparatusStress concentrationMetal

The invention provides a repairing processing method of corrosion parts of an original tank composite layer, belongs to the technical field of metal tank processing, and discloses two types of repairing processing methods of different corrosion areas and different corrosion degrees of the original composite layer of a tank and other equipment. The repairing processing method comprises the steps ofa ''flitch plate type'' repairing method and a ''plug welding type'' repairing method; the ''flitch plate type'' repairing method is a repairing mode performing by adopting a ''flitch plate '' technology principle and comprises a ''patch type'' flitch plate repairing method and an ''embedded type'' flitch plate repairing method, and the repairing technology is mainly applied to the conditions ofnot too large corrosion parts and not too obvious corrosion of the original composite layer of the tank and other equipment; the ''plug welding type'' repairing method is a repairing mode performing by adopting a ''plug welding'' technology principle, is mainly applied to the conditions of larger corrosion areas, more serious corrosion of the original composite layer of the tank and other equipment, due to larger areas in a repairing position, the ''plug welding type'' repairing ensures surfacing, avoids the generation of stress concentration, and the performance is good after repairing. The repairing technology is scientific and reasonable, and is convenient and fast.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

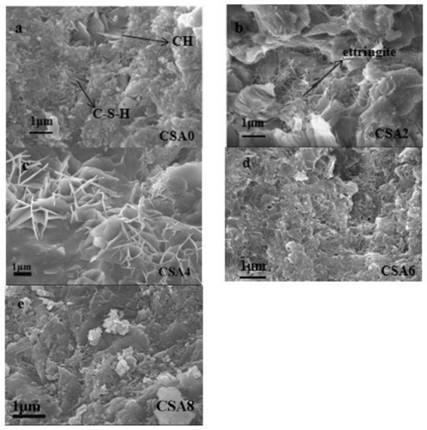

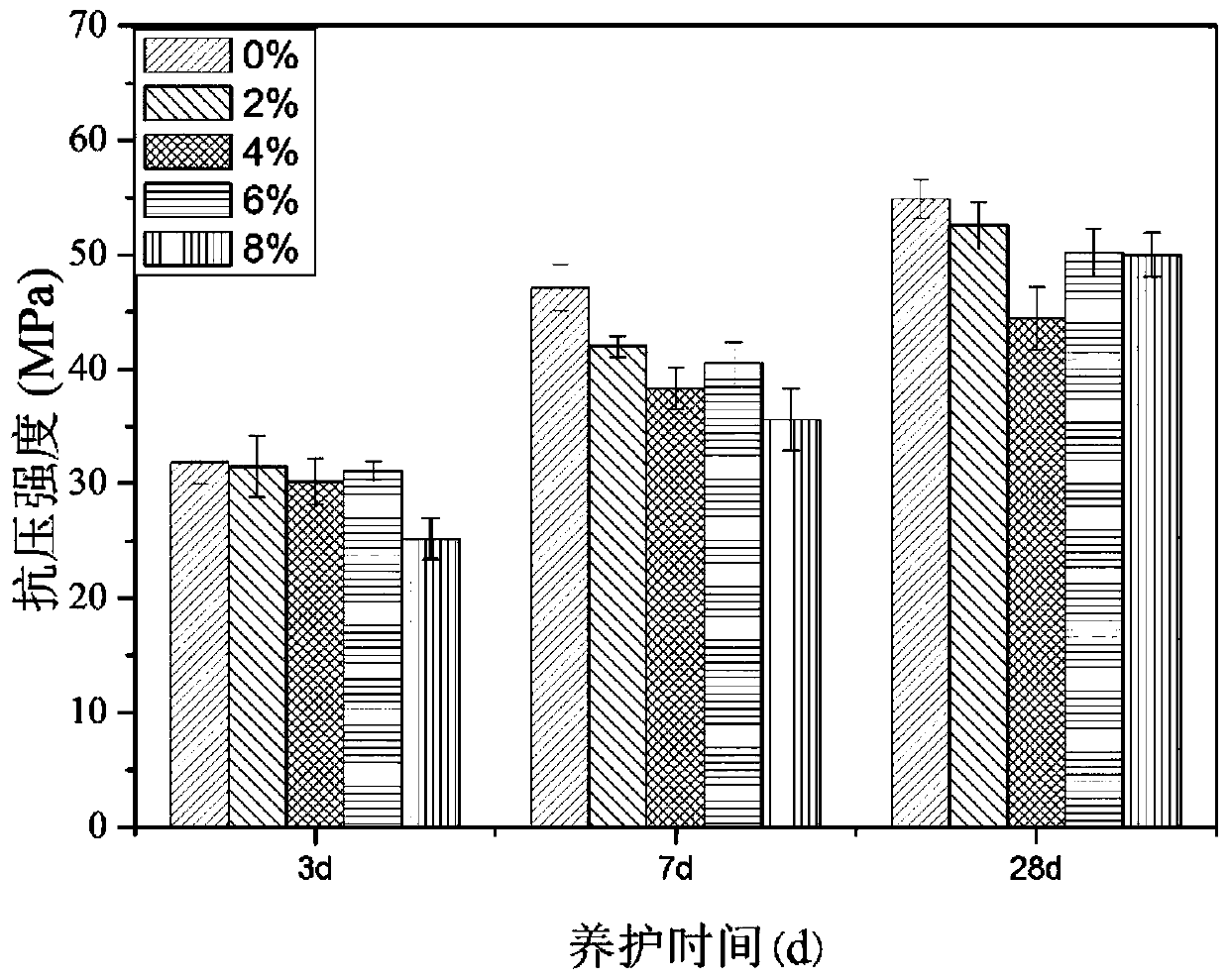

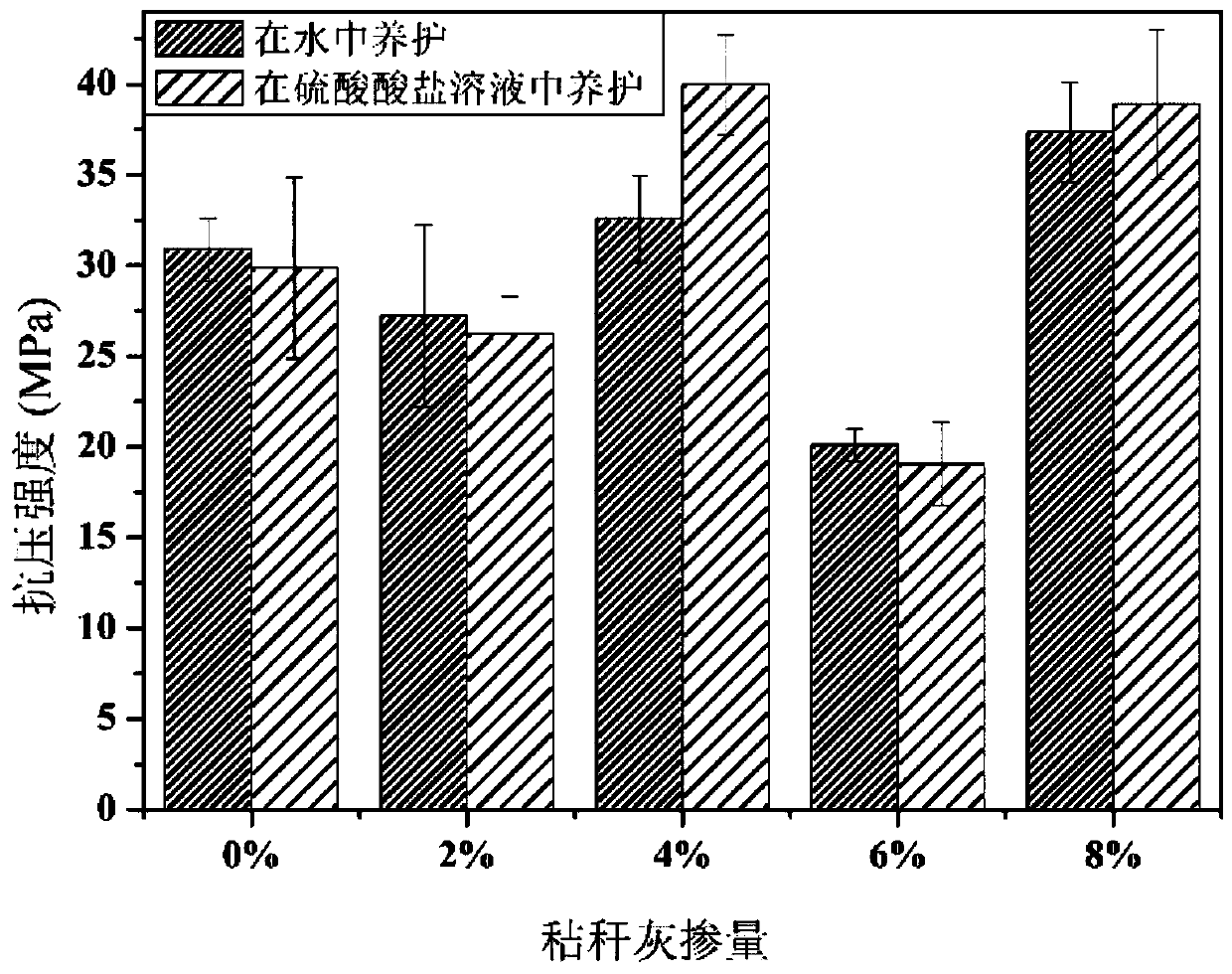

Method for preparing nano-modified cement-based biomass material by using high-temperature calcined straw ash

The invention provides a method for preparing a nano-modified cement-based biomass material by using high-temperature calcined straw ash. The method comprises the following steps: firstly, taking a plant straw as a raw material for calcination treatment; then putting the calcined powder into a muffle furnace for secondary calcination treatment to obtain straw ash; taking an acrylic monomer as theraw material and coating a polymer in situ on the surface of the nano-silica powder and preparing a silicon oxide powder on the surface of the polymer; and finally, mixing and grinding cement, flyash,the straw ash, a water-reducing agent and the obtained composite structure material according to weight parts to obtain the cement-based biomass material. The straw ash prepared by the method disclosed by the invention contains more water hardness active substances and greatly improves sulfate erosion resistance of cement mortar to a certain extent.

Owner:UNIV OF JINAN

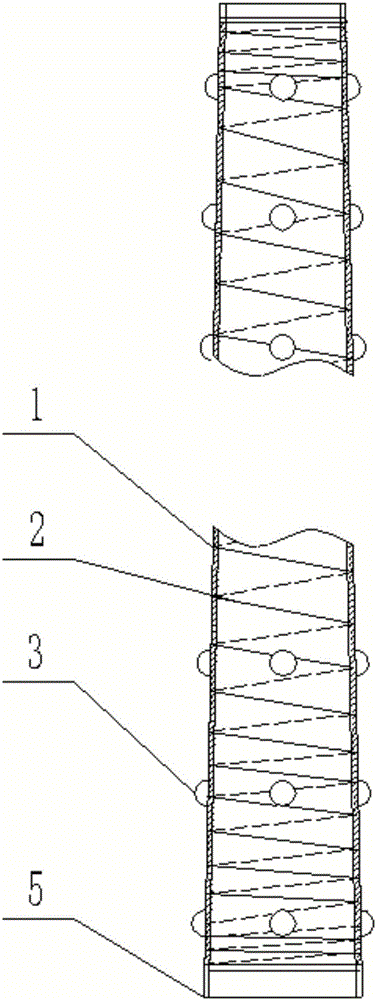

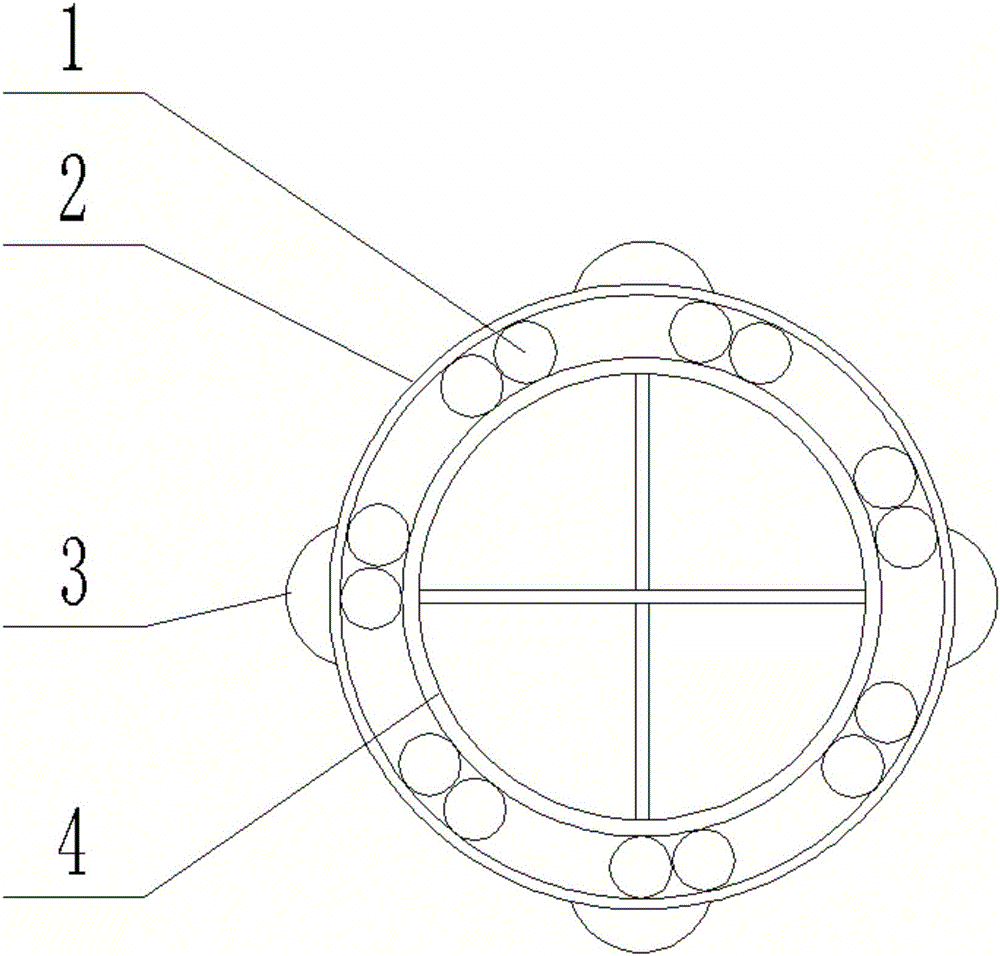

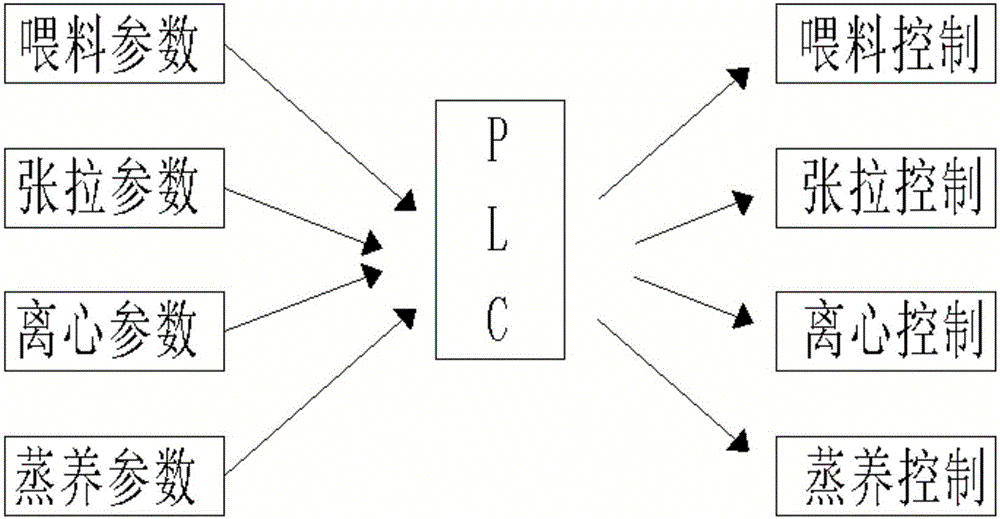

Telegraph pole production process

ActiveCN105965686AImprove the instantaneous carrying capacityReduced crack resistanceCeramic shaping apparatusTowersPre stressSlurry

The invention relates to the field of cement product prefabricated parts, in particular to a telegraph pole production process. The telegraph pole production process is characterized in that the process includes the following steps that high-strength ribs are straightened and subjected to fixed length treatment and shearing, and main ribs are formed; a set of main ribs distributed around the axis are arranged, a set of erecting rings at equal intervals are welded on the inner sides in the axial direction of the main ribs, a conical rebar framework is formed, and rib hanging disks are installed at the two ends of the rebar framework; spiral ribs are arranged in the whole-length range of the rebar framework and bound firmly with iron wires; the rebar framework is pre-tensioned, and a plurality of circles of cushion blocks are arranged on the surface at equal intervals; the rebar framework is hoisted into a telegraph pole steel mold base, mold assembly is performed after concrete slurry is poured in, tensioning is performed, and then the centrifuging process is performed; and a telegraph pole formed after centrifuging is hoisted into a steaming pond to be subjected to steaming, natural curing is performed after steaming of the telegraph pole ends, and demolding is performed. The telegraph pole production process can improve the strength and the prestress performance of the telegraph pole; and meanwhile, steel materials can be saved, waste of concrete is reduced, and the production cost is reduced.

Owner:BEIHAI JINGYI CONCRETE PROD

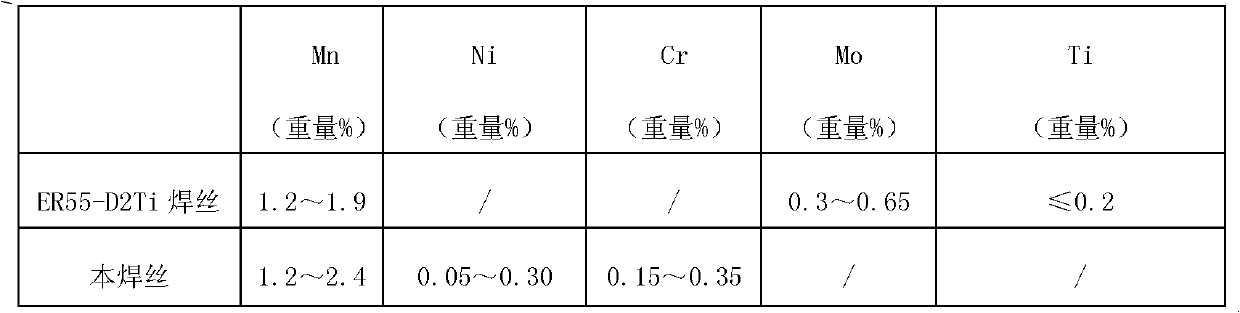

Solid welding wire for high-toughness structural steel

ActiveCN101905393AIncrease contentMeet welding requirementsArc welding apparatusWelding/cutting media/materialsChemical compositionSheet steel

The invention provides a solid welding wire for high-toughness structural steel, which comprises the following chemical components by weight percent: C: 0.06-0.12, Si: 0.4-0.8, Mn: 1.2-2.4, Ni: 0.05-0.30, Cr: 0.15-0.30, S: not more than 0.015, P: not more than 0.020 and the balance of Fe and other unavoidable impurities. As for the solid welding wire for the high-toughness structural steel provided by the invention, yield strength for deposited metal is more than 500MPa and tensile strength is more than 600MPa; after welding, welding seams have beautiful shaping, little splash and low crack sensitivity, thus meeting the welding requirement for a low-alloy high strength steel plate; and relative to an ER55-D2Ti welding wire or a 60kg of welding wire containing Ni-Mo system, the solid welding wire of the invention lowers production cost and use cost on the premise of guaranteeing intensity and impact toughness, thus being suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

Bentonite waterproof paint and production method thereof

InactiveCN102816524ALarge specific surface areaGood UV absorbing functionConjugated diene hydrocarbon coatingsBituminous coatingsMechanical propertyButadiene-styrene rubber

The invention discloses a bentonite waterproof paint and a production method thereof. The paint is composed of the components of: 40-55 parts of mixed asphalt, 5-7 parts of nano-grade bentonite, 1-7 parts of a styrene-butadiene rubber solution, 0.2-0.7 parts of mica powder, 0.1-0.5 parts of dodecyl trimethyl ammonium bromide, and 40-55 parts of deionized water. The particle size of the nano-grade bentonite is 20-100mm. When the paint is used in construction under a temperature below -15 DEG C, the components are: mixed asphalt 35-55%, the nano-grade bentonite 6-20%, and diesel oil 34-50%. The paint is advantaged no toxicity, no odor, cold construction, high work efficiency, low cost, and good mechanical performances. The method is advantaged in no three-waste pollution during productions. The paint can be used in roofing plate calking, plate surface coating, old roofing repairing, underground water proofing and damp proofing, washroom leakage preventing, wood decay preventing, and road paving.

Owner:绵阳堃山矿业有限公司

Anti-freeze and anti-cracking concrete

The invention discloses anti-freeze and anti-cracking concrete. The anti-freeze and anti-cracking concrete comprises Portland cement, limestone powder, steel slag powder, sand, fine stones, modified rubber powder, potassium water glass, expanded perlite, natural zeolite ultrafine powder, polypropylene fibers, glass fibers, water reducing agents and water. The anti-freeze and anti-cracking concretehas the advantages of high workability, frost resistance and crack resistance, and effectively prolonged service life in a harsh environment.

Owner:蚌埠市方阵商品混凝土有限公司

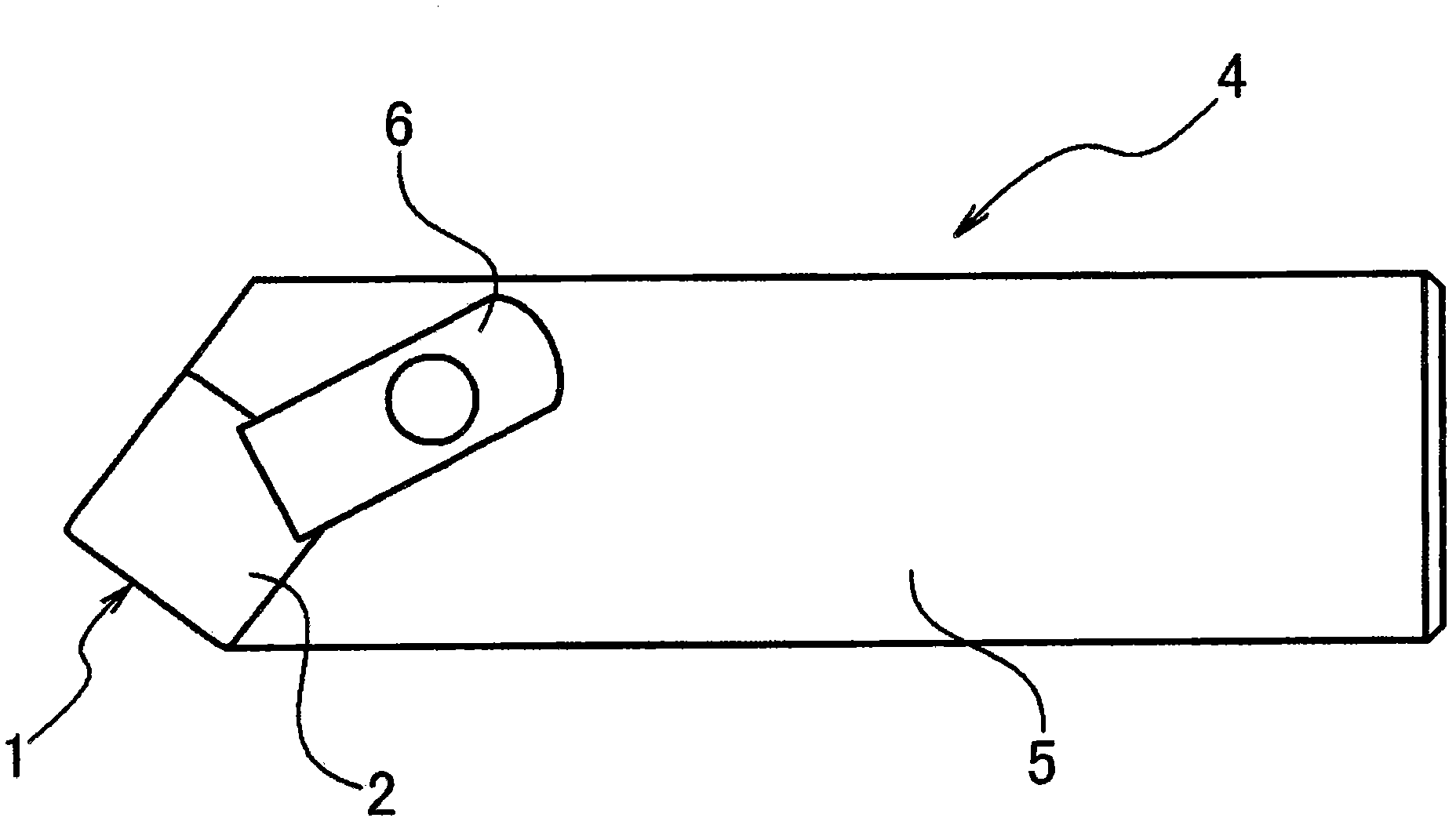

Cutting insert and cutting tool

InactiveCN102105248AExtended service lifeReduced crack resistanceWorkpiecesTurning toolsEngineeringThermal expansion

Owner:NGK SPARK PLUG CO LTD

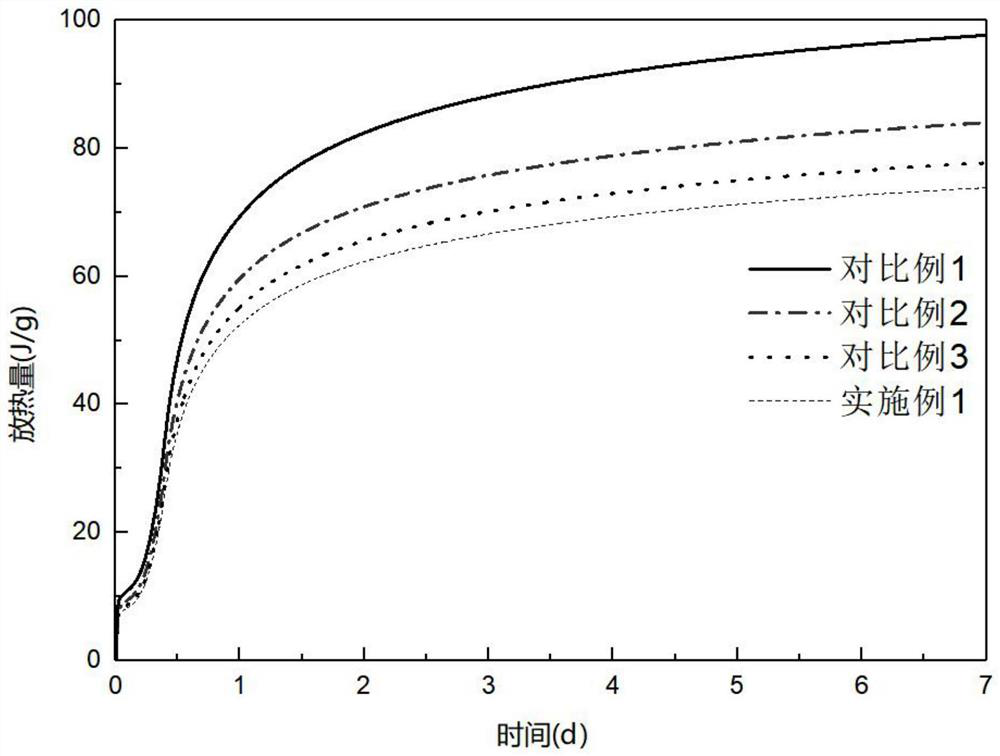

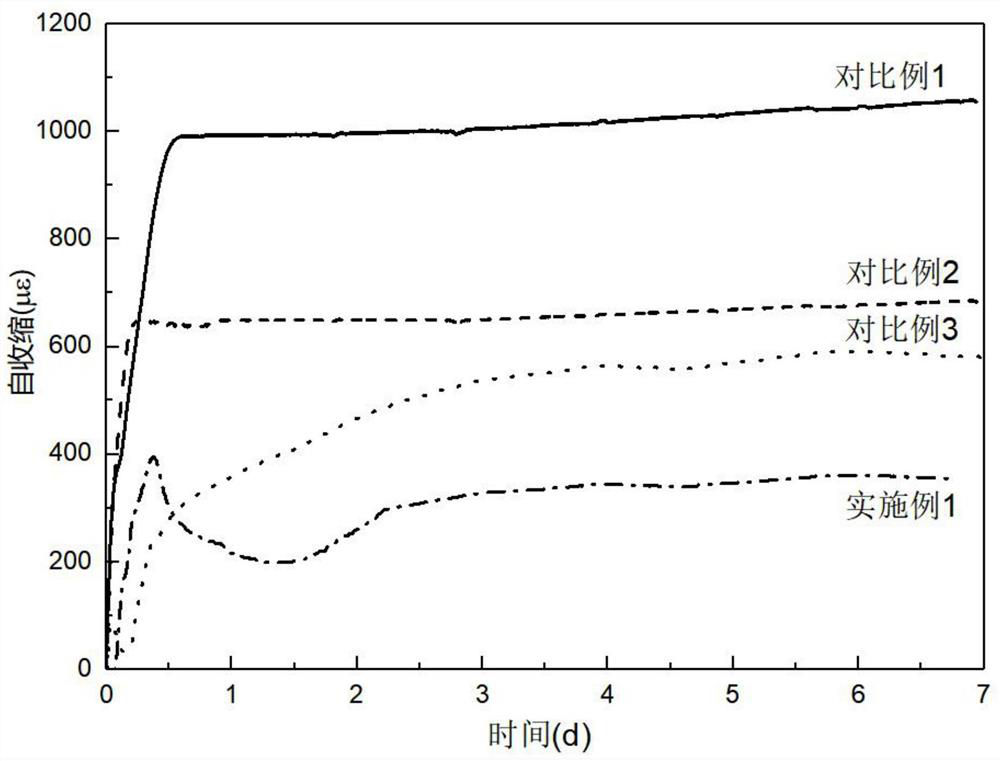

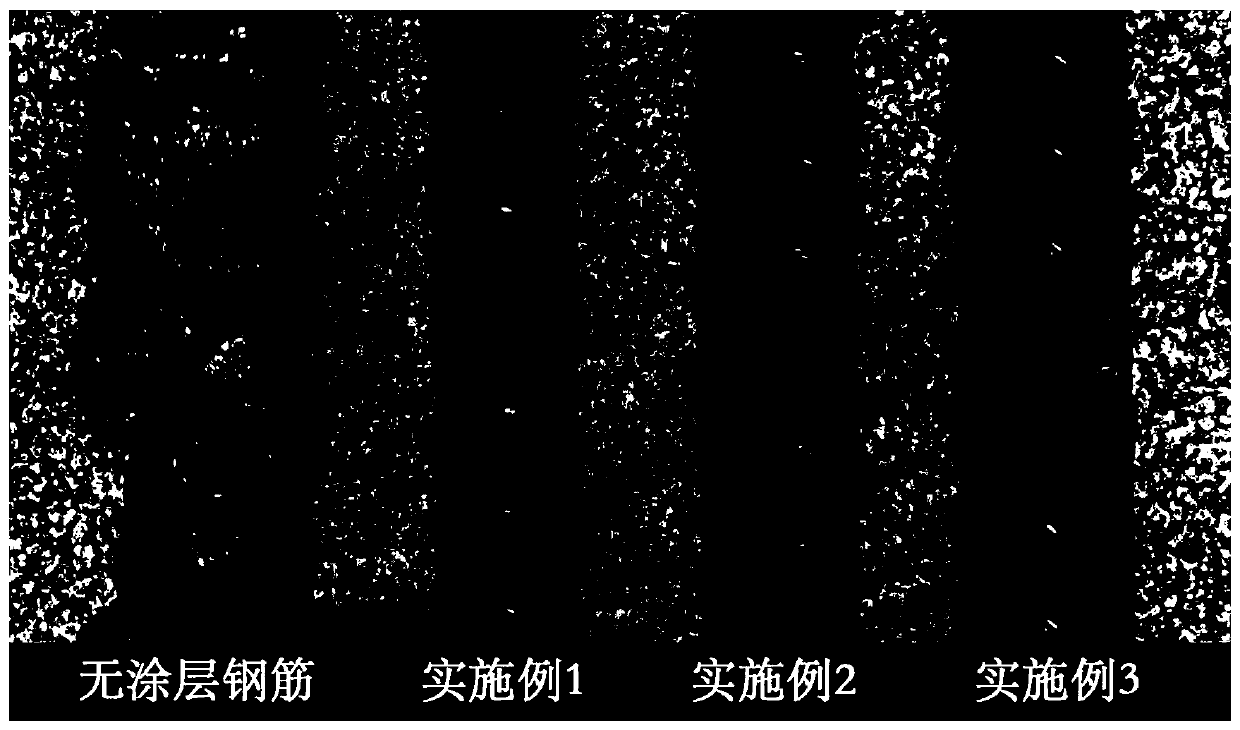

Low-shrinkage high-crack-resistance ultra-high performance concrete and preparation method thereof

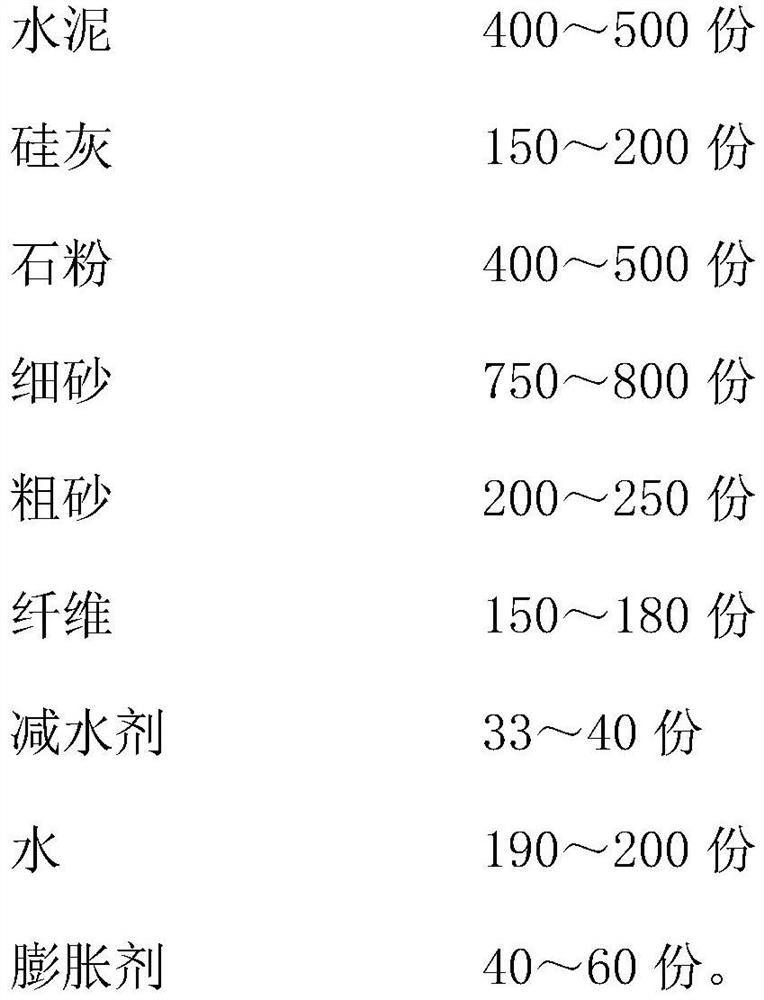

PendingCN113773018AReduce heat of hydration and temperature deformationReduce environmental pollutionSolid waste managementSilica fumePowder

Owner:中山市灵湾新材料科技有限公司

Inorganic anticorrosive coating layer for high-strength metal

ActiveCN110684379AHigh tensile strengthImprove antioxidant capacityAnti-corrosive paintsAluminum silicateSilicon oxide

The invention discloses an inorganic anticorrosive coating layer for a high-strength metal. The coating layer is formed on a high-strength metal surface by a coating through high-temperature sinteringat 500-800 DEG C, the coating comprises 25-35 parts of silicon oxide, 10-25 parts of phosphorus pentoxide, 10-25 parts of aluminum oxide, 2-15 parts of a fiber, 15-30 parts of a modifier and 1-3 parts of an anti-cracking agent, wherein the fiber is one or a combination of two or three of alumina silicate fiber, basalt fiber and calcium carbonate fiber; a plurality of sealing holes of which the diameters account for 1 / 30-1 / 10 of the thickness of the coating layer are distributed inside the coating layer; the number of the sealing holes is reduced from inside to outside; the aperture of a porous inner layer close to the high-strength metal surface is 2-15%; and the aperture of a dense outer layer far away from the high-strength metal surface is 0-2%. The coating layer is good in toughness,good in adhesion performance to a substrate, excellent in corrosion resistance, diverse in construction mode and low in use cost, and no crack penetrating through the coating layer can be caused in case of micro strain of 2800-3000.

Owner:ZHEJIANG UNIV

Production method and raw material formula of strongly-effective anticracking glue

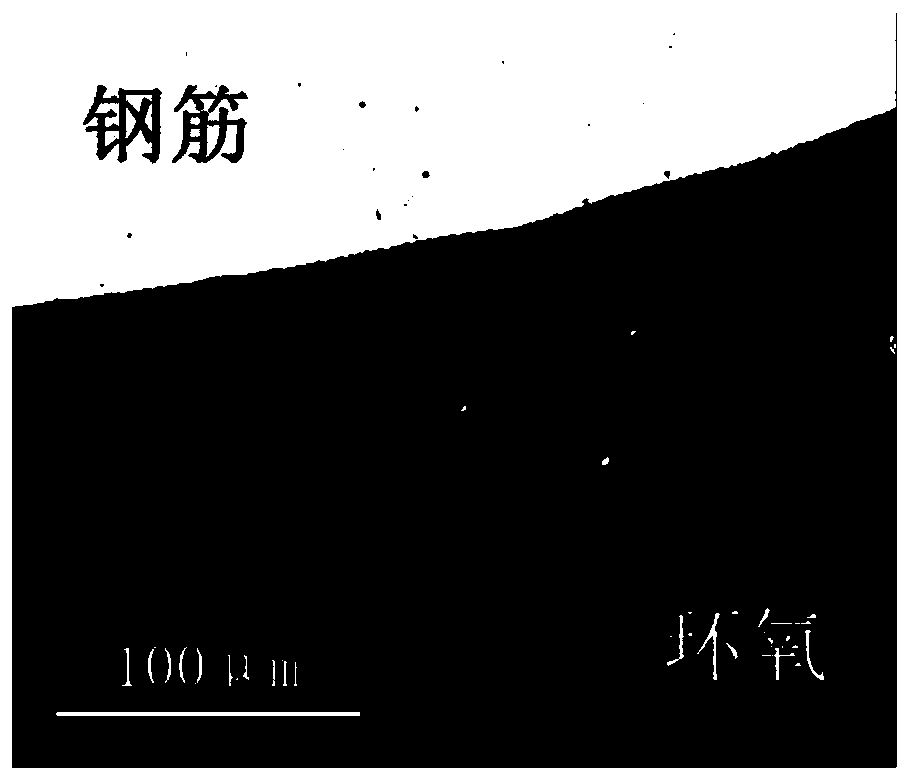

ActiveCN104119828AImprove protectionEasy to masterNon-macromolecular adhesive additivesOther chemical processesEpoxySodium Bentonite

The invention relates to a production method and a raw material formula of strongly-effective anticracking glue which comprises a main agent and a curing agent, the main agent comprises the following raw materials: 40%-50% of epoxy resin, 5%-15% of a diluent, 5%-25% of bentonite and 30%-60% of Shuangfei powder, the raw materials are mixed according to the proportion and then are made into paste for standby use through mixing; the curing agent comprises the following raw materials: 40%-50% of fatty amine, 5%-15% of a diluent, 5%-25% of bentonite and 30%-60% of Shuangfei powder, the raw materials are mixed according to the proportion and then are made into paste for standby use through mixing; the standby paste main agent and the standby paste curing agent are evenly mixed in the weight ratio of 2 to 1, or evenly mixed in the weight ratio of 1 to 1 or a proper weight ratio, and then the strongly-effective anticracking glue is coated or scraped at seam crossing; the strongly-effective anticracking glue product eliminates the need of other anticracking handling after use, the working procedure can be completed in one step, and the construction is convenient, time saving, labor saving and material saving and can be completed by scraping once.

Owner:福建山外山涂料科技开发有限公司

Anti-freezing concrete and preparation method thereof

ActiveCN113292289AIncrease elasticityImprove crack resistanceSolid waste managementFiberFreeze thawing

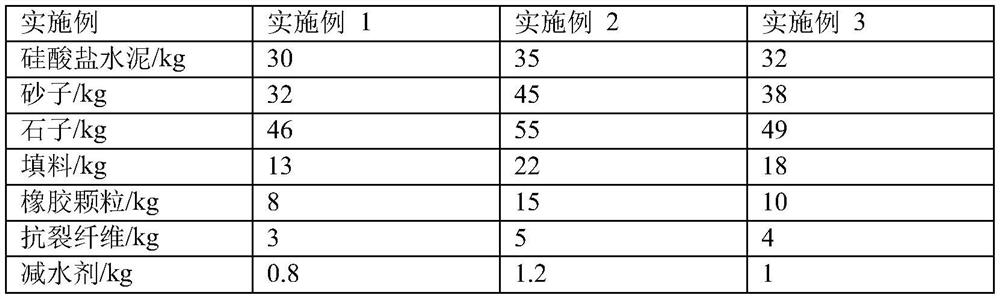

The invention relates to the field of concrete, and particularly discloses anti-freezing concrete and a preparation method thereof. The anti-freezing concrete is composed of the following components in parts by weight: 30 to 35 parts of Portland cement, 15 to 20 parts of water, 32 to 45 parts of sand, 46 to 55 parts of pebbles, 13 to 22 parts of filler, 0.8 to 1.2 parts of a water reducing agent, 3 to 5 parts of anti-crack fibers, 8 to 15 parts of rubber particles, 0.5 to 1 part of a waterproof agent, 0.1 to 0.3 part of an anti-freezing agent and 0.3 to 0.6 part of an air entraining agent, wherein the surface of the concrete is coated with a surface reinforcing agent. The anti-crack fibers in the concrete can improve the crack resistance of the concrete and reduce cracks, so that water permeation is reduced; the rubber particles and the anti-crack fibers can improve the elastic modulus of the concrete, the air entraining agent introduces air holes in the concrete, frost heaving pressure can be buffered, and freeze-thaw damage can be reduced; and the waterproof agent has a waterproof effect, and the anti-permeability is improved, so moisture infiltration is reduced, and the freeze-thaw resistance is improved.

Owner:海阳市利安建材有限公司

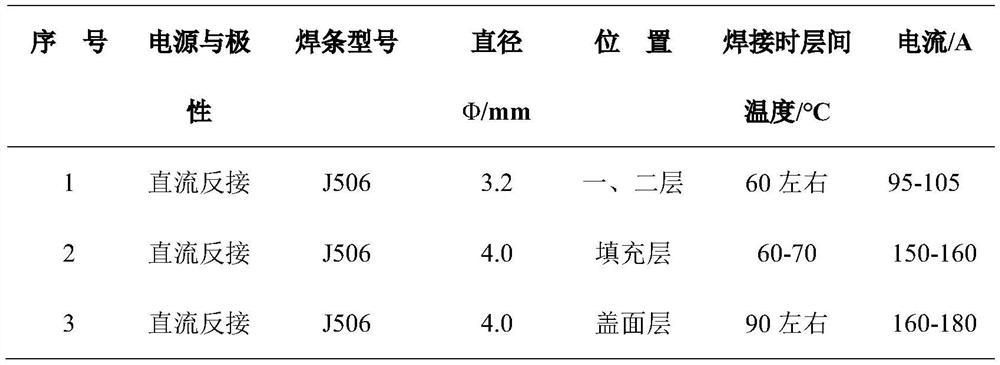

Method for repairing and welding copper mold bottom plate made of nodular cast iron

The invention provides a method for repairing and welding a copper mold bottom plate made of nodular cast iron. The method comprises the following steps that 1, a to-be-repaired part of the copper mold bottom plate is cleaned and ground until metal luster is exposed; 2, a bevel edge U-shaped groove is opened on the to-be-repaired part of the copper mold bottom plate and cut and ground; 3, metal isfused in the bevel edge U-shaped groove, and the bevel edge U-shaped groove is fixed to the copper mold base plate base material together by using carbon steel bolts; 3, a crack arrest hole is formedin the position of 50mm-100mm, away from the to-be-paired part of the copper mold bottom plate, and a carburized layer of the hypotenuse U-shaped groove carries out cutting and grinding treatment; 4,the to-be-repaired part of the copper mold bottom plate is locally preheated; 5, a bottom layer of the to-be-repaired part of the copper mold bottom plate is welded by using a baked J506 type weldingrod; 6, a copper mold bottom plate crack welding area is slowly cooled after slow cooling by adopting a heat preservation and slow cooling mode. According to the method, the strength and the fusion of a weld joint of the copper mold bottom plate can be improved, and the problems of weld crack and sheet peeling of the copper mold bottom plate after welding are effectively solved.

Owner:JINCHUAN GROUP LIMITED

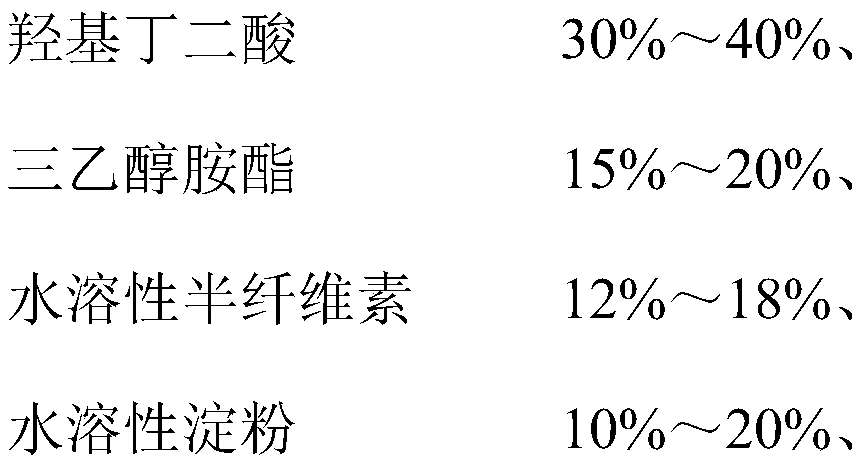

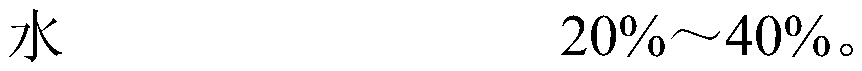

Soil stabilizer capable of improving drying shrinkage performance of compacted soil and preparation method thereof

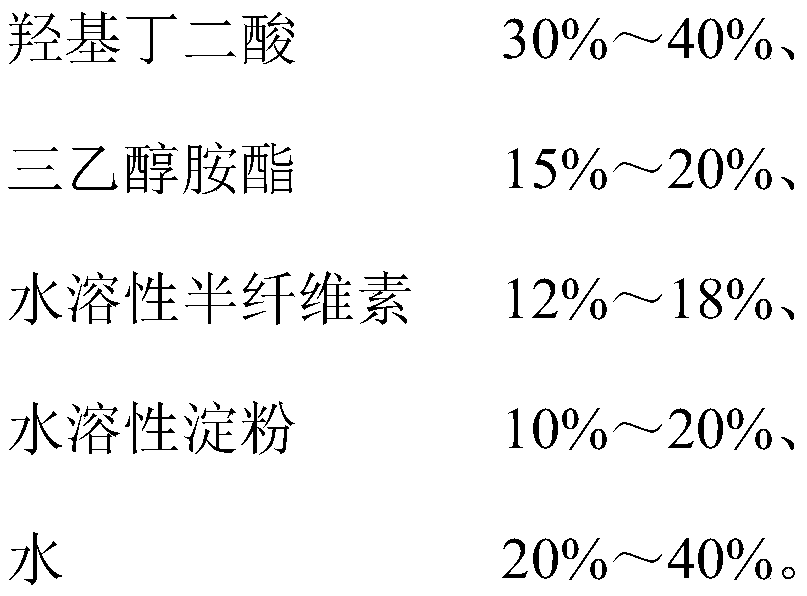

InactiveCN111575010AEffective consolidationHigh strengthRoadwaysBuilding constructionsButanedioic acidSoil science

The invention discloses a soil stabilizer capable of improving the drying shrinkage performance of compacted soil and a preparation method of the soil stabilizer. The soil stabilizer is prepared fromthe following raw materials (in percentage by mass): 30%-40% of hydroxysuccinic acid, 15%-20% of triethanolamine ester, 12%-18% of water-soluble hemicellulose, 10%-20% of water-soluble starch and 20%-40% of water. The soil stabilizer of the invention have the following beneficial effects that: (1) the formula of the soil stabilizer is reasonable and scientific in collocation, the properties of soil can be changed, so the effects of solidifying and hardening the soil and reducing the shrinkage of the soil in the hardening process are achieved, dry shrinkage resistance is excellent, and the soilstabilizer is an ideal soil stabilizer for projects such as highway subgrades or subbases; and (2) the soil stabilizer provided by the invention is mainly applied to reinforcement soil of highway subgrades or subbases and other projects, can also be used for soil reinforcement of water conservancy projects, airport projects and the like, and has a wide application range.

Owner:SHAANXI COMM CONSTR GRP CO LTD

Ultralow-hydrogen and high-tenacity metal powder core type seamless flux-cored welding wire for all-position welding

ActiveCN106891104ALow solderabilityReduced crack resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconMachinability

The invention provides an ultralow-hydrogen and high-tenacity metal powder core type seamless flux-cored welding wire for all-position welding. The seamless flux-cored welding wire comprises outer skin and flux core powder, wherein the inner part of the outer skin is filled with the flux core powder, and the outer skin is a low-carbon steel band. The seamless flux-cored welding wire is characterized in that the flux core powder comprises the following components in a percent by weight: 10-15% of low-carbon ferromanganese, 15-20% of atomized ferrosilicon, 2-5% of rutile, 1-5% of cryolite, 1-3% of atomized nickel powder, 1-2% of quartz, 0.5-2% of feldspar and the balance of iron powder. The seamless flux-cored welding wire is suitable for the all-position welding of carbon steel and low-alloy steel which are welded under the protection of mixed gas containing 75-85% of Ar and 15-25% of CO2. The seamless flux-cored welding wire is great in welding machinability, stable in mechanical properties, great in crack resistance, low in hydrogen dispersion and high in moisture absorbability and can be used for all-position welding.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Fiber concrete and preparation method thereof

The invention relates to the technical field of concrete, in particular to a preparation method of fiber concrete. The preparation method comprises the following steps: 1, performing strong acid soaking treatment on plant fibers, then performing strong alkali soaking treatment, and performing shearing and drying to obtain pretreated fibers; 2, the pretreated fibers are weighed and soaked in a water-retaining agent, stirring is conducted for 1-1.5 h, then an antioxidant is added, uniform mixing, heating and stirring are conducted, and modified plant fibers are obtained; 3, the recycled aggregate, the water reducing agent, the inorganic filler, the defoaming agent, the cement, the water, the corrosion inhibitor and the surfactant are weighed and evenly mixed with the modified plant fibers, stirring is conducted for 40-80 min, fiber concrete slurry is obtained, the fiber concrete slurry is poured into a mold to be fixed and formed, and the fiber concrete is obtained and has the good anti-cracking effect.

Owner:东莞市建业混凝土有限公司

Fibre-reinforced anti-crack mortar dry powder

The invention provides a fiber mortar dried powder material for strengthening the anti-crack, which comprises functionality the materials of cement, sand, silicon aluminum hollow spheroid, alkali proof fiber, mineral contraction inhibitor, cement hydration regulation agent, modifier and so on. Wherein, the cement hydration regulation agent comprises cement hydration slow hardening components and molding moisture and negative setup components. The mortar dried powder material for strengthening the anti-crack is able to be used through adding water to solve the problem of inaccurate calculation and material wasting of the traditional method owing to the preparation of the material in the scene. The prepared mortar solves the problem of crack owing to the stress of the ordinary mortar. The invention has the advantages of molding moisture, slow hardening, waterproof and easy construction, which is mainly used as the anti-crack mortar for the construction of heat preservation and heat insulation wall and also other construction walls.

Owner:武汉科华高新材料发展有限公司

Ternary boride composite cermet with ferro-nickel as raw material and preparing method and application thereof

The invention relates to ternary boride composite cermet with ferro-nickel as a raw material and a preparing method and application thereof. The ternary boride composite cermet is prepared from, by mass, 100 parts of ferro-nickel, 36-60 parts of molybdenum, 12-15 parts of an aluminum core tube and 3-5 parts of a steel core tube through electric arm melting. With the ferro-nickel as the raw material, the Mo2NiB2 and Mo2FeB2 composite ternary boride cermet is produced through the electric arm melting process, and compared with the vacuum reaction sintering process adopted widely at present, theproduction efficiency is high and the production cost is low.

Owner:SHANDONG UNIV

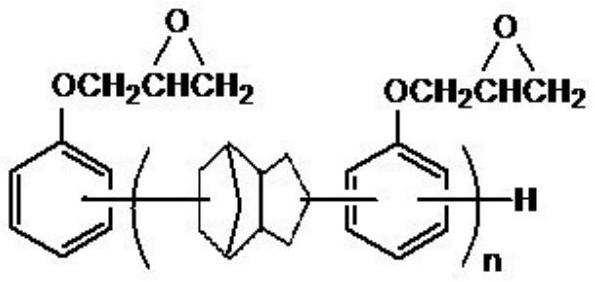

Preparation method of copper-clad plate with low dielectric constant, low dielectric loss and low CTE

PendingCN113978061ALow hygroscopicityLow elastic modulusSynthetic resin layered productsLaminationPolymer scienceDielectric loss

The invention belongs to the technical field of copper-clad plate production, and relates to a preparation method of a copper-clad plate with low dielectric constant, low dielectric loss and low CTE. The method comprises the following steps: (1) preparing a resin glue solution: mixing 60-100 parts by weight of special epoxy resin, 150-200 parts by weight of SMA resin, 10-40 parts by weight of benzoxazine resin, 0.1-20 parts by weight of a cross-linking curing agent, 0.1-1 part by weight of a dispersing agent, 40-100 parts by weight of a solvent, 30-80 parts by weight of a flame retardant, and 10-150 parts by weight of a filling material, and carrying out emulsifying and uniformly stirring; (2) preparing a prepreg; and (3) preparing the copper-clad plate with low dielectric constant, low dielectric loss and low CTE. The dielectric constant of the prepared copper-clad plate is less than 3.9, the dielectric loss is less than 0.007, the Z-CTE is less than or equal to 1.05%, the T288 can reach 120 minutes without layering, the copper-clad plate has lower dielectric loss and higher heat resistance, is suitable for the high-level design of a high-frequency and high-speed circuit board, and greatly improves the packaging efficiency and the reliability of a PCB (Printed Circuit Board).

Owner:SHANDONG JINBAO ELECTRONICS

Anti-cracking thermal insulation polyethylene water delivery pipe

The invention discloses an anti-cracking thermal insulation polyethylene water delivery pipe, and belongs to the technical field of building high polymer materials. The anti-cracking thermal insulation polyethylene water delivery pipe is manufactured according to the following steps: weighing the following components in sequence in parts by weight: 50-60 parts of polyethylene resin, 2-3 parts of colorant, 7-15 parts of flame retardant, 2-3 parts of lubricant and 20-40 parts of additive; mixing polyethylene resin and a colorant in a mixer; adding a flame retardant, a lubricant and an additive into the mixer, conducting stirring and mixing under the conditions that the temperature is 70-110 DEG C and the rotating speed is 800-1000 r / min to obtain a mixture, extruding and granulating the mixture to obtain a master batch, and extruding and molding the master batch to obtain the anti-cracking thermal insulation polyethylene water delivery pipe. The obtained anti-cracking thermal insulationpolyethylene water delivery pipe has excellent anti-freezing performance and anti-cracking performance.

Owner:常州富思通管道有限公司

Single-component indoor wall repairing material and preparation method thereof

The invention discloses a single-component indoor wall repairing material and a preparation method thereof and relates to the technical field of wall materials. The single-component indoor wall repairing material comprises 55-75 parts of silicate cement, 34-36 parts of seaweed powder, 30-35 parts of a carbon fiber-graphene enhancer, 24-26 parts of ethyl acetate, 20-22 parts of titanium dioxide, 14-16 parts of dimethicone, 14-16 parts of sodium carbonate, 14-16 parts of a seeping gelling agent, and suitable water. The single-component indoor wall repairing material is used for repairing wall cracks and has good stability and high strength, cohesive property may well meet the repairing requirement, layering is decreased, and peeling is relieved.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Self-extinguishing flame-retardant cable sheath material and preparation method thereof

InactiveCN103897401AHigh tear strengthHigh strengthInsulated cablesInsulated conductorsChemistryCarbon black

The invention discloses a self-extinguishing flame-retardant cable sheath material, comprising the following raw materials in parts by weight: 75-100 parts of dimethyl siloxane-methyl vinyl siloxane copolymer, 20-30 parts of fumed silica 15-20 parts of precipitated white carbon black, 11-15 parts of octamethylcyclotetrasiloxane, 4-10 parts of zinc oxide, 35-45 parts of talcum powder, 2-3 parts of hydroxyl silicone oil, 0.11-0.15 parts of selenium oxide, 1-1.8 parts of polysiloxane, 0.00024-0.0005 parts of platinum catalyst, 18-23 parts of aluminium hydroxide, 20-30 parts of magnesium hydrate, and 30-50 parts of calcium metasilicate. The invention also discloses a preparation method of the self-extinguishing flame-retardant cable sheath material. The self-extinguishing flame-retardant cable sheath material disclosed by the invention is free of pollution, good in high-temperature self-extinguishing effect, and simple in preparation process, and has certain strength and support ability after being sintered.

Owner:ANHUI DINGXING CABLE

Welding process of three-way valve seat and valve body

ActiveCN102990200AReduce toughnessReduced crack resistanceArc welding apparatusHeat-affected zonePower flow

The invention relates to a welding process of a valve seat and a valve body, in particular to a welding process of a three-way valve seat and a valve body of a supercritical thermal power unit; the welding process comprises the following steps that the beneficial impact of multi-layer welding is fully utilized, multi-layer welding is adopted, and a latter layer plays the roles of dehydrogenating and improving the tissue of a heat affected zone to a former layer; heat input is controlled through a method in which low welding current welds more quickly, and the heat input of welding is strictly controlled; and high-strength steel is more sensitive to the heat input of welding, and over heat input can reduce the toughness of a welding connector and thus reduce the anti-cracking performance. Post heat treatment is carried out soon after welding, so that cold cracks are prevented from generating in a period of time after welding, and the welding requirements are met. According to the welding process, the problem that WB36 and F6a special steel welding is difficult is fully solved, cracking and other phenomena after welding are avoided, and the weld seam quality can be fully ensured.

Owner:DALIAN DAGAO VALVE

Treatment process method for reinforcing wet wicker for weaving

PendingCN113787579ATo achieve heat-resistant reinforcementDense microstructureWood treatment detailsReed/straw treatmentCorrosion resistantDry ice

The invention discloses a treatment process method for reinforcing wet wickers for weaving, and belongs to the technical field of wickers. The wickers in the wet state, namely fresh wickers, are directly utilized, peeling, drying and liquid soaking are not needed in the reinforcing process, reinforcing liquid is directly injected in a reinforcing liquid injection and replacement mode, by means of the short-time biological characteristics of the cut wickers, the reinforcing liquid enters the wickers, the reinforcing effect is achieved through dry ice freezing and shaping storage, and in the process, molds can be adopted for shaping, and structures of different shapes are achieved. In the prior art, the shape of the wickers is changed by adopting fire-forced bending and box making, the method disclosed by the invention can also realize lower-requirement and more convenient wicker modeling, the weaving wickers have the effects of improving mechanical strength, increasing weight and preventing water after being subjected to enhanced liquid-liquid treatment, the wicker is not easy to deform, the treatment process is simple and convenient, and the obtained wet wickers has the advantages of high mechanical strength, high heat resistance, high corrosion resistance, high hardness and high specific gravity.

Owner:阜南佳利工艺品股份有限公司

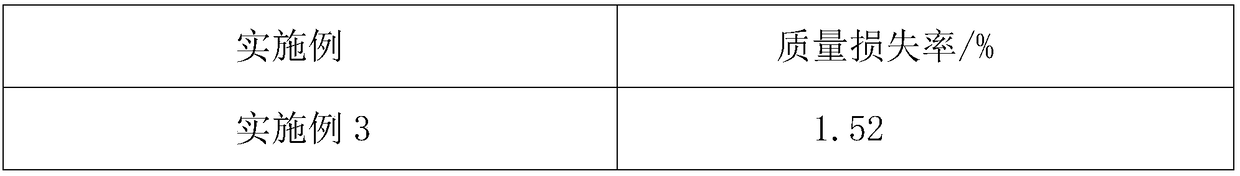

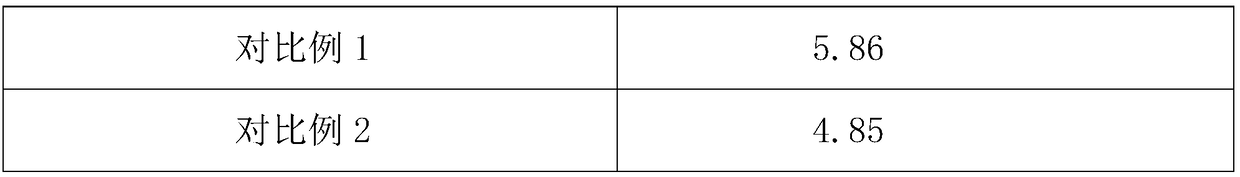

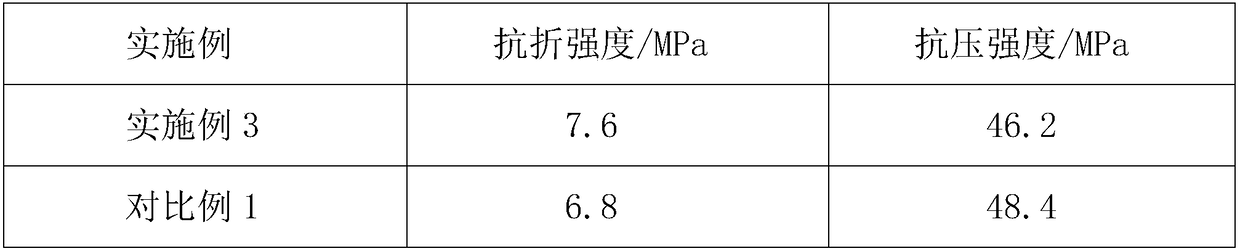

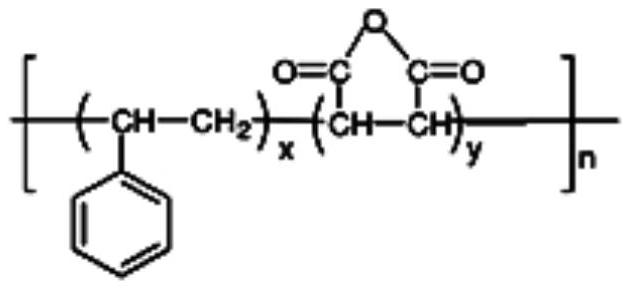

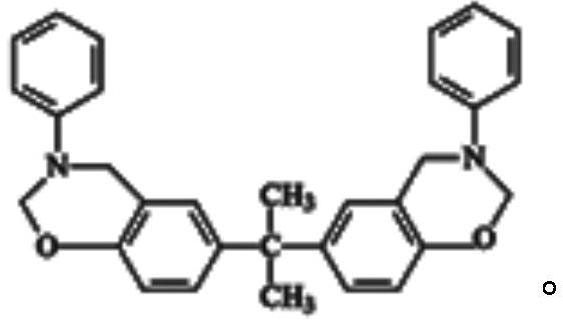

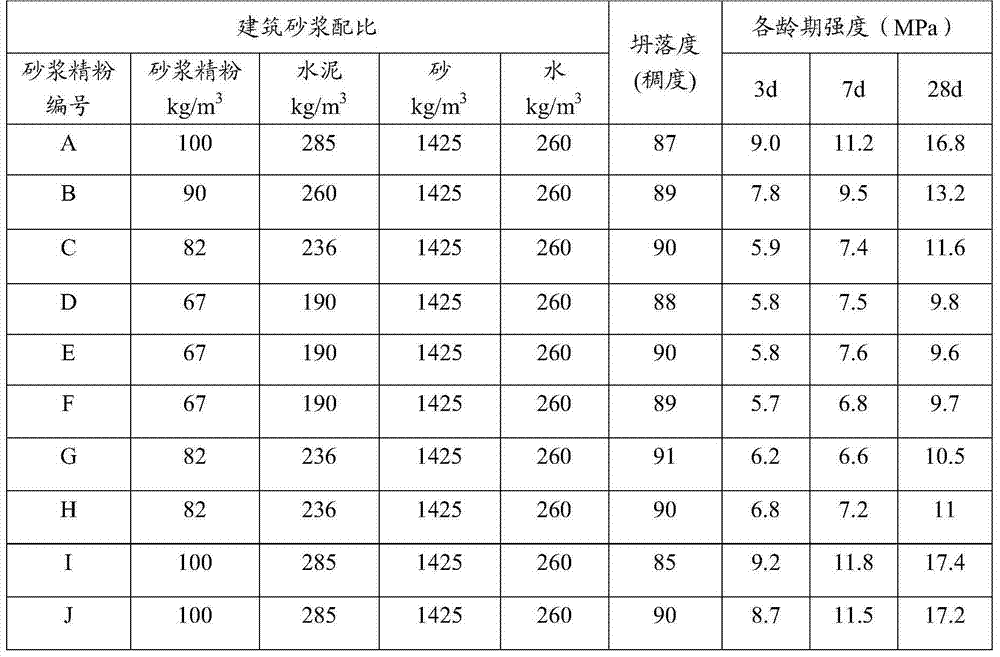

Mortar fine powder and preparation method thereof

The invention provides a mortar fine powder and a preparation method thereof, and belongs to the field of building materials. The mortar fine powder comprises the following compositions in parts by weight: 97-99.9 parts of limestone powder, 0.03-1 part of a water repellent, 0.03-1 part of cellulose, 0.0-0.5 part of polyacrylamide and 0.02-0.5 part of an air entraining agent. When the mortar fine powder is used as building mortar, the building mortar not only has the advantages of good workability, but also is improved in compressive strength and reduced in cracking resistance. Performance tests show that the building mortar modified by the mortar fine powder is improved in 28-day compressive strength by 5%, improved in caking ability by 20% and reduced in shrinking percentage by 30%.

Owner:湖南瑞吉达科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com