Cutting insert and cutting tool

A technology of cutting inserts and insert holders, which is applied in the field of cutting tools and can solve problems such as difficulty in using sintered crystal whiskers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

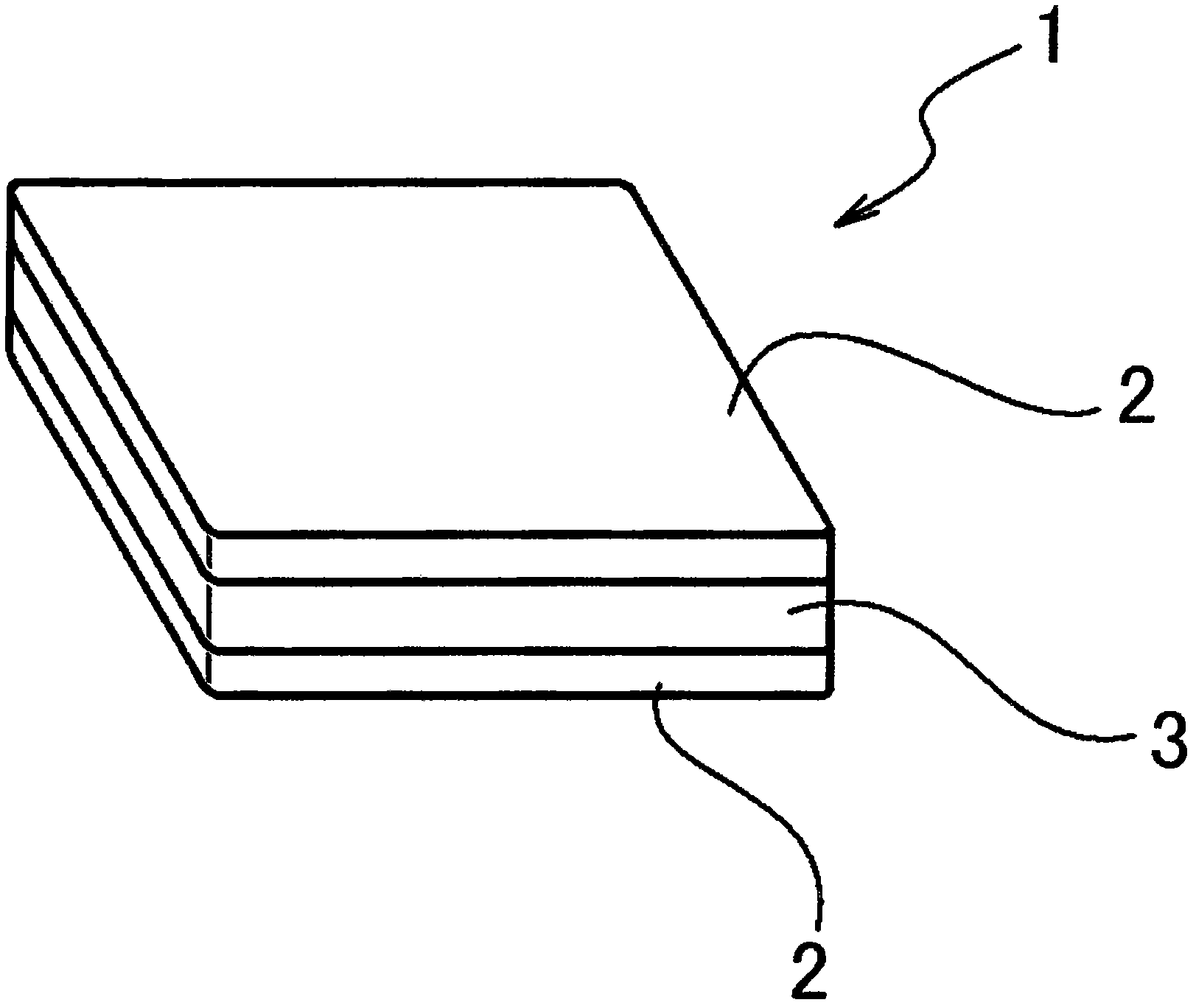

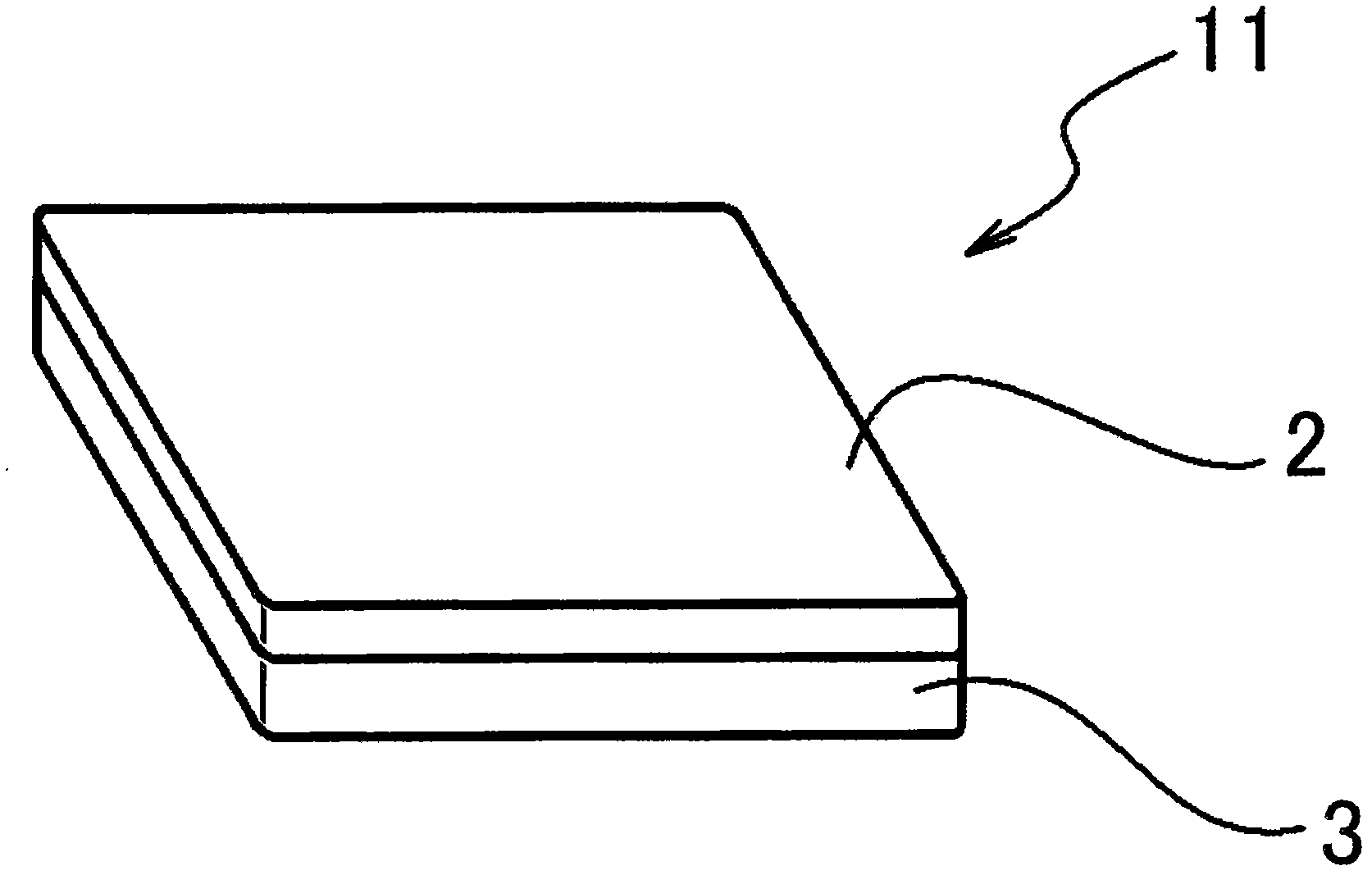

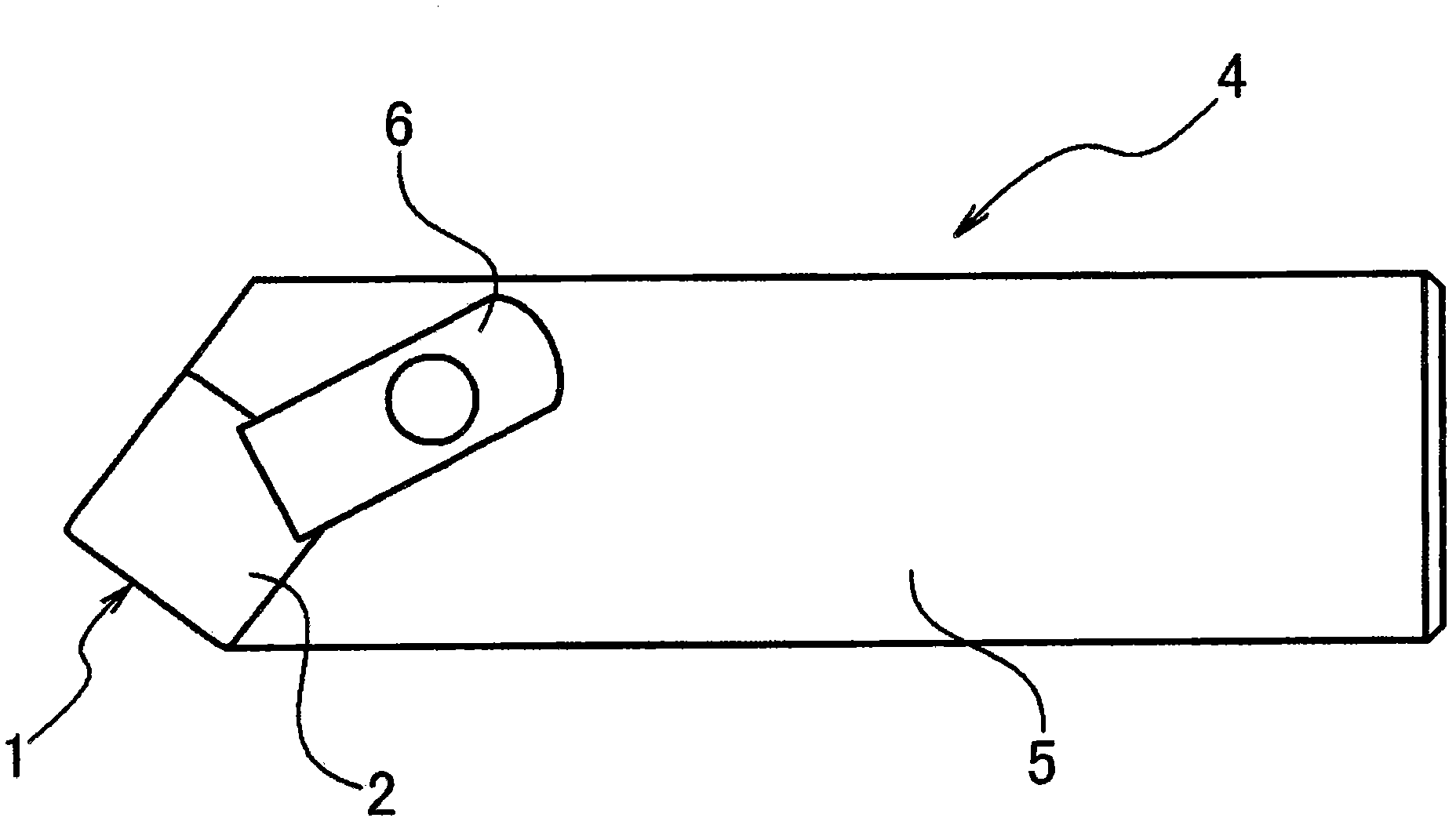

Image

Examples

Embodiment Construction

[0040] In order to simultaneously improve crack resistance and wear resistance, the inventors of the present invention realized the cutting edge of the present invention with original insight, which will be described below.

[0041] In order to manufacture a cutting edge made of ceramics excellent in crack resistance, it is necessary for the ceramics to include whiskers. Therefore, we have studied a cutting insert having a cutting edge made of ceramics to which SiC whiskers are added instead of ceramics containing SiC fine powder contained in the cutting edge prepared in the example disclosed in Patent Document 2 above.

[0042] When grinding ferrous materials with cutting inserts made of ceramics containing a large number of whiskers, the whiskers wear themselves out. Therefore, in order to improve the wear resistance of the cutting insert, it is necessary to reduce the amount of whiskers. On the other hand, when the amount of whiskers is reduced for the purpose of wear resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com