Preparation method of copper-clad plate with low dielectric constant, low dielectric loss and low CTE

A low dielectric constant, low dielectric technology, applied in the preparation of low CTE copper clad laminates, low dielectric constant, low dielectric loss, can solve the problems of large dielectric loss dimensional stability, limited applications, etc., to achieve good Effects of mechanical and electrical properties, high Tg, and high product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a copper clad laminate with low dielectric constant, low dielectric loss, and low CTE, comprising the steps of:

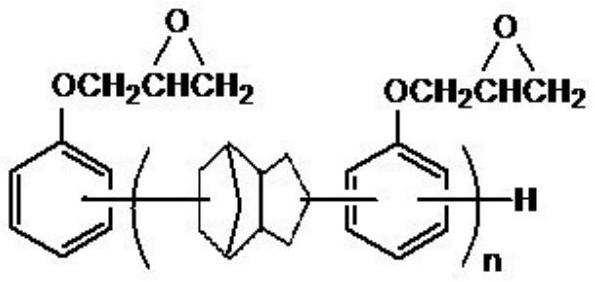

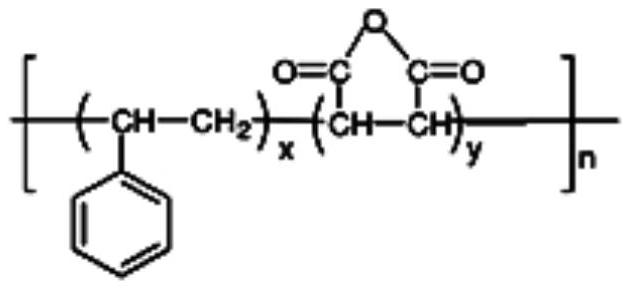

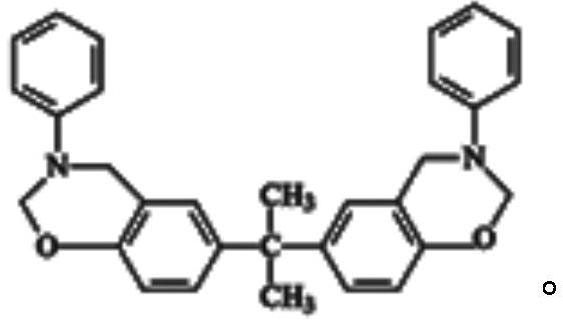

[0035] (1) Preparation of resin glue: by weight, 85 parts of special epoxy resin dicyclopentadiene phenol type epoxy resin (epoxy equivalent is 260-280g / eq, purchased from Nippon Kayaku), 180 parts SMA resin (the copolymerization ratio of styrene and maleic anhydride is 6:1, Mw:6000-6500, purchased from Sartomer, USA), 25 parts of DCPD type low-dielectric benzoxazine resin, 0.1 part of cross-linking curing Agent 2-methyl-4-ethylimidazole, 0.1 part of dispersant BYK-W 903 type wetting and dispersing agent, 60 parts of solvent butanone, 60 parts of flame retardant decabromodiphenyl ether (bromine content 81%-83%) ), 50 parts of high-purity ultrafine spherical nano-amorphous silicon powder (SiO 2 The content is up to 99.9%, the average particle size is 3-5μm, the maximum particle size is not more than 20μm), 50 parts of ultra-fine electr...

Embodiment 2

[0039] A method for preparing a copper clad laminate with low dielectric constant, low dielectric loss, and low CTE, comprising the steps of:

[0040](1) Preparation of resin glue: by weight, 75 parts of special epoxy resin dicyclopentadiene phenol type epoxy resin (epoxy equivalent is 260-280g / eq, purchased from Nippon Kayaku), 170 parts SMA resin (the copolymerization ratio of styrene and maleic anhydride is 6:1, Mw:6000-6500, purchased from Sartomer, USA), 30 parts of DCPD type low dielectric benzoxazine resin, 0.1 part of cross-linking curing Agent 2-methyl-4-ethylimidazole, 0.1 parts of dispersant BYK-W 903, 40 parts of methyl ethyl ketone, 20 parts of xylene, 60 parts of flame retardant decabromodiphenyl ether (bromine content 81%-83% ), 70 parts of high-purity ultrafine spherical nano-amorphous silicon powder (SiO 2 The content is 99.9%, the average particle size is 3-5μm, the maximum particle size is not more than 20μm), 30 parts of ultra-fine electronic grade E-glass...

Embodiment 3

[0044] A method for preparing a copper clad laminate with low dielectric constant, low dielectric loss, and low CTE, comprising the steps of:

[0045] (1) Preparation of resin glue: by weight, 60 parts of special epoxy resin dicyclopentadiene phenol type epoxy resin (epoxy equivalent is 260-280g / eq, purchased from Nippon Kayaku), 150 parts SMA resin (the copolymerization ratio of styrene and maleic anhydride is 6:1, Mw:6000-6500, purchased from Sartomer, USA), 40 parts of DCPD type low dielectric benzoxazine resin, 0.2 part of 2-methyl Base-4-ethylimidazole, 0.04 parts of zinc 2-ethyl octanoate, 0.1 parts of dispersant BYK-W 903, 40 parts of solvent butanone, 45 parts of flame retardant decabromodiphenyl ether (bromine content 81%-83 %), 50 parts of high-purity ultrafine spherical nano-amorphous silicon powder (SiO 2 The content is 99.9%, the average particle size is 3-5μm, the maximum particle size is not more than 20μm), 30 parts of ultra-fine electronic grade E-glass powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com