Low-shrinkage high-crack-resistance ultra-high performance concrete and preparation method thereof

An ultra-high performance, high crack resistance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as limitation, large shrinkage cracking risk, etc. Good economic and environmental protection benefits, broad application prospects and value effects

Pending Publication Date: 2021-12-10

中山市灵湾新材料科技有限公司

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] At present, UHPC is mainly used in small-sized concrete products such as architectural decorations, steel-UHPC composite bridge deck pavement, and pre

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Login to View More

Abstract

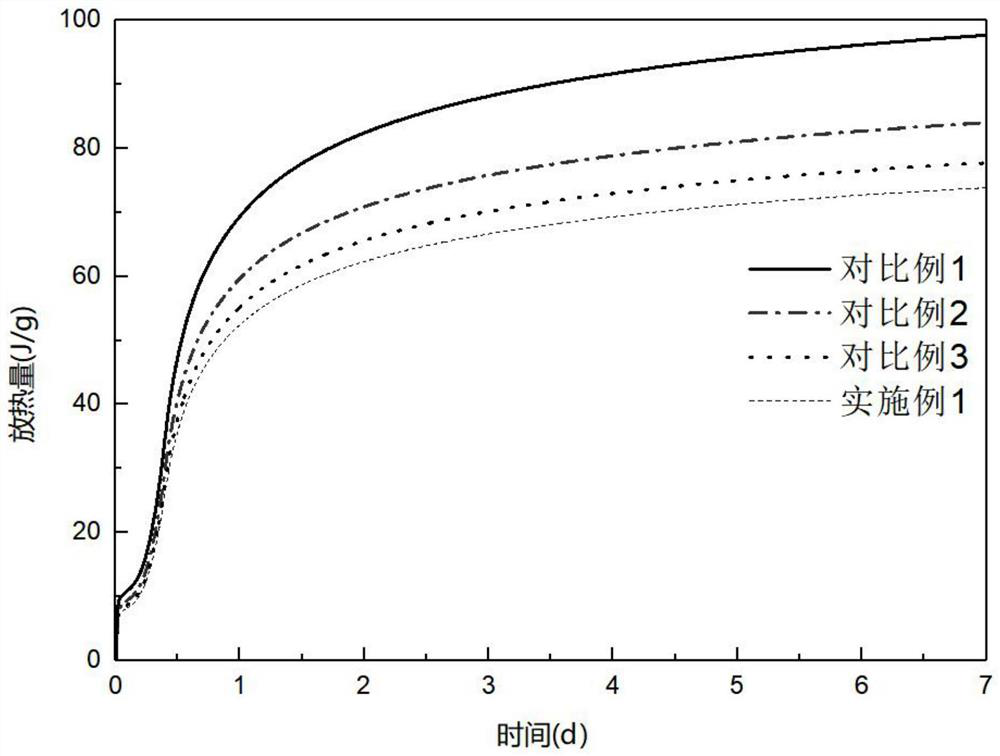

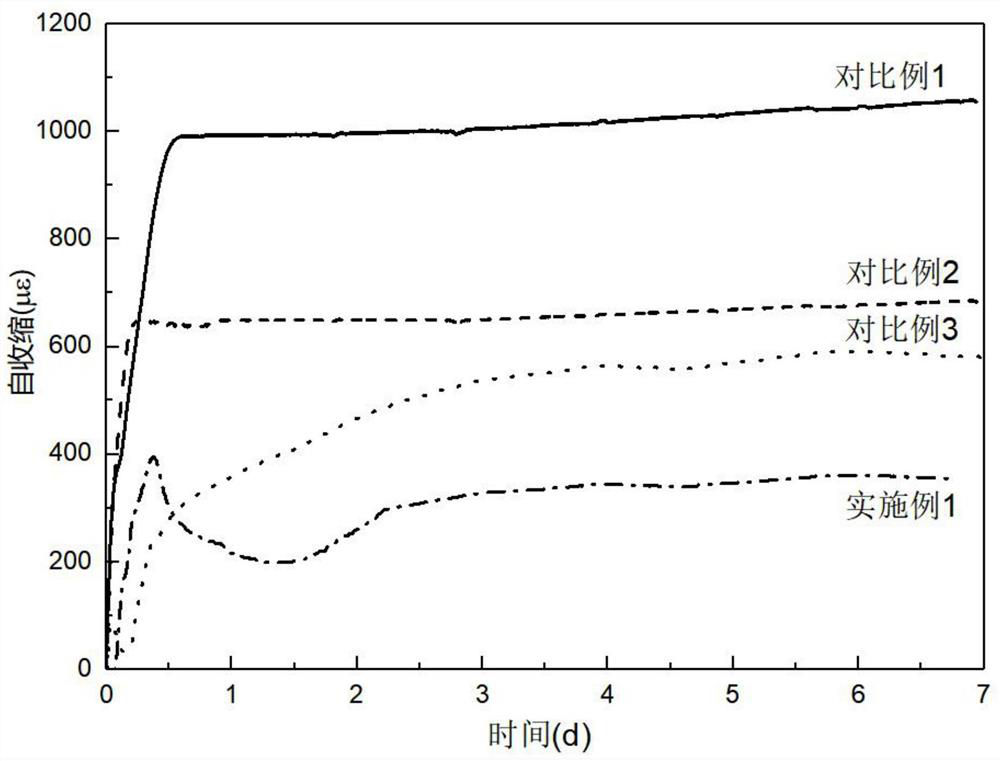

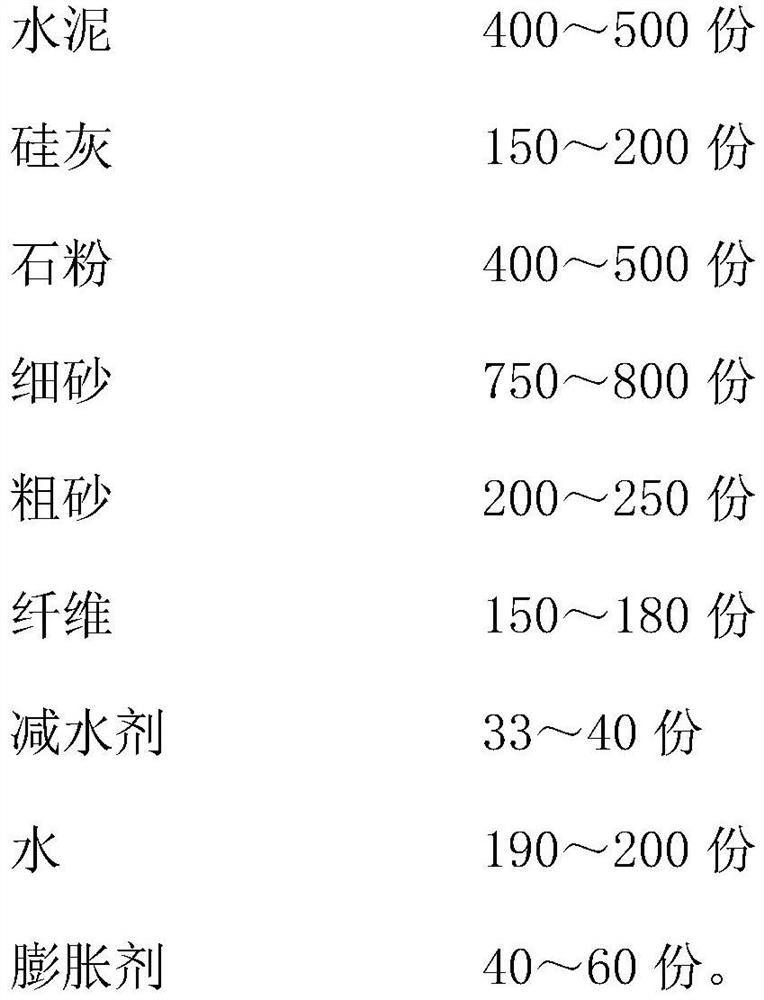

The invention discloses low-shrinkage high-crack-resistance ultra-high performance concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 400 to 500 parts of cement, 150 to 200 parts of silica fume, 400 to 500 parts of stone powder, 750 to 800 parts of fine sand, 200 to 250 parts of coarse sand, 150 to 180 parts of fiber, 33 to 40 parts of a water reducing agent, 190 to 200 parts of water and 40 to 60 parts of and expanding agent. The preparation method comprises the following steps: pouring cement, silica fume, stone powder and an expanding agent into a concrete stirring pot, and uniformly stirring; adding fine sand and coarse sand, and uniformly stirring; pouring 50% of water and a mixture of the residual water and a water reducing agent, and stirring until slurry is formed; continuously stirring the slurry, and slowly adding steel fibers; and pouring, vibrating and forming, covering the surface with a film, removing the mold after one day, and carrying out standard curing to obtain the low-shrinkage high-crack-resistance ultra-high performance concrete. The prepared low-shrinkage high-crack-resistance ultra-high performance concrete is good in working performance and simple in preparation method, reduces pollution, and further has good economic benefits and engineering application value.

Description

technical field [0001] The invention belongs to the technical field of building materials, and in particular relates to a low-shrinkage, high-crack-resistant ultra-high-performance concrete and a preparation method thereof. Background technique [0002] Ultra-high performance concrete (UHPC) refers to a new type of cement-based building material with ultra-high strength (compressive strength ≥ 150MPa), high durability and high toughness. According to the principle of close packing, UHPC improves the gradation of particles, reduces internal defects, and improves the compactness and uniformity of materials by removing coarse aggregates and using fine sand of about 1mm as aggregates; using silica fume, fly ash and The pozzolanic effect and filling effect of mineral powder and other active mineral admixtures improve the pore structure of the material; through the use of polycarboxylate high-efficiency water reducer, the water-binder ratio is greatly reduced, and the porosity is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B18/12C04B14/48C04B22/14C04B22/06C04B111/34

CPCC04B28/04C04B18/12C04B14/48C04B22/148C04B22/064C04B22/143C04B2111/343C04B2201/50C04B18/146C04B14/06C04B2103/302Y02W30/91

Inventor 王武峰杨焕敏夏亮亮余睿张晶晶

Owner 中山市灵湾新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com