Telegraph pole production process

A production process and technology for utility poles, applied in the field of prefabricated components of cement products, can solve problems such as complex production process, high production cost, and loss of prestress, and achieve the effects of ensuring accuracy, large tension, and reducing crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

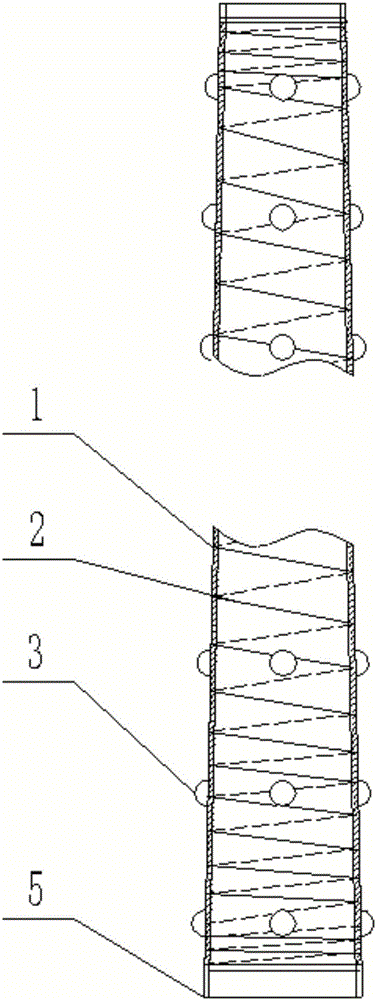

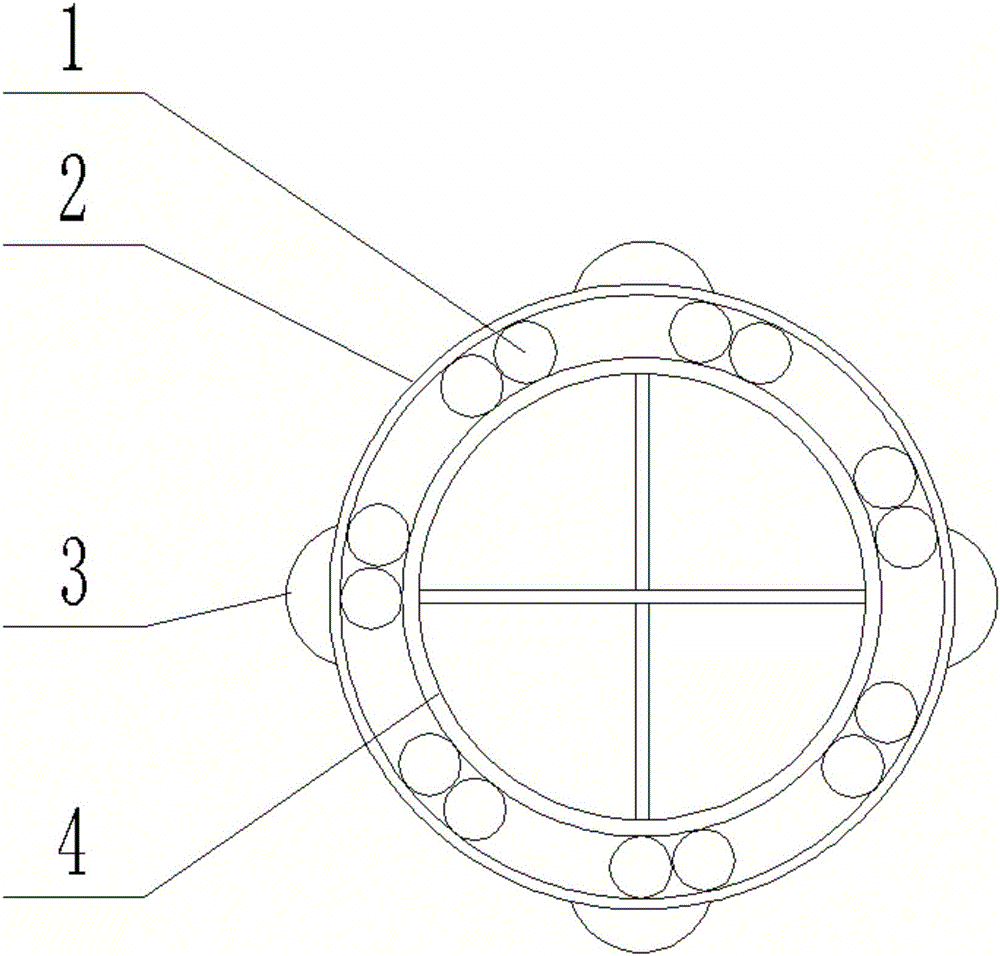

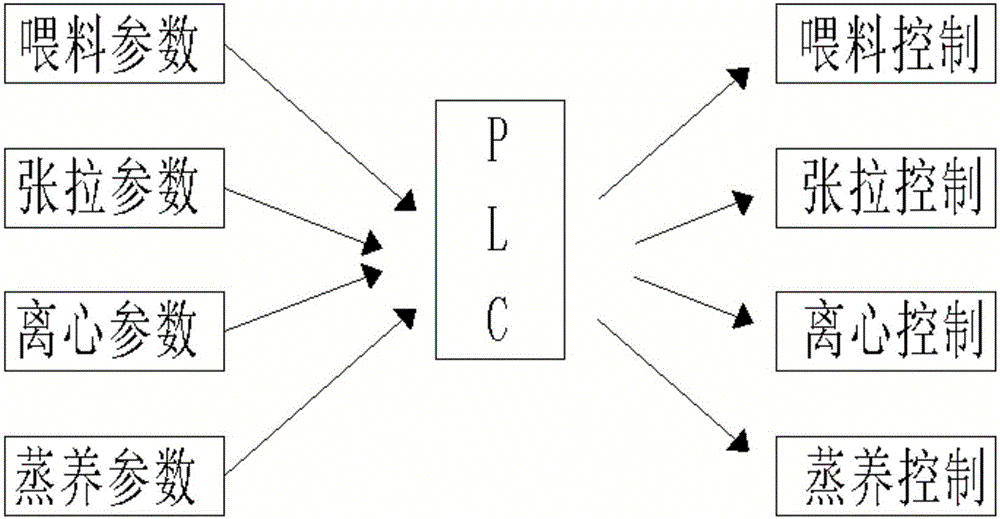

[0035] Such as Figure 1 to Figure 4 As shown, the process of this embodiment is mainly used to produce φ190×12m electric poles, including the following steps:

[0036] S1: Straighten, lengthen and cut the high-strength tendons to form the main rib 1, the number of which is 14, the tensile strength of the main rib 1 is ≥ 1570Mpa, and the maximum elongation is 0.56%. Changhe pier head, the verticality of the shear end face of the main reinforcement 1 is ≤3°, the sheared burr and flash are ≤0.3mm, the length is fixed twice, and the relative error of its length does not exceed 1.5 / 10000 of the length of the steel bar. Head diameter: Ф8±0.1 mm, thickness: 8±0.1mm, strength ≥1491Mpa, heading deflection ≤0.3mm. ;

[0037] S2: Arrange a group of main ribs 1 distributed around the axis according to the size and taper of the proposed pole, and then weld a group of erection rings 4 evenly spaced along its axial direction on the inner side. The plane of the erection rings 4 is perpendi...

Embodiment 2

[0046] The difference from Example 1 is that the process of this example is mainly used to produce φ130×6m electric poles, including the following steps:

[0047] S1: Straighten, lengthen and cut high-strength tendons to form main tendons 1 with 6 tendons. Changhe pier head, the verticality of the shear end face of the main reinforcement 1 is ≤3°, the sheared burr and flash are ≤0.3mm, the length is fixed twice, and the relative error of its length does not exceed 1.5 / 10000 of the length of the steel bar. Head diameter: Ф8±0.1 mm, thickness: 8±0.1mm, strength ≥1491Mpa, heading deflection ≤0.3mm;

[0048] S2: Arrange a group of main ribs 1 distributed around the axis according to the size and taper of the proposed pole, and then weld a group of erection rings 4 evenly spaced along its axial direction on the inner side. The plane of the erection rings 4 is perpendicular to the skeleton axis and vertical The deviation shall not exceed 1 / 40 of the diameter of the erecting ring. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com