Production technology of high-strength post-tensioned reinforced concrete poles and poles

A technology of reinforced concrete and production technology, applied in the field of electric poles, can solve the problems of shortage of land resources, lack of reach, land occupation, etc., and achieve the best safety and reliability, high post-tensioning tension, and reduced tip diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

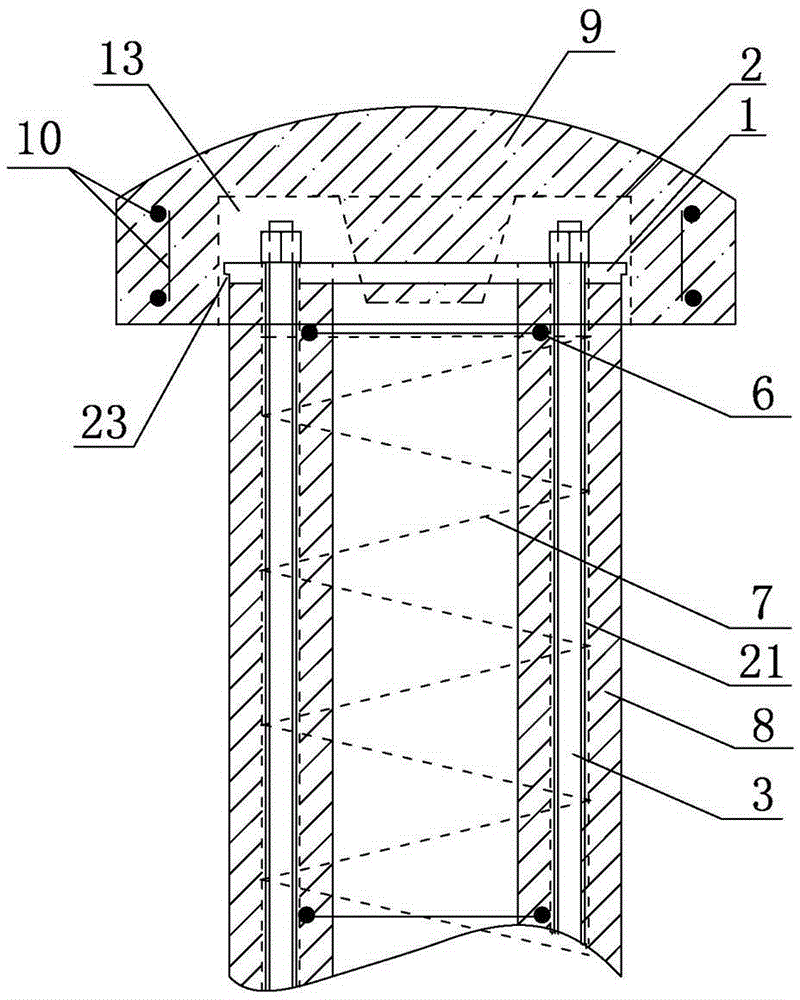

[0042] Embodiment 1: as Figure 1-Figure 5 As shown, the process of this embodiment is mainly used to produce the whole single rod, and the specific steps are as follows,

[0043] 1.1. Arrange a group of non-prestressed tendons distributed around its axis according to the size of the proposed pole (tip diameter ∮190mm, length 12m) and taper (1:75), and each non-prestressed tendon is relative to the axis of the proposed pole The taper is 1:75; then weld a circle of inner hoops 6 (made by bending steel bars with a diameter of 6mm) at intervals of 500mm along the axial direction of the cage on the inside of the cage surrounded by non-prestressed tendons, and The inner steel hoops 6 are coaxially arranged, and the inner steel hoops are welded within a range of one meter from both ends; a prestressed anchor steel plate 1 is installed coaxially at each end of the cage. In this example, the prestressed anchoring steel plate 1 adopts No. 45 steel, and is made through quenching and te...

Embodiment 2

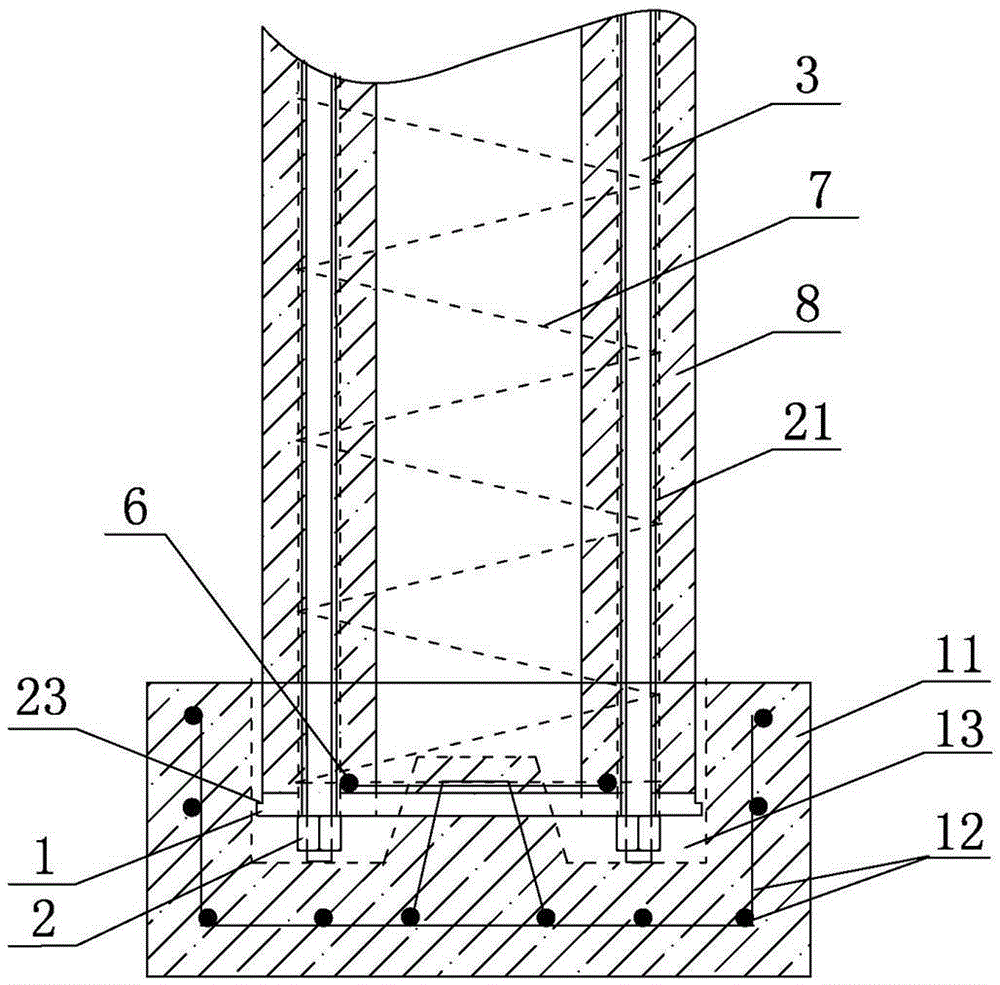

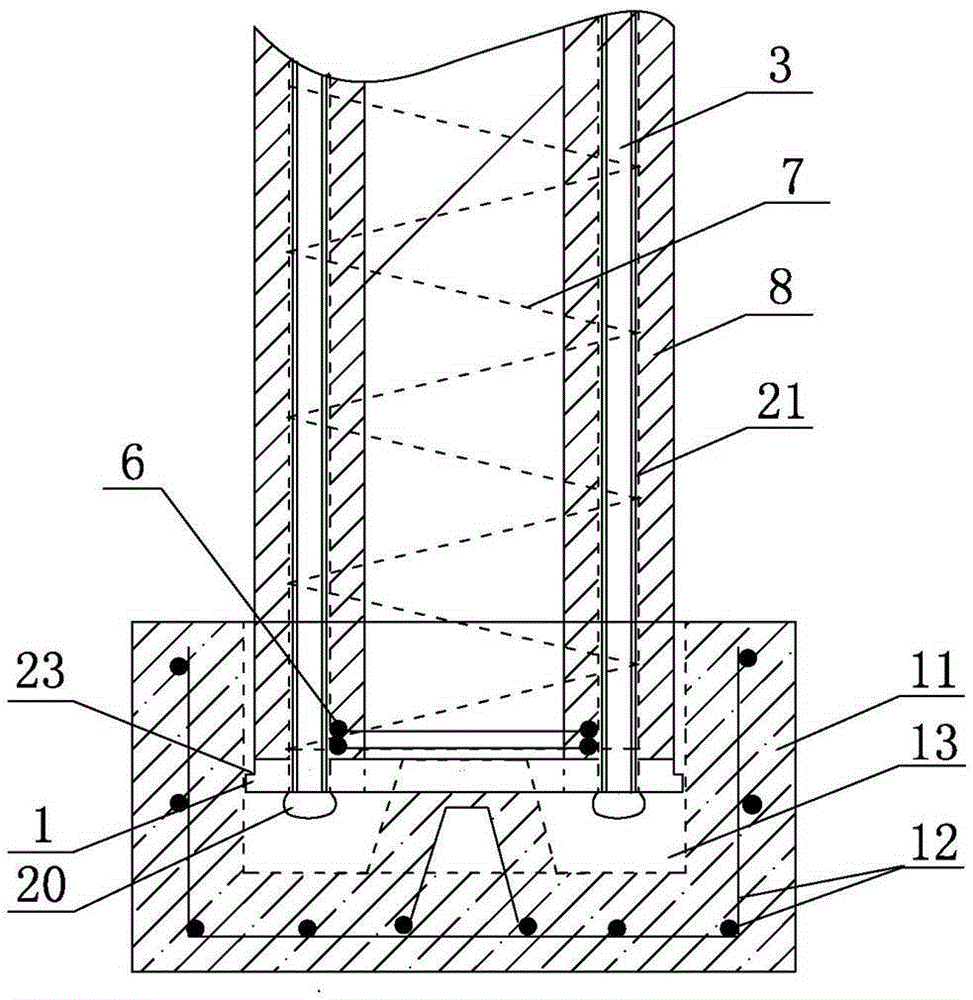

[0054] Embodiment 2: as Figure 1-4 , Figure 6-10 As shown, the process of this embodiment is mainly used to produce ∮270mm×15m electric poles, which are spliced in the form of upper section 6m and lower section 9m. The specific steps are as follows:

[0055] 1.1. Arrange a group of non-prestressed tendons distributed around its axis according to the size and taper (1:75) of the proposed pole section, and the taper of each non-prestressed tendon relative to the axis of the proposed pole section is 1:75 ; Then in the inside of the cage surrounded by each non-prestressed tendon, along the axial direction of the cage, a circle of steel hoops 6 (bent by steel bars with a diameter of 6mm) is welded at intervals of 500mm, and each inner steel hoop 6 is Arranged coaxially, within a range of one meter from both ends, welding is carried out in the form of double inner steel hoops; and then a prestressed anchor steel plate 1 is coaxially installed at both ends of the cage. In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com