Patents

Literature

32results about How to "No destructive damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

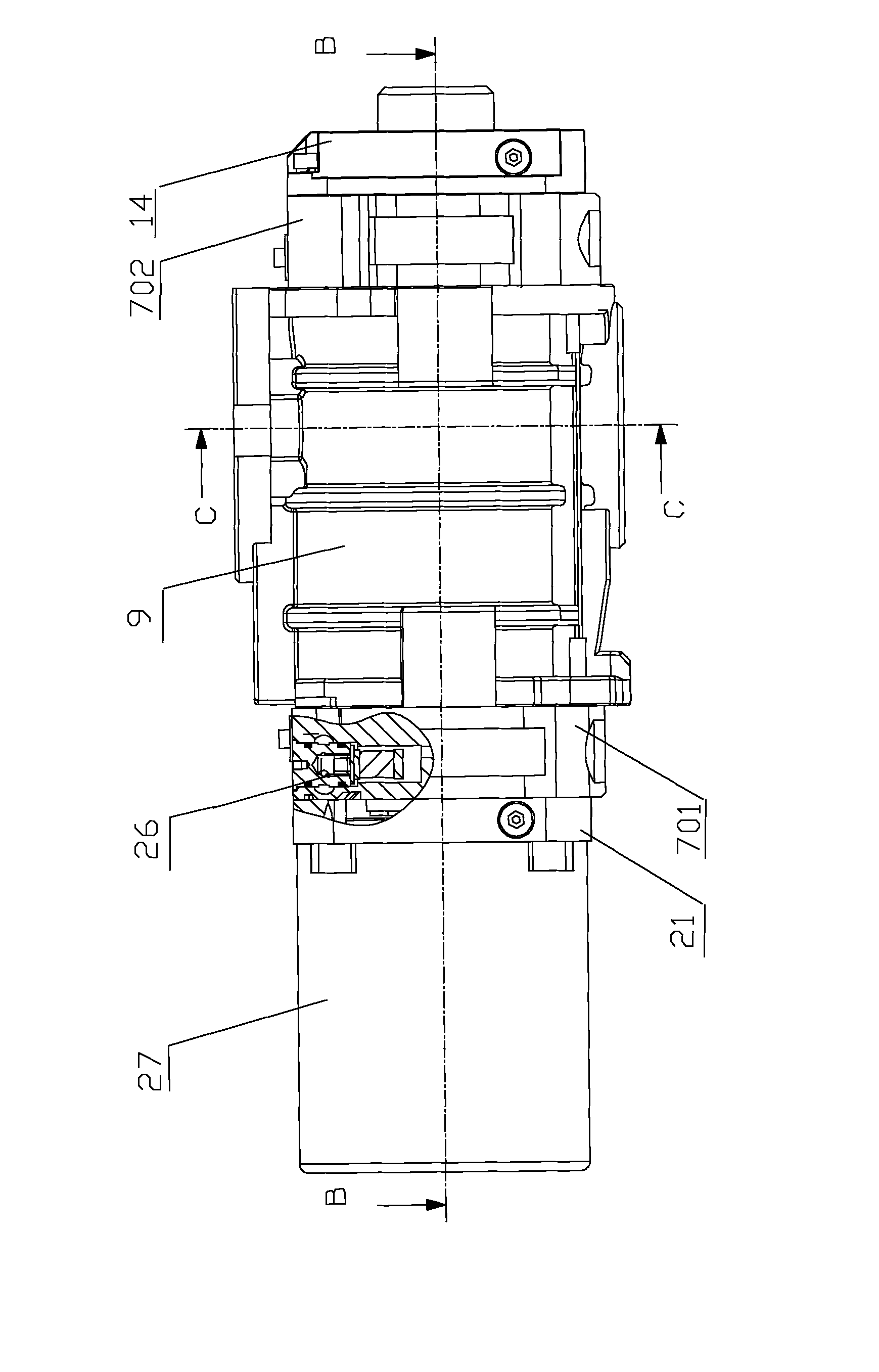

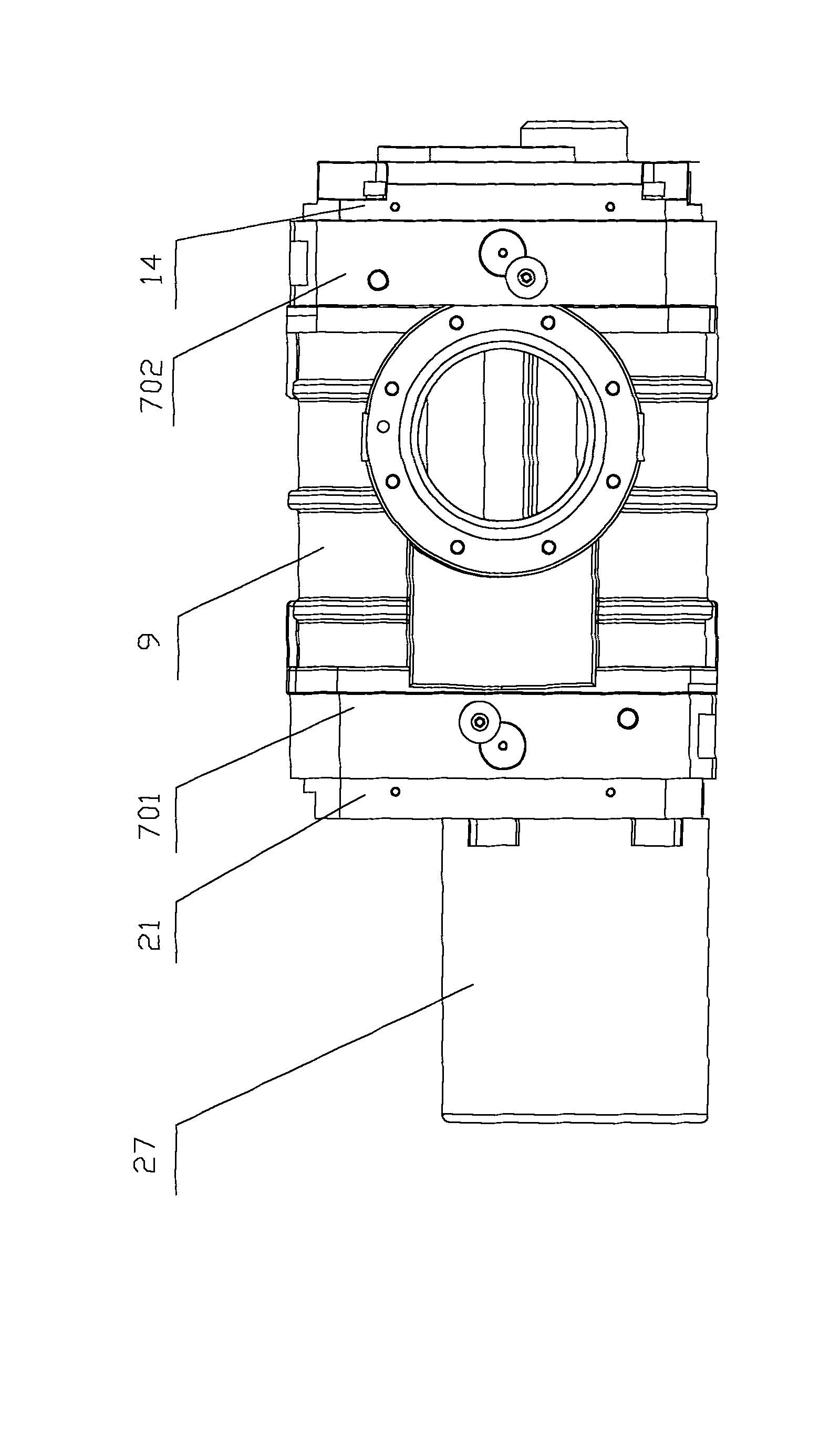

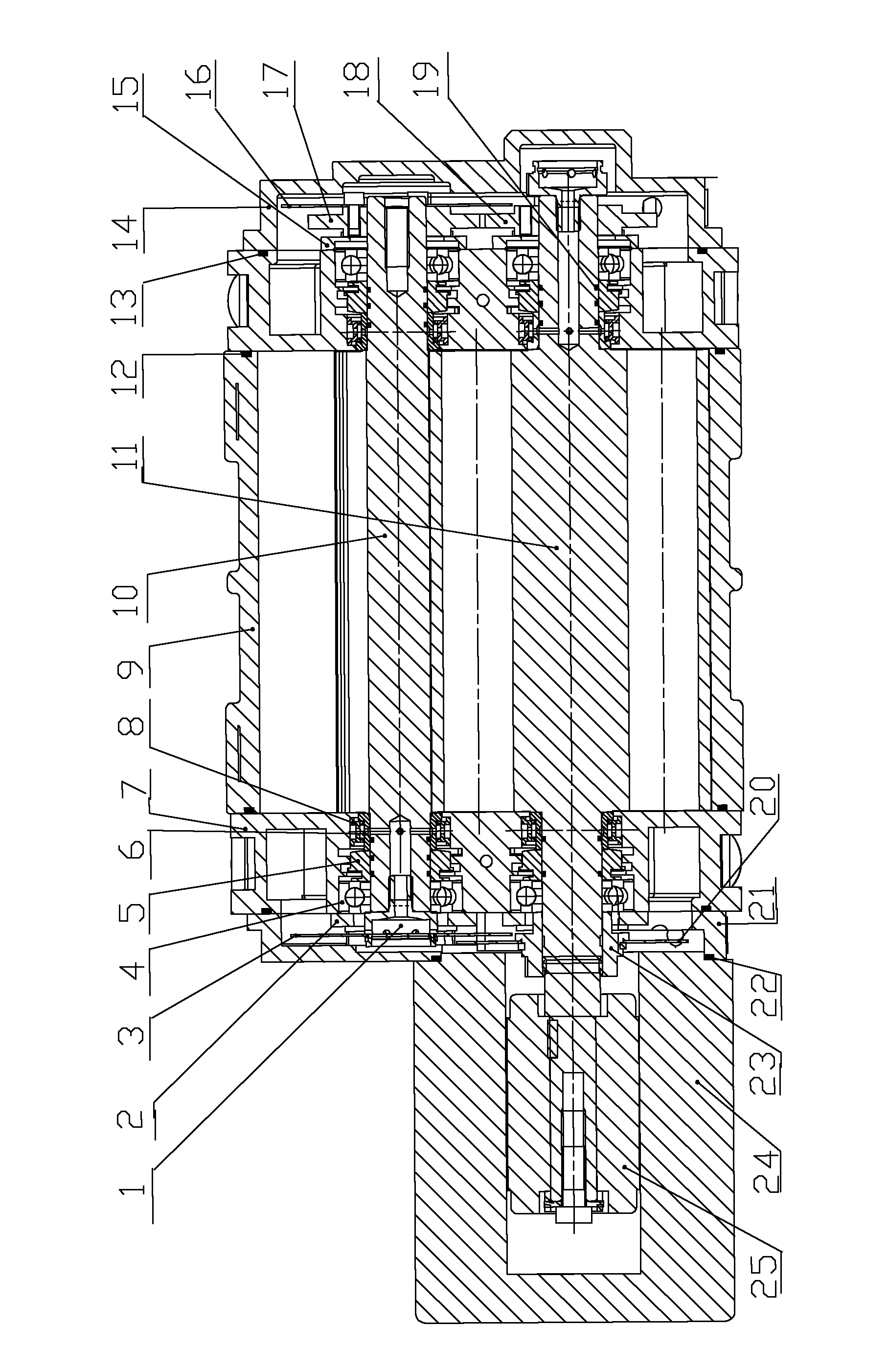

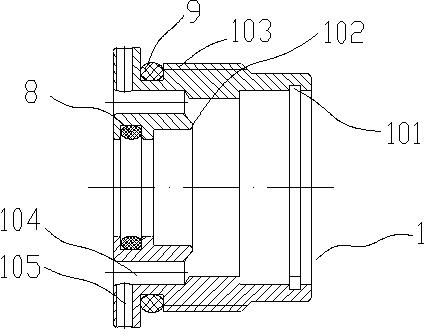

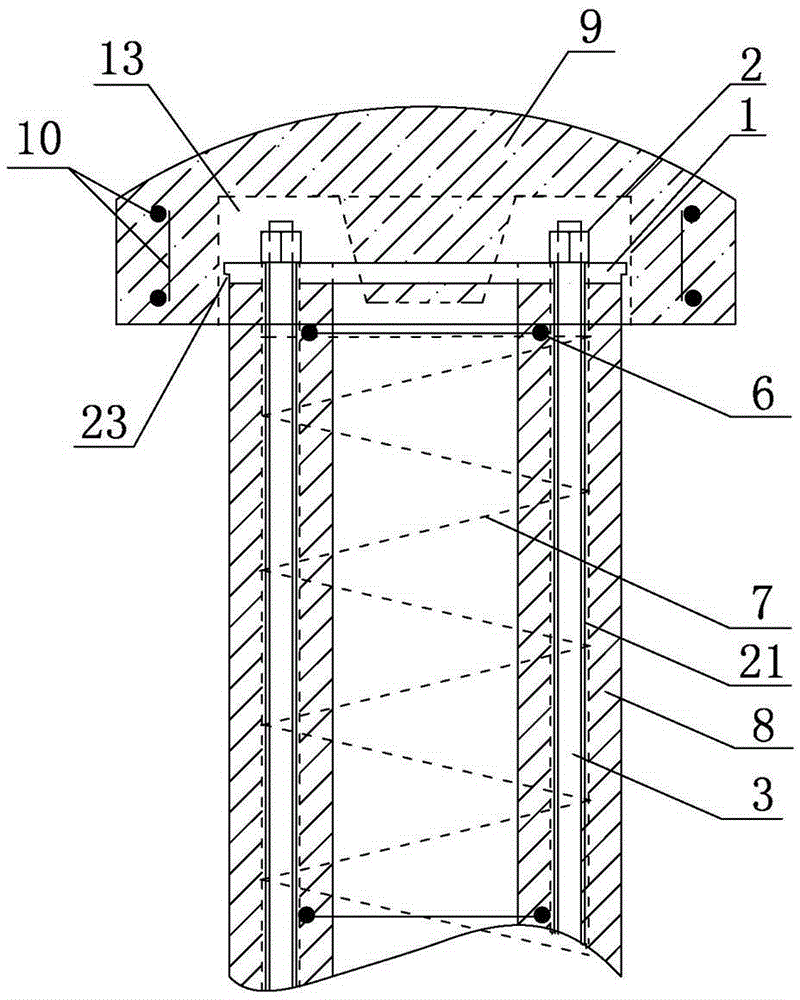

Roots vacuum pump

ActiveCN103104489AReduce volumeExtended maintenance cycleSealing arrangement for pumpsRotary piston pumpsDrive motorEngineering

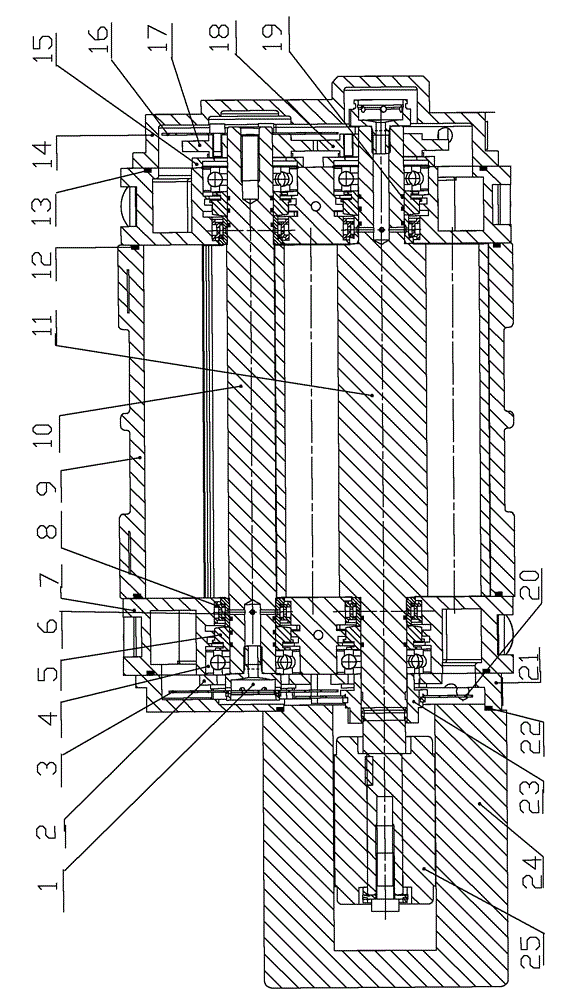

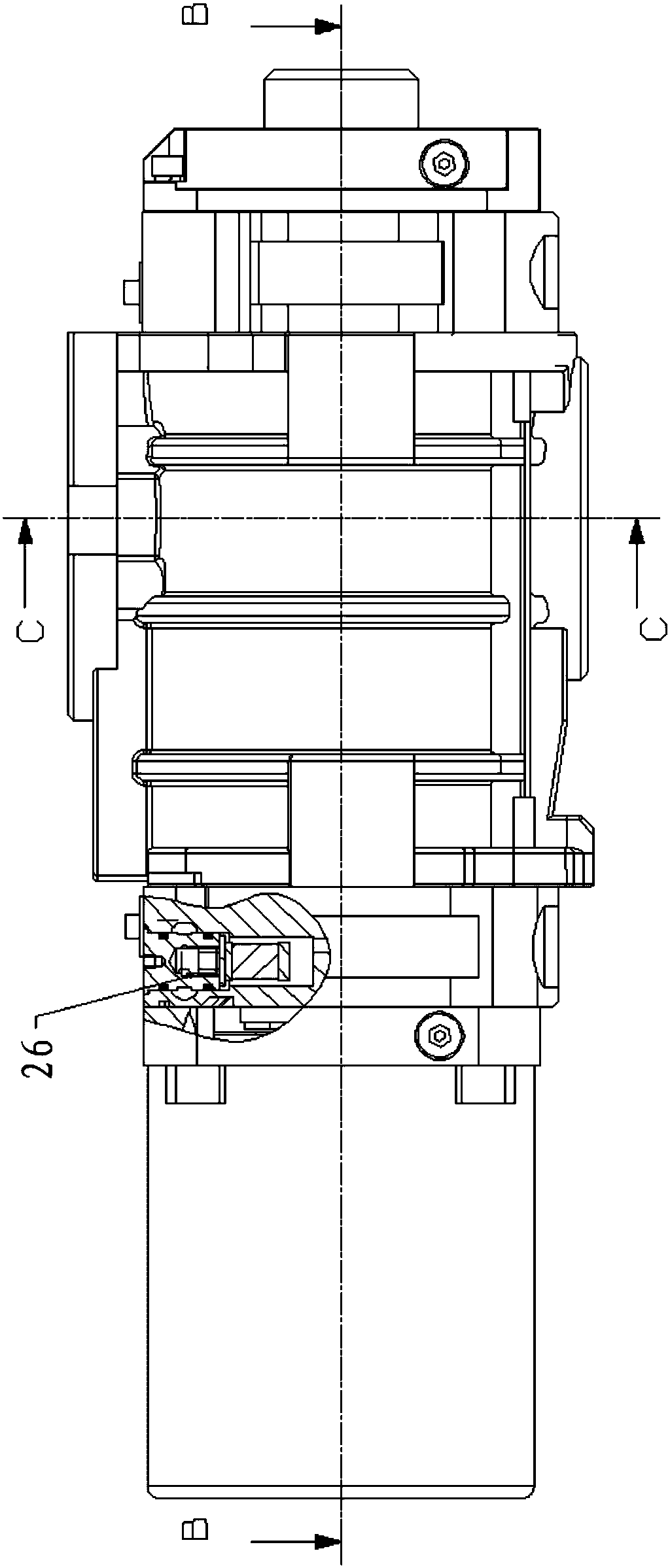

The invention relates to the technical field of vacuum pumps, and in particular relates to a roots vacuum pump. The vacuum pump comprises a motor, front and back bearing cavities, a roots cavity and a gear cavity, wherein the front and back bearing cavities are located at the both sides of the roots cavity, and the gear cavity is connected with the back bearing cavity; the roots cavity is provided with an air inlet and an air outlet and is internally provided with a driving rotor shaft and a driven rotor shaft; the driving rotor shaft and the driven rotor shaft are respectively and correspondingly provided with a roots driving rotor and a roots driven rotor; one end of the driving rotor shaft is connected with the motor, and the other end of the driving rotor shaft is provided with a driving gear; one end of the driven motor shaft is provided with a driven gear which is in transmission connection with the driving gear and accommodated in a gear box; and the front bearing cavity and the back bearing cavity are internally provided with bearings and bearing support rings which are sleeved and fixed at the both ends of the driving rotor shaft and the driven rotor shaft. The roots vacuum pump has the advantages of being small in size, high in pumping speed, energy-saving, space-saving, and applicable to IC equipment.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

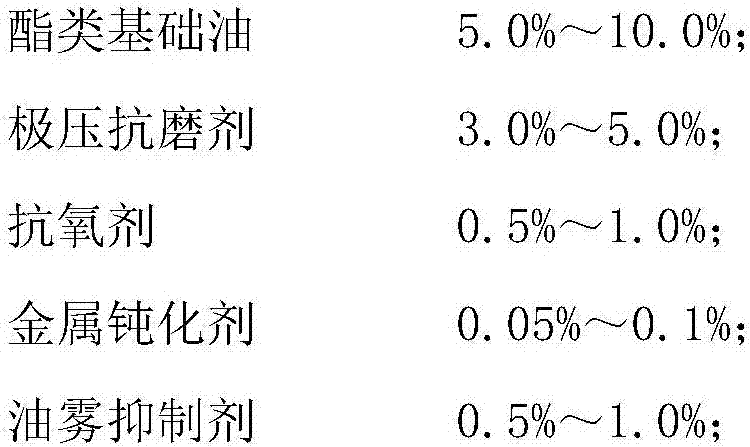

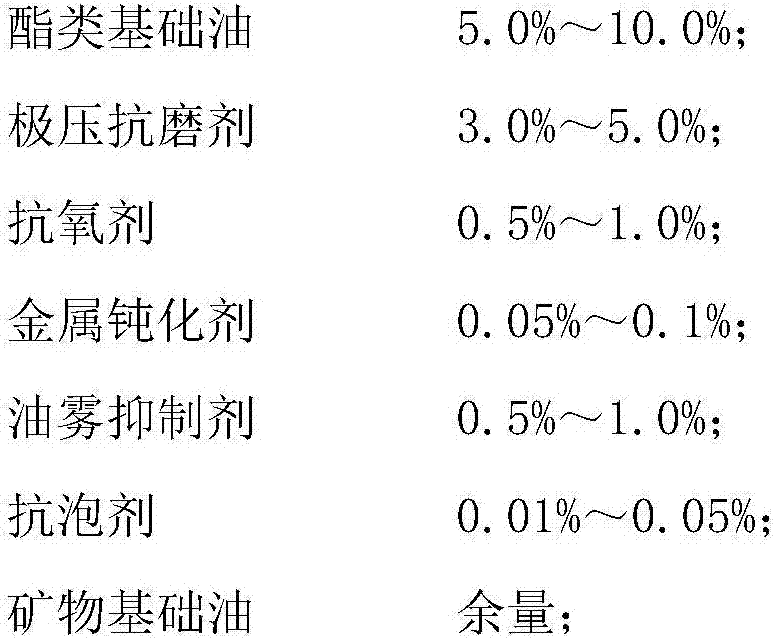

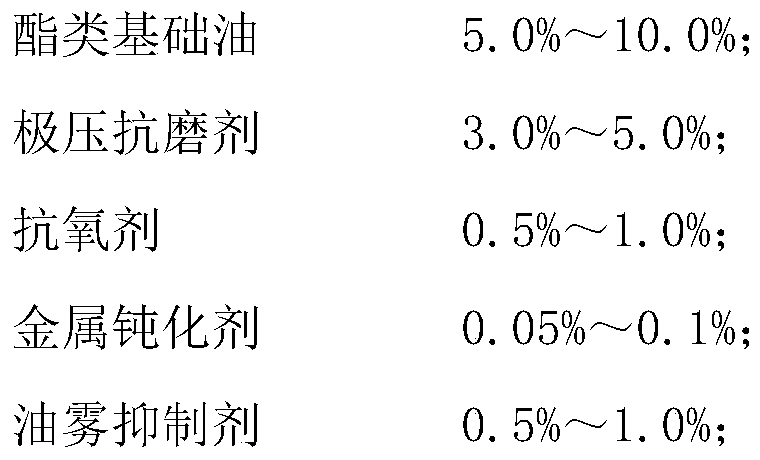

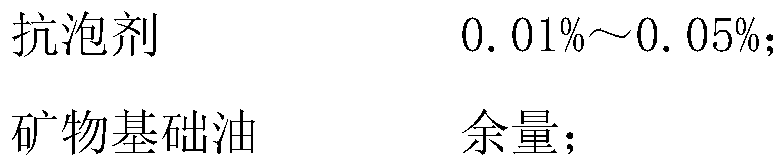

Environmentally-friendly super-finishing grinding oil and preparation method thereof

The invention relates to environmentally-friendly super-finishing grinding oil and a preparation method thereof. The environmentally-friendly super-finishing grinding oil is prepared from, by weight, 5.0%-10.0% of ester base oil, 3.0%-5.0% of an extreme-pressure and anti-wear agent, 0.5%-1.0% of an antioxygen, 0.05%-0.1% of a metal desactivation agent, 0.5%-1.0% of an oil mist inhibitor, 0.01%-0.05% of an anti-foaming agent and mineral base oil balance. The sum of the percentages of the above components is 100%. The environmentally-friendly super-finishing grinding oil has high lubrification, cooling, rust protection and corrosion protection performances; meanwhile, heavy metals, chlorine and low oil mist do not exist in the environmentally-friendly super-finishing grinding oil, so that the environmental-friendly super-finishing grinding oil is harmless to an operator and the environment.

Owner:辽宁海华科技股份有限公司

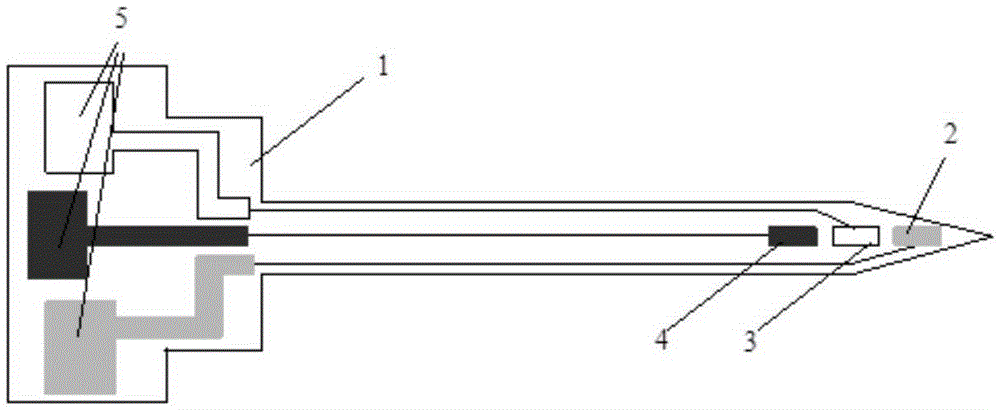

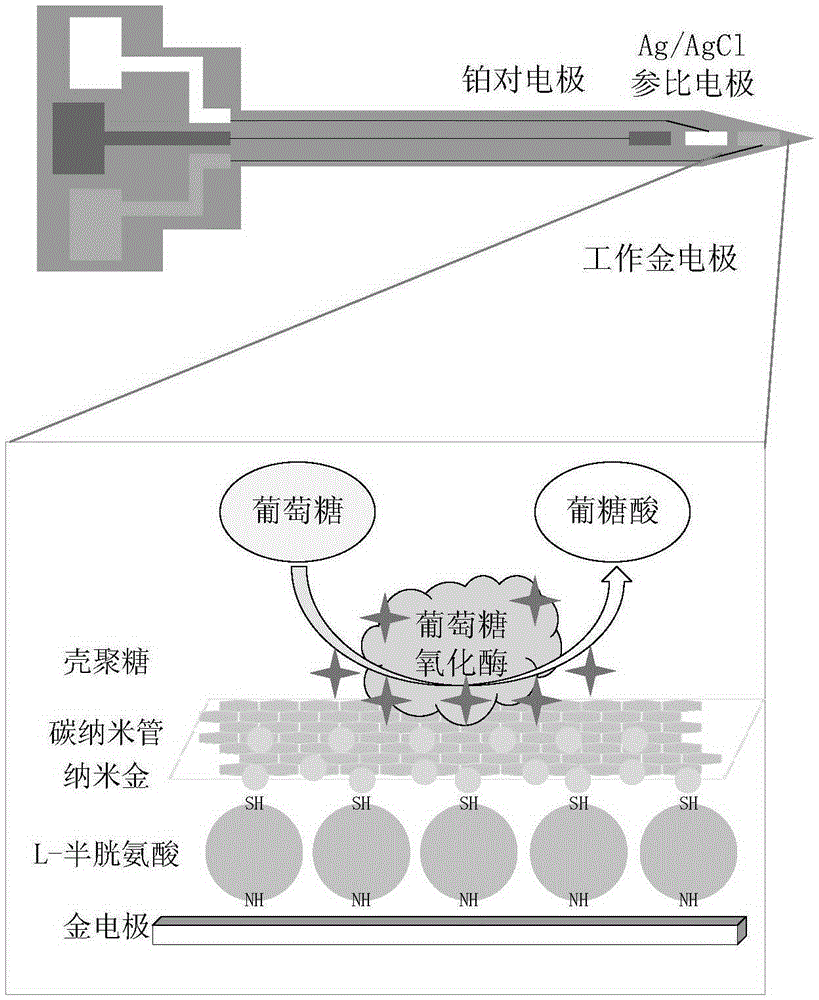

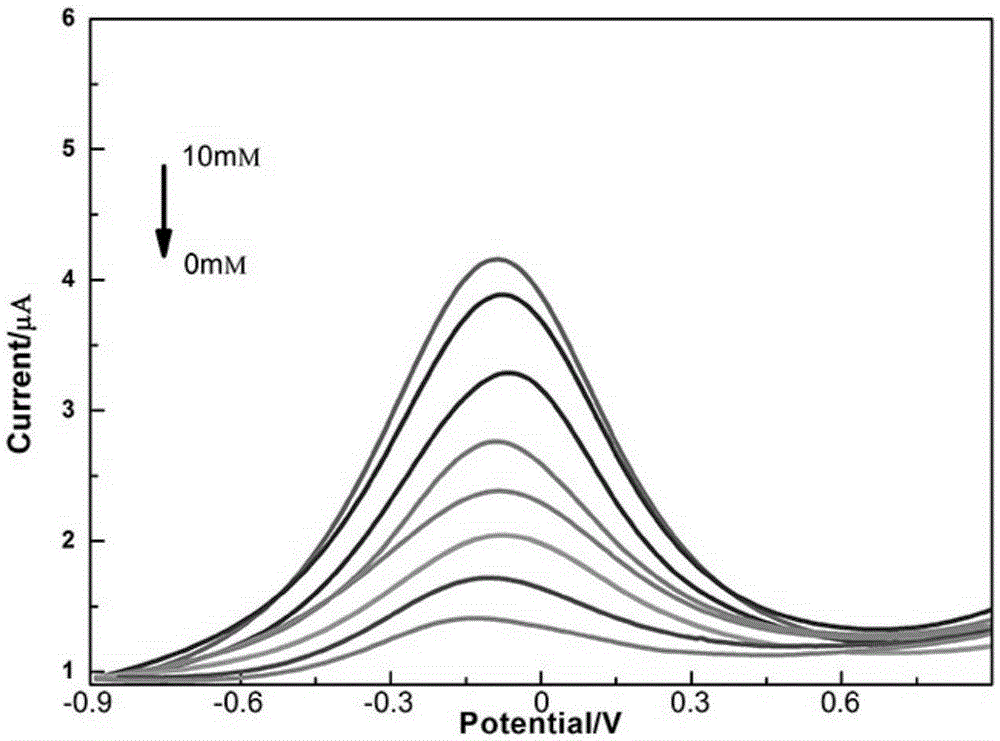

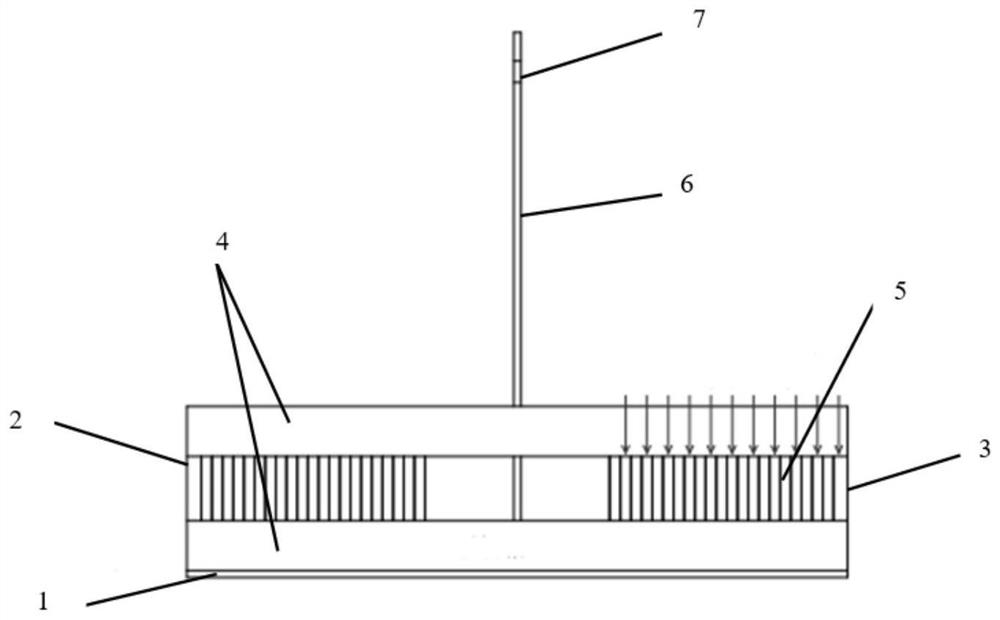

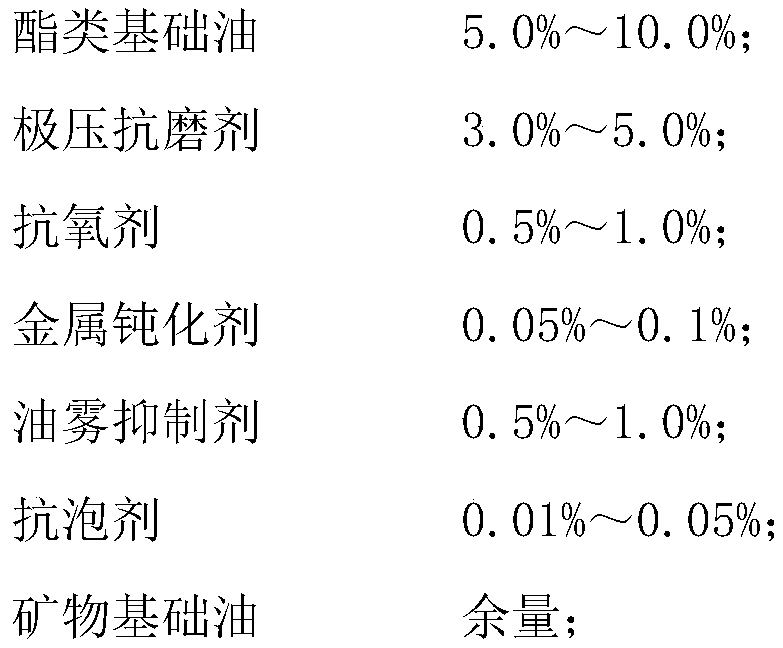

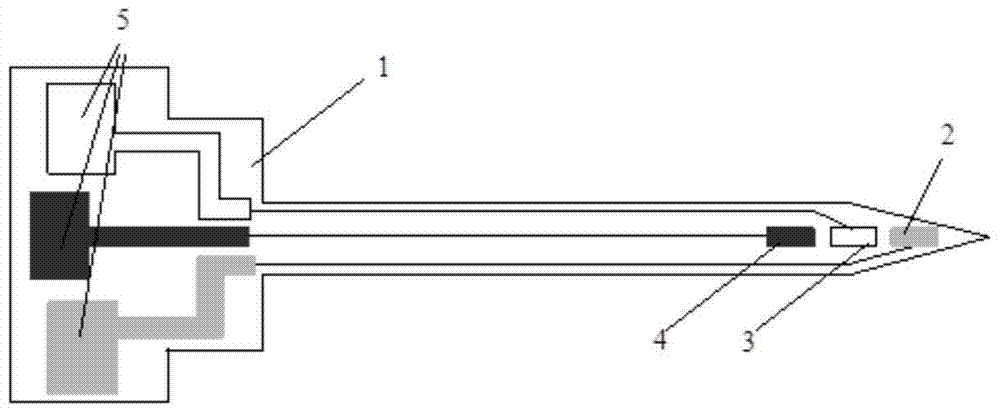

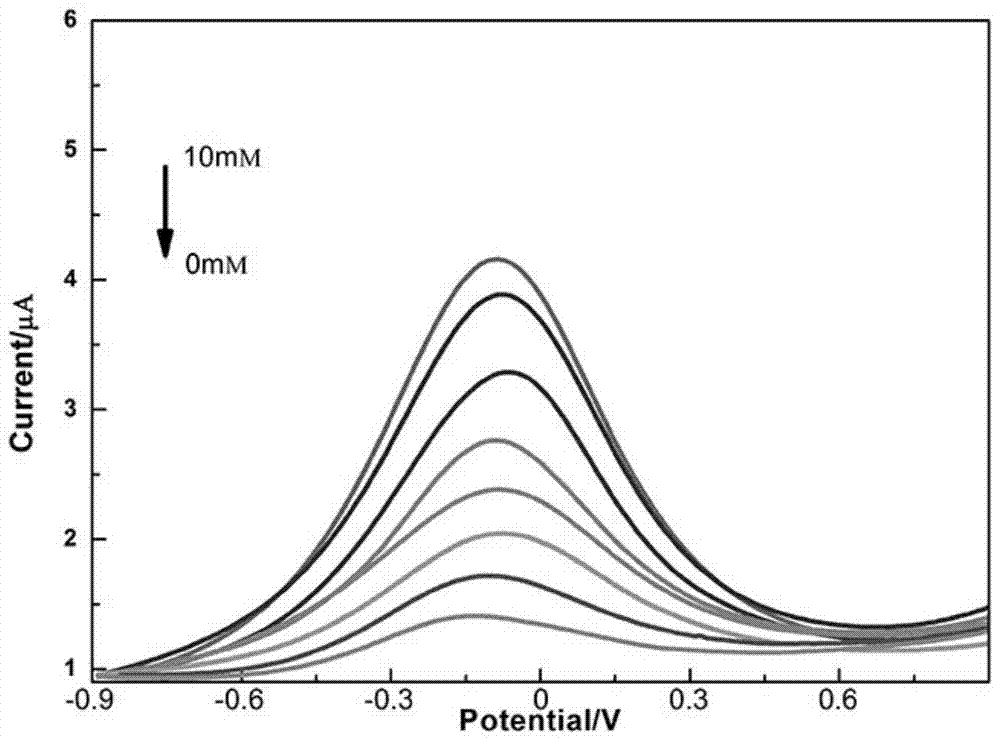

On-line plant glucose detection method and device based on microelectrode biosensing technology

ActiveCN105319260ARealize real-time detectionRealize online detectionMaterial electrochemical variablesPlant tissueSurface cleaning

The invention provides an on-line plant glucose detection method based on the microelectrode biosensing technology. The method comprises the steps of inserting a glucose oxidase microelectrode into a to-be-detected plant tissue, and connecting an electrochemical workstation for cyclic voltammetry scan, so as to achieve the on-line glucose detection of the plant tissue. The invention also provides a device used for achieving the detection method. The device comprises the electrochemical workstation and the glucose oxidase microelectrode which are connected through a conducting wire. According to the on-line plant glucose detection method and the device, the real-time detection of the plant glucose content can be achieved, the detected part of the plant does not need to be separated from the plant body, and has no destructive damage; the vivo detection can be carried out only through surface cleaning and tissue fixing, and continuous results are obtained for dynamic analysis; the detection device provided by the invention is convenient to carry and simple in detection condition, can be operated in the field, and achieves continuous on-line detection.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

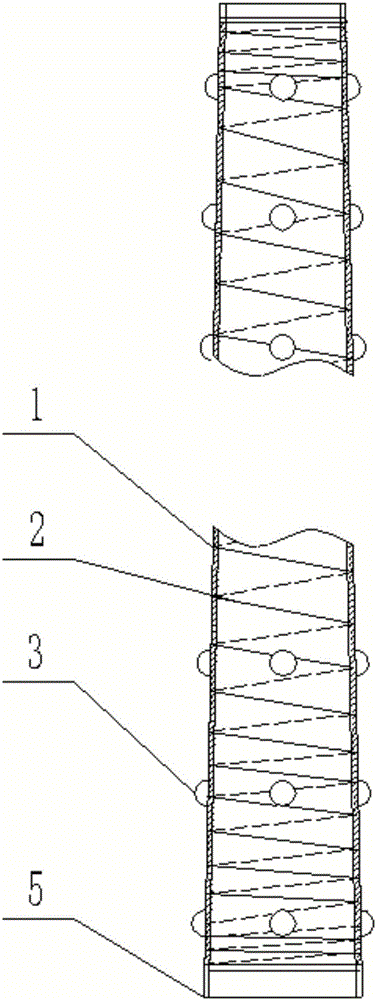

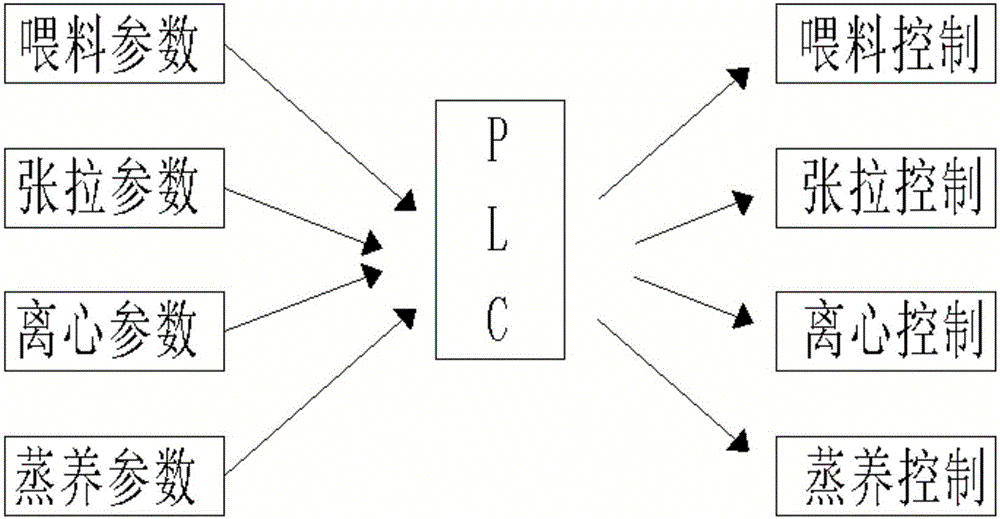

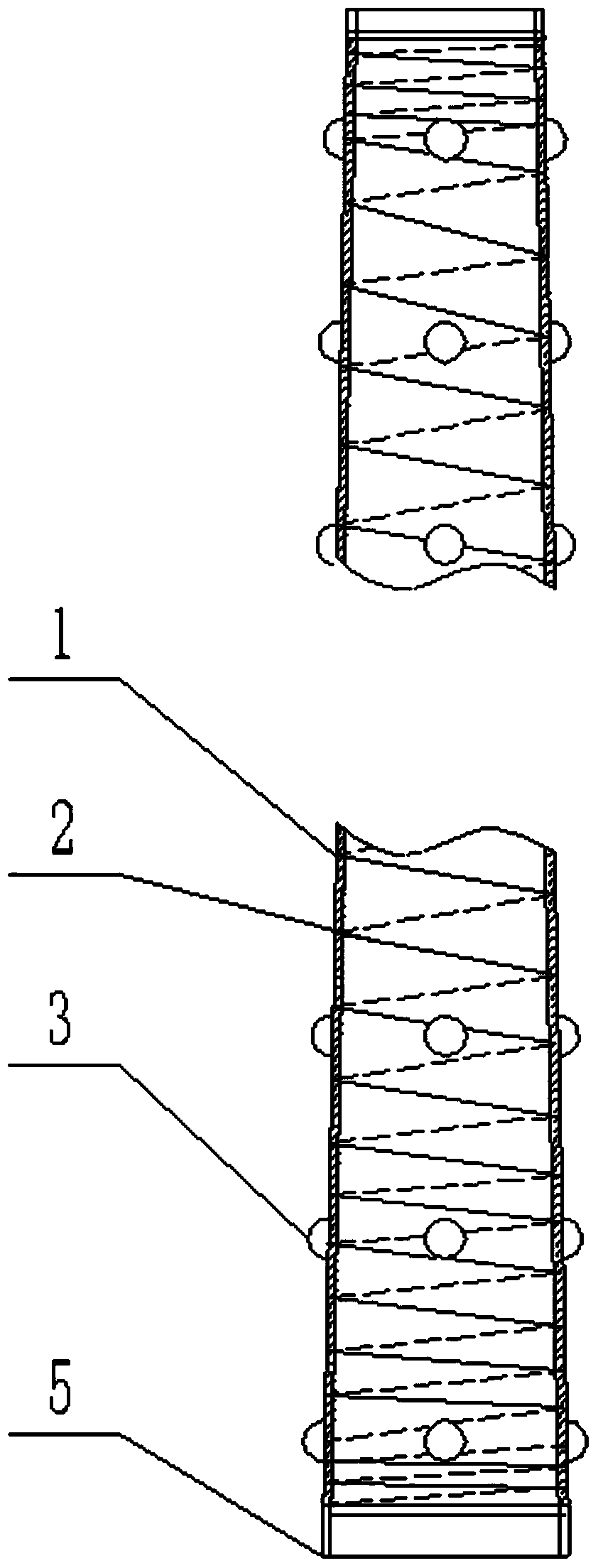

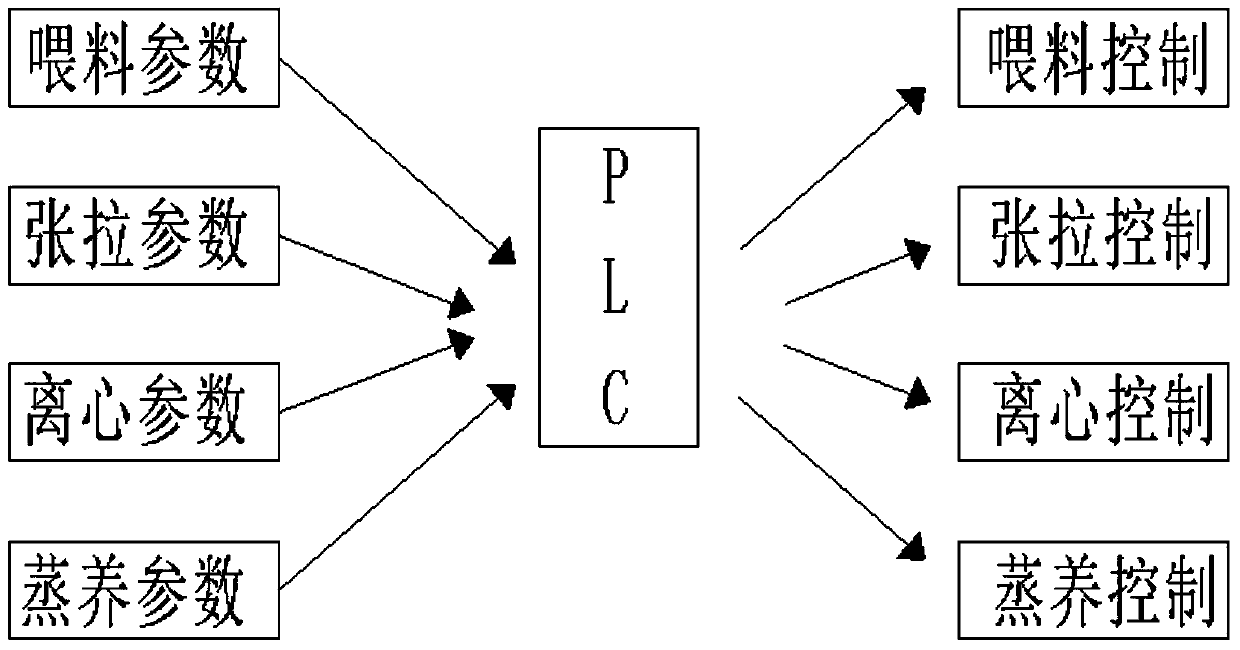

Telegraph pole production process

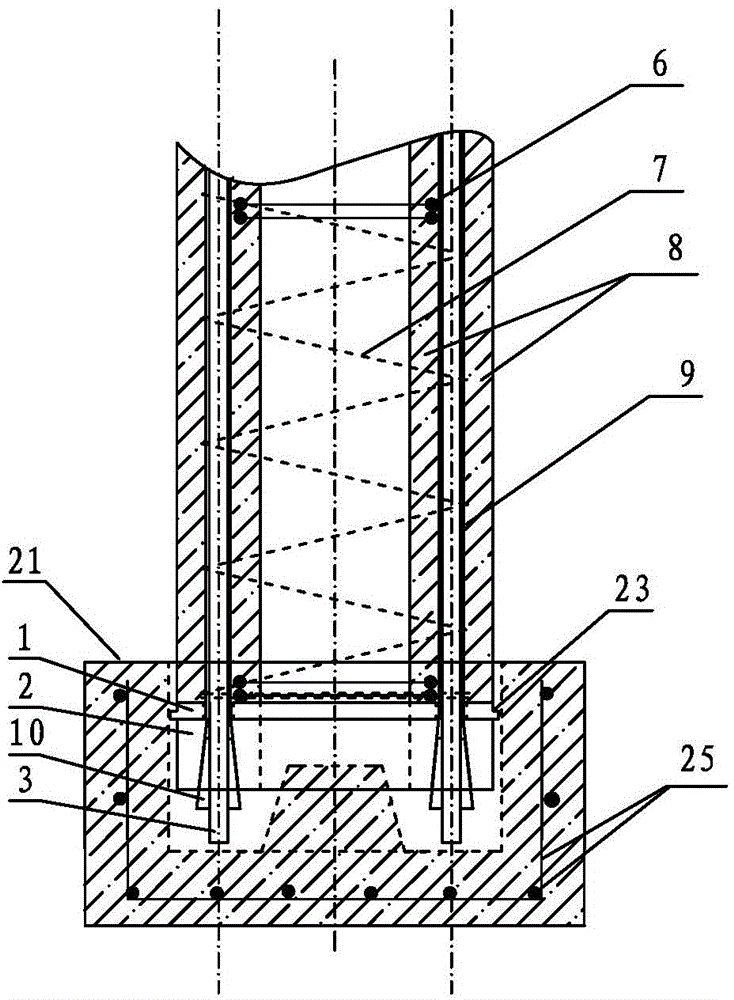

ActiveCN105965686AImprove the instantaneous carrying capacityReduced crack resistanceCeramic shaping apparatusTowersPre stressSlurry

The invention relates to the field of cement product prefabricated parts, in particular to a telegraph pole production process. The telegraph pole production process is characterized in that the process includes the following steps that high-strength ribs are straightened and subjected to fixed length treatment and shearing, and main ribs are formed; a set of main ribs distributed around the axis are arranged, a set of erecting rings at equal intervals are welded on the inner sides in the axial direction of the main ribs, a conical rebar framework is formed, and rib hanging disks are installed at the two ends of the rebar framework; spiral ribs are arranged in the whole-length range of the rebar framework and bound firmly with iron wires; the rebar framework is pre-tensioned, and a plurality of circles of cushion blocks are arranged on the surface at equal intervals; the rebar framework is hoisted into a telegraph pole steel mold base, mold assembly is performed after concrete slurry is poured in, tensioning is performed, and then the centrifuging process is performed; and a telegraph pole formed after centrifuging is hoisted into a steaming pond to be subjected to steaming, natural curing is performed after steaming of the telegraph pole ends, and demolding is performed. The telegraph pole production process can improve the strength and the prestress performance of the telegraph pole; and meanwhile, steel materials can be saved, waste of concrete is reduced, and the production cost is reduced.

Owner:BEIHAI JINGYI CONCRETE PROD

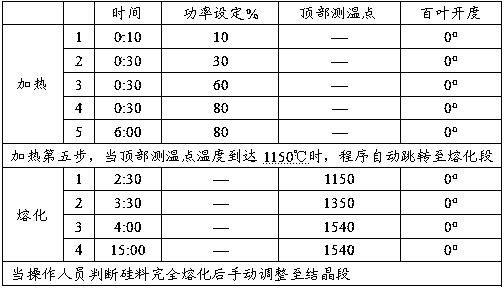

Method for casting large-sized silicon ingot

ActiveCN103668427ADoes not damage the heating structureNo destructive damagePolycrystalline material growthFrom frozen solutionsCrucibleIngot

The invention discloses a method for casting a large-sized silicon ingot, relating to the technical field of manufacturing methods of silicon ingots. The method comprises the following steps: (1) modifying a thermal field in a G5 ingot furnace till the thermal field is consistent with the arrangement requirements of a bottom plate, side plates and a crucible of the G6 ingot furnace, and arranging the bottom plate, the side plates and the crucible of the G6 ingot furnace in the thermal field; (2) heating; (3) melting; (4) crystallizing; (5) annealing; (6) cooling. By adopting the method, upgrade of the thermal field is realized on the premise of not changing large-sized thermal field components such as heaters, radiators and the like, and the yield of a Jinggong 500N ingot furnace is released to the maximum extent; meanwhile, the modification cost of the method is low, the original heating structure of the thermal field is not damaged, damage to thermal field components is eliminated, the thermal field can be directly changed into a G5 small-sized silicon ingot thermal field under an proper production demand, and convenience is brought to use.

Owner:YINGLI GRP

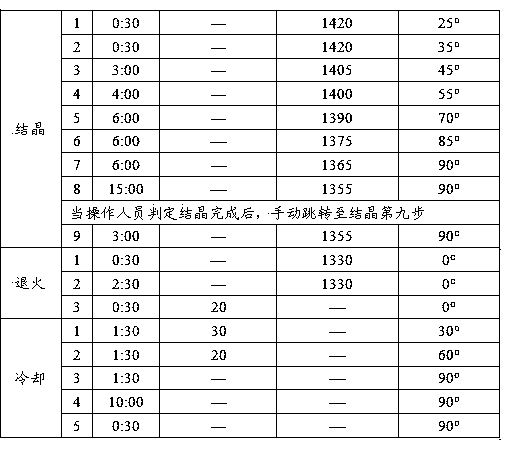

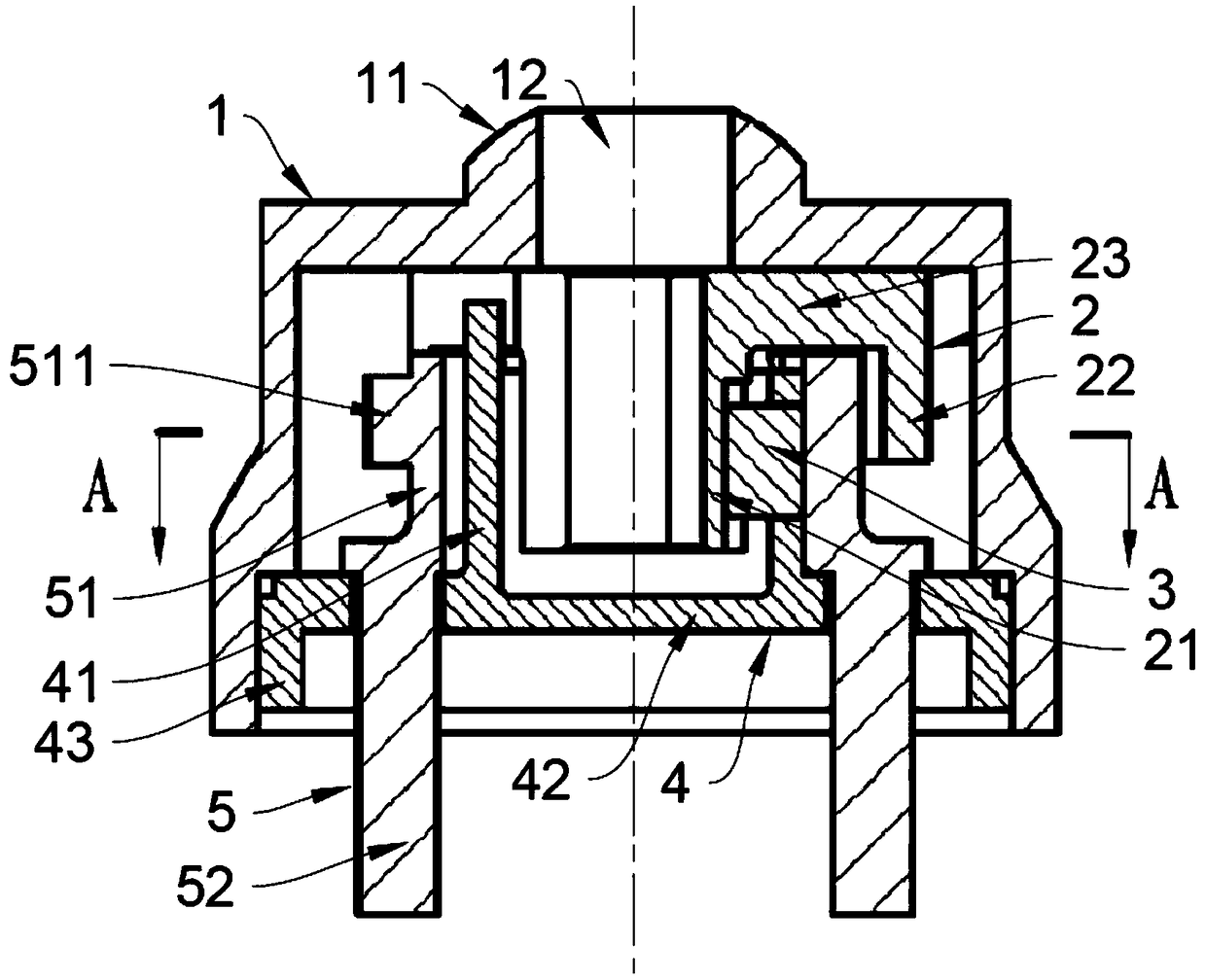

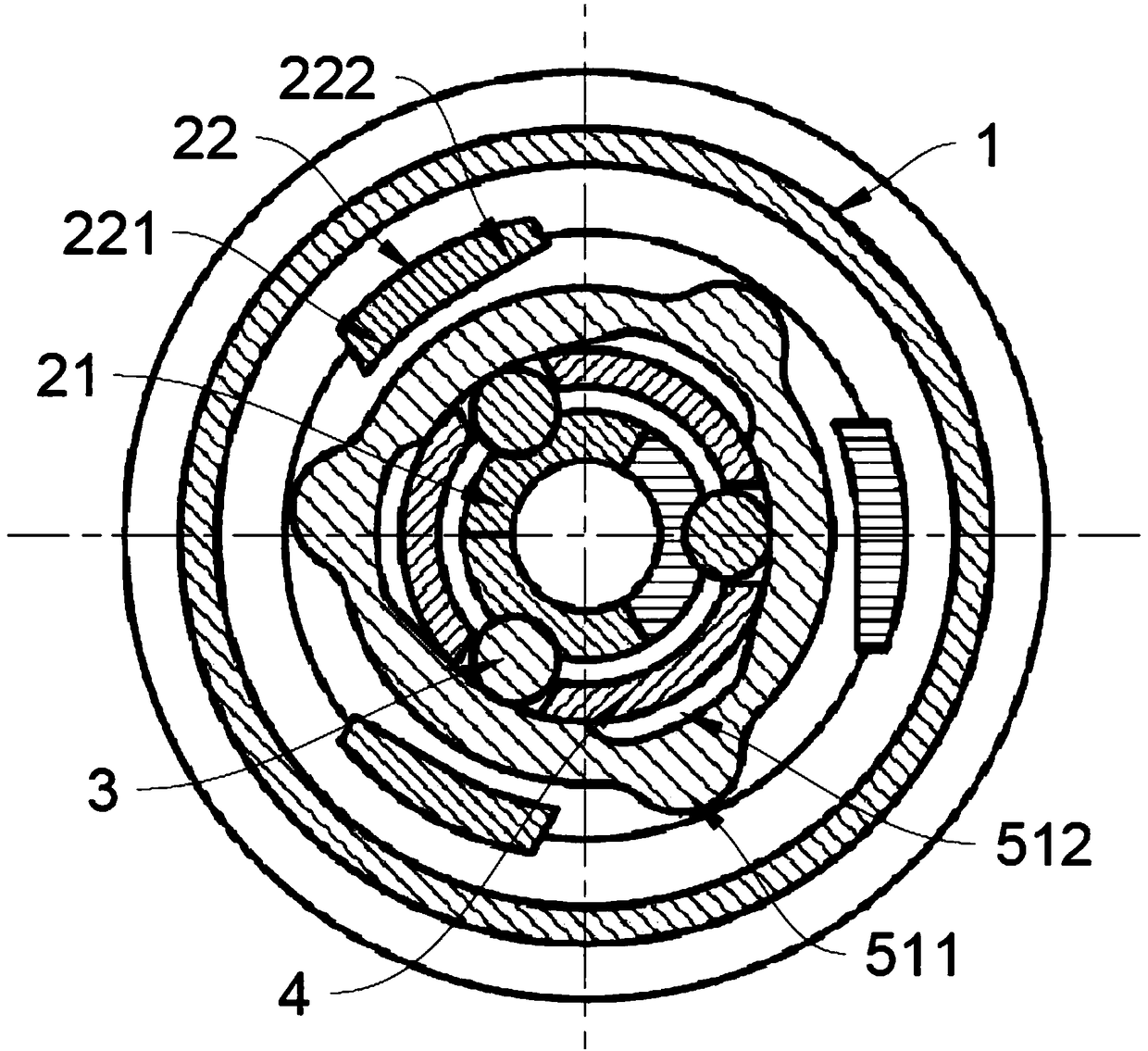

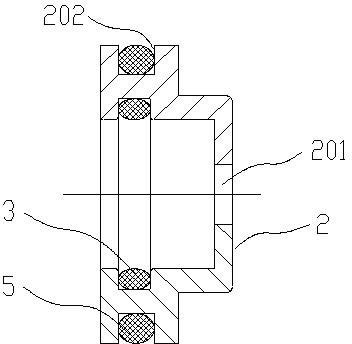

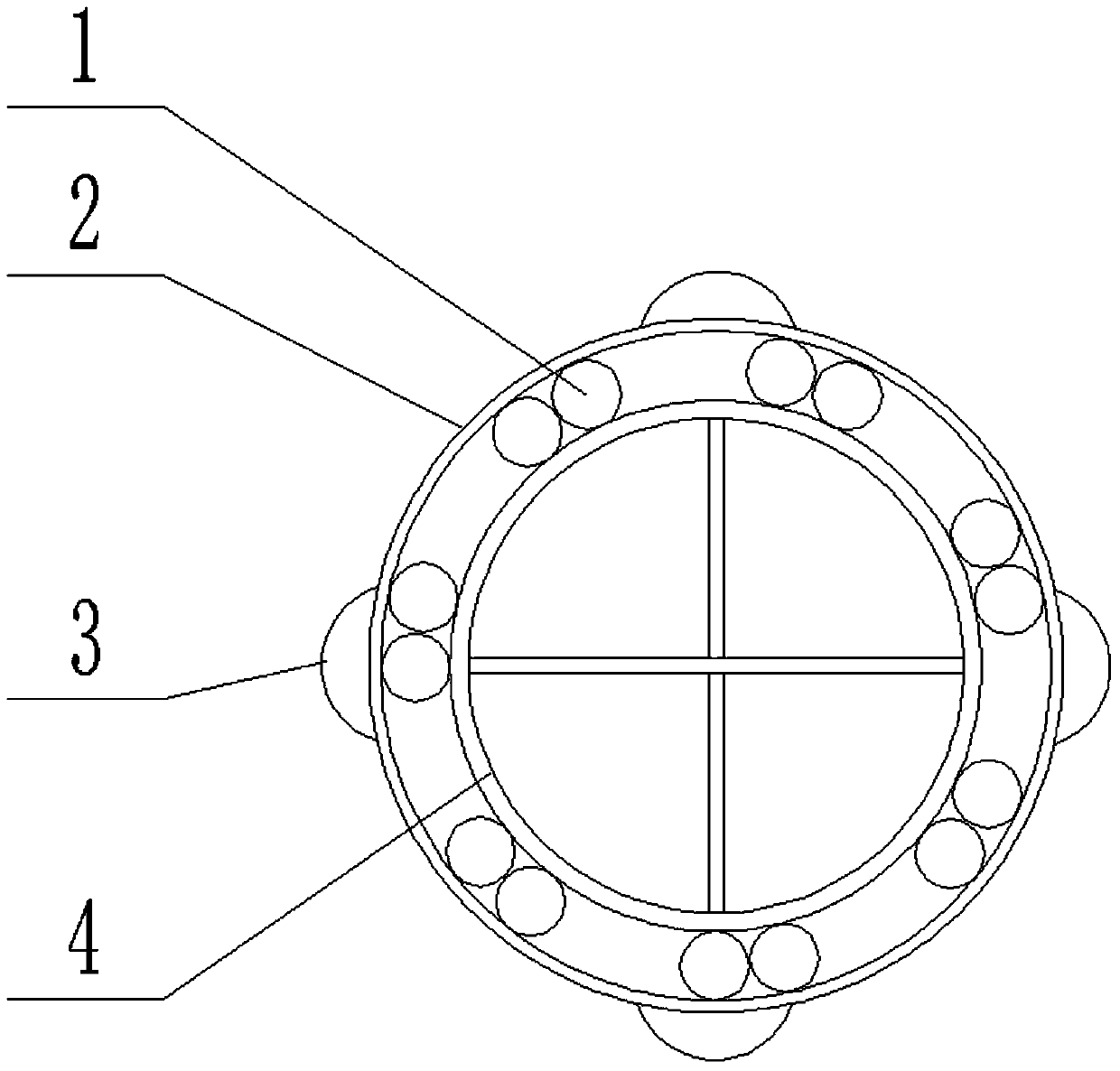

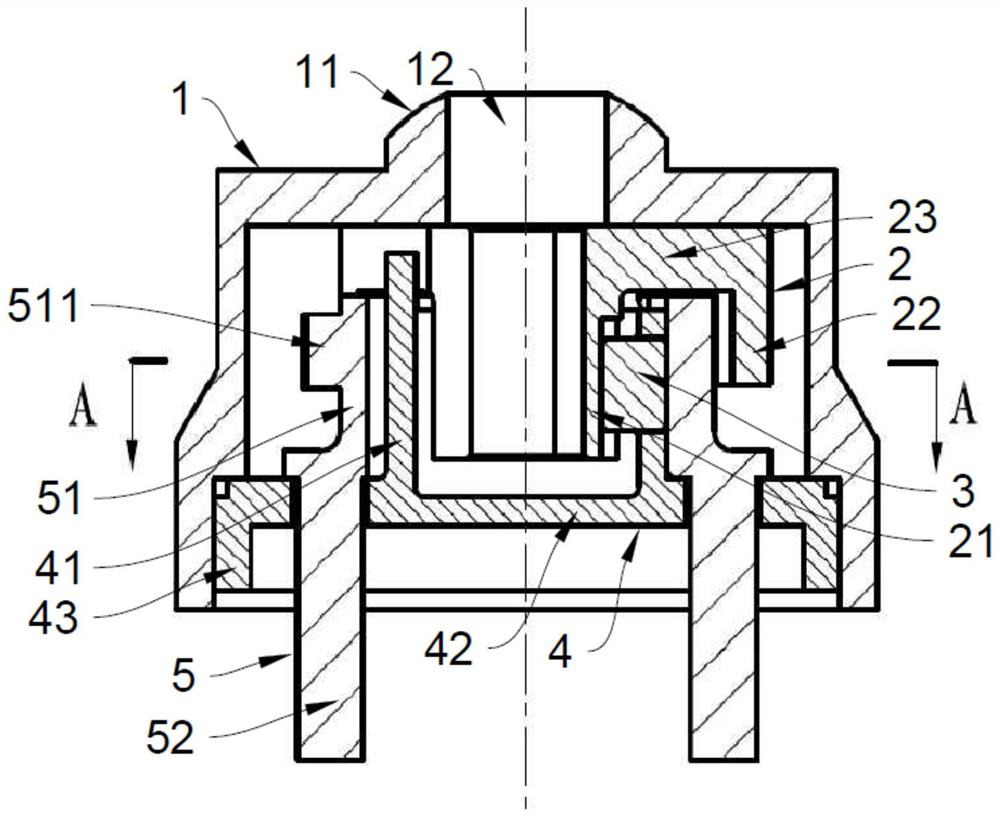

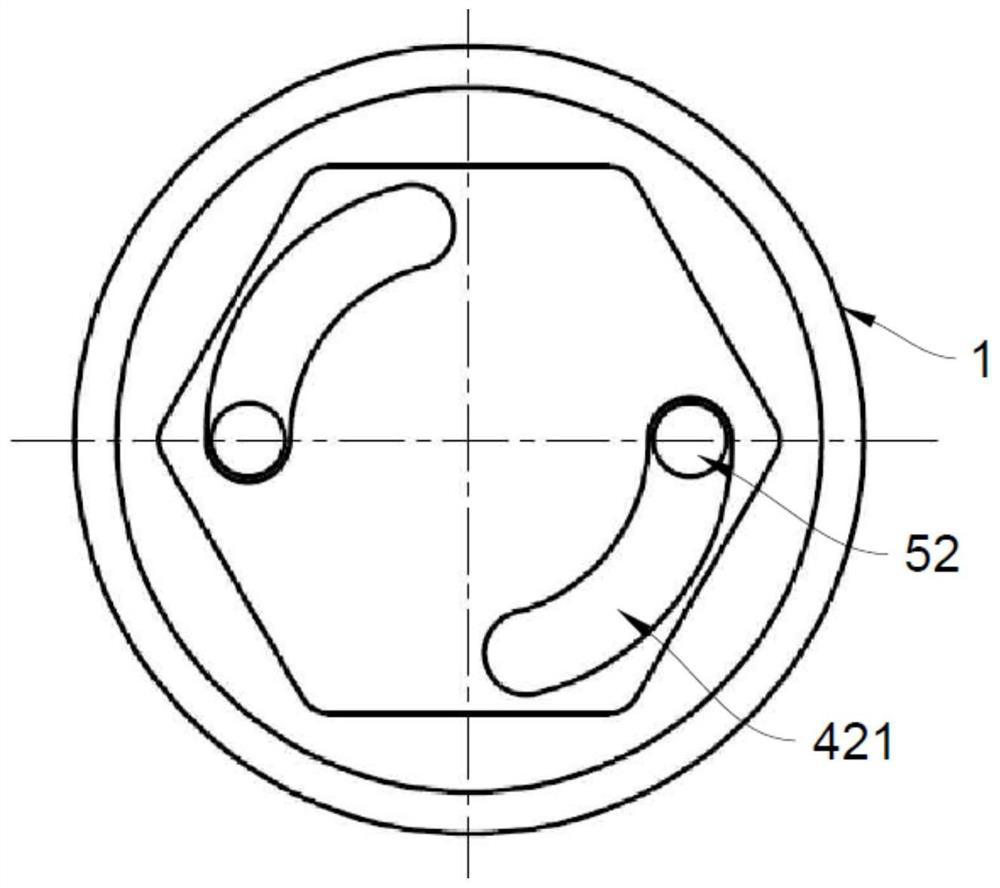

Separating nut

The invention relates to a separating nut which comprises a shell, at least two split nuts, an annular connecting piece and a rotating ring. The annular connecting piece is arranged in the shell, andthe vertical direction of the rotating ring is limited by the annular connecting piece or the shell. The split nuts are limited by the annular connecting piece in the circumferential direction, and the displacement in the radial direction is controlled through rotation of the rotating ring. In the locked state, all the split nuts form a complete internal thread together, the rotating ring rotates,the split nuts are controlled to move outwards, and the separating nut enters an unlocked state. The locked state and the unlocked state of the separating nut are controlled through rotation of the rotating ring, and the process of unlocking and separating the nut does not have destructive damage to parts so that the separating nut can be repeatedly used, and the mechanical property of the separating nut can be detected before application. In addition, a shear frustum for bearing shear force is arranged on the upper portion of the shell, and the problem that a separating nut cannot bear shearforce is solved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

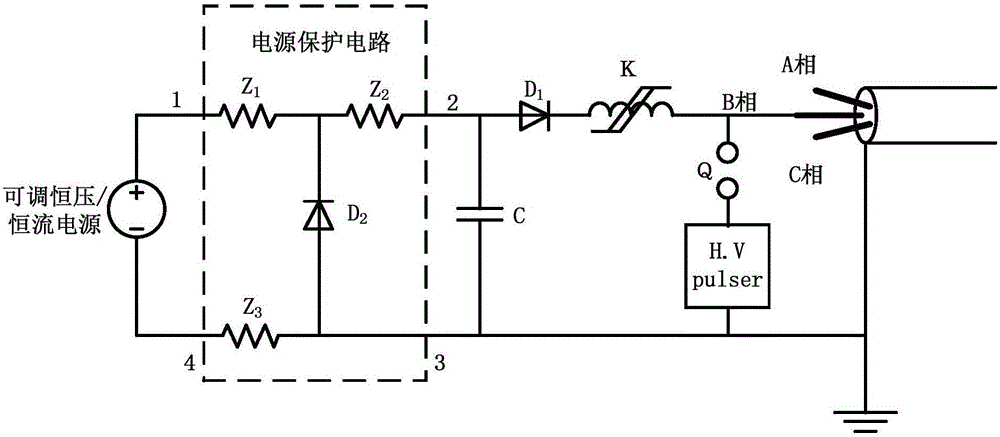

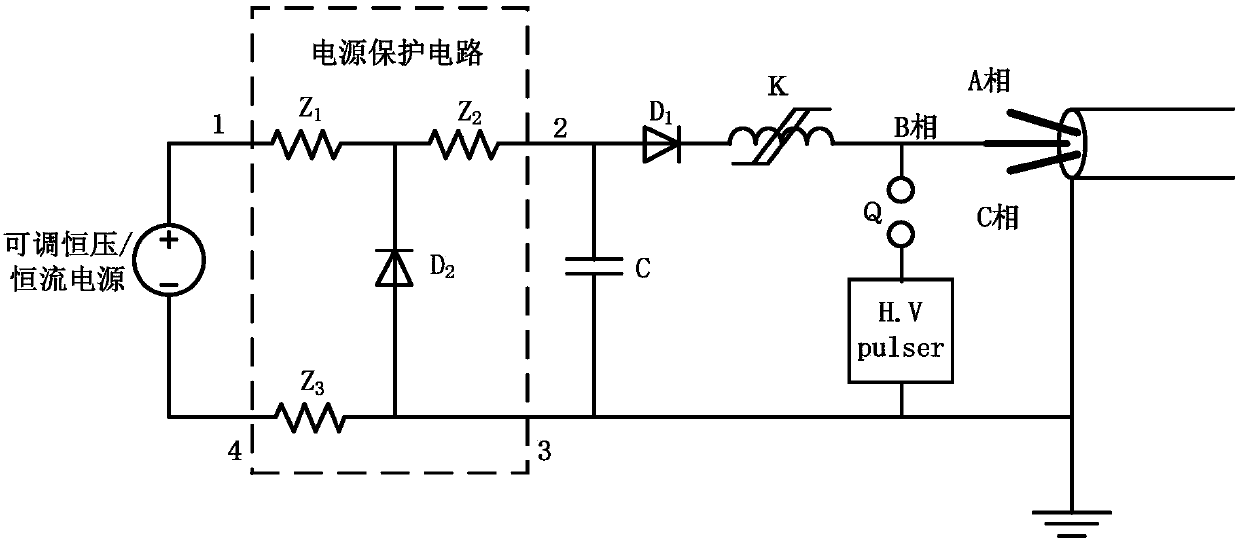

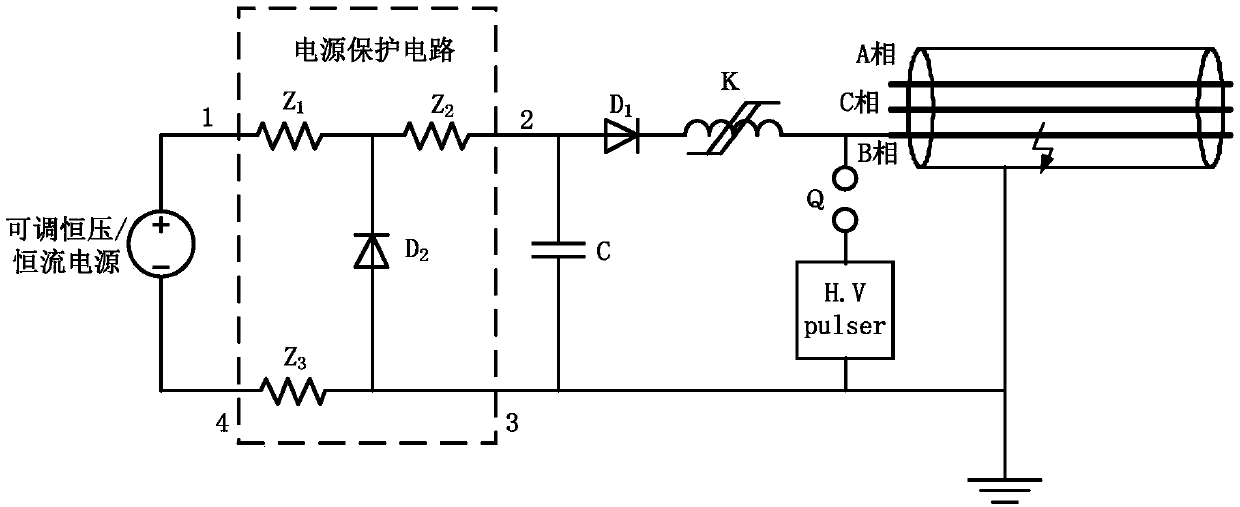

Resistance lowering device and method for a power cable high-resistance fault point

ActiveCN105807185ALow resistanceWon't go outFault location by conductor typesHigh resistanceElectrical resistance and conductance

The invention discloses a resistance lowering device and method for the power cable high-resistance fault point.The resistance lowering device comprises a high-voltage pulse generating part and a direct-current arc maintaining part, wherein the high-voltage pulse generating part and the direct-current arc maintaining part are in parallel.The high-voltage pulse generating part is connected with the direct-current arc maintaining part through a sphere gap, a magnetic switch and a silicon stack; when the resistance lowering device for the power cable high-resistance fault point operates, pulse voltage is firstly output, and a direct current for keeping arc burning is finally output.When the resistance lowering device for the power cable high-resistance fault point operates, a high-voltage pulse firstly acts on a high-resistance fault point of a cable, after the high-resistance fault point of the cable is broken down by the high-voltage pulse and arc discharging is carried out, resistance is decreased to be close to a short circuit, and the direct-current arc maintaining part provides the direct current for the high-resistance fault point to keep arc burning till the high-resistance fault point is subjected to resistance lowering.According to the resistance lowering device and method, under the condition that the power cable is not damaged, main insulation of the cable of the high-resistance fault point can be partly carbonized within ten more seconds to dozens of seconds, and resistance to ground of the fault point is subjected to resistance lowering.

Owner:西安宇铭电物理技术有限责任公司 +2

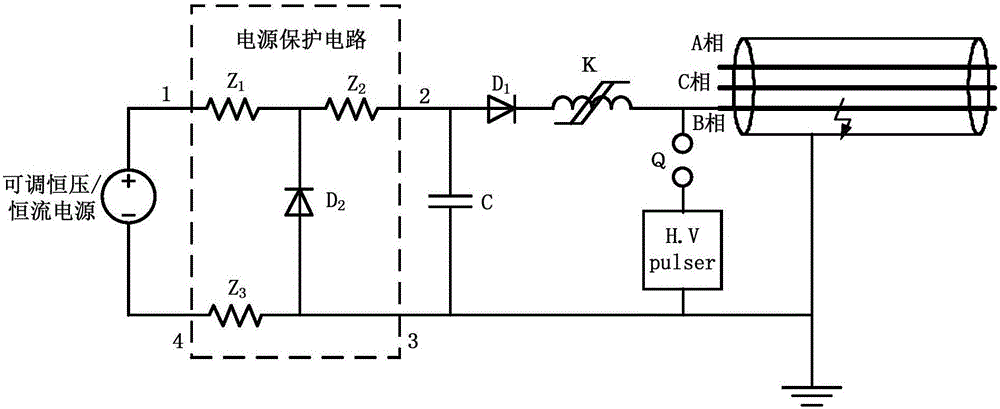

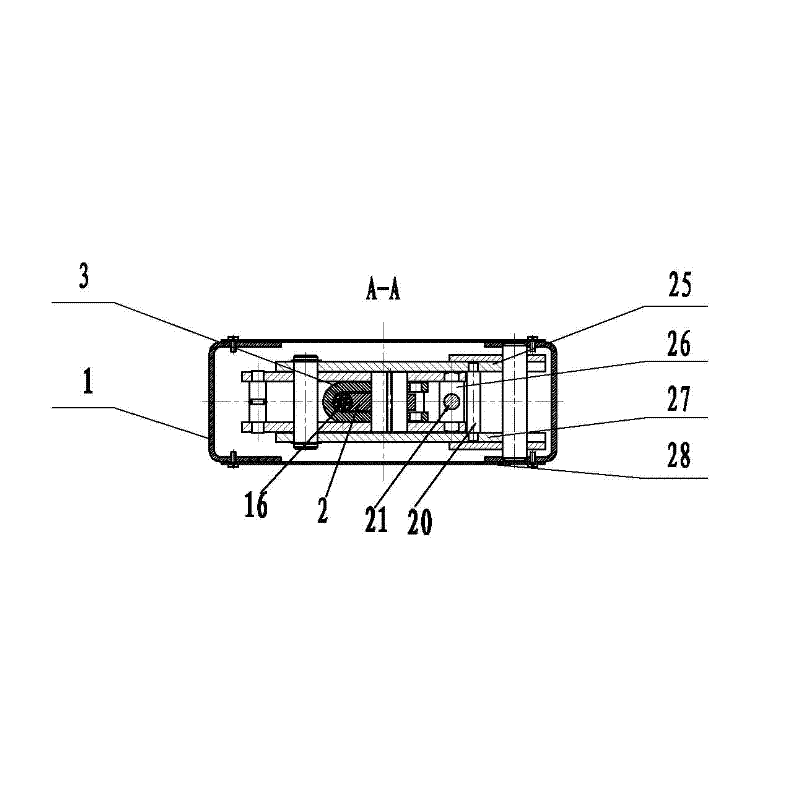

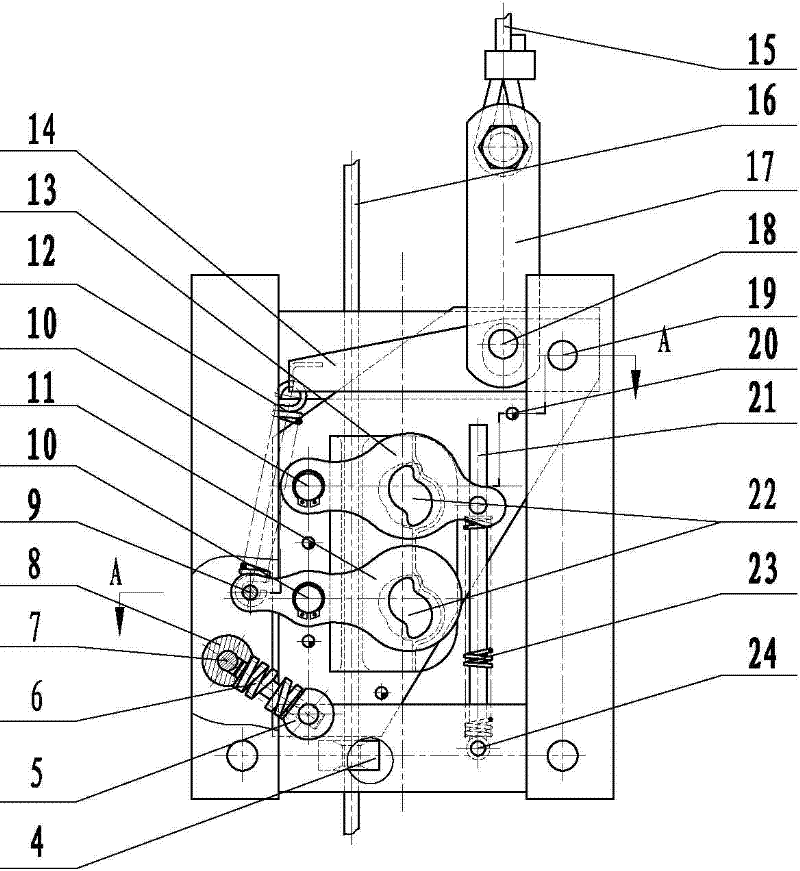

Double-eccentric-shaft anti-falling lock

The invention discloses a double-eccentric-shaft anti-falling lock which comprises a mounting frame (1), a rear positioning plate (25) and a front positioning plate (27), wherein the rear positioning plate (25) and the front positioning plate (27) are riveted and positioned through four positioning pins (20); the left upper ends of the rear positioning plate (25) and the front positioning plate (27) are hinged to the mounting frame (1) through positioning shafts (19); and the right lower ends of the rear positioning plate (25) and the front positioning plate (27) are hinged with the mounting frame (1) through buffering structures. The double-eccentric-shaft anti-falling lock is characterized in that a U-shaped plate part (3) and a locking plate part (2) are arranged between the rear positioning plate (25) and the front positioning plate (27), are provided with similarly half smooth through slots matched with the outer diameter of a safety rope (16) and double-eccentric-hole structures matched with a motion mechanism of two eccentric shafts (22) respectively, and are connected with a rocker plate I (11) and a rocker plate II (13) through the two eccentric shafts (22). The double-eccentric-shaft anti-falling lock has a simple structure and is high in safety, and relatively high in buffering capacity.

Owner:NANJING CHENGUANG GRP

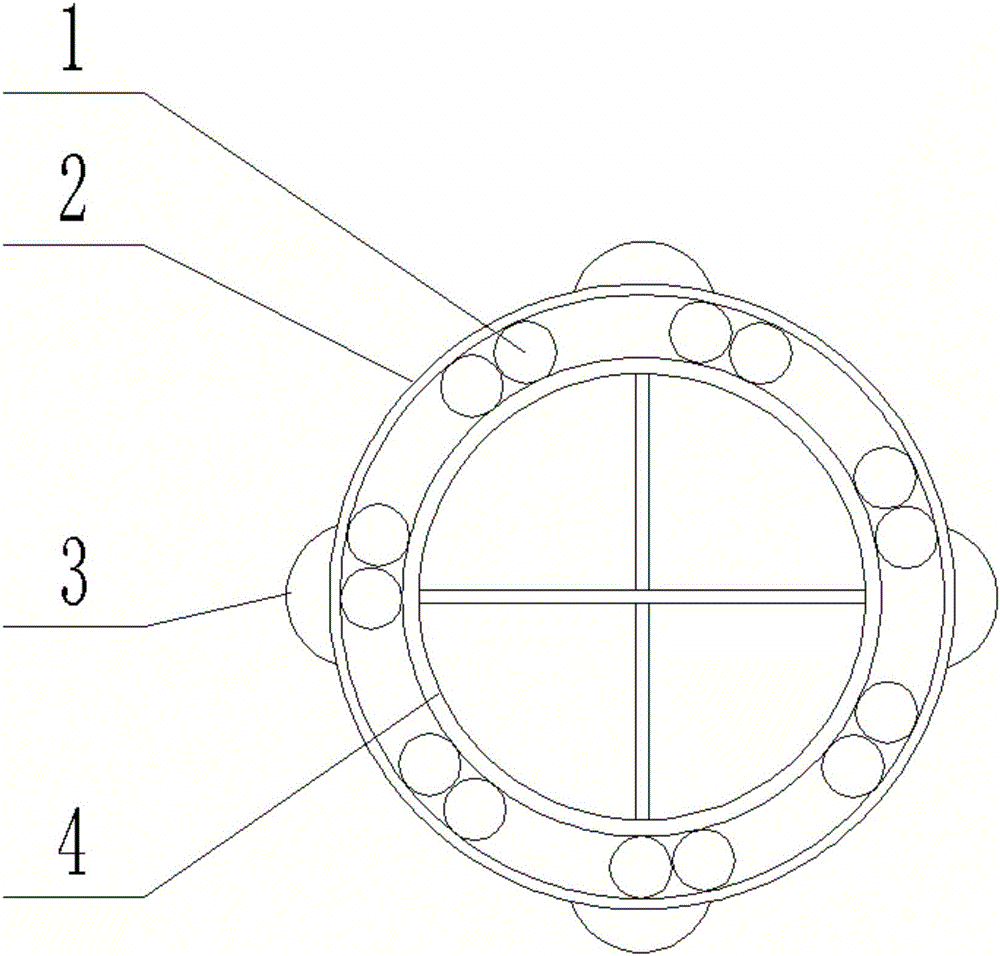

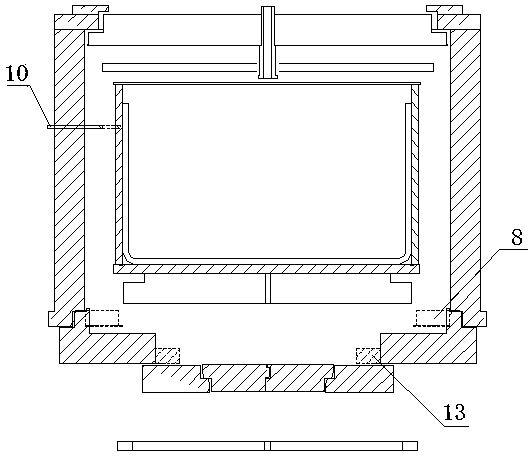

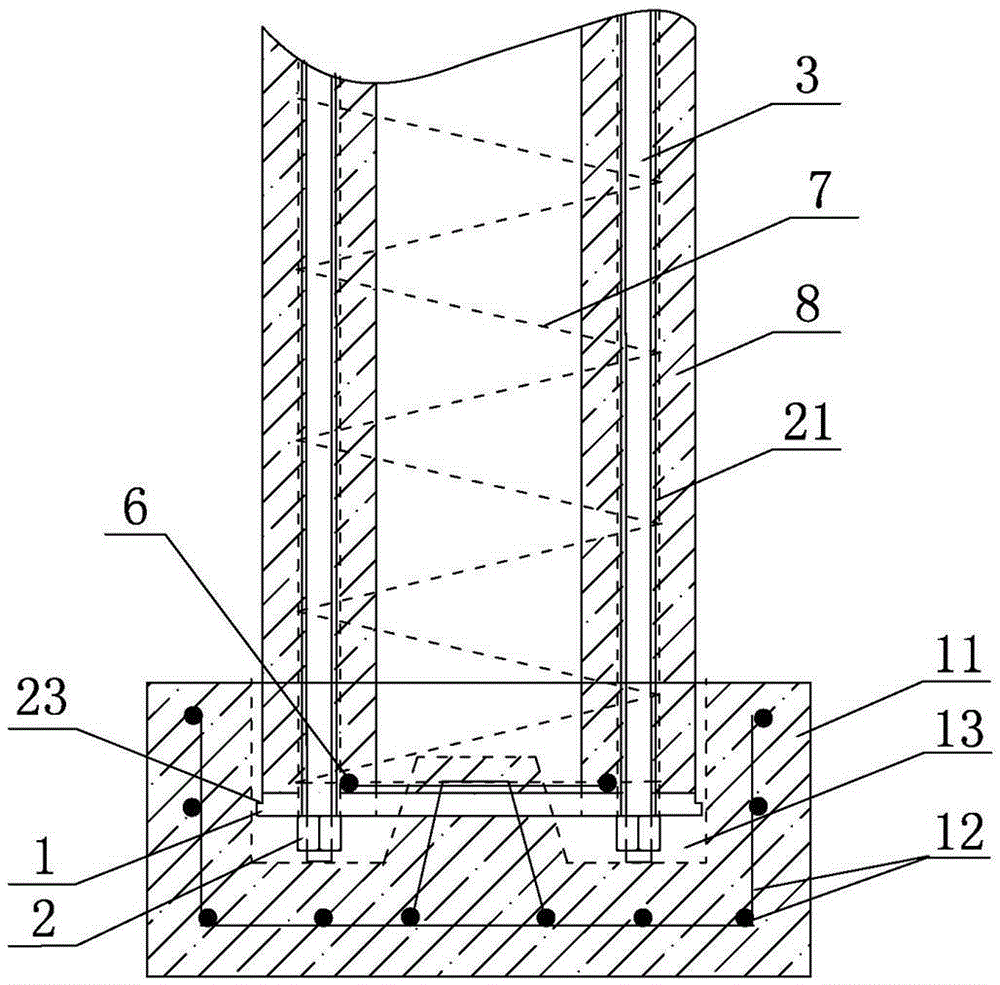

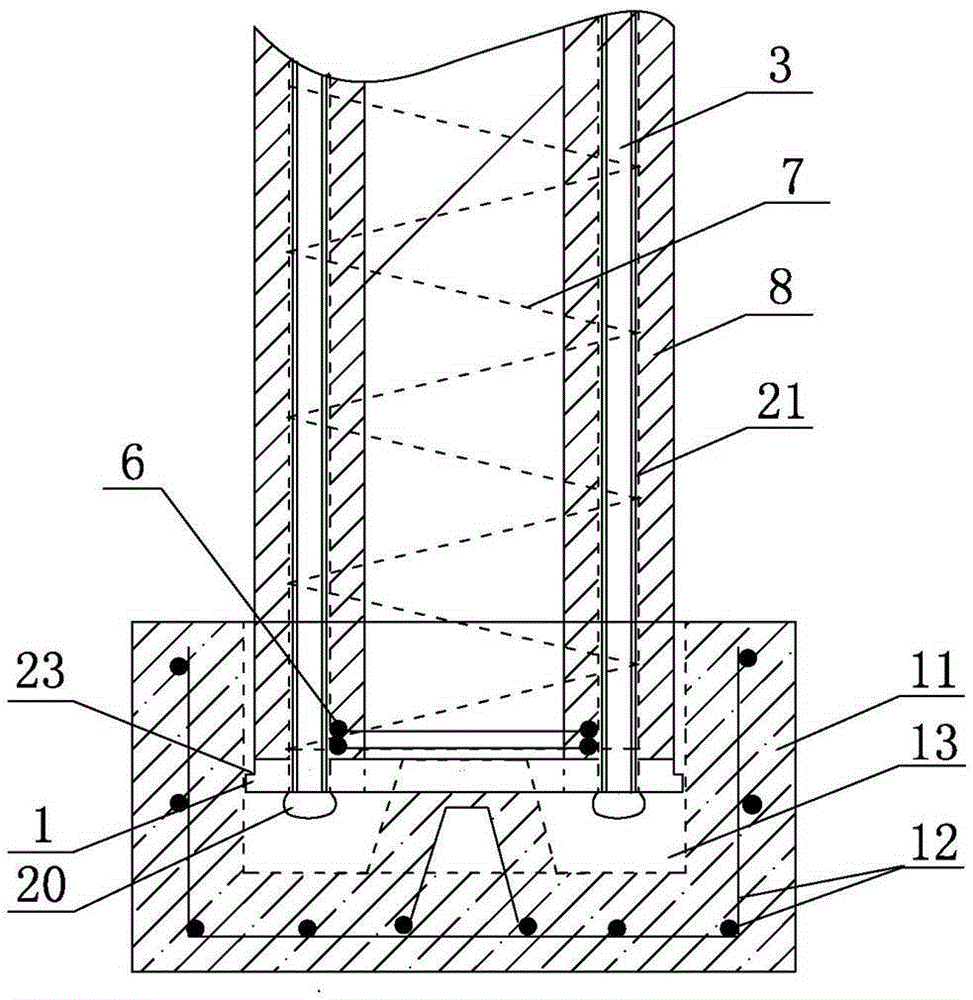

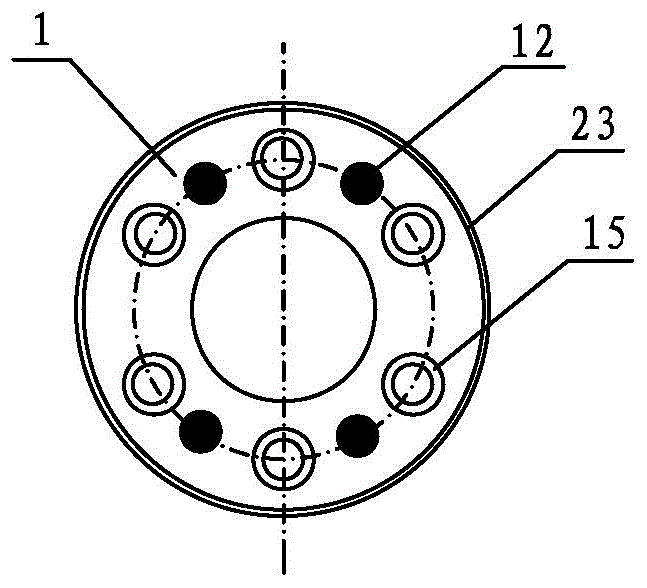

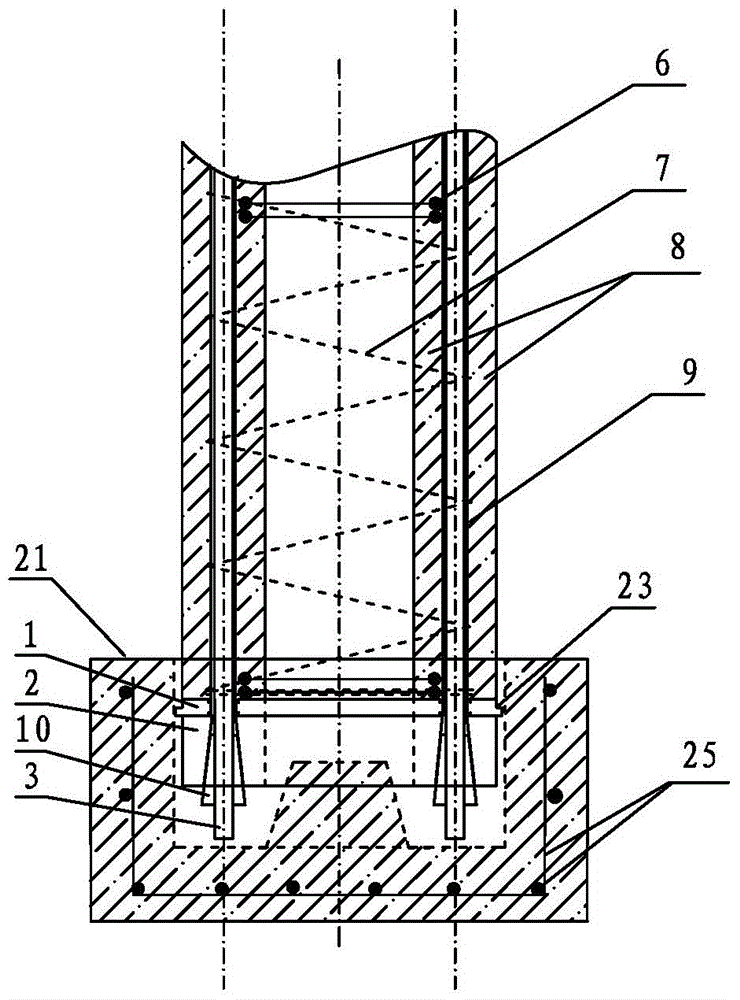

Production technology of large bending moment and high strength post tensioning reinforced concrete electric pole and electric pole

ActiveCN103909574AIncrease bending momentHigh strengthShaping reinforcementsTowersReinforced concretePre stress

The invention relates to a production technology of a large bending moment and high strength post tensioning reinforced concrete electric pole and an electric pole, and mainly aims at providing the production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole and the electric pole produced by using the post tensioning production technology. The production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole includes the steps of 1, weaving a reinforcement cage, and confirming that taper degrees of all seamless steel tubes in the reinforcement cage relative to the axis of the reinforcement cage are equal; 2, hoisting the reinforcement cage into a base seat of an electric pole steel mold, pouring concrete sizing agents into the electric pole steel mold, closing the mold, lifting the mold off the base seat and placing the mold on a balance position after centrifugal shaping, performing mold releasing after three days of natural curing, and performing the natural curing for 21 days; 3, disposing a pre-stressed steel strand in the seamless steel tubes in penetration mode, anchoring one end of the pre-stressed steel strand, tensioning the other end of the pre-stressed steel strand, and locking up the tensioned end of the pre-stressed steel strand after design value is achieved. The production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole is used on the electric pole in an electric line.

Owner:STATE GRID CORP OF CHINA +3

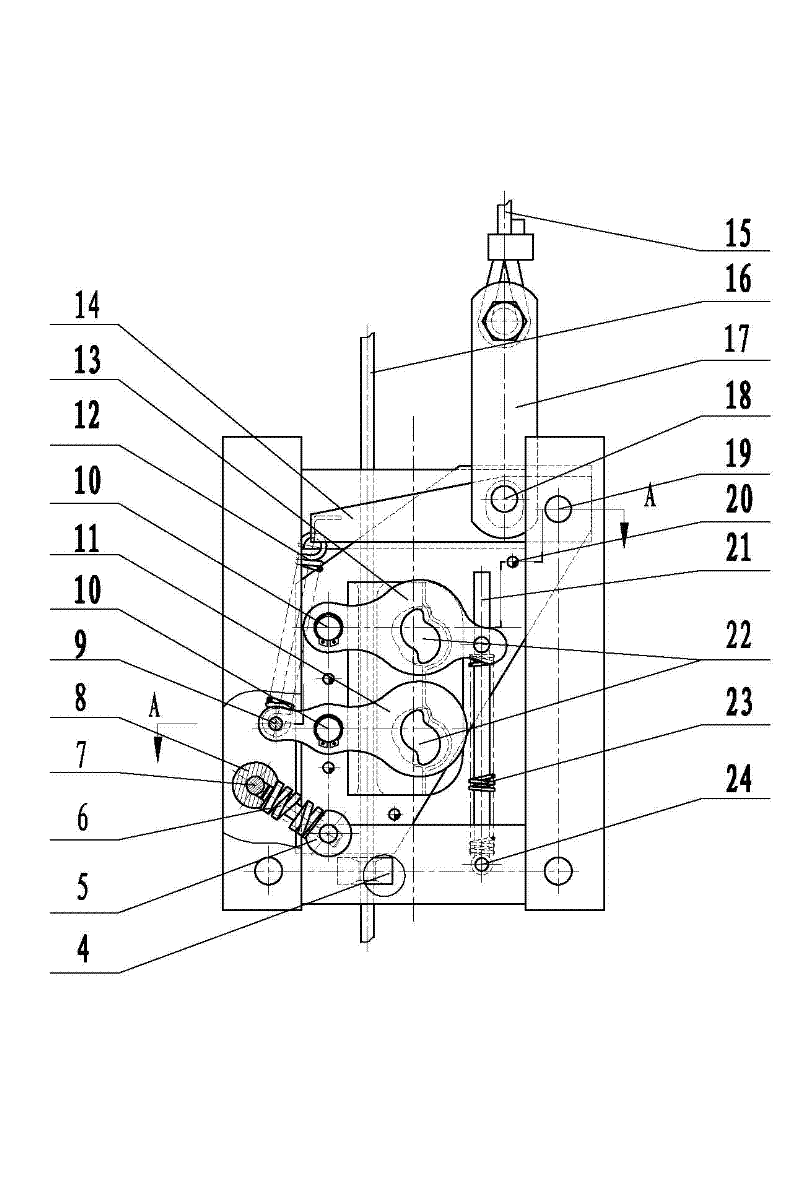

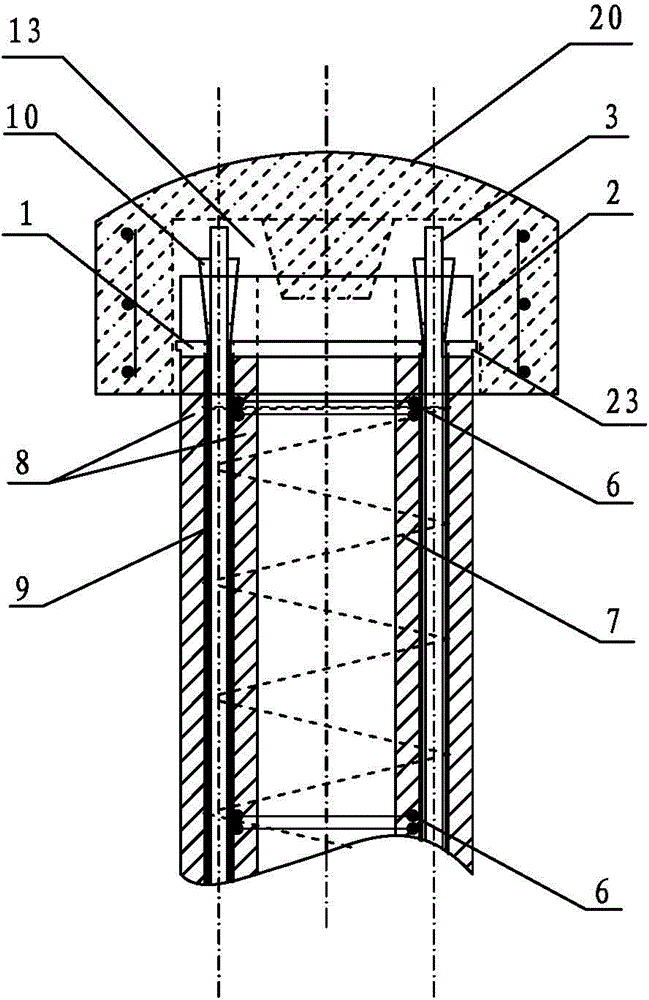

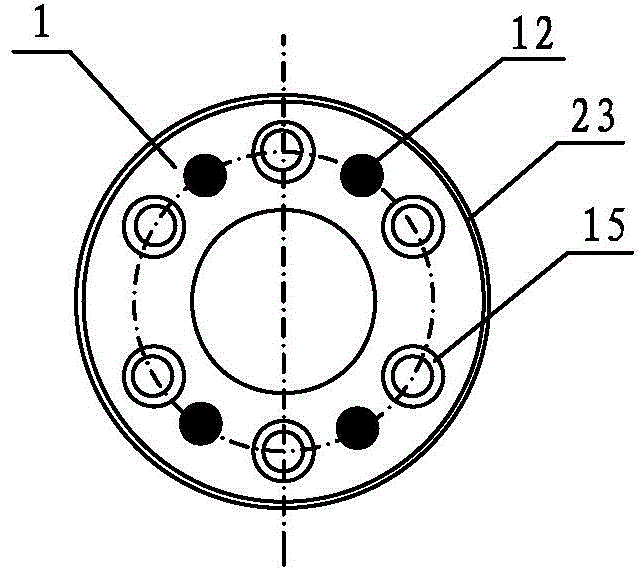

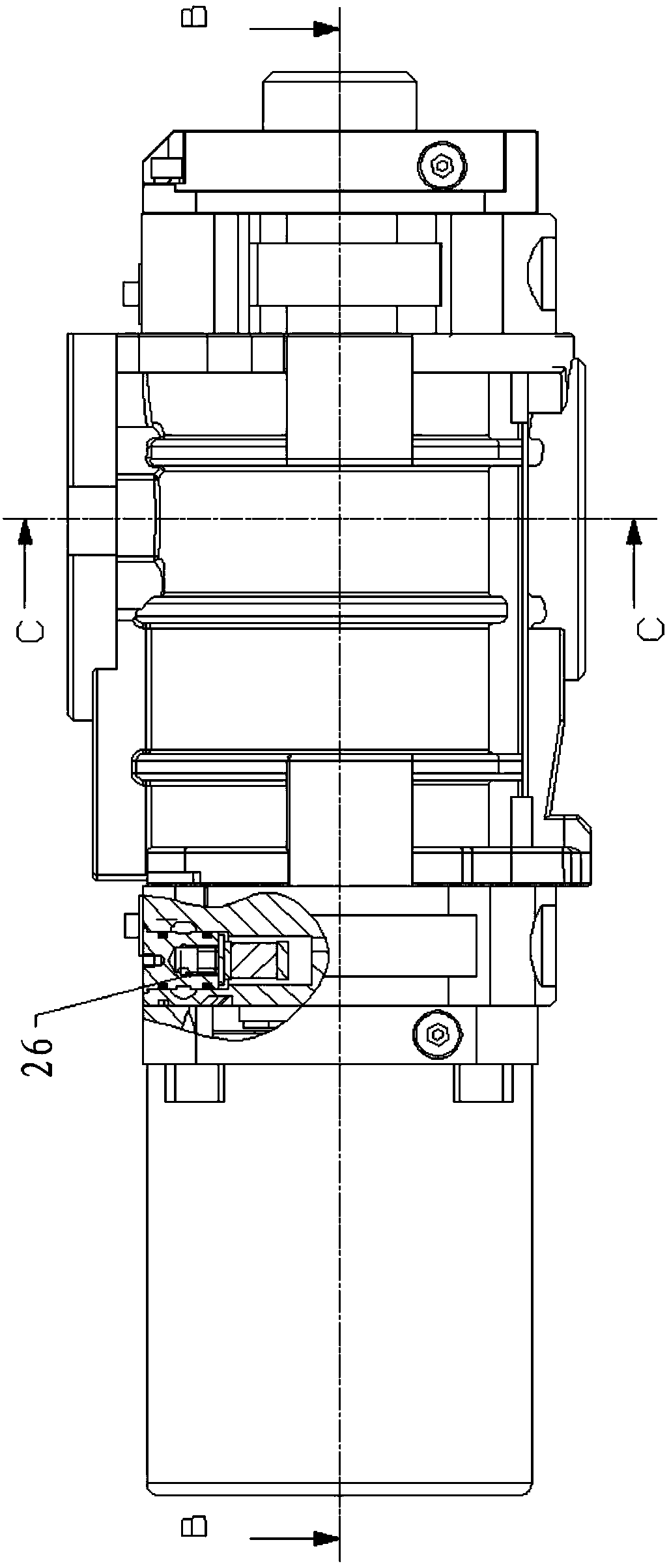

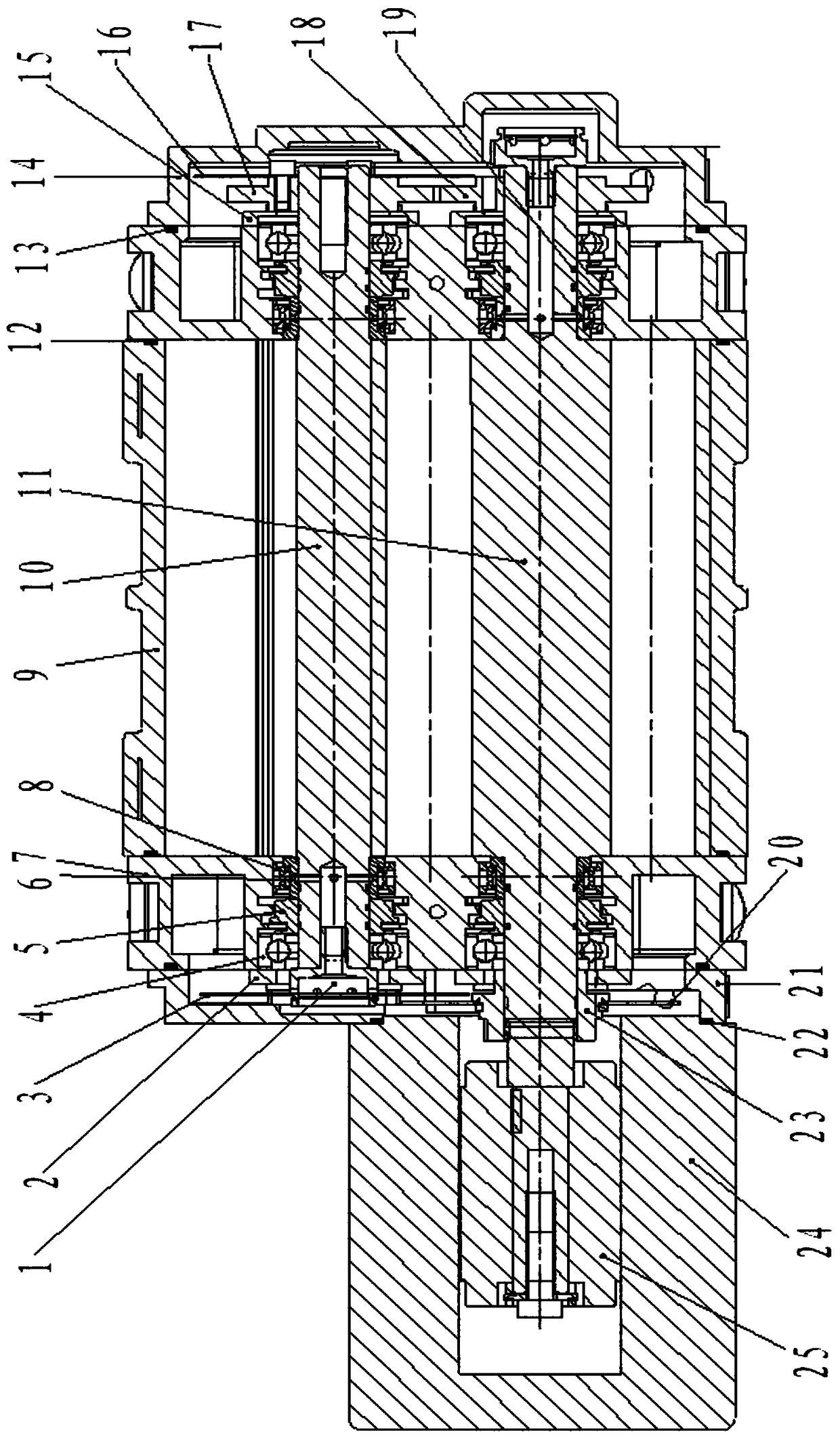

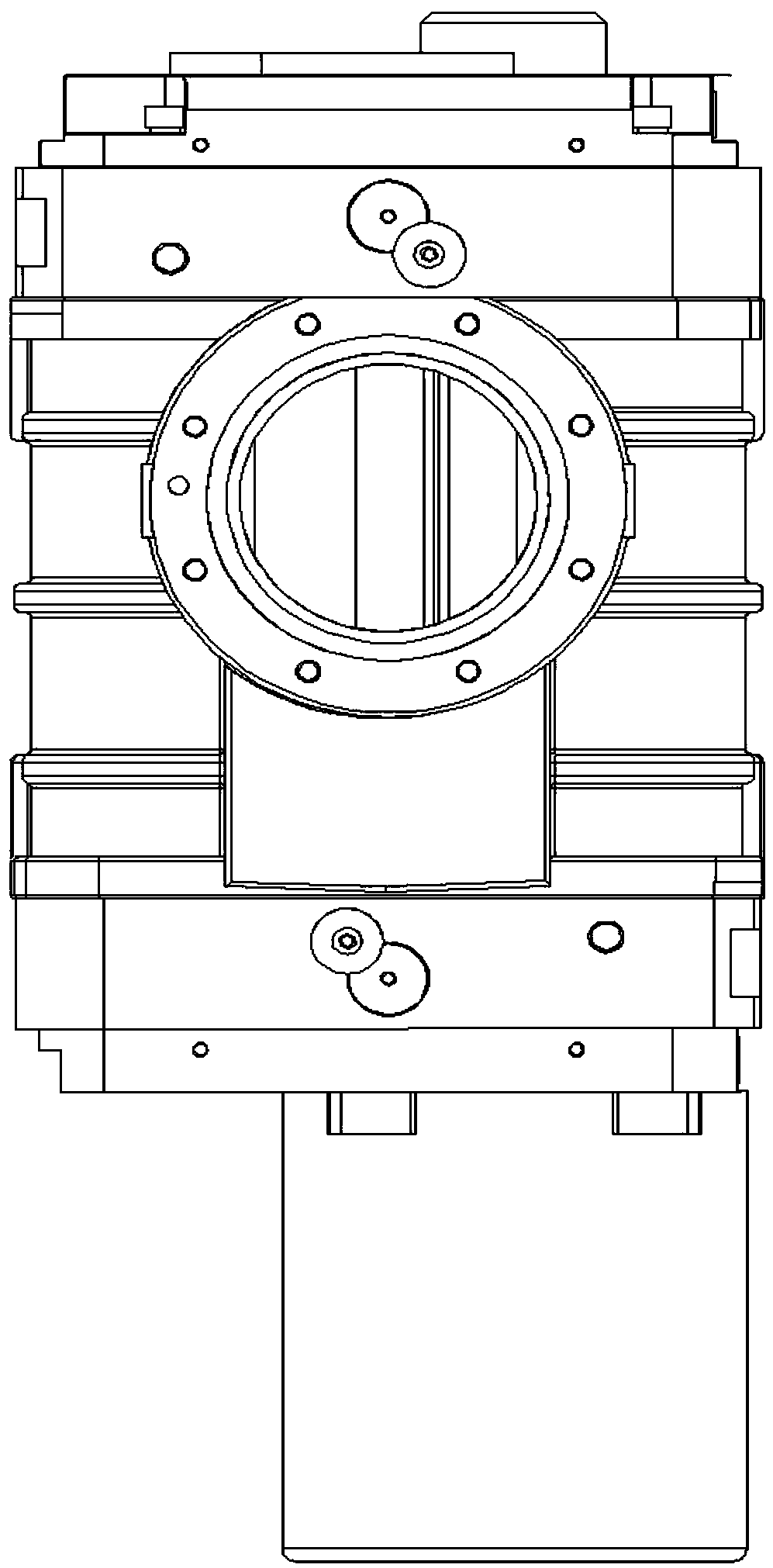

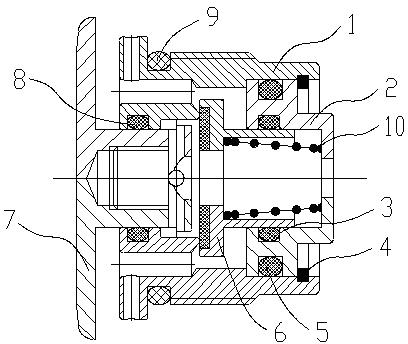

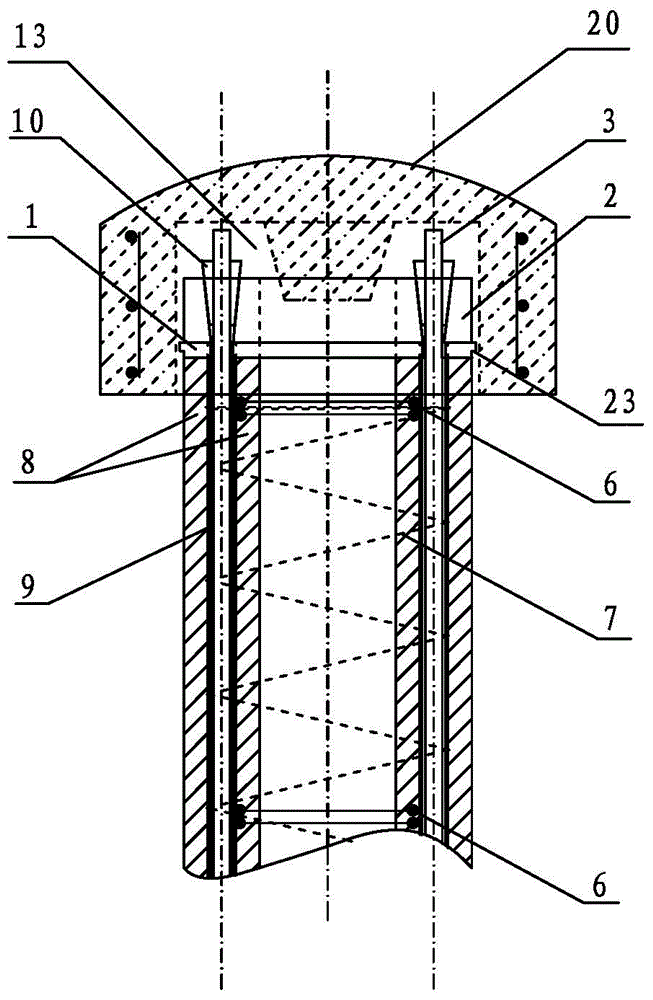

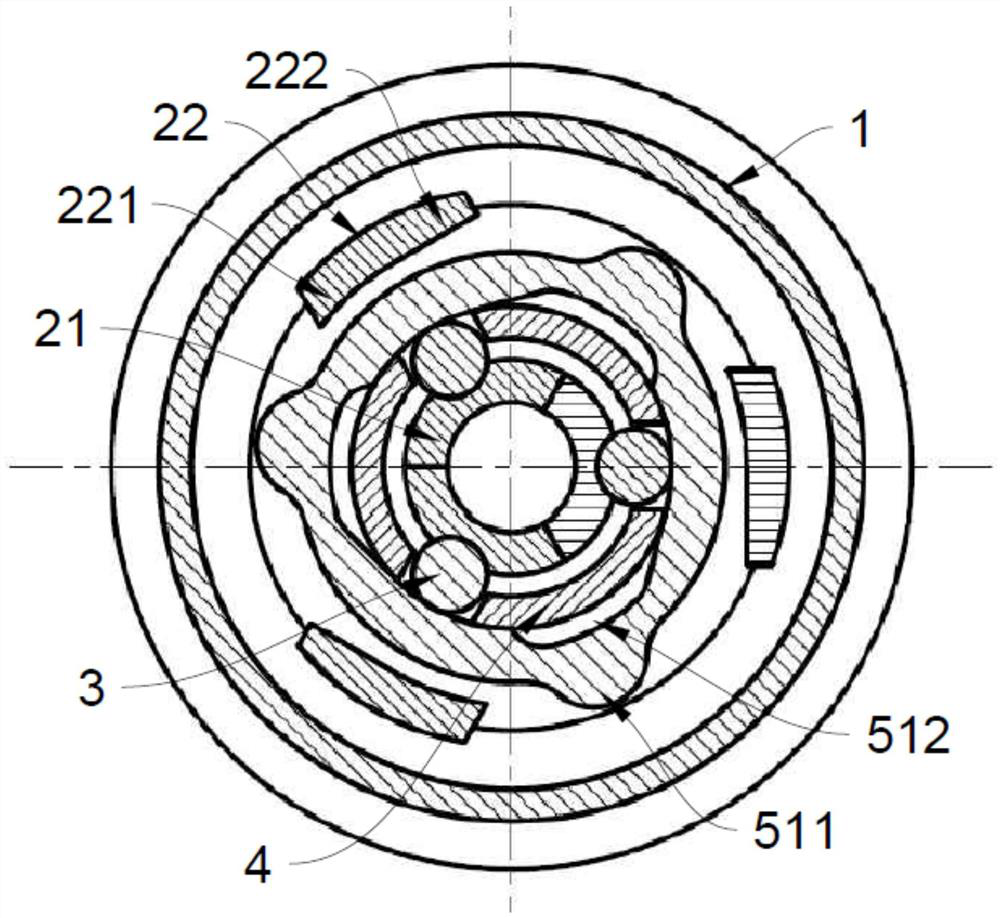

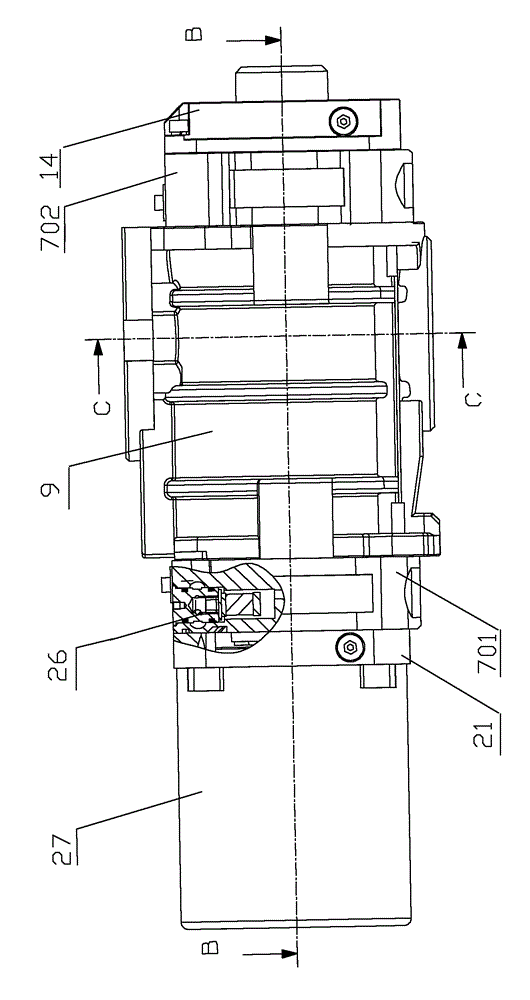

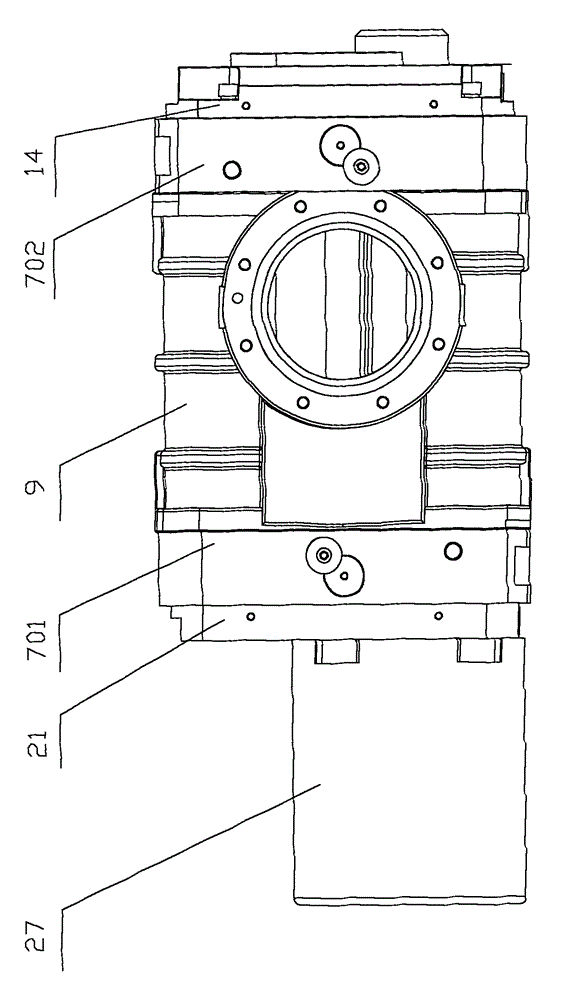

Vacuum motor

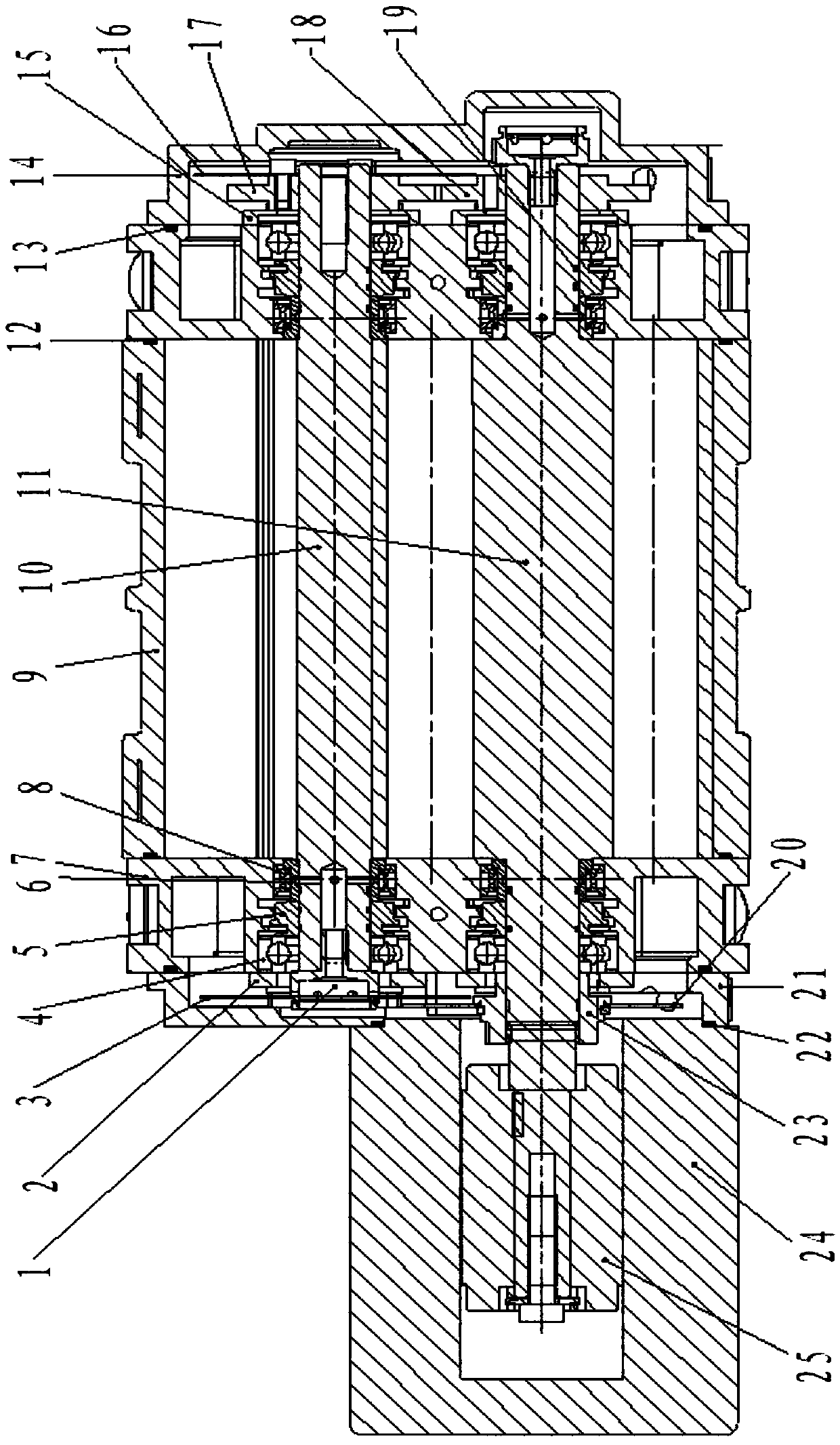

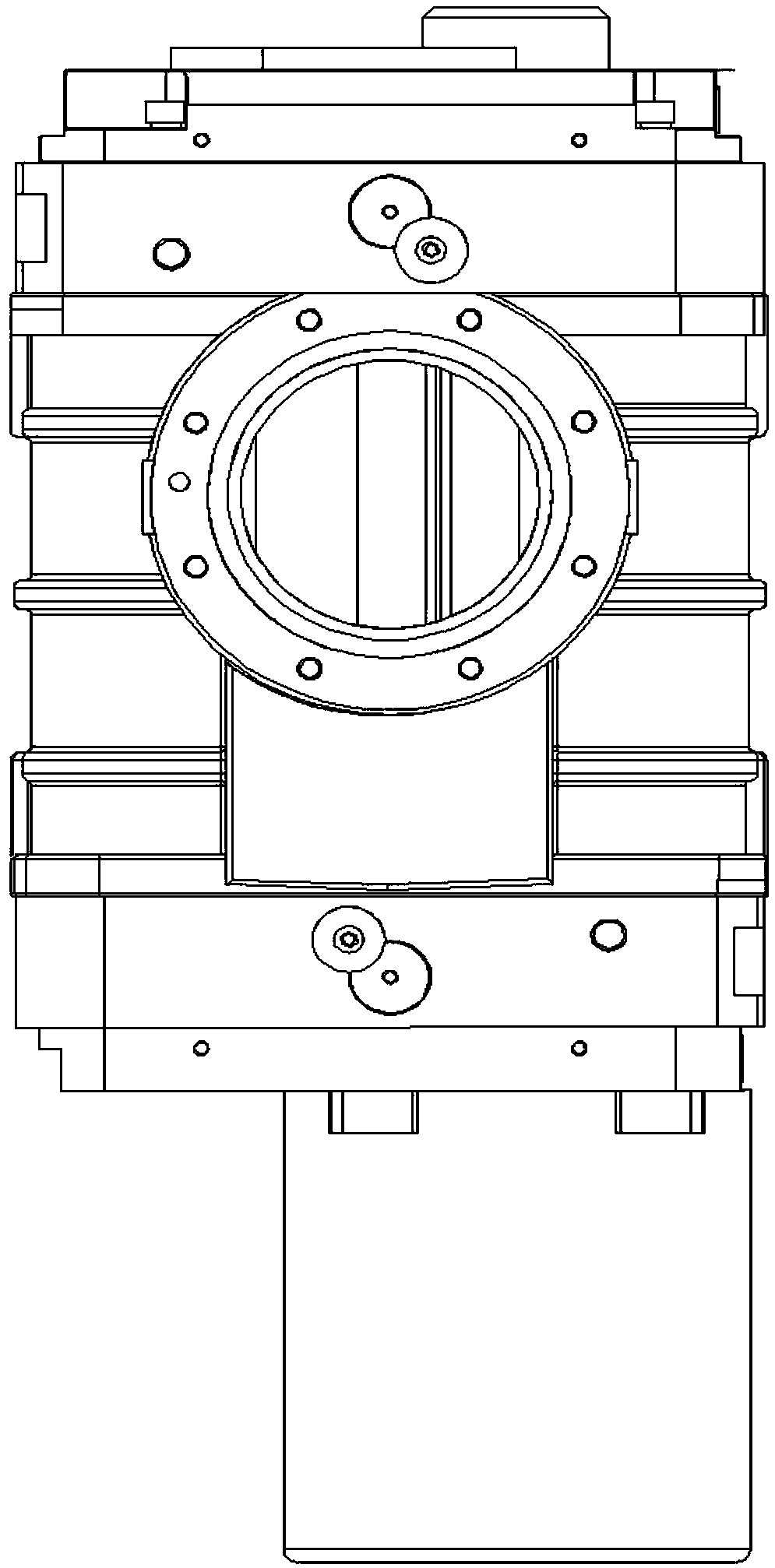

InactiveCN109058110AReduce volumeHigh pumping speedSealing arrangement for pumpsRotary piston pumpsMotor vibrationStator

The invention discloses a vacuum motor. The vacuum motor comprises a motor cavity, a bearing cavity, a Roots cavity, a gear cavity, a motor, a driving rotor shaft, a driven rotor shaft, a driven gear,a driving gear, a driving Roots rotor and a driven Roots rotor; the motor is characterized in that the bearing cavity and the gear cavity are arranged on the two sides of the Roots cavity, the motorcavity is connected with the bearing cavity, shaft seal devices are arranged between the bearing cavity and the Roots cavity and between the Roots cavity and the gear cavity, the motor is small in size, large in pulling speed and capable of saving energy and space, due to frequency control, the service life is long, a Teflon dual-lip shaft seal is adopted, the maintaining period of a pump is prolonged, an oil and gas separation device is adopted, the leakage problem of oil steam to a vacuum chamber is solved, the structure that a motor rotor and a pump shaft are integrated, and a motor statoris arranged outside an oil chamber is adopted, the problems of motor dynamic seal and motor vibration are solved, a heat expansion assembling structure is adopted in gear assembling, and unbalance andvibration of a motion part are reduced.

Owner:FUSHUN COAL MINE MOTOR MFG

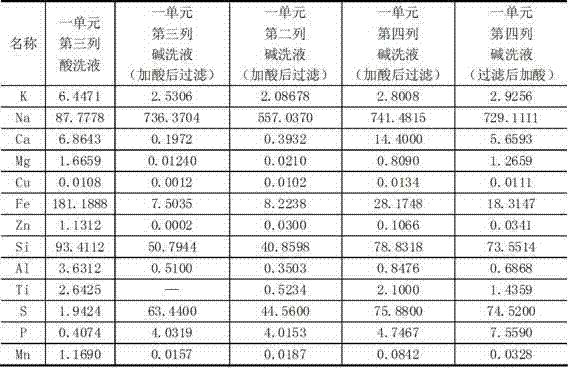

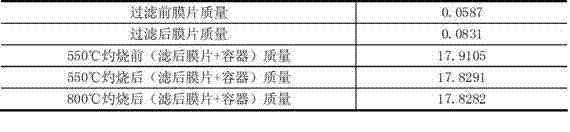

Non-destructive method for reverse osmosis system dirt block

InactiveCN103041711ANo destructive damageReduce analysis costsSemi-permeable membranesNon destructiveOptical spectrometer

The invention relates to a non-destructive method for a reverse osmosis system dirt block. According to the method, a plasma emission spectrometer is adopted for analyzing the elements of inlet water of the reverse osmosis system, waste liquid after reverse osmosis chemical cleaning and blocked dirty material of the reverse osmosis system, so as to determine the reason for the reverse osmosis system dirt block. The method can be carried out when the reverse osmosis system runs, other tests and measures can be conducted at the same time, and reverse osmosis membranes are not damaged, so that the analysis cost is effectively lowered.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

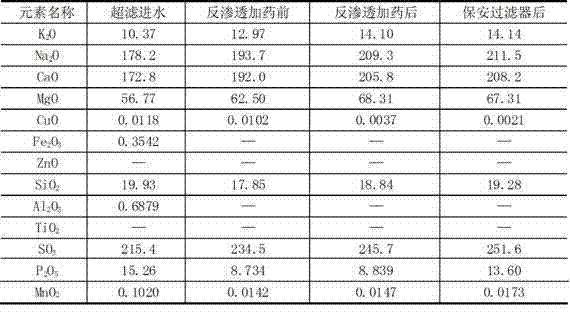

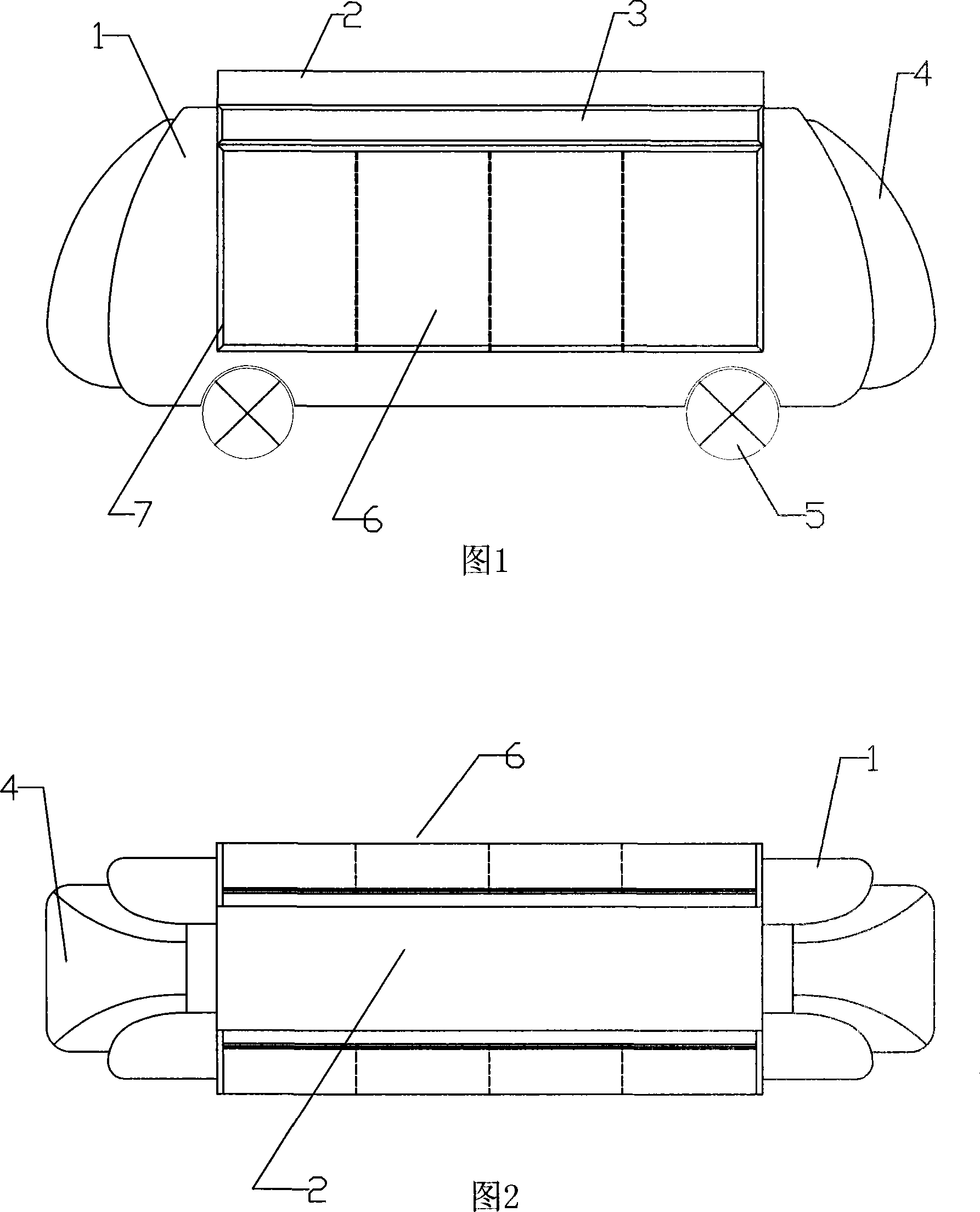

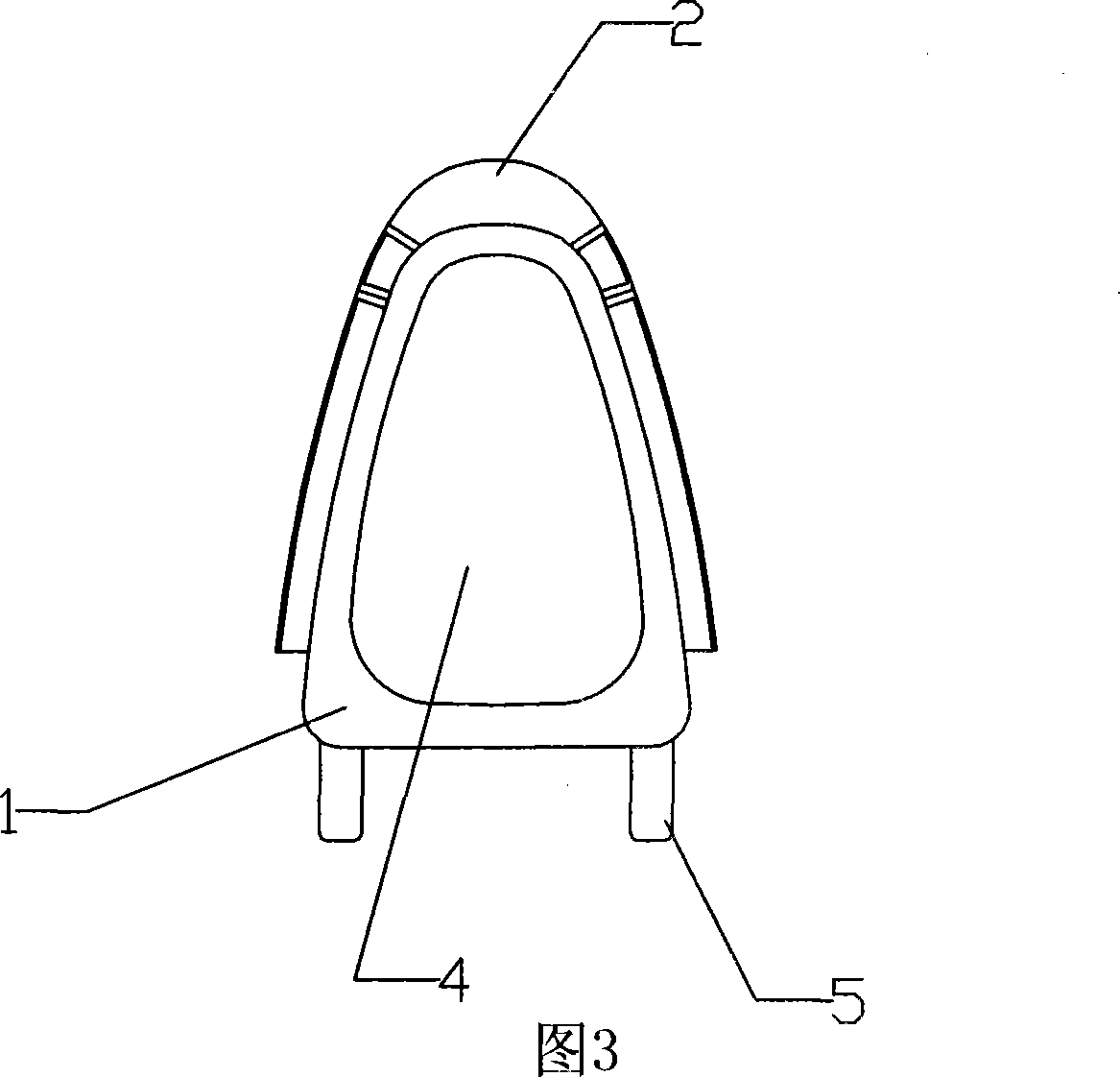

Outdoor mobile advertisement propagation car

The present invention discloses an outdoor mobile advertisement loudspeaker which solves the problem that present outdoor mobile advertisement loudspeaker is set on ordinary truck, the shape is limited by the truck shape and has not considerable change, so advertisement effect is worse. A technical solution is: a mobile advertisement loudspeaker including a vehicle body, a window for setting advertisement picture mounted on vehicle body, a road wheel mounted on bottom is provided, and has characteristics in that said vehicle body is an enclosed case, said window is set on outer side along with vehicle body lengthwise direction and covers main parts of the outer side. A protuberant advertisement board can be vertical arranged on the vehicle body directly, and outer outline of the vehicle body is smooth arc transition.

Owner:徐君义

Air return valve for inner air return independent discharge spring braking air chamber

InactiveCN102466046ANo destructive damageAvoid inhalationFluid braking transmissionLift valveInterior spaceEngineering

The invention relates to the technical field of automobile parts, in particular to an air return valve for an inner air return independent discharge spring braking air chamber to solve the problem that external harmful substance enters and damages a cylinder body, so the service life of an energy storage cavity is threatened seriously. The air return valve is characterized in that through holes are formed in a valve seat in an axial direction; hole steps are arranged in the through holes; valve ports are formed at the hole steps; axial air holes are formed between the valve ports and a cylinder wall of the valve seat in the axial direction; the end of the cylinder wall of the valve seat is provided with radial air holes which are vertical to the axial air holes; a valve bush and a valve are arranged in a large-diameter through hole, facing the hole steps, in the valve seat; one end of the valve is adhered to the valve ports, and the other end of the valve is in fit with inner holes formed in the valve bush in the axial direction; valve springs are arranged in the valve; a valve plug is arranged at the end of a small-diameter through, facing the hole steps, in the valve seat; and one end, facing the valve, of the valve plug is provided with a flow guide hole. A piston assembly end cover is saved, the inner space is fully utilized, the air return valve is sealed reliably and a sealing component is not damaged.

Owner:NINGBO WANFENG AUTOMOBILE BRAKE

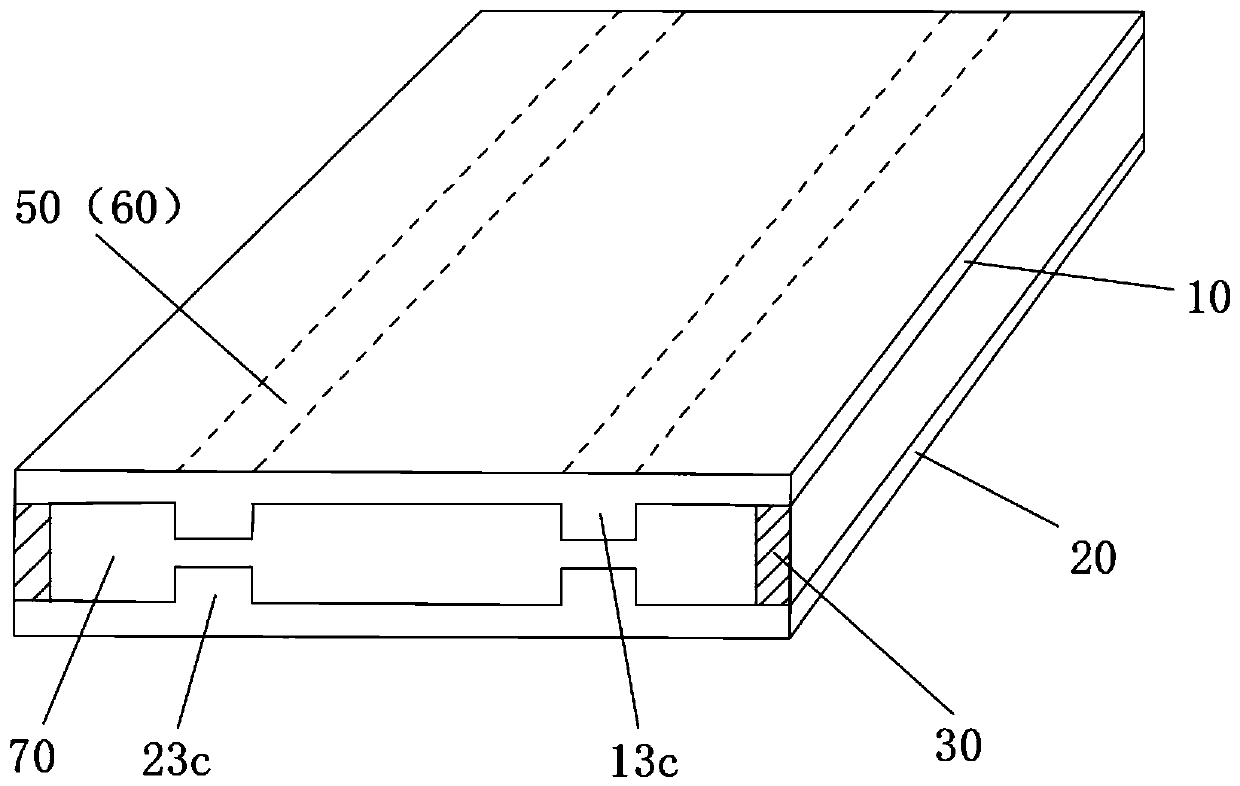

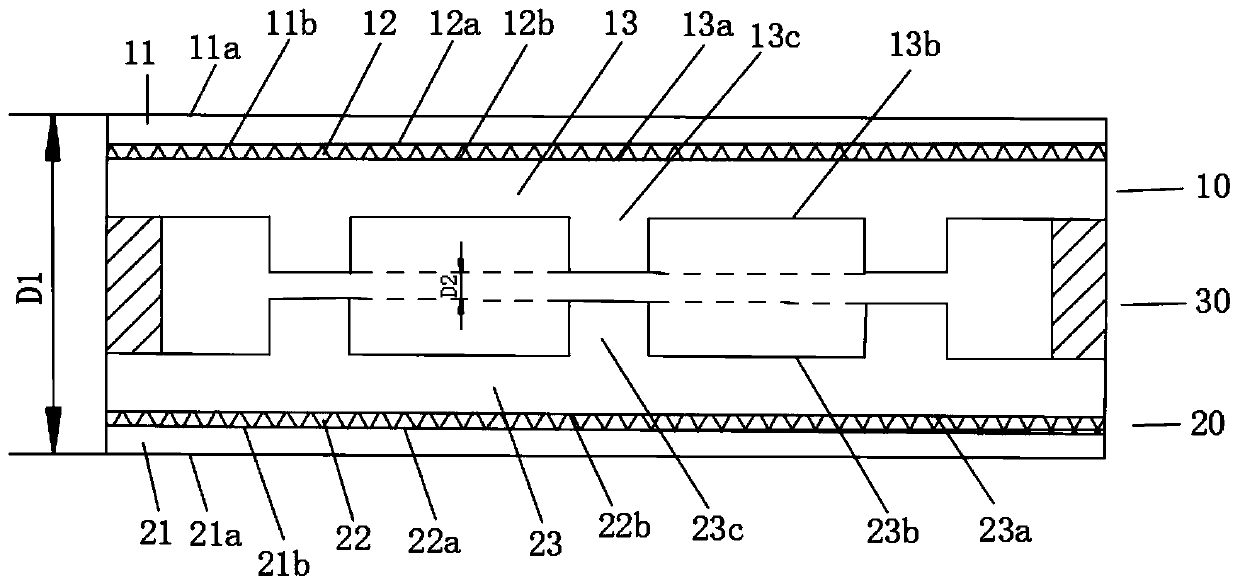

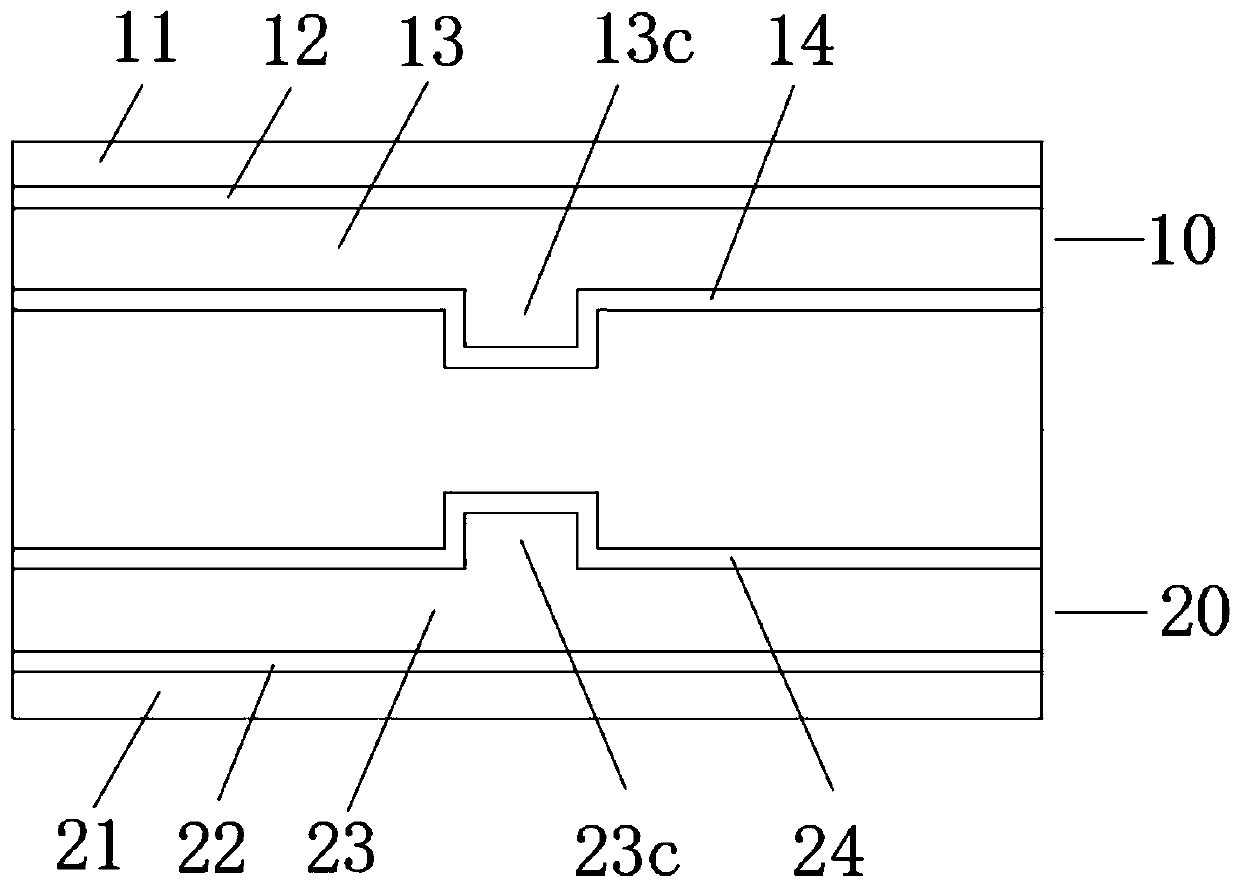

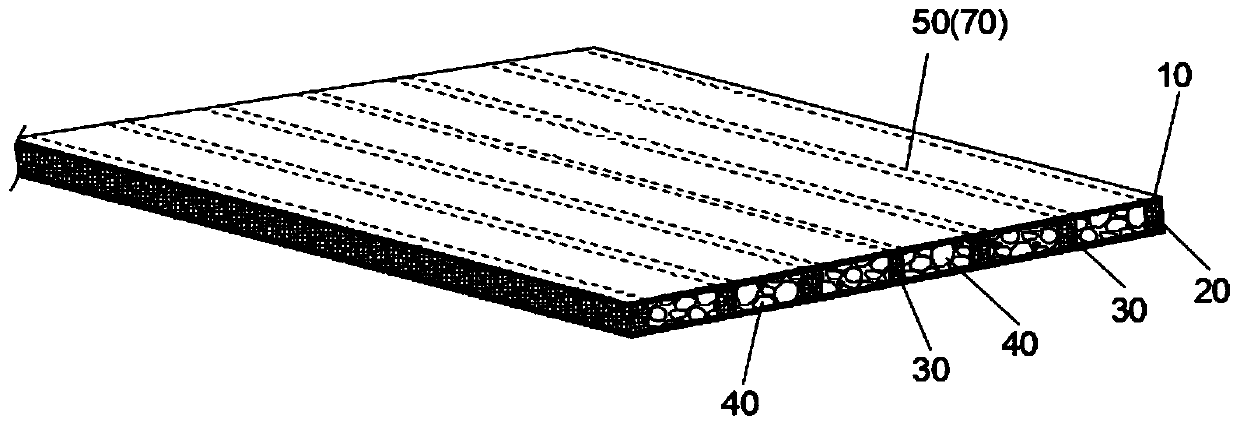

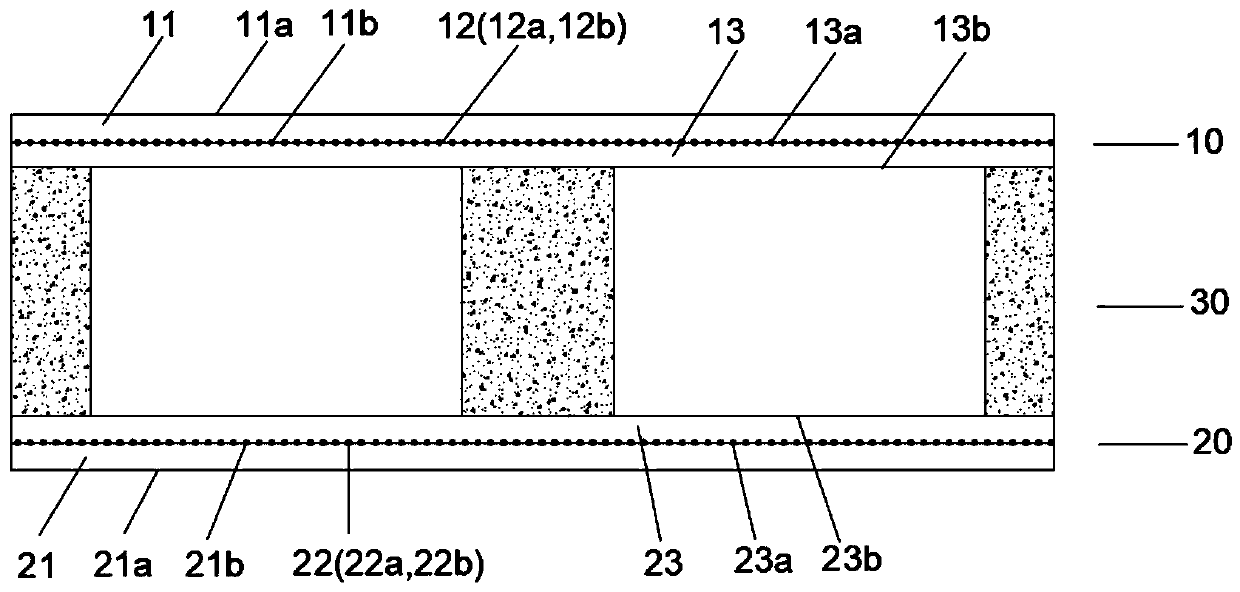

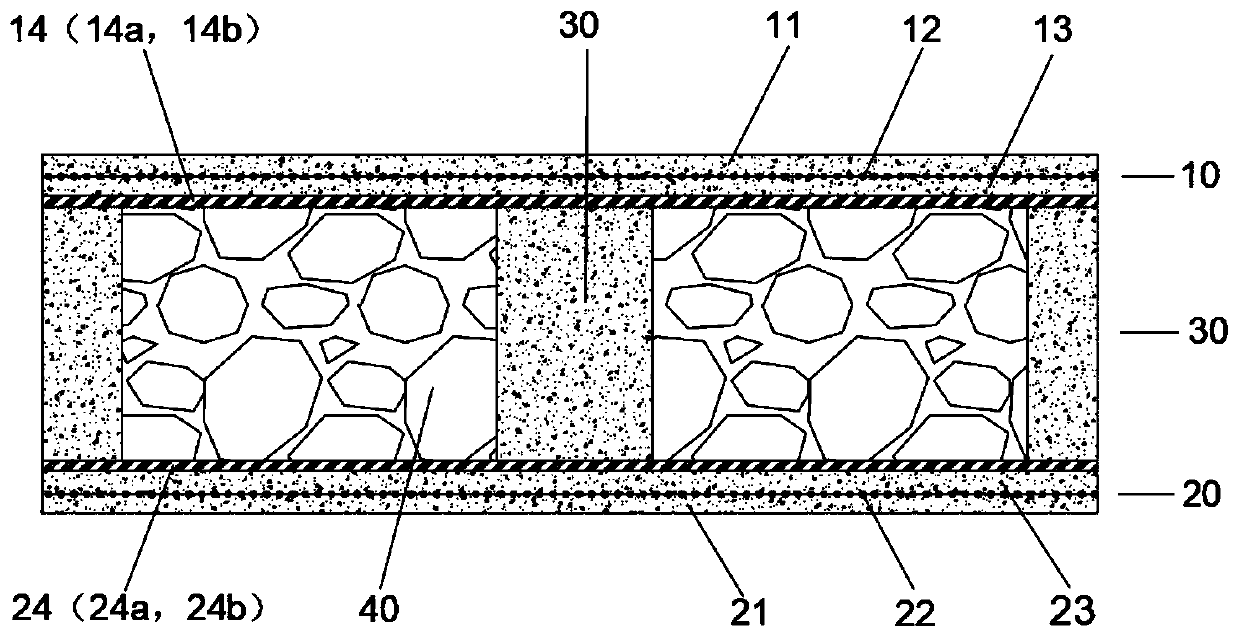

Composite board

PendingCN110847484AAvoid warpingAvoid paradigmatic deformationWallsSynthetic resin layered productsStructural engineeringComposite plate

The invention discloses a composite board. The composite board comprises a first board body, a second board body and connecting pieces for connecting the first board body and the second board body, wherein the first board body and the second board body have respective characteristics in a one-to-one correspondence mode, each of the first board body and the second board body comprises a base plate,a stretch resistance layer and a compression resistance layer, and the compression layers comprise a plurality of protruding ribs which are parallel to one another and are uniformly arranged. The first board body and the second board body are opposite mutually, the protruding ribs on the first board body and the protruding ribs on the second board body are mutually opposite and kept at a second predetermined distance D2, and the stretch resistance layers of the first board body and the second board body have equal predetermined stretch prestress. The composite board can be used for wall spacepanels of construction modules or decoration panels or boards for other purposes.

Owner:SHANGHAI XINGYE MATERIALS TECH CO LTD

Composite board

PendingCN110863601AAvoid warpingAvoid paradigmatic deformationHeat proofingSound proofingEngineeringComposite plate

Owner:SHANGHAI XINGYE MATERIALS TECH CO LTD

Method for detecting binding force of DPC ceramic copper-plated substrate

PendingCN114002260AReduce the risk of influx of customers, causing inconvenienceReduced risk of inconvenienceMaterial thermal analysisMetallurgyLaboratory oven

The invention discloses a method for detecting a binding force of a DPC ceramic copper-plated substrate. The method comprises the following steps: producing a baking jig, coating the surface of the jig with a polybenzimidazole coating, reducing the surface hardness of the jig to load the DPC ceramic copper-plated substrate, and heating the DPC ceramic substrate by using a high-temperature nitrogen oven to comprehensively detect batch products. In the detection process, nitrogen atmosphere protection exists in the furnace, products cannot be oxidized or damaged, the products can be continuously used, and therefore the risk that defective products flow into customers and inconvenience is caused due to sampling detection omission is reduced, and the method is widely applied to the technical field of DPC ceramic copper-plated substrates.

Owner:江苏富乐华半导体科技股份有限公司

Production technology of high-strength post-tensioned reinforced concrete poles and poles

ActiveCN103950100BHigh strengthIncrease elasticityShaping reinforcementsTowersReinforced concretePre stress

The invention relates to a production technology of a high-strength post-tensioned reinforced concrete electric pole and the electric pole. The technical problem to be solved by the invention is to provide the production technology of the high-strength post-tensioned reinforced concrete electric pole and the electric pole produced by utilizing a post-tensioning technology. According to the technical scheme for solving the problem, the production technology comprises the following steps: firstly, weaving a reinforced cage, and ensuring that the tapers of the prestress steel rods relative to the axis of an electric pole to be manufactured are the same; secondly, hoisting the reinforced cage in an electric pole steel mould base, pouring concrete slurry, closing the mould, hoisting and placing in a balanced manner after centrifugal forming, demoulding after natural curing for three days, and then naturally curing for 21 days; thirdly, tensioning the tensioning ends of the prestress steel rods, locking nuts when design value is reached, and sawing unwanted parts of the prestress steel rods. The production technology is used for electric poles in power transmission and distribution lines.

Owner:STATE GRID CORP OF CHINA +3

A production process for electric poles

ActiveCN105965686BImprove the instantaneous carrying capacityReduced crack resistanceCeramic shaping apparatusTowersPre stressSlurry

The invention relates to the field of cement product prefabricated parts, in particular to a telegraph pole production process. The telegraph pole production process is characterized in that the process includes the following steps that high-strength ribs are straightened and subjected to fixed length treatment and shearing, and main ribs are formed; a set of main ribs distributed around the axis are arranged, a set of erecting rings at equal intervals are welded on the inner sides in the axial direction of the main ribs, a conical rebar framework is formed, and rib hanging disks are installed at the two ends of the rebar framework; spiral ribs are arranged in the whole-length range of the rebar framework and bound firmly with iron wires; the rebar framework is pre-tensioned, and a plurality of circles of cushion blocks are arranged on the surface at equal intervals; the rebar framework is hoisted into a telegraph pole steel mold base, mold assembly is performed after concrete slurry is poured in, tensioning is performed, and then the centrifuging process is performed; and a telegraph pole formed after centrifuging is hoisted into a steaming pond to be subjected to steaming, natural curing is performed after steaming of the telegraph pole ends, and demolding is performed. The telegraph pole production process can improve the strength and the prestress performance of the telegraph pole; and meanwhile, steel materials can be saved, waste of concrete is reduced, and the production cost is reduced.

Owner:BEIHAI JINGYI CONCRETE PROD

A device and method for reducing the resistance of a high-resistance fault point of a power cable

ActiveCN105807185BReduce arcingLower resistanceFault location by conductor typesHigh resistanceEngineering

Owner:西安宇铭电物理技术有限责任公司 +2

A kind of environment-friendly superfine grinding oil and preparation method thereof

ActiveCN107338096BLow carbon residueHigh aniline pointLubricant compositionOil mistMaterials science

The invention relates to environmentally-friendly super-finishing grinding oil and a preparation method thereof. The environmentally-friendly super-finishing grinding oil is prepared from, by weight, 5.0%-10.0% of ester base oil, 3.0%-5.0% of an extreme-pressure and anti-wear agent, 0.5%-1.0% of an antioxygen, 0.05%-0.1% of a metal desactivation agent, 0.5%-1.0% of an oil mist inhibitor, 0.01%-0.05% of an anti-foaming agent and mineral base oil balance. The sum of the percentages of the above components is 100%. The environmentally-friendly super-finishing grinding oil has high lubrification, cooling, rust protection and corrosion protection performances; meanwhile, heavy metals, chlorine and low oil mist do not exist in the environmentally-friendly super-finishing grinding oil, so that the environmental-friendly super-finishing grinding oil is harmless to an operator and the environment.

Owner:辽宁海华科技股份有限公司

Plant online glucose detection method and device based on microelectrode biosensing technology

ActiveCN105319260BRealize real-time detectionRealize online detectionMaterial electrochemical variablesPlant tissueGlucose detection

The invention provides an online glucose detection method for plants based on microelectrode biosensing technology. The glucose oxidase microelectrode is inserted into the plant tissue to be tested, connected to an electrochemical workstation for cyclic voltammetry scanning, and the online glucose detection of the plant tissue is realized. . The present invention also provides a device for realizing the above detection method. The device includes an electrochemical workstation and a glucose oxidase microelectrode, and the two are connected by wires. The invention can realize the real-time detection of the glucose content of the plant, and the detected part of the plant does not need to be isolated from the body, without destructive damage, and only needs to clean the surface and fix the tissue to detect in vivo, and obtain continuous results for dynamic analysis. The detection device of the invention is portable, has simple detection conditions, can be operated in the field, and realizes continuous on-line detection.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

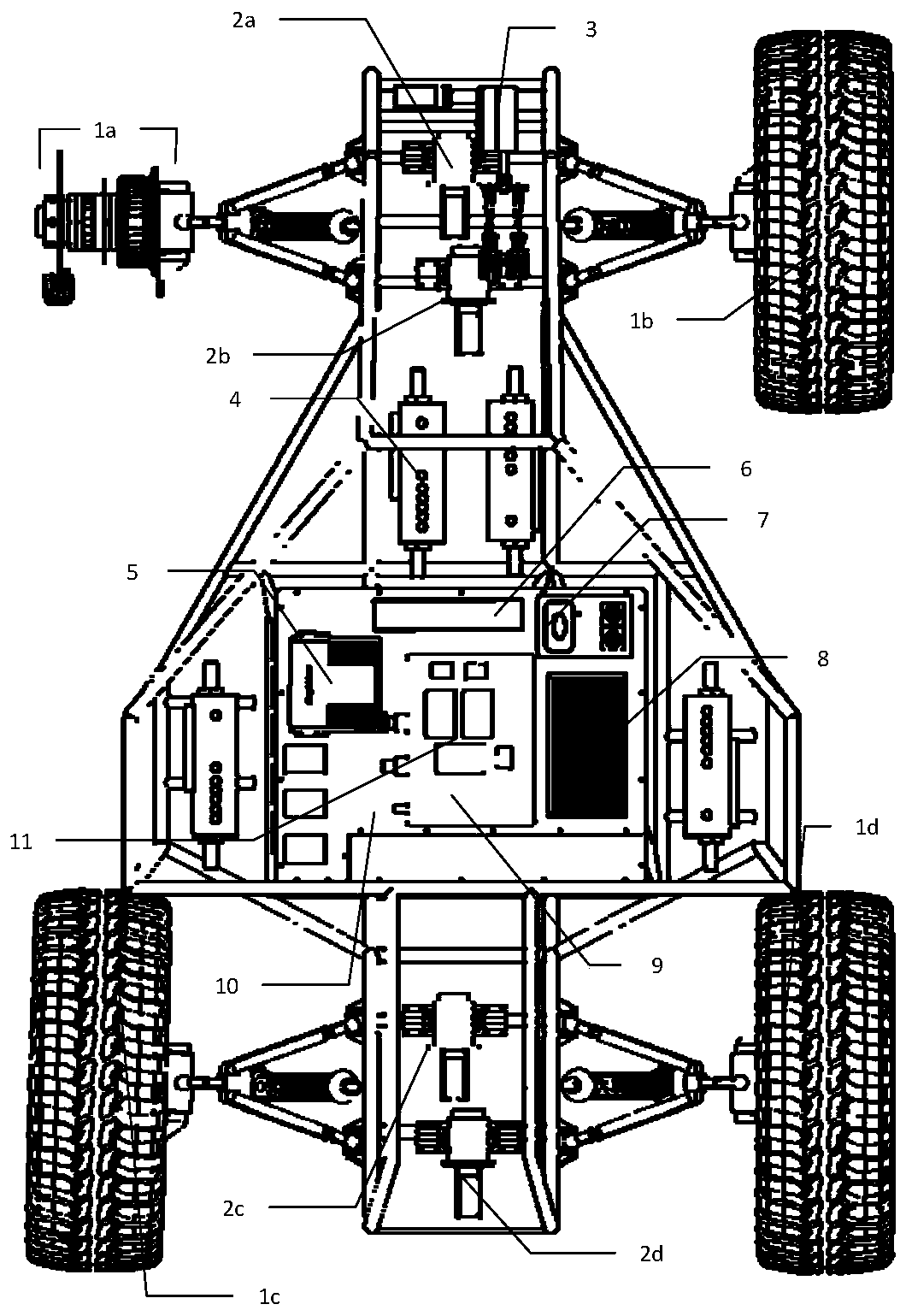

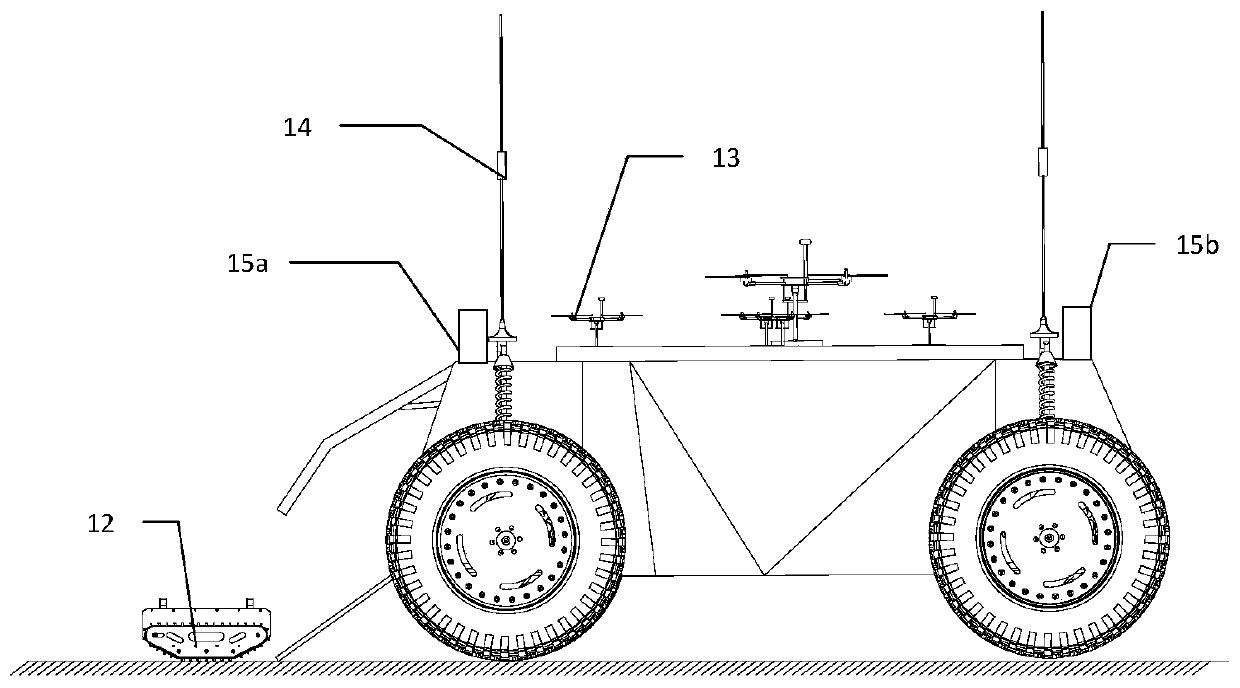

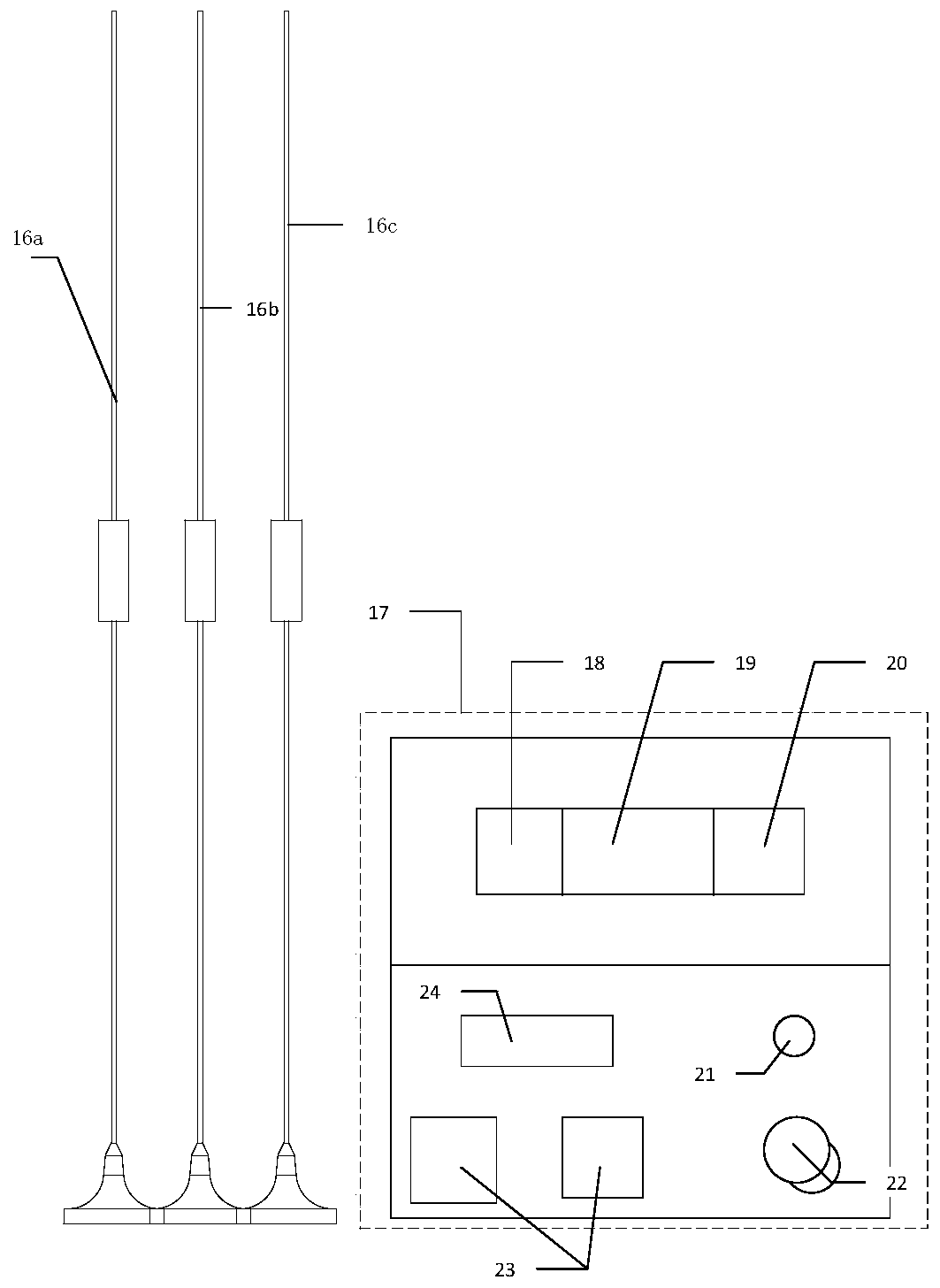

An all-wheel steering unmanned platform driven by hub motors

ActiveCN107444101BGuaranteed powerSimplify bulky form factorMotor depositionVehiclesSteering angleRemote control

The invention provides a full wheel steering unmanned platform driven by hub motors. The full wheel steering unmanned platform comprises a ground remote control station, an image acquisition module, a platform main body controller and tire steering mechanisms. The platform main body controller receives a motion control command sent by the ground remote control station, and according to the rotation mode and the rotation angle, the target rotation angle value and rotation direction of each tire are calculated and obtained; according to the difference between actual rotation angle values and a target rotation angle value and the rotation directions, a steering angle control signal of each tire is generated and sent to the corresponding tire steering mechanism; the tires are driven to deflect the corresponding rotating angles relative to the platform forward direction till the actual rotation angle values of the tires are equal to the target rotation angle value; the rolling torque and the rolling directions are sent to the corresponding tires, the hub motors inside the tires are driven to continuously rotate forwards or backwards according to the corresponding speed. The problems that a traditional unmanned vehicle is complex in mechanical structure, poor in maneuverability, narrow in application range and the like are solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

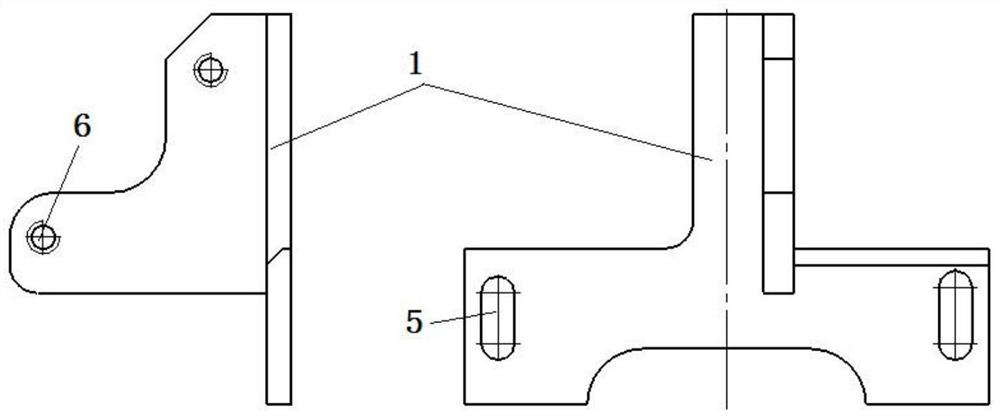

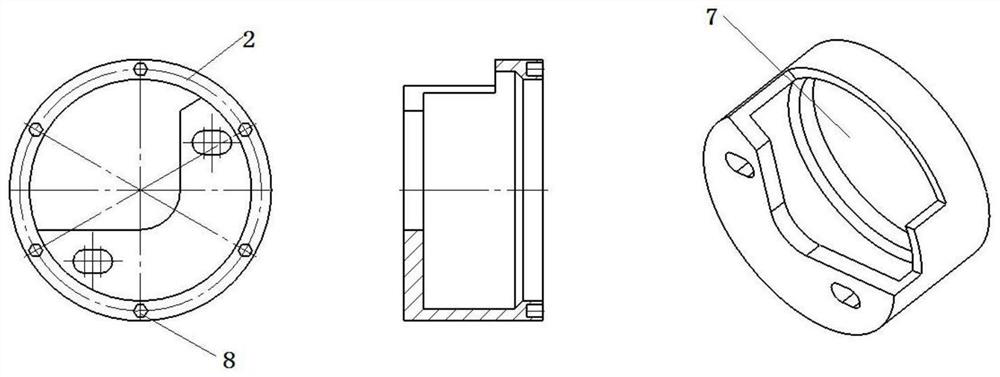

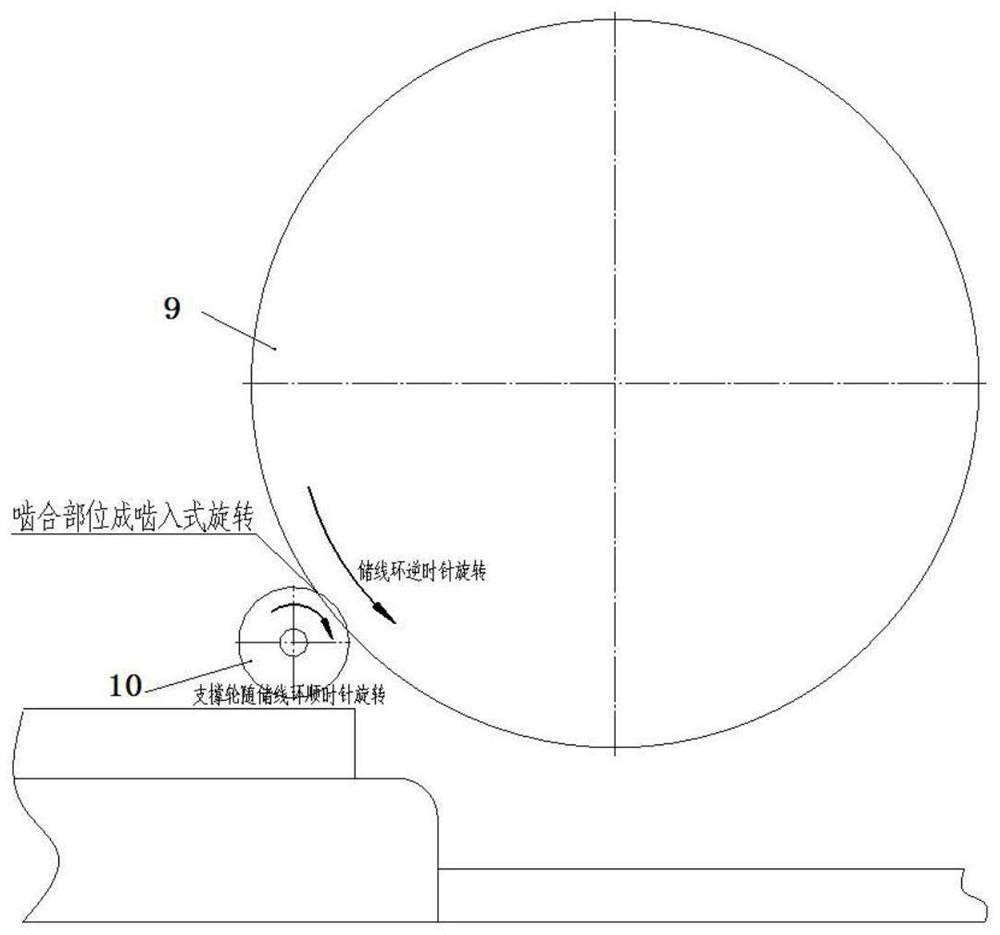

Semi-automatic annular winding machine protection device

The invention discloses a semi-automatic annular winding machine protection device which comprises a support, a protective cover, magnets and a baffle, the protective cover is fixed to the support, the protective cover half wraps a supporting wheel, the meshing position of the supporting wheel and a wire storage ring is located in a notch structure in the protective cover, the baffle is attracted to the front side of the protective cover through the multiple magnets, and the baffle is fixed to the support. The sealing part is used for sealing exposed parts of the supporting wheels; and the shield is made of polytetrafluoroethylene. According to the invention, through protection of the supporting wheel, an existing engaging-in type structure is converted into a single wire storage ring rotating structure, so that engaging-in injury is avoided. The protective cover is made of polytetrafluoroethylene materials, destructive damage to equipment is avoided, the overall structure is simple, and future maintenance is more convenient and faster.

Owner:DALIAN NORTH INSTR TRANSFORMER GROUP

Production technology and pole of post-tensioned reinforced concrete pole with large bending moment and high strength

ActiveCN103909574BIncrease bending momentHigh strengthShaping reinforcementsTowersReinforced concretePre stress

The invention relates to a production technology of a large bending moment and high strength post tensioning reinforced concrete electric pole and an electric pole, and mainly aims at providing the production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole and the electric pole produced by using the post tensioning production technology. The production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole includes the steps of 1, weaving a reinforcement cage, and confirming that taper degrees of all seamless steel tubes in the reinforcement cage relative to the axis of the reinforcement cage are equal; 2, hoisting the reinforcement cage into a base seat of an electric pole steel mold, pouring concrete sizing agents into the electric pole steel mold, closing the mold, lifting the mold off the base seat and placing the mold on a balance position after centrifugal shaping, performing mold releasing after three days of natural curing, and performing the natural curing for 21 days; 3, disposing a pre-stressed steel strand in the seamless steel tubes in penetration mode, anchoring one end of the pre-stressed steel strand, tensioning the other end of the pre-stressed steel strand, and locking up the tensioned end of the pre-stressed steel strand after design value is achieved. The production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole is used on the electric pole in an electric line.

Owner:STATE GRID CORP OF CHINA +3

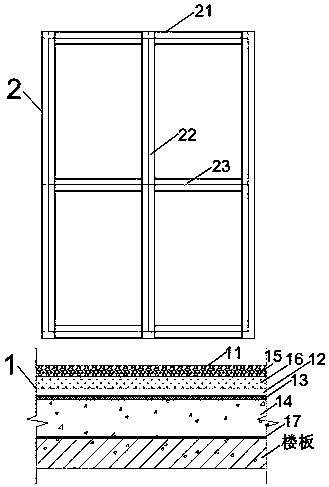

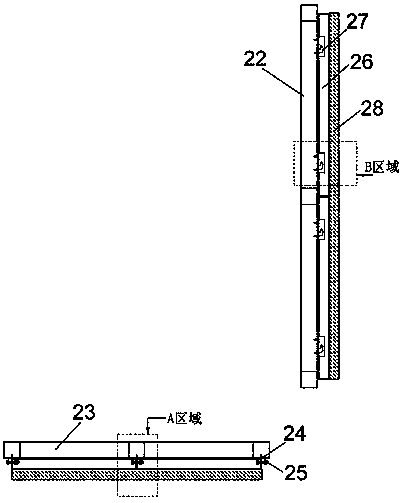

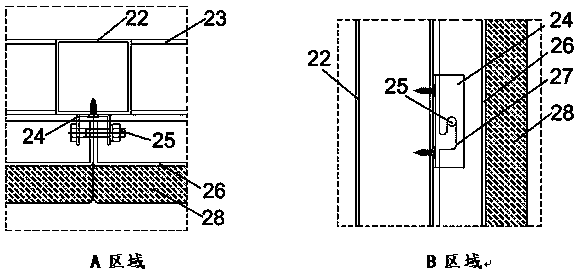

A production system for assembling sound-insulating and heat-insulating decorative materials

ActiveCN107268917BVersatileNovel ideaLamination ancillary operationsCovering/liningsSurface layerKeel

The invention provides a sound-insulation heat-insulation decorative system. The sound-insulation heat-insulation decorative system comprises a marble composite board paving structure (1) and a tight seam hanging type aluminum single board structure (2), wherein the marble composite board paving structure (1) comprises a marble composite board (11), a mastic layer (12), a mastic cushion layer (13) and a cement mortar layer (14) sequentially from top to bottom, wherein the marble composite board (11) is the composition of a marble surface layer (15) and a granite base layer (16); and the tight seam hanging type aluminum single board structure (2) comprises a keel base layer (21), a U-shaped hanging piece (24) and a aluminum single board (26), wherein the U-shaped hanging piece (24) is fixed to the keel base layer (21), two through holes are symmetrically formed in the two side walls of the U-shaped hanging piece (24), and bolts (25) are fixed to the U-shaped hanging piece (24); and the aluminum single board (26) is hanged on the bolts (25) through L-shaped hanging groove (27) which is formed in an edge-folding mode, and the surface of the aluminum single board (26) is compounded with a aluminum honeycomb board (28).

Owner:SHENZHEN BUILDING DECORATION (GRP) CO LTD

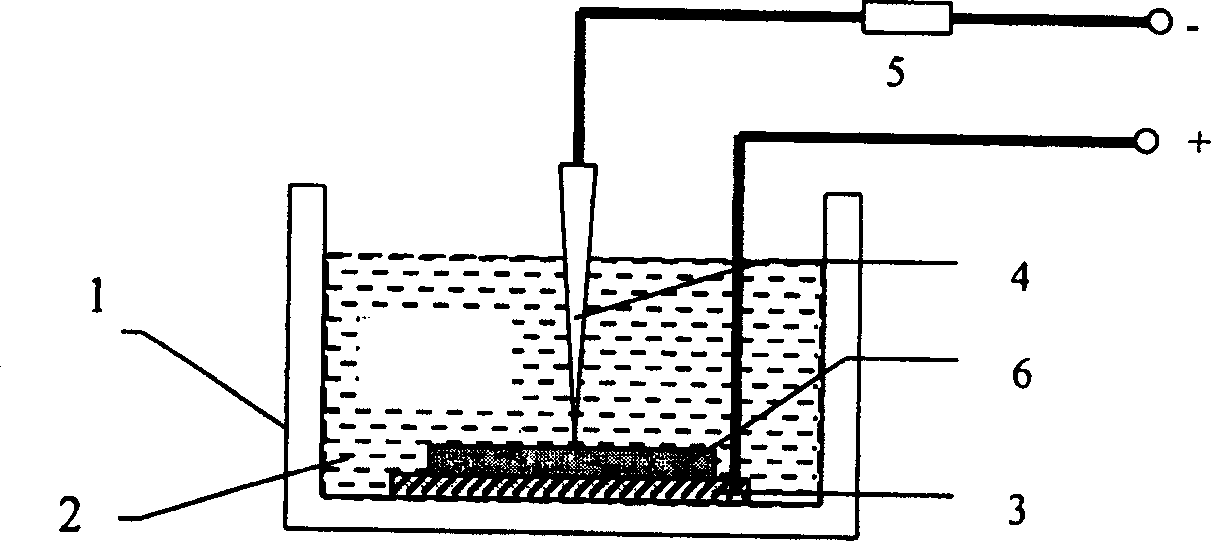

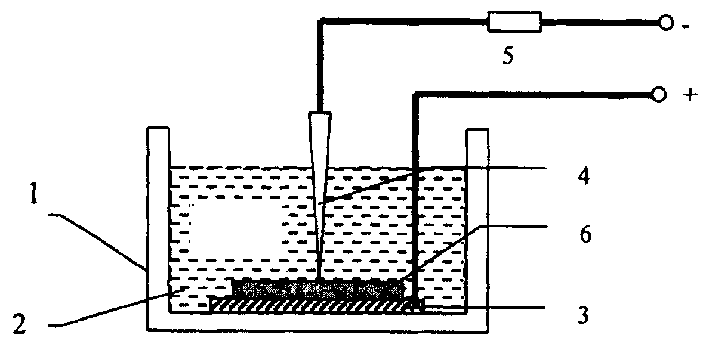

Electrochemical glass and silicon chip perforator

InactiveCN1191919CNo destructive damageFast perforationMetal working apparatusElectrolysisCurrent limiting

The electrochemical glass and silicon chip perforator includes electrolyzer with alkali solution held, graphite electrode or nickel electrode connected to power source negative pole and perforating probe of tungsten metal connected to power source positive pole via a current limiting resistor. The glass and silicon chip is set horizontally on the graphite electrode or the nickel electrode, and the power soure provides pulsed DC voltage of 40-100 V. The present invention has the advantages of fast perforating speed, simple structure, easy operation and carrying about, and no damage to the surface of the glass and silicon chip.

Owner:HARBIN INST OF TECH

a split nut

Owner:SHANGHAI AEROSPACE SYST ENG INST

Method for detecting stability of battery SEI film

PendingCN113945853AAccurately understand the situationNo destructive damageElectrical testingProcess engineeringBattery cell

The invention belongs to the technical field of battery detection, and particularly relates to a method for detecting the stability of a battery SEI film, the method comprises the following steps: S1, charging a plurality of batteries at constant current and constant voltage respectively until the current reaches a preset cut-off current; s2, respectively discharging the plurality of batteries until the voltage reaches the SEI film decomposition critical voltage; and S3, heating and storing the plurality of batteries, and respectively recording the storage time of the batteries from the beginning of storage to the gas generation of the batteries. According to the method for detecting the stability of the battery SEI film, the stability of the battery can be evaluated on the premise that a battery cell is not damaged, the evaluation operation is simple, and the accuracy is high.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Roots vacuum pump

ActiveCN103104489BReduce volumeExtended maintenance cycleSealing arrangement for pumpsRotary piston pumpsDrive motorEngineering

The invention relates to the technical field of vacuum pumps, and in particular relates to a roots vacuum pump. The vacuum pump comprises a motor, front and back bearing cavities, a roots cavity and a gear cavity, wherein the front and back bearing cavities are located at the both sides of the roots cavity, and the gear cavity is connected with the back bearing cavity; the roots cavity is provided with an air inlet and an air outlet and is internally provided with a driving rotor shaft and a driven rotor shaft; the driving rotor shaft and the driven rotor shaft are respectively and correspondingly provided with a roots driving rotor and a roots driven rotor; one end of the driving rotor shaft is connected with the motor, and the other end of the driving rotor shaft is provided with a driving gear; one end of the driven motor shaft is provided with a driven gear which is in transmission connection with the driving gear and accommodated in a gear box; and the front bearing cavity and the back bearing cavity are internally provided with bearings and bearing support rings which are sleeved and fixed at the both ends of the driving rotor shaft and the driven rotor shaft. The roots vacuum pump has the advantages of being small in size, high in pumping speed, energy-saving, space-saving, and applicable to IC equipment.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Vacuum pump

InactiveCN109578276AReduce volumeExtended maintenance cycleRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsMotor vibrationEngineering

The invention discloses a vacuum pump. Bearing cavities and gear cavities are formed in the two sides of a roots cavity. Motor cavities are connected with the bearing cavities. Shaft sealing devices are arranged between the bearing cavities and the roots cavity as well as between the roots cavity and the gear cavities correspondingly. The shaft sealing devices are arranged on a driving rotor shaftand a driven rotor shaft. Motors are rotor shaft shield variable frequency motors. The bearing cavities and the gear cavities are each provided with a lubricating device. Oil-gas separation devices are arranged in the bearing cavities in the two ends. The vacuum pump is small in size and high in pumping speed, and energy and space are saved. Variable frequency speed control is conducted, and service life is long. Teflon double-lip shaft seals are adopted, and the maintenance period of the pump is prolonged. The oil-gas separation devices are adopted, and the leakage problem of oil vapor to avacuum chamber is solved. The structure that motor rotors and a pump shaft are integrated, and motor stators are outside an oil chamber is adopted, motor dynamic sealing and motor vibration problems are solved, a heat expansion assembly structure is adopted for gear assembly, and the unbalance degree and vibration of a motion part are reduced.

Owner:石静轩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com