Production technology and pole of post-tensioned reinforced concrete pole with large bending moment and high strength

A technology of reinforced concrete and production technology, applied in the field of electric poles, can solve the problems of shortage of land resources, lack of reach, land occupation, etc., achieve the best safety and reliability, save steel, and have the effect of large bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

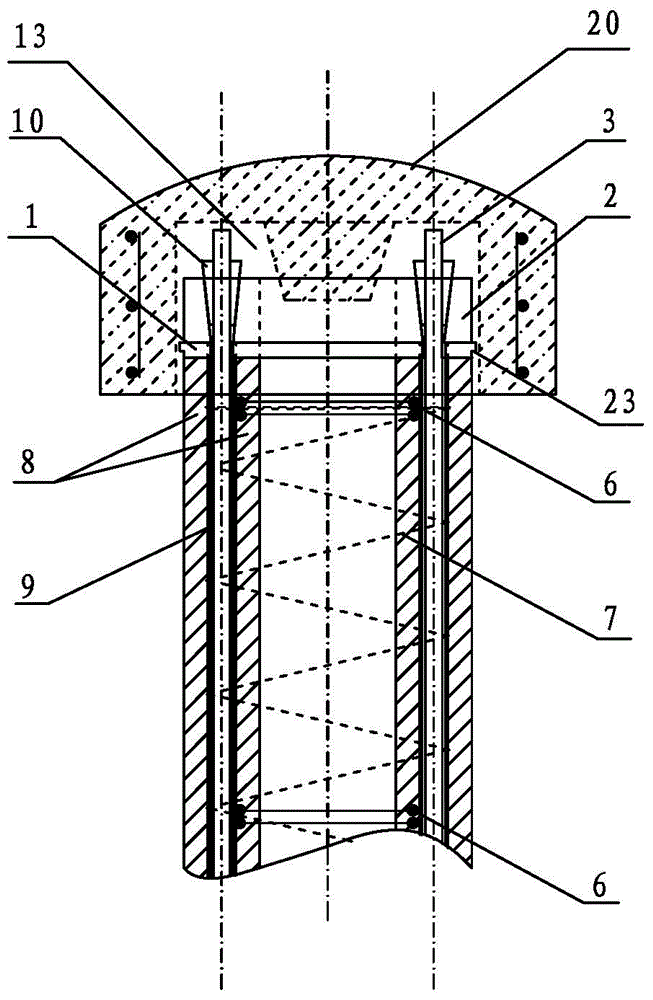

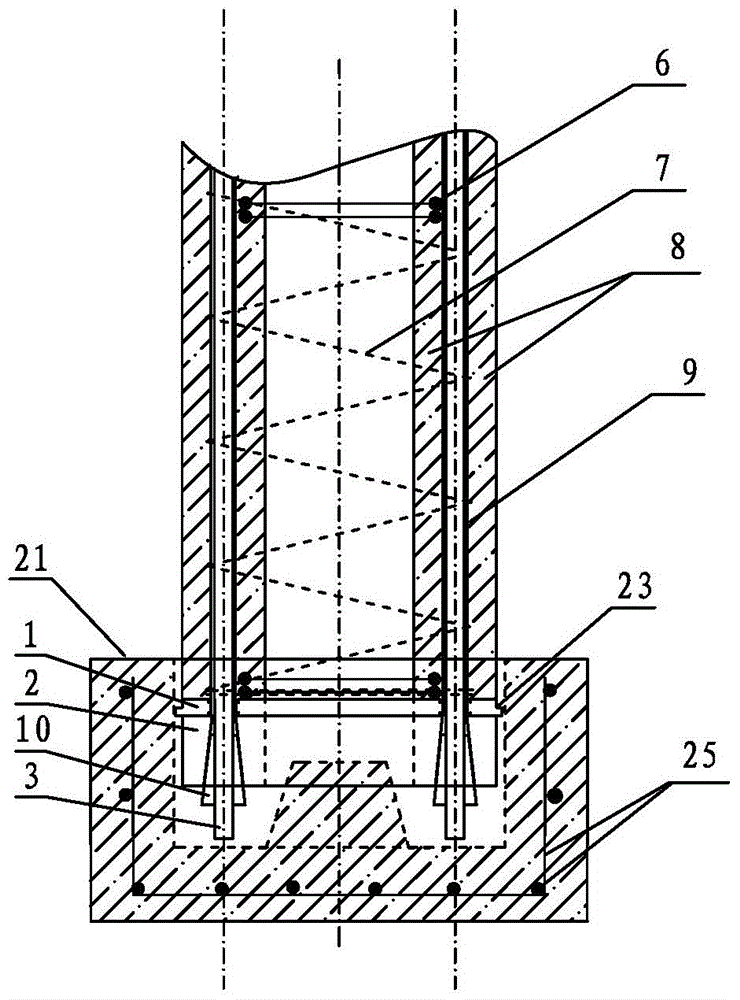

[0050] Embodiment 1: as Figure 1-Figure 7 As shown, the process of this embodiment is mainly used to produce the whole single rod, and the specific steps are as follows,

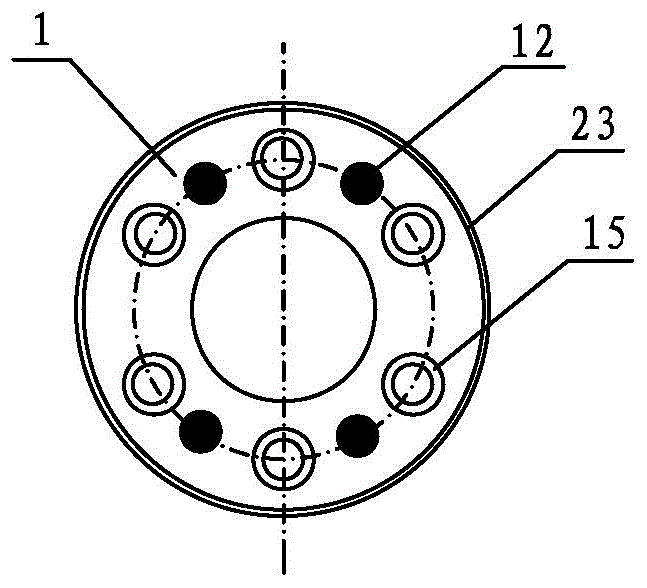

[0051] 1.1. Set two coaxially arranged disc-shaped prestressed anchor steel plates 1 at both ends according to the length of the proposed pole, that is, the distance between the two prestressed anchor steel plates 1 is the length of the proposed pole; in this example The medium prestressed anchoring steel plate 1 is made of No. 45 steel, and is made through quenching and tempering heat treatment, and its thickness is 12-20 mm, which is determined according to the tension value. The outer side of the prestressed anchoring steel plate 1 is processed with a shoulder clip 23 whose thickness is half of the thickness of the prestressed anchoring steel plate 1. After the electric pole is manufactured, the shoulder clip 23 protrudes from the pole body; Holes 15 (the present embodiment is six), each group of holes ...

Embodiment 2

[0062] Embodiment 2: as Figure 1-Figure 6 As shown, the process of this embodiment is mainly used to produce ∮270mm×15m electric poles, which are spliced in the form of upper section 6m and lower section 9m. The specific steps are as follows:

[0063] 1.1. Set two coaxially arranged disc-shaped prestressed anchor steel plates 1 at both ends according to the length of the upper section of the proposed pole, that is, the distance between the two prestressed anchor steel plates 1 is the length of the upper section of the proposed pole ; In this example, the prestressed anchor steel plate 1 is made of No. 45 steel, which is made by quenching and tempering heat treatment, and its thickness is 15mm. The outer side of the prestressed anchoring steel plate 1 is processed with a shoulder clip 23 whose thickness is half of the thickness of the prestressed anchoring steel plate 1. After the electric pole is manufactured, the shoulder clip 23 protrudes from the pole body; the prestress...

Embodiment 3

[0080] Embodiment 3: as Figure 1-Figure 6 As shown, the process of this embodiment is mainly used to produce ∮270mm×18m electric poles, which are spliced in the form of an upper section of 9m and a lower section of 9m. The specific production process is basically the same as that of Example 2, the difference lies in the reinforcement of each pole different.

[0081] For the 9m pole section in the upper section, the reinforcement is as follows Figure 14 As shown, eight seamless steel pipes 9 are arranged in the reinforcement cage, that is, eight prestressed steel strands 3 are arranged as prestressed tendons (the tension value is 872.59KN), and eight non-prestressed main reinforcements 4 are arranged at the same time, which are connected with the seamless The steel pipes 9 are arranged alternately, and their length is 9m. There are four short bars 5, two of which are 6.5m in length as the first-level short bars, and the remaining two are 4m in length as the second-level sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com