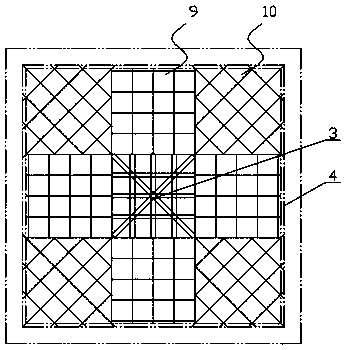

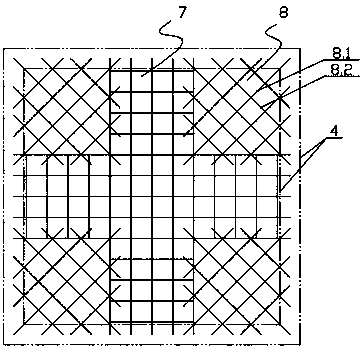

A rice-shaped reinforced structure of a floor slab

A rice-shaped, floor slab technology, applied to structural elements, building components, building structures, etc., can solve the problems of small thickness in the middle of the floor slab, excess reinforcement, cracks, etc., to eliminate cracks, increase bearing capacity, and improve engineering quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

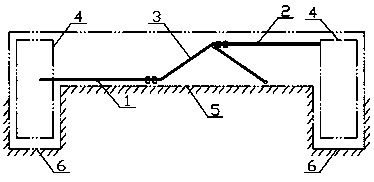

[0026] In order to make the technical scheme and technical effect of the present invention more obvious and easy to understand, the following will be described in detail in conjunction with the accompanying drawings.

[0027] The present invention combines experimental and practical experience, according to the different forces of different locations of the floor, configures different steel bars, that is, the middle part is strengthened, the four corners are reduced, and the role of the upper layer is played. The performance of the material is used to save materials; at the same time, the invention can achieve factory prefabrication processing (welding) into a net, which reduces the binding amount of the on-site reinforcement personnel, not only reduces labor, but also improves construction efficiency and engineering quality. Improve the positioning reliability of the beam cover reinforcement (beam middle reinforcement mesh), and ensure that the beam cover reinforcement is in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com