Vacuum motor

A technology for vacuum motors and motor chambers, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc. It can solve the problems of not being used in IC equipment, high power consumption, and low ultimate vacuum, so as to achieve long service life and energy saving and space, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

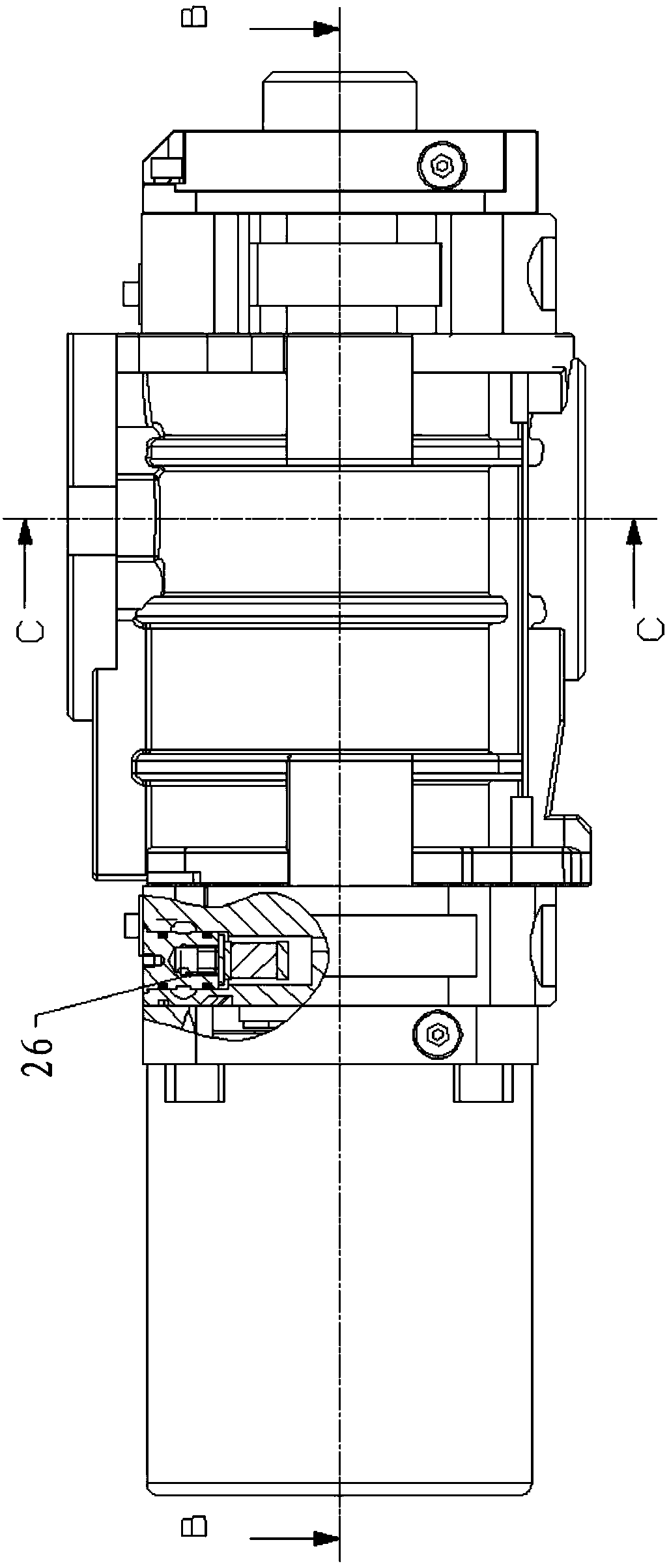

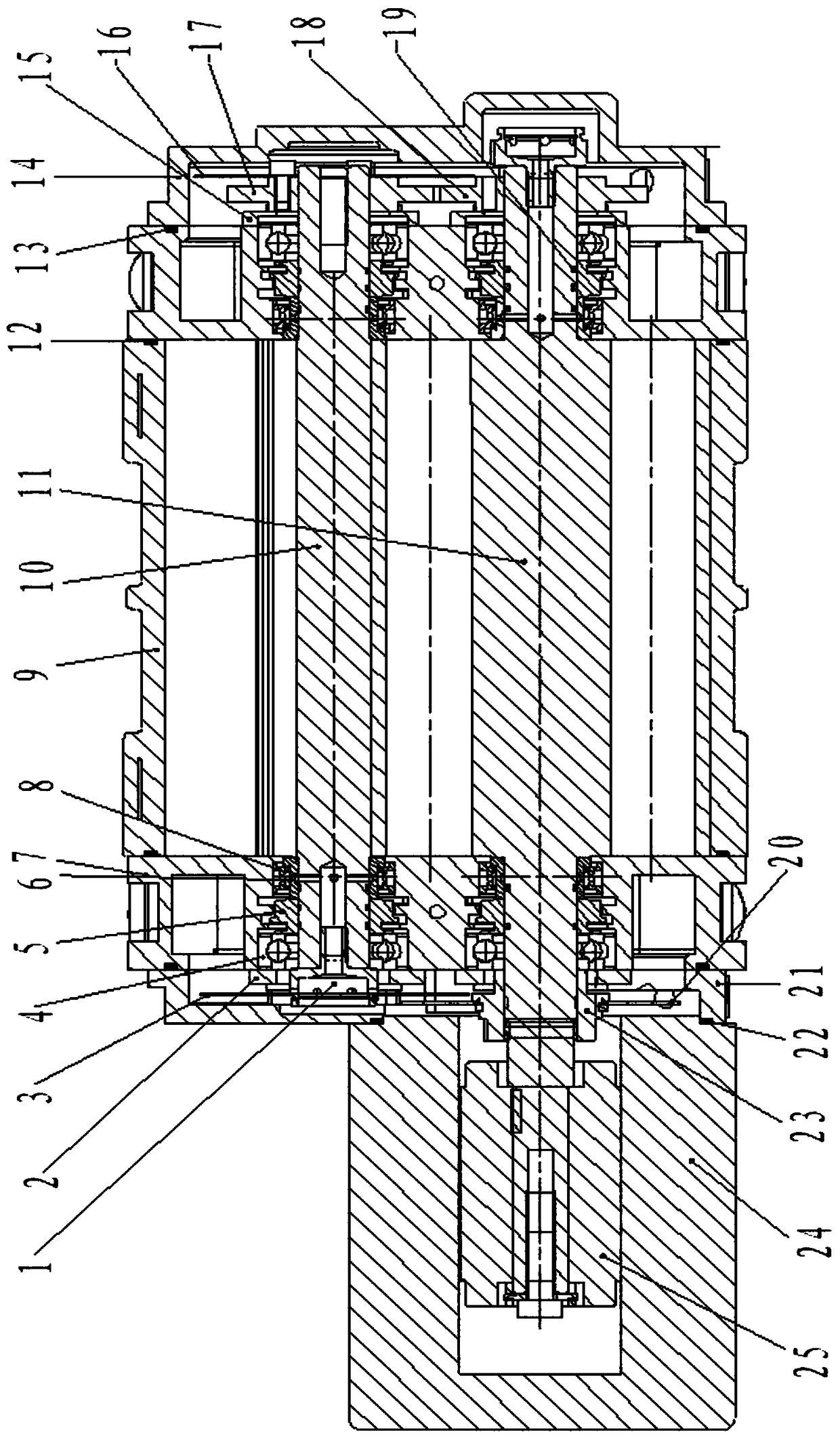

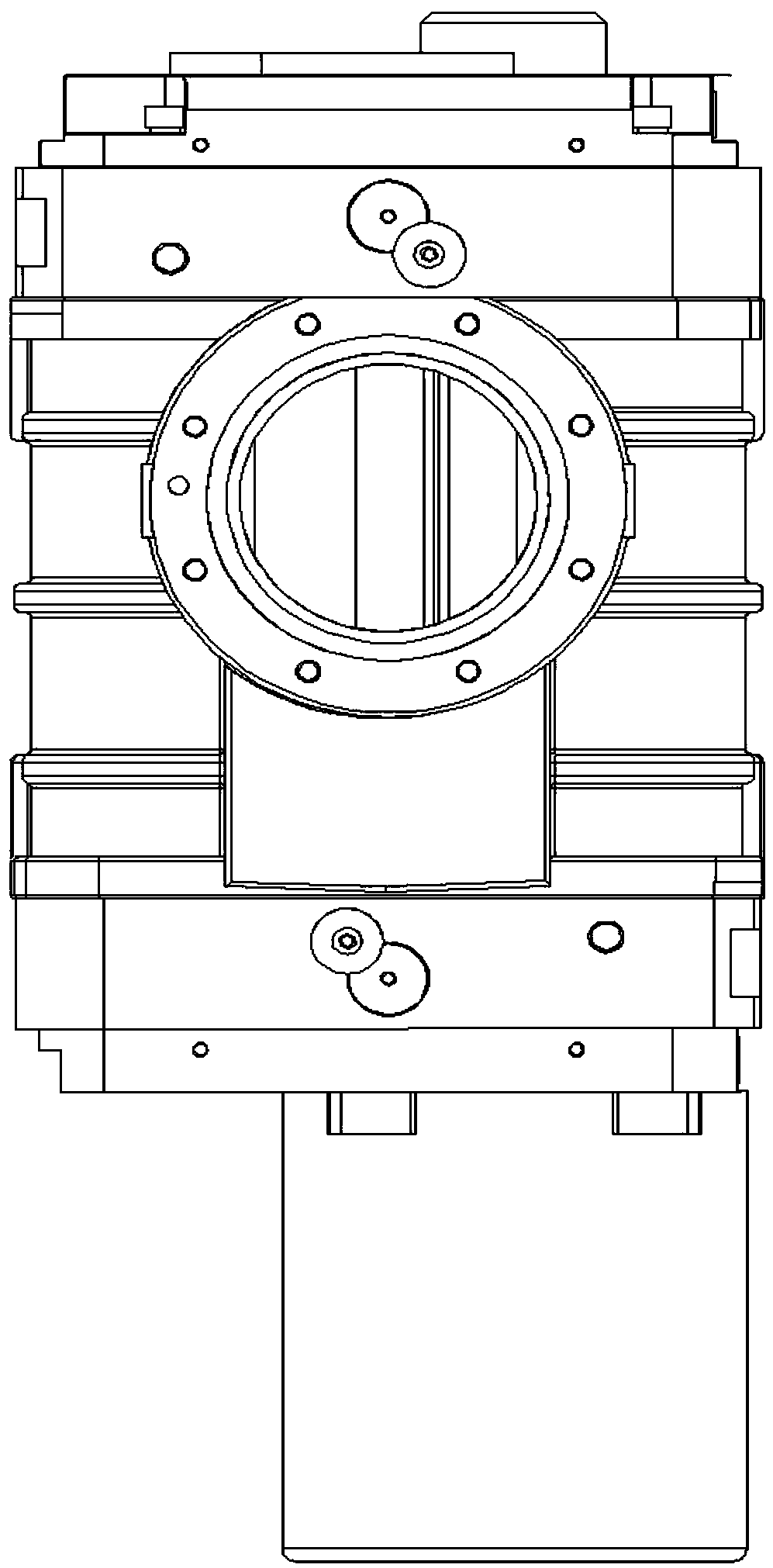

[0016] like Figure 1-Figure 4 As shown, the present invention includes a shaft end fixing nut 1, a motor side bearing gland 2, a motor side driven oil slinger 3, a bearing 4, a bearing support ring 5, a shaft seal ring 6, a bearing cavity 7, and a double-lip shaft seal 8 , Roots cavity 9, driven rotor shaft 10, driving rotor shaft 11, sealing ring 12, sealing ring 13, gear cavity 14, gear side bearing gland 15, gear side driven oil thrower 16, driven gear 17 , driving gear 18, rectangular sealing ring 19, active oil throwing pan 20, motor cavity 21, motor sealing ring 22, driving shaft sleeve 23, rotor shaft shielding variable frequency motor 24, motor rotor 25, oil and gas separation device 26, roots cavity 9. The bearing cavity 7 and the gear cavity 14 are installed at both ends. The bearing 4, the bearing support ring 5, and the double-lip shaft seal 8 are installed in the bearing cavity 7 bearing seat and the gear cavity bearing cavity bearing seat in turn, and the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com