Electrochemical glass and silicon chip perforator

A glass sheet and electrochemical technology, applied in metal processing and other directions, can solve the problems of glass or silicon sheet damage, unfavorable batch processing, and rising costs, and achieve the effects of fast perforation speed, no destructive damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

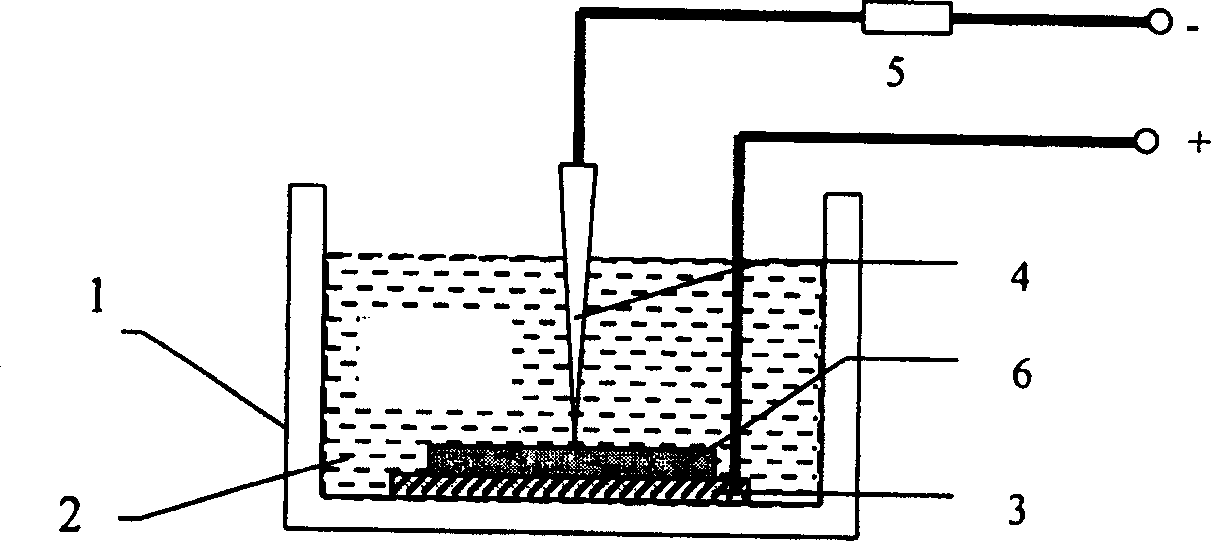

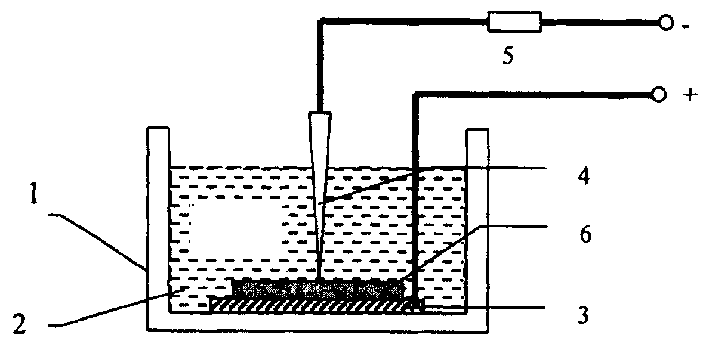

[0010] Embodiment 1, the composition of the device for perforating glass sheets and silicon sheets by the electrochemical method includes an electrolytic cell 1, in which a sodium bicarbonate solution 2 with a concentration of 20% is installed, and the negative electrode 3 of the electrolytic cell is a graphite electrode or a nickel electrode, The perforation probe 4 is used as the anode of the electrolytic cell. The material of the perforation probe is metal tungsten. The current-limiting resistor 5 is connected in series on the perforation probe. A pulsating DC voltage is applied between the perforation probe and the negative electrode. The voltage range is 40-100V.

Embodiment 2

[0011] Embodiment 2, the composition of the device for perforating glass sheets and silicon sheets by the electrochemical method includes an electrolytic cell 1, in which a potassium hydroxide solution 2 with a concentration of 40% is installed, and the negative electrode 3 of the electrolytic cell is a graphite electrode or a nickel electrode, The perforation probe 4 is used as the anode of the electrolytic cell. The material of the perforation probe is metal tungsten. The current-limiting resistor 5 is connected in series on the perforation probe. A pulsating DC voltage is applied between the perforation probe and the negative electrode. The voltage range is 40-100V.

[0012] During processing, according to the connection structure shown in the accompanying drawings, after the connection is completed, the probe is placed at the place where the glass sheet or the silicon sheet 6 needs to be perforated. Processing can be carried out by applying a pulsating DC voltage in the ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com