Patents

Literature

40results about How to "Won't go out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

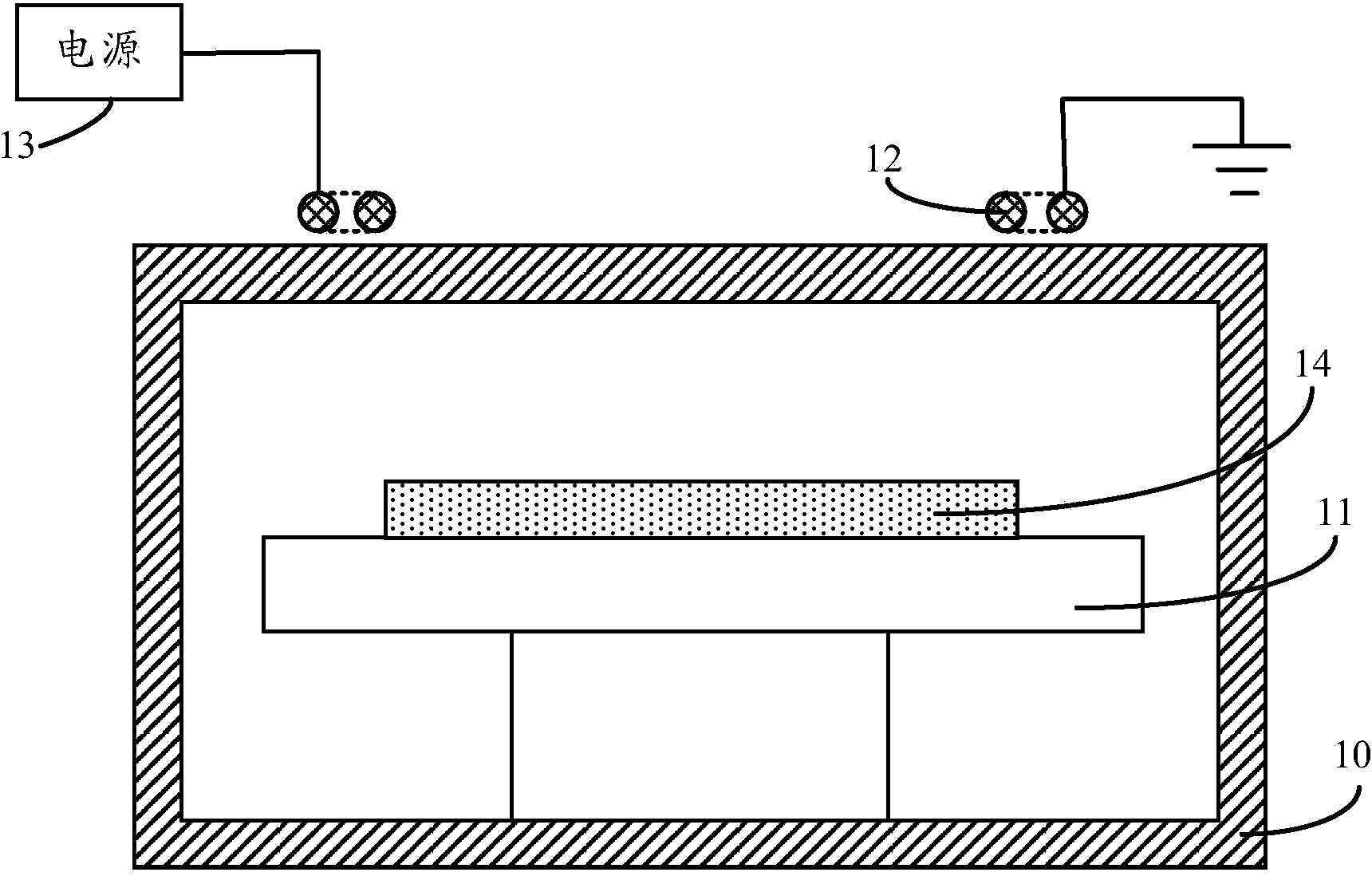

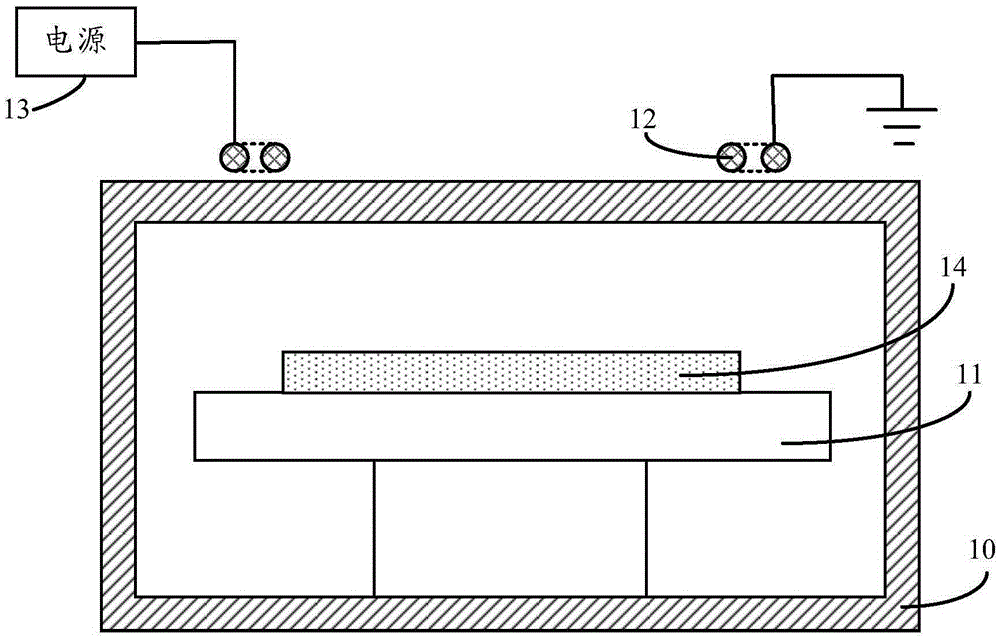

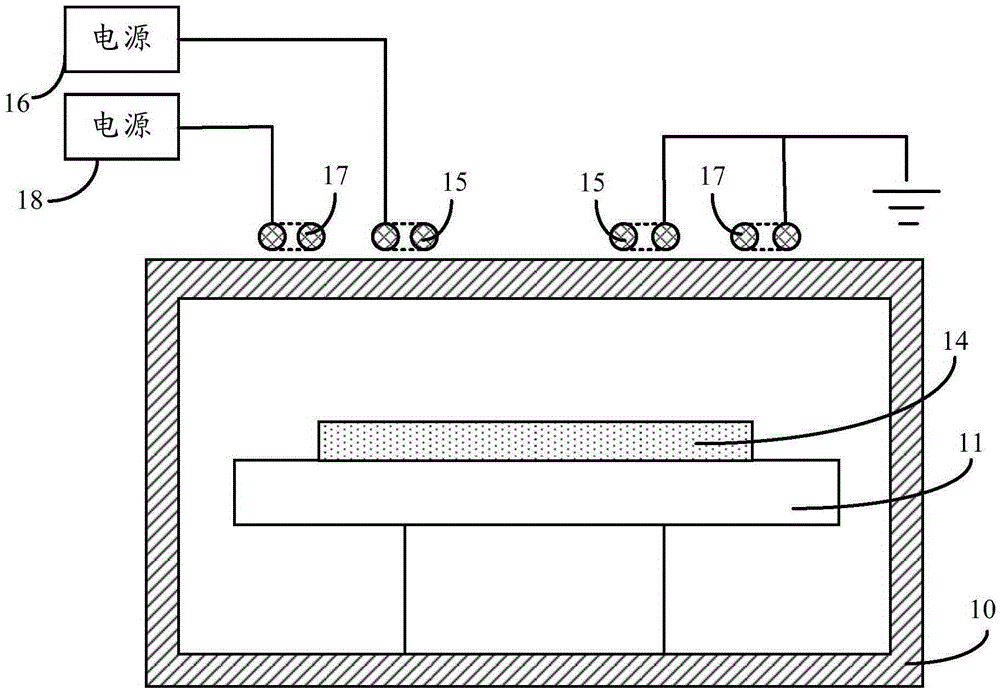

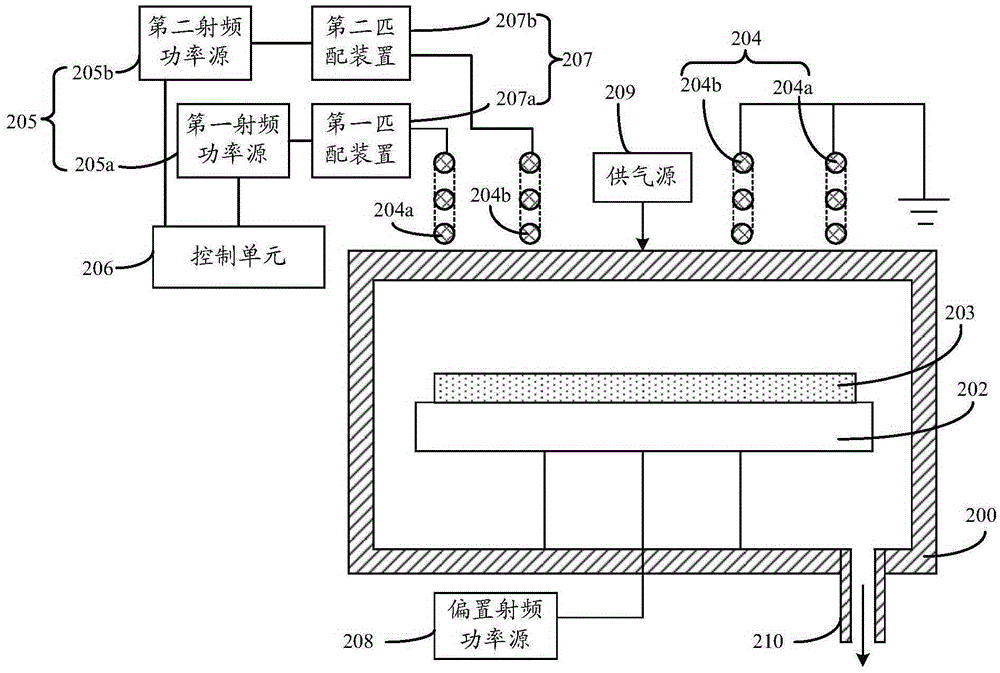

Plasma treatment device and plasma treatment method

ActiveCN103476196AUniform density distributionStable density distributionPlasma techniqueRadio frequency signalTherapeutic effect

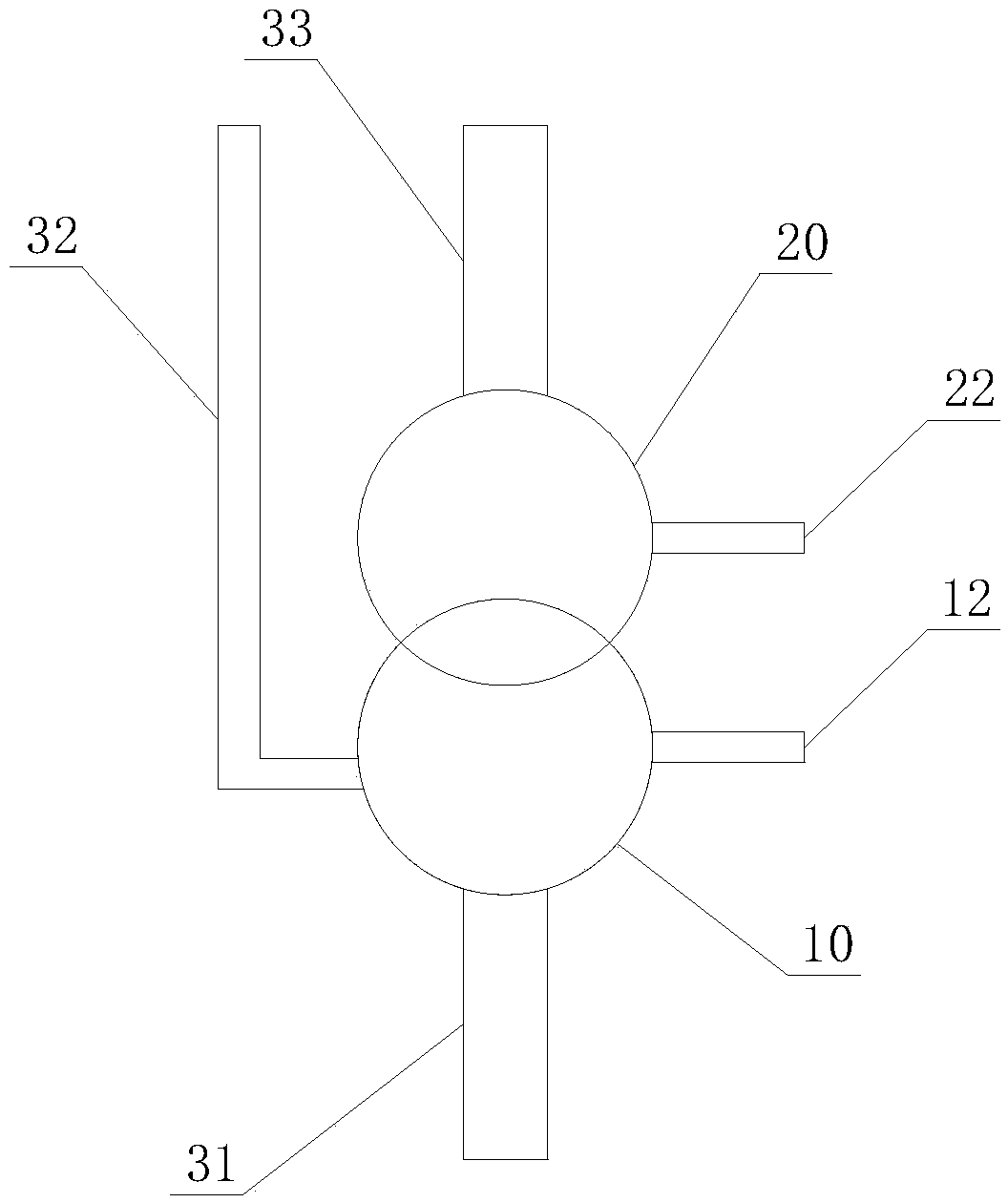

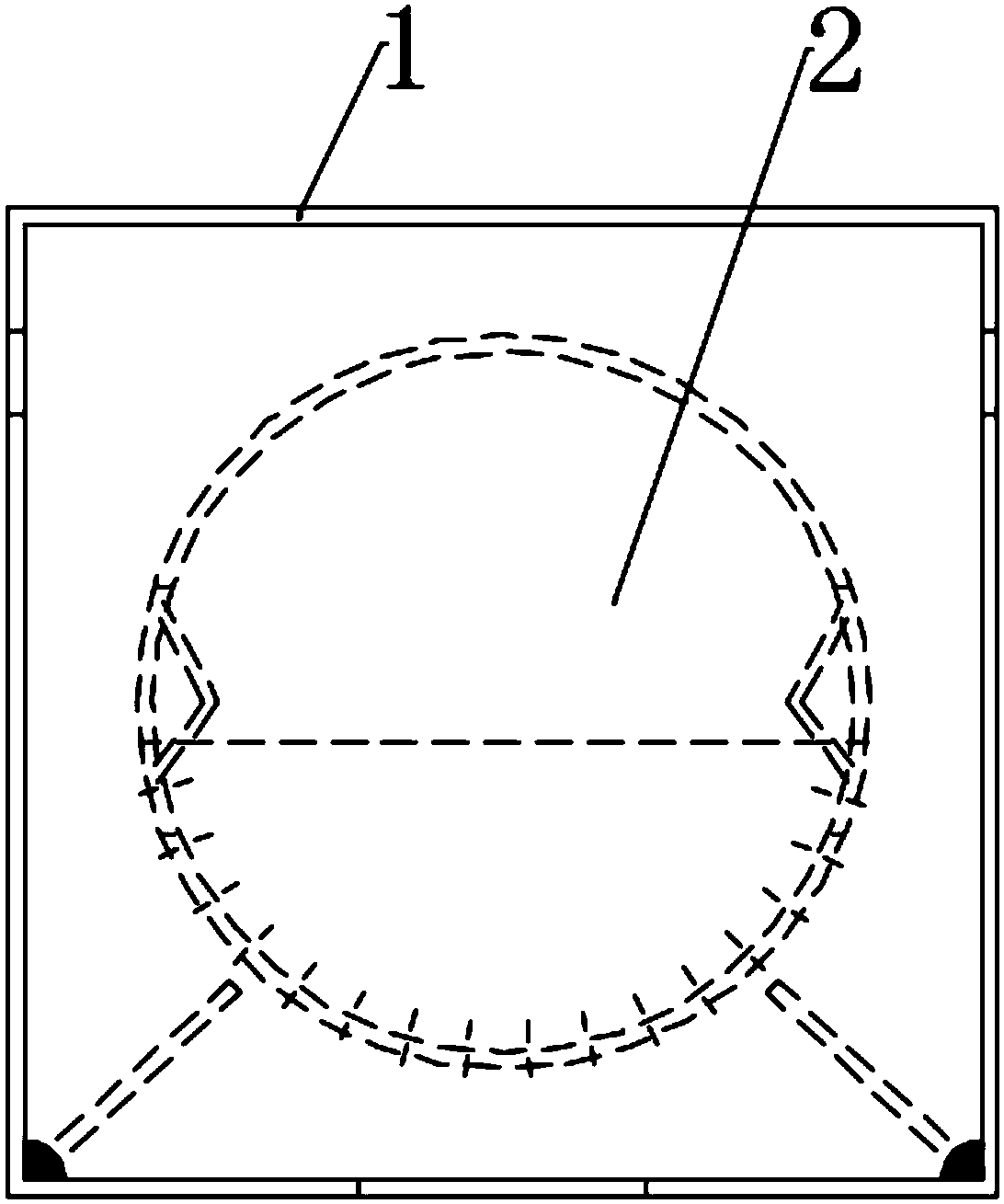

Provided are a plasma treatment device and a plasma treatment method. The plasma treatment device comprises a plurality of concentrically-distributed inductive coupling coils arranged at the top of a reaction cavity and used for plasma treatment of gas in the reaction cavity, a plurality of radio-frequency power sources for respectively providing impulse type radio-frequency signals for the inductive coupling coils, and a control unit connected to the first radio-frequency power source and the second radio-frequency power source at least and used for controlling the impulse type radio-frequency signals formed by shifting of radio-frequency power output by the first radio-frequency power source and the second radio-frequency power source between the high-power output and the low-power output, wherein the inductive coupling coils are opposite to a wafer supporting table, the low-power output is larger than zero, and the control unit enables the impulse type radio-frequency power output by the first radio-frequency power source and the second radio-frequency power source to be independent and adjustable. The plasma distribution in the plasma treatment device is even, and the plasma treatment effect is good.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

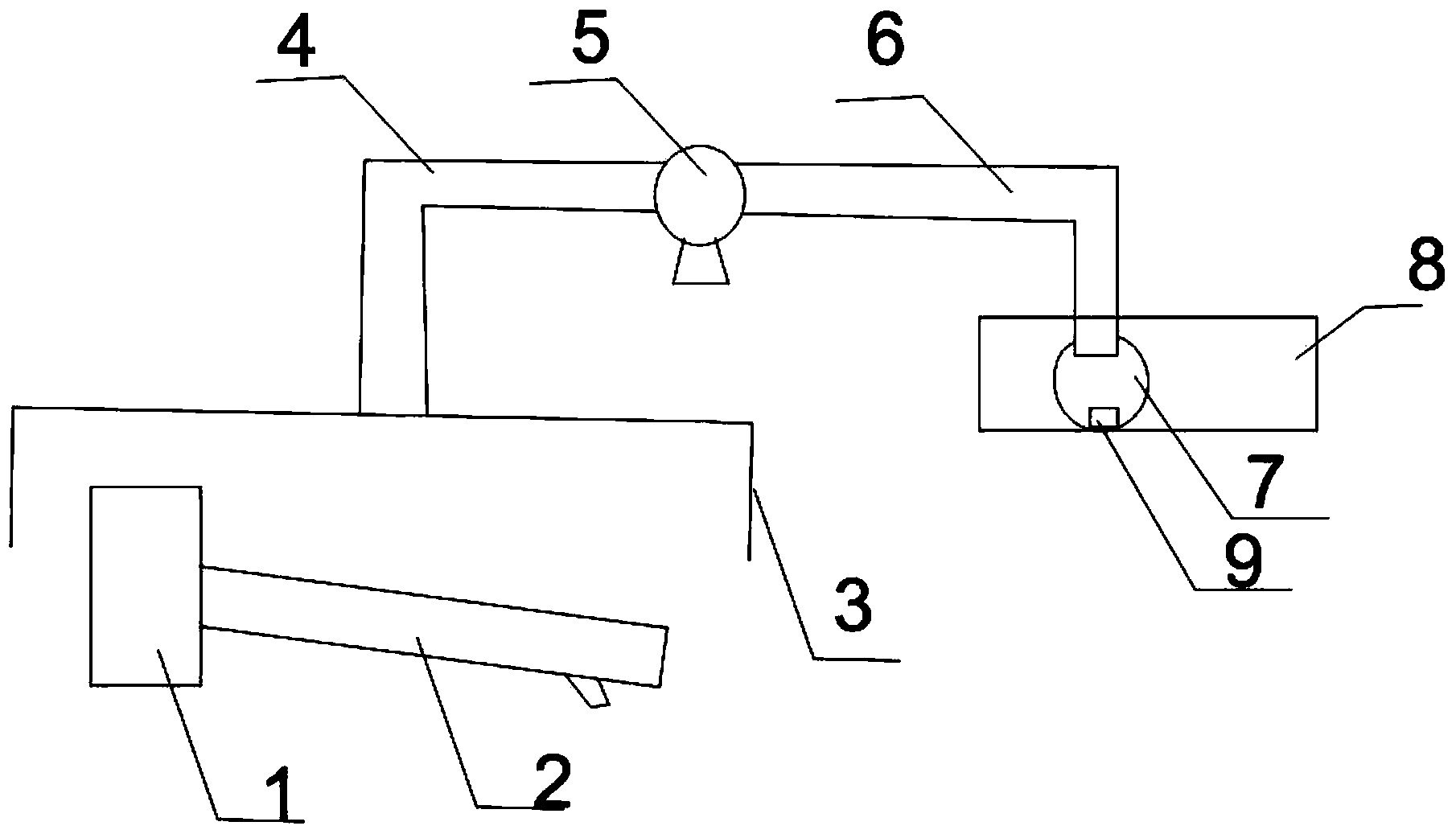

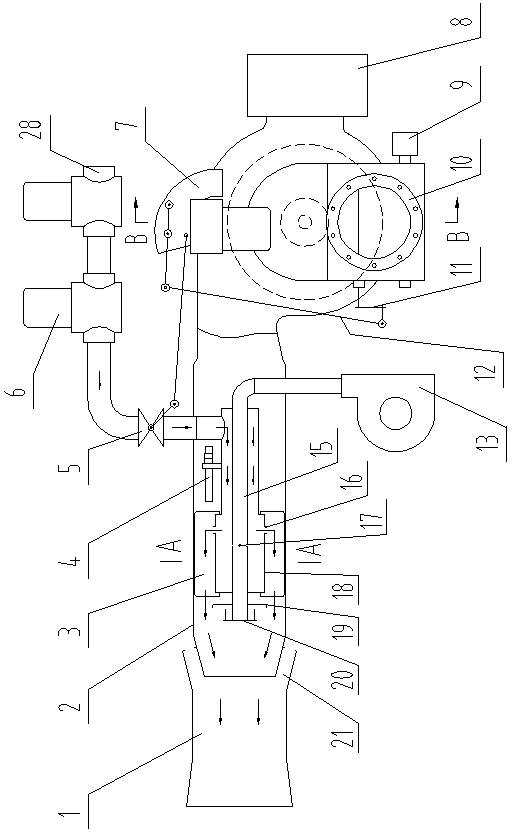

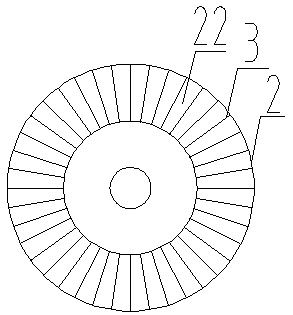

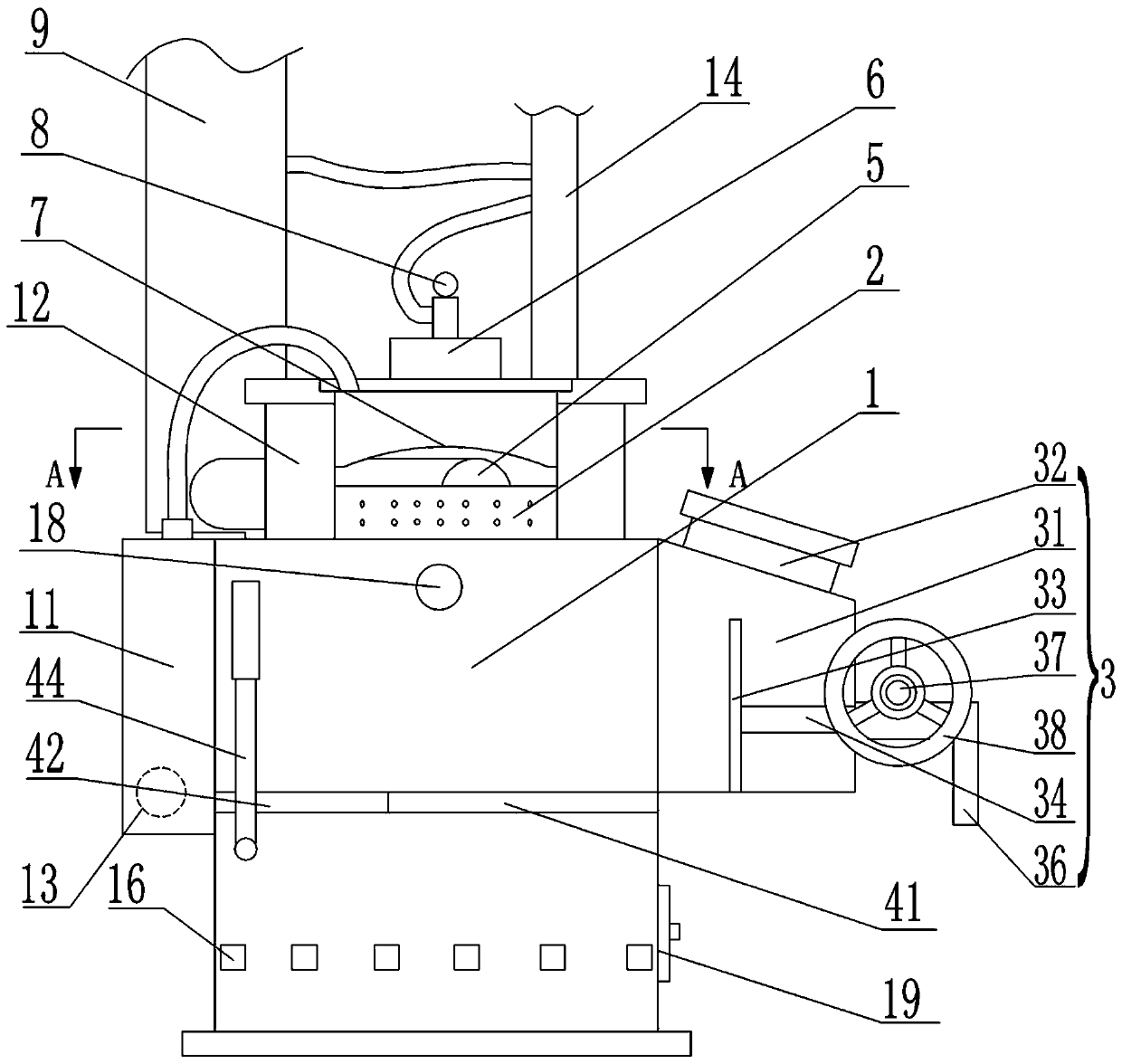

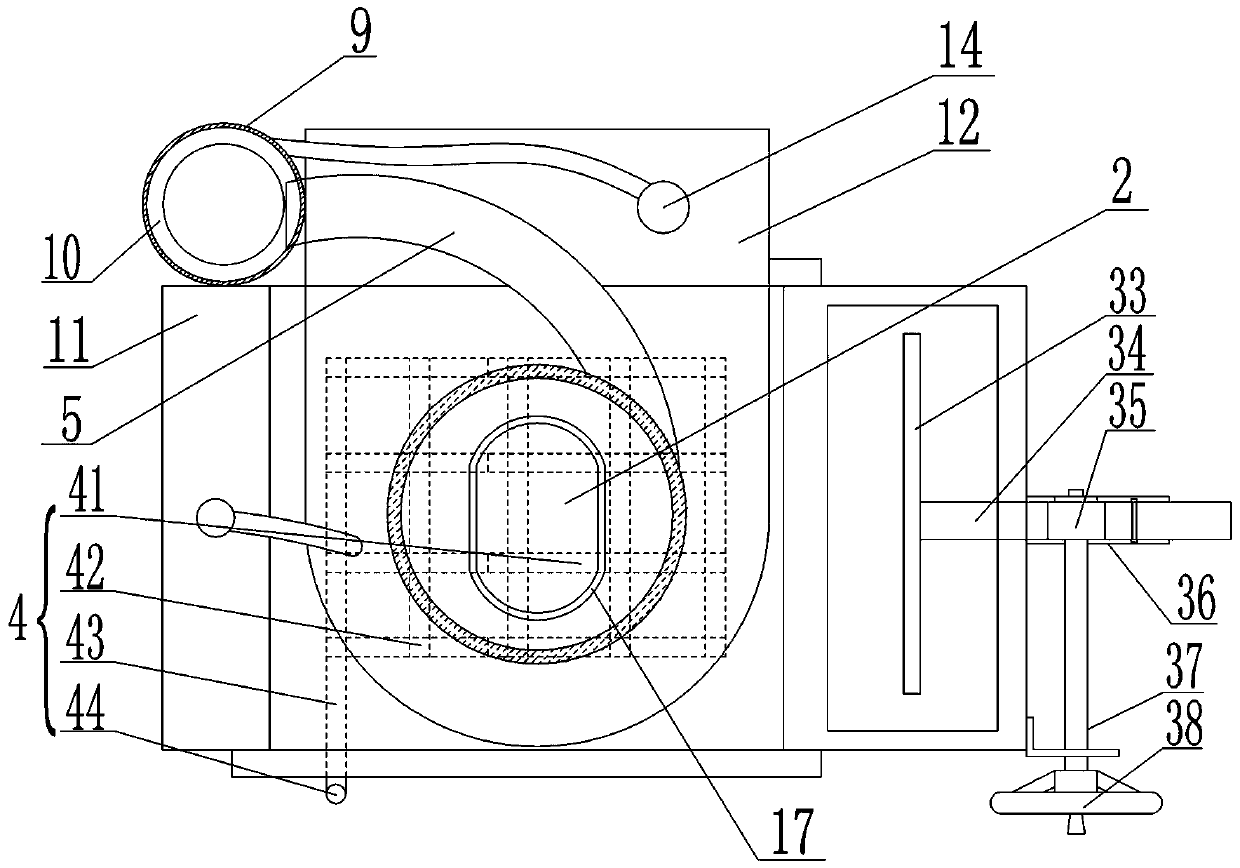

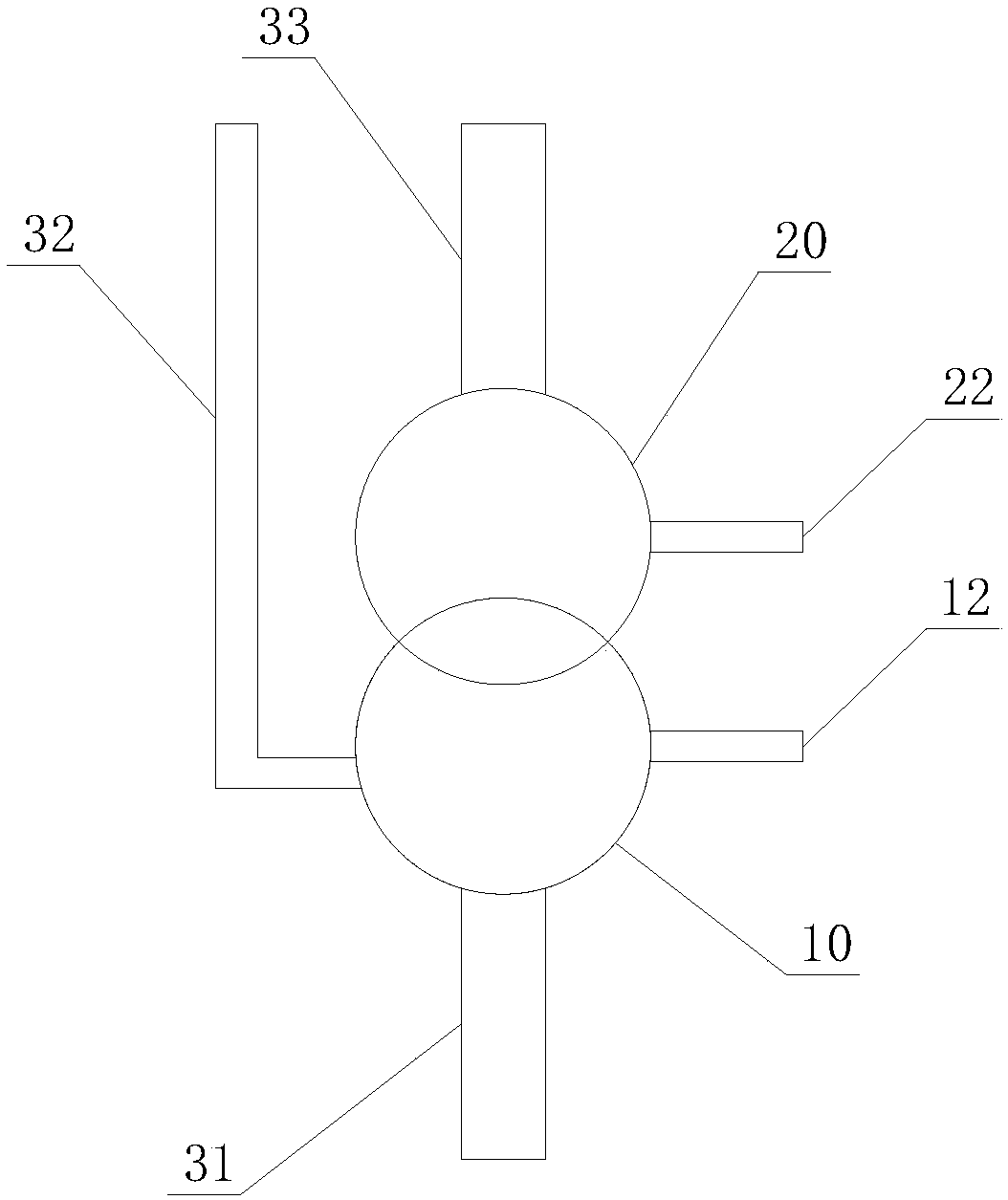

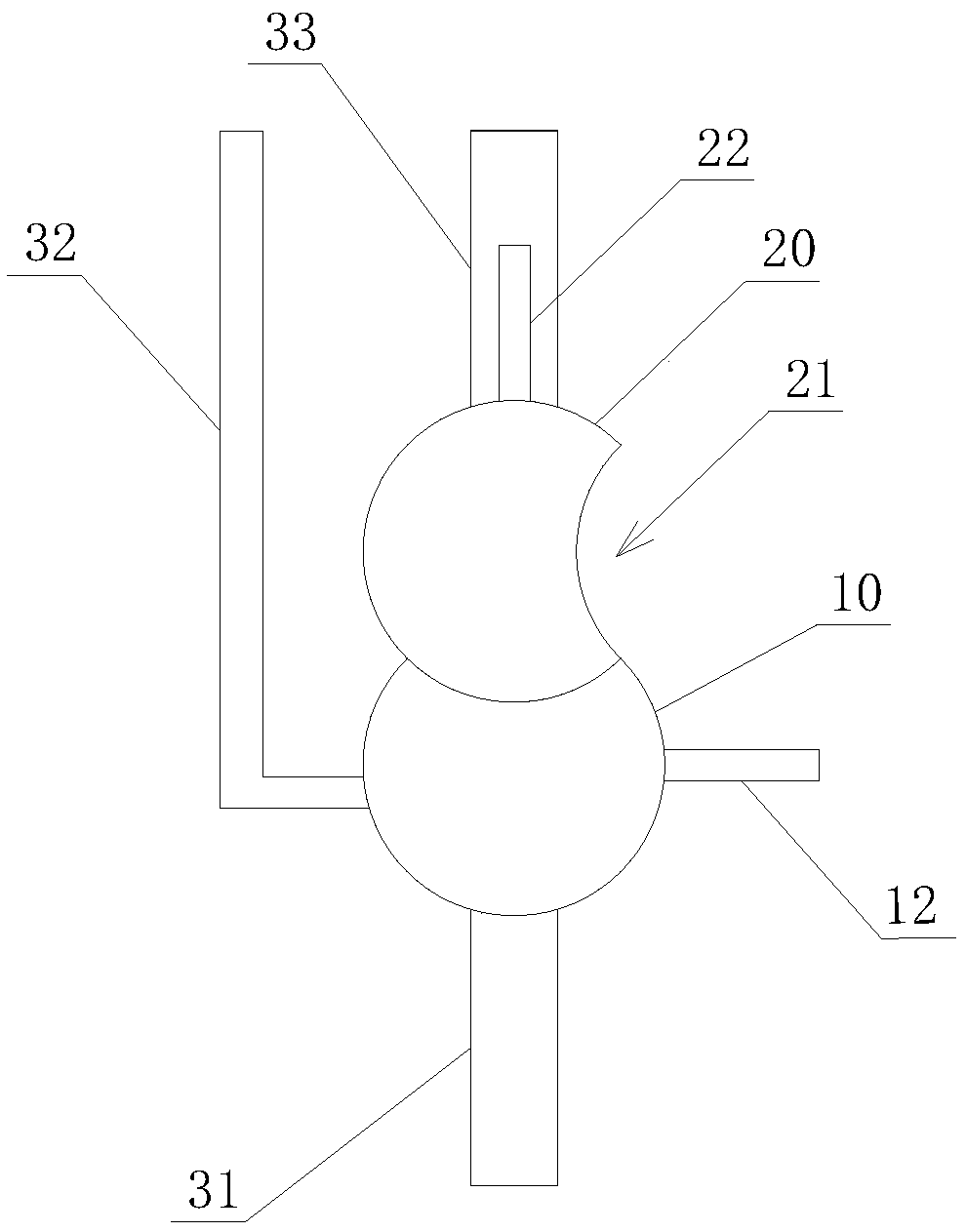

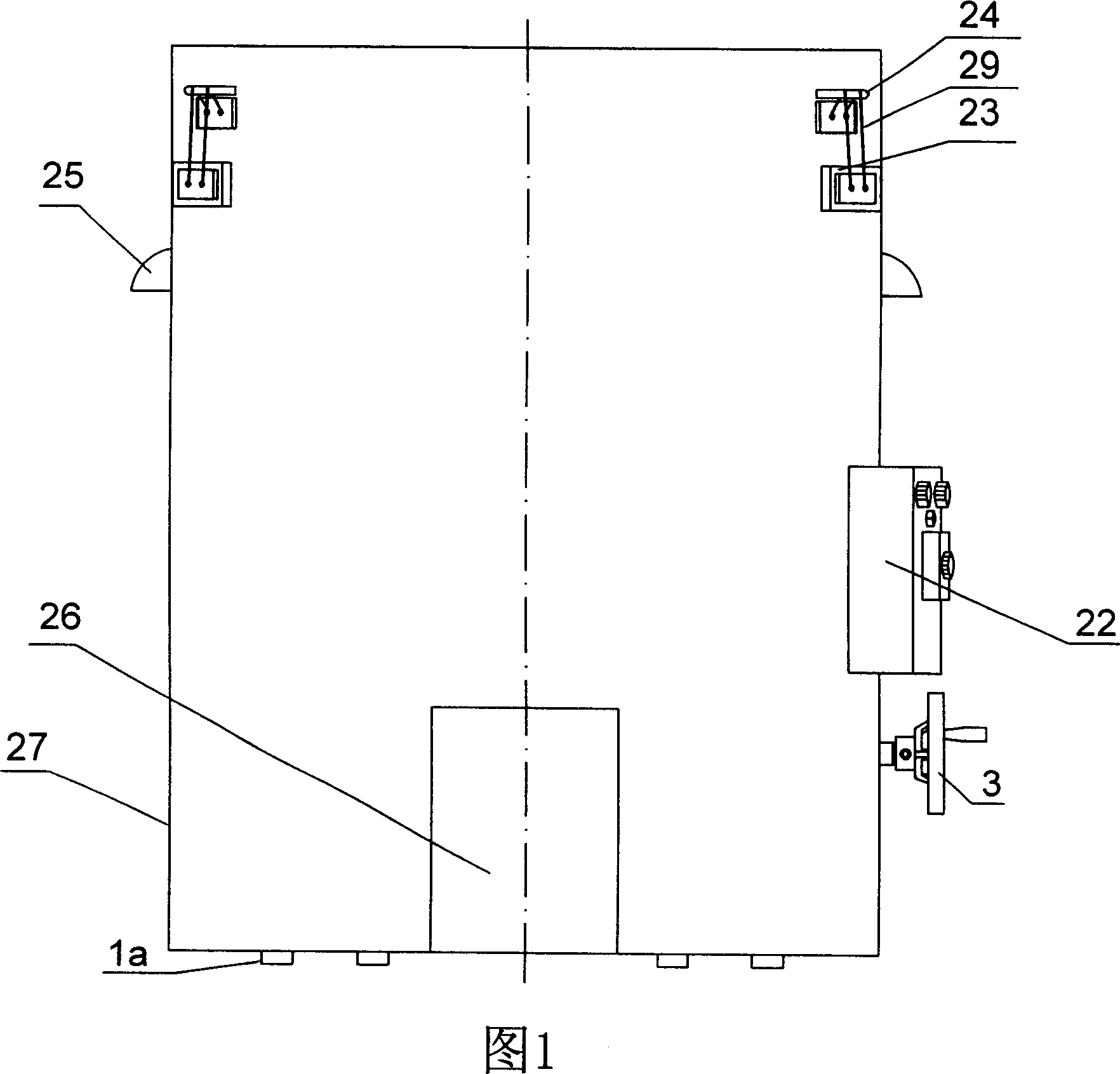

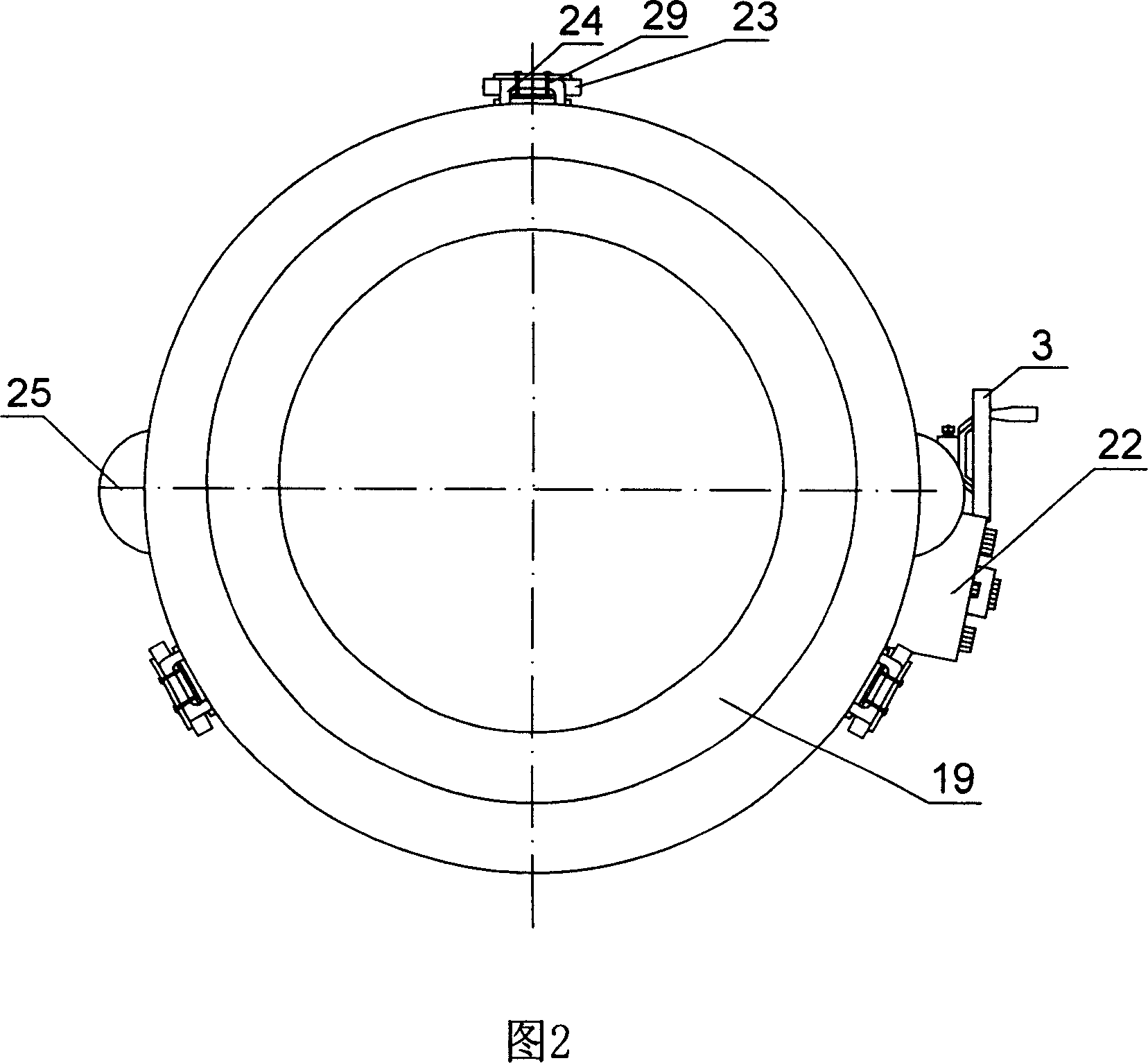

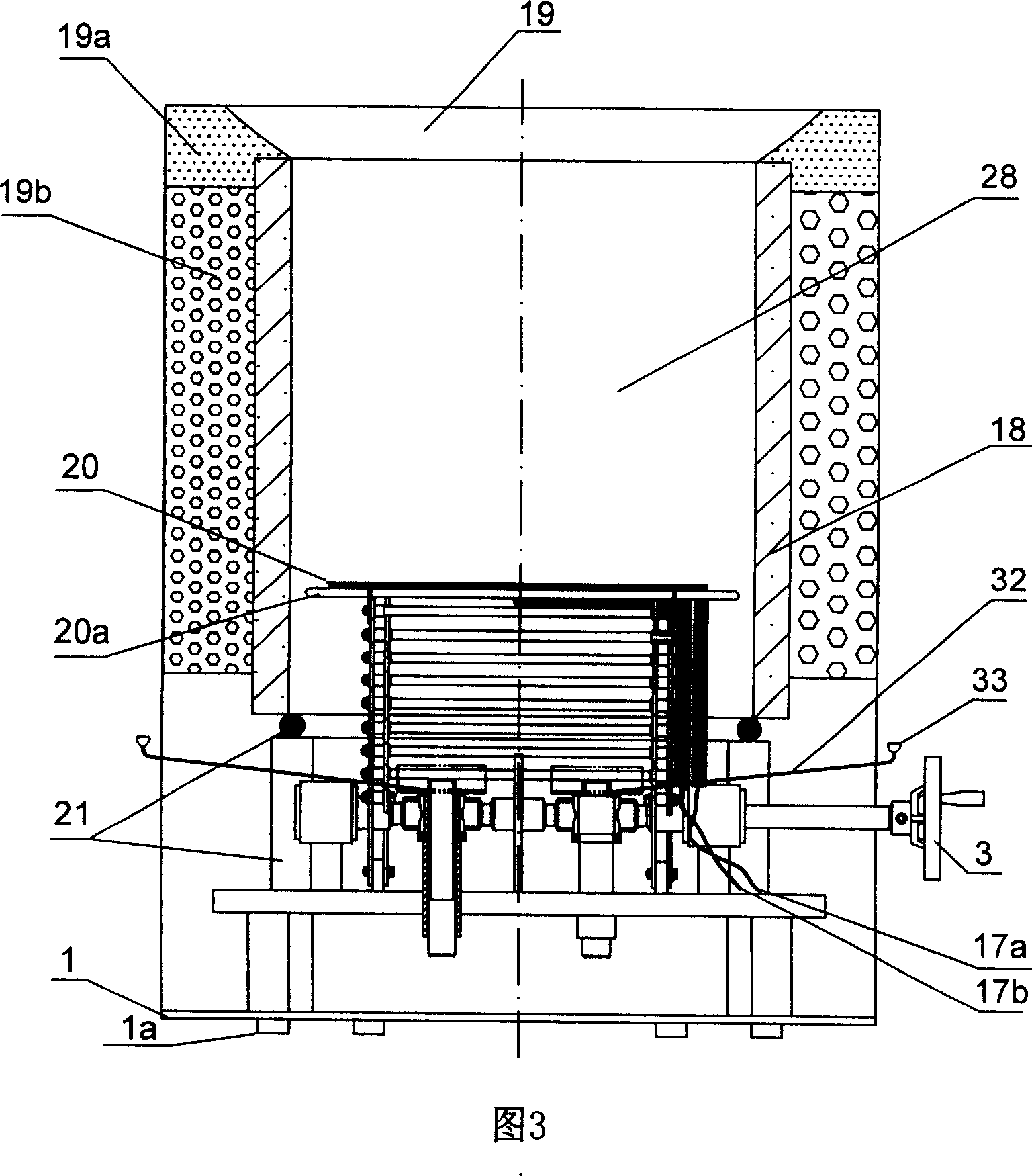

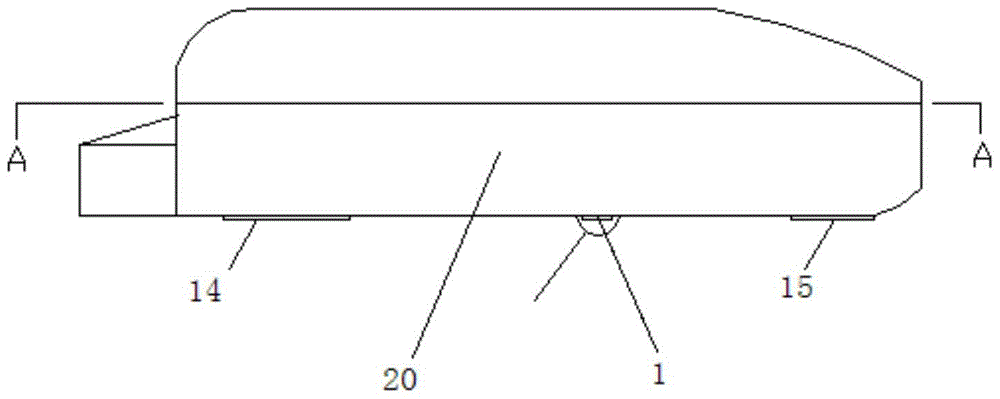

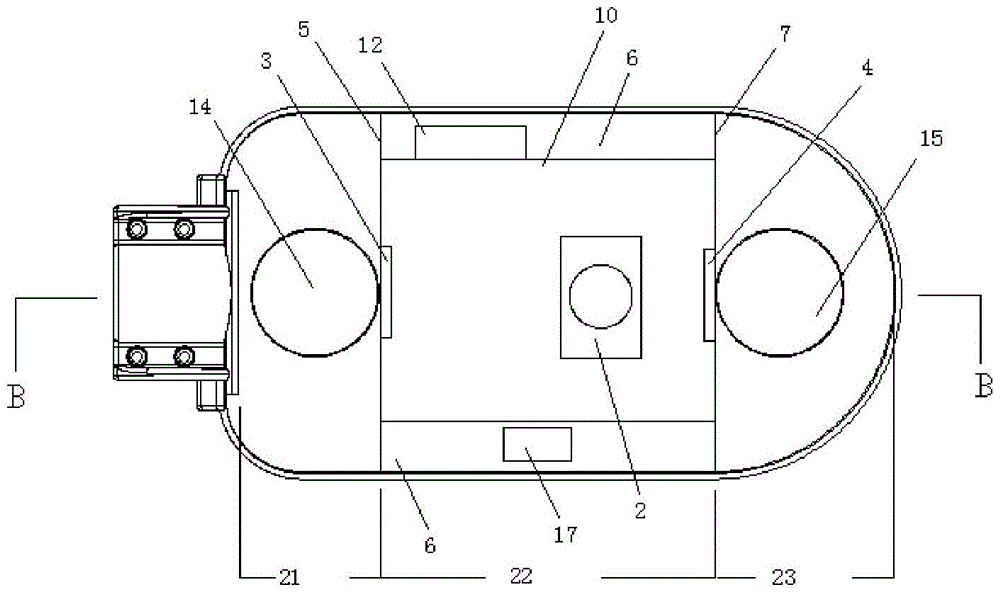

Waste tire rubber powder grinding system

InactiveCN104028359AEmission reductionImprove the environmentCombination devicesDirt cleaningFiltrationWaste tires

The invention discloses a waste tire rubber powder grinding system. The waste tire rubber powder grinding system comprises a rubber grinder and a vibrating screen, wherein the head part of the vibrating screen is arranged under a discharging opening of the rubber grinder. The waste tire rubber powder grinding system is characterized in that a dust absorption hood is arranged above the rubber grinder and the vibrating screen; the dust absorption hood covers the rubber grinder and the vibrating screen; an air outlet in the top of the dust absorption hood is connected with a pipeline; the other end of the pipeline is connected with an air exhaust fan; an air outlet of the air exhaust fan is connected with an air outlet pipe; a pipe opening of the air outlet pipe is sleeved with a filtration bag; a weight balancing block is assembled in the filtration bag; the filtration bag is immersed in a water tank. A dust removal device is additionally arranged above the grinder and the vibrating screen, and thus the emission of powder dust is reduced and the workshop environment is greatly improved.

Owner:CHONGQING JUYI RUBBER PROD

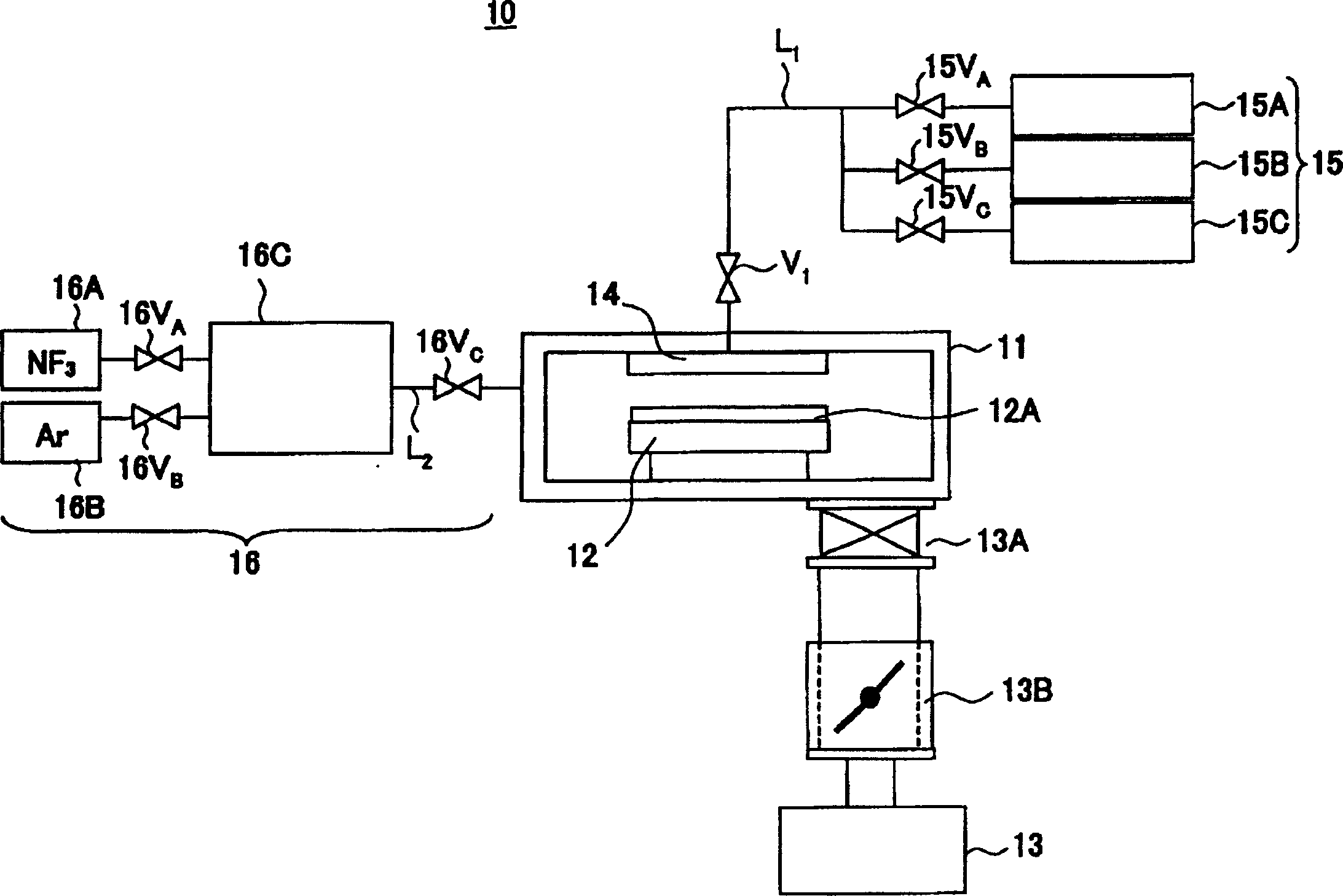

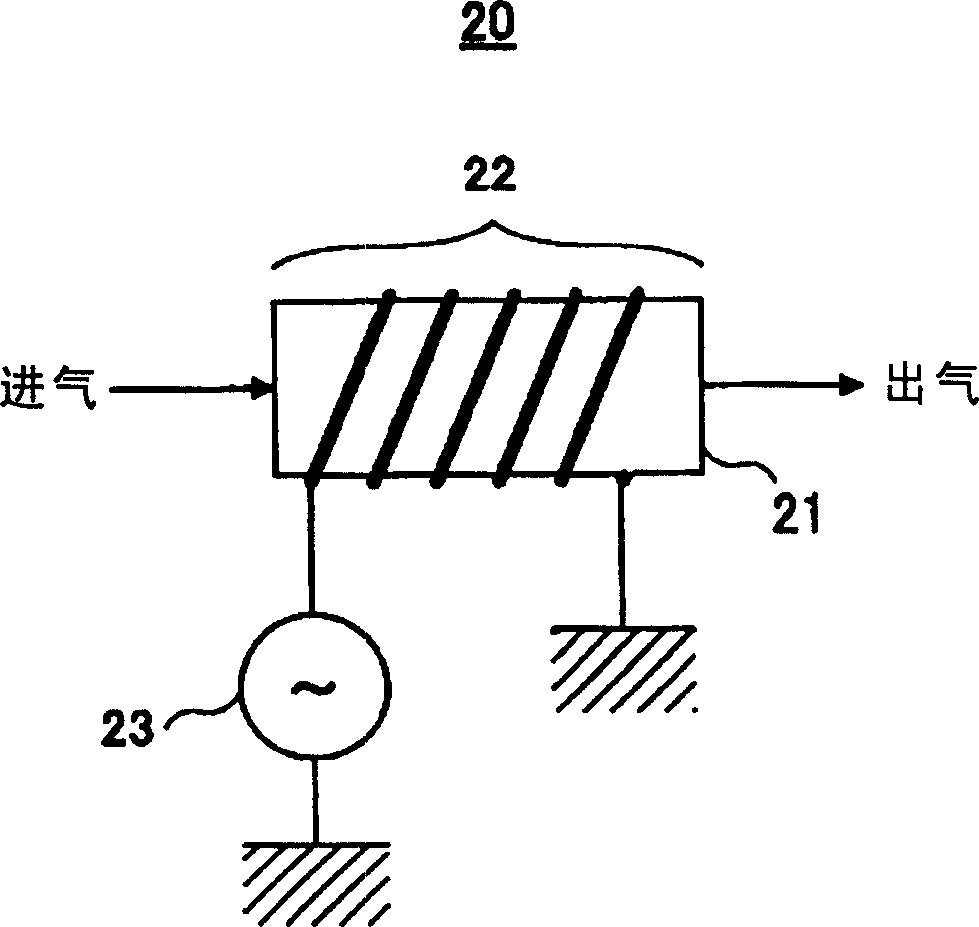

Method for generating plasma, method for cleaning and method for treating substrate

InactiveCN1813342AEasy to handleDealing with Effective ImplementationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasPlasma ignition

The invention relates to a plasma generating method in a ring-shaped plasma generating device, wherein the plasma generating device comprises a gas pathway which is provided with a gas inlet and a gas outlet and forms a ring-shaped pathway and a coil which winds on a part of the gas pathway. The plasma generating method comprises following steps: providing mixture gas of Ar gas which contains at least 5%NF3 and NF3 gas into the gas pathway, driving the coil by high-frequency electrical energy, and thereby enabling a procedure of plasma ignition, wherein the procedure of plasma ignition is executed under total pressure of 6.65-66.5Pa.

Owner:TOKYO ELECTRON LTD

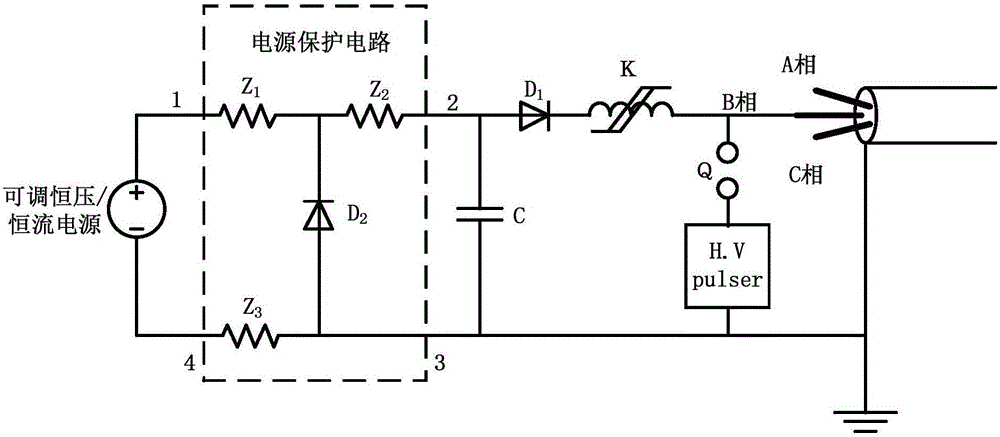

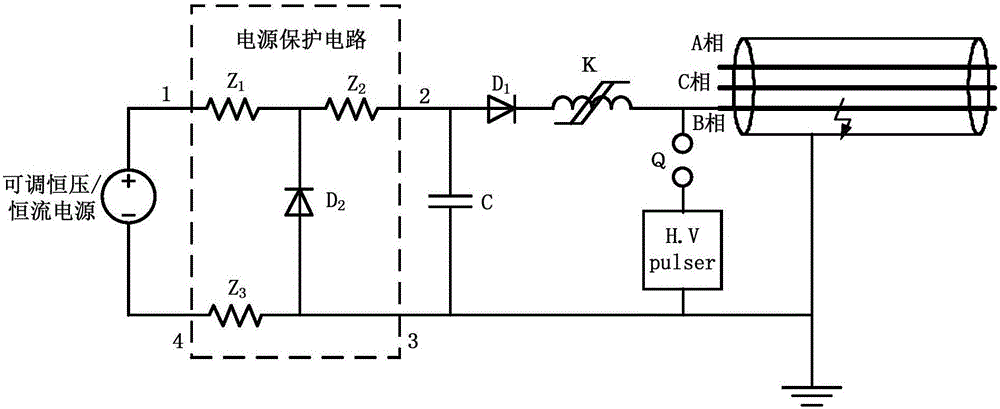

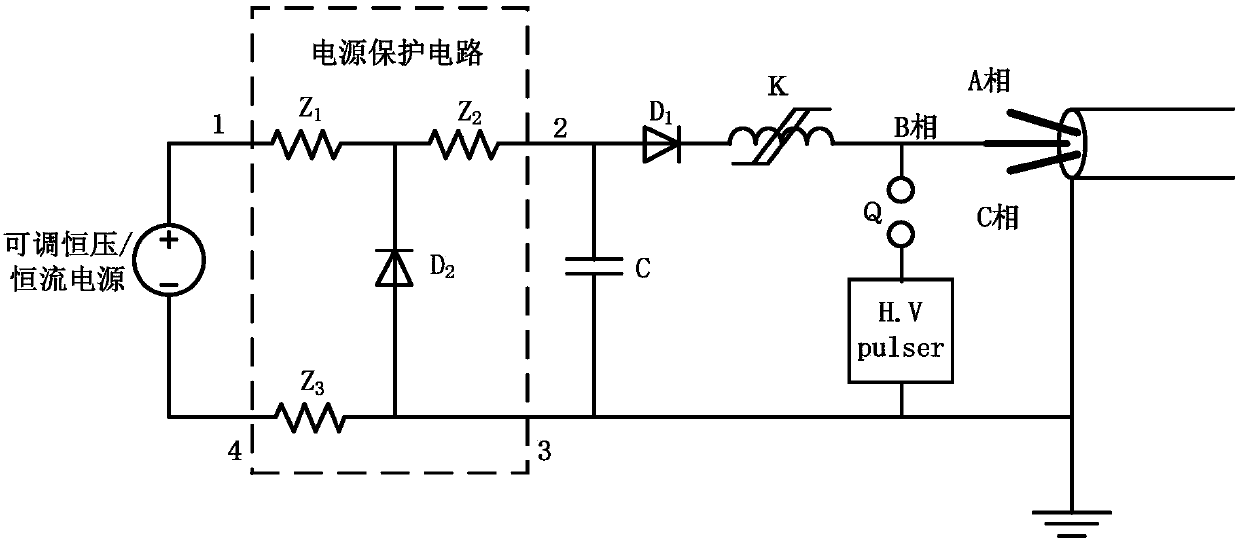

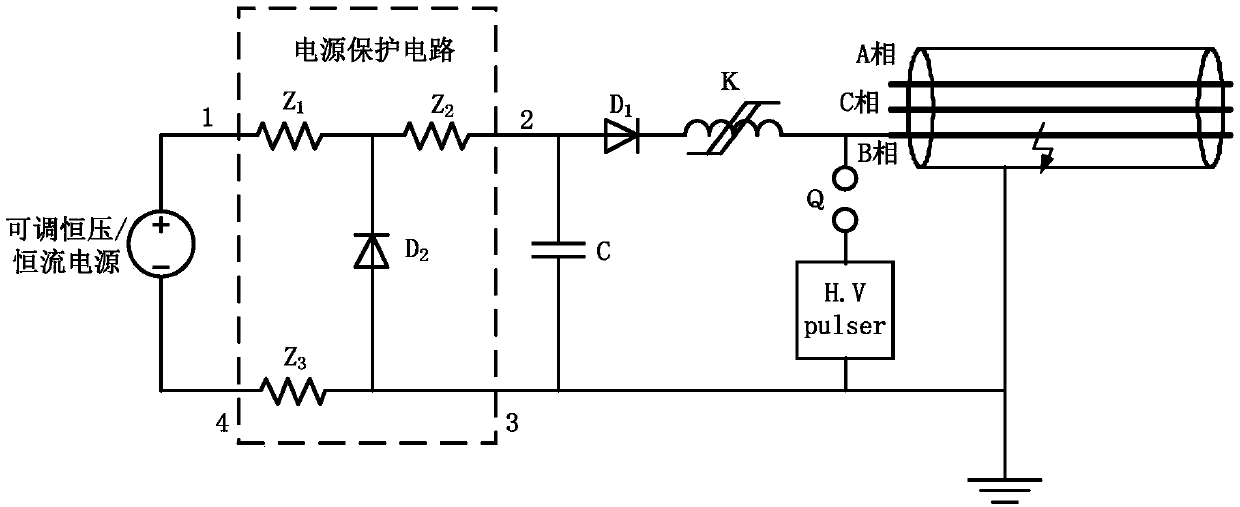

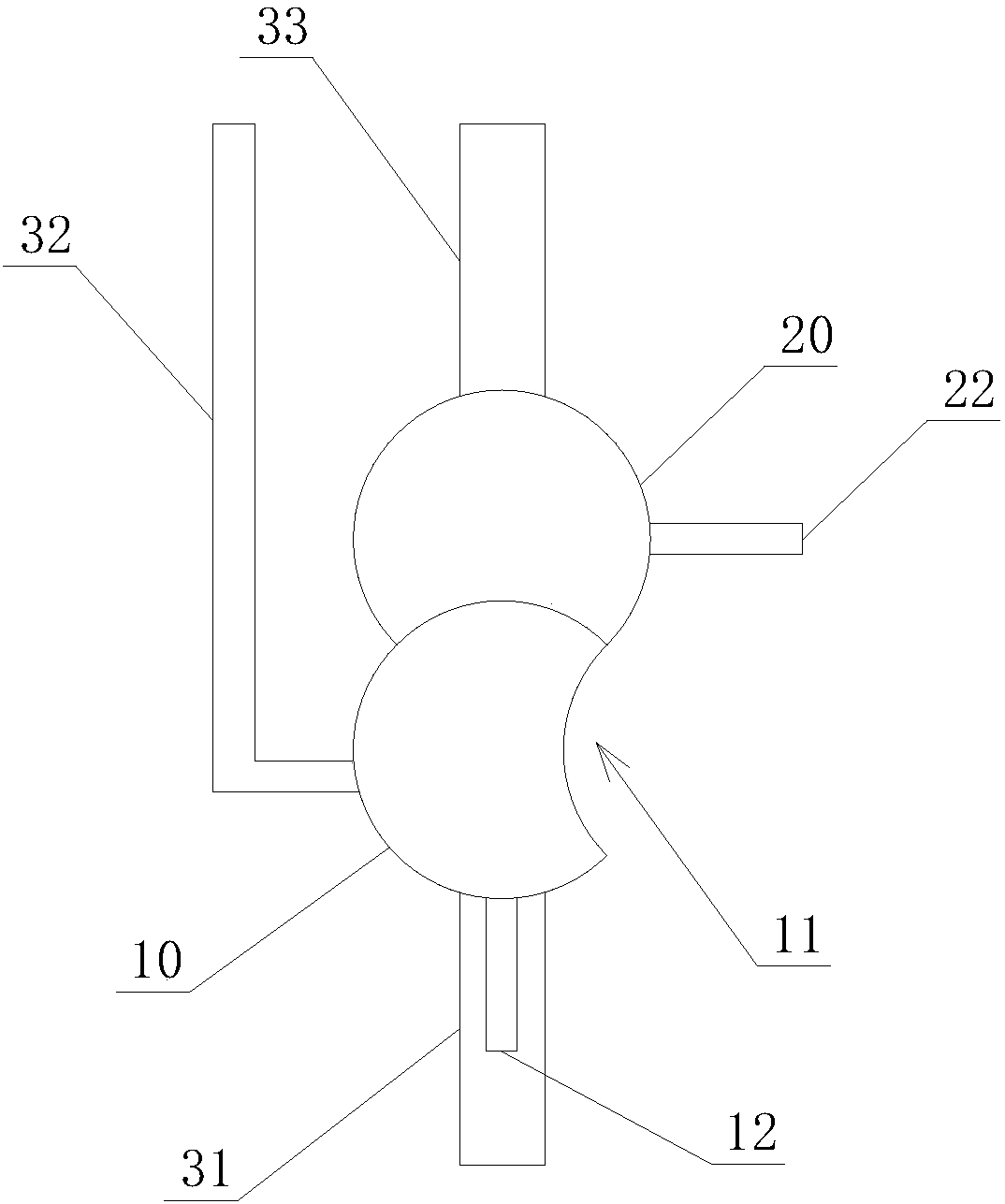

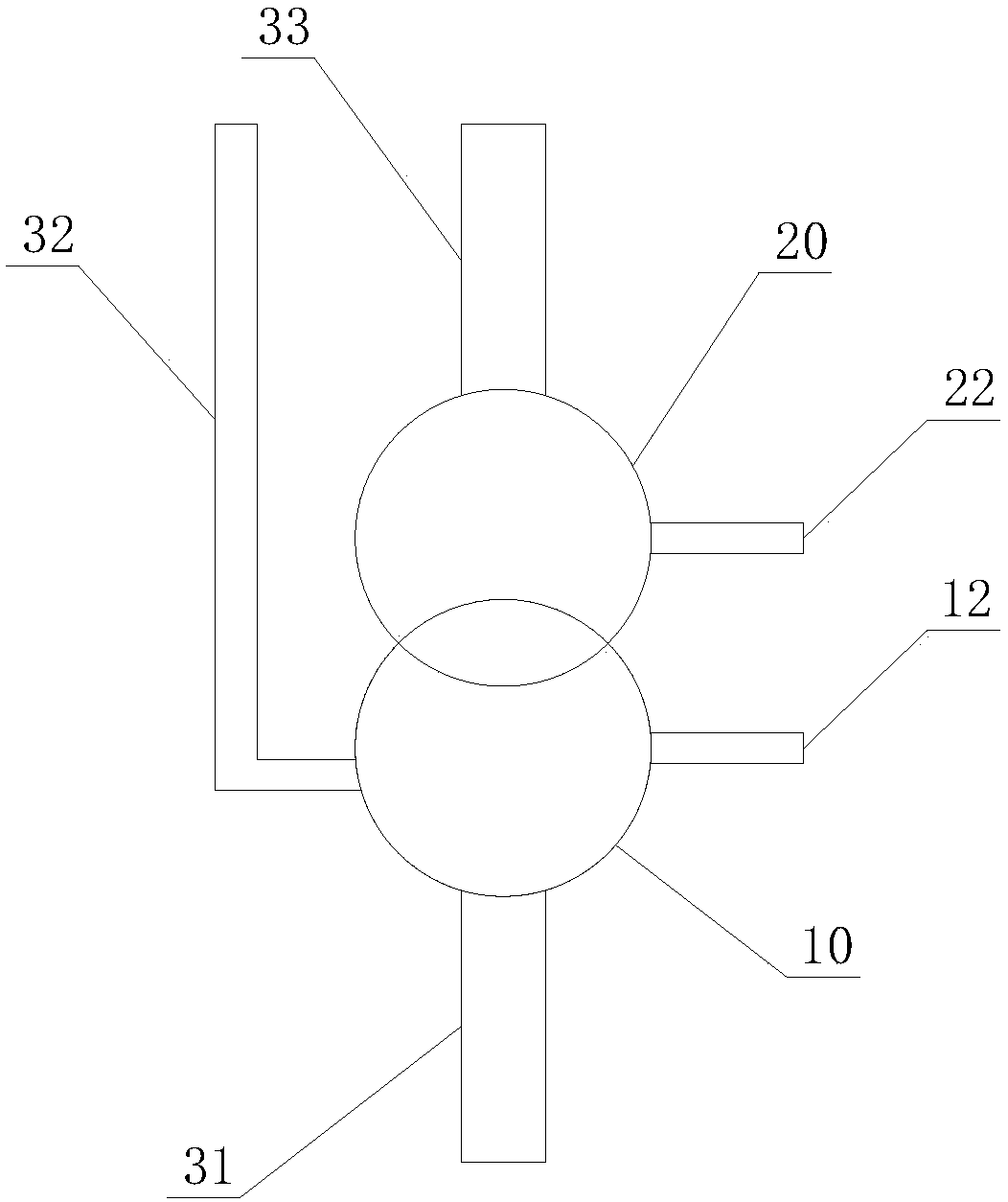

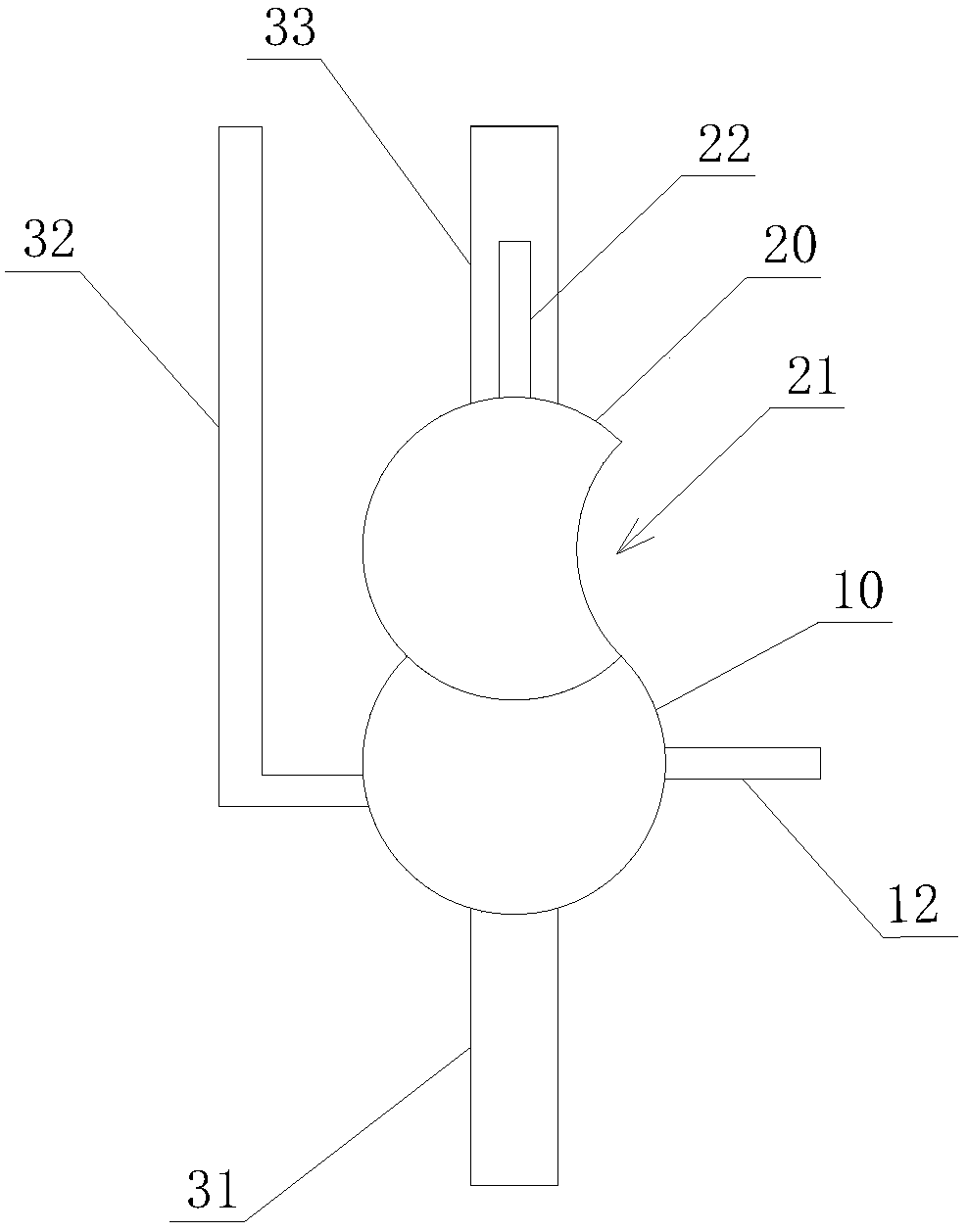

Resistance lowering device and method for a power cable high-resistance fault point

ActiveCN105807185ALow resistanceWon't go outFault location by conductor typesHigh resistanceElectrical resistance and conductance

The invention discloses a resistance lowering device and method for the power cable high-resistance fault point.The resistance lowering device comprises a high-voltage pulse generating part and a direct-current arc maintaining part, wherein the high-voltage pulse generating part and the direct-current arc maintaining part are in parallel.The high-voltage pulse generating part is connected with the direct-current arc maintaining part through a sphere gap, a magnetic switch and a silicon stack; when the resistance lowering device for the power cable high-resistance fault point operates, pulse voltage is firstly output, and a direct current for keeping arc burning is finally output.When the resistance lowering device for the power cable high-resistance fault point operates, a high-voltage pulse firstly acts on a high-resistance fault point of a cable, after the high-resistance fault point of the cable is broken down by the high-voltage pulse and arc discharging is carried out, resistance is decreased to be close to a short circuit, and the direct-current arc maintaining part provides the direct current for the high-resistance fault point to keep arc burning till the high-resistance fault point is subjected to resistance lowering.According to the resistance lowering device and method, under the condition that the power cable is not damaged, main insulation of the cable of the high-resistance fault point can be partly carbonized within ten more seconds to dozens of seconds, and resistance to ground of the fault point is subjected to resistance lowering.

Owner:西安宇铭电物理技术有限责任公司 +2

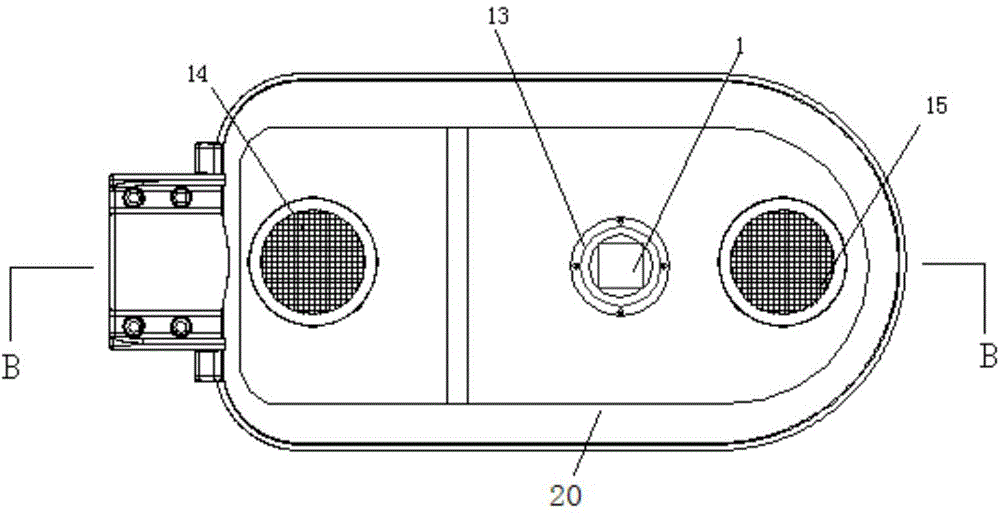

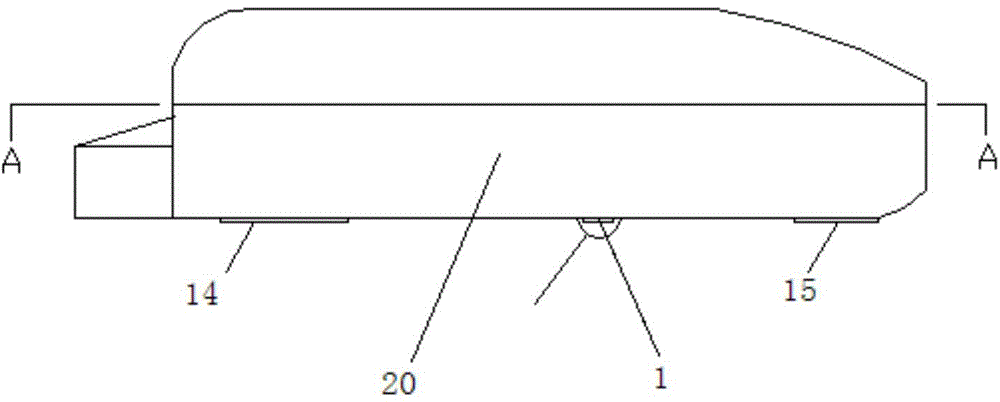

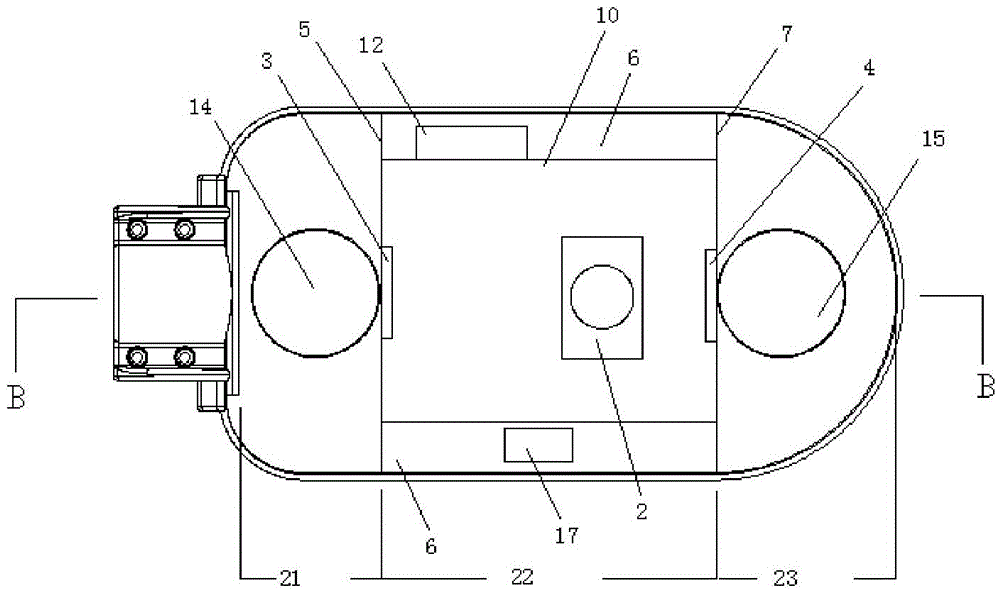

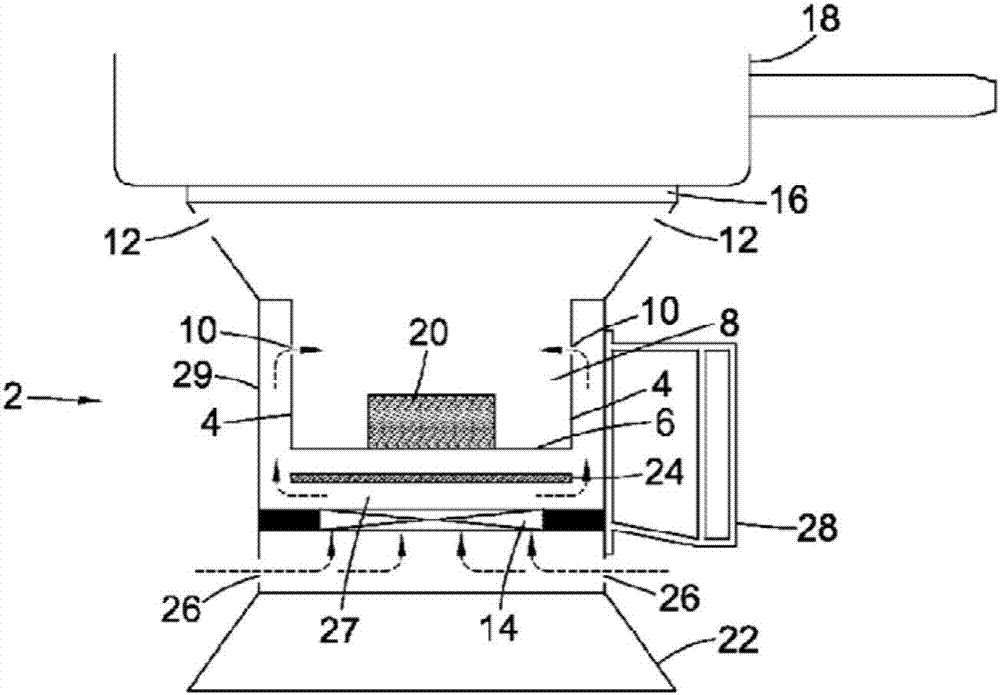

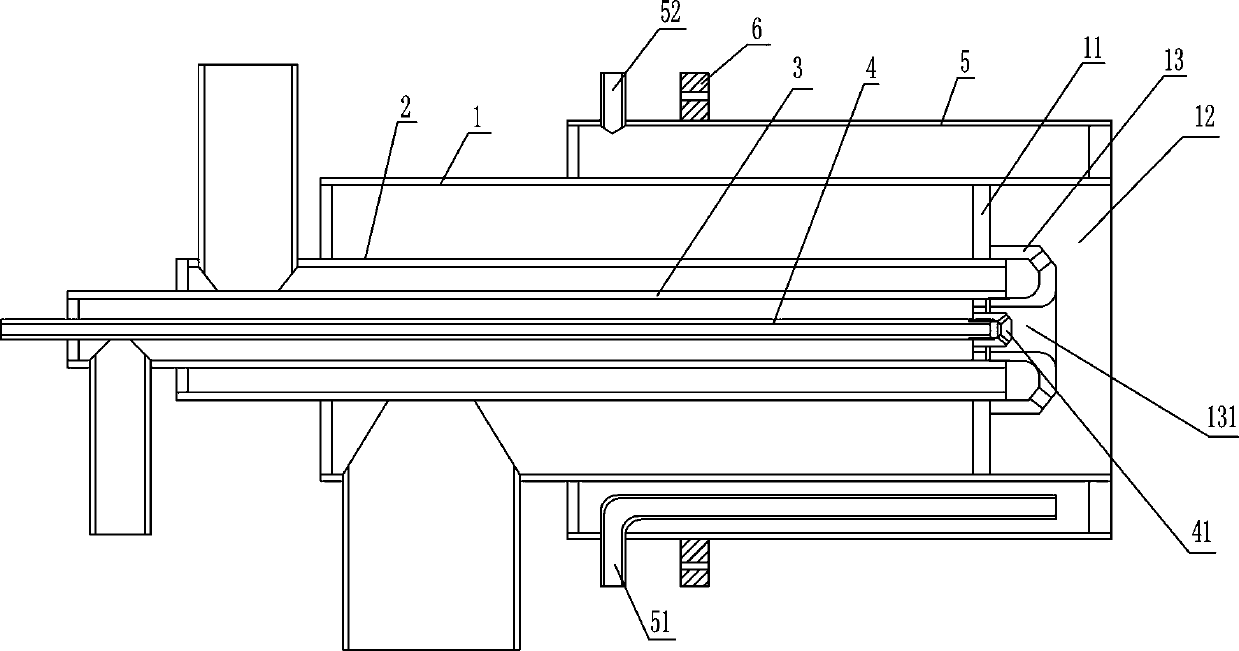

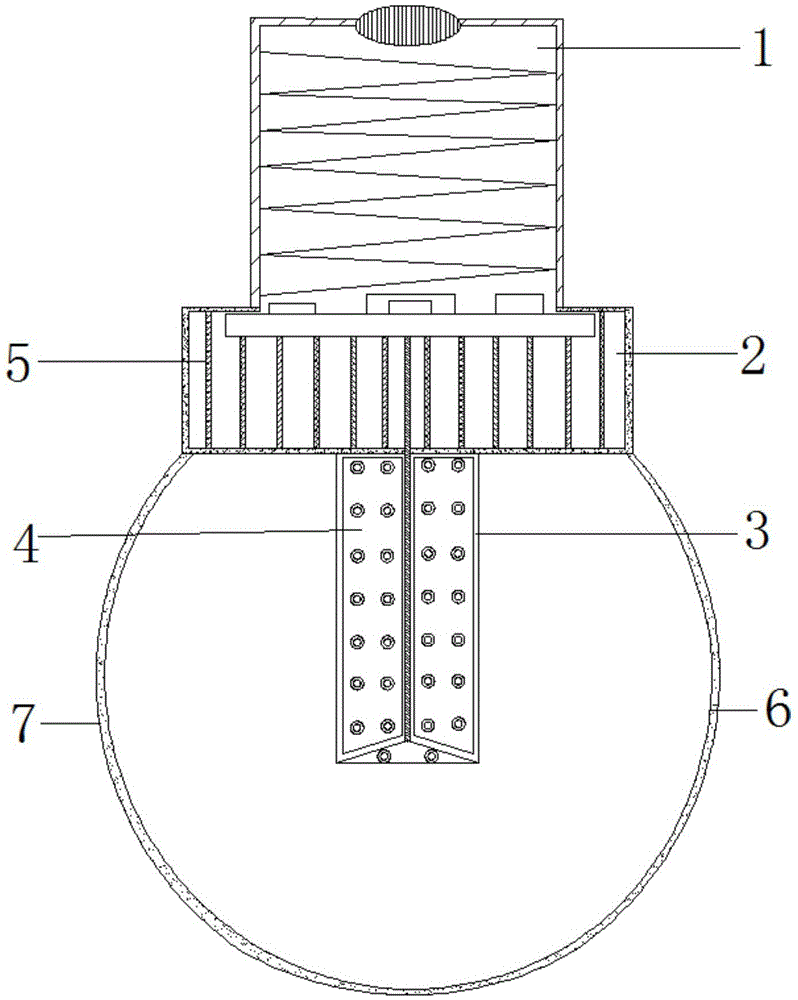

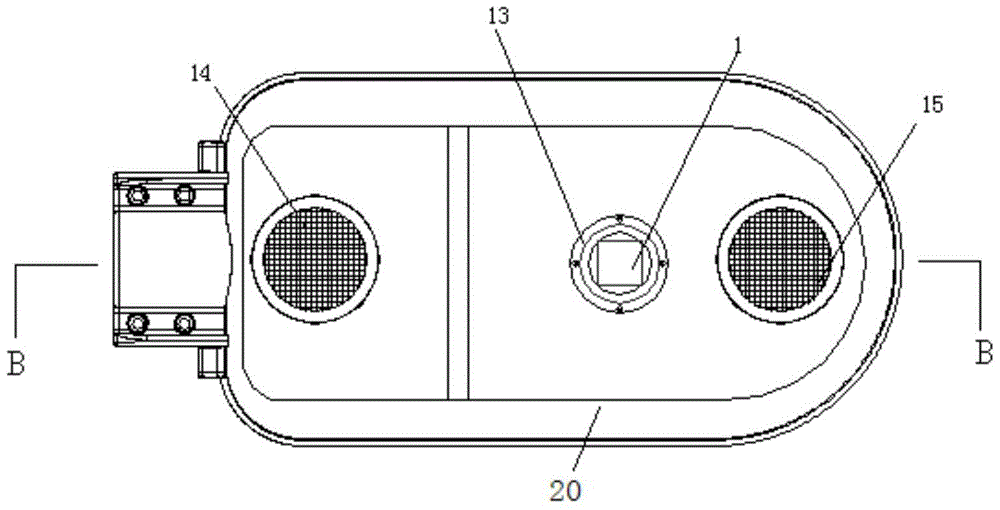

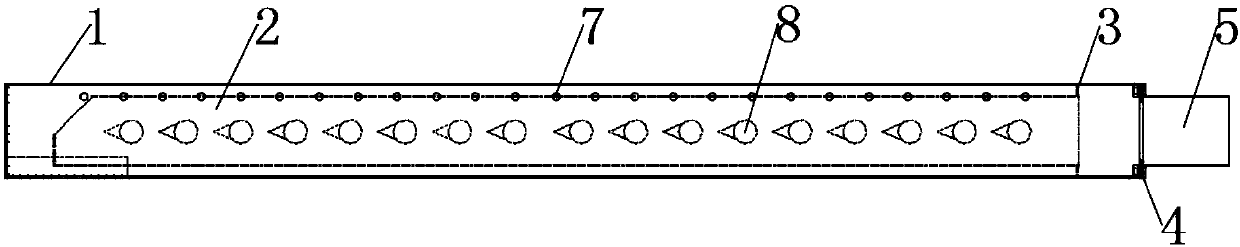

Forced-cooling high-power LED lamp

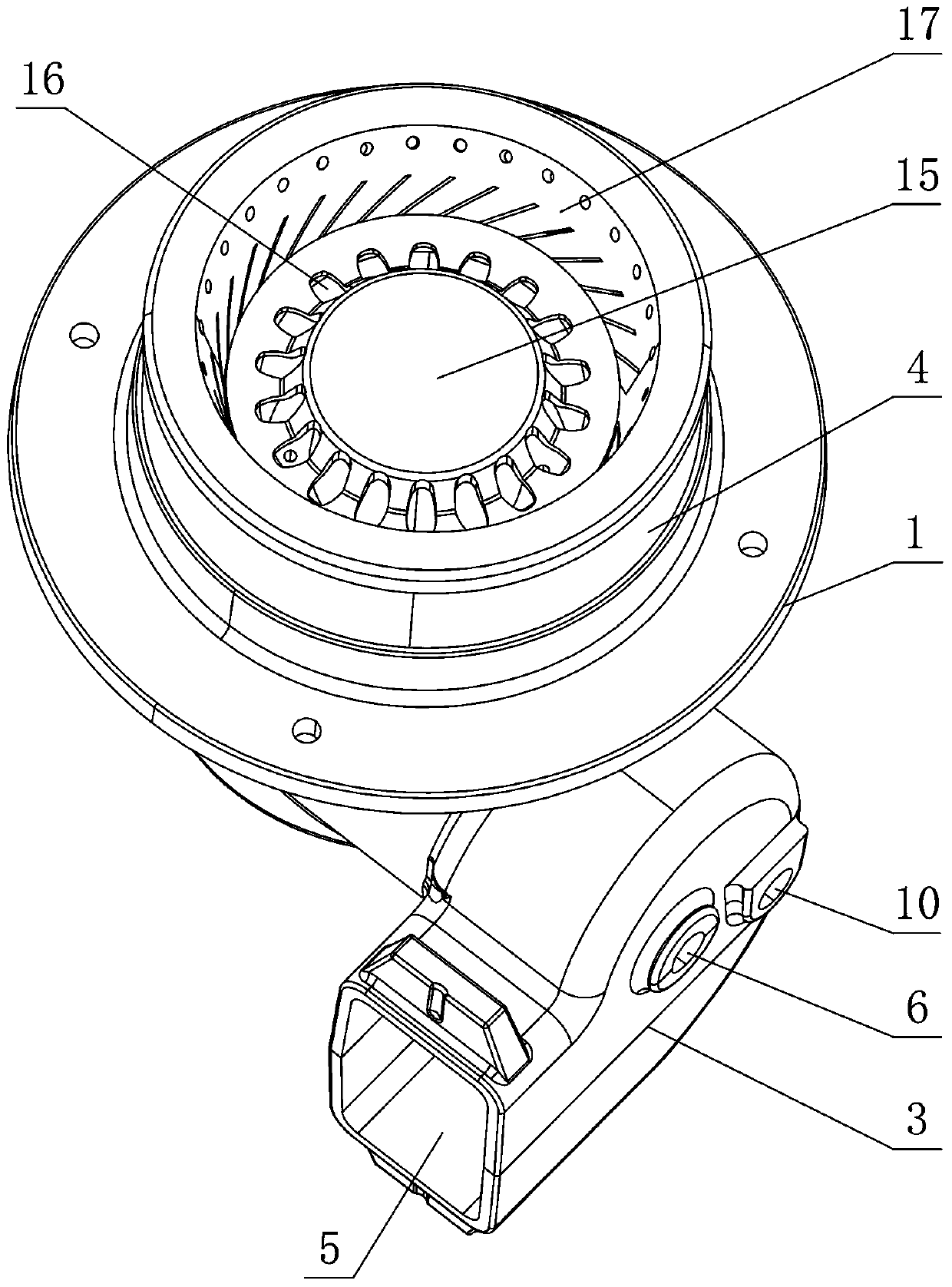

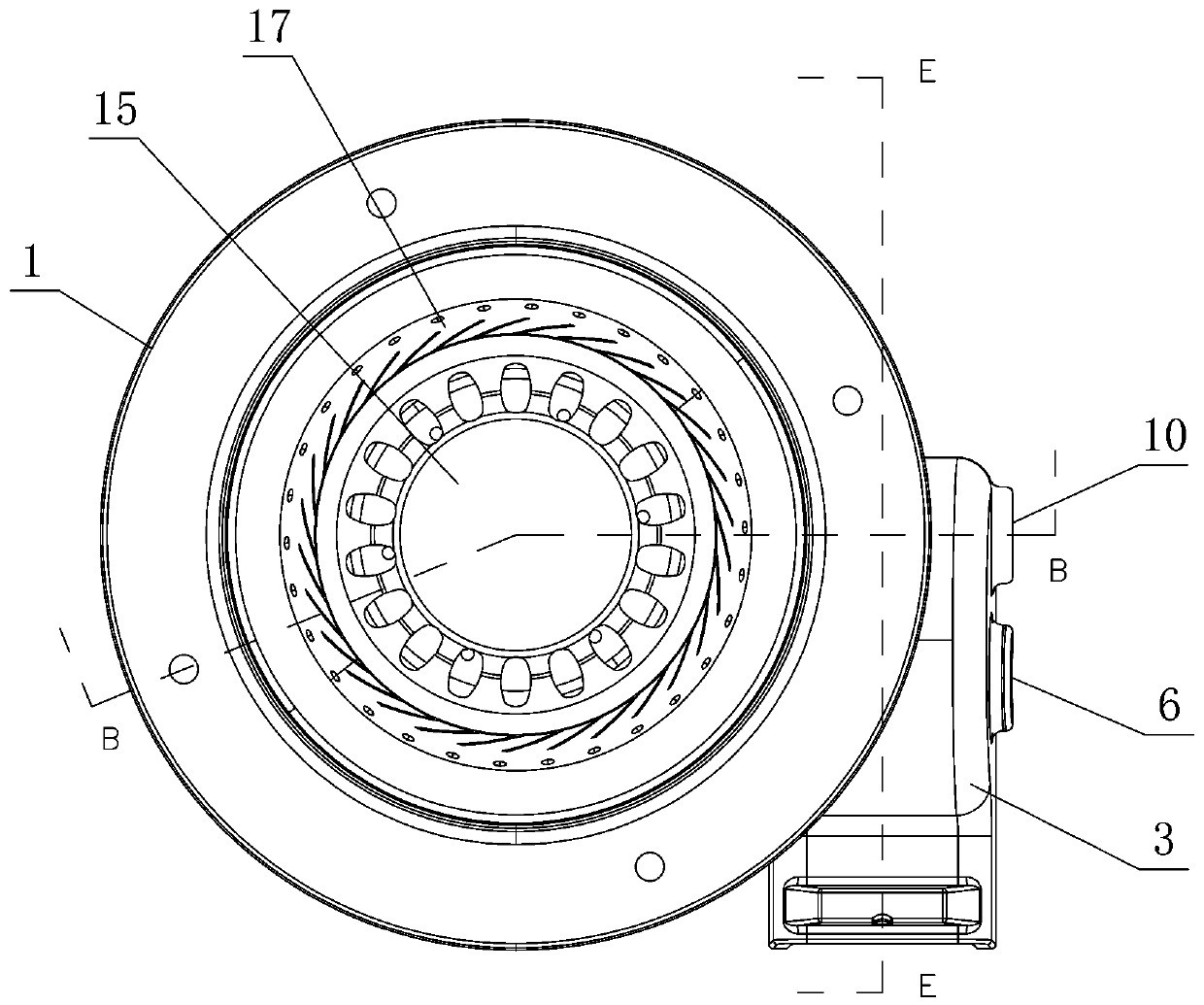

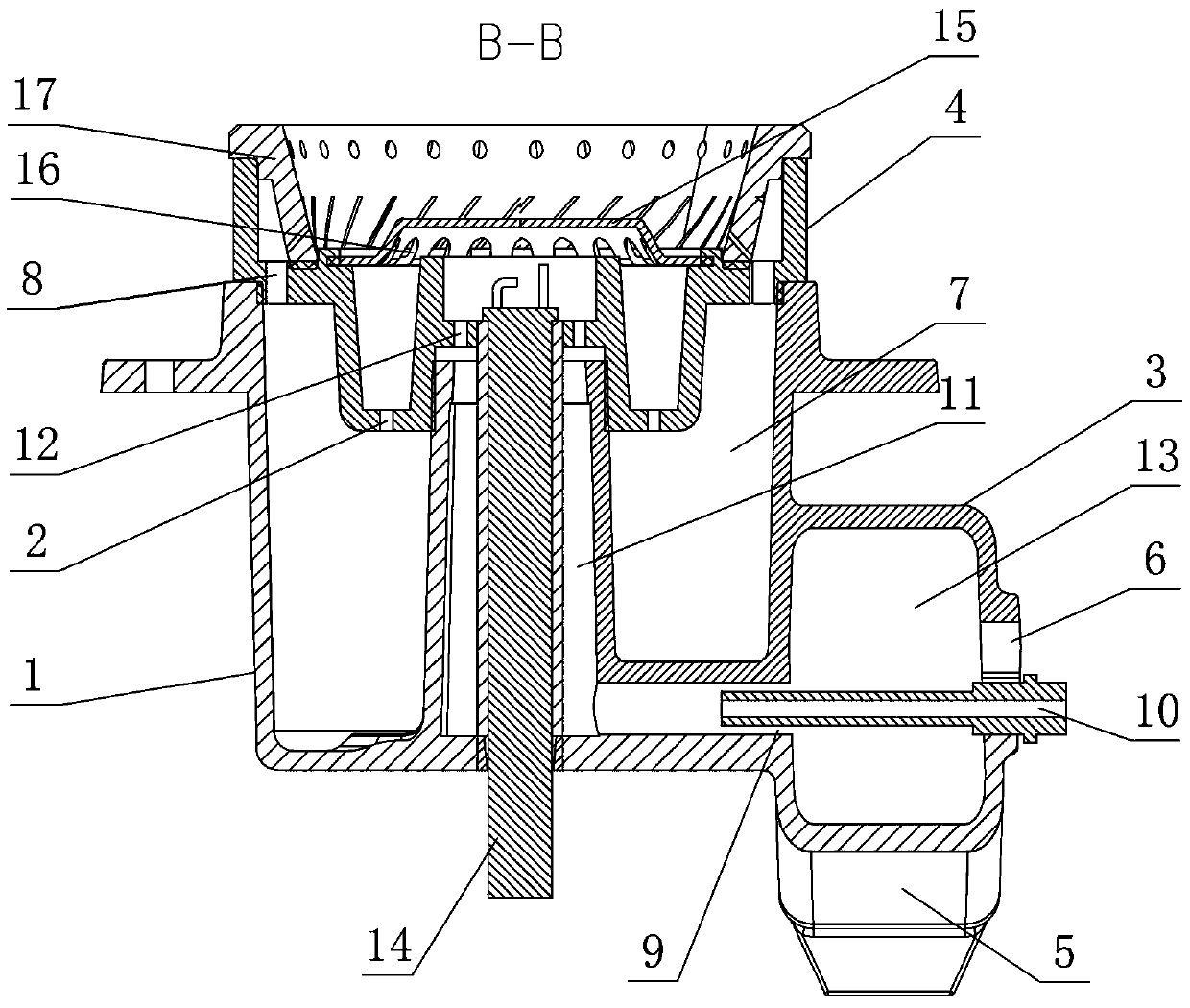

ActiveCN104132271AEfficient heat dissipationAchieve maintenance-freePoint-like light sourceElectric circuit arrangementsJunction temperatureEngineering

The invention relates to LED illumination lamps, in particular to a forced-cooling high-power LED lamp. The forced-cooling high-power LED lamp comprises a lamp shell, an air inlet area, a heat dissipation area and an air exhaust area, and the air inlet area, the heat dissipation area and the air exhaust area are assembled in the lamp shell. An air inlet separation plate is arranged between the air inlet area and the heat dissipation area, and air inlet separation plate air guide holes are formed in the air inlet separation plate. An air exhaust separation plate is arranged between the heat dissipation area and the air exhaust area, and air exhaust separation plate air guide holes are formed in the air exhaust separation plate. The forced-cooling high-power LED lamp has the advantages of being high in power, light, high in light efficiency, low in junction temperature, high in energy efficiency, low in cost, free of maintenance and capable of being intelligently controlled.

Owner:天津朝辉照明科技有限公司

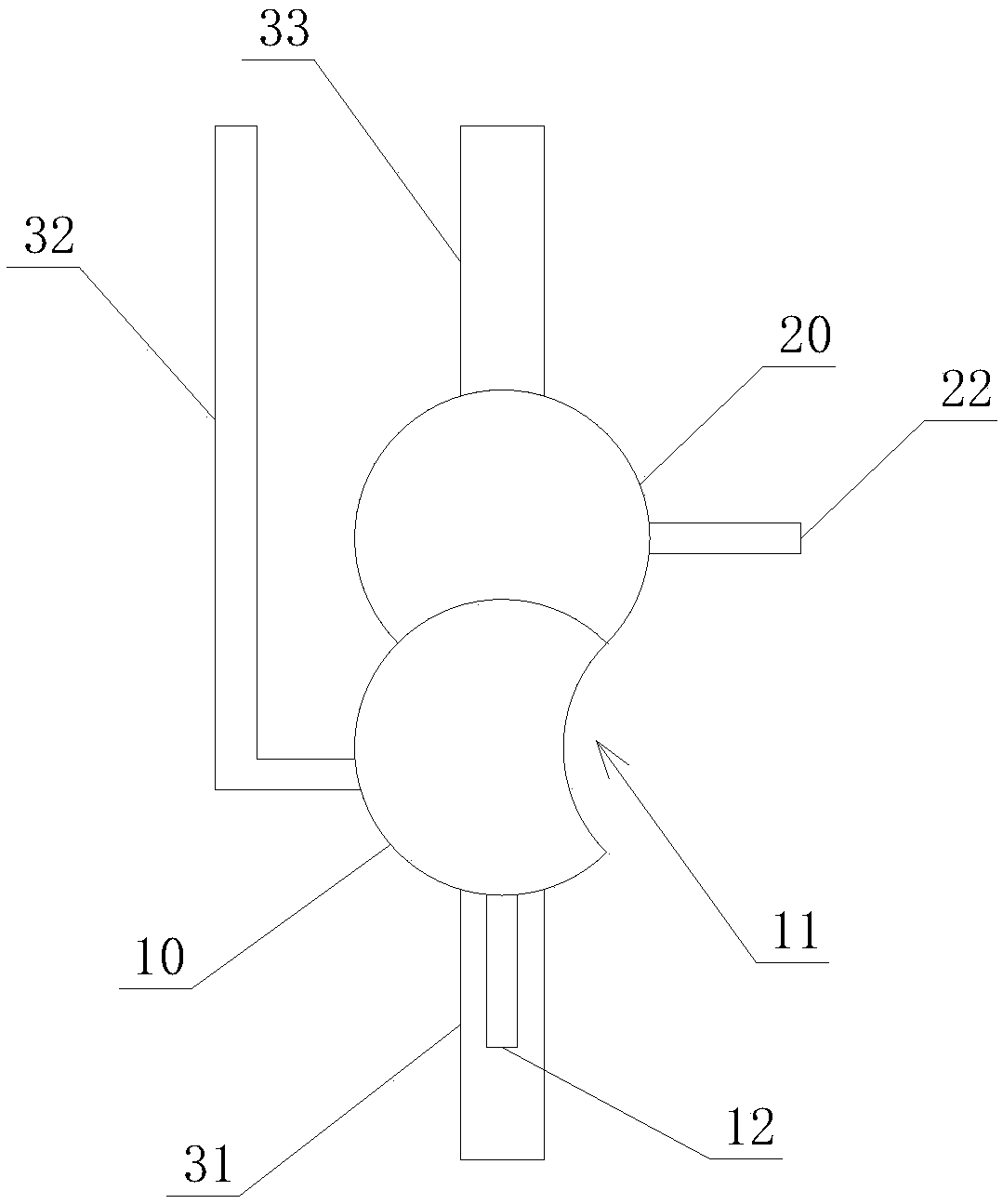

Low nitrogen oxide emission burner device

PendingCN109579009AEliminate flash explosion riskLarge thermal load turndown ratioGaseous fuel burnerGas separationOxide

The invention relates to a low nitrogen oxide emission burner device. A tubular gas chamber is arranged inside an air pipe; a multi-chamber premixer structure is formed by gas separation plates and gas spray orifices on the outer cylindrical surface of the gas chamber; a central air pipe is arranged inside the air pipe; a gas inlet hole is formed in the outer circular surface of the central air pipe; one end of the central air pipe is connected to a kindling material draught fan, and the other end of the central air pipe is provided with a kindling material burning head; the front end of the air pipe is provided with a secondary mixing device which sucks part of flue gas in a furnace hearth by a gas inlet annular passage of a furnace chamber of the secondary mixing device through the negative pressure effect formed by high-speed and high-temperature airflow at the front end of the air pipe; the air pipe is connected to a main draught fan which is connected to an air inlet channel; a flue gas introduction cavity and an air introduction cavity are arranged inside the air inlet channel; two stages of ventilation doors are arranged at the lower part of the air introduction cavity; andthe proportion of air and flue gas entering the main draught fan is adjusted through the two stages of ventilation doors. The low nitrogen oxide emission burner device is based on two-premixing, two-mixing, two-air distribution, two-adjustment and one-stabilization design structure and realizes the ultra-low nitrogen combustion.

Owner:唐山冀东石油机械有限责任公司 +1

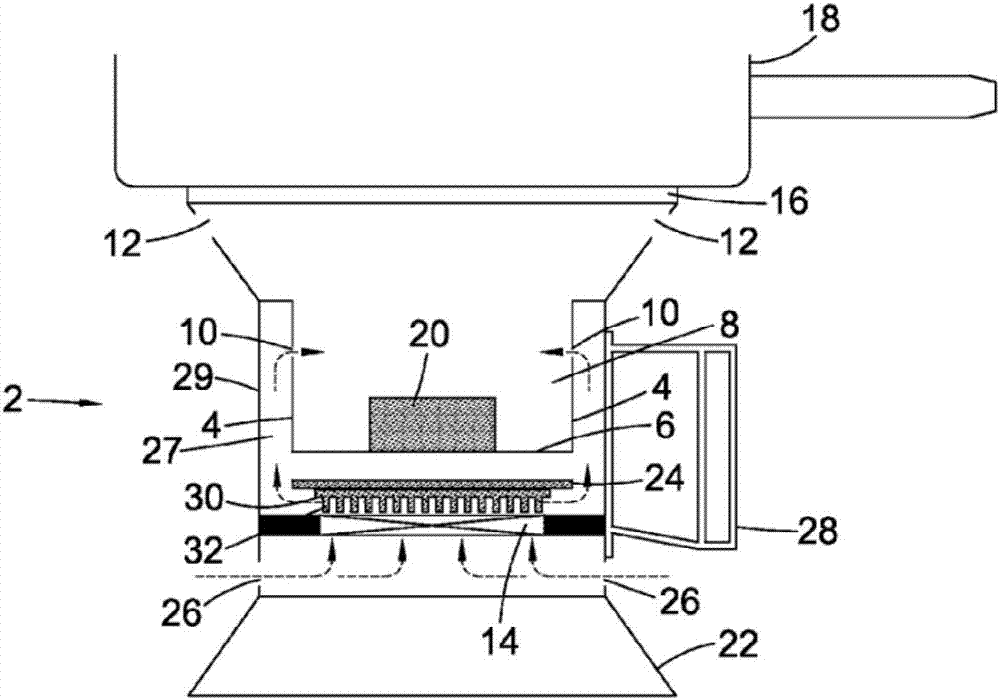

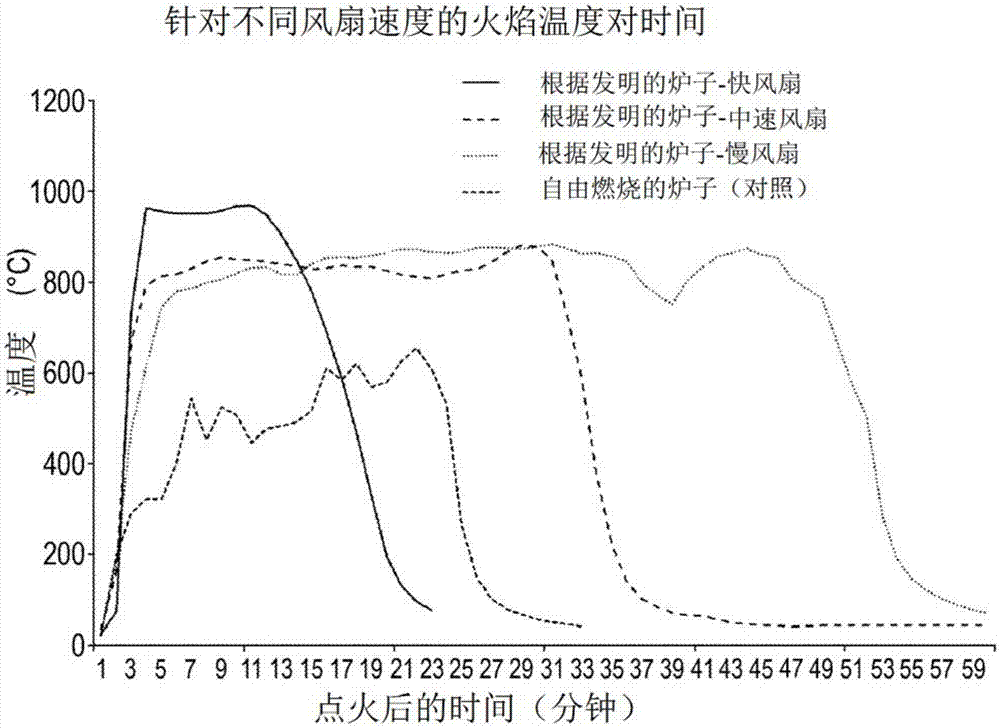

Cooking stove

InactiveCN107072442AFree burningRun out quicklyDomestic stoves or rangesCapillary burnersCombustion chamberHigh energy

Owner:STANDARD BRANDS (UK) LTD

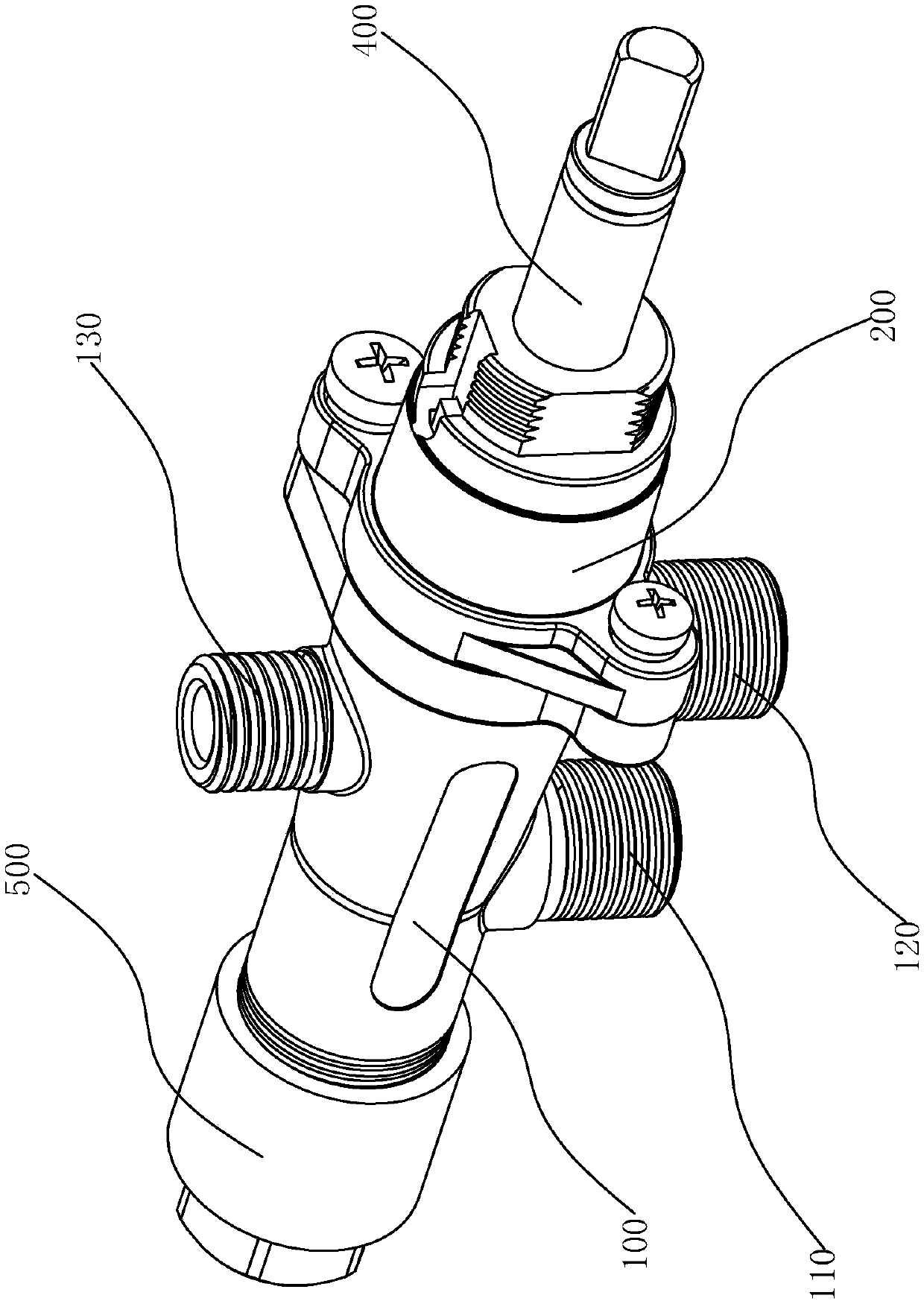

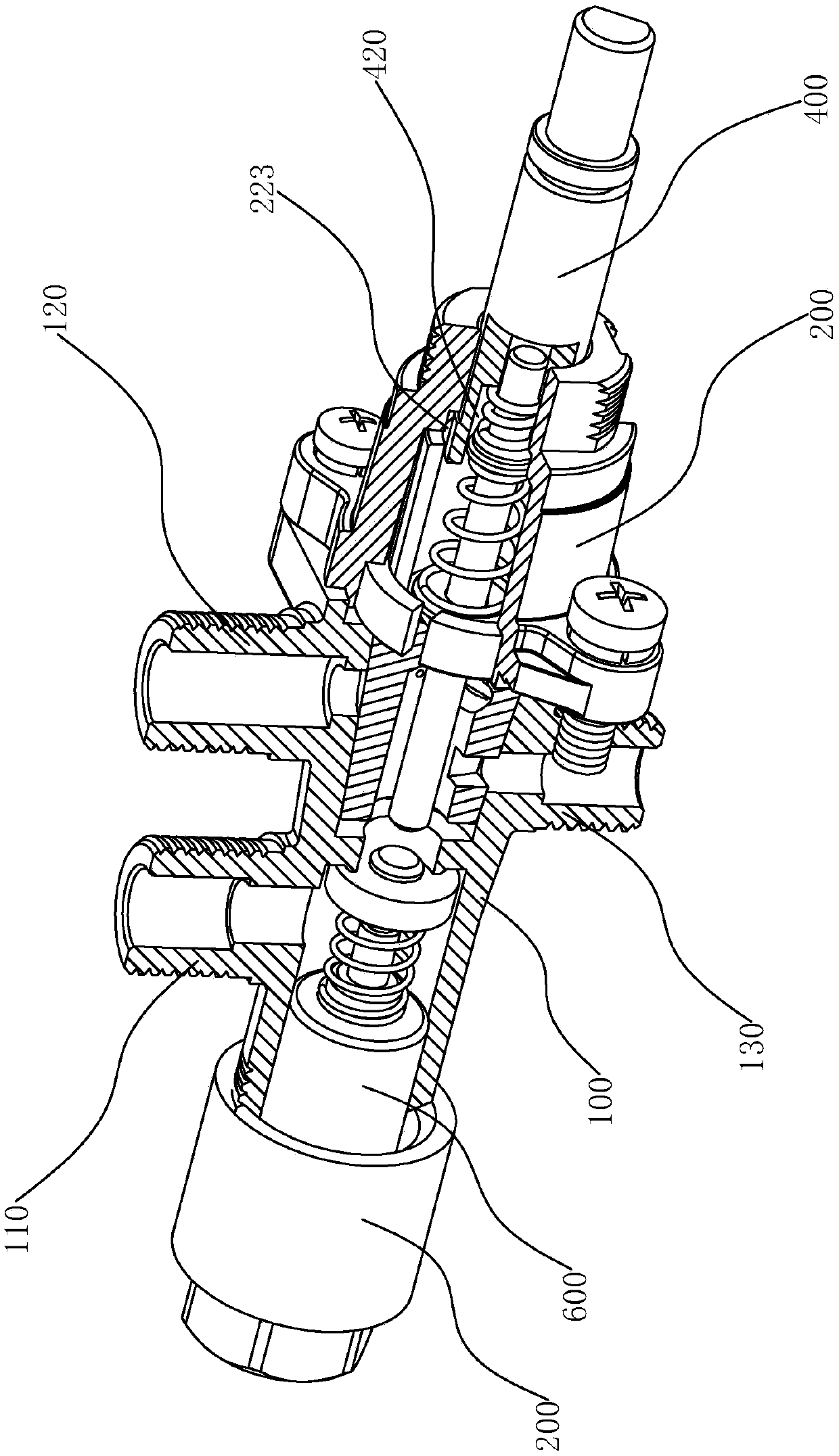

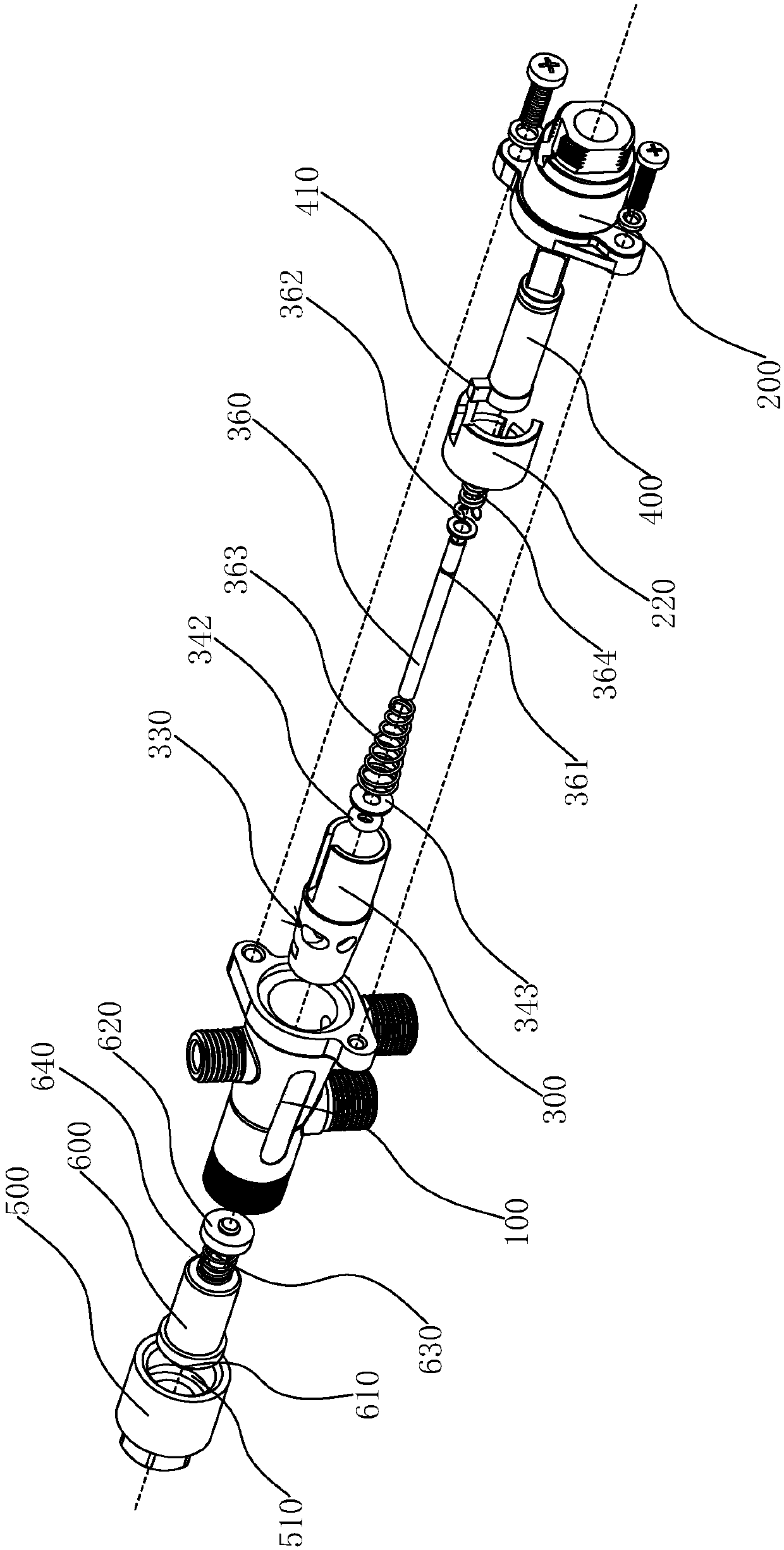

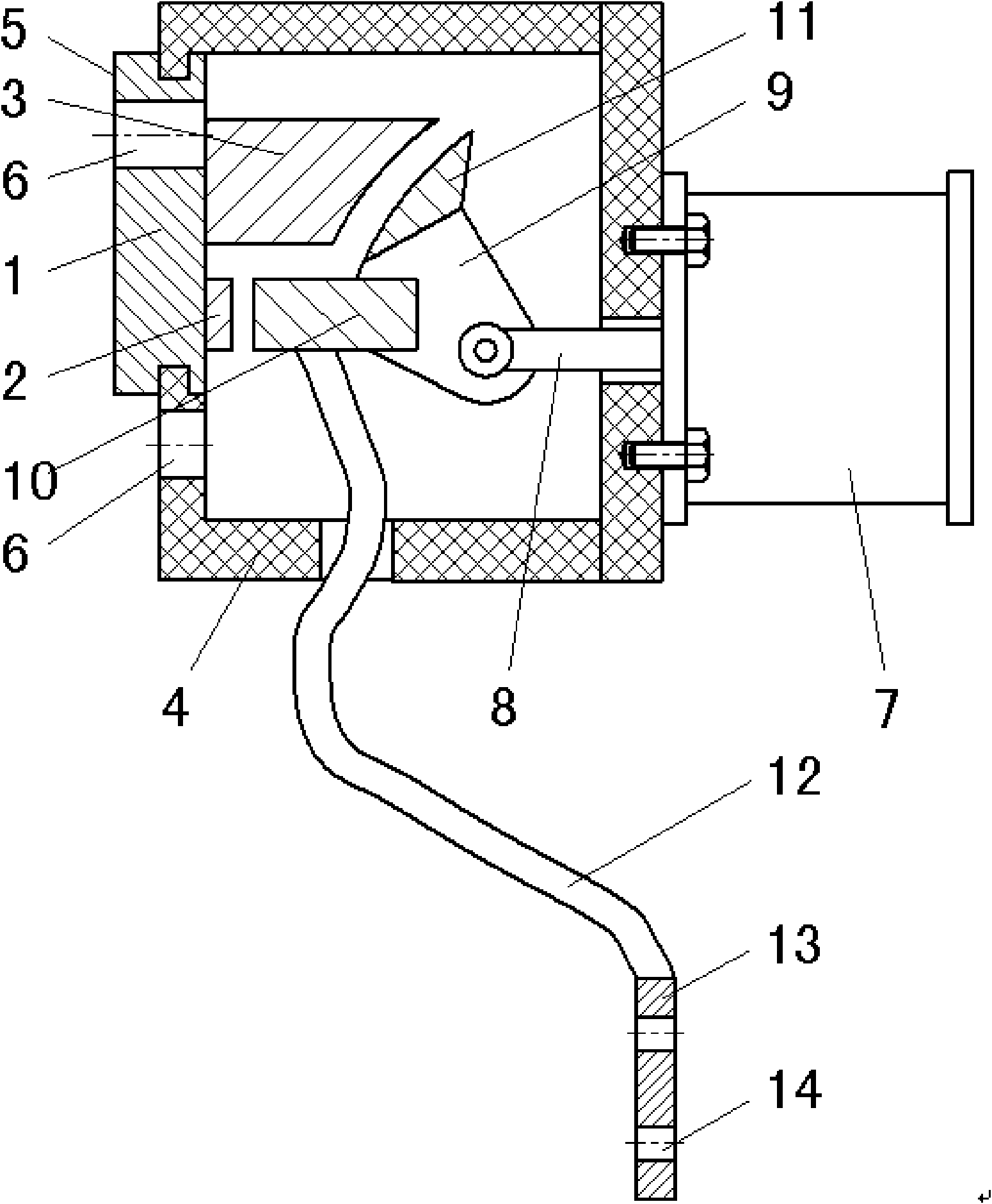

Flow control valve

InactiveCN109958794ASmall and constant air supplyNo ignition failurePlug valvesDomestic stoves or rangesCombustorProduct gas

The invention provides a flow control valve and belongs to the technical field of control valves. Through the flow control valve, the technical problems that the gas flow of an existing combustor is difficult to control and the combustor is not safe in use are solved. The flow control valve comprises a valve body and a front end cover. The outer surface of the valve body is provided with a gas inlet pipe, a gas outlet pipe and an ignition gas pipe. The valve body is internally provided with a spacer block. The spacer block is provided with a first through hole. The gas inlet pipe communicateswith a second containing cavity. The gas outlet pipe and the ignition gas pipe communicate with a first containing cavity. A valve element is arranged in the first containing cavity. The rear end of the valve element is provided with a shaft hole coaxial with the first through hole. The outer surface of the rear end of the valve element is provided with an ignition gas hole and a gas outlet hole communicating with the shaft hole. When the valve element rotates in the first containing cavity, the ignition gas pipe communicates with the ignition gas hole, and the gas outlet pipe communicates with the gas outlet hole. An ignition gas channel and a combustion gas channel supply gas respectively. When the ignition gas channel conducts ignition, the gas supply flow of the ignition gas channel isstable, the ignition efficiency is high, and the ignition process is safe.

Owner:郑霄

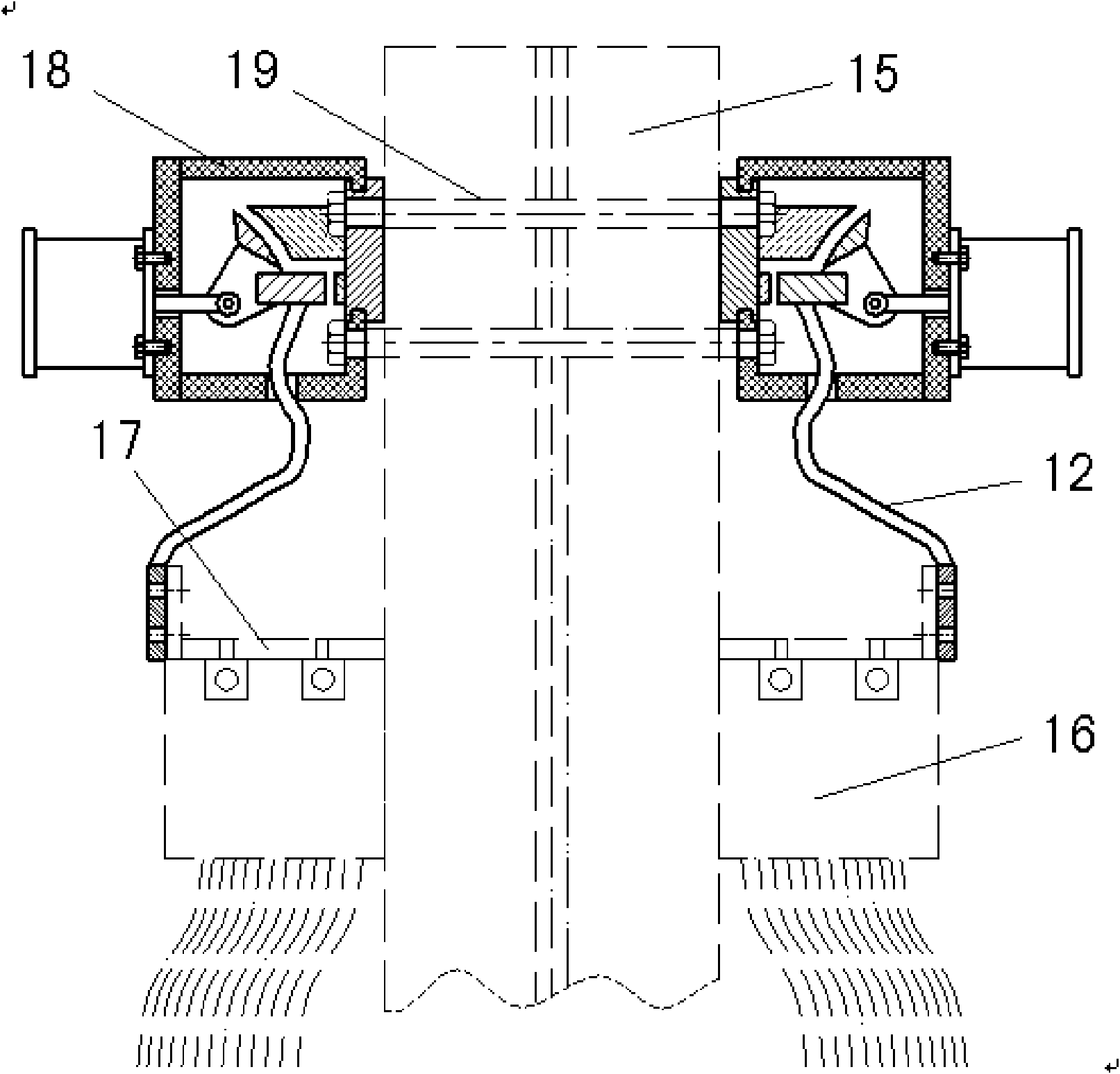

Composite burner of low heating value blast furnace gas

PendingCN109099422AWon't go outReduce security risksGaseous fuel burnerCombustion chamberProcess engineering

The invention discloses a composite burner of low heating value blast furnace gas. The composite burner of the low heating value blast furnace gas comprises a first conveying pipe used for conveying the low heating value blast furnace gas and a second conveying pipe used for conveying oxygen. The second conveying pipe is arranged in the first conveying pipe in a penetrating through mode, and a flame stabilizing plate is arranged at an outlet of the first conveying pipe. The outlet of the first conveying pipe and the flame stabilizing plate can enclose a mixed combustion chamber, an oxygen spray nozzle is arranged at the center of the flame stabilizing plate, and an outlet of the second conveying pipe communicates with the oxygen spray nozzle. A third conveying pipe used for delivering airis arranged in the second conveying pipe, a fourth conveying pipe used for conveying natural gas is arranged in the third conveying pipe, an ignition through hole is formed in the center of the oxygenspray nozzle, and a natural gas spray nozzle communicating with an outlet of the fourth conveying pipe is arranged in the ignition through hole. The composite burner of the low heating value blast furnace gas can adopt the natural gas which always combusts at the center to light the low heating value blast furnace gas all the time, and thus the low heating value blast furnace gas can keep combustion all the time, and safety hazards are greatly reduced.

Owner:JIANGSU XINZHOU WEAR-RESISTANT TECH CO LTD

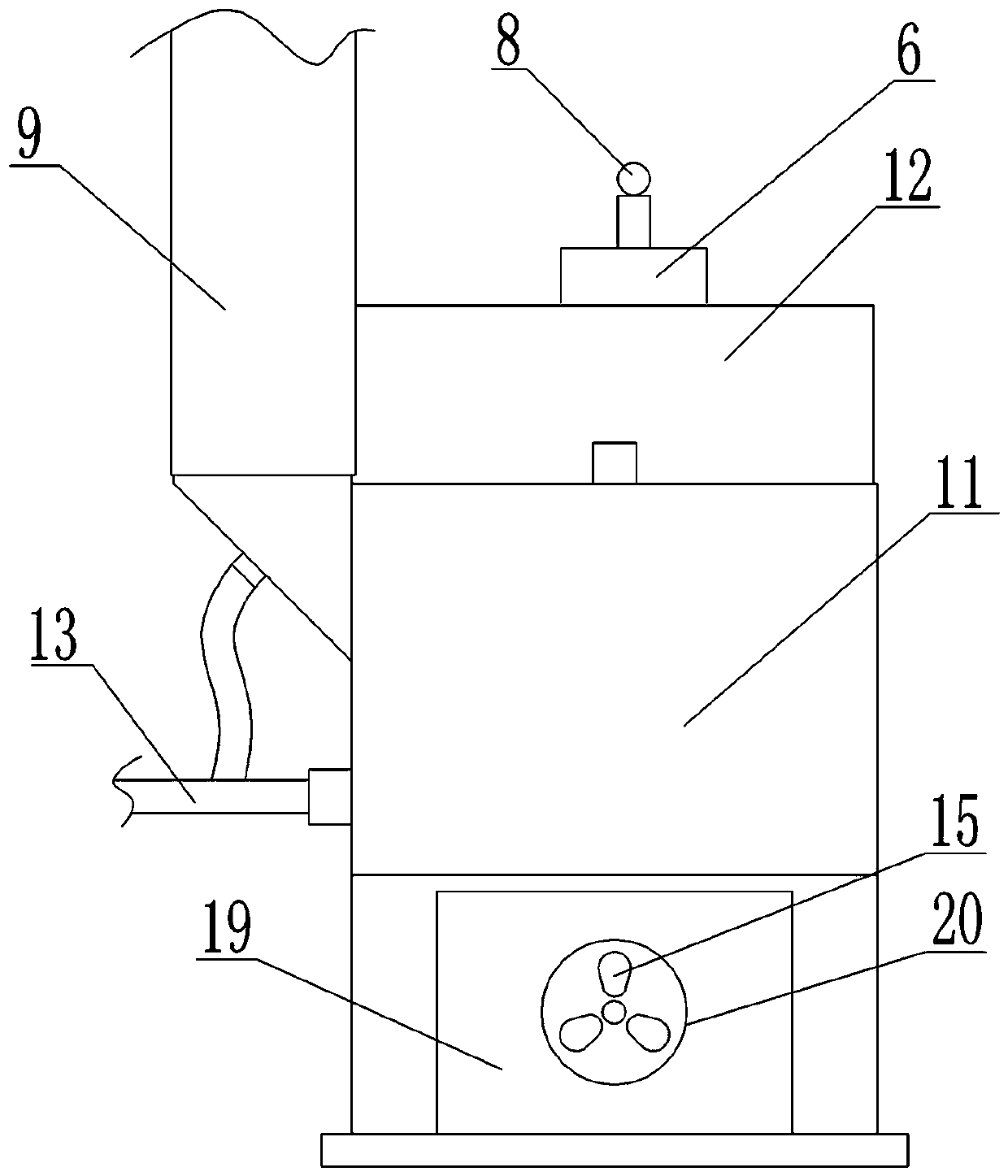

Efficient energy-saving heating furnace

PendingCN111536556AFast heatingEfficient heatingLighting and heating apparatusStove/ranges for heating waterCombustion chamberPollutant emissions

The invention discloses an efficient energy-saving heating furnace, and belongs to the technical field of furnaces. The furnace comprises a furnace body, a combustion chamber, a packing device, an ashsmashing device, a smoke discharging device and a furnace grate, a heat collection water drum is mounted on the furnace body, a cavity is formed in the heat collection water drum, a concave face is mounted on one face, a waste heat recycling device is mounted on the smoke discharging device, and is internally provided with a coiled corrugated pipe, a water tank and a water sleeve are mounted on the furnace body, a heating circulating water system is mounted on the furnace body and comprises a water outlet pipe and a water returning pipe, the water returning pipe is connected with the water tank and one end of the corrugated pipe in the waste heat recycling device, the other end of the corrugated pip is connected with the water outlet pipe, the water tank connects the cavity of the water collection water drum and the water outlet pipe through a pipeline, the water sleeve is connected with the water outlet pipe through a pipeline, the heating area is increased, the combustion heat can be efficiently used, combustion is sufficient, fuel is saved, pollutant emissions can be reduced, safety property is high, the packing is rapid and convenient, and the furnace is suitable for all heating furnaces.

Owner:内蒙古鑫泓庆能源科技发展有限公司

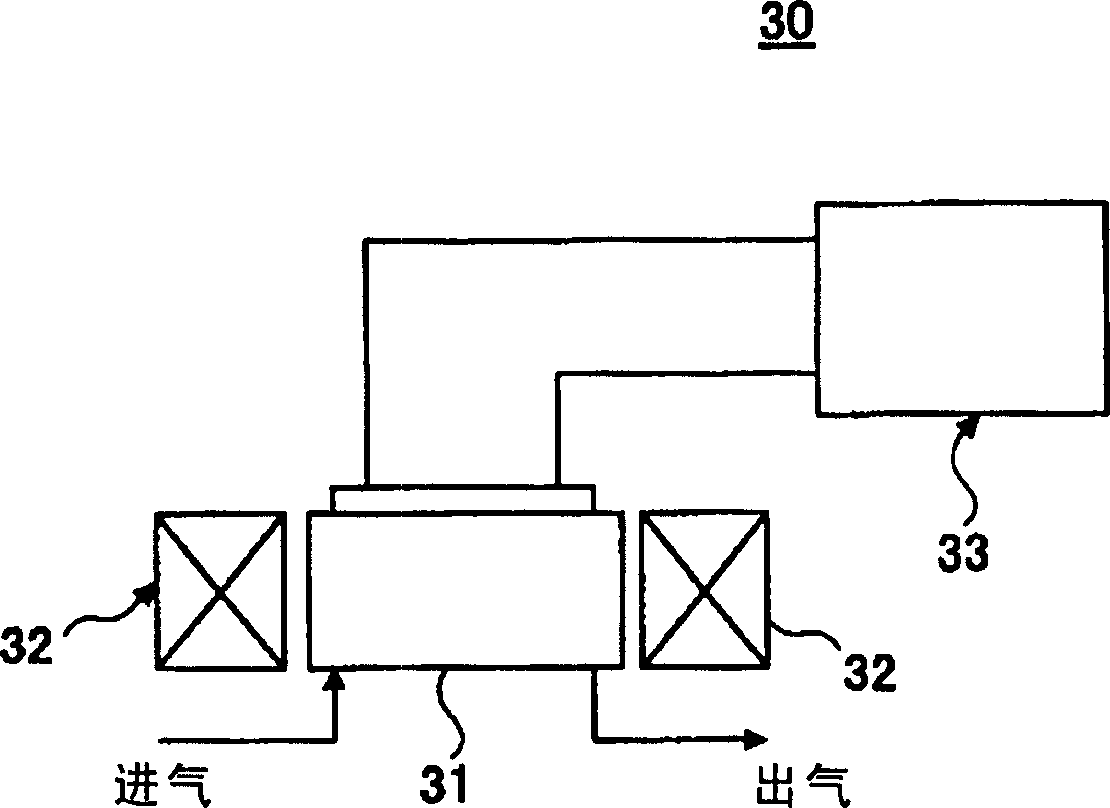

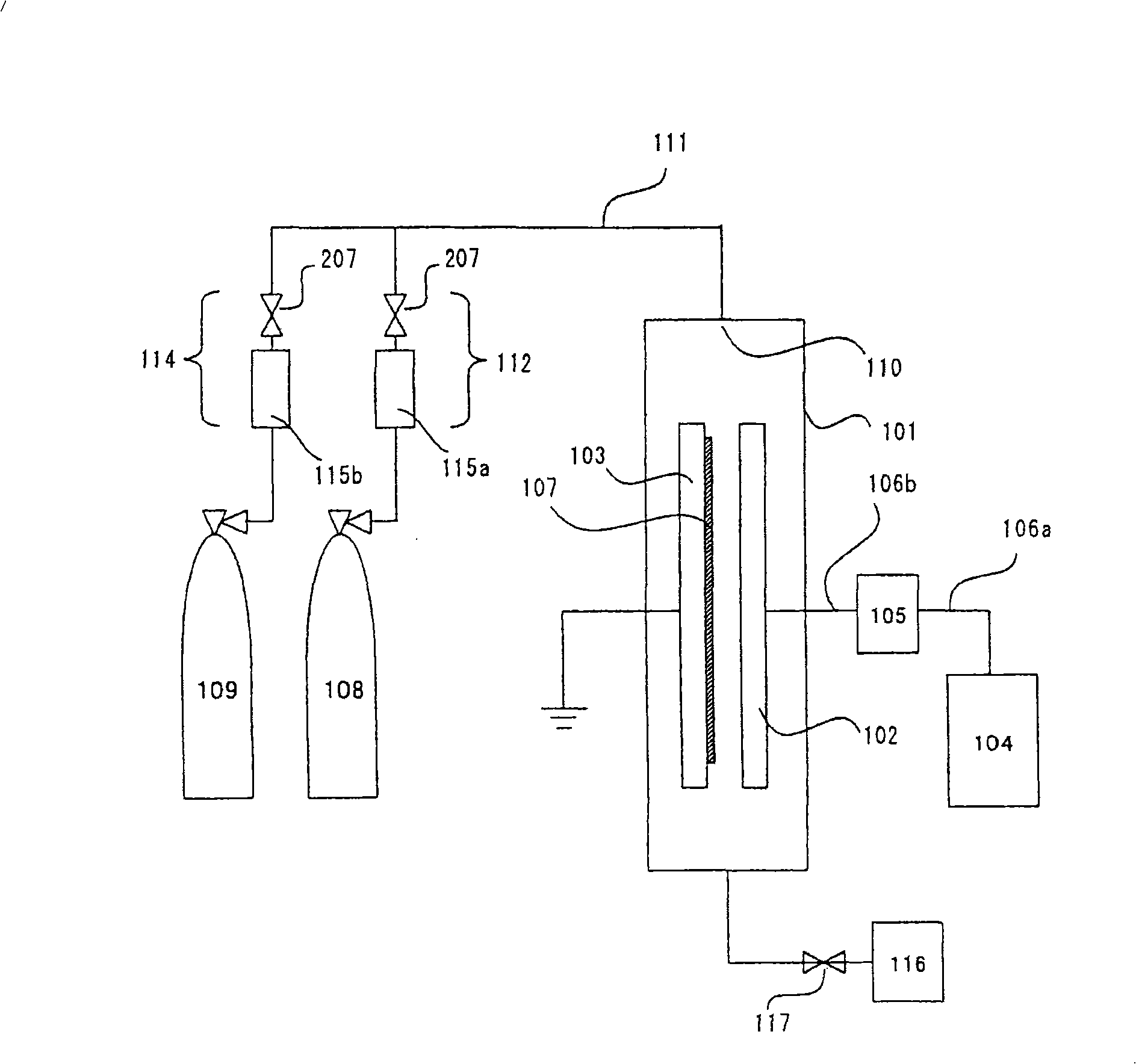

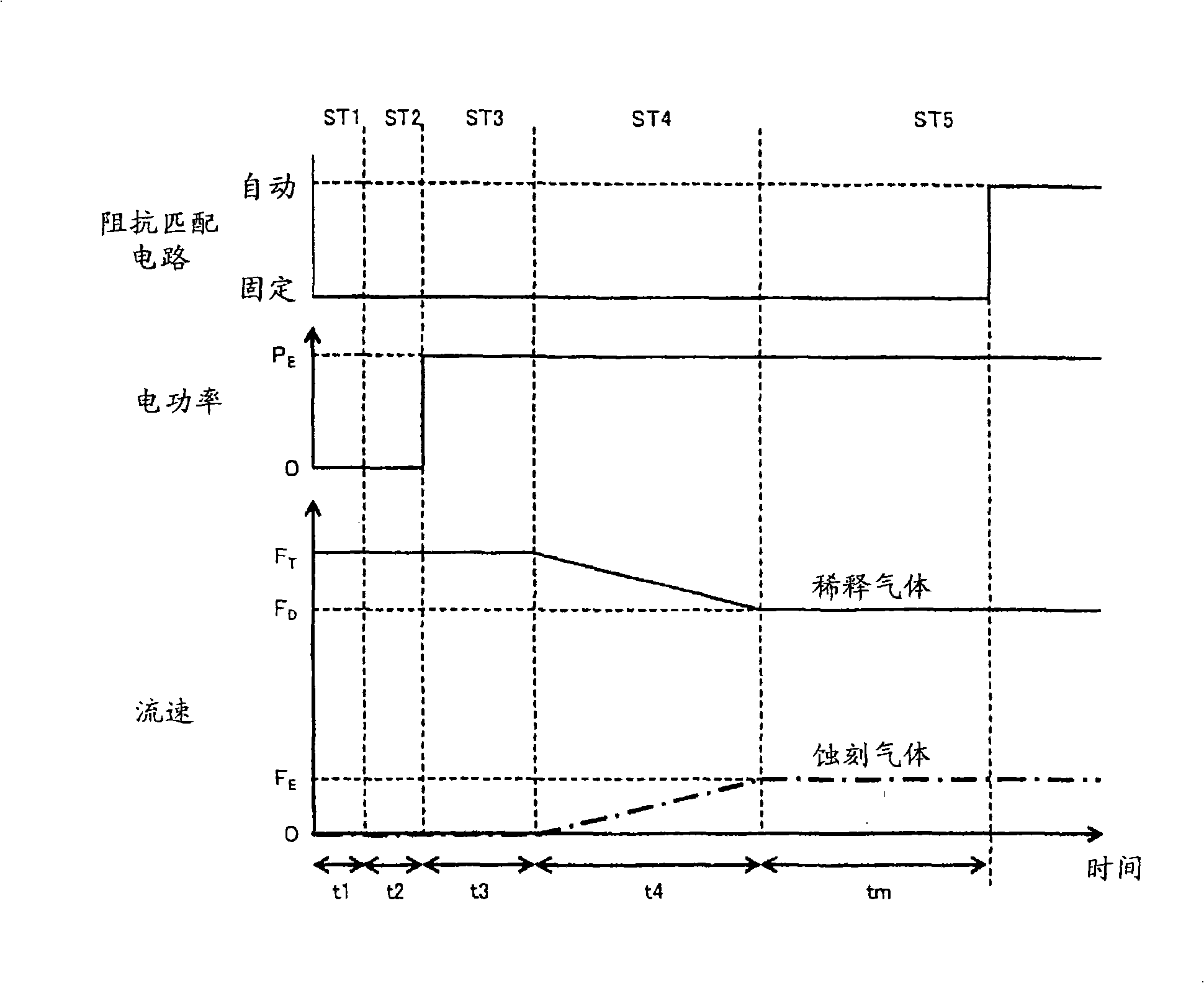

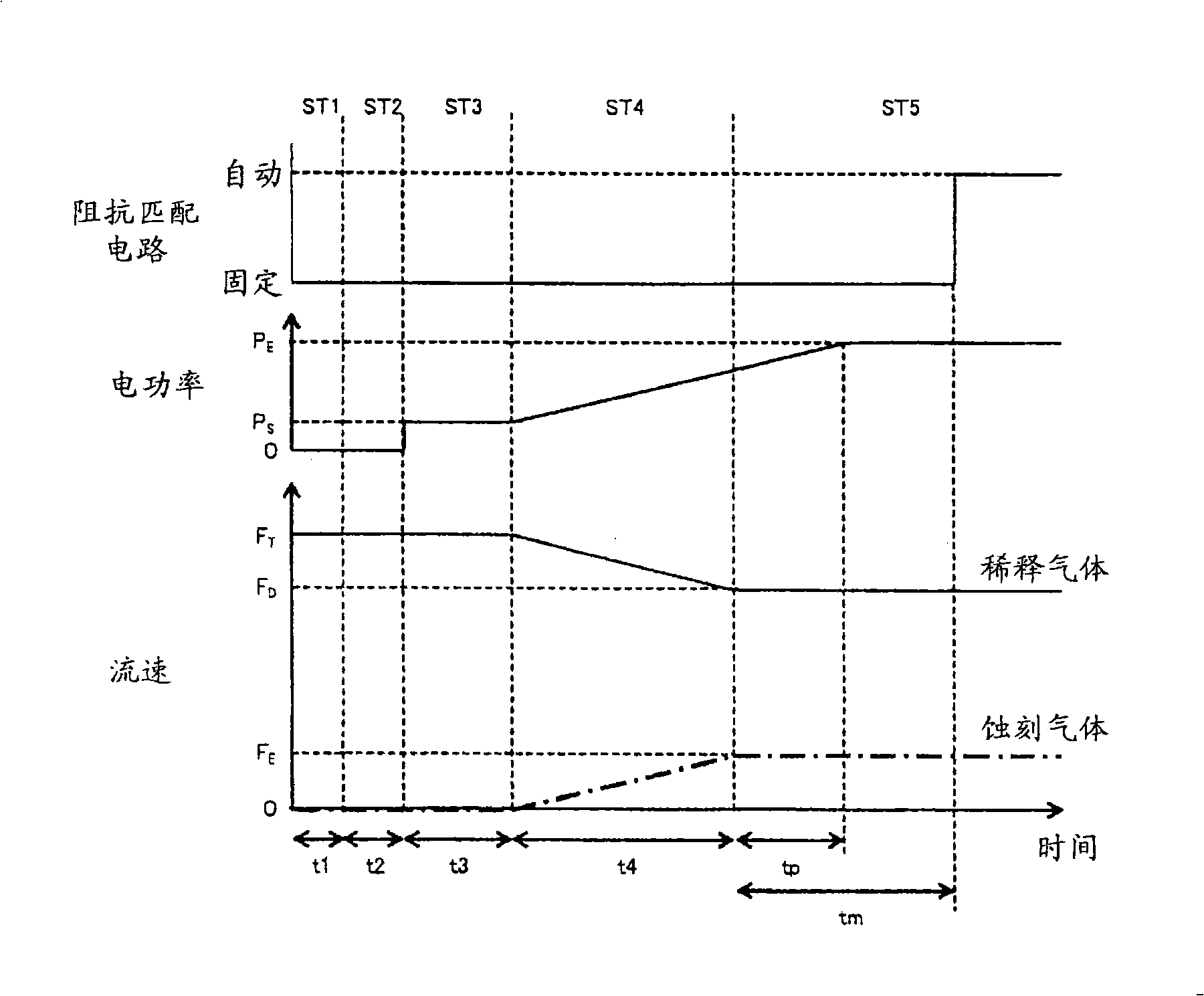

Plasma etching method

InactiveCN101336470AIncrease flow rateReduce flow rateElectric discharge tubesSemiconductor/solid-state device manufacturingStreamflowReaction chamber

Plasma is generated by using a diluent gas which is decomposed more easily than an etching gas. Then, the etching gas is introduced into a plasma process reaction vessel (101) to increase the flow quantity, and at the same time, the flow quantity of the diluent gas of a substantially the same flow quantity is adjusted to be reduced. Pressure fluctuation in the plasma process reaction vessel (101) is reduced, the gas flow quantity is set at a prescribed value while maintaining the generated plasma, and desired conditions are obtained.

Owner:SHARP KK

Arc-extinguishing commutation switch and manufacture method thereof

ActiveCN101609753AReduce arcingIncrease contact areaHigh-tension/heavy-dress switchesAir-break switchesElectric arcEngineering

The invention discloses an arc-extinguishing commutation switch and a manufacture method thereof. The method comprises the following steps: making a static contact base by a cubic material with high conductivity; respectively welding a static main contact and a static arc contact on the static contact base; covering an arc-extinguishing cover outside the static main contact and the static arc contact and exposing the pressing surface of the static contact base outside the arc-extinguishing cover; mounting a magnetic pushing mechanism on an arc-extinguishing cover plane corresponding to the static contact base; and hinging a movable main contact and a movable arc contact on a pushing rod of the magnetic pushing mechanism. The arc-extinguishing commutation switch made by the method bears a great current and has a small electric arc in closing and switching off the switch; low electric potential at both ends of the switch after being switched off can satisfy the need for safely connecting the upright column and the short-circuited block when an electrolytic tank is stopped or opened.

Owner:GUIYANG AL-MG DESIGN & RES INST

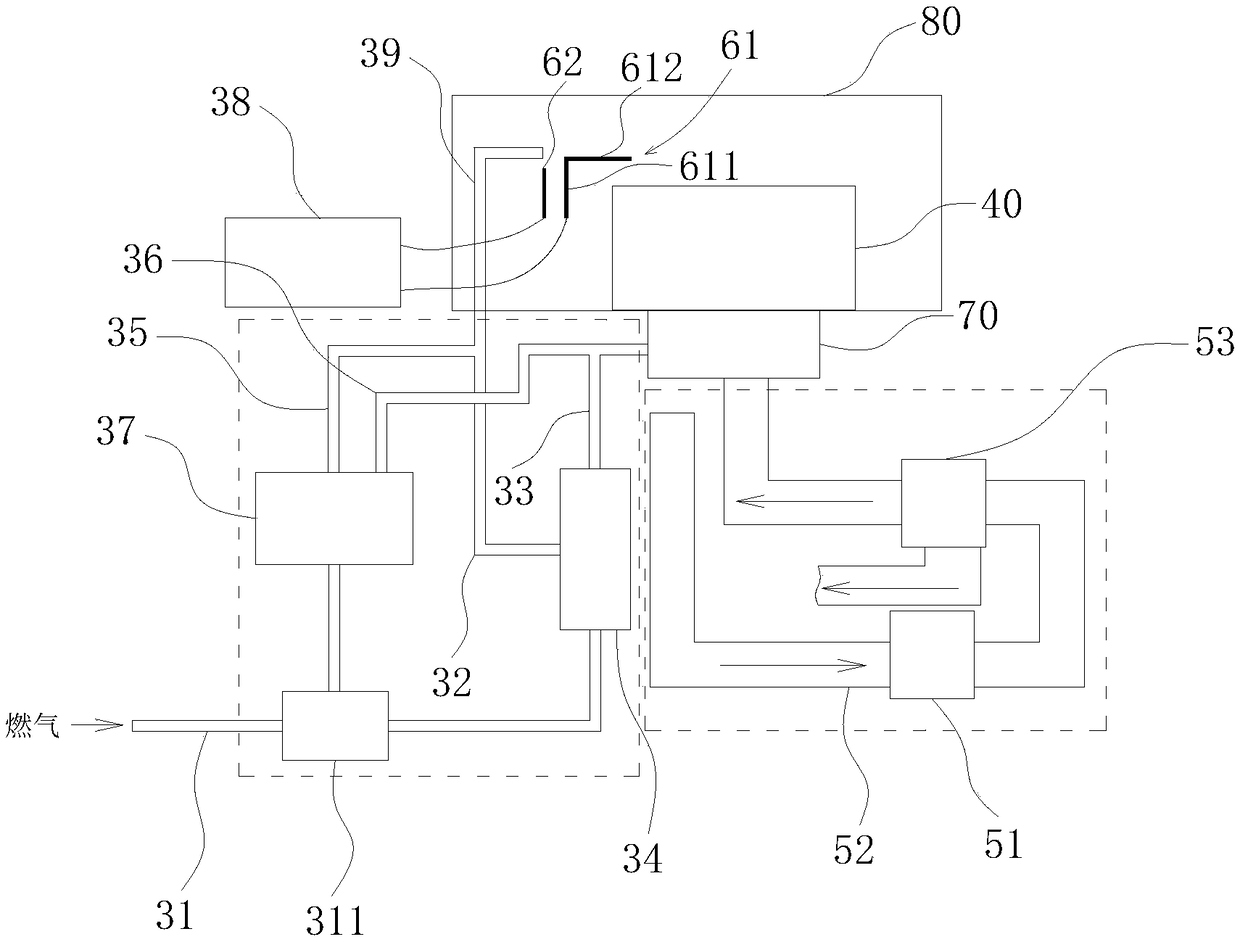

Wind and gas control system for fuel gas stove

ActiveCN108644820ANo misuseImprove securityDomestic stoves or rangesGaseous fuel burnerControl systemFuel gas

The invention relates to a wind and gas control system for a fuel gas stove. The wind and gas control system comprises an automatic ignition gas path unit and a manual ignition gas path unit; the manual ignition gas path unit comprises a pilot flame gas path and a main flame gas path; a first rotary disc used for controlling a pilot flame gas path valve is arranged on the pilot flame gas path; a second rotary disc used for controlling a main flame gas path valve is arranged on the main flame gas path; a first notch is formed in the first rotary disc; a second notch is formed in the second rotary disc; when the edge of the first rotary disc is clamped in the second notch and limits rotation of the second rotary disc, the pilot flame gas path valve and the main flame gas path valve are at aninitial closing state; when the first rotary disc rotates until the first notch and the second notch are opposite and limiting of rotation of the second rotary disc is relieved, the pilot flame gas path valve is at an opening state; and when the second rotary disc rotates until the edge of the second rotary disc is clamped in the first notch to limit rotation of the first rotary disc, the main flame gas path valve is at an opening state. By adopting the wind and gas control system, manual ignition of the stove is safely realized.

Owner:ANHUI HANSUM INSTR EQUIP

Turbine furnace shell

PendingCN111140889AExtended service lifeAvoid safety hazardsStoves/ranges foundationsDomestic stoves or rangesEngineeringEnvironmental geology

The invention belongs to the technical field of gas stove furnace shells, and particularly relates to a turbine furnace shell. The turbine furnace shell includes a furnace shell body, a turbine-shapedejector tube arranged on one side of the furnace shell body and a furnace core covered on the top of the furnace shell body. A high fire channel and a low fire channel are arranged in the furnace shell body. The high fire channel includes an air inlet, a high fire air inlet, a high fire flow channel and a plurality of high fire air outlets. The low fire channel includes a low fire air supply portfor supplying air to a low fire flow channel, a low fire air inlet, the low fire flow channel and a plurality of low fire air outlets. The low fire flow channel is arranged at the center of the furnace shell body, the high fire flow channel is arranged on the outer circle of the low fire flow channel in a surrounding mode, the top end of the low fire flow channel and the top end of the high fireflow channel are connected with the furnace core, the multiple high fire air outlets are evenly formed in the connection position of the furnace core and the high fire flow channel, and the multiple low fire air outlets are evenly formed in the connection position of the furnace core and the low fire flow channel. The low-fire combustion is more stable, the overall combustion fire force is stronger, and the service life is longer.

Owner:浙江博立灶具科技有限公司

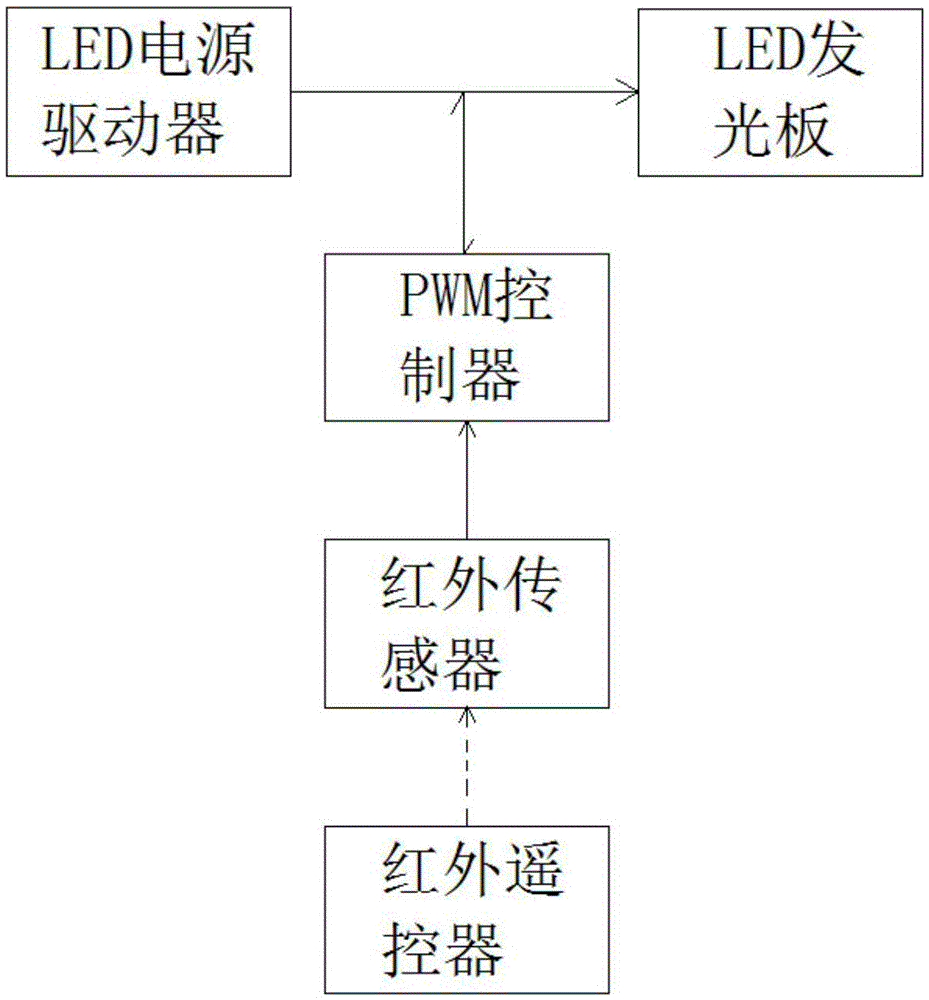

LED intelligent bulb lamp

InactiveCN105485537ALarge light angleExtended lighting rangeElectric circuit arrangementsLighting heating/cooling arrangementsElectricityWhole body

The invention provides an LED intelligent bulb lamp. The LED intelligent bulb lamp comprises a lamp holder, a lamp body, a lamp housing, an LED light source assembly and an LED electric source drive, wherein the lamp housing is a subtransparent light housing of which the illumination angle is 240 degrees or above; a lamp pole which is protruded towards the direction of the lamp housing is connected to the lower end of the lamp body; the LED light source assembly consists of a plurality of LED light emitting plates which are respectively and correspondingly attached to the surface of the whole body of the lamp pole and the lower end surface of the lamp pole; the LED electric source drive is arranged in the lamp body, is connected with the LED light emitting plates, and provides electricity supply; a controller is also connected to the LED electric source drive, consists of a pulse controller and a wireless receiver, and is provided with a corresponding wireless transmitting device. According to the LED intelligent bulb lamp disclosed by the invention, the lamp housing and the lamp pole are combined, so that the LED intelligent bulb lamp has a wide illumination angle, the illumination area is extended, and the illumination dark space is greatly reduced; besides, the luminance of the bulb lamp can be adjusted in a wireless manner, and the luminance of each light emitting part after light adjustment is harmonized and uniform.

Owner:JIANGXI HUIRONG IND

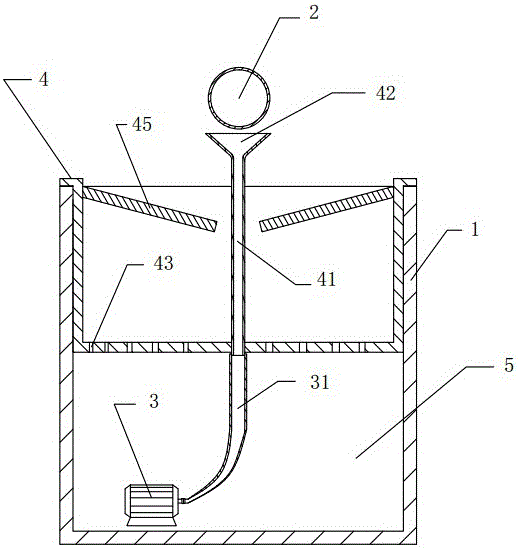

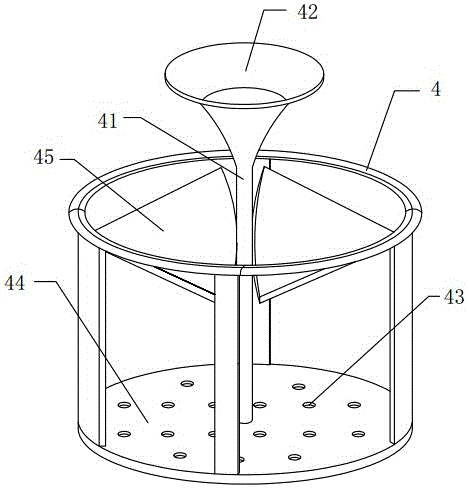

Glass cigarette ash cup provided with fortune ball

The invention relates to the field of ashtrays, and in particular to a glass cigarette ash cup provided with a fortune ball. The cigarette ash cup comprises a cylindrical cup body, and further comprises a filter screen rack, a water pump and the fortune ball which are arranged in the cup body, wherein the filter screen rack comprises a rack body and a water retaining side; by virtue of the water retaining side, the cup body is divided into an upper cavity layer and a lower cavity layer; two fan-shaped movable plates are connected to the rack body; the water pump is located within the lower cavity layer of the cup body; a pipeline is connected to the water pump; a water pillar, which is provided with a trumpet-shaped port, is connected into the filter screen rack by virtue of a screw thread; the bottom of the water pillar extends out of the water retaining side and is connected to the pipeline by virtue of a screw thread; and the fortune ball is arranged on the trumpet-shaped port of the water pillar. With the application of the glass cigarette ash cup provided by the invention, cigarette ash can be prevented from flying around, the cigarette ash, which accumulates in the upper cavity layer, is free from smell, and the cigarette ash, which does not accumulate on the surface of the cigarette ash cup, is free from influence on the appearance of the cigarette ash cup.

Owner:CHONGQING XINGYUAN GLASSWARE CO LTD

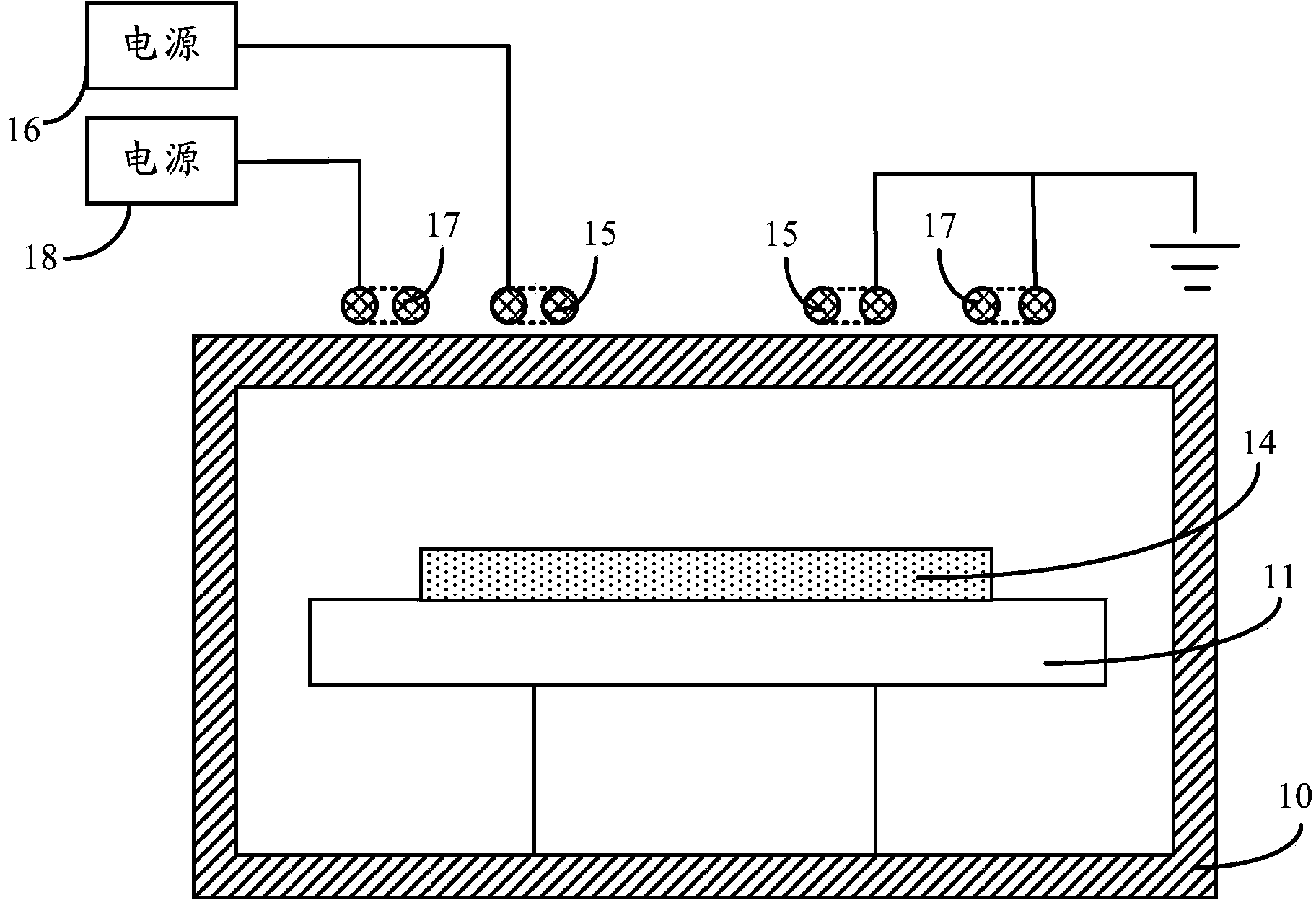

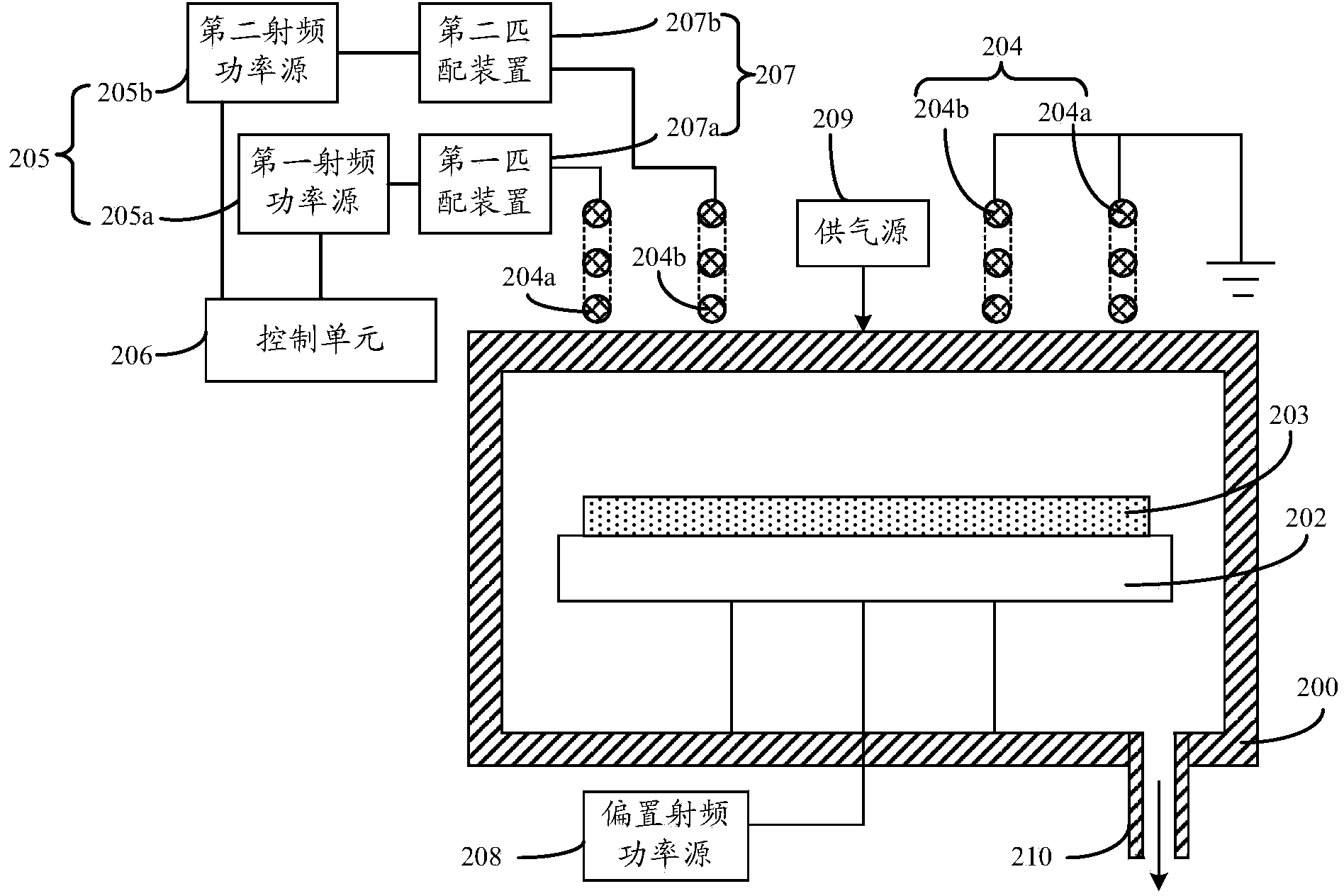

Plasma processing device and plasma processing method

ActiveCN103476196BUniform density distributionStable density distributionPlasma techniqueRadio frequency signalTherapeutic effect

Provided are a plasma treatment device and a plasma treatment method. The plasma treatment device comprises a plurality of concentrically-distributed inductive coupling coils arranged at the top of a reaction cavity and used for plasma treatment of gas in the reaction cavity, a plurality of radio-frequency power sources for respectively providing impulse type radio-frequency signals for the inductive coupling coils, and a control unit connected to the first radio-frequency power source and the second radio-frequency power source at least and used for controlling the impulse type radio-frequency signals formed by shifting of radio-frequency power output by the first radio-frequency power source and the second radio-frequency power source between the high-power output and the low-power output, wherein the inductive coupling coils are opposite to a wafer supporting table, the low-power output is larger than zero, and the control unit enables the impulse type radio-frequency power output by the first radio-frequency power source and the second radio-frequency power source to be independent and adjustable. The plasma distribution in the plasma treatment device is even, and the plasma treatment effect is good.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

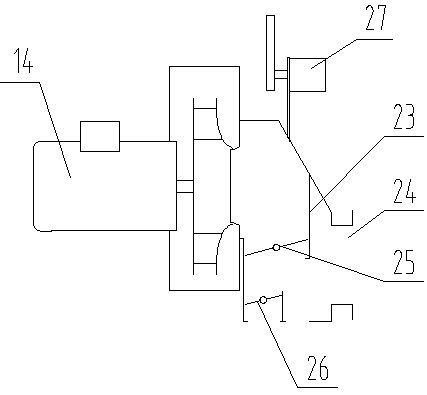

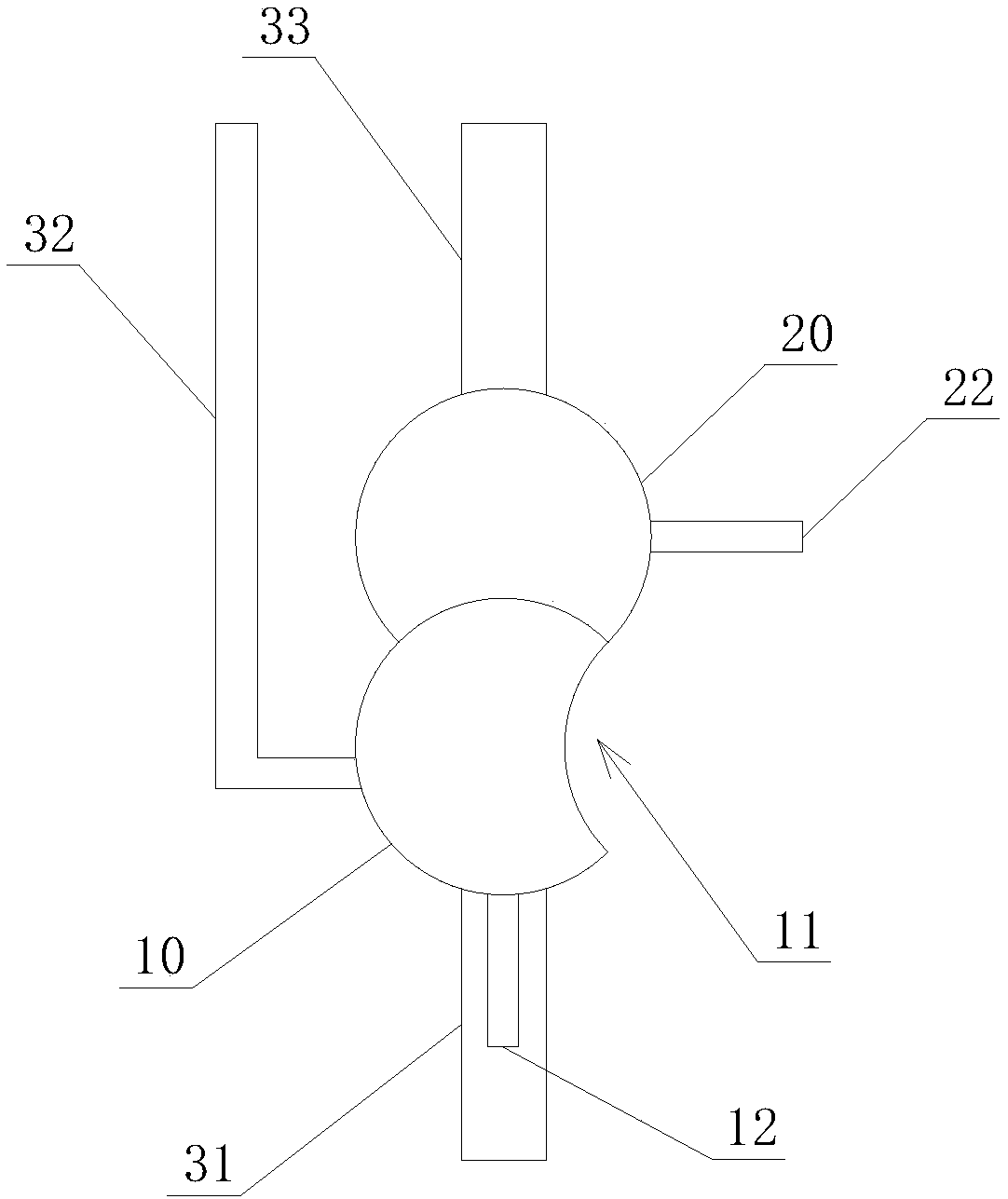

A fool-proof device for manually igniting a stove

ActiveCN108266757BNo misuseImprove securityDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a foolproof device for manual ignition of a cooking range. The foolproof device includes a first turntable for controlling a pilot flame gas passage valve and a second turntable for controlling a main flame gas passage valve. The first turntable is provided with a first notch. The second turntable is provided with a second notch. When the disk edge of the first turntable except the first notch is stuck in the second notch and limits the rotation of the second turntable, the pilot flame gas passage valve and the main flame gas passage valve are initially closed, when the first turntable rotates to the first notch and is opposite to the second turntable and the limitation of the second turntable rotation is released, the pilot flame gas passage valve is open, and when the disk edge of the rotating second turntable except the second notch is stuck in the first notch and limits the rotation of the first turntable, the main flame gas passage valve is open. The foolproof device greatly improves the safety of the manual ignition of the cooking range, and ensures that the pilot flame will not be extinguished due to the misoperation of the manual ignition valve in the case of the main fire ignition.

Owner:ANHUI HANSUM INSTR EQUIP

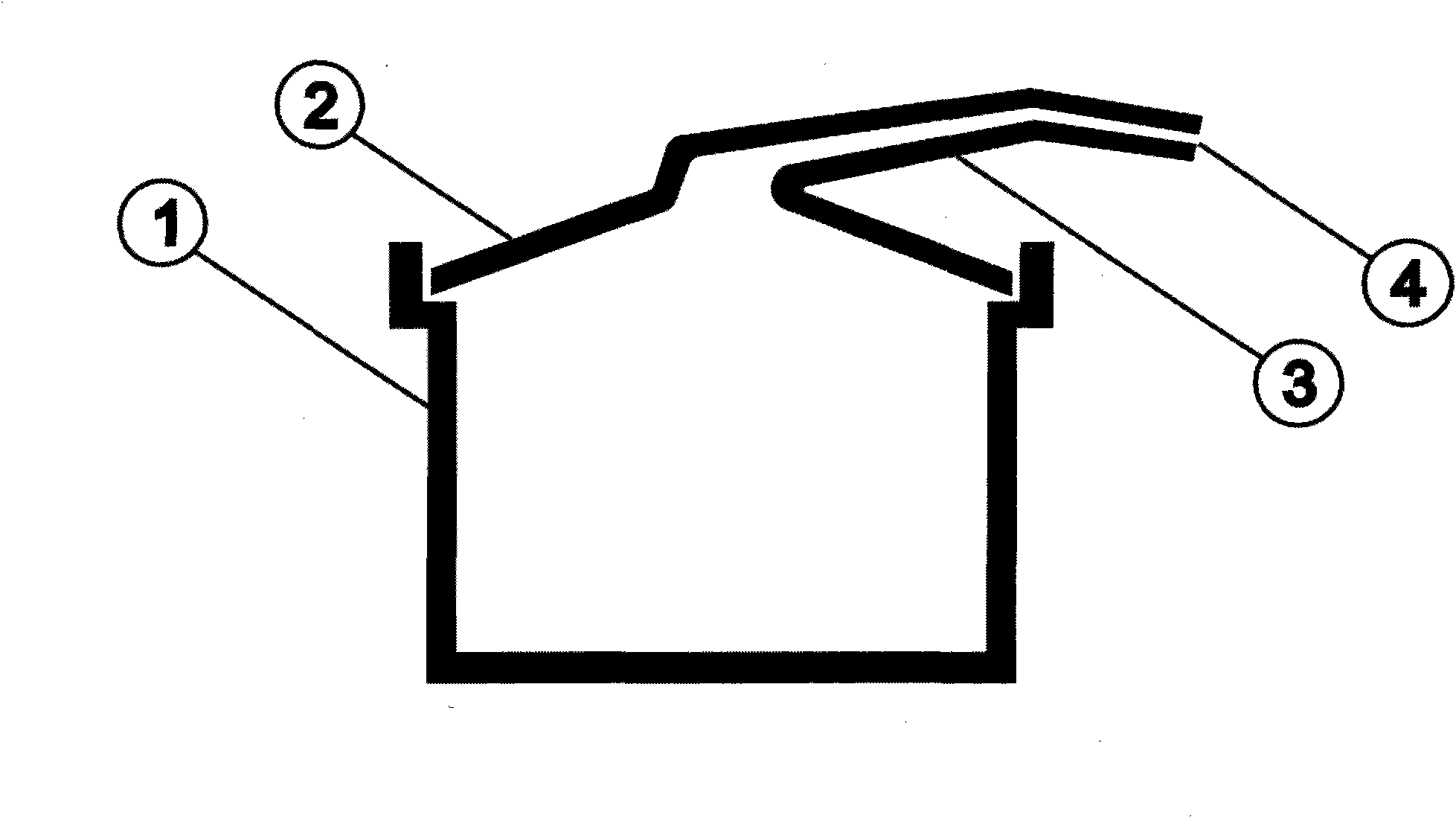

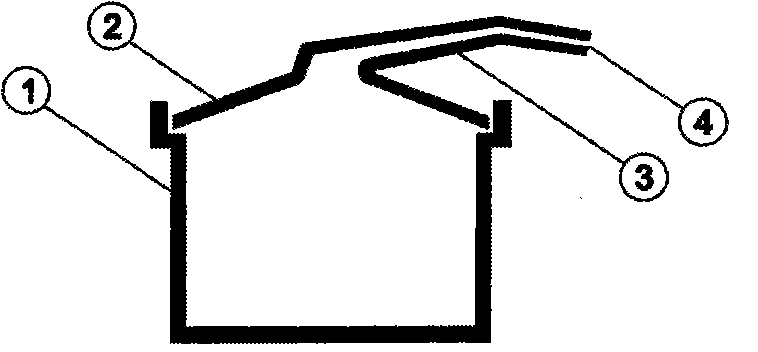

Cooling duct type overflow guiding pot

InactiveCN102462372AWon't go outSimple structureCooking vesselsHigh volume manufacturingAerospace engineering

The invention is named a cooling duct type overflow guiding pot, and relates to an overflow guiding pot. At present, the potential safety hazard that overflow liquid flows down along the edge of a pot to extinguish fire is not completely avoided by the publicly known safety pot for preventing the fire of an overflow pot from being extinguished; an overflow guiding pot which guides the overflow liquid reasonably to prevent the overflow liquid from contacting the fire safely and effectively is not provided in the market; and the invention aims to provide the cooling duct type overflow guiding pot which can safely guide the overflow liquid and is low in cost. Measures that a pot cover is connected below a cooling duct, an overflow guiding port is formed above the cooling duct, the pot cover is buckled with the overflow guiding pot, and the cooling duct extends and exceeds the outer side of the overflow guiding pot are adopted to fulfill the aim. The invention has the advantages that: the pot has a simple structure, is low in manufacturing cost, easy to manufacture in batches and easy and convenient to use, effectively guides the overflow liquid in the pot under the condition that the fire is not extinguished, and has high safety protection performance.

Owner:金英俊

Coal ball stove

InactiveCN101004271AIncreased load-bearing capacityWide range of optionsDomestic stoves or rangesLighting and heating apparatusElectric controlElectric ignition

The present invention discloses an egg-shaped coal stove with electric ignition function. It includes stove shell, stove top, fire hole, stove cavity, fire door, stove bottom plate, stove legs, refractory cement, heat-insulating filler, stove core, electroheating tube, and input / output high-temperature-resisting wire, electroheating tube fixing frame, stove core supporting frame and electric control device. Said invention also provides the working principle of said electric ignition type egg-shaped coal stove and its concrete operation method.

Owner:叶纯金

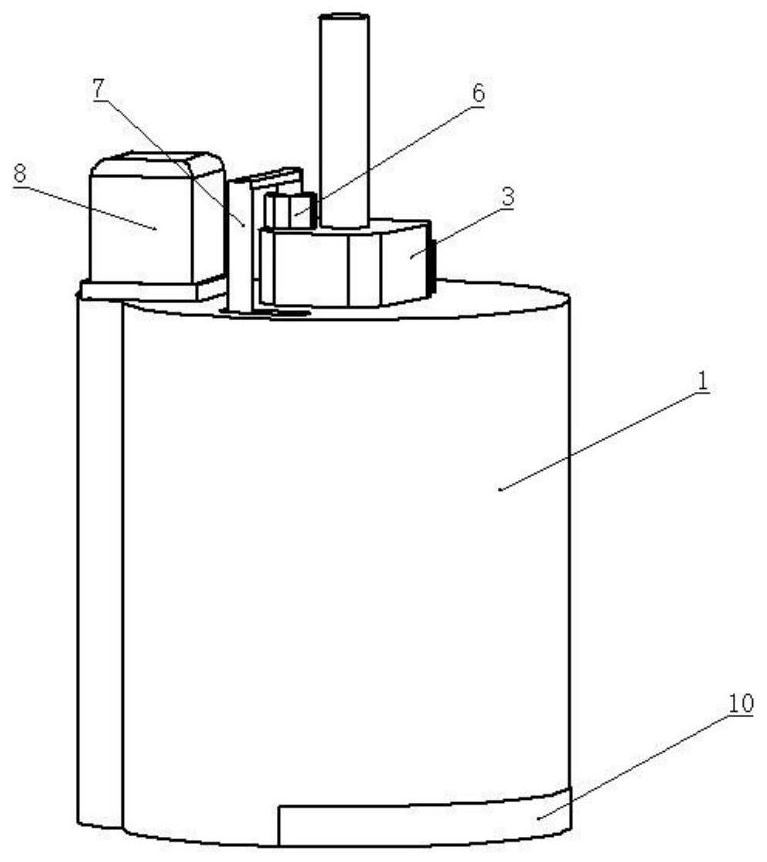

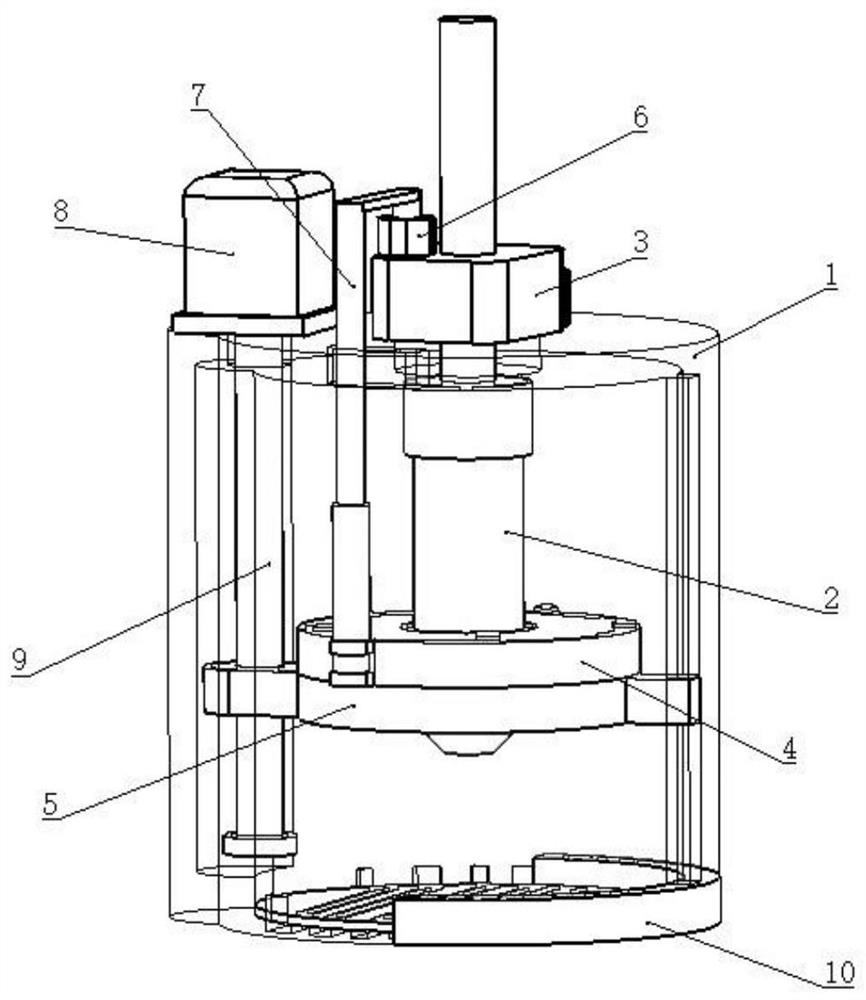

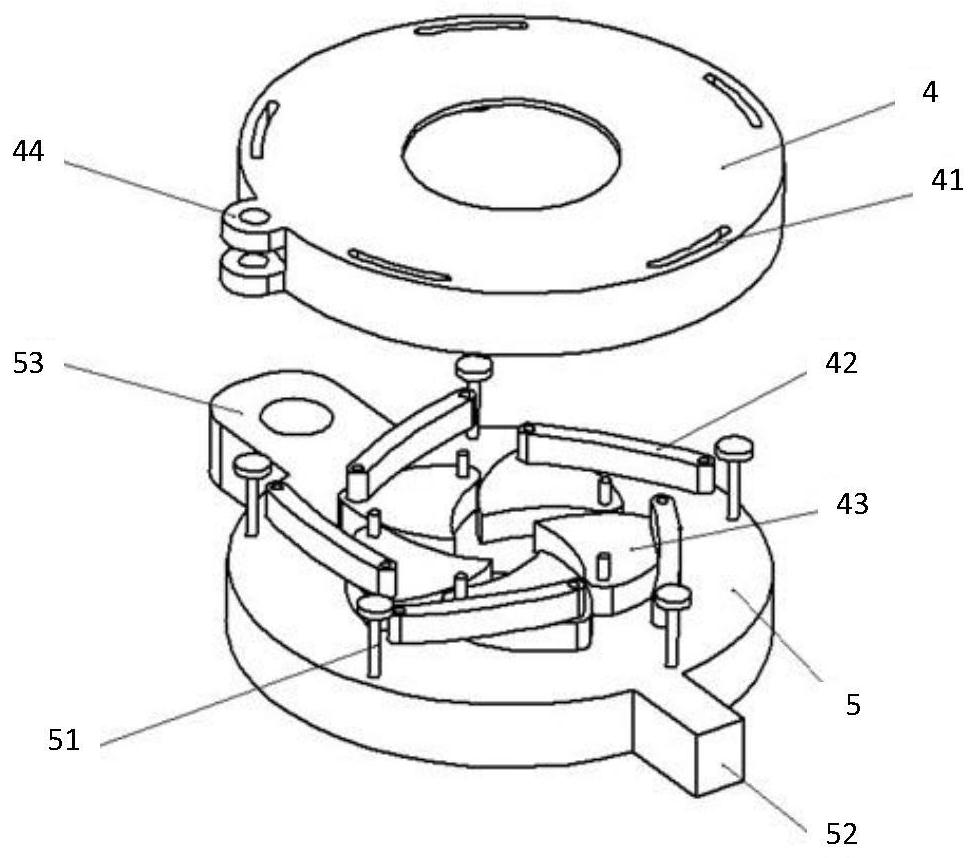

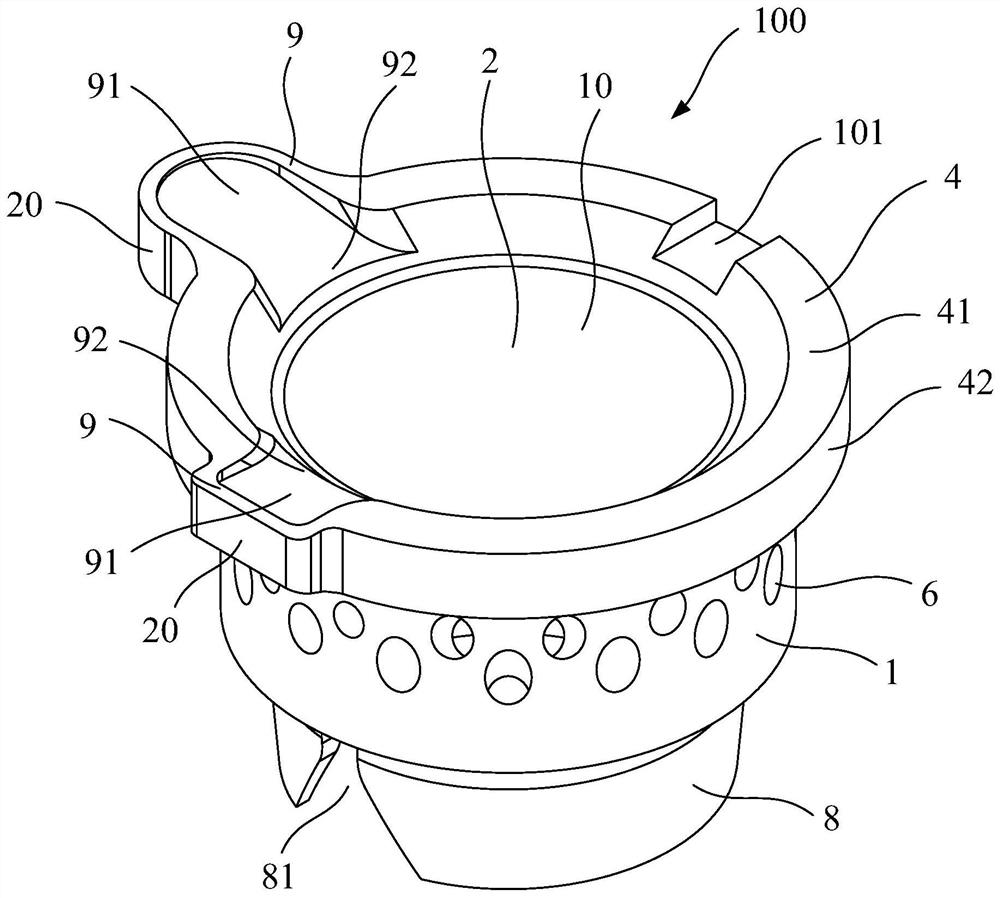

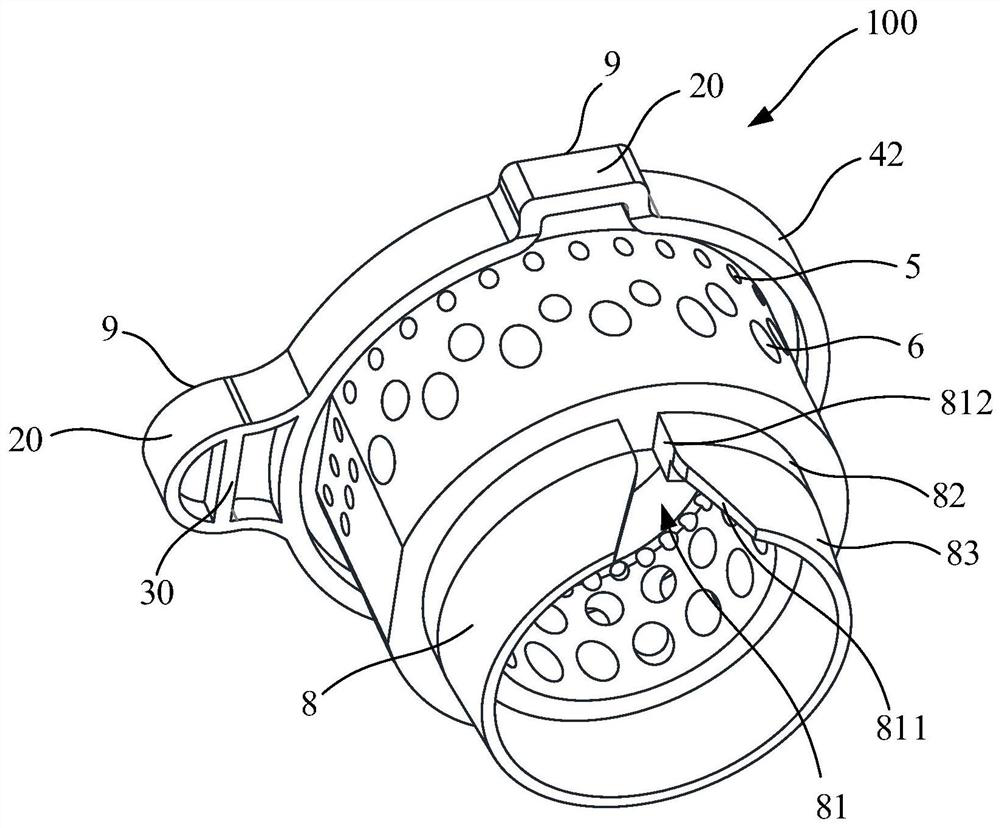

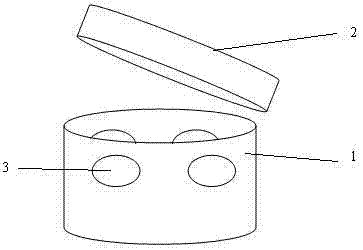

Mechanical iris type moxibustion ash removal device for moxibustion equipment

PendingCN111658498ATimed clearAsh removal realizedDevices for heating/cooling reflex pointsCleaning using toolsReciprocating motionSurgery

The invention discloses a mechanical iris type moxibustion ash removal device for moxibustion equipment. The device comprises an approximately cylindrical and vertically-arranged shell; a moxa stick driving device for driving a moxa stick to reciprocate up and down is arranged in the center of the top surface of the shell; the output end of the moxa stick driving device penetrates through the topsurface of the shell and then is connected with the moxa stick; a mechanical iris device is arranged in the shell and is horizontally arranged outside the moxa stick in a sleeving mode; and the top surface of the shell is also provided with a feeding driving device for driving the mechanical iris device to reciprocate up and down, and an opening and closing driving device for driving the mechanical iris device to open and close. Residual ash can be removed regularly, the ash removal effect is good, and moxa sticks cannot be extinguished in an ash removal process.

Owner:ZHEJIANG UNIV OF TECH

A device and method for reducing the resistance of a high-resistance fault point of a power cable

ActiveCN105807185BReduce arcingLower resistanceFault location by conductor typesHigh resistanceEngineering

Owner:西安宇铭电物理技术有限责任公司 +2

Foolproof device for manual ignition of cooking range

ActiveCN108266757ASimple structureEasy to useDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

The invention relates to a foolproof device for manual ignition of a cooking range. The foolproof device includes a first turntable for controlling a pilot flame gas passage valve and a second turntable for controlling a main flame gas passage valve. The first turntable is provided with a first notch. The second turntable is provided with a second notch. When the disk edge of the first turntable except the first notch is stuck in the second notch and limits the rotation of the second turntable, the pilot flame gas passage valve and the main flame gas passage valve are initially closed, when the first turntable rotates to the first notch and is opposite to the second turntable and the limitation of the second turntable rotation is released, the pilot flame gas passage valve is open, and when the disk edge of the rotating second turntable except the second notch is stuck in the first notch and limits the rotation of the first turntable, the main flame gas passage valve is open. The foolproof device greatly improves the safety of the manual ignition of the cooking range, and ensures that the pilot flame will not be extinguished due to the misoperation of the manual ignition valve in the case of the main fire ignition.

Owner:ANHUI HANSUM INSTR EQUIP

A forced heat dissipation high-power LED lamp

ActiveCN104132271BEfficient heat dissipationAchieve maintenance-freeElectric circuit arrangementsLighting heating/cooling arrangementsJunction temperatureEngineering

The invention relates to LED illumination lamps, in particular to a forced-cooling high-power LED lamp. The forced-cooling high-power LED lamp comprises a lamp shell, an air inlet area, a heat dissipation area and an air exhaust area, and the air inlet area, the heat dissipation area and the air exhaust area are assembled in the lamp shell. An air inlet separation plate is arranged between the air inlet area and the heat dissipation area, and air inlet separation plate air guide holes are formed in the air inlet separation plate. An air exhaust separation plate is arranged between the heat dissipation area and the air exhaust area, and air exhaust separation plate air guide holes are formed in the air exhaust separation plate. The forced-cooling high-power LED lamp has the advantages of being high in power, light, high in light efficiency, low in junction temperature, high in energy efficiency, low in cost, free of maintenance and capable of being intelligently controlled.

Owner:天津朝辉照明科技有限公司

Burner cap

The invention discloses a burner cap. The burner cap comprises an annular outer ring, an upper cap face, a waterproof eave and a plurality of flame stabilizing holes; the upper end face is located onthe end face of the outer ring, and a gas mixing chamber is formed between the inner circumferential face of the outer ring and the upper cap face; the waterproof eave is arranged along the outer circumferential face of the upper cap face; and the flame stabilizing holes are formed in the mode of penetrating the outer ring and enable the gas mixing chamber to communicate with an external space, and the extension line of at least one flame stabilizing hole extends to the waterproof eave. According to the burner cap, the waterproof eave is arranged along the outer circumferential face of the upper cap face, the extension lines of the flame stabilizing holes are made to extend to the waterproof eave, that is, outlets of the flame stabilizing holes are located in a safe space formed between the waterproof eave and the outer circumferential face of the outer ring, thus flames in the flame stabilizing holes can keep stable and cannot be extinguished by overflowing liquid, the flame stabilizing holes are also not blocked due to entering of the liquid, and the flame stabilizing effect is good.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

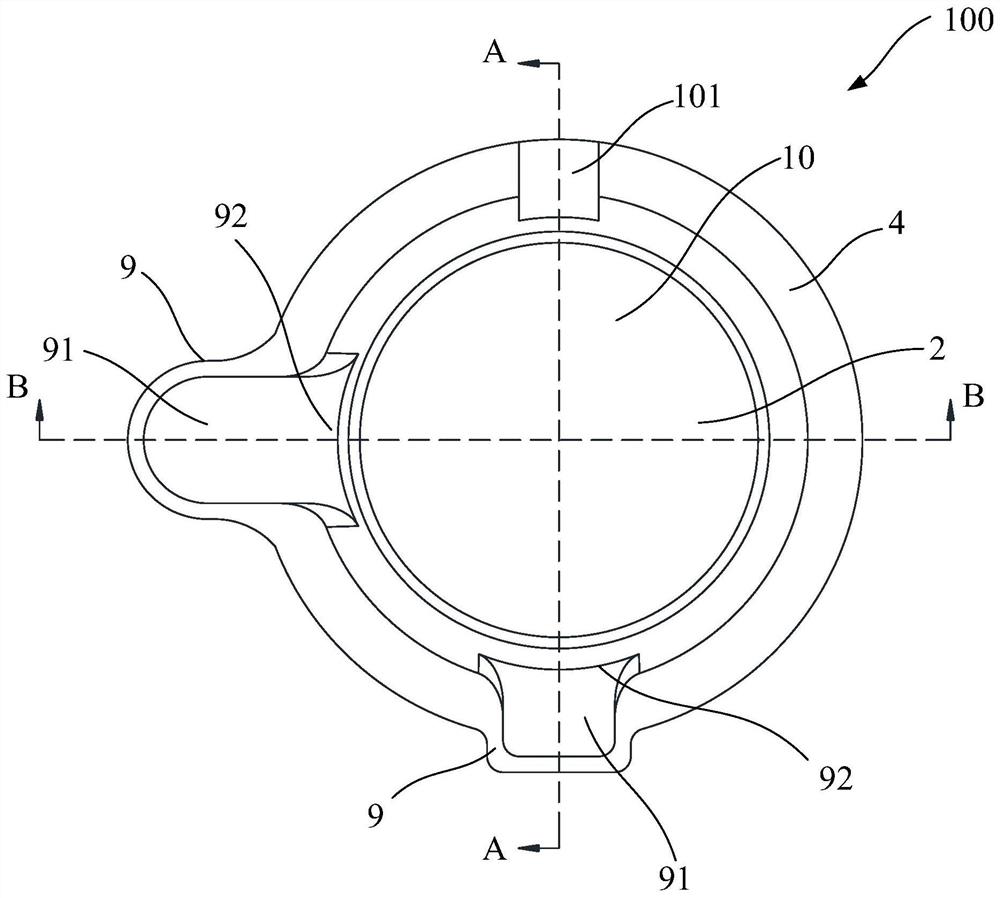

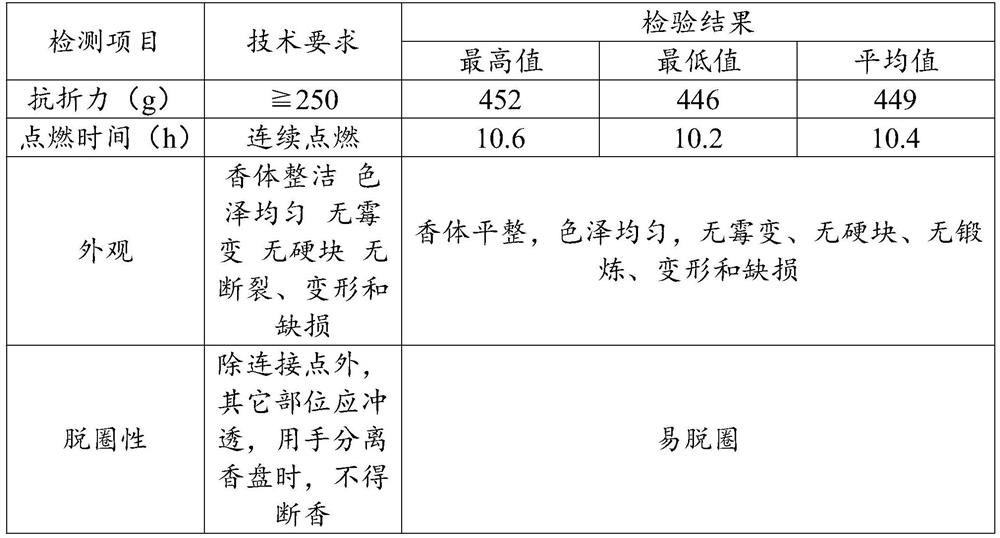

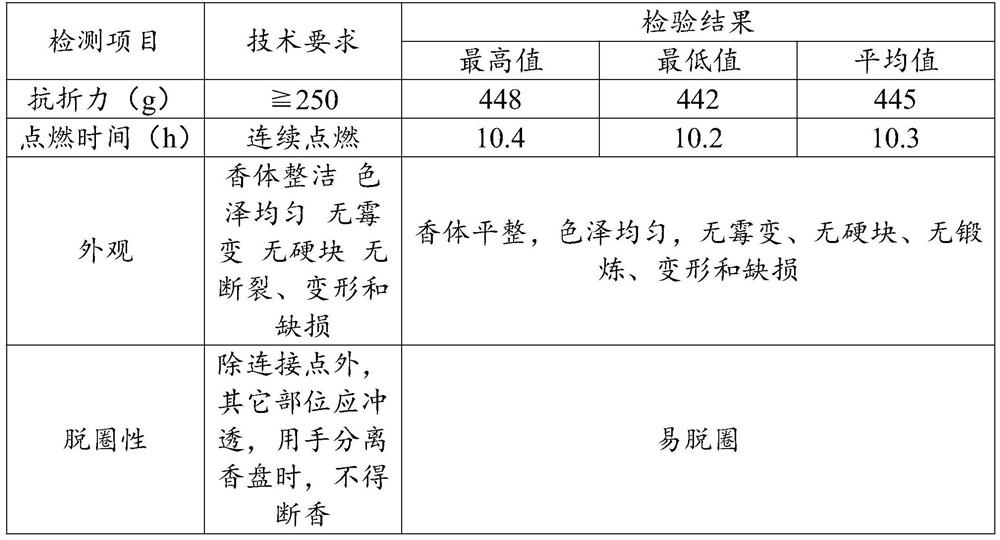

Mosquito-repellent incense with good combustion performance and preparation method thereof

The invention discloses mosquito-repellent incense with good combustion performance. The mosquito-repellent incense is prepared from the following components of: 110 to 130kg of wood powder; 20 to 40kg of viscous powder; 10 to 20kg of insect expelling substances; 2 to 5kg of graphene; and 5 to 10kg of aluminum oxide. The preparation method comprises the following steps of: weighing the raw materials in parts by weight, sieving the raw materials and removing impurities; mixing the impurity-removed wood flour, viscous powder, pyrethroid and aluminum oxide; adding water into the mixture, stirringuntil the water content is 50-60%, adding the graphene, and uniformly stirring to obtain a mixture; and feeding the mixture into a mosquito-repellent incense forming machine so as to be subjected toextrusion, blank pressing, punch forming, demolding, drying, flushing and tray stacking to obtain the mosquito-repellent incense. The continuous ignition time of the mosquito-repellent incense is long, and the mosquito-repellent incense exerts no harm to a human body.

Owner:柳州市旭光科技有限公司

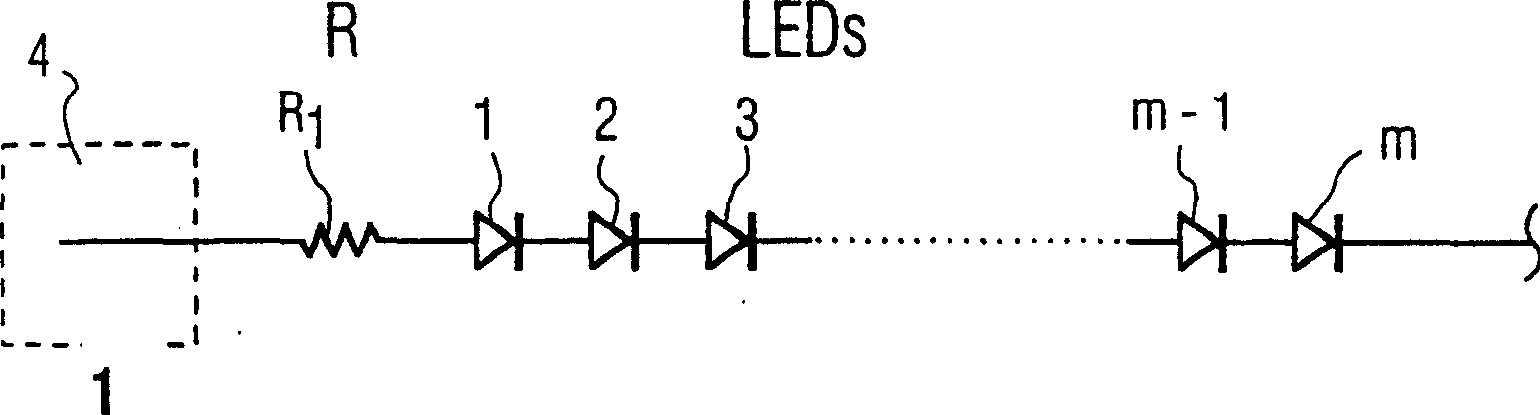

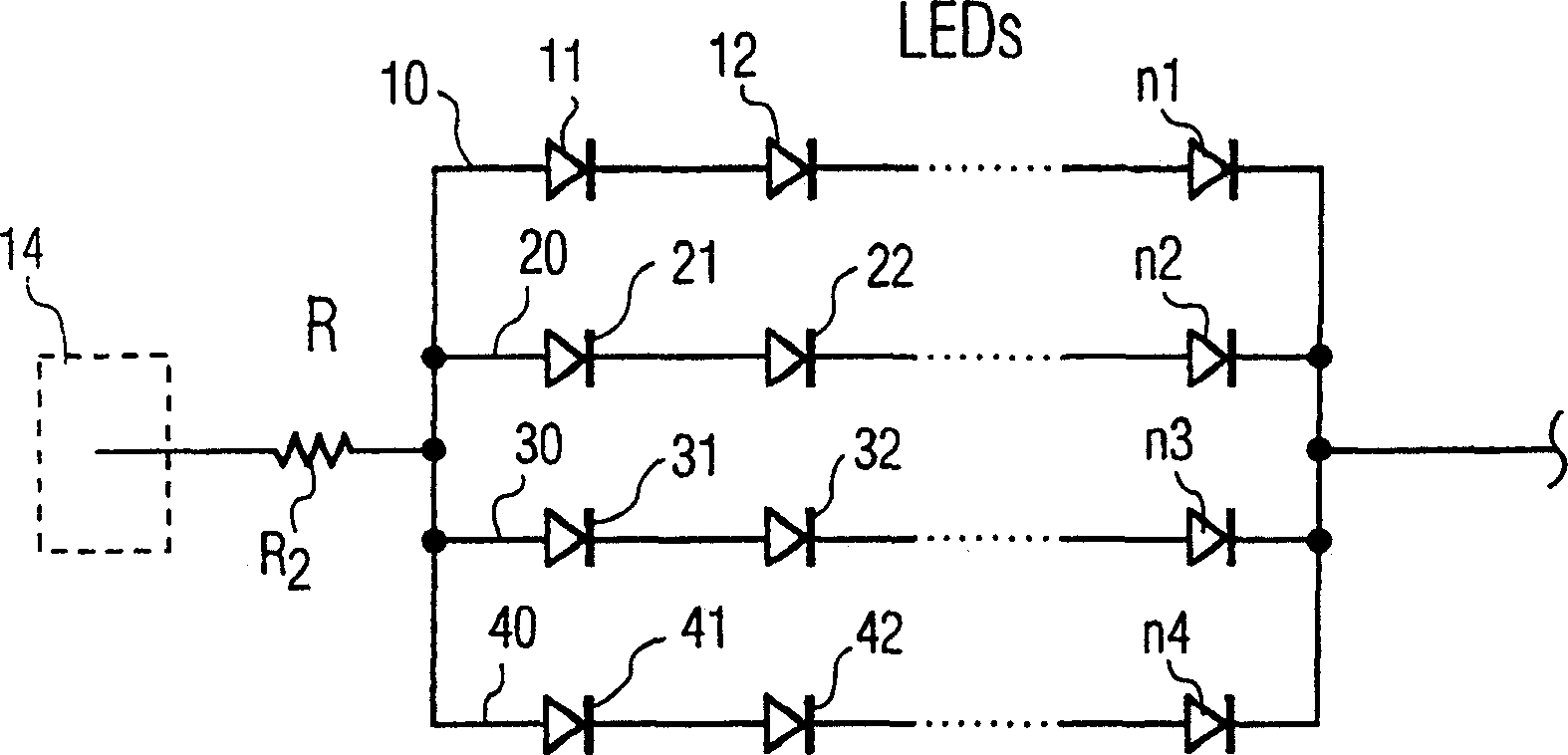

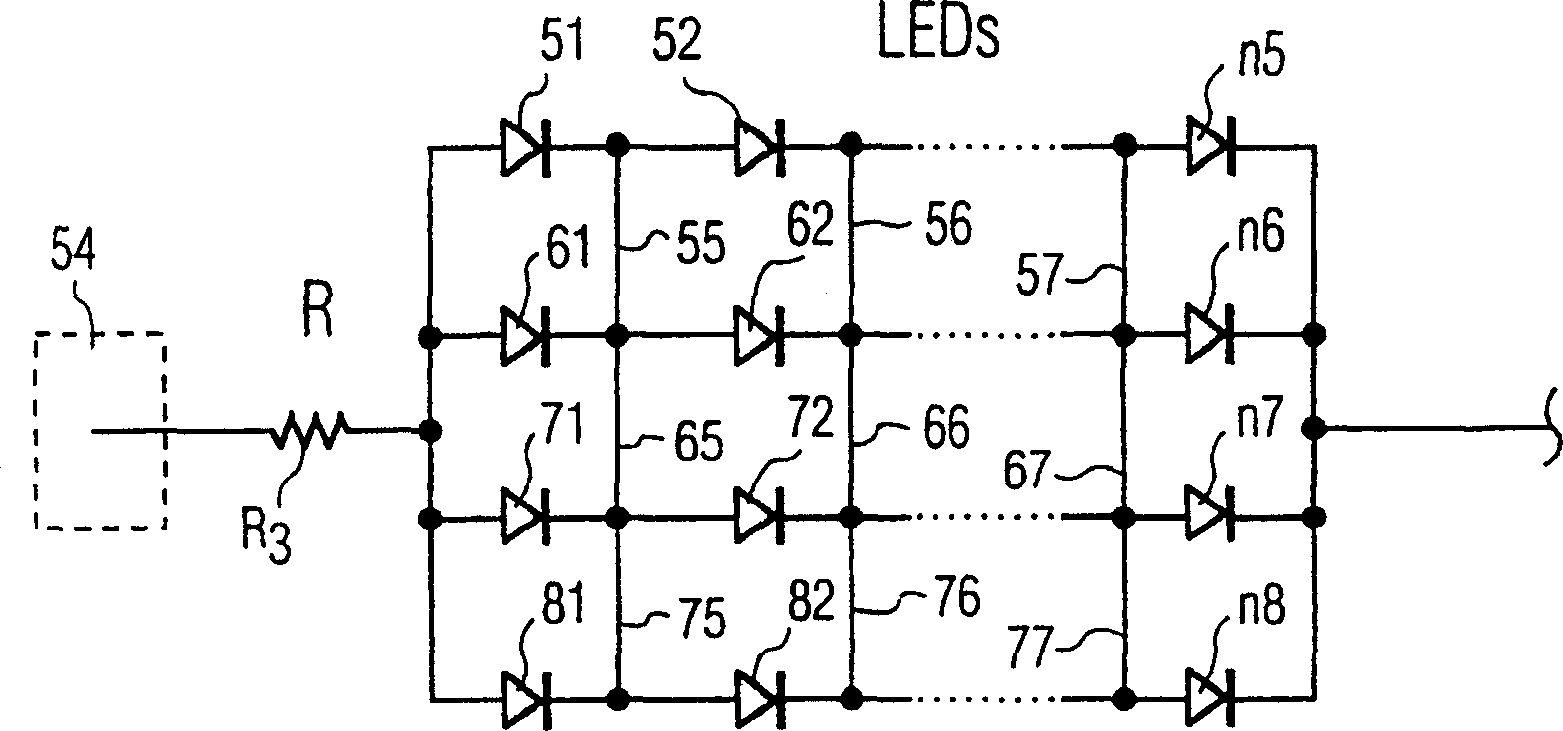

Three-dimensional lattice structure based LED array for illumination

InactiveCN1189062CDifferent forward voltage characteristicsDifferent brightnessPoint-like light sourceElectrical apparatusMulti unitDriving current

A lighting system comprising a plurality of light-emitting diodes and a power supply source for driving current through a plurality of parallel disposed, electrically conductive branches, wherein the branches comprise at least one cell. The branches are configured to display the light-emitting diodes according to a three-dimensional arrangement. In each cell, each branch has a light-emitting diode with an anode terminal and a cathode terminal. The anode terminal of each light-emitting diode is coupled to the cathode terminal of a light-emitting diode of an adjacent branch via a shunt. The shunt further comprises a light-emitting diode. In each cell, each light-emitting diode may have a different forward voltage characteristic, while still insuring that all of the light-emitting diodes in the arrangement have the same brightness. Upon failure of one light-emitting diode in a cell, the remaining light-emitting diodes in the same cell are not extinguished and, in a multiple cell embodiment, the light-emitting diodes in the successive cells are not extinguished.

Owner:SIGNIFY HLDG BV

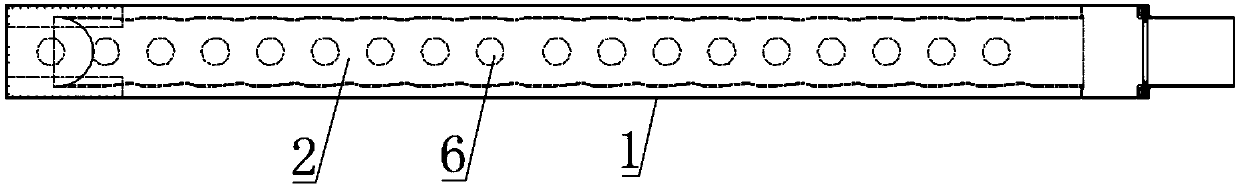

Two-disk proportional tunnel kiln control heating pipe

PendingCN108105767AWon't go outSolve the temperature shock problemGaseous fuel burnerTunnel kilnEngineering

The invention discloses a two-disk proportional tunnel kiln control heating pipe. The two-disk proportional tunnel kiln control heating pipe comprises a mixed air hose, a combustion tube and a nozzleinstallation opening. The upper portion of the front surface and the upper portion of the back surface of the mixed air hose are each provided with a row of small heat air openings. A row of main heatair outlets are formed in the lower portion of the mixed air hose. The combustion tube is installed inside the mixed air hose. The middle of the front side and the middle of the back side of the combustion tube are each provided with a row of circular holes. The right end of the combustion tube abuts against the left side of a rubber asbestos pad, and the right side of the rubber asbestos pad abuts against the nozzle installation opening. The sizes of flames can be controlled by adjusting the proportion of fuel gas and air, the flames can be kept to fluctuate within a small range, and the temperature impact problem can be well solved; and the flames cannot extinguish in the process, heat is evenly distributed into an inner bore through the small heat air openings and the main heat air outlets in the surface of the mixed air hose, the same cross section in the inner bore can obtain heat approaching as much as possible, and thus baked products can be evenly heated to the greatest extent.

Owner:佛山市顺德区奥利焙食品机械有限公司

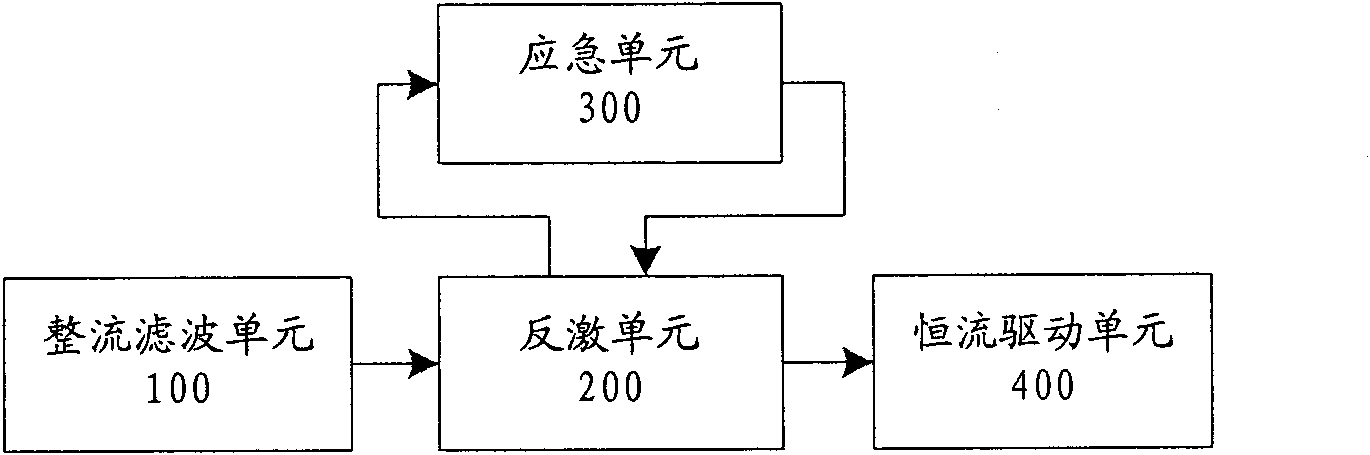

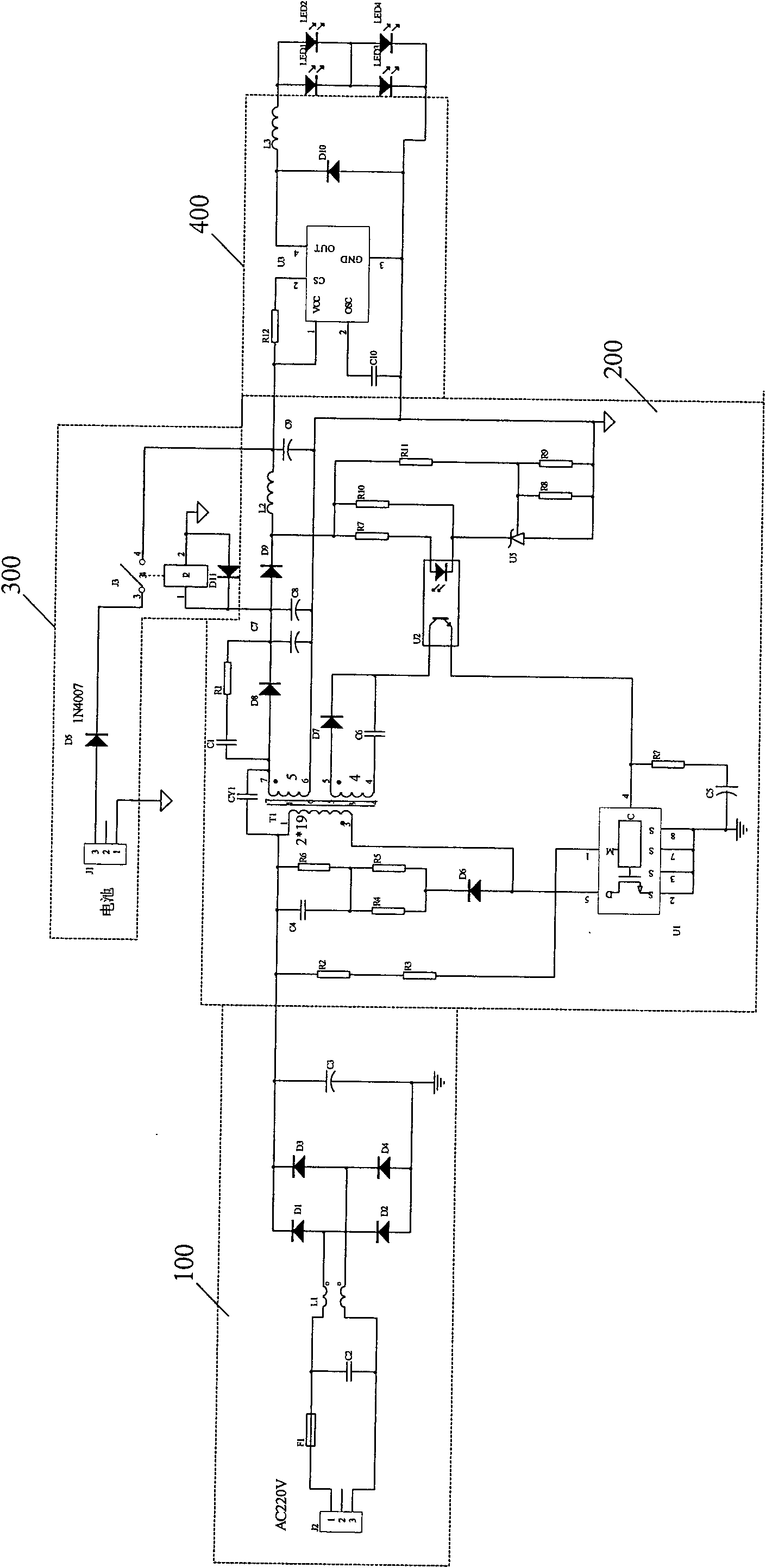

High power LED drive circuit with emergency function

InactiveCN101742783BGuaranteed standby working timeWon't go outAc-dc conversion without reversalEfficient power electronics conversionEngineeringAlternating current

The invention relates to a high power LED drive circuit with the emergency function, comprising a rectifying and filtering unit, a reverse excitation unit, a constant current driving unit and an emergency unit, wherein the rectifying and filtering unit is connected with the input end of the LED drive circuit and is used for rectifying and filtering the input alternating current signals; the reverse excitation unit is connected with the rectifying and filtering unit and is used for PWM wave modulation according to load change; the constant current driving unit is connected with the reverse excitation unit and is used for driving the LED to work at constant current; and the emergency unit is connected with the reverse excitation unit and provides power to the constant current driving unit when no alternating current input is detected by detecting the current of the reverse excitation unit. The LED drive circuit is simple and can automatically switch to the emergency power supply so as not to go out even though the mains supply has failure. The leakage current of the cells in the circuit is almost zero, thus ensuring the standby working time of the cells.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com