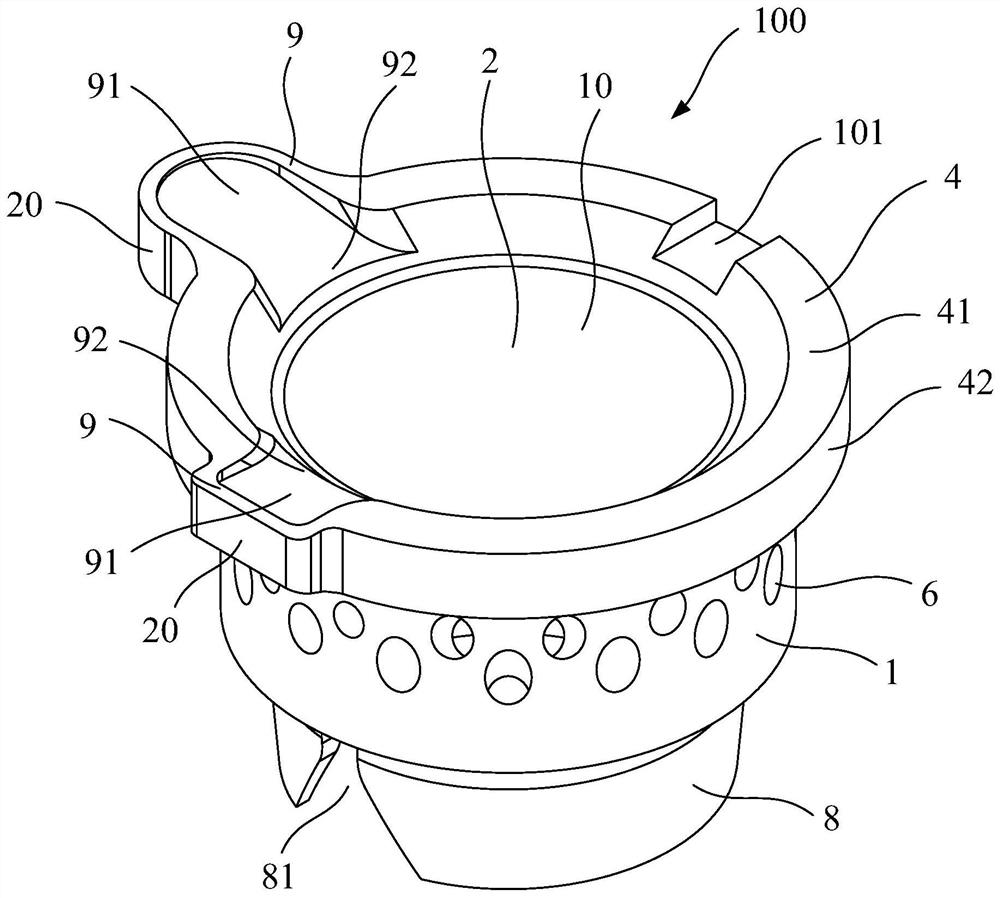

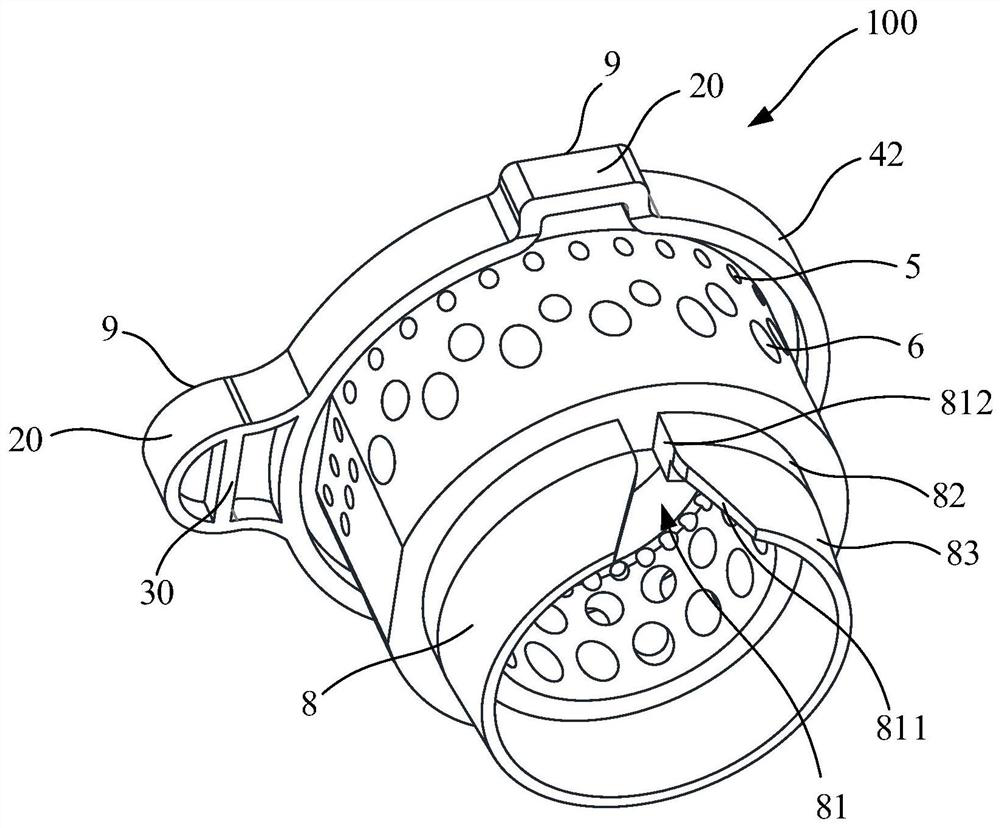

Burner cap

A fire cover and fire hole technology, which is applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of poor flame stability and easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

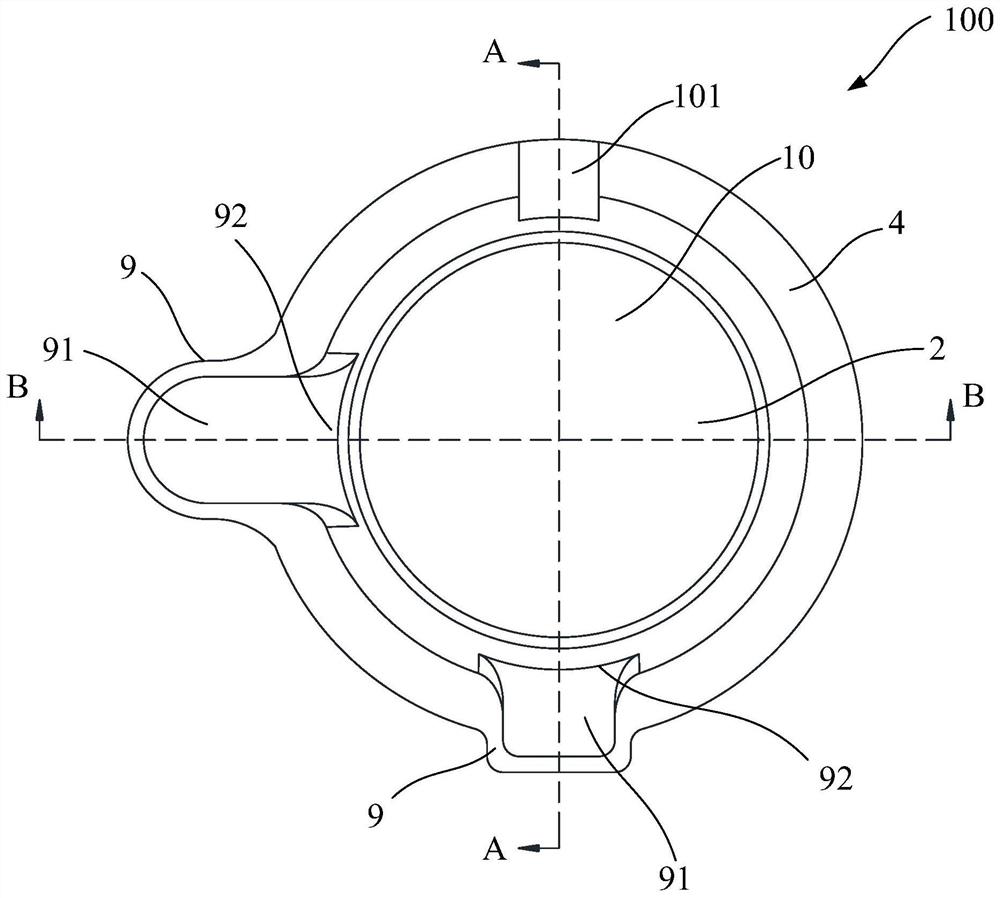

[0108] Most of the structure of the fire cover of embodiment 2 of the present invention is identical with embodiment 1, and difference is:

[0109] like Figure 10 As shown, the radial distance between the inner surface 421 of the vertical stop 42 and the axis of the outer ring 1 gradually decreases along the direction away from the upper cover surface 2, that is, the inner surface 421 of the vertical stop 42 gradually approaches the axis of the outer ring 1 . When the fire cover 100 was installed on the fire cover mounting seat 200, the inner surface 421 of the vertical baffle 42 had a certain inclination, so that the dripping speed of the liquid attached to the inner surface 421 of the vertical baffle 42 would slow down, and the liquid dripped The impact force is reduced when falling.

[0110] like Figure 10 As shown, the radial distance between the outer surface 422 of the vertical stop 42 and the axis of the outer ring 1 gradually increases along the direction away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com