Low nitrogen oxide emission burner device

A technology of low nitrogen oxides and burners, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of lack of technically mature and excellent products, achieve firm and stable flames, reduce the concentration of nitrogen oxides, and reduce combustion Effect of Temperature and Burning Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

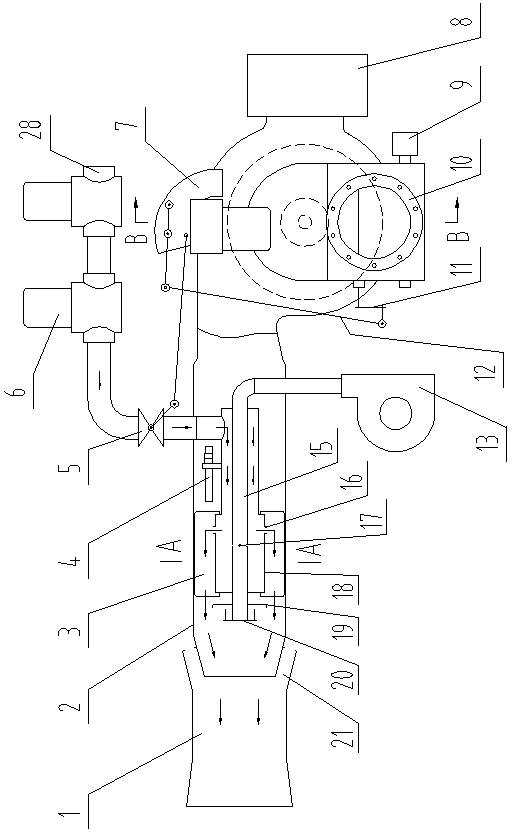

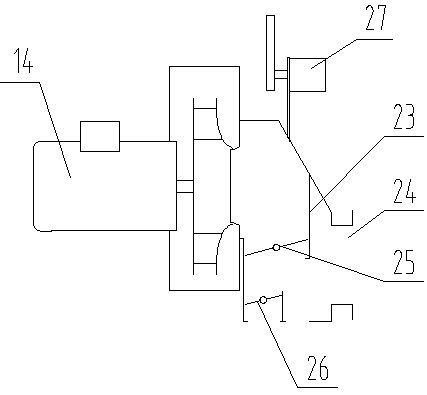

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] The first embodiment is a burner device with low nitrogen oxide emission in an integrated structure in which the main fan 14 is directly connected to the air duct 2 .

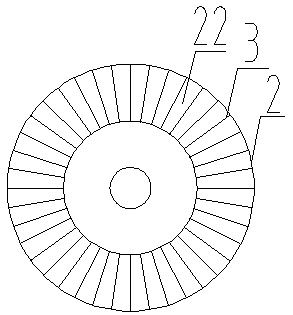

[0027] see figure 1 , figure 2 , image 3 The inside of the air duct 2 is provided with a tubular gas chamber 18, and the tubular structure is a variable-diameter tubular structure. The diameter of the front section is thick, and the diameter of the rear section is thin. The outer cylindrical surface of the thick tube diameter section of the gas chamber 18 is provided with at least dozens of long gas partition plates 3 radially arranged, and a plurality of gas partition plates 3 divide the gap between the gas chamber 18 and the air duct 2. The annular cavity is divided into several premixing chambers 22 with small volume, and small-diameter gas injection holes 16 are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com