Waste tire rubber powder grinding system

A technology of waste tire rubber and crushing system, which is applied in the fields of dust removal, grain treatment, and separation of dispersed particles. It can solve the problems of heavy dust, poor working environment, and unfavorable physical and mental health of workers, and achieve the effect of improving the workshop environment and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

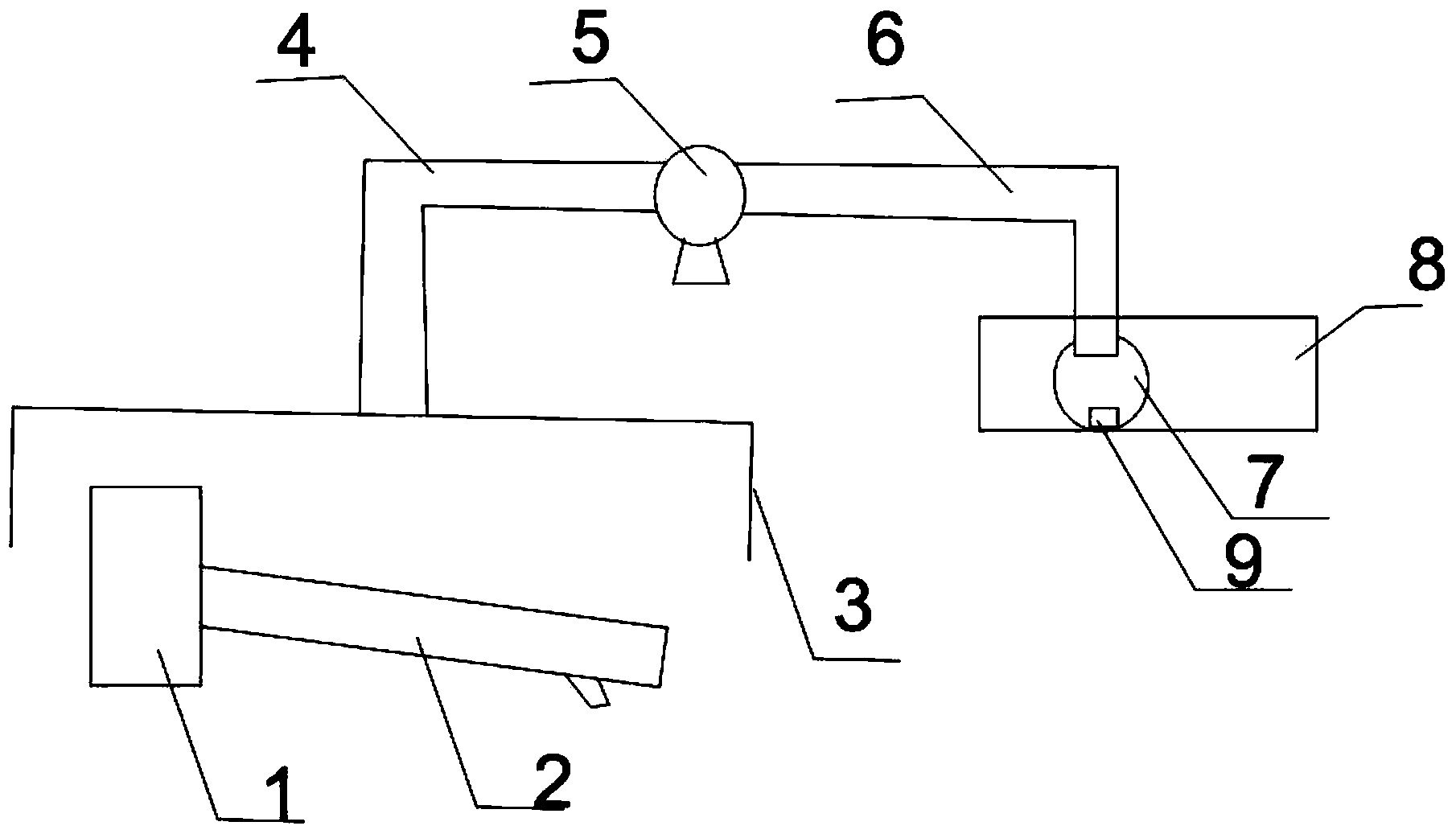

[0013] like figure 1 As shown, the right rubber pulverizer 1, vibrating screen 2, dust hood 3, pipeline 4, exhaust fan 5, air outlet 6, filter bag 7, pool 8 and Counterweight 9.

[0014] The head of the vibrating screen 2 is located below the discharge port of the rubber pulverizer 1. The vibrating screen 2 includes a screen box, and a screen mesh is arranged in the screen box to divide the screen box into an upper layer coarse particle cavity and a lower layer fine rubber powder cavity. There is a discharge hopper at the tail of the fine rubber sub-chamber, and a discharge port is also set at the tail of the upper coarse particle cavity. , which will not be repeated here.

[0015] Above the rubber pulverizer 1 and the vibrating screen 2 is a dust hood 3, and the dust hood 3 is fixed above the rubber pulverizer 1 and the vibrating screen 2 through a frame, and the frame is not shown in the figure. The dust hood 3 is covered above the rubber pulverizer 1 and the vibrating sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com