Mosquito-repellent incense with good combustion performance and preparation method thereof

A combustion performance, mosquito-repellent incense technology, applied in the direction of botany equipment and methods, chemicals for biological control, insecticides, etc., can solve the problems of affecting the mosquito repellent effect, unable to continuously ignite, human injury, etc., to achieve the benefit of continuous Ignite, enhance mechanical properties, prevent smoke effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The mosquito-repellent incense with good combustion performance includes the following components: 110kg of wood powder, 40kg of sticky powder, 10kg of insect repellent, 5kg of graphene and 5kg of aluminum oxide, and the fineness of each component is 300 mesh.

[0024] The preparation method of above-mentioned mosquito-repellent incense comprises the steps:

[0025] 1) Weighing and removing impurities: pass the raw materials through a 200-mesh sieve, remove impurities, weigh the raw materials according to the above weight,

[0026] 2) Mix the impurity-removed wood powder, sticky powder, pyrethroid and aluminum oxide, add water therein, stir until the water content is 50%, add graphene, and stir evenly to obtain a mixture; Wherein, the speed of stirring is 200r / min;

[0027] 3) The mixture is sent to the mosquito coil molding machine for extrusion, compaction, stamping, demoulding, drying, trimming, and stacking to obtain mosquito coils.

Embodiment 2

[0029] The mosquito-repellent incense with good combustion performance includes the following components: 130kg of wood powder, 20kg of sticky powder, 20kg of insect repellent, 2kg of graphene and 10kg of aluminum oxide, and the fineness of each component is 400 mesh.

[0030] The preparation method of above-mentioned mosquito-repellent incense comprises the steps:

[0031] 1) Weighing and removing impurities: pass the raw materials through a 300-mesh sieve, remove impurities, and weigh the raw materials according to the above weight;

[0032] 2) Mix the impurity-removed wood flour, viscous powder, pyrethroid and aluminum oxide, add water therein, stir until the water content is 60%, add graphene, and stir evenly to obtain a mixture; Wherein, the speed of stirring is 100r / min;

[0033] 3) The mixture is sent to the mosquito coil molding machine for extrusion, compaction, stamping, demoulding, drying, trimming, and stacking to obtain mosquito coils.

Embodiment 3

[0035] The mosquito-repellent incense with good combustion performance includes the following components: 120kg of wood powder, 30kg of sticky powder, 13kg of insect repellent, 3kg of graphene and 6kg of aluminum oxide, and the fineness of each component is 350 mesh.

[0036] The preparation method of above-mentioned mosquito-repellent incense, comprises the steps:

[0037] 1) Weighing and removing impurities: pass the raw materials through a 250-mesh sieve, remove impurities, and use the raw materials according to the weight;

[0038] 2) Mix the impurity-removed wood flour, viscous powder, pyrethroid and aluminum oxide, add water therein, stir until the water content is 55%, add graphene, and stir evenly to obtain a mixture; Wherein, the speed of stirring is 150r / min;

[0039] 3) The mixture is sent to the mosquito coil molding machine for extrusion, compaction, stamping, demoulding, drying, trimming, and stacking to obtain mosquito coils.

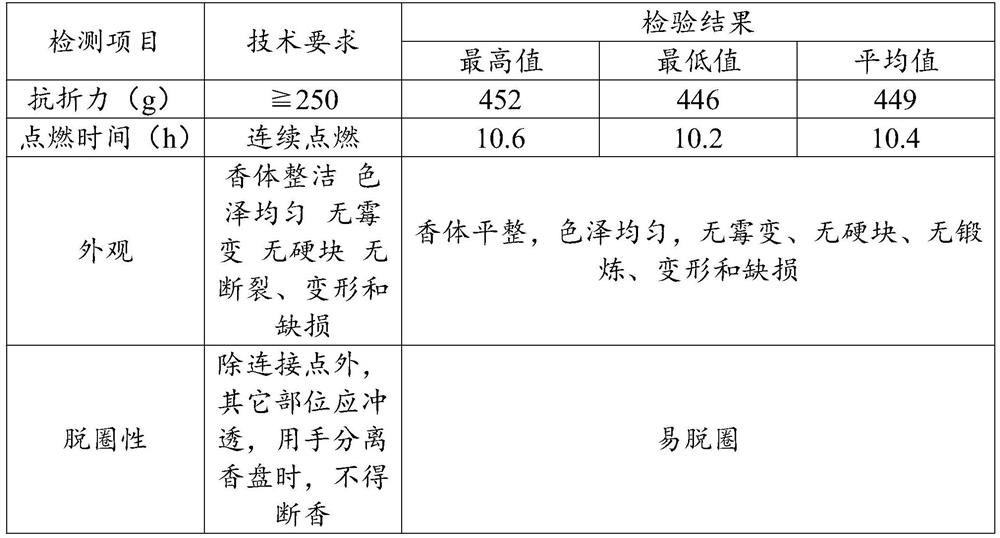

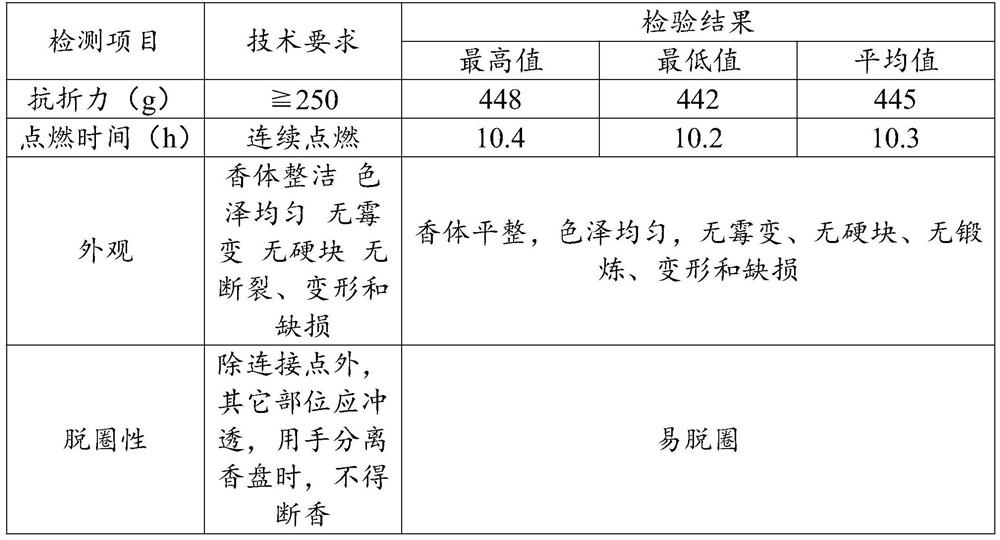

[0040] Carry out performance tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com