Backlight module and liquid crystal display device

A technology for liquid crystal display devices and liquid crystal panels, which is applied to lighting devices, fixed lighting devices, cooling/heating devices for lighting devices, etc., can solve problems such as poor heat dissipation performance, easy burns to users due to the temperature of the front case, and impact on heat dissipation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

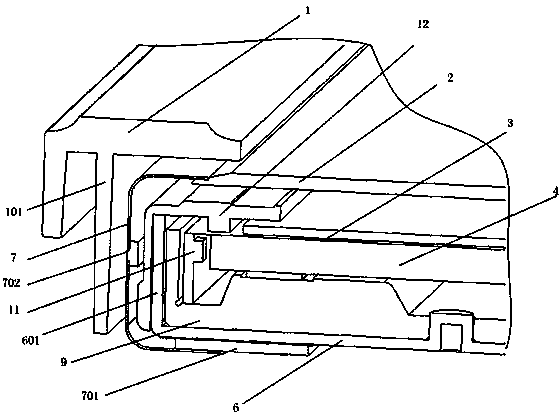

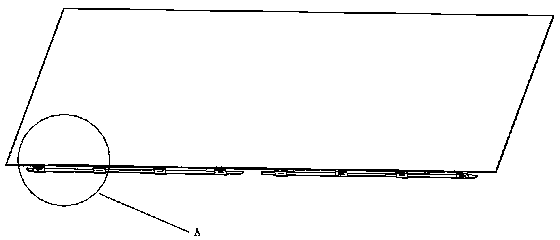

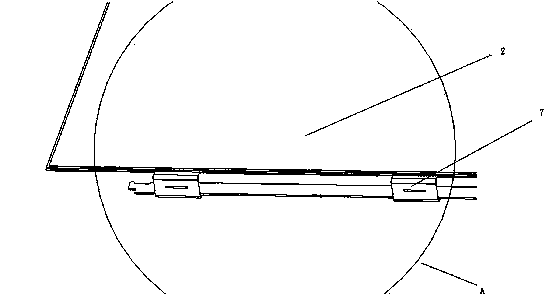

[0034] This embodiment provides a liquid crystal display device, such as Figure 7 As shown, it includes: the back plate 6 including the back plate flange 601 around and the inner cavity surrounded by the bottom plate, the plastic frame 12, the diaphragm assembly 3, the light guide plate 4, the liquid crystal panel 2, and the light source assembly 11 with LED lights set on the PCB board The light source assembly 11 is arranged on the inner wall of the back panel flange 601 of the back panel 6 through the LED lamp cooling fin 9, wherein the LED lamp cooling fin 9 made of L-shaped aluminum material is accommodated in the inner cavity of the back panel 6, One folded side of the L-shaped LED lamp heat sink 9 is connected to the PCB board of the light source 11, and the other side is connected to the back plate folded edge 601 of the back plate 6, and the bottom surface of the other folded edge of the L-shaped LED lamp heat sink 9 is fixed. On the bottom surface of the inner cavity...

Embodiment 2

[0045] In this embodiment, a side-type backlight module is provided, such as Figure 7 As shown, it includes: the backboard 6 surrounded by the backboard flange 601 and the inner cavity surrounded by the bottom board, the plastic frame 12, the diaphragm assembly 3, the light guide plate 4, the liquid crystal panel 2, and the light source assembly 11 with the LED lamp set on the PCB board, The light source assembly 11 is arranged on the inner wall of the back panel flange 601 of the back panel 6 through the LED lamp cooling fin 9, wherein the LED lamp cooling fin 9 made of L-shaped aluminum material is accommodated in the inner cavity of the back panel 6, L One side of one folded edge of the L-shaped LED lamp heat sink 9 is connected to the PCB board of the light source 11, and the other side is connected to the back plate folded edge 601 of the back plate 6, and the bottom surface of the other folded edge of the L-shaped LED lamp heat sink 9 is fixed on On the bottom surface o...

Embodiment 3

[0051] In this embodiment, a direct-type backlight module (not shown) is provided. Those skilled in the art know that the direct-type backlight module is different from the side-type backlight module. The only difference from the embodiment is that the light guide plate Replace it with a diffuser plate, and set the light source assembly 11 in the inner cavity of the back plate 6, set the diffuser plate in the inner cavity, and set a support frame for supporting the diffuser plate on the bottom plate of the back plate 6, and the other parts are the same as the implementation Example 2 is the same and will not be repeated here.

[0052] It should be noted that the above-mentioned liquid crystal display device may specifically be any product or component with a display function such as a liquid crystal television, a liquid crystal display, a digital photo frame, a mobile phone, and a tablet computer.

[0053] In the description of the various embodiments above, specific features,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com