Flame-proof nitrocellulose lacquer prepared by halogen-free flame retardant and preparation method thereof

A technology of flame retardant and nitro paint, applied in the direction of coating, etc., can solve the problems of human body and environmental pollution, non-compliance with safety and fire protection implementation requirements, toxicity and other problems, and achieve the effect of reducing combustion and inhibiting the effect of chain reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Nitro paint prepared by using halogen-free flame retardant, its component distribution ratio is 13% of nitrocellulose, 27% of mixed solution, 3% of mixing aid, 7% of halogen-free flame retardant, 30% of plasticized resin, transparent 10% raw material solution, 10% color paste; the mixed solution is a true solvent of esters, ketones, and alcohol ethers; the film-forming agent is mainly nitrocellulose, combined with plasticized resin alkyd resin, modified rosin resin, and acrylic resin , amino resin soft and hard resin together, and also added with dibutyl phthalate, dioctyl phthalate, oxidized castor oil plasticizer.

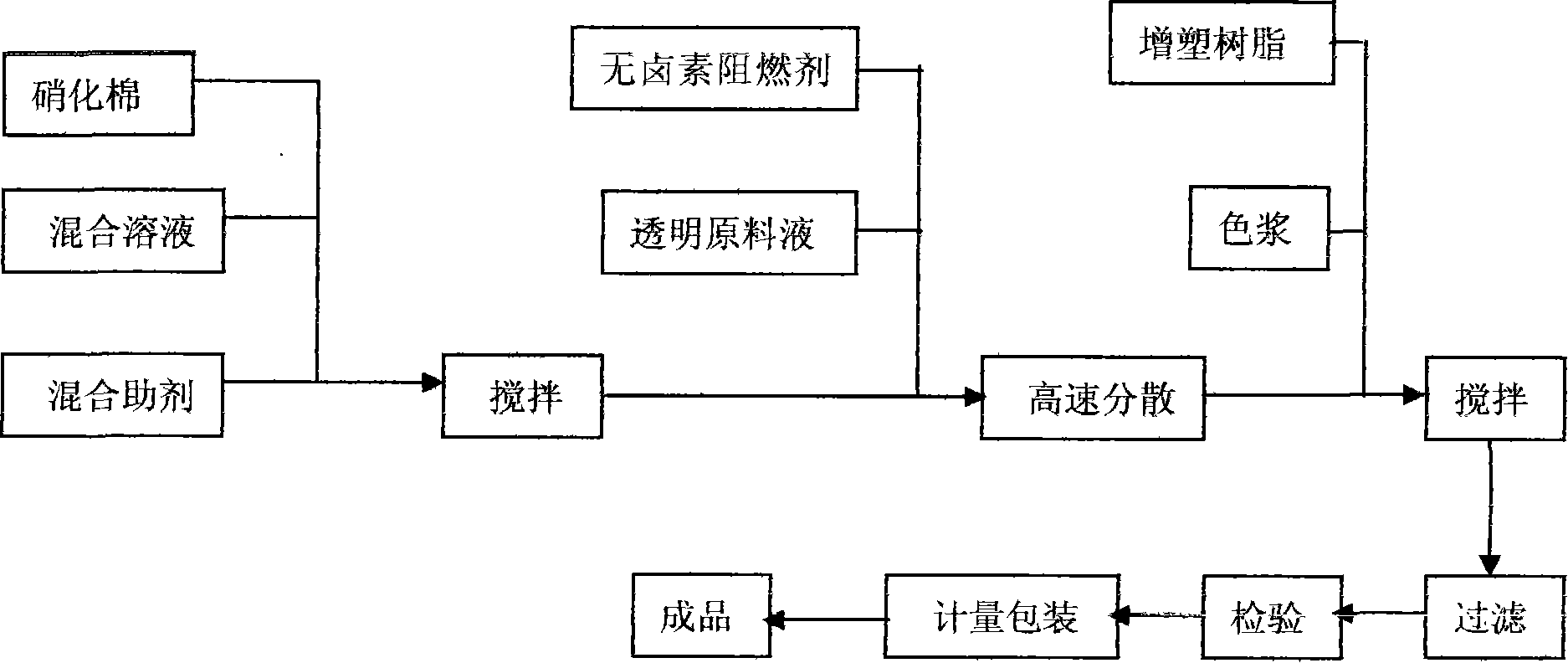

[0017] Its specific technological process includes the following steps:

[0018] In a mixing container, mix and stir nitrocellulose, mixed solution, and mixing aid for 20 minutes, then add halogen-free flame retardant, transparent raw material solution, mix and disperse at high speed for 25 minutes, then add plasticizing resin and color paste to it and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com