Hydrogen-rich gas production equipment as well as hydrogen-rich gas production process and solar condensation heat collecting coal gasifier

A technology for concentrating solar energy and producing equipment, which is applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

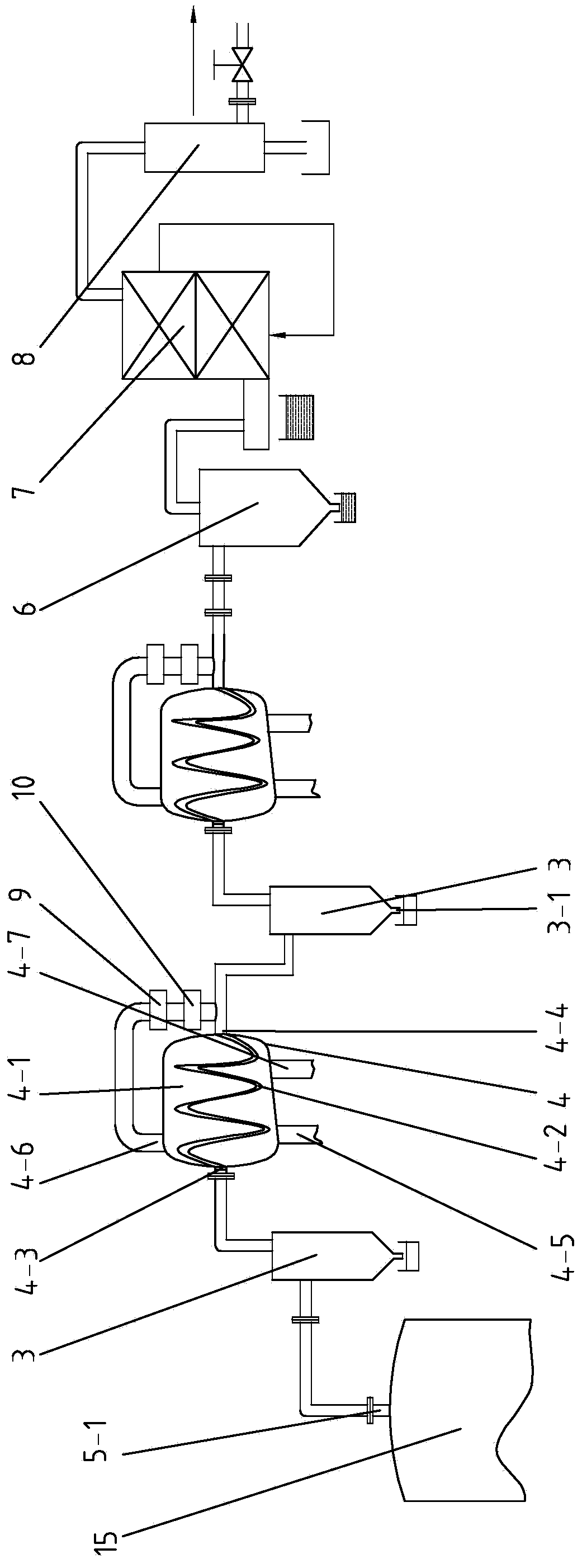

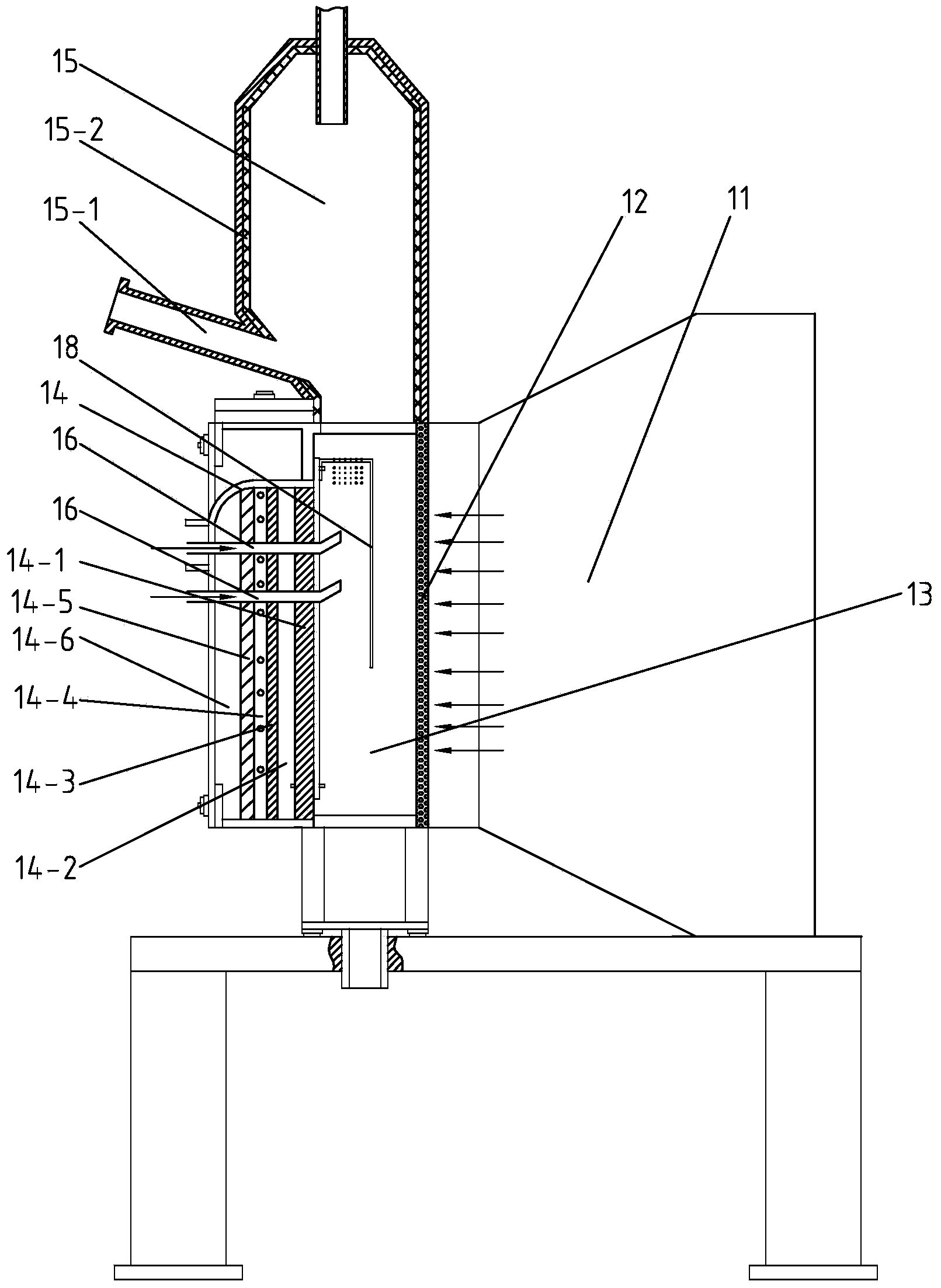

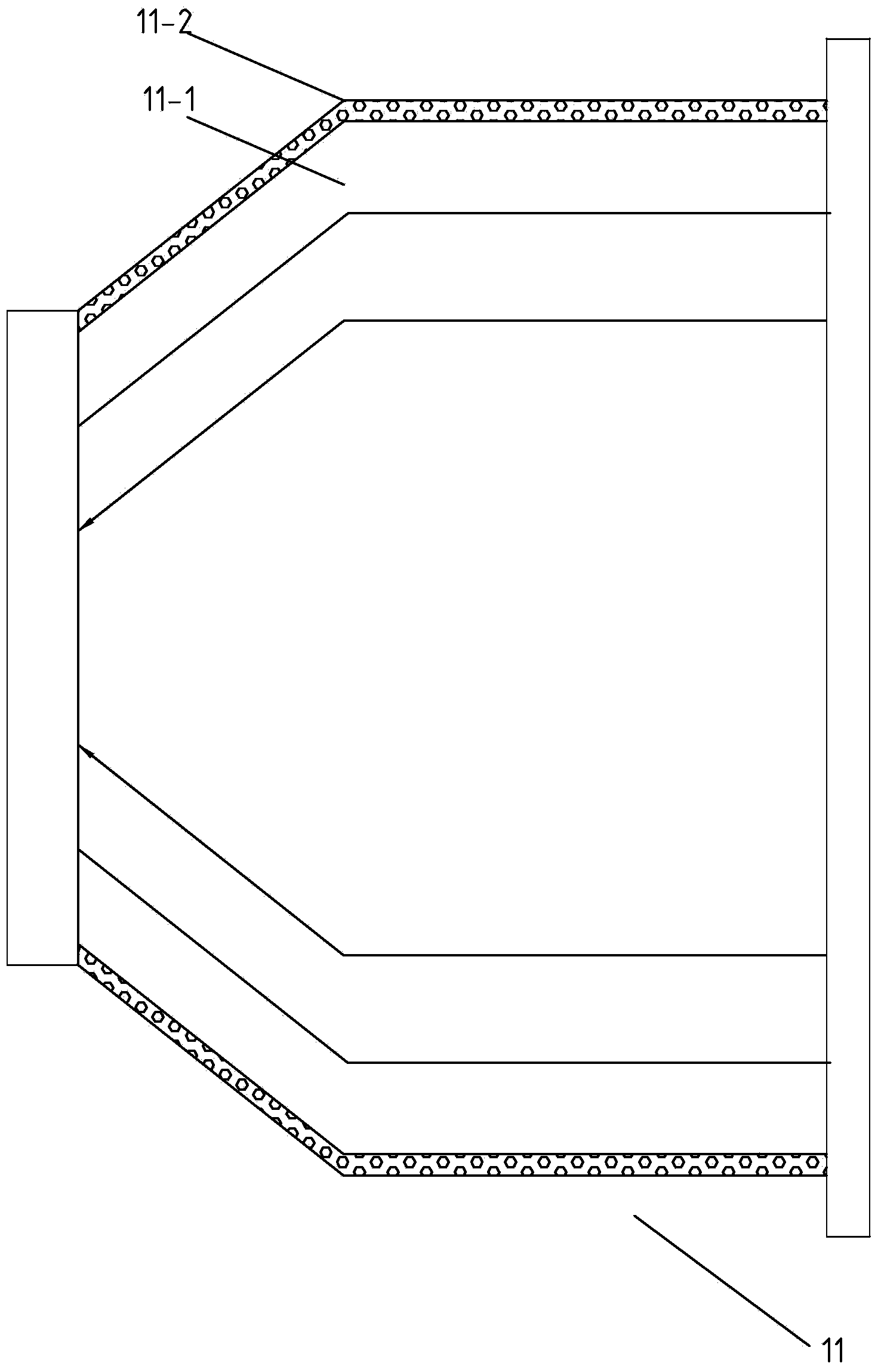

[0020] Such as figure 1 As shown, a hydrogen-rich gas production equipment, which includes a solar concentrating heat-collecting coal gasifier, a multi-stage hydrogen-rich gas production device, a water washing tower 7 and a desulfurizer 8, a hydrogen-rich gas production device includes a cyclone separator 3 and a spiral Tubular heat exchanger 4; spiral tube heat exchanger 4 has heat exchange chamber 4-1, spiral tube assembly 4-2, water gas inlet 4-3, water gas outlet 4-4, mixture outlet 4-5, gas outlet 4-6 and the inlet 4-7 of the hydropyrolysis product that can be fed into water or steam under the action of the hydropyrolysis catalyst, the heat exchange chamber 4-1 is located on the periphery of the spiral tube assembly 4-2, and the The water ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com