Patents

Literature

40results about How to "Achieve dissociation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

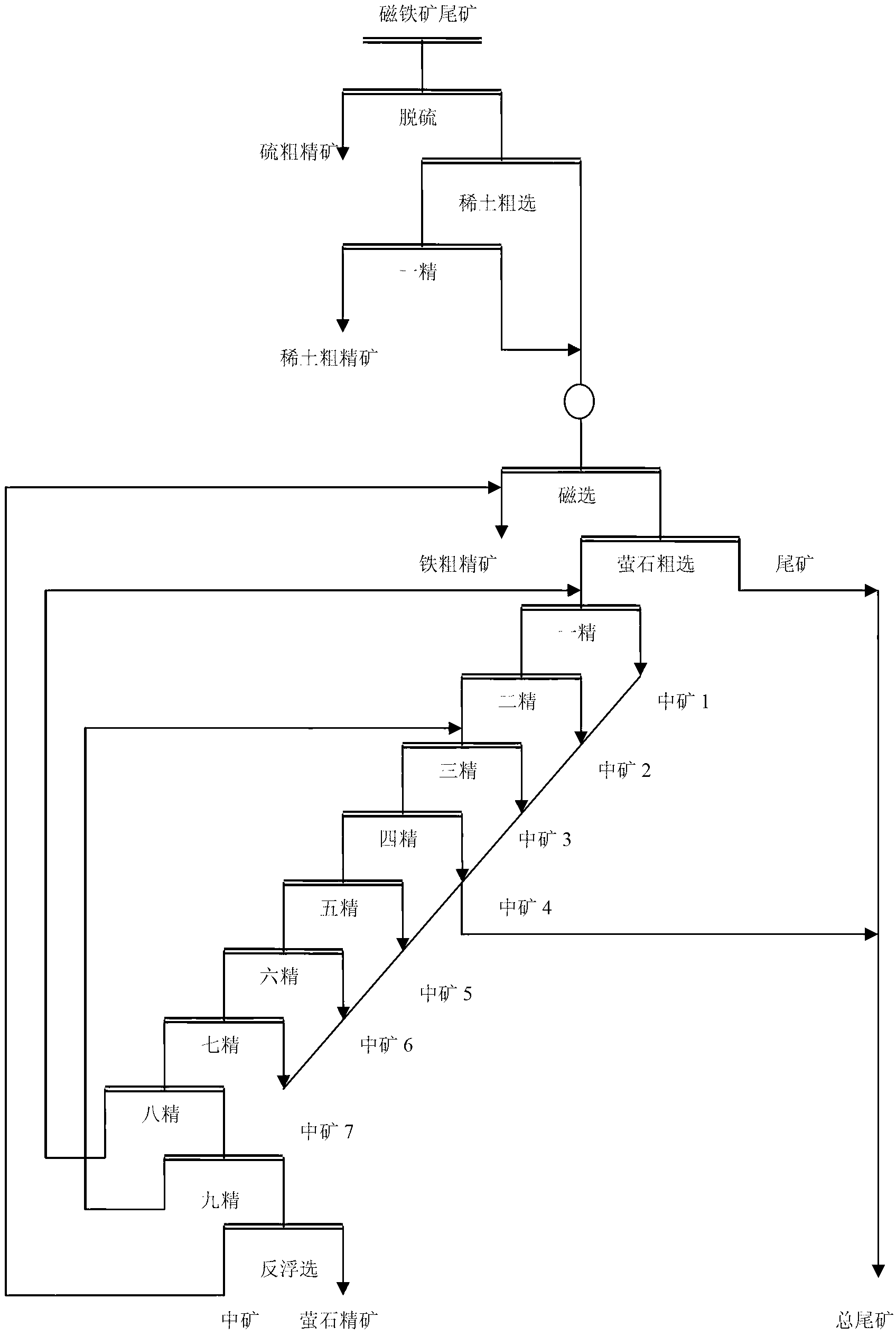

Mineral processing technology for recycling fluorite from baotite, magnetite and tailing

The invention belongs to the technical field of mineral engineering and provides a mineral processing technology for recycling fluorite from baotite, magnetite and tailing. In the tailing, mineral particle size of the fluorite is thin, iron-bearing mineral, rare-earth mineral, gangue mineral and the fluorite mineral are closely symbiotic and floatability of minerals such as rear earth, barite, apatite, calcite and dolomite is close to the fluorite mineral, so that separation of the fluorite mineral is difficult. According to the mineral processing technology for recycling the fluorite from the baotite, the magnetite and the tailing, priority desulfuration, rear earth flotation, ore grinding, iron selection through magnetic separation, fluorite selection through direct flotation and a reverse flotation sorting technology are performed on the magnetite and the tailing to enable pyrite, the rare earth, the iron-bearing mineral and the fluorite to be picked out in sections, efficient, high selective, easy-to-operate inhibitor and collecting agent combination is utilized in sorting of fluorite which is mostly performed monomer separation, so that fine fluorite of high grade and high recovery rate is obtained, a purpose of synthetically recycling valuable minerals is achieved, and effective separation of the fluorite mineral and the gangue mineral is achieved.

Owner:包钢集团矿山研究院(有限责任公司)

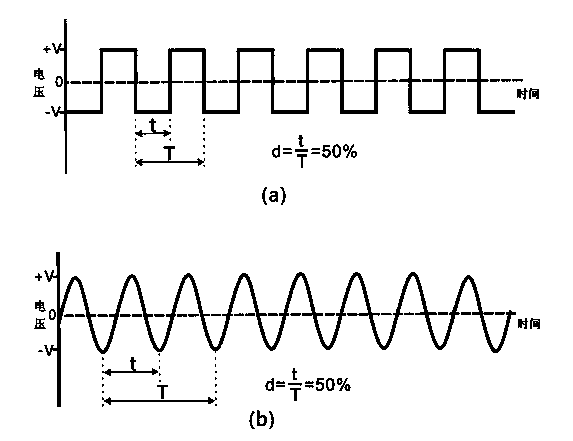

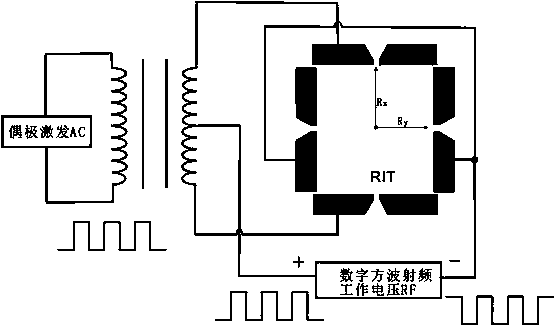

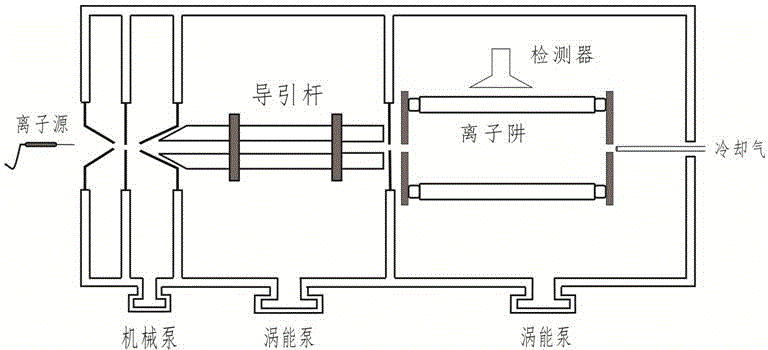

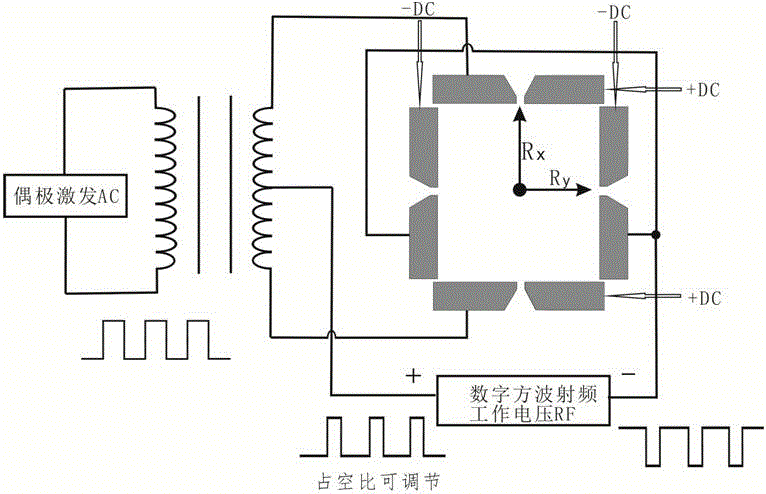

Cascade mass spectrometry method performed in ion trap mass analyzer

ActiveCN103413751AAchieve dissociationSimplify the experimental processStability-of-path spectrometersMaterial analysis by electric/magnetic meansHigh energyMass analyzer

The invention belongs to the technical field of mass spectrometry and particularly relates to a cascade mass spectrometry method performed in an ion trap mass analyzer. The cascade mass spectrometry method performed in the ion trap mass analyzer specifically comprises three stages of ion selective segregation, collision induction dissociation and mass scanning and analyzing. According to the cascade mass spectrometry method performed in the ion trap mass analyzer, in the stage of collision induction dissociation, by changing the period of a radio frequency signal, namely changing the frequency of radio-frequency voltage loaded on an ion trap, parent ions with a certain mass-to-charge ratio undergo resonance excitation so as to obtain energy. The high-energy ions which undergo resonance excitation collide with neutral molecules in the ion trap and are dissociated, outcome ions are generated, and the cascade mass spectrometry is achieved. The cascade mass spectrometry method performed in the ion trap mass analyzer has the advantages that only arrangement of software can be used for changing the scanning period of the stage of collision induction dissociation in order to achieve collision induction dissociation, and thus, an experiment device and a method of cascade mass spectrometry can be obviously simplified.

Owner:FUDAN UNIV

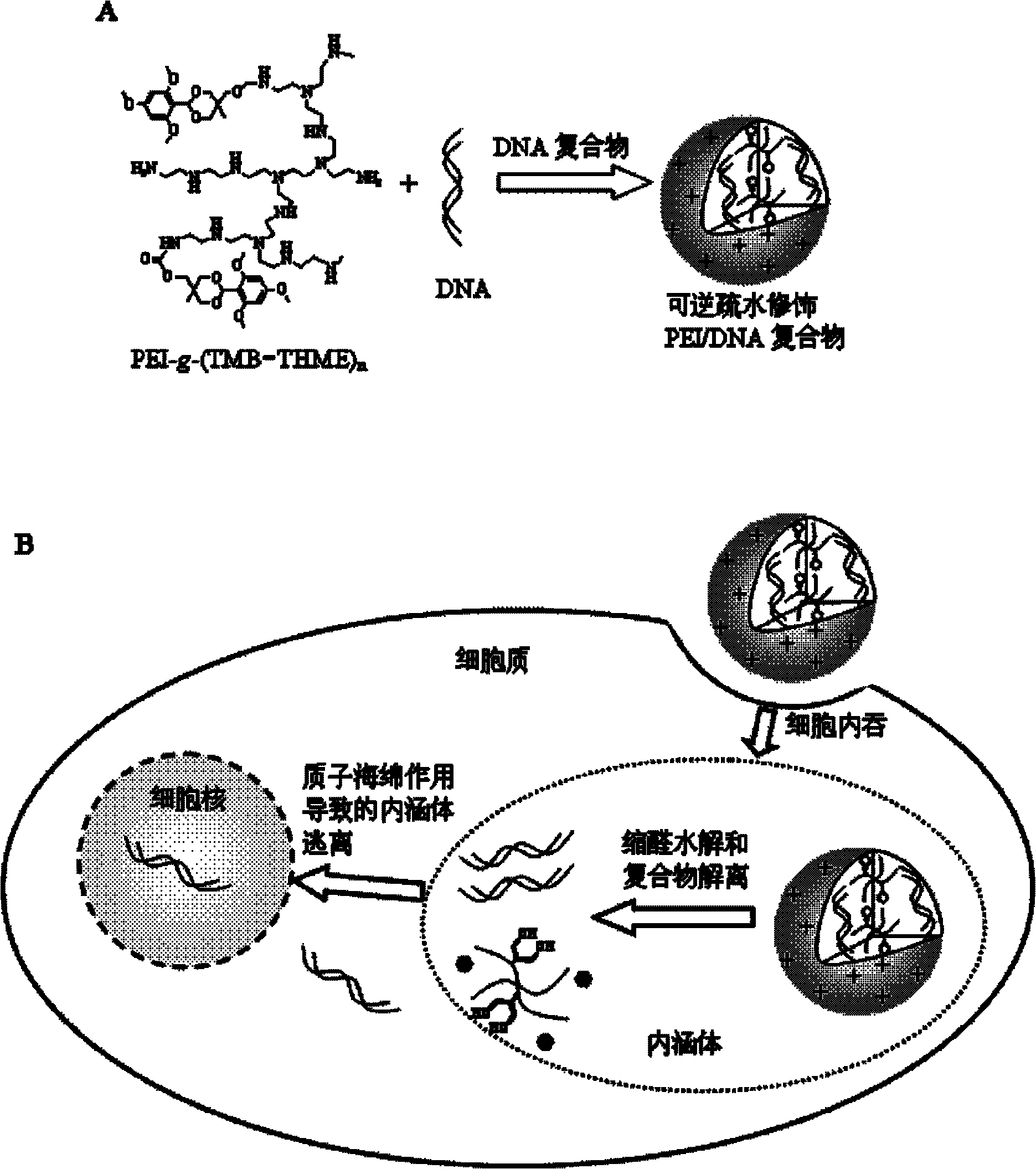

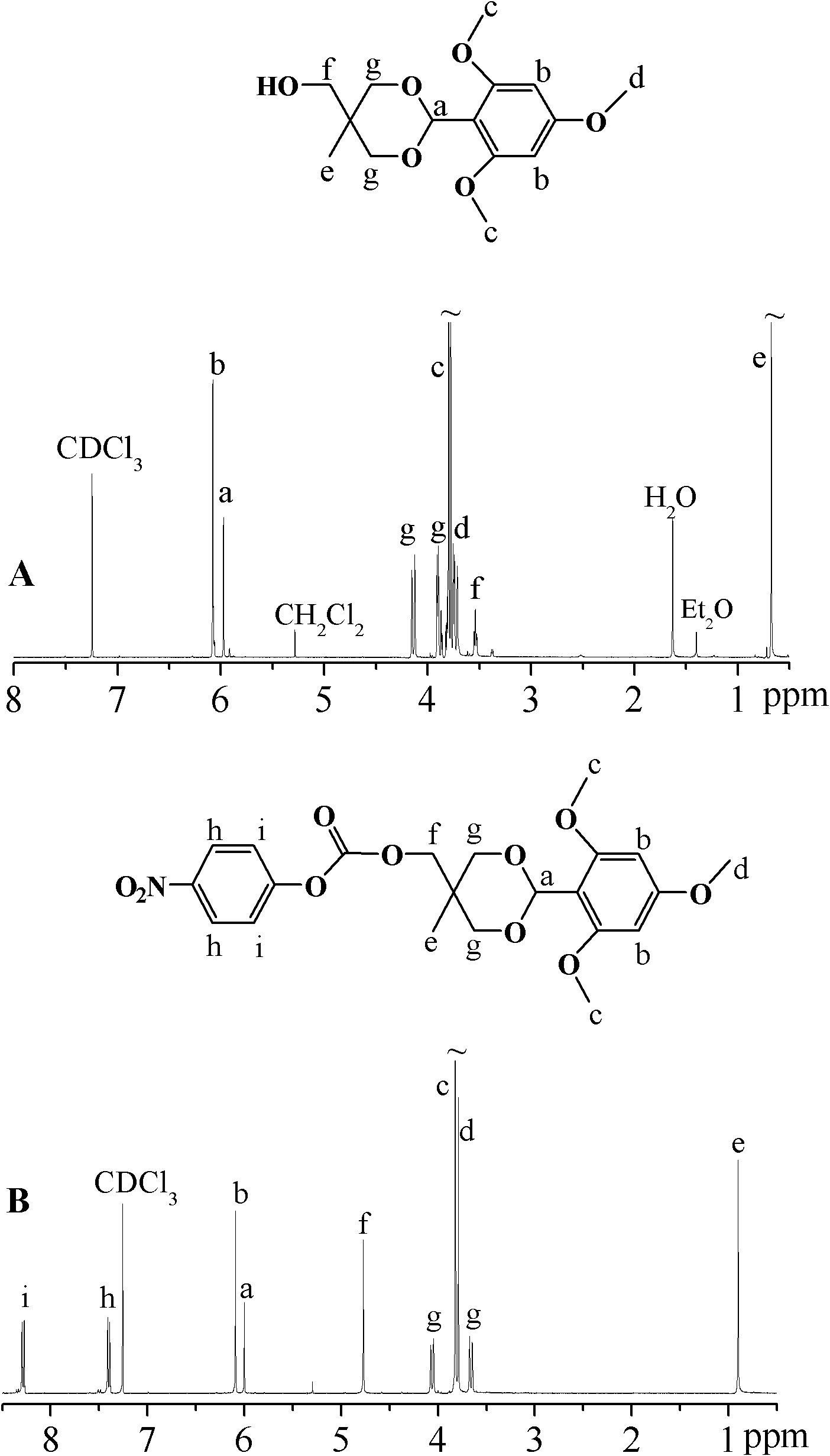

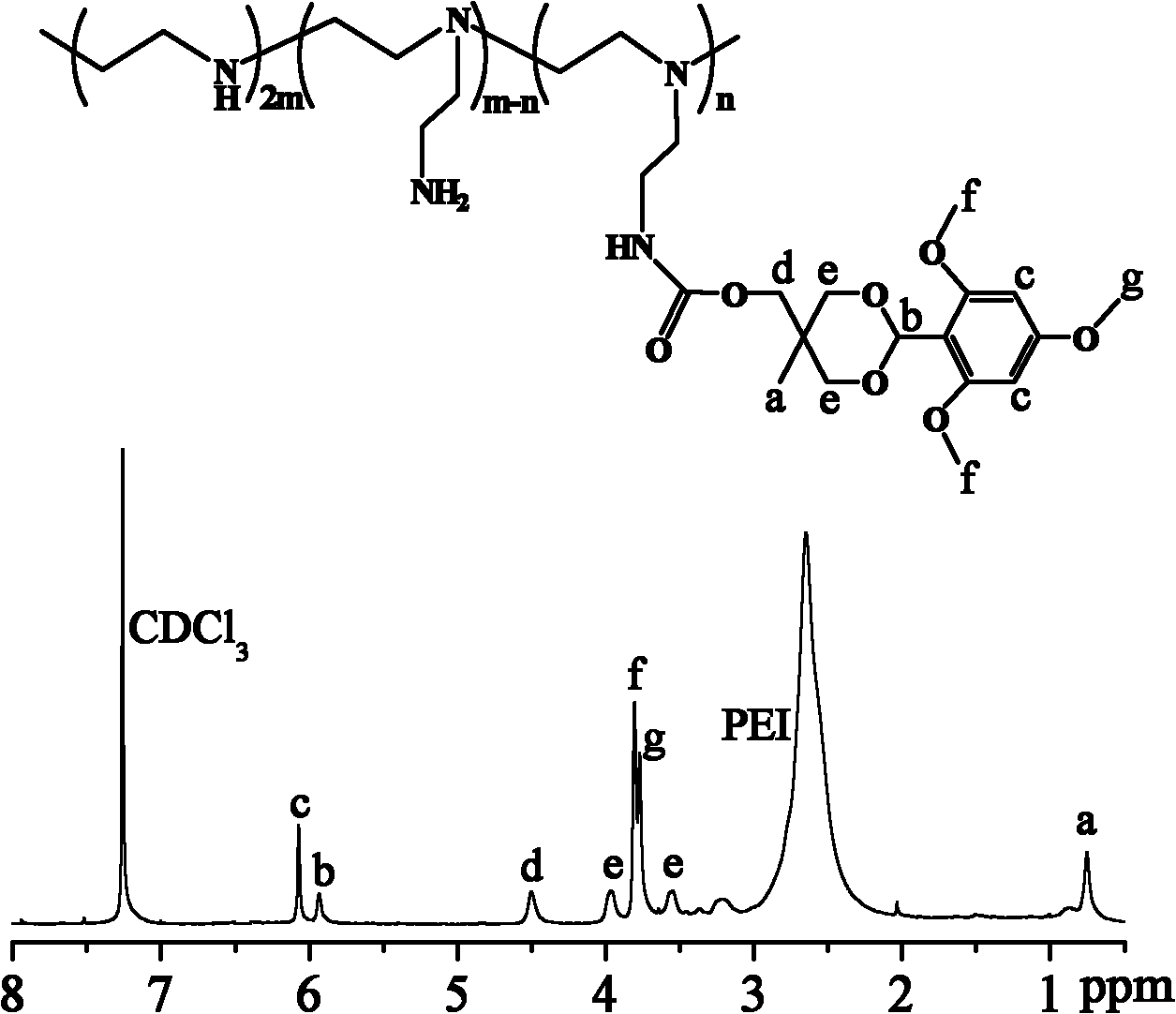

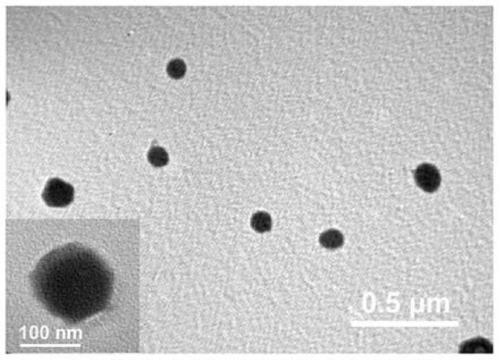

Hydrophobic-group-modified polyethyleneimine derivative and application thereof

InactiveCN102181053AEnhance DNA complex abilityImprove composite effectVector-based foreign material introductionPolymer modifiedPolyetherimide

The invention belongs to the field of polymer modification, and particularly relates to an acid-sensitive hydrophobic modified polyethyleneimine and application thereof as a gene vector. The derivative contains an acid-sensitive acetal functional group; and specifically, the derivative is an acetal-molecular trimethoxy benzylacetal-trihydroxy ethylacetal (TMB-THME) modified polyethyleneimine derivative, named polyethyleneimine-(trimethoxy benzylacetal-trihydroxy ethane). The polyethyleneimine-(trimethoxy benzylacetal-trihydroxy ethane) provided by the invention enhances the DNA (deoxyribonucleic acid) compounding capability of PEI (polyetherimide) and the interaction with cells, can convert a hydrophobic group into a hydrophilic group in an endosome, and implements the dissociation of theDNA compound and the intracellular release of the DNA; and the cytotoxicity is low.

Owner:SUZHOU UNIV

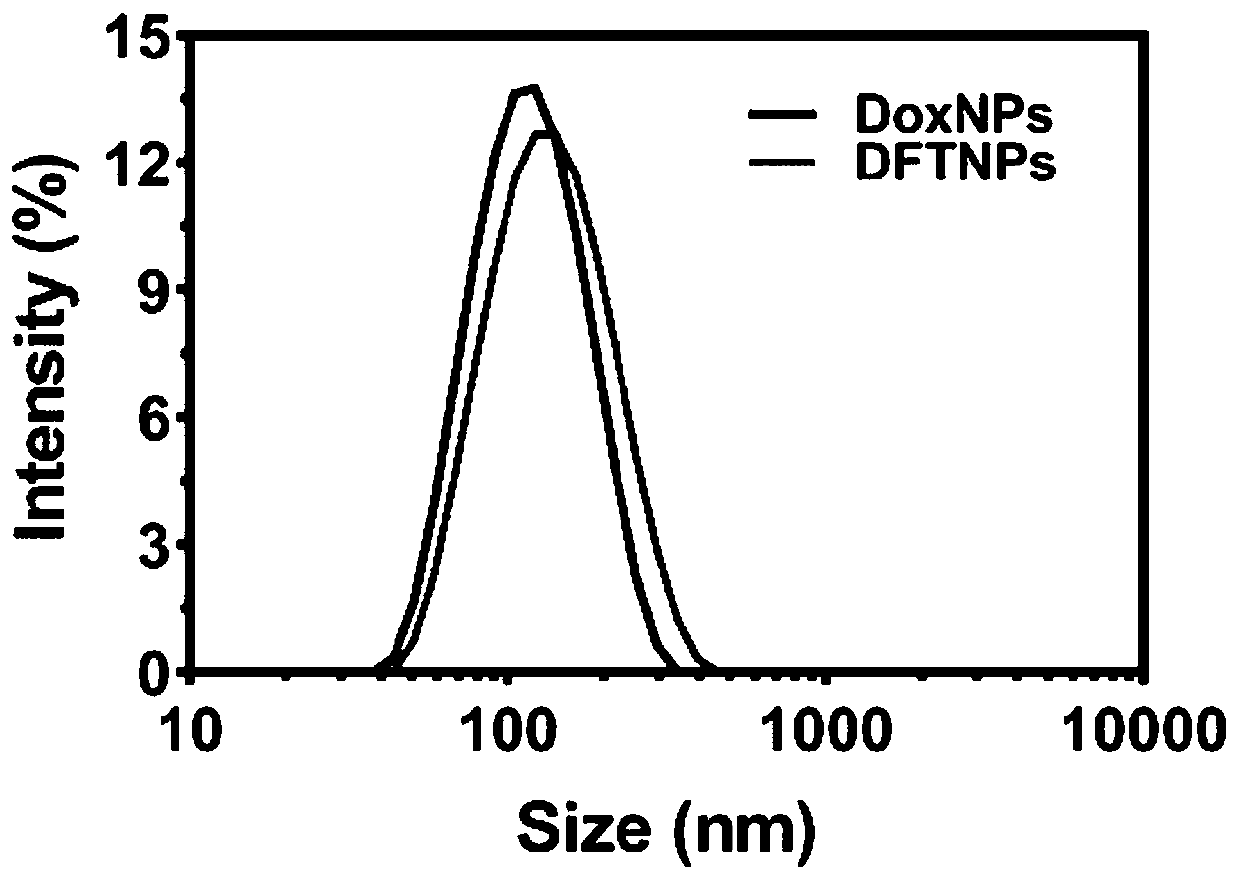

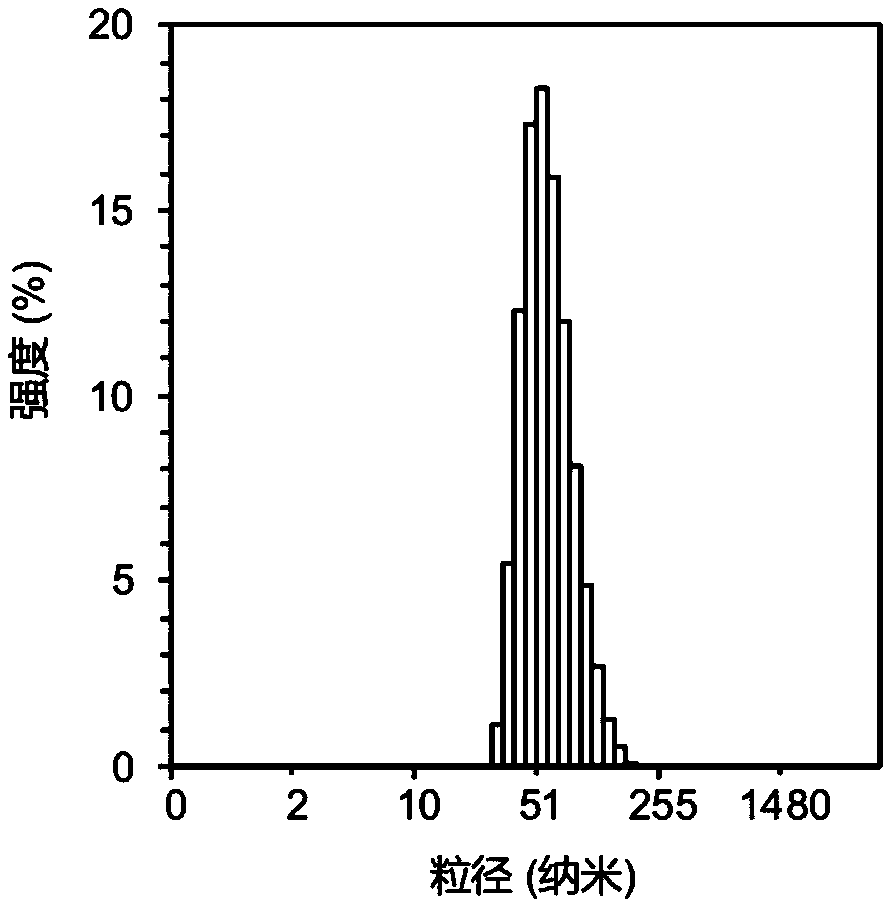

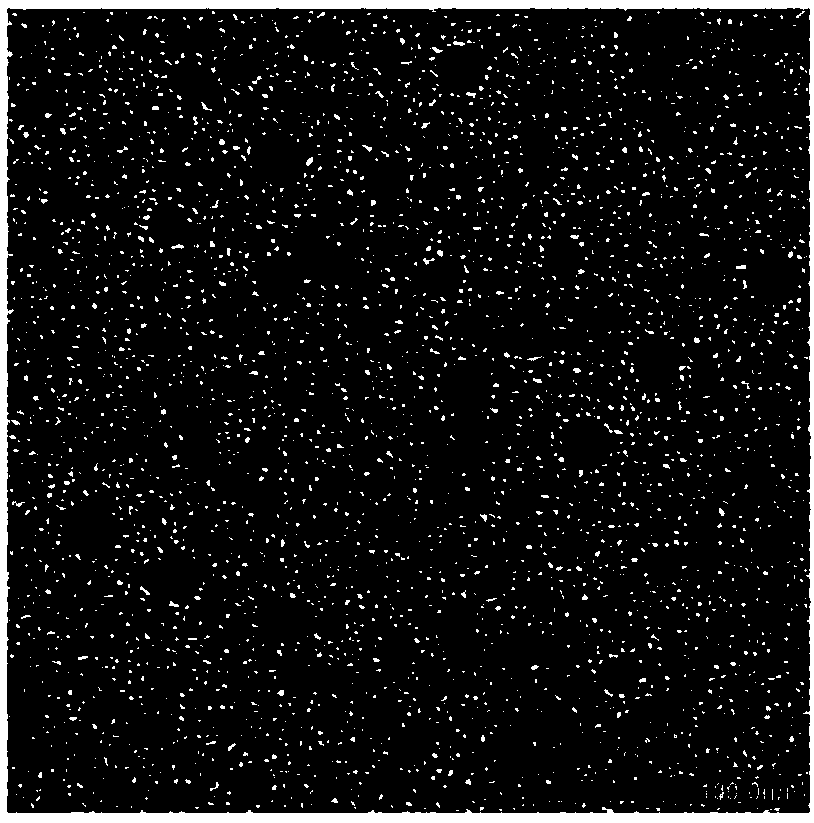

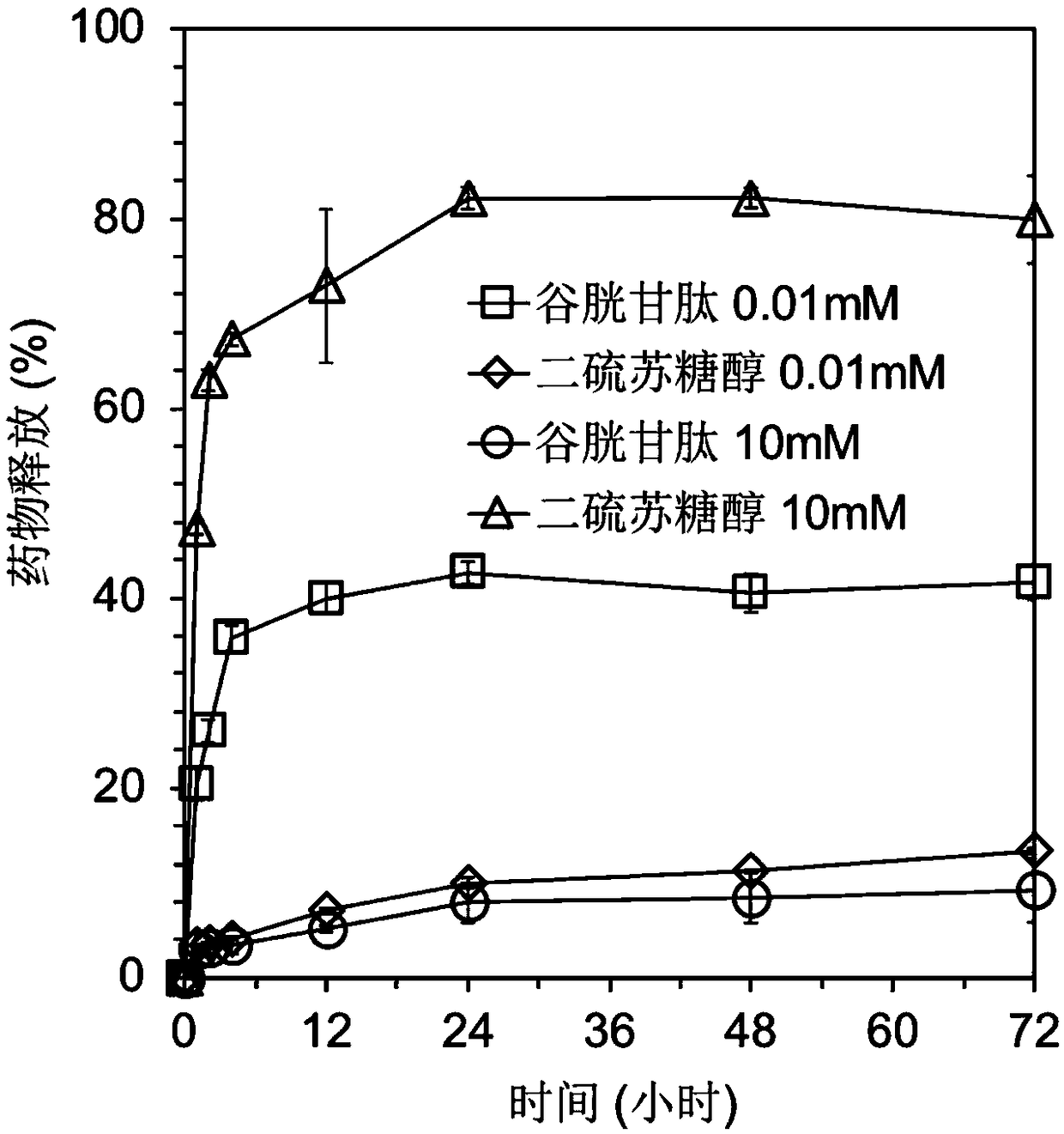

Application of nanoparticles as tumor microenvironment responsive drug or imaging agent

InactiveCN111529510AImplement fixed-point releaseEasy to operateOrganic active ingredientsEnergy modified materialsTumor therapyImaging agent

The invention belongs to the field of biological medicines, and relates to application of nanoparticles, in particular to application of the nanoparticles as tumor microenvironment responsive drugs orimaging agents. The nanoparticle comprises a chelate shell formed by tannic acid and ferric ions, and chemotherapeutic drugs are entrapped in the chelate shell. In a tumor microenvironment, the nanoparticle can slowly release a chemotherapeutic drug entrapped in the nanoparticle and slowly release iron ions in the nanoparticle to enhance the nuclear magnetic resonance imaging effect. The technical scheme can be applied to medical practice of tumor imaging and tumor treatment.

Owner:CHONGQING MEDICAL UNIVERSITY

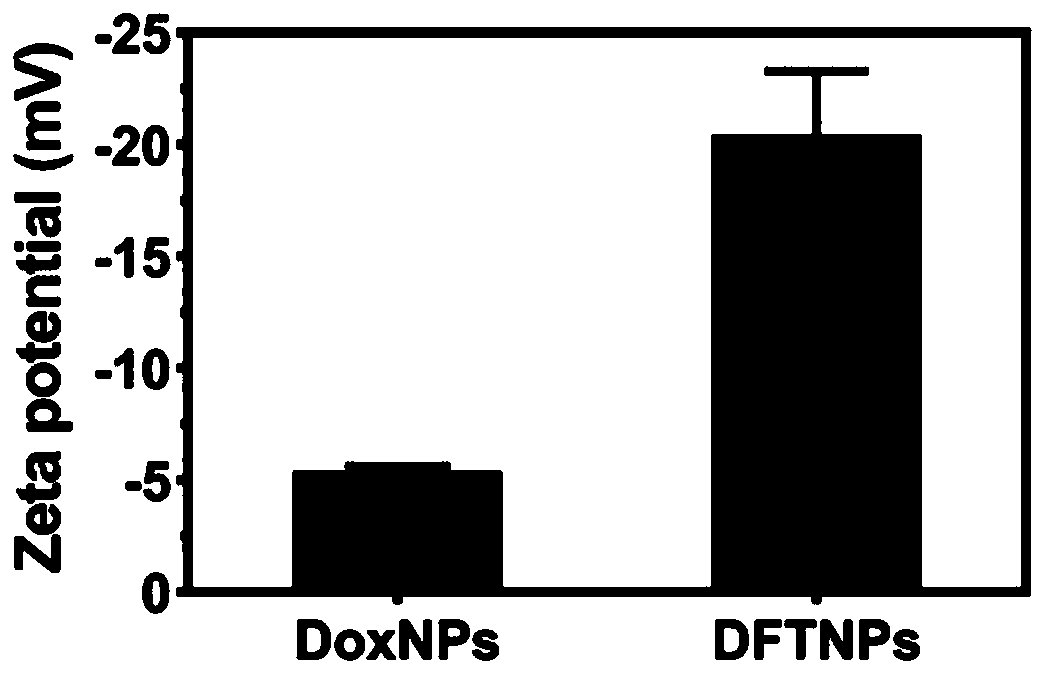

Information safety destruction and recycling method of semiconductor storage medium

InactiveCN103191825AEasy to controlRealize safe destructionGas current separationMagnetic separationMagnetic separatorAir separation

The invention discloses an information safety destruction and recycling method of a semiconductor storage medium. The method comprises the following steps of: (1) performing one-stage crushing on the semiconductor storage medium to be destructed; (2) separating a ferro-magnetic material by a magnetic separator; (3) performing multi-stage crushing by a multi-stage crusher; (4) removing nonmetal particles with the particle size less than 0.05mm to 0.5mm from the material by a multi-stage air separation system; and (5) screening the material through a vibrating screen. According to the method, the information of the semiconductor storage medium can be safely destructed and recycled. The method has the characteristics of good destruction effect, high degree of automation, high applicability and the like.

Owner:SHANGHAI JIAO TONG UNIV

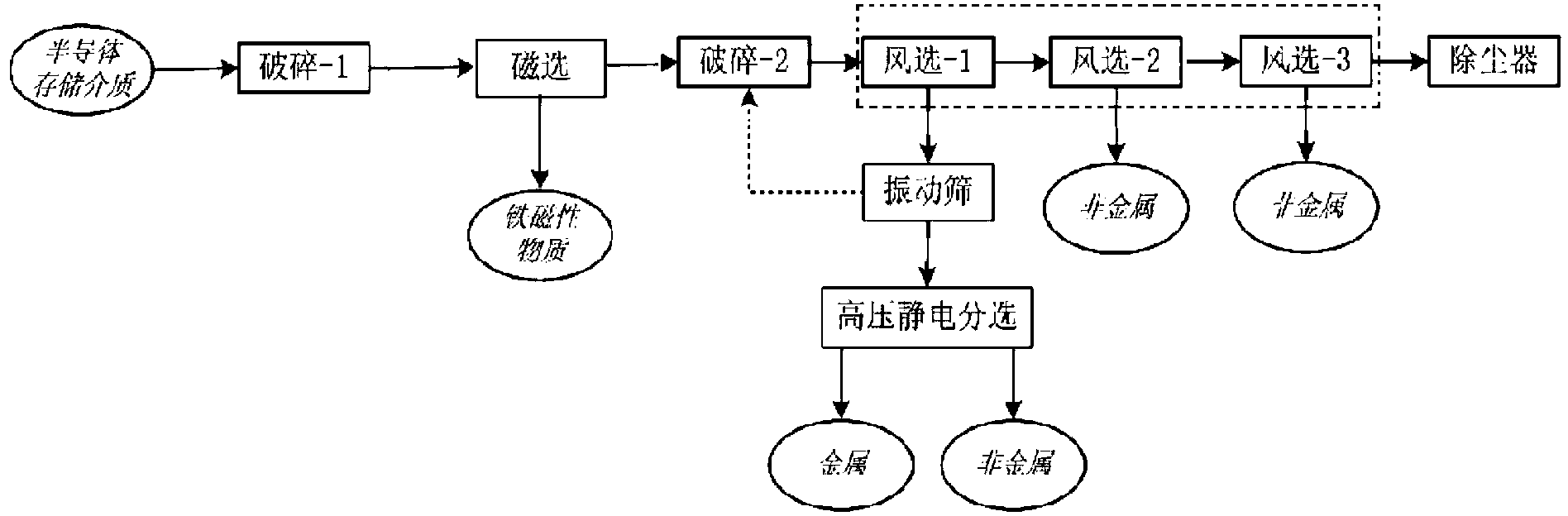

Method for analyzing tandem mass spectrometry driven by direct current voltage in ion trap mass analyzer

InactiveCN104362070AAchieve dissociationSimplify deviceStability-of-path spectrometersSpectrometer circuit arrangementsHigh energyMass analyzer

The invention belongs to the technical field of mass spectrometry analysis and particularly relates to a method for analyzing tandem mass spectrometry driven by direct current voltage in an ion trap mass analyzer. The method specifically comprises the three stages of ion selection isolation, collision induction dissociation and mass analysis, wherein in the stage of collision induction dissociation, bias direct current voltage is generated in the center of an ion trap by exerting asymmetric waveform radio frequency working voltage on electrodes of the ion trap mass analyzer; by means of the bias direct current voltage, isolated parent ions with the certain mass-to-charge ratio are made to deviate from the constraint center of the ion trap to obtain energy so as to be excited, ions excited to a high-energy state can collide with neutral molecules in the ion trap and are dissociated, and thus tandem mass spectrometry analysis is achieved. The method for analyzing the tandem mass spectrometry driven by the direct current voltage in the ion trap mass analyzer has the advantages that an additional direct current main is not needed, the bias direct current voltage can be achieved only through control of software, time-sequence control is achieved, and an experimental device and method can be obviously simplified.

Owner:FUDAN UNIV

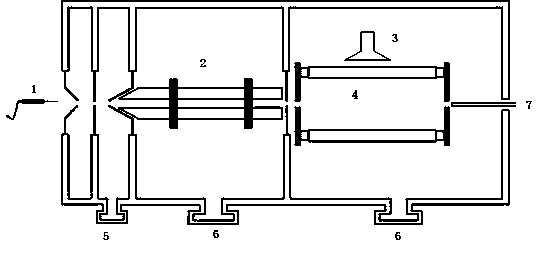

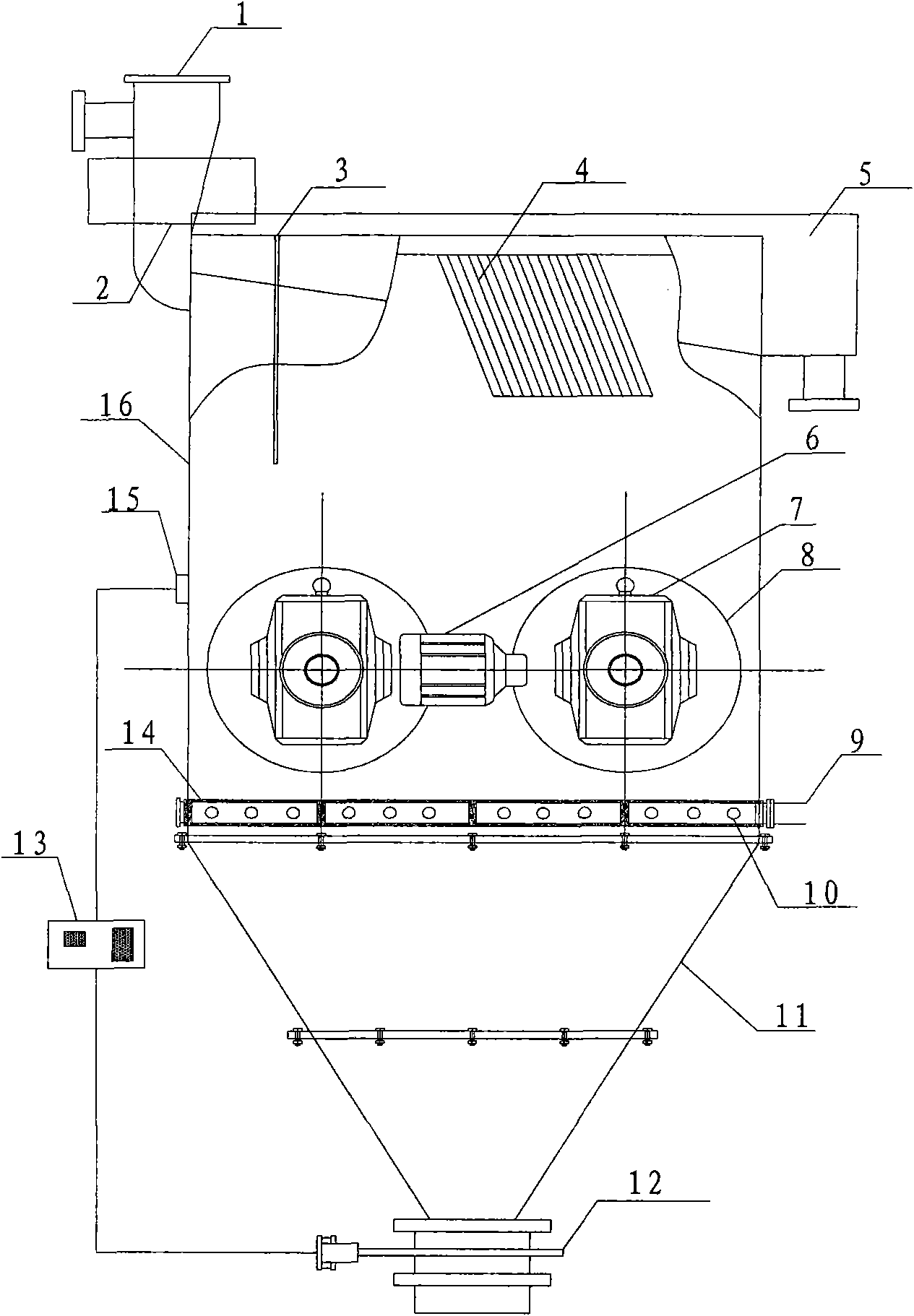

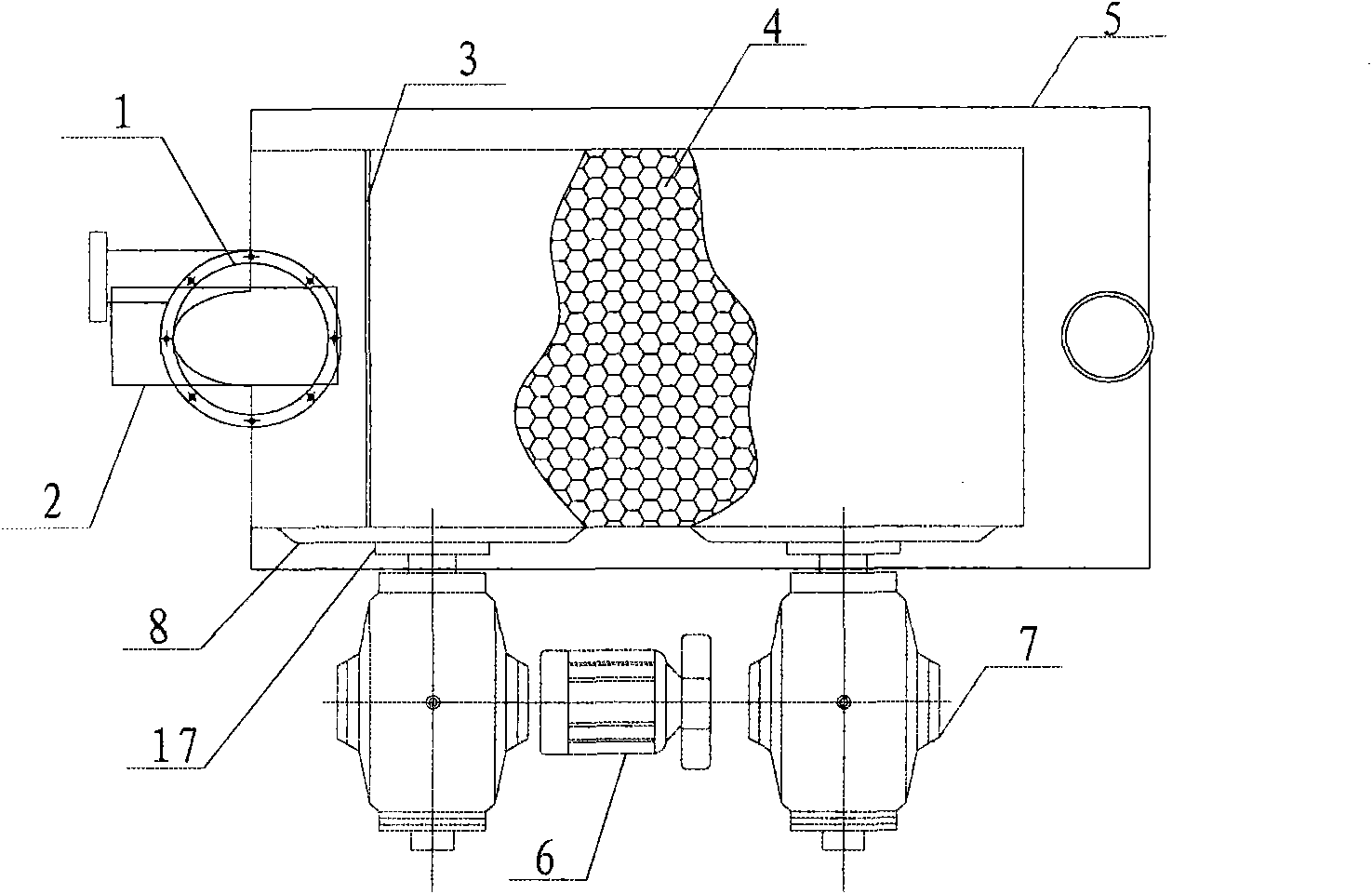

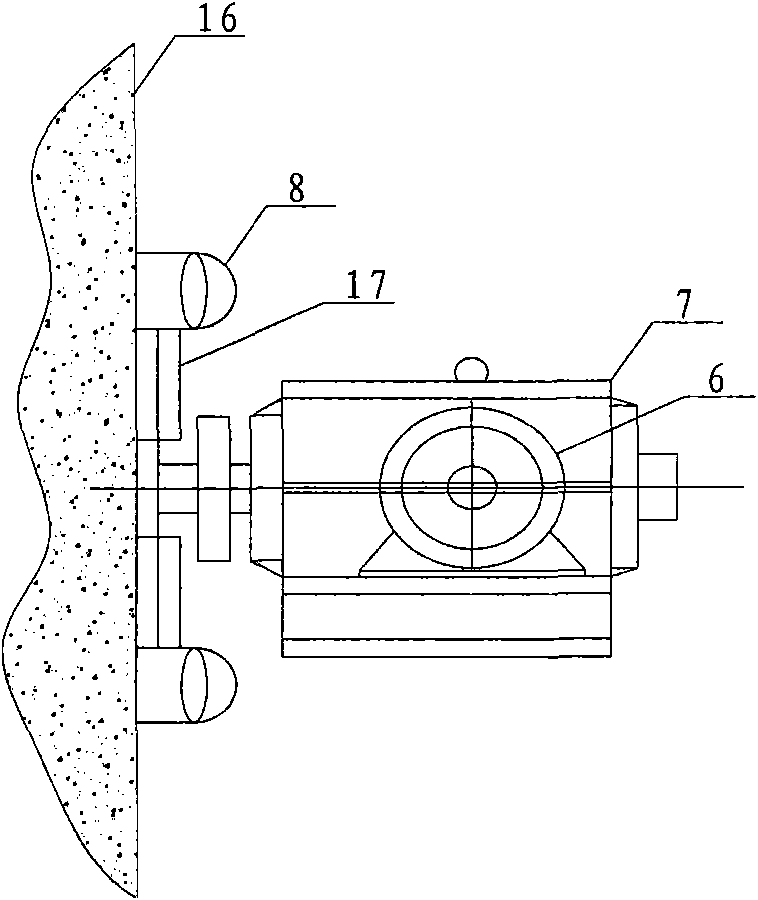

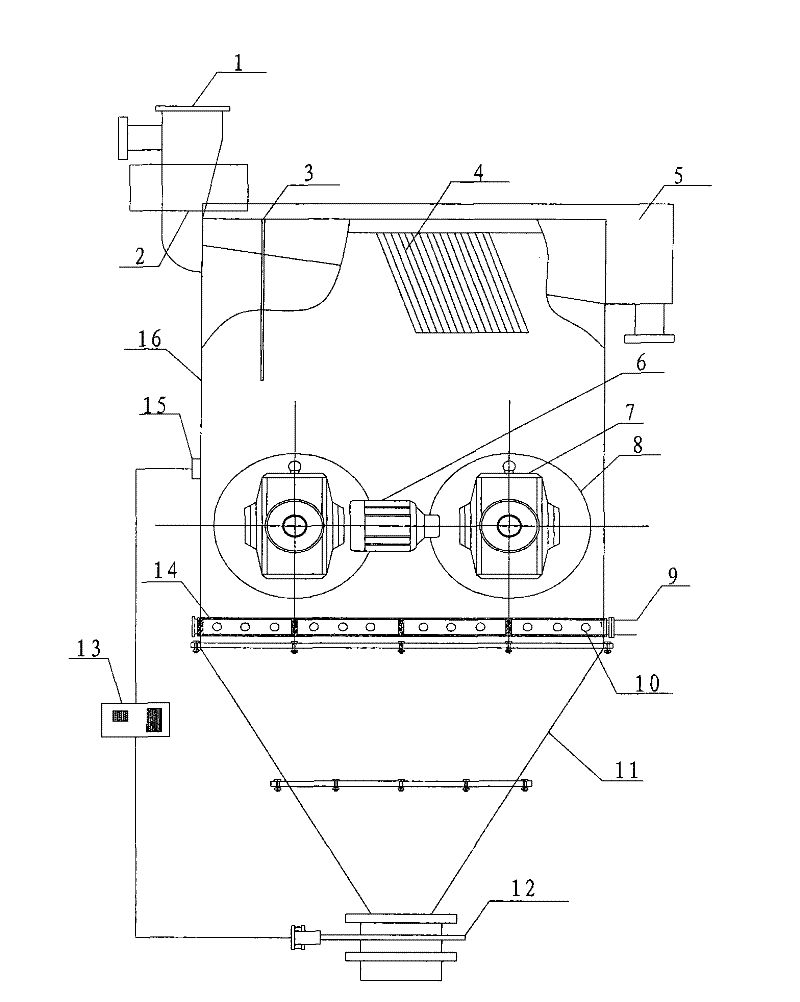

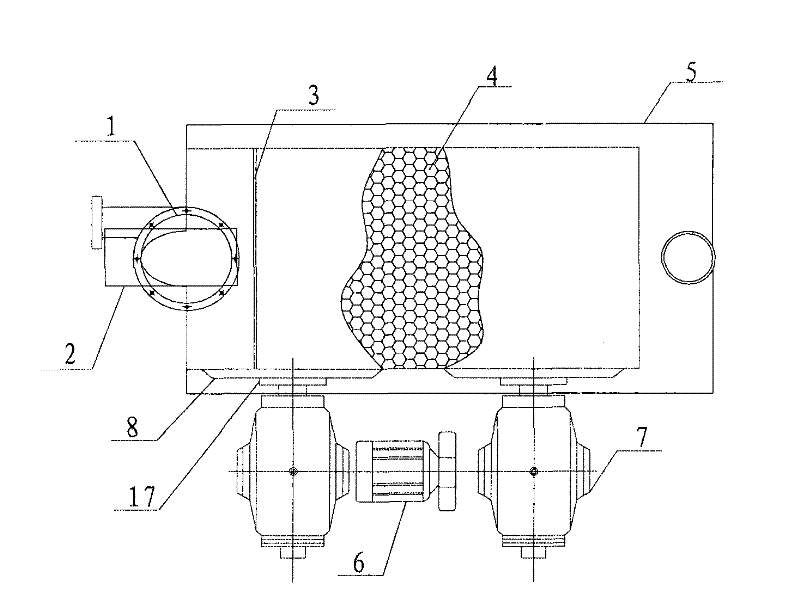

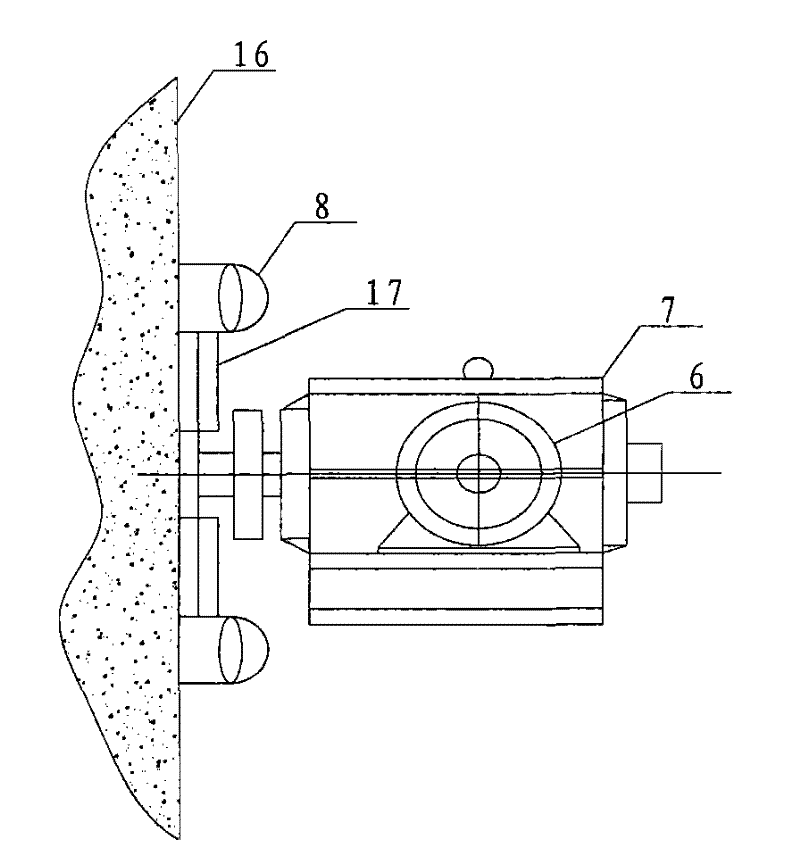

Hindered bed separator

InactiveCN101628256AImprove sorting effectImprove processing powerWet separationUltrasonic generatorEngineering

The invention relates to a hindered bed separator. The separator comprises a separator bed body (16), a feeding well (1) arranged at one side of the upper part of the separator bed body, an underflow collecting cone (11) at the bottom of the separator lathe bed, a clean coal overflow collecting tank (5) arranged at the upper part of the separator bed body and a control system, and is characterized in that a supersonic generator (2) is arranged below a feeding port of the feeding well (1); a plurality of inclined pipes (4) are arranged at the upper part of an inner cavity of the separator bed body in the equispaced manner, the lower pipe orifices of the inclined pipes are communicated with the inner cavity of the separator bed body, and the upper pipe orifices are communicated with the clean coal overflow collecting tank (5); a pipenet current distributor is paved in the cavity of the joint part of the separator bed body (16) and the underflow collecting cone (11); and a pulsating device is arranged on one side wall of the separator bed body for generating pulsating current.

Owner:HENAN POLYTECHNIC UNIV

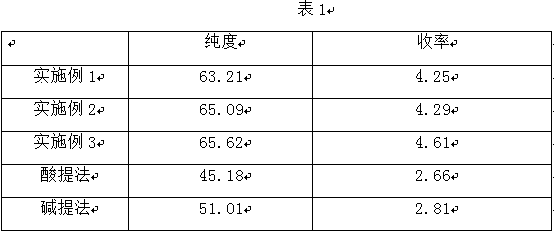

Method for extracting beta-glucan from Sparassis crispa

The invention discloses a method for extracting beta-glucan from Sparassis crispa. The method realizes pretreatment of the Sparassis crispa abd effective destroy of cells through physical grinding andaddition of a wall-breaking enzyme in order to dissolves out contents, so the extraction rate of the glucan is increased; high-pressure microwave treatment makes separation of glucan and cell tissuesfurther realized in order to achieve dissociation, so finally the glucan is obtained by extraction; and starch, proteins and other polysaccharides can be effectively removed by adding an impurity removal enzyme and ammonium sulfate, so that the purity of glucan is greatly improved.

Owner:FUQING CITY FIRE KIRIN EDIBLE FUNGUS TECH DEV

Method for separating EVA and battery piece in solar module

InactiveCN111640697AAchieve dissociationTake out without damageFinal product manufactureSemiconductor/solid-state device manufacturingPhysical chemistryEngineering

The invention discloses a method for separating EVA and a battery piece in a solar module. The method comprises the steps of 1) removing an aluminum frame of the solar module through a frame removingmachine; 2) heating the frameless assembly, and manually tearing off a TPT back plate; (3) conducting EVA scratching treatment; 4) carrying out embrittlement of EVA; 5) stripping the EVA and ultra-white glass; 6) stripping the EVA and the battery piece; and 7) detecting and classifying the battery pieces, re-detecting the taken-out battery pieces, re-packaging the qualified battery pieces into anassembly, and extracting metals such as silver and aluminum from the battery pieces with unqualified electrical properties or damaged battery pieces by utilizing a wet metal dissolving and extractingprocess to obtain a high-purity silicon wafer. The invention innovatively provides a method for embrittlement of EVA at a low temperature, EVA is dissociated from the battery piece by utilizing the embrittlement and cracking properties of EVA at a low temperature (glass state temperature) or below, and the complete and lossless battery piece is finally stripped through mechanical force in a low-temperature state.

Owner:镇江润驰新材料科技有限公司

Method for determining content of large flaky graphite in flaky graphite ore

InactiveCN105823712AHigh purityAccurately reflect granular characteristicsPreparing sample for investigationParticle size analysisMaceralParticle-size distribution

The invention discloses a method for determining the content of large flaky graphite in a flaky graphite ore. The method comprises the following steps: crushing the ore without destroying graphite flakes through using heat cracking fragmentation to realize dissociation of graphite and gangue mineral, and dissolving the gangue mineral in a mixed acid. Finally obtained graphite has high purity, and basically keeps the original occurrence granularity of the raw ore. The method can be used for determining the content and the granularity distribution of the large graphite flakes, and can accurately reflect the granularity characteristic of graphite in the graphite raw ore, and a determination result is helpful for accurately assessing the values of the graphite ore.

Owner:SHANDONG UNIV OF TECH

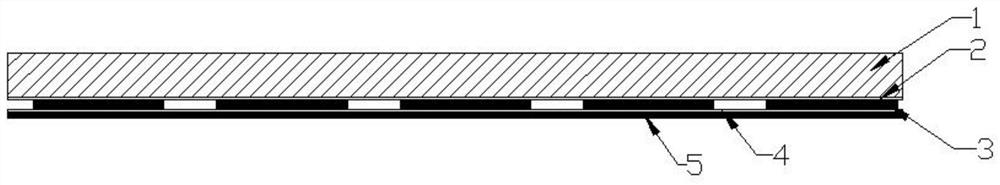

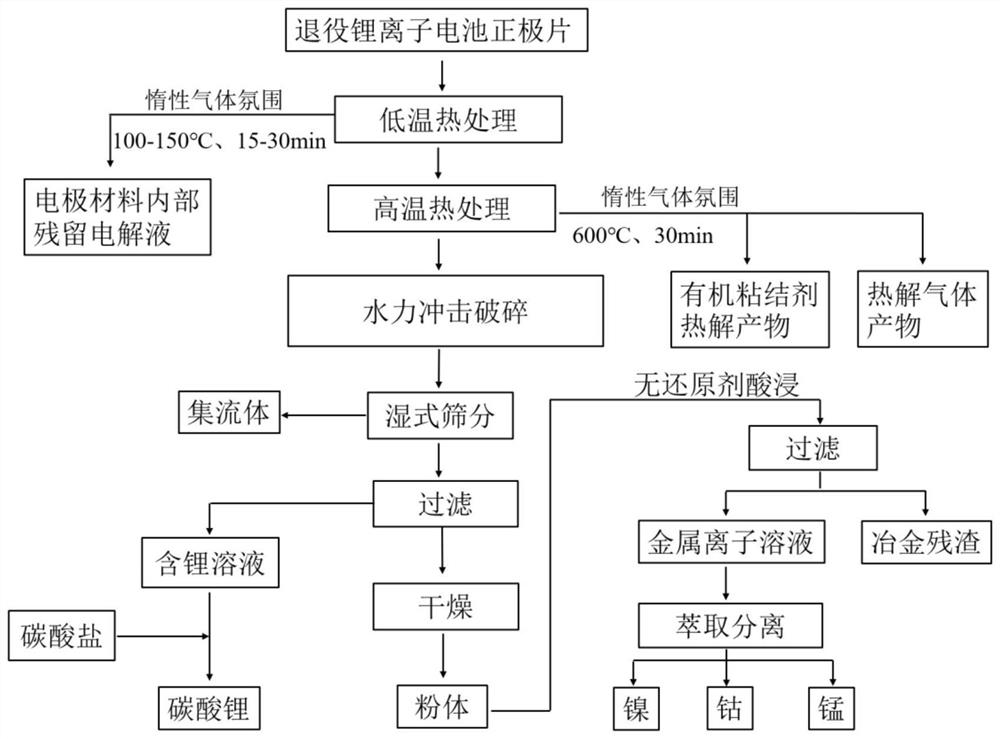

Multi-process efficient synergistic retired lithium ion battery positive electrode material recovery method

ActiveCN111786008AShorten the resource processReduce environmental pollutionChemical industryWaste accumulators reclaimingCurrent collectorLithium electrode

The invention discloses a multi-process efficient synergistic retired lithium ion battery positive electrode material recovery method, and belongs to the field of retired lithium ion battery recovery.Firstly, a positive plate of a retired lithium ion battery is disassembled; residual electrolyte in the positive plate is removed through heat treatment; then organic matters in the retired lithium ion battery electrode material are removed through pyrolysis, finally, efficient dissociation between the retired lithium ion battery electrode material and a current collector and between electrode material particles is realized through hydraulic crushing, and separation of a fine-grained electrode material and a coarse-grained current collector can be realized through screening; thermal reductionof high-valence transition metal ions in the positive electrode material is synchronously realized through regulation and control of pyrolysis parameters, and leaching of the water-soluble lithium salt is synchronously realized in the hydraulic crushing process. According to the method, multi-process synergistic coupling of organic matter removal in the electrode material, efficient dissociationof the electrode material and thermal reduction of the high-valence transition metal is realized, and the resource path of the retired lithium ion battery is shortened.

Owner:CHINA UNIV OF MINING & TECH

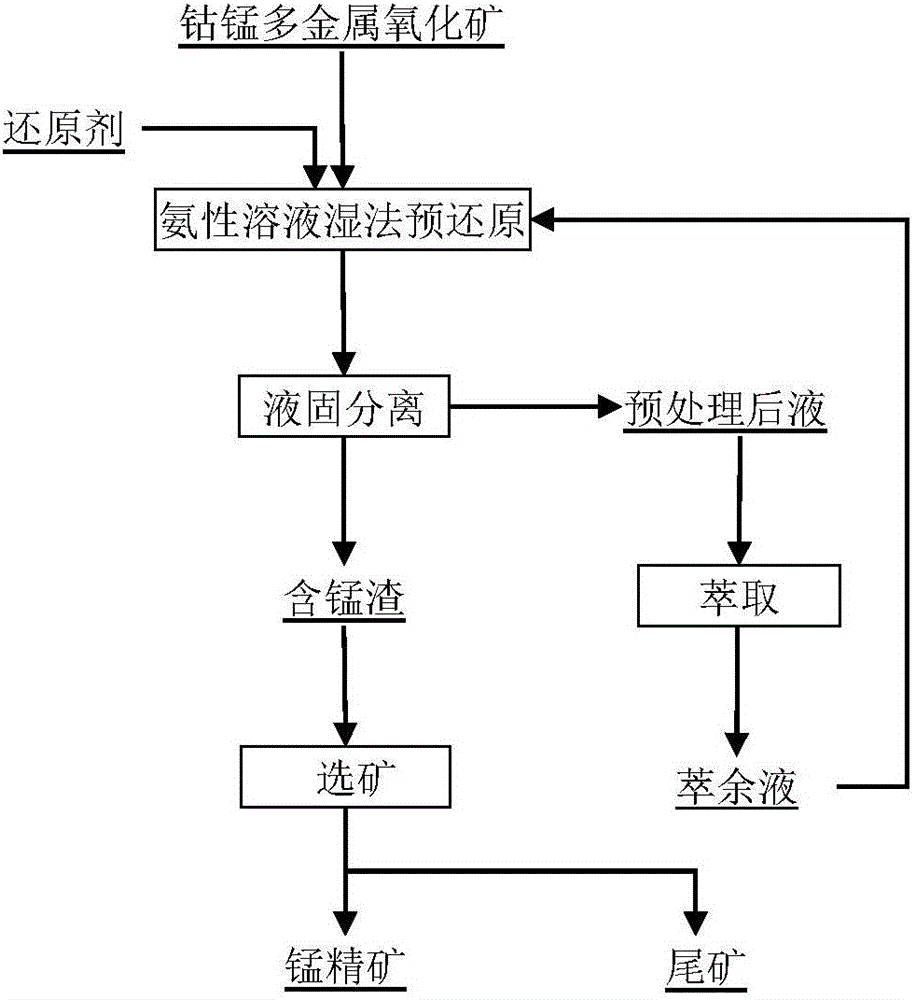

Method for recovering manganese from cobalt and manganese polymetallic oxidized ore

The invention discloses a method for recovering manganese from cobalt and manganese polymetallic oxidized ore and belongs to the field of comprehensive utilization of cobalt and manganese polymetallic ore. Cobalt and manganese polymetallic oxidized ore undergoes wet reduction pretreatment in an ammonia solution by using a reducing agent; and manganese mineral and impurity minerals undergo chemical dissociation and activation, and then high intensity magnetic separation and flotation separation are carried out to recover manganese so as to obtain manganese concentrate. According to the invention, manganese is recovered from cobalt and manganese polymetallic oxidized ore by chemical activation and physical concentration. The technological process is simple, and cost is low.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

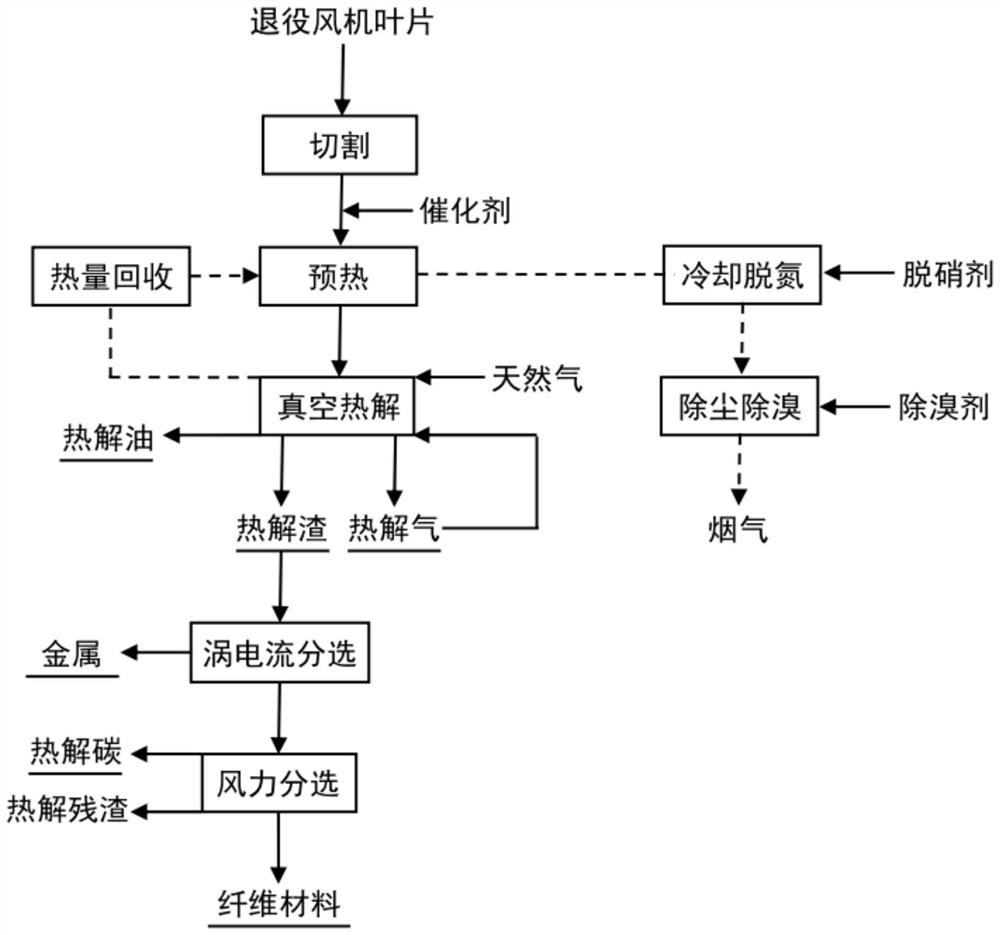

Vacuum pyrolysis treatment and recovery method for retired fan blades

ActiveCN114653729AAchieve dissociationAccurate temperature controlSolid waste disposalTransportation and packagingCatalytic pyrolysisFiber

The invention discloses a vacuum pyrolysis treatment and recovery method for retired fan blades, which comprises the following steps: (1) blade pretreatment: crushing the retired fan blades, adding a pyrolysis catalyst, and uniformly mixing; then, the combustion flue gas subjected to high-temperature treatment is introduced for preheating treatment; (2) vacuum pyrolysis: carrying out catalytic pyrolysis treatment on the pre-treated retired fan blade in a vacuum negative pressure state to obtain pyrolysis gas, pyrolysis oil and pyrolysis residues; (3) carrying out eddy current separation on the pyrolysis residues to obtain metal, and carrying out wind separation to obtain pyrolytic carbon, a fiber material and pyrolysis residues; (4) cooling and denitrifying the combustion flue gas generated in the step (1); and (5) removing dust and bromine from the cooled and denitrified combustion flue gas. According to the method, the retired fan blade can be efficiently treated, and resources such as fiber materials and metal in the retired fan blade can be recycled.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

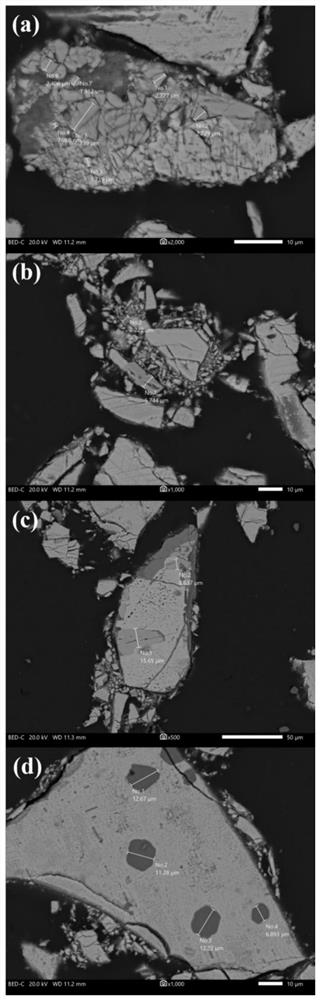

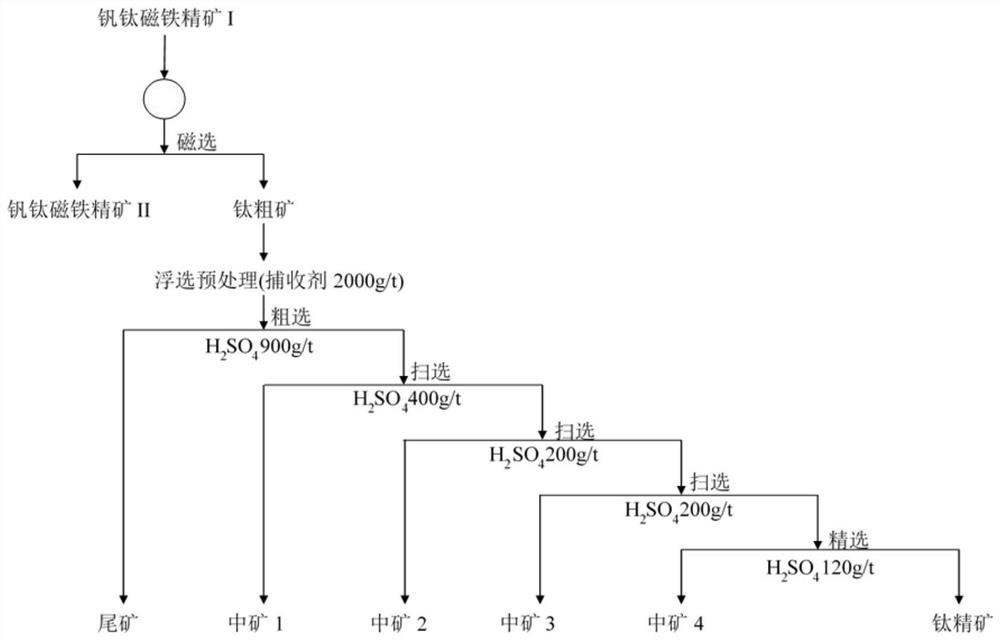

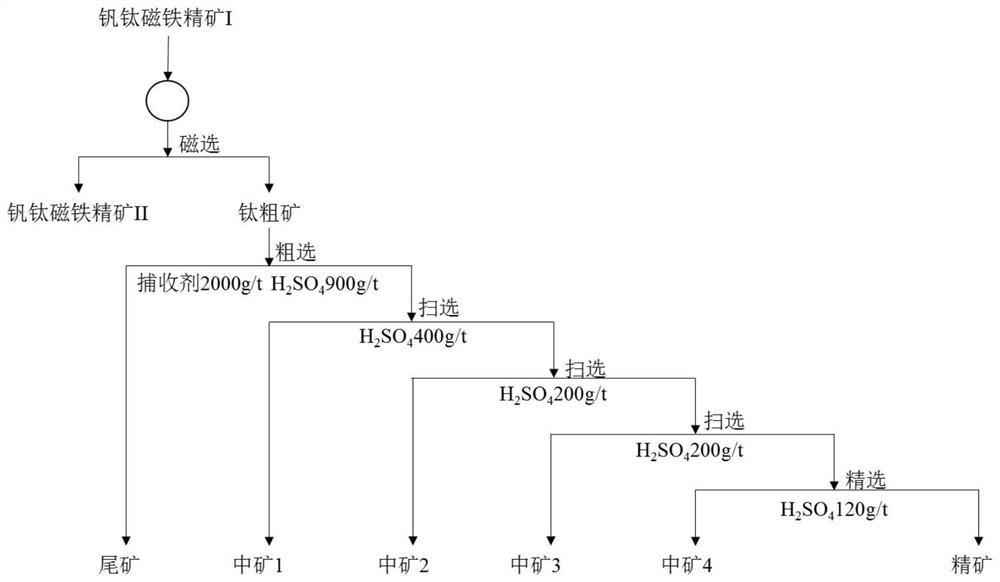

Beneficiation method of vanadium-titanium magnetite concentrate

ActiveCN113560030AAchieve dissociationSolve the difficult problem of substantive sortingProcess efficiency improvementGrain treatmentsMagnetiteTitanium

The invention belongs to the field of mineral separation, and particularly relates to a beneficiation method of vanadium-titanium magnetite concentrate. The beneficiation method comprises the following steps: (1) mixing vanadium-titanium magnetite concentrate I and an aqueous solution dissolved with a dispersing agent to prepare ore pulp; (2) carrying out wet ball milling treatment on the ore pulp, and controlling the proportion of fine ore with the granularity being minus 15 microns after ball milling to be 95% or above; and (3) carrying out magnetic separation on the ground fine ore to obtain iron-rich vanadium-titanium magnetite concentrate II and titanium-rich coarse titanium ore after separation. The magnetic field intensity in the magnetic separation process is 0.1-1.3 T. In addition, the invention further relates to a method for carrying out pretreatment-flotation on the obtained coarse titanium ore, and through combined control over the ore grinding process and conditions, efficient separation of iron and titanium can be achieved based on an ore grinding mechanism.

Owner:CENT SOUTH UNIV

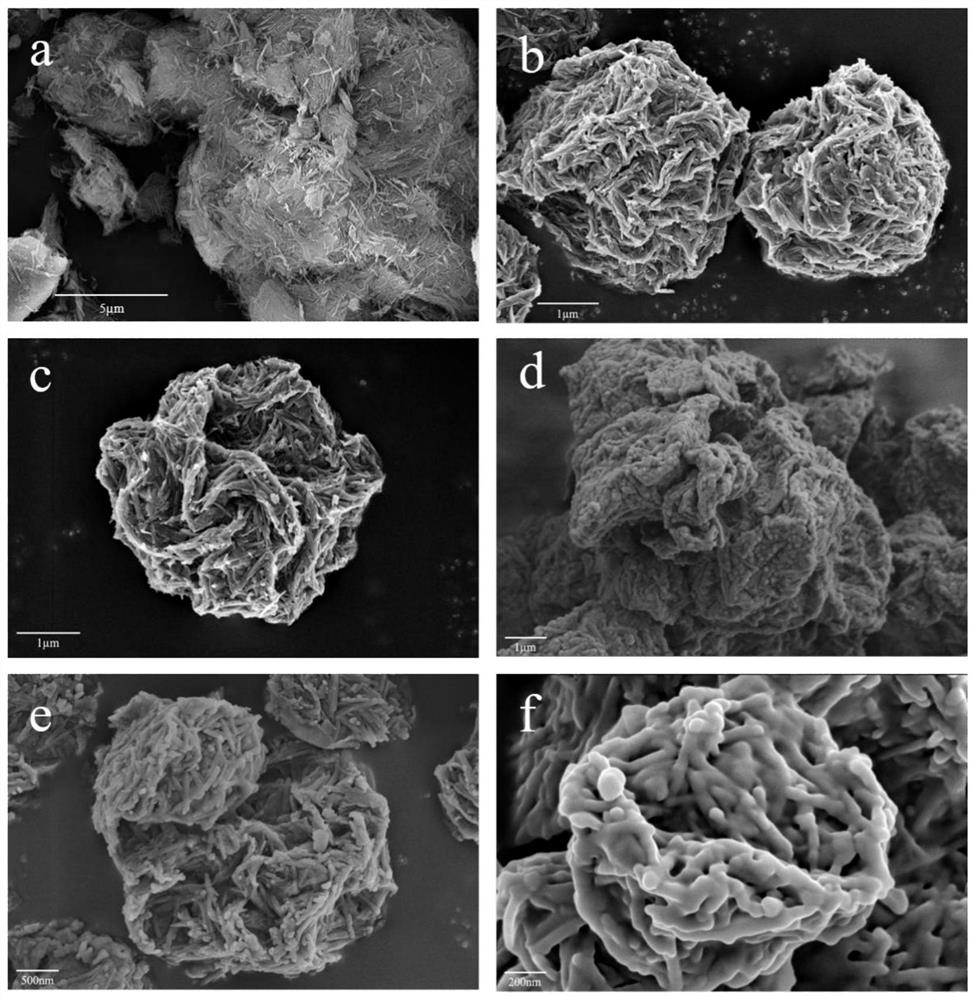

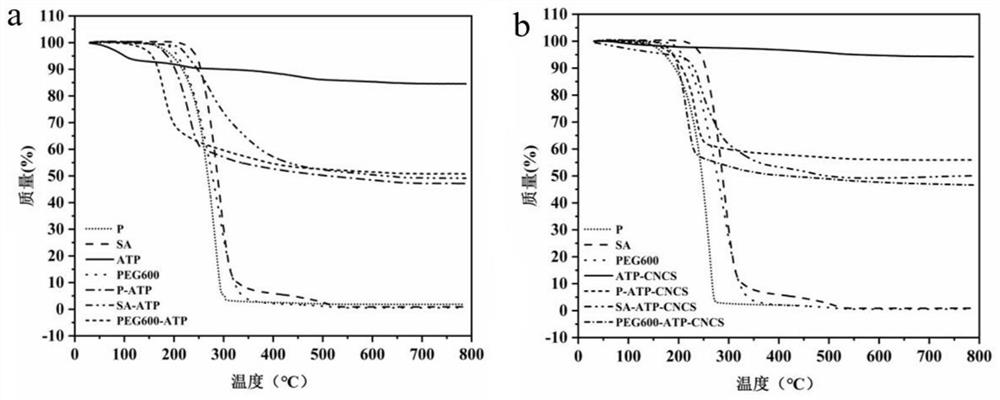

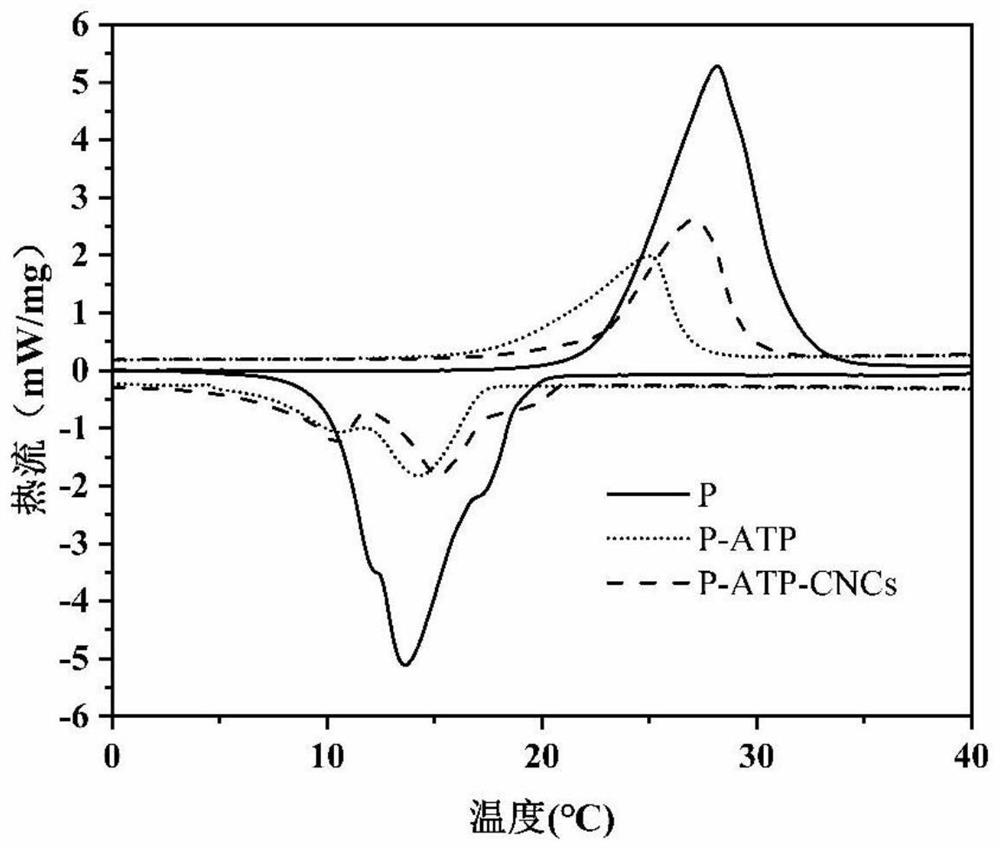

Preparation method of composite mineral microsphere-based phase change heat storage material

ActiveCN113637459AAchieve dissociationGood dispersionEnergy storageHeat-exchange elementsComposite materialSodium phosphates

The invention discloses a preparation method of a composite mineral microsphere-based phase change heat storage material. The preparation method comprises the steps of (1) carrying out acid activation on attapulgite to obtain acid-activated attapulgite; (2) mixing the acid-activated attapulgite with sodium hexametaphosphate and water to obtain an attapulgite suspension; mixing cellulose nanocrystals with sodium hexametaphosphate and water to obtain a cellulose nanocrystal solution, mixing the attapulgite suspension with a cellulose nanocrystal solution, and performing spray drying to obtain attapulgite / cellulose nanocrystal composite microspheres; (3) calcining to obtain composite mineral microspheres; and (4) carrying out vacuum impregnation on the composite mineral microspheres and a phase change material to obtain the composite mineral microsphere-based phase change heat storage material. According to the invention, the cellulose nanocrystals are introduced, spray drying and calcination are adopted to prepare the composite mineral microspheres with the hollow porous sphere-like three-dimensional structure, and the structure and the rough surface of the composite mineral microspheres provide richer adsorption sites for the phase change material, so that the heat storage performance of the phase change heat storage material is improved.

Owner:CENT SOUTH UNIV

Multifunctional high molecular micelle drug delivering system and preparation method and application thereof

ActiveCN109125739AAchieve dissociationImprove stabilityEnergy modified materialsPharmaceutical non-active ingredientsSide chainPolyethylene glycol

The invention belongs to the technical field of targeted drug delivery, and relates to a multifunctional high molecular micelle drug delivering system and a preparation method and application thereof.Some side chains of a polyethylene glycol-polylysine block copolymer are chemically modified by dimethyl 3,3'-dithiobispropionimidate dihydrochloride to obtain thiol-containing groups, and then a thiol-containing boron neutron capturing therapeutic drug disodium thiol dodecaborane reacts with the side chains through disulfide bonds to form stable multifunctional high molecular micelles in a watersolution through self-assembly and the crosslinkinging action of some free disulfide bonds; the prepared high molecular micelles can deliver the thiol-containing drug disodium thiol dodecaborane or other thiol-containing drugs or prodrugs, so that the content of the drug delivered to tumor cells is increased and a targeted therapeutic effect on tumors is enhanced.

Owner:SICHUAN UNIV

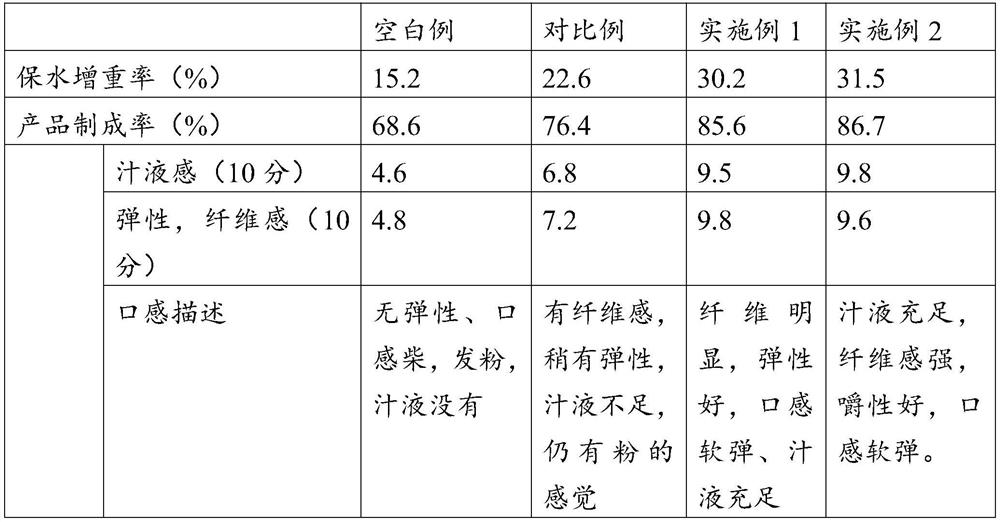

Special modifier for chicken breast and processing method of chicken breast

PendingCN114698790ARaise the pHImprove water holding capacityFood ingredient as antioxidantFood ingredient as taste affecting agentGluconic acidSodium triphosphate

The invention belongs to the technical field of chicken food. The chicken breast quality improver provided by the invention comprises a first improvement component and a second improvement component, the first improvement component comprises sodium carbonate, sodium citrate, sodium pyrophosphate, sodium tripolyphosphate and table salt; and the second improvement component comprises gluconic acid-delta-lactone and embedded fumaric acid. The sodium carbonate, the sodium citrate, the sodium pyrophosphate, the sodium tripolyphosphate, the table salt, the gluconic acid-delta-lactone and the embedded fumaric acid are comprehensively used, so that the meat quality improvement effect of each component is outstanding, the water retention and weight gain rate and the product yield of the chicken breast meat product are increased, the dissolution rate of salt-soluble protein in the chicken breast meat processing process is increased, and the quality of the chicken breast meat is improved. The bitterness of alkali is removed, and the characteristic flavor of the product is maintained.

Owner:广东无穷食品集团有限公司

Direct combustion activation process for coal gangue, and geopolymer preparation process

The invention relates to the technical field of coal gangue application, and discloses a direct combustion activation process for coal gangue, and a geopolymer preparation process. The direct combustion activation process for coal gangue comprises the following steps: 1, raw material preparation and pretreatment: crushing the coal gangue into coal gangue particles; 2, middle-stage treatment: subjecting the coal gangue particles and fuel to mixing and combustion, and introducing high-pressure air to blow up the coal gangue particles; 3, cooling treatment: rapidly cooling a coal gangue material treated in the step 2; and 4, secondary grinding: grinding the coal gangue material obtained in the step 3. The invention has the beneficial effects that the coal gangue is activated through a specific process and then is used for preparing a geopolymer, and the geopolymer is applied to building materials, high-strength materials, solid core and solid waste materials, sealing materials and high-temperature-resistant materials. Through a technical route and principles different from technical routes and principles in the prior art, the coal gangue is utilized to the maximum extent, a large amount of coal gangue is consumed, and remarkable economic benefits and social benefits are achieved.

Owner:北京荣露材料科技有限公司

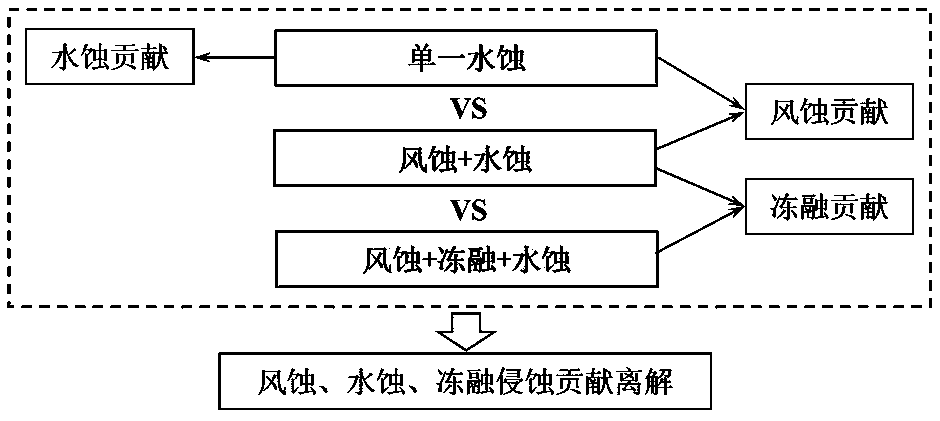

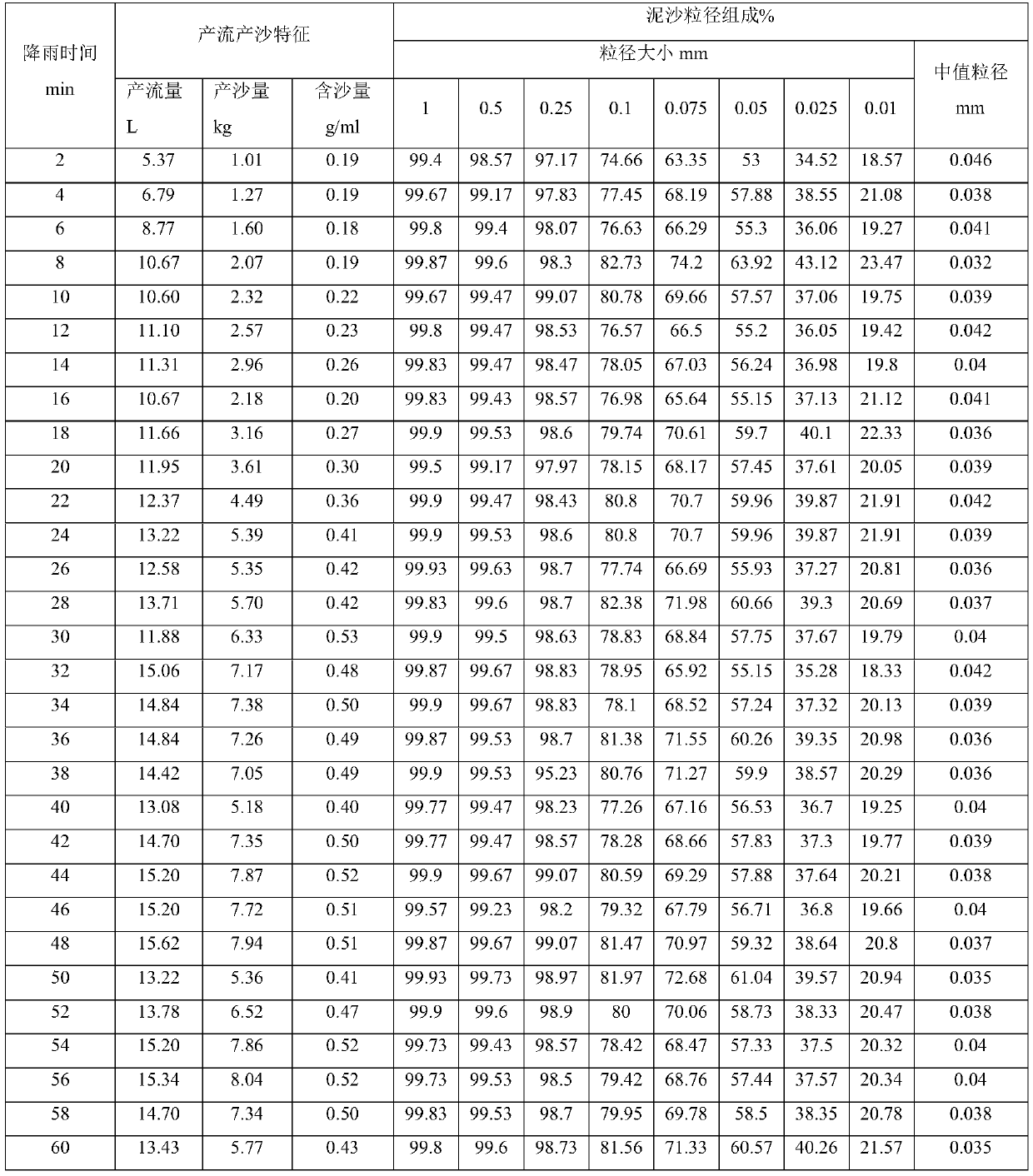

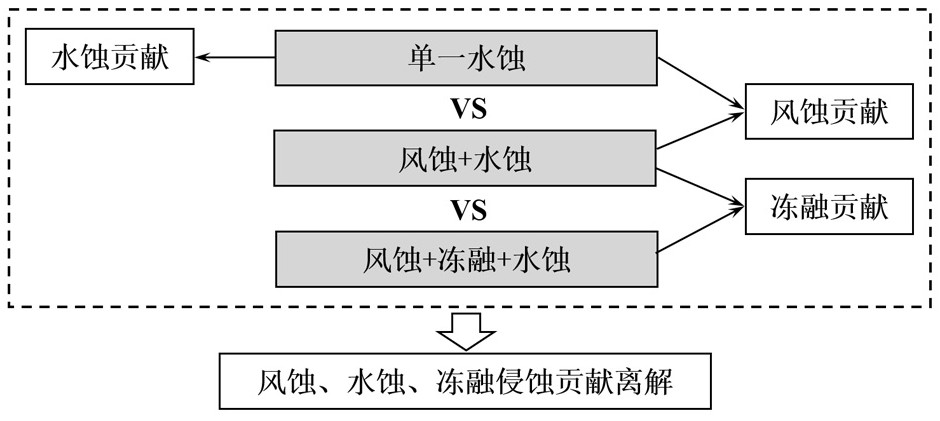

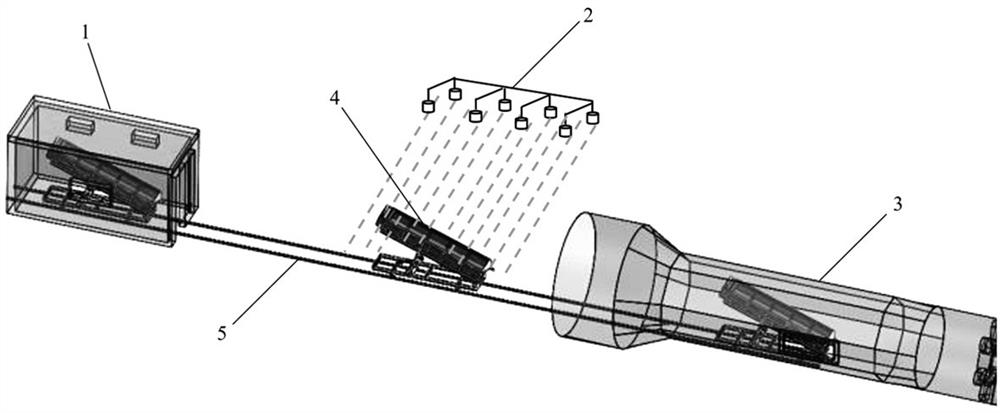

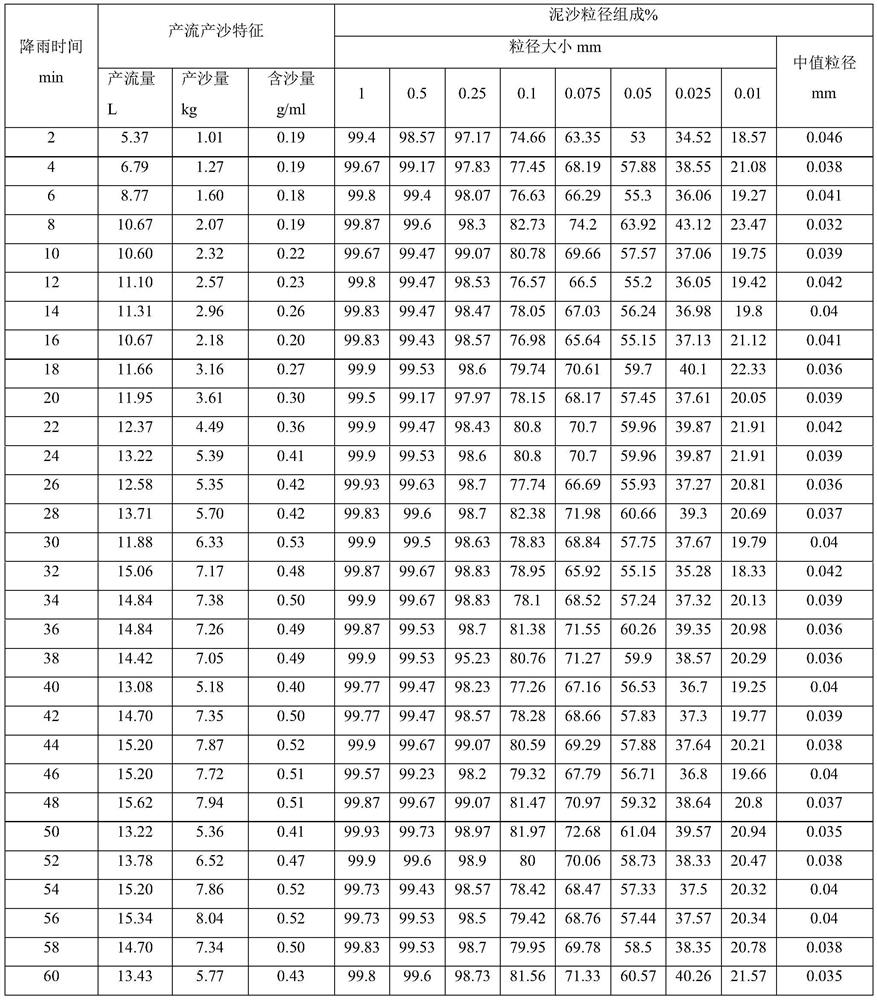

Method for simulating and quantifying influence of composite erosion on water and soil loss

ActiveCN111504891APractical technical solutionsShorten the test processWeather/light/corrosion resistanceSoil scienceEngineering

The invention discloses a method for simulating and quantifying the influence of a composite erosion effect on water and soil loss. That is to say, means like an artificial simulated rainfall test, awind tunnel test and a freeze-thaw cycle test are comprehensively utilized. The filled test soil tank along the track are moved among the regions of the indoor artificial rainfall-wind tunnel-freeze thawing cycle solid model; through combined application of multiple test devices, simulation of different composite erosion modes is achieved, the water and soil loss influence quantity under differentcomposite erosion effects is determined, and the contribution rate of each driving factor such as hydraulic power, wind power and freeze thawing on the water and soil loss influence is separated according to a driving factor dissociation scheme. According to the technical scheme, the method is practical and effective, the water and soil loss influence quantity under different dynamic coupling effects in the composite erosion system can be quantified, and the contribution rate of each driving factor in the composite erosion system can be separated.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

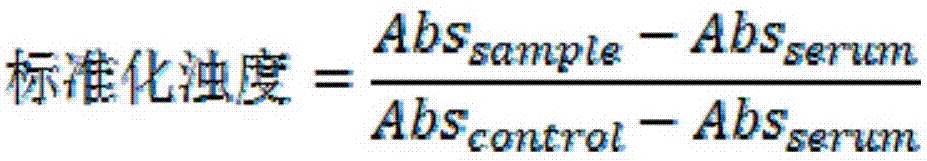

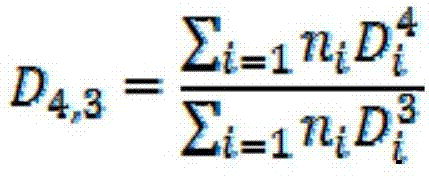

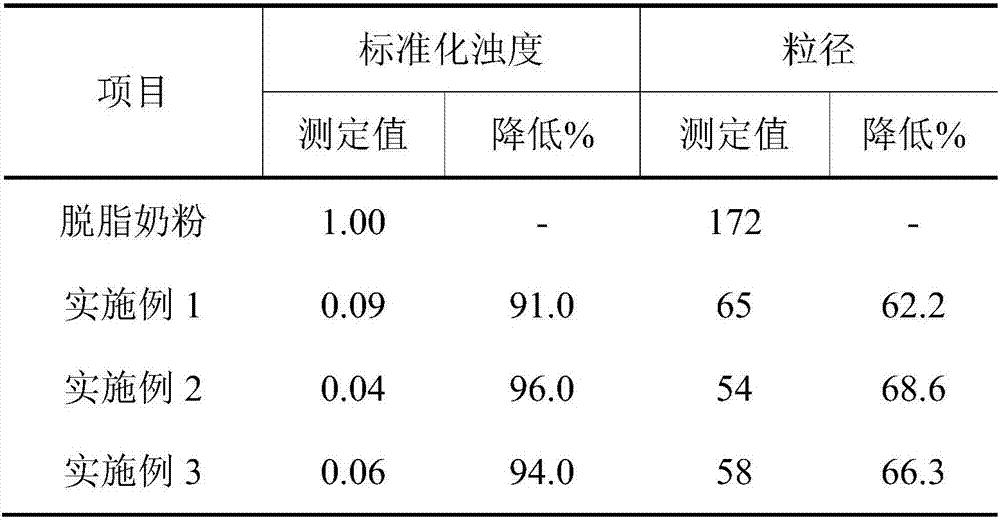

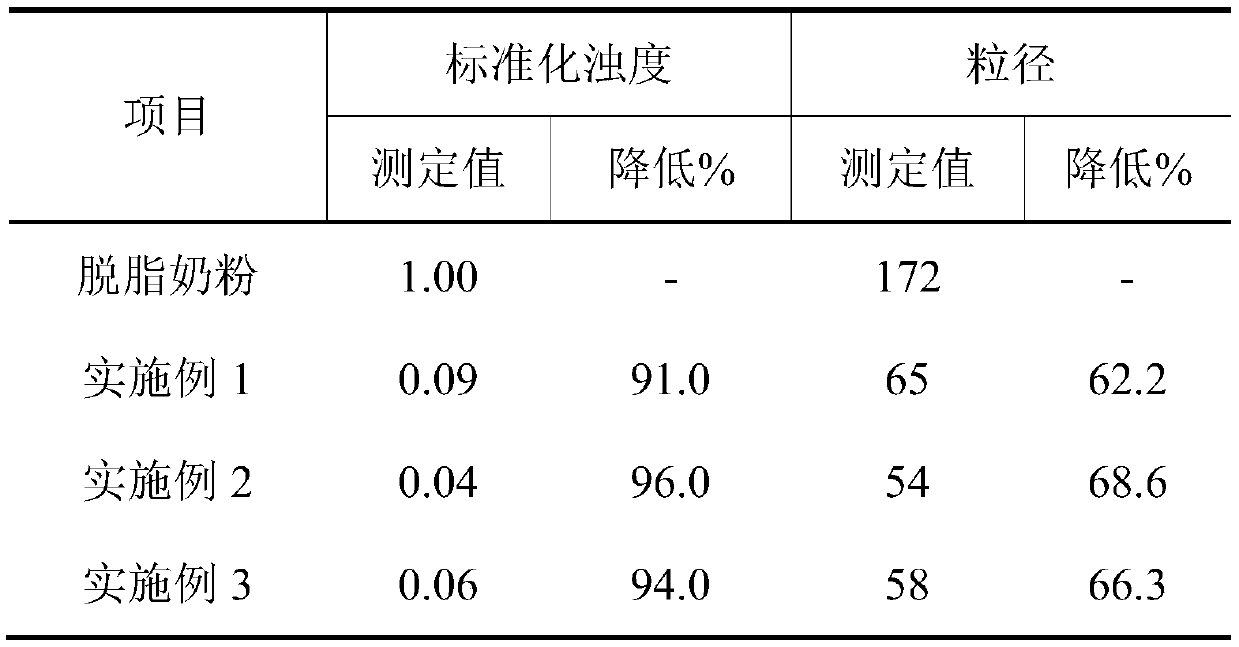

Preparation method of transparent milk

ActiveCN107873842AReduce aggregationReduce hydrophobic effectMilk preparationProtein solutionTurbidity

The invention discloses a preparation method of transparent milk. The preparation method of the transparent milk comprises the following steps of dissolving skimmed milk powder in deionized water; adjusting pH value of the solution to 10-12 by using an alkali solution; and then, carrying out stirring, and adjusting the pH of the solution back to neutral by using an acid solution so as to obtain the transparent milk On the basis of causing no damage to the primary structure of the milk proteins, the hydrophobic effects and the ionic effects inducing inter-protein linkages are weakened by the preparation method of the transparent milk so that the effect of protein depolymerization is achieved; and thus, particle size of the milk proteins is greatly reduced. Finally, turbidity of the transparent milk is reduced by 95% or above, and a clear protein solution with transparent / semi-transparent property is formed; moreover, the transparent milk has significantly improved storage stability, andthus, commercialized application potential of transparent milk product solutions is further improved.

Owner:JIANGNAN UNIV

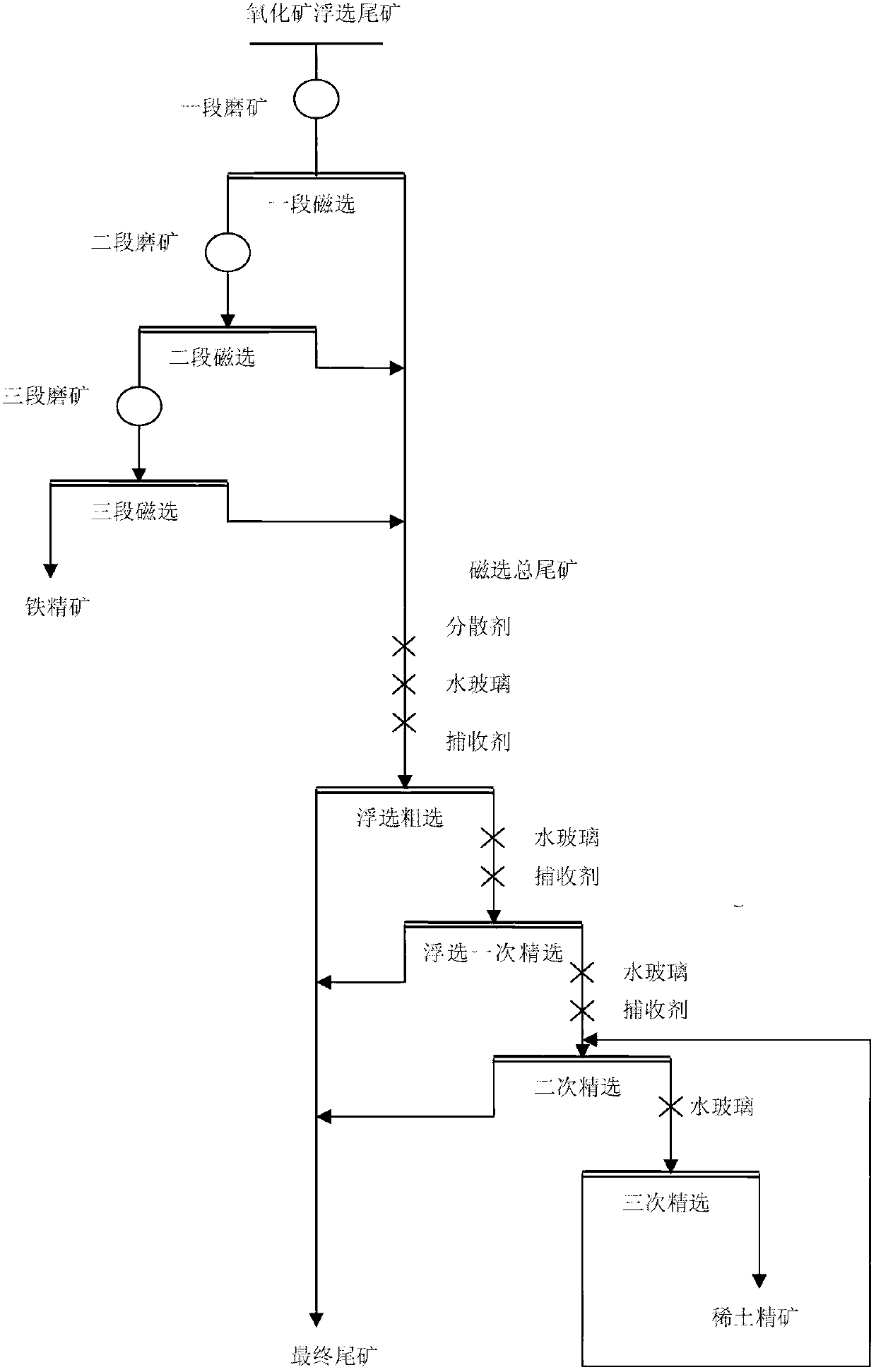

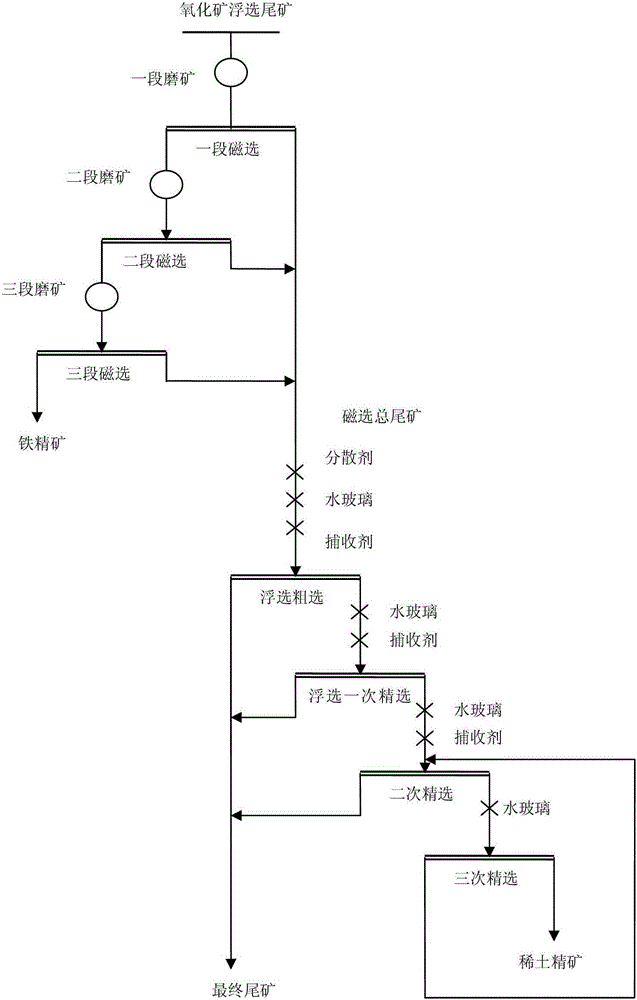

Mineral separation process for recycling iron and rare earth in baotite oxidized ore flotation tailings

ActiveCN103272685AAchieve dissociationRaise the gradeFlotationMechanical material recoveryMevalonic acidMagnetic separation

The invention belongs to the technical field of mineral engineering, and aims to provide a mineral separation process for recycling iron and rare earth in baotite oxidized ore flotation tailings. At present, useful minerals cannot be recycled due to the fact that mineral separation difficulty of oxidized ore flotation tailings in a BaoTou steel concentrating mill is large. Three sections of ore grinding and three sections of magnetic separation are adopted, and iron ore concentrate which has the iron grade larger than 64% and the recycling rate larger than 56% is obtained from the oxidized ore flotation tailings containing 26%-33% of iron. Then total tailings in an iron recycling process serve as rare earth flotation materials, sodium polyphosphate serves as pulp dispersing agents, 2-hydroxy3-naphthyl mevalonic acid or salicylhydroxami acid and alkyl hydroximic acid in a mass ratio of 6-8:1 serve as rare earth collecting agents, water glass serves as efficient flotation combination reagents of pH regulators and inhibitor, the dispersing state of pulp micro-fine particle minerals is well controlled, the rare earth separation process with once coarse separation and three-time fine separation is adopted, and rare earth ore concentrate which has the grade larger than 58% and the recovery rate larger than 64% is obtained from feed with the 7-9% rare earth grade.

Owner:包钢集团矿山研究院(有限责任公司)

A method for simulating and quantifying the impact of combined erosion on soil and water loss

ActiveCN111504891BPreserve integrityEffective stripping erosion contribution rateWeather/light/corrosion resistanceFreeze thawingSoil science

The invention discloses a method for simulating and quantifying the influence of compound erosion on water and soil loss, that is, by comprehensively utilizing artificial simulated rainfall test, wind tunnel test and freeze-thaw cycle test means, the filled test soil tank is artificially rained indoors along the track. The wind tunnel-freeze-thaw cycle physical model moves between regions, and through the joint use of various test devices, the simulation of different composite erosion modes is realized to determine the impact of water and soil loss under different composite erosion effects, and then dissociate according to the driving factors According to the scheme, the contribution rate of various driving factors such as hydraulic power, wind power, freeze-thaw, etc. to soil erosion is separated. The technical solution of the invention is practical and effective, and can not only quantify the amount of influence of water and soil loss under different dynamic coupling effects in the composite erosion system, but also separate the contribution rate of each driving factor in the composite erosion system.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Method for co-extracting vanadium, titanium and chromium from vanadium slag

ActiveCN113234935AFully exposedAchieve dissociationProcess efficiency improvementOXALIC ACID DIHYDRATEOxalate

The invention provides a method for co-extracting vanadium, titanium and chromium from vanadium slag. According to the method, pyroxene and fayalite wrapping spinel are selectively reduced through a method of low-temperature hydrogen reduction, iron removal by ferric trichloride and low-temperature oxalic acid leaching of the vanadium slag, the structure of the spinel is destroyed, and dissociation of a spinel phase and a silicate phase is realized, so that the spinel phase is fully exposed, the vanadium slag is directly leached at a low temperature and the spinel structure is destroyed by utilizing the acidity and strong complexing property of oxalic acid, so that vanadium, titanium and chromium are complexed with oxalate to enter a solution, and co-extraction of vanadium, titanium and chromium is realized. According to the method, vanadium, titanium and chromium are extracted from the vanadium slag, and the leaching rates are all larger than 99%.

Owner:UNIV OF SCI & TECH BEIJING

Hindered bed separator

Owner:HENAN POLYTECHNIC UNIV

Ore dressing process for recovering iron and rare earth from oxidized ore flotation tailings in Baotou Mine

ActiveCN103272685BAchieve dissociationRaise the gradeFlotationMechanical material recoveryRare earthMaterials science

The invention belongs to the technical field of mineral engineering, and aims to provide a mineral separation process for recycling iron and rare earth in baotite oxidized ore flotation tailings. At present, useful minerals cannot be recycled due to the fact that mineral separation difficulty of oxidized ore flotation tailings in a BaoTou steel concentrating mill is large. Three sections of ore grinding and three sections of magnetic separation are adopted, and iron ore concentrate which has the iron grade larger than 64% and the recycling rate larger than 56% is obtained from the oxidized ore flotation tailings containing 26%-33% of iron. Then total tailings in an iron recycling process serve as rare earth flotation materials, sodium polyphosphate serves as pulp dispersing agents, 2-hydroxy3-naphthyl mevalonic acid or salicylhydroxami acid and alkyl hydroximic acid in a mass ratio of 6-8:1 serve as rare earth collecting agents, water glass serves as efficient flotation combination reagents of pH regulators and inhibitor, the dispersing state of pulp micro-fine particle minerals is well controlled, the rare earth separation process with once coarse separation and three-time fine separation is adopted, and rare earth ore concentrate which has the grade larger than 58% and the recovery rate larger than 64% is obtained from feed with the 7-9% rare earth grade.

Owner:包钢集团矿山研究院(有限责任公司)

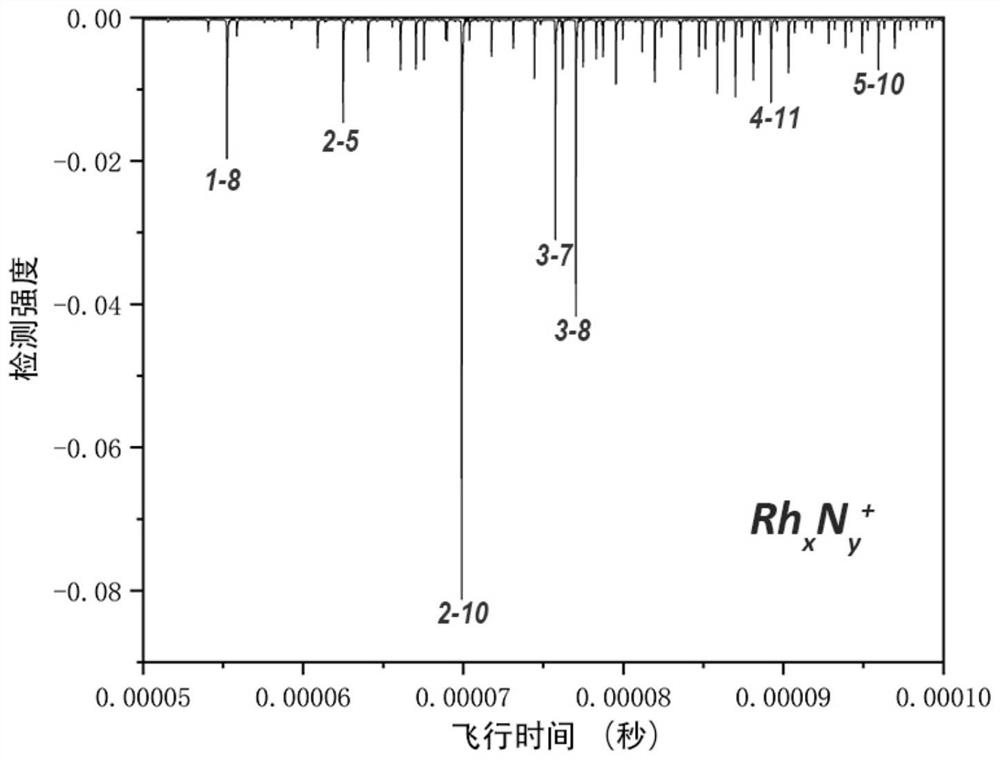

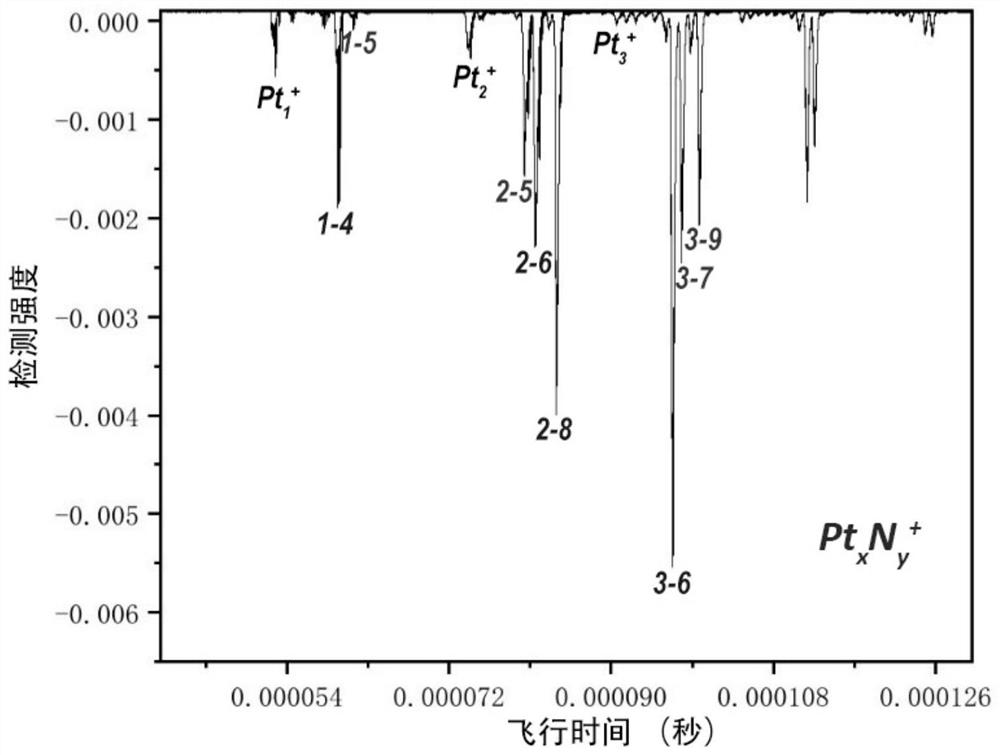

Plasma-assisted method for catalyzing nitrogen activation dissociation by metal cluster

InactiveCN112114026AAchieve dissociationAvoid high temperature and pressureNitrogen-metal/silicon/boron binary compoundsMaterial analysis by electric/magnetic meansMetal clustersNitrogen gas

The invention discloses a plasma-assisted method for catalyzing nitrogen activation dissociation by metal cluster, and belongs to the technical field of cluster science. The method comprises the following steps: in a vacuum cavity, nitrogen or mixed gas of nitrogen passes through a metal plasma area, and then activated dissociation of the nitrogen is achieved. According to the method, dissociationof nitrogen molecules can be achieved through a method of generating metal plasmas through laser sputtering under the room temperature condition, and high temperature and high pressure in the nitrogen catalytic reaction process in the prior art are avoided. The method disclosed by the invention is simple and convenient to operate, a used metal target material is selectable, and a reliable methodis provided for nitrogen dissociation and subsequent nitrogen-containing compound generation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

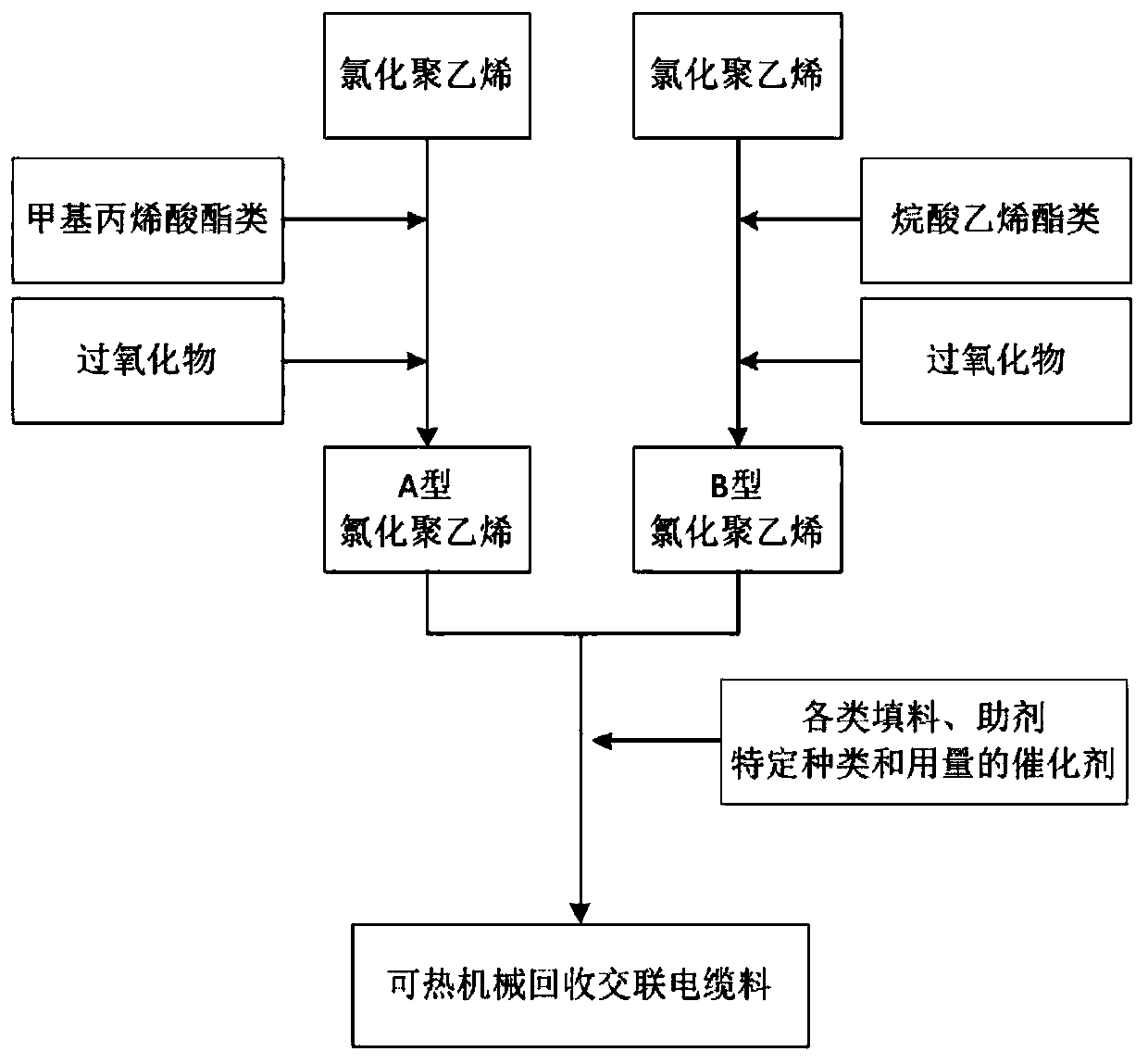

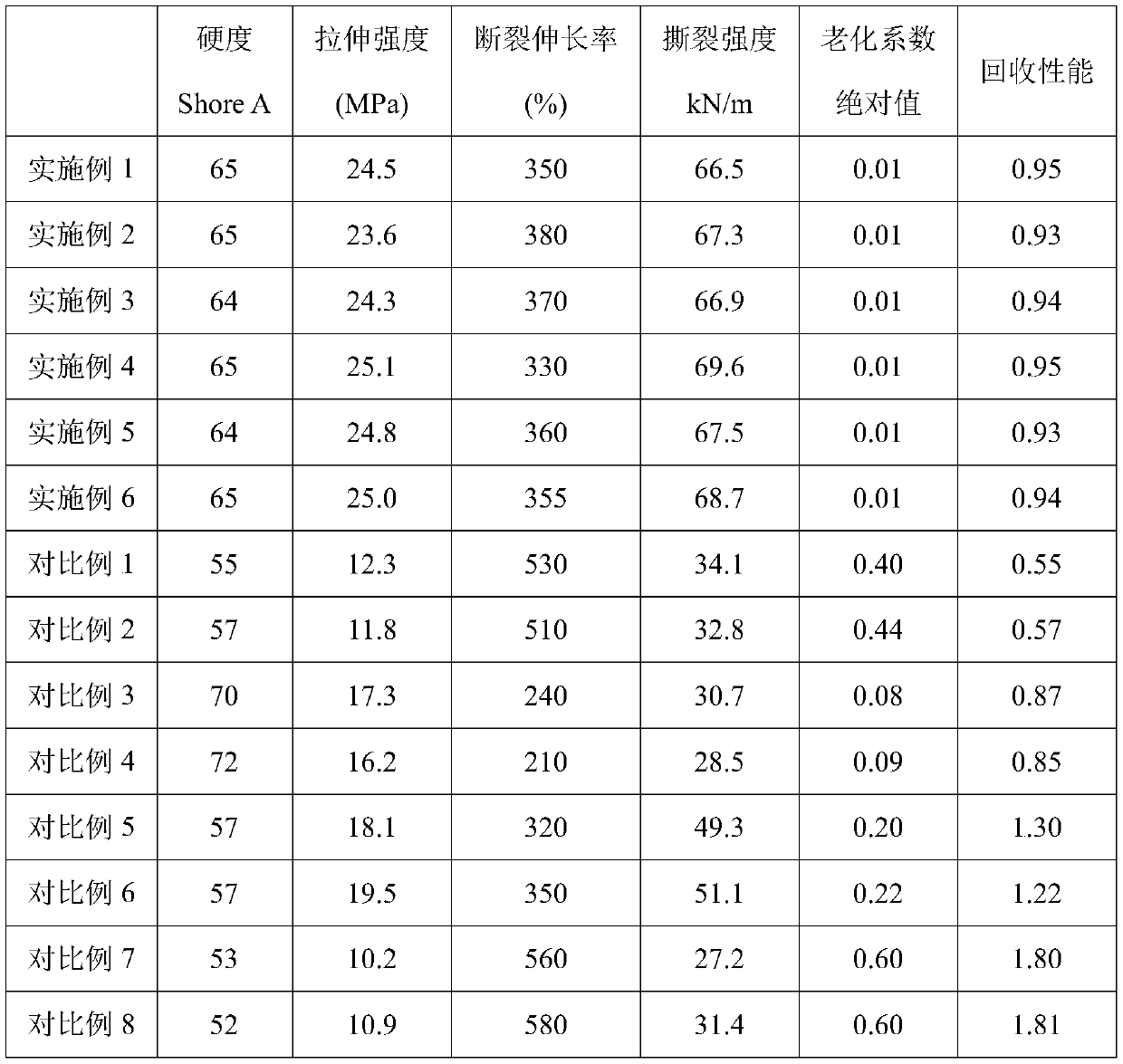

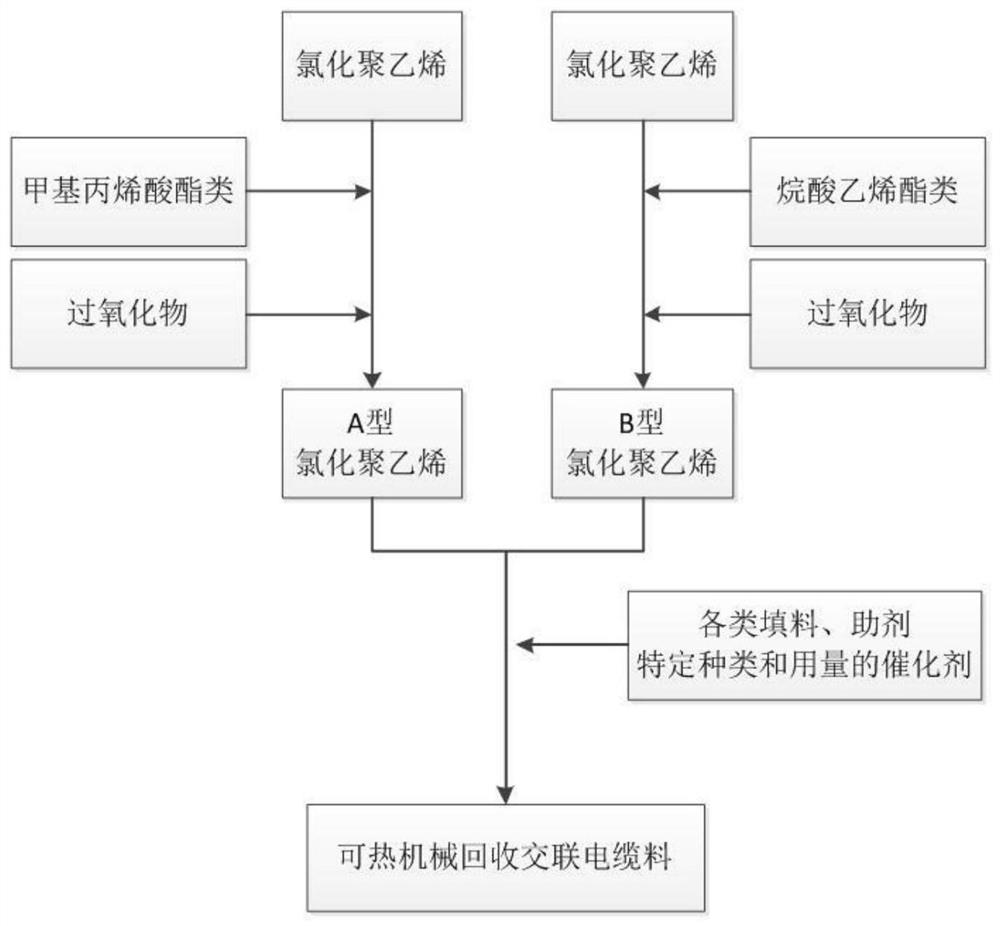

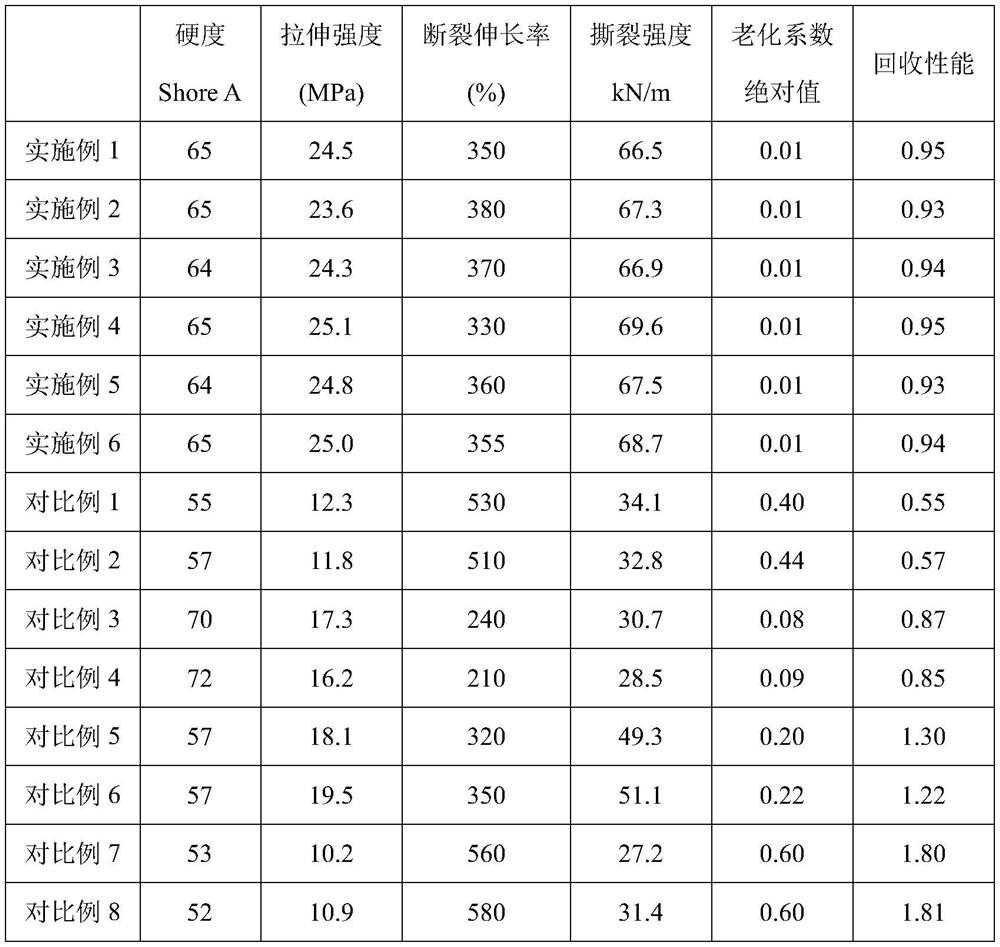

Thermo-mechanically-recoverable crosslinked cable material and preparation method thereof

ActiveCN109694538AIncreased distance between molecular chainsReduce de-HCl reactionPlastic/resin/waxes insulatorsMethacrylateSide chain

The invention discloses a thermo-mechanically-recoverable crosslinked cable material and a preparation method thereof, and belongs to the field of wires and cables. The molecular chain of chlorinatedpolyethylene is grafted with specific amounts of methacrylate and vinyl alkanoate small molecules through adopting a chemical grafting process, and the side chain of the grafting ester functional group is used to increase the spacing of the molecular chain of the chlorinated polyethylene in order to achieve plasticization, so the HCl removal reaction in the processing forming process of the chlorinated polyethylene is effectively reduced; two different ester side groups form an active crosslinking point, and crosslinking bonds are formed in an ester exchange form under the action of a catalystin the molding process, so the strength and the durability of the cable material are improved, and the stability of the cable material is ensured; and the ester group crosslinking bonds can achieve the dissociation of ester bonds under the action of a special catalyst, a thermal field and mechanical stress in order to obtain the recyclability of the cable material.

Owner:WUXI HUAMEI CABLE

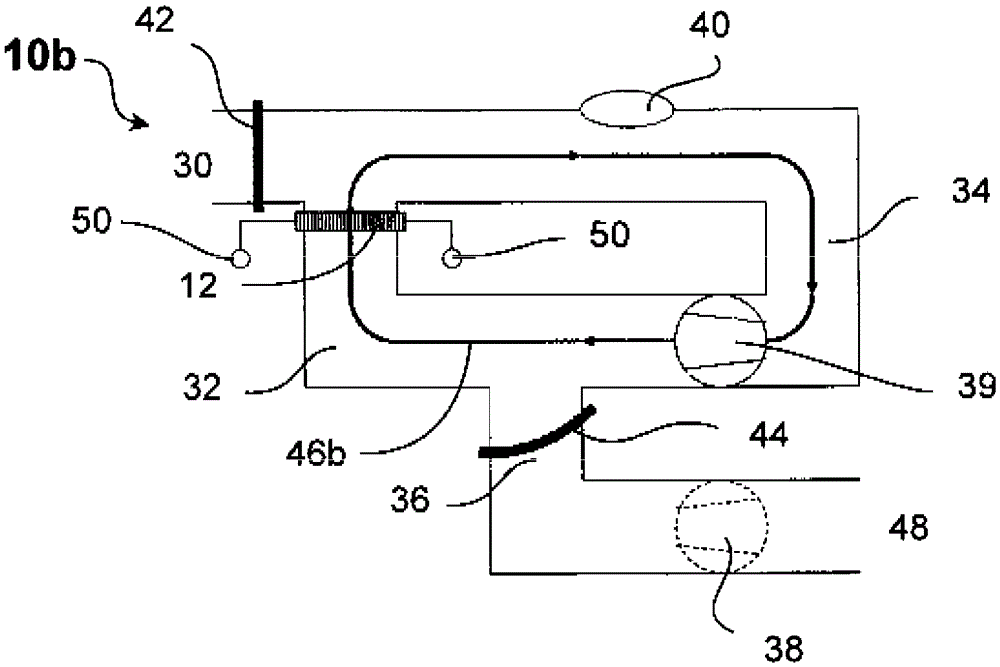

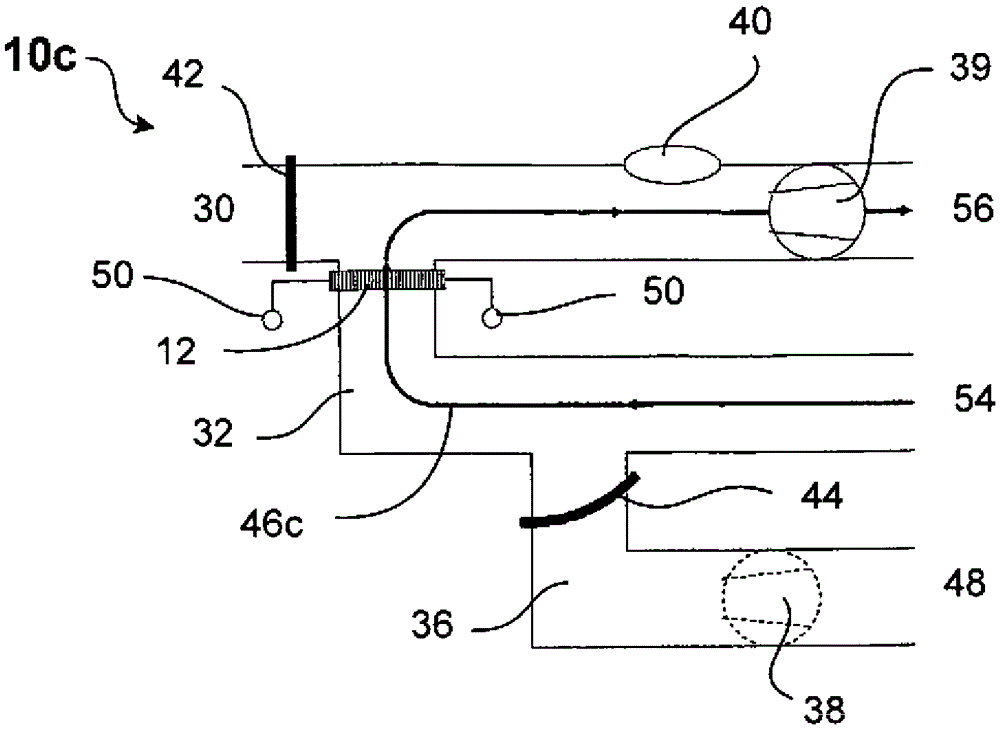

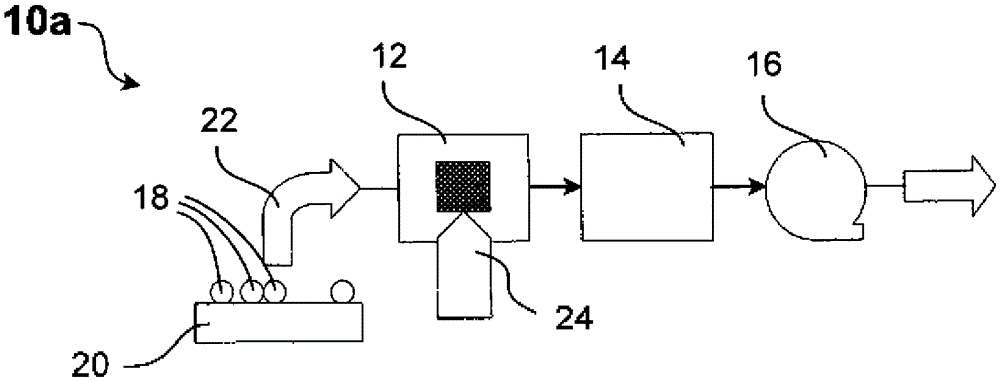

Method and apparatus for detecting explosive particles in a gas stream

InactiveCN103038621BAccumulate for a long timeEasy to desorbWithdrawing sample devicesPreparing sample for investigationChemical physicsExplosive Agents

In a method and apparatus for detecting explosive particles in a gas flow (46), the gas flow (46) is directed over a defined period of time through an adsorption mesh (12), wherein the explosive particles (18) are adsorbed to Thereon, the adsorption net (12) is subsequently heated to a heating temperature at which the explosive particles (18) are desorbed, and the gas flow with the desorbed explosive particles is conveyed to a detector (40) for its detection , wherein a microfilter (12) with a smaller pore size than the particle size of the explosive particles (18) is used as the adsorption net. This makes it possible to collect virtually all explosive particles ( 18 ) present in the gas flow ( 46 ) and feed them to the subsequent detection, thereby increasing the sensitivity of the detection.

Owner:SPHEREA

A kind of preparation method of transparent milk

ActiveCN107873842BReduce aggregationReduce hydrophobic effectMilk preparationBiotechnologyProtein solution

The invention discloses a preparation method of transparent milk. The preparation method of the transparent milk comprises the following steps of dissolving skimmed milk powder in deionized water; adjusting pH value of the solution to 10-12 by using an alkali solution; and then, carrying out stirring, and adjusting the pH of the solution back to neutral by using an acid solution so as to obtain the transparent milk On the basis of causing no damage to the primary structure of the milk proteins, the hydrophobic effects and the ionic effects inducing inter-protein linkages are weakened by the preparation method of the transparent milk so that the effect of protein depolymerization is achieved; and thus, particle size of the milk proteins is greatly reduced. Finally, turbidity of the transparent milk is reduced by 95% or above, and a clear protein solution with transparent / semi-transparent property is formed; moreover, the transparent milk has significantly improved storage stability, andthus, commercialized application potential of transparent milk product solutions is further improved.

Owner:JIANGNAN UNIV

A thermomechanically recyclable cross-linked cable material and its preparation method

ActiveCN109694538BIncreased distance between molecular chainsReduce de-HCl reactionPlastic/resin/waxes insulatorsMethacrylateTrans esterification

Owner:WUXI HUAMEI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com