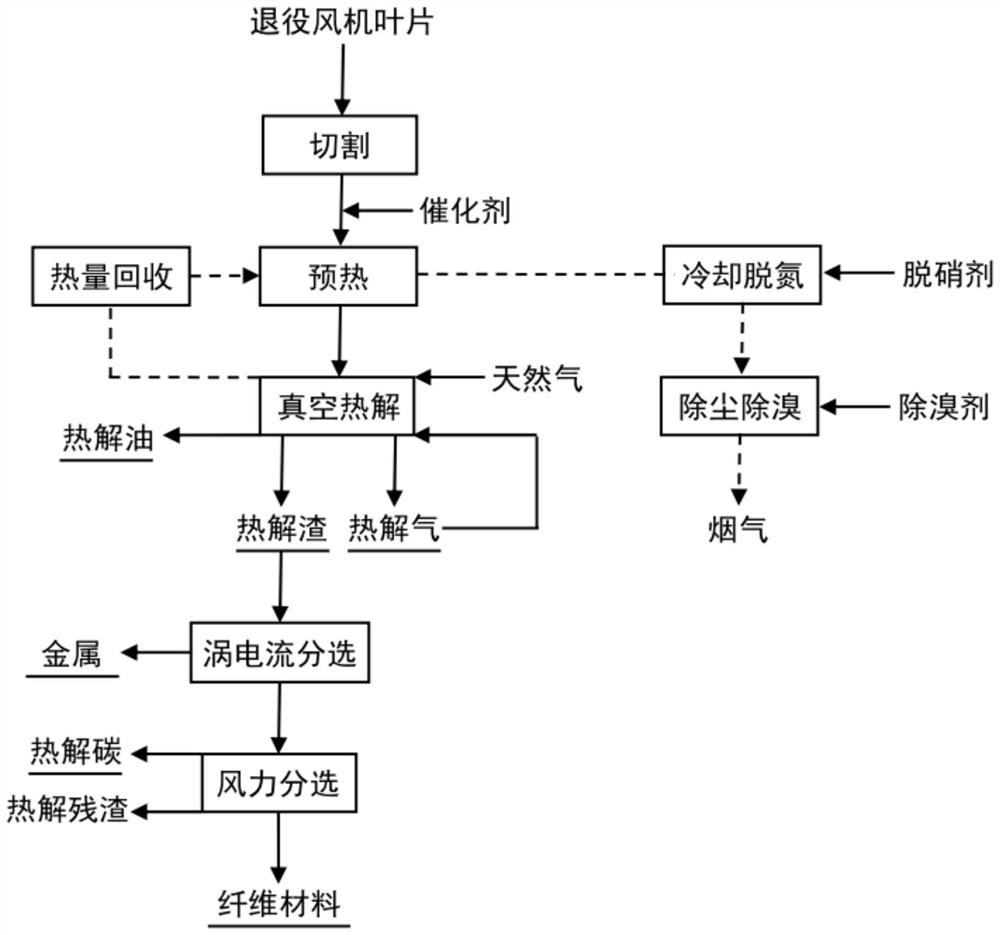

Vacuum pyrolysis treatment and recovery method for retired fan blades

A fan blade, vacuum pyrolysis technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc. Pyrolysis treatment, reduction of generation and emissions, effect of lowering pyrolysis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Blade pretreatment: The decommissioned fan blades with a resin content of 40.90% are crushed into small pieces of about 50*400mm by double-shaft cutting equipment, and calcium oxide is added to mix them evenly. The feeding ratio of decommissioned fan blades to calcium oxide is 1 ton. : 19.79kg. It is sent into the preheating chamber, and the combustion flue gas after high temperature treatment is introduced into the preheating chamber for preheating treatment. The outlet temperature is 260℃, the preheating temperature is 280℃, and the preheating time is 26min

[0030](2) Vacuum pyrolysis: the decommissioned fan blades pretreated in step (1) are sent to the steel belt continuous vacuum pyrolysis furnace, and the retired fan blades are sent to the steel belt continuous vacuum pyrolysis furnace before the catalytic pyrolysis treatment In the exhaust chamber of the furnace, the exhaust chamber is evacuated to exhaust the air so that the air pressure in the exhaust cham...

Embodiment 2

[0037] (1) Blade pretreatment: The decommissioned fan blades with a resin content of 40.90% are crushed and processed into small pieces of about 50*400mm by double-shaft cutting equipment, and calcium oxide is added to mix them evenly. The feeding ratio of decommissioned fan blades to calcium oxide is 1 ton : 19.79kg. It is sent into the preheating chamber, and the combustion flue gas after high temperature treatment is passed into the preheating chamber for preheating treatment. The outlet temperature is 260℃, the preheating temperature is 280℃, and the preheating time is 21min

[0038] (2) Vacuum pyrolysis: the decommissioned fan blades pretreated in step (1) are sent to the steel belt continuous vacuum pyrolysis furnace, and the retired fan blades are sent to the steel belt continuous vacuum pyrolysis furnace before the catalytic pyrolysis treatment In the exhaust chamber of the furnace, the exhaust chamber is evacuated to exhaust the air so that the air pressure in the ex...

Embodiment 3

[0046] (1) Blade pretreatment: The decommissioned fan blades with a resin content of 29.71% are crushed into small pieces of about 50*400mm by double-shaft cutting equipment, and calcium oxide is added to mix them evenly. The feeding ratio of decommissioned fan blades to calcium oxide is 1 ton : 14.38kg. It is sent into the preheating chamber, and the combustion flue gas after high temperature treatment is passed into the preheating chamber for preheating treatment. The outlet temperature was 260°C, the preheating temperature was 280°C, and the preheating time was 26 minutes.

[0047] (2) Vacuum pyrolysis: the decommissioned fan blades pretreated in step (1) are sent to the steel belt continuous vacuum pyrolysis furnace, and the retired fan blades are sent to the steel belt continuous vacuum pyrolysis furnace before the catalytic pyrolysis treatment In the exhaust chamber of the furnace, the exhaust chamber is evacuated to exhaust the air so that the air pressure in the exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com