Patents

Literature

36results about How to "Shorten pyrolysis time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

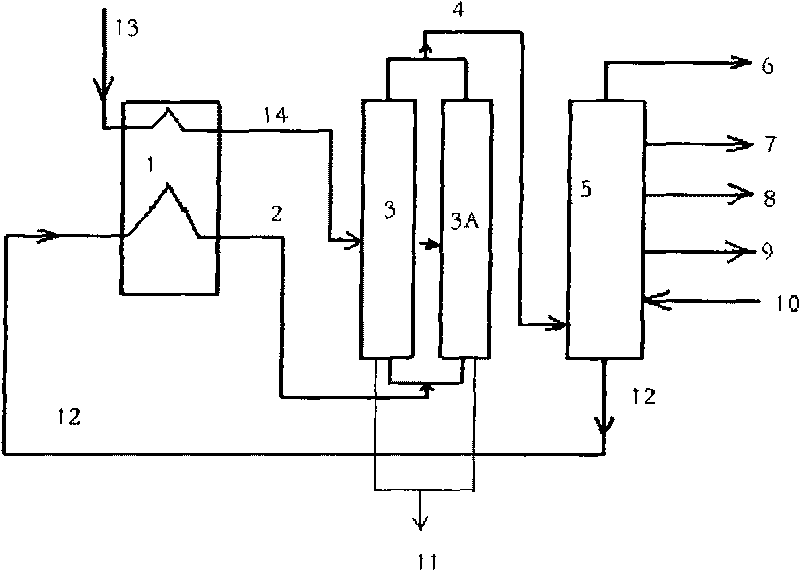

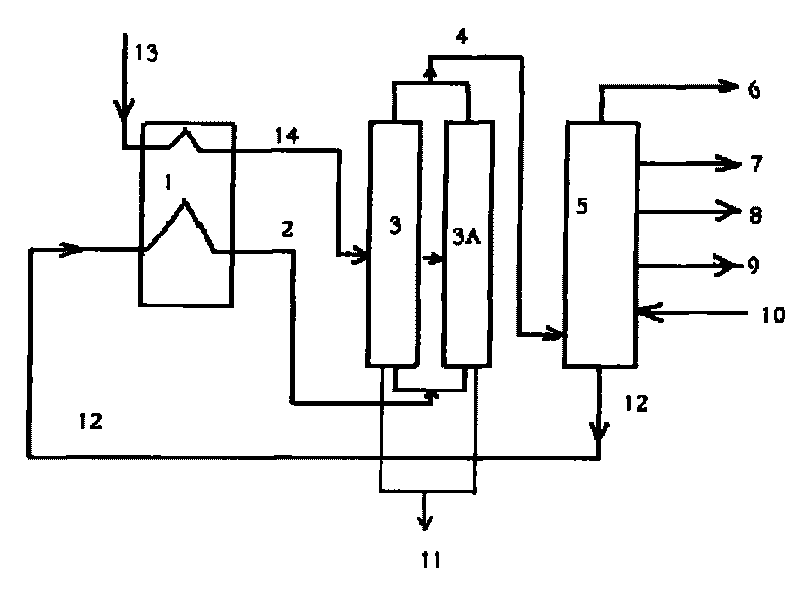

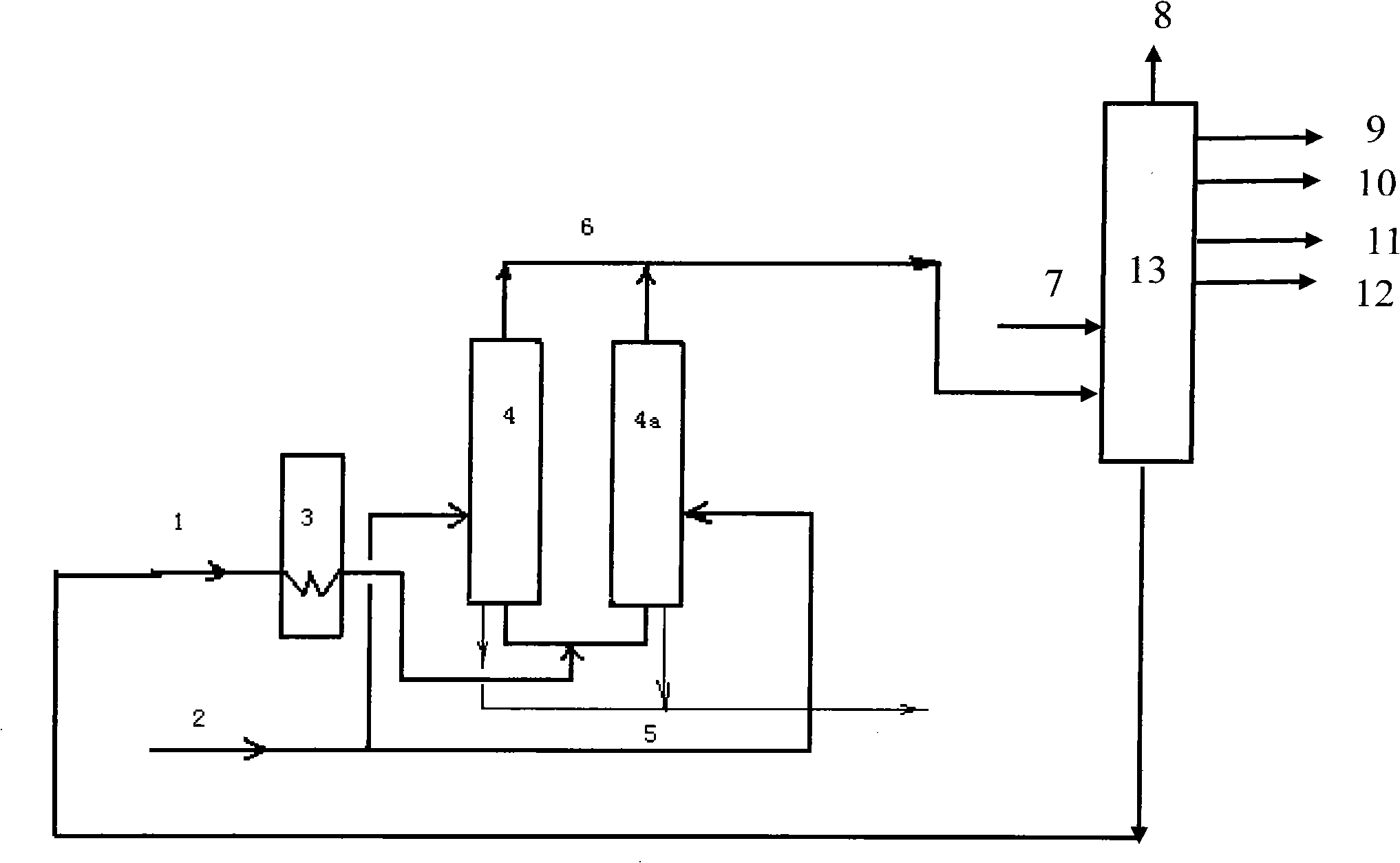

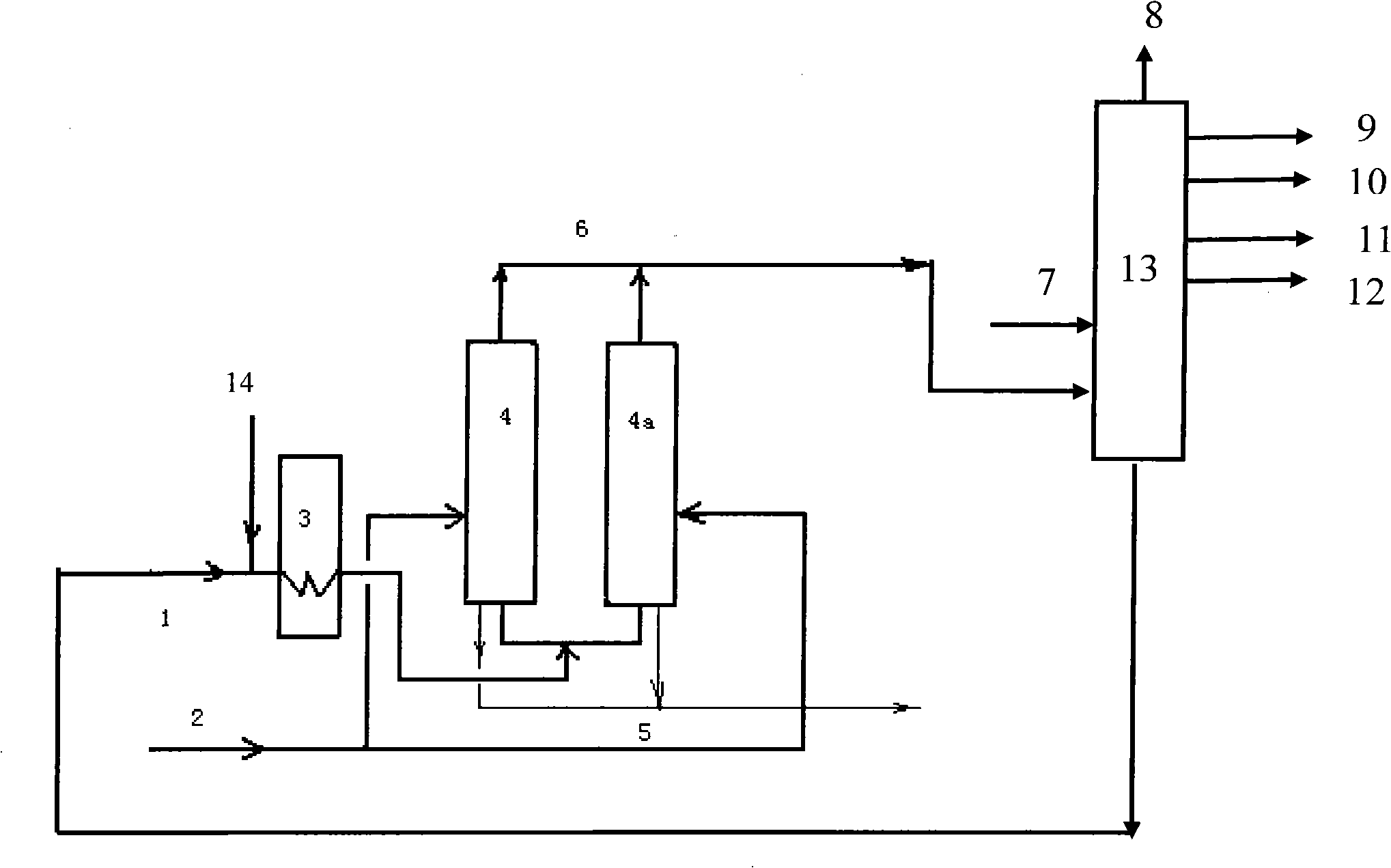

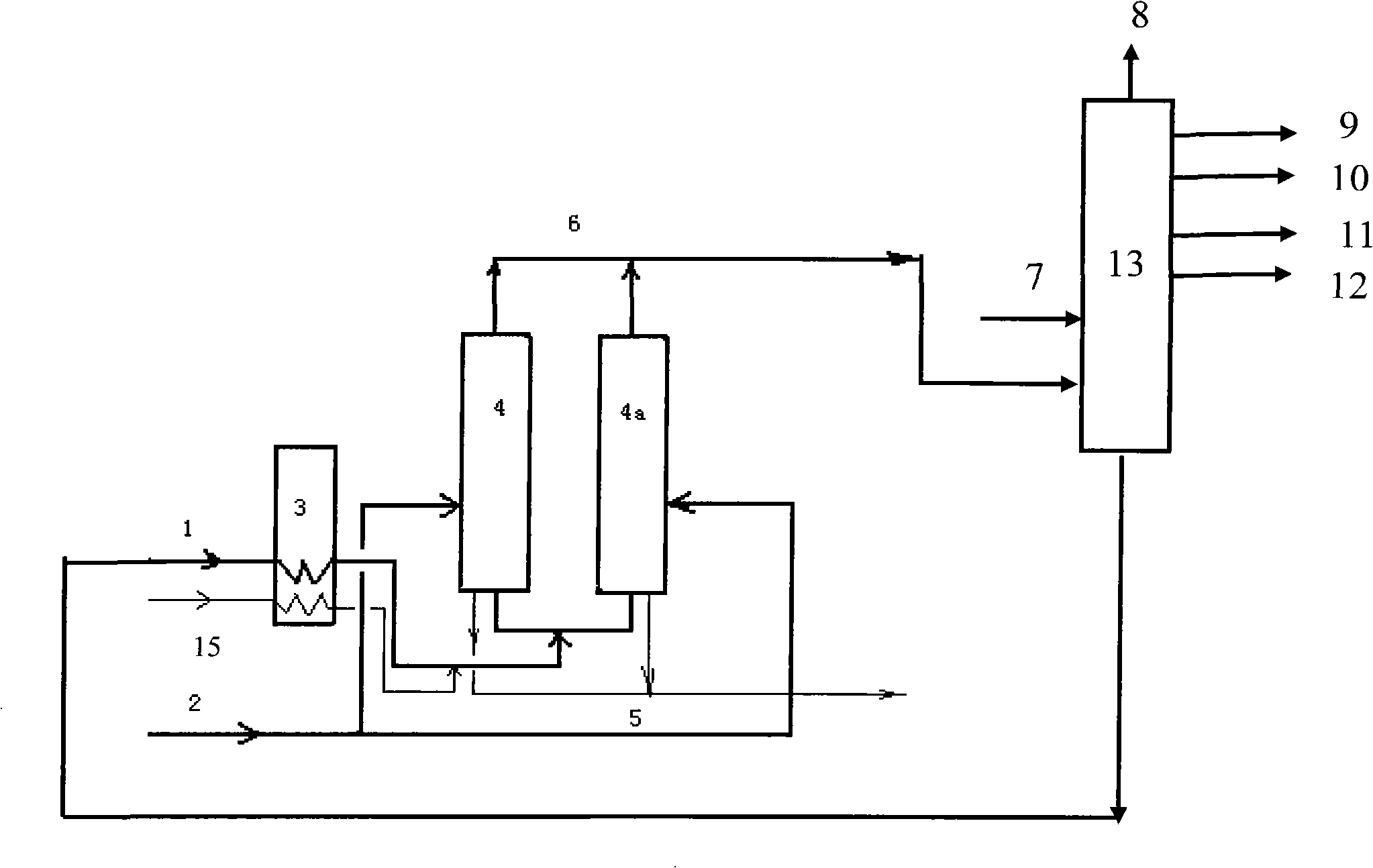

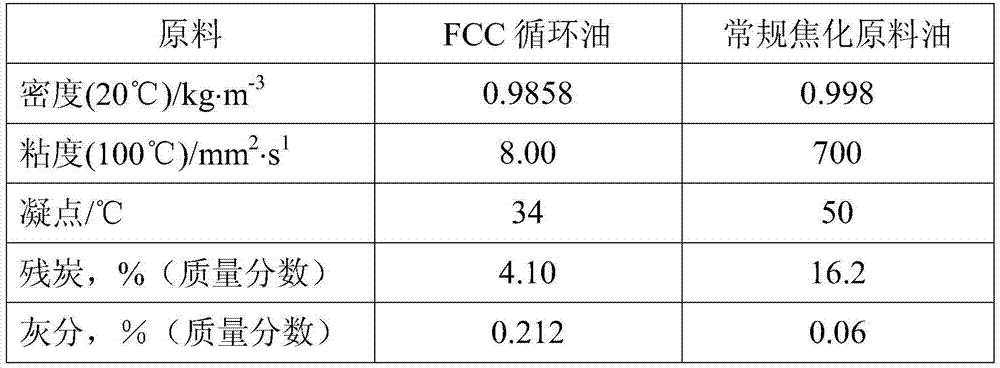

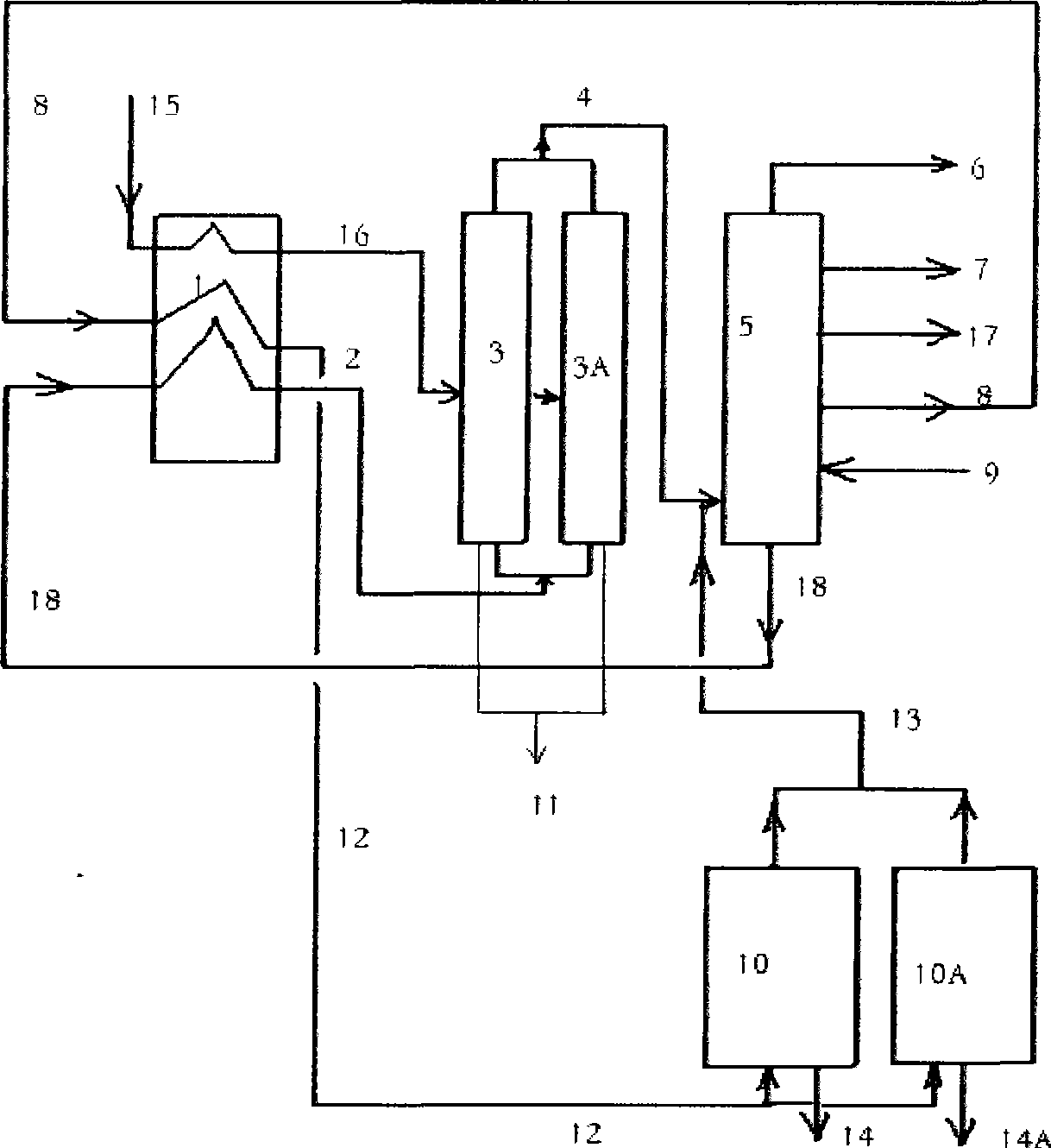

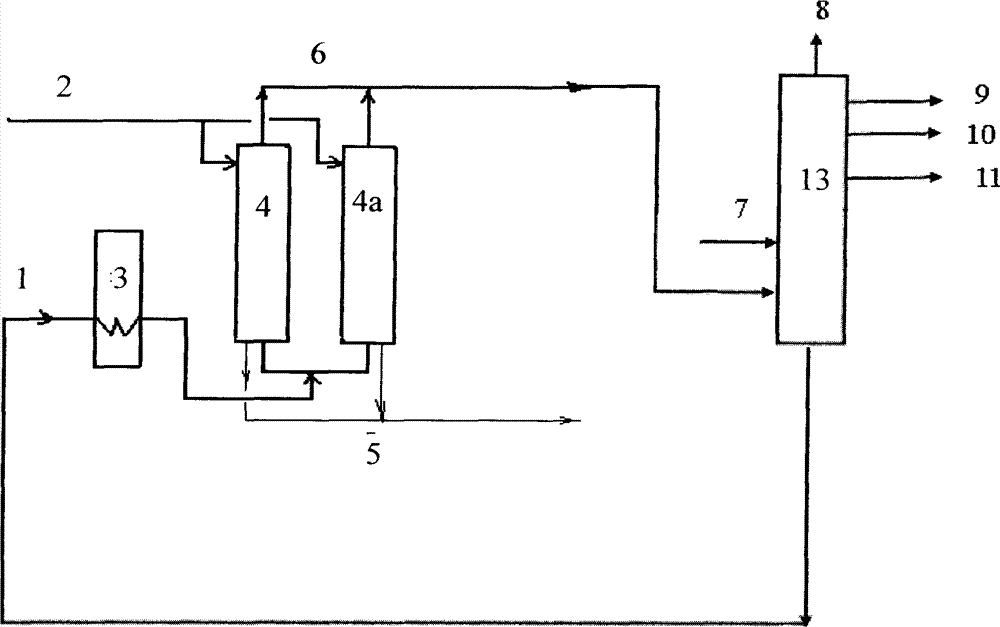

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Superheat water vapor in-situ pyrolysis oil-rich coal efficient oil extraction method

The invention relates to a superheat water vapor in-situ pyrolysis oil-rich coal efficient oil extraction method. In the method, the well spacing manner of two horizontal heat injection wells and onehorizontal production well is adopted, and hydrofracture / supercritical carbon dioxide fracture / controllable shock wave fracture technology is adopted, a large-scale grid fractures is formed inside thecoal layer, and blended grout of iron ore and lime is injected in the fractures to improve the thermal conductivity of oil-rich coal and heat uniformity of the oil-rich coal; and low-temperature plasma electrodes are planted in the horizontal sections of the two heat injection wells, and auxiliary pyrolysis to oil-rich coal is carried out through adopting the low-temperature plasma technology. According to the invention, a reliable heat source is provided, the heat conduction efficiency is improved, underground pyrolysis temperature is maintained while increasing the capability of gas bearingand oil gas bearing, and the pyrolysis oil preparation efficiency and light oil proportion of the oil-rich coal are improved.

Owner:XIAN UNIV OF SCI & TECH

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

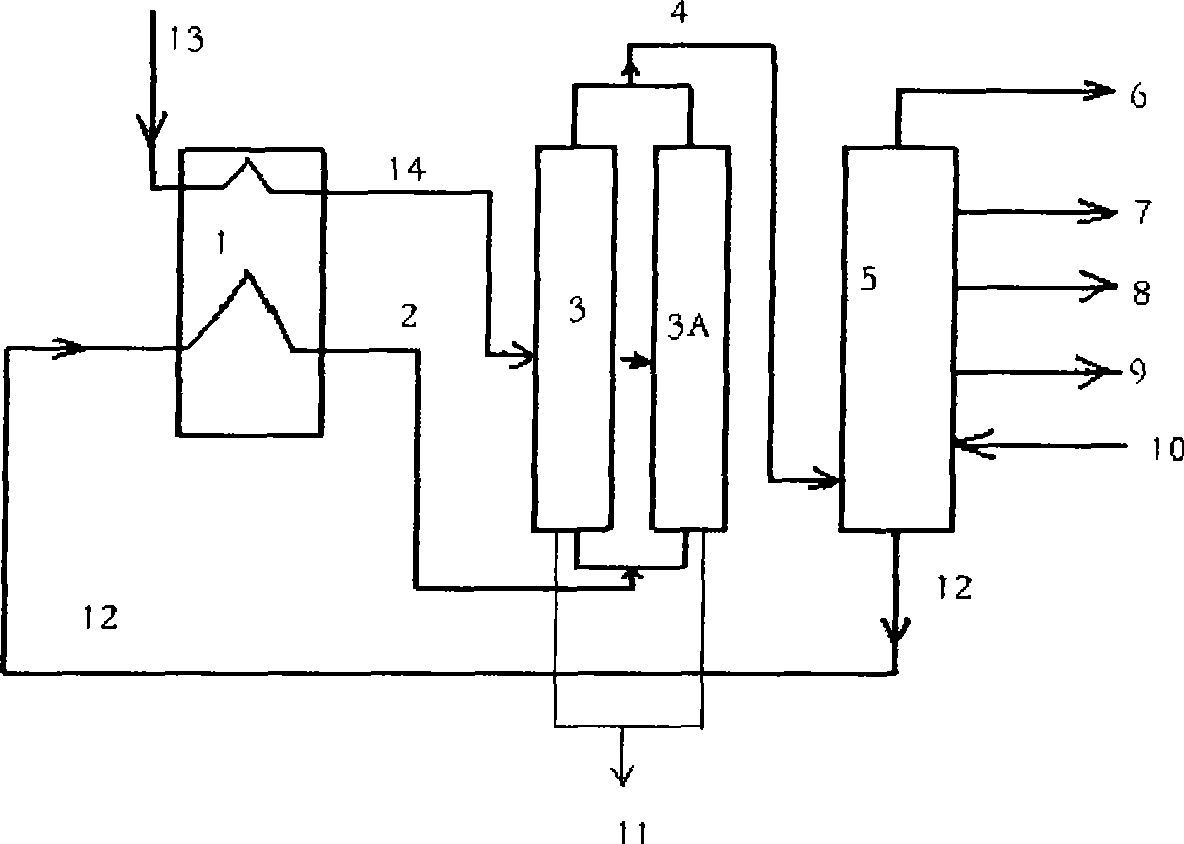

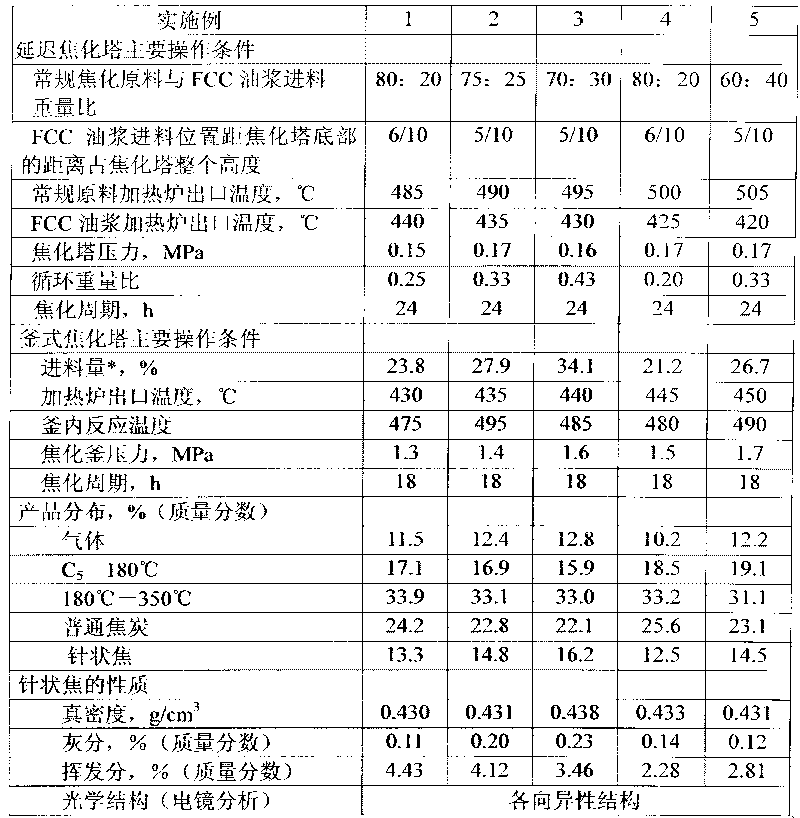

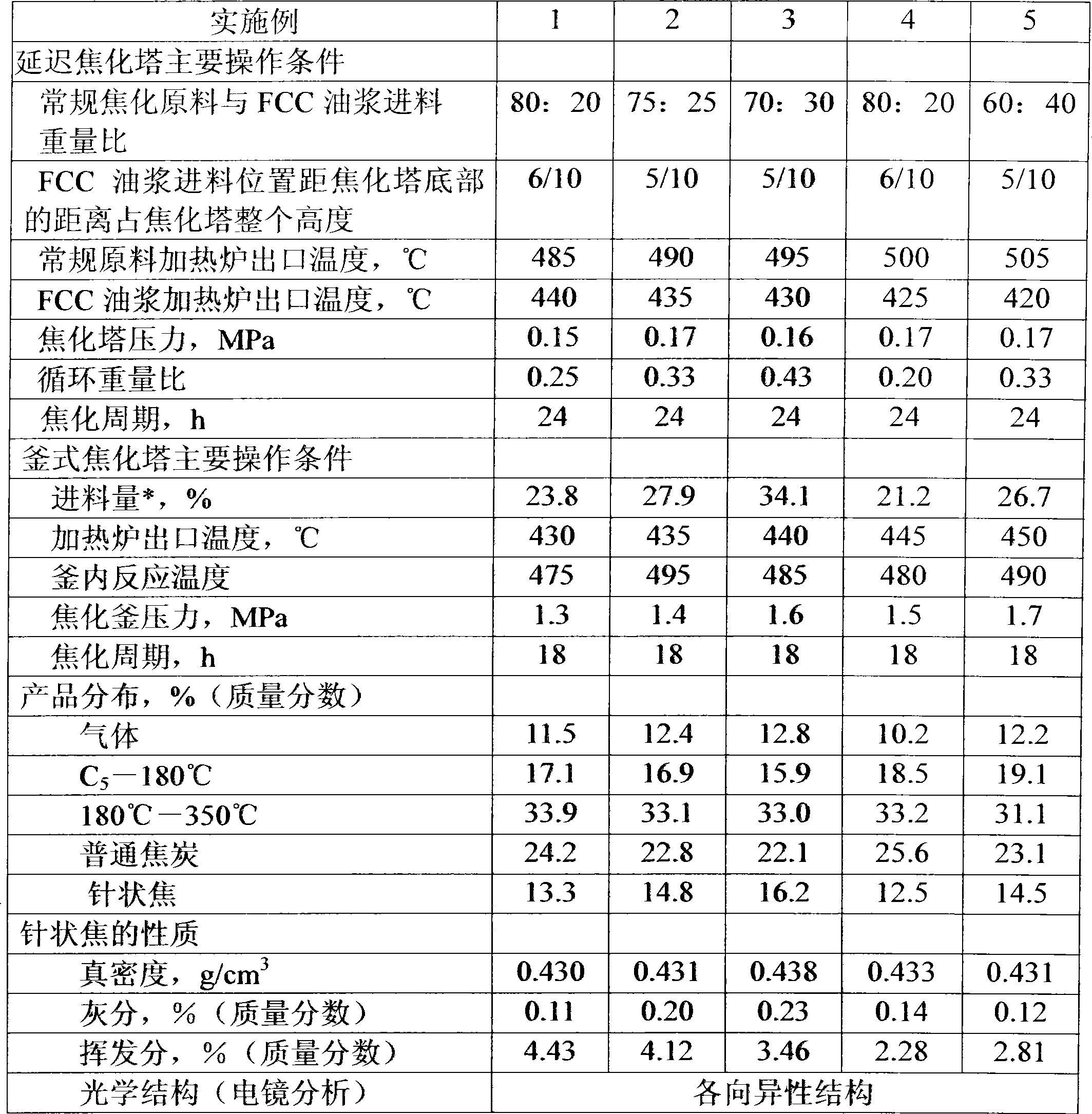

Production method of needle coke

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

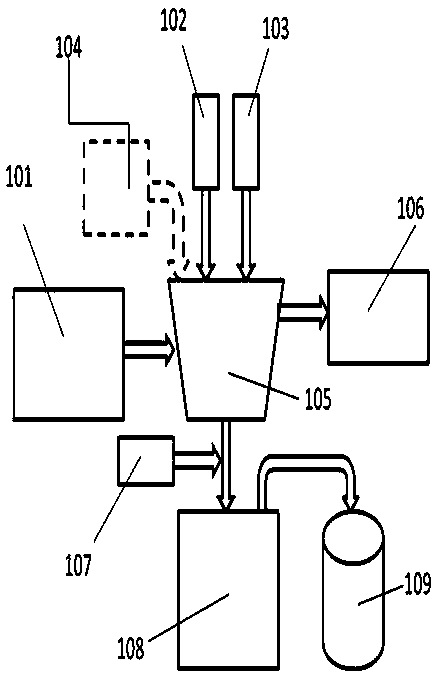

Method for accelerating microwave pyrolytic process of oily sludge by pyrolyzing residue thereof

InactiveCN101798163ASpeed up the pyrolysis processReduce energy consumptionSludge treatment by pyrolysisByproduct vaporizationMicrowave pyrolysisNitrogen

The invention discloses a method for accelerating the microwave pyrolytic process of oily sludge by pyrolyzing residue thereof, which comprises the following steps: carrying out microwave pyrolysis on the oily sludge or sludge under the condition of nitrogenization, controlling the temperature to be 700-850 DEG C and performing microwave incineration for 5-15min to obtain solid microwave residue; mixing the microwave residue with the oily sludge or the sludge evenly, wherein the weight of the microwave residue is 0.5-5% of the oily sludge or the sludge; and then carrying out microwave pyrolysis on the oily sludge or the sludge under the condition of nitrogenization. The invention can accelerate the pyrolytic process of the oily sludge or the sludge, shorten the pyrolytic time, effectively save the energy consumption of the oily sludge or the sludge processing, and improve the processing efficiency; the residue after the microwave pyrolysis can be recycled; and the method of the invention has low cost, is economical and can be popularized and utilized.

Owner:SINOPEC PETROLEUM ENG DESIGN +1

Coking method for processing highly acid crude oil

ActiveCN101280213AReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerCorrosion

The invention discloses a method of processing highly-acidic crude oil through the delayed coking process; the method includes that the low temperature highly-acidic crude oil is fed from the middle-lower part and the high temperature low-acidic coking raw material is fed from the bottom; the high temperature oil gas generated by the high temperature cracking of the low-acidic coking raw material is mixed with the low temperature highly-acidic crude oil so that the highly-acidic crude oil is enabled to realize the purpose of the deacidification through the pyrolysis deacidification under high temperature; meanwhile, the cracking temperature of the low-acidic coking raw material is lowered; the high temperature cracking time of the conventional raw materials; thereby, the coking yield is reduced and the stable operation period of the single tower is prolonged; besides, the preheating temperature of the highly-acidic crude oil can avoid the strong corrosion stage of the acid; the corrosion on the heating device caused by the acid can be reduced or avoided when the temperature is even lower than the corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

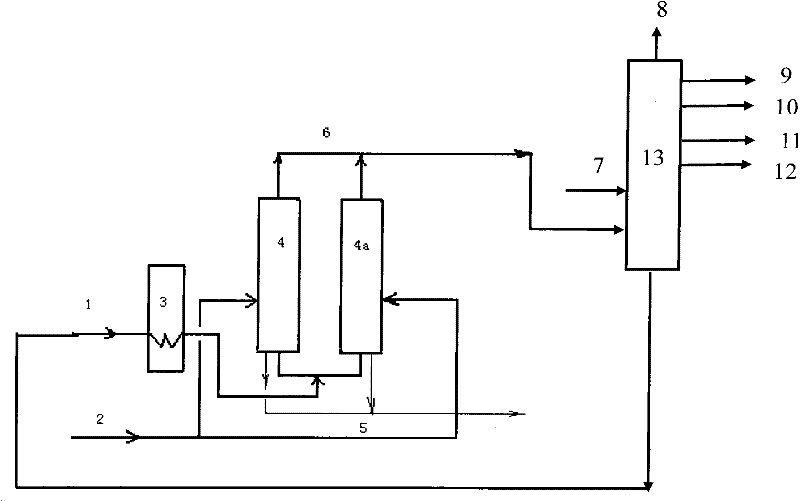

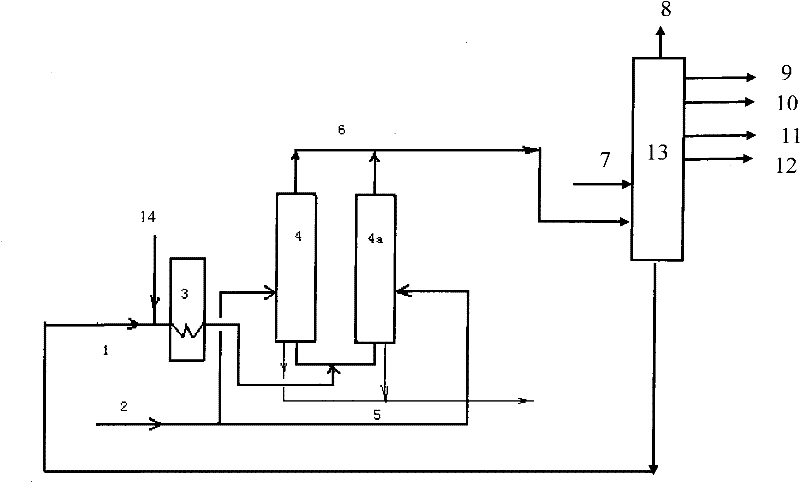

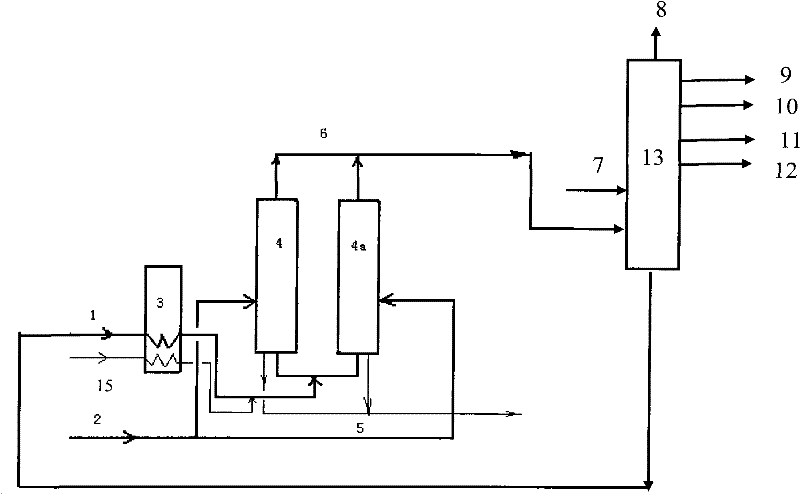

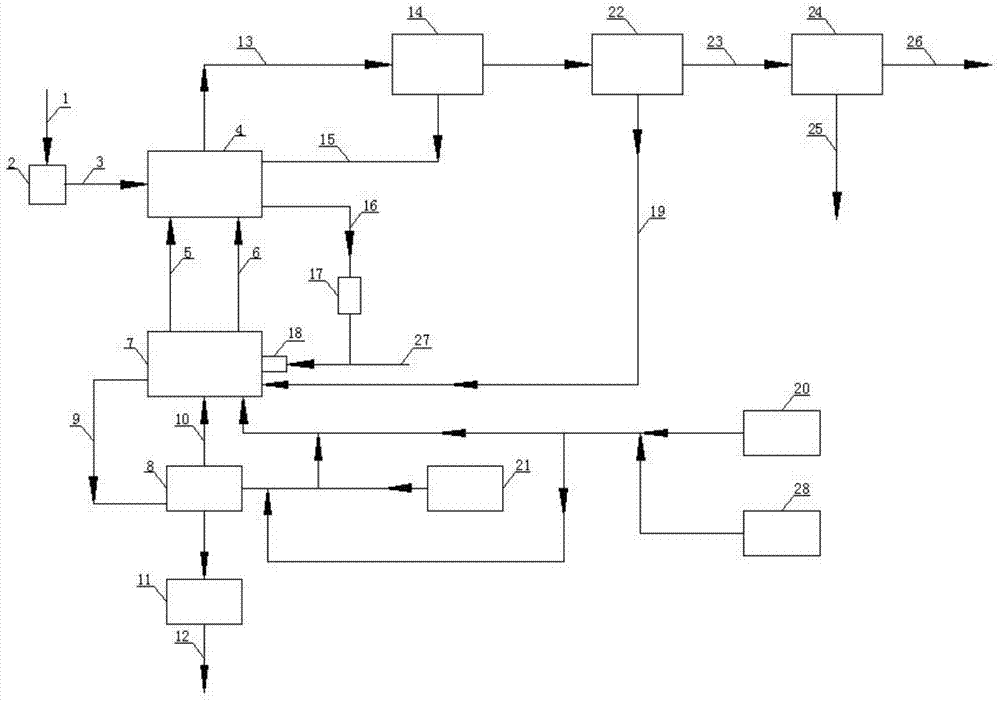

Circular treatment method and process system for fluorine-containing high-ammonia-nitrogen industrial wastewater

InactiveCN109250842AReduce concentrationReduce the types of dosingWater contaminantsMultistage water/sewage treatmentProcess systemsHigh concentration

The invention provides a new circular treatment method for simultaneously removing fluorinions and ammonia from fluorine-containing high-ammonia-nitrogen industrial wastewater. The fluorine removing agent provides a phosphorus source for precipitation and ammonia removal simultaneously, the type of agent addition is reduced, and the concentration of residual phosphorus in effluent is reduced. Magnesium-process desulfurized wastewater in thermal power plants or old brine after potassium extraction in salt lakes can be used as a magnesium source instead of conventional magnesium salt reagents, waste is treated by waste, other industrial wastewater is recycled in an ammonia removal process, and the sustainable development circular economy treatment technology is achieved. At the same time, provided is a circular treatment system for the fluorine-containing high-ammonia-nitrogen industrial wastewater. Microwave radiation replaces a traditional heating process, the heating rate is fast, theheating is uniform, the pyrolysis time of struvite is greatly shortened, and the ammonia gas concentration obtained by decomposition is high. After acid recovery, a high-concentration ammonia salt solution can be obtained. The investment and operation cost of the whole set of circular treatment system for the fluorine-containing high-ammonia-nitrogen industrial wastewater is low. The concentration of fluorinions and ammonia nitrogen in the treated effluent is stable, the removal rate of the fluorinions can reach 98%, and the removal rate of ammonia nitrogen can reach 97% or more.

Owner:国能朗新明环保科技有限公司

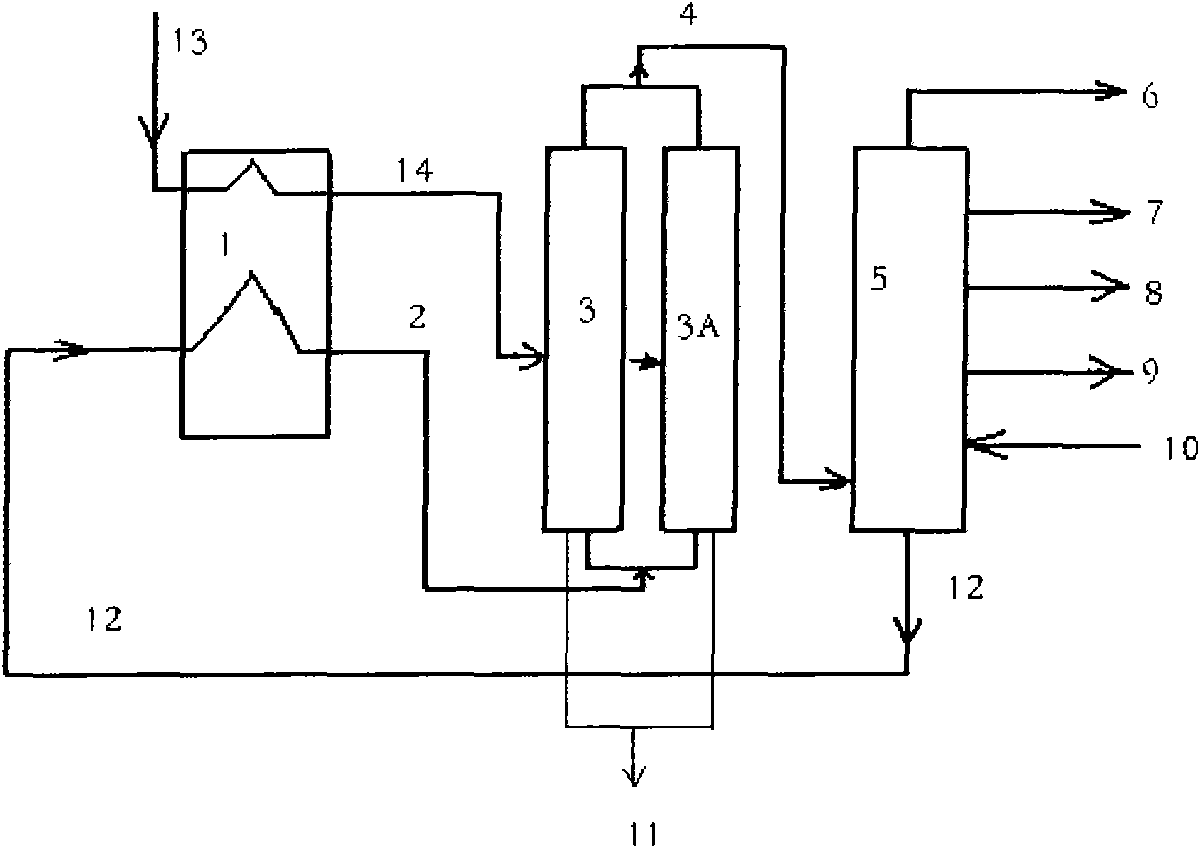

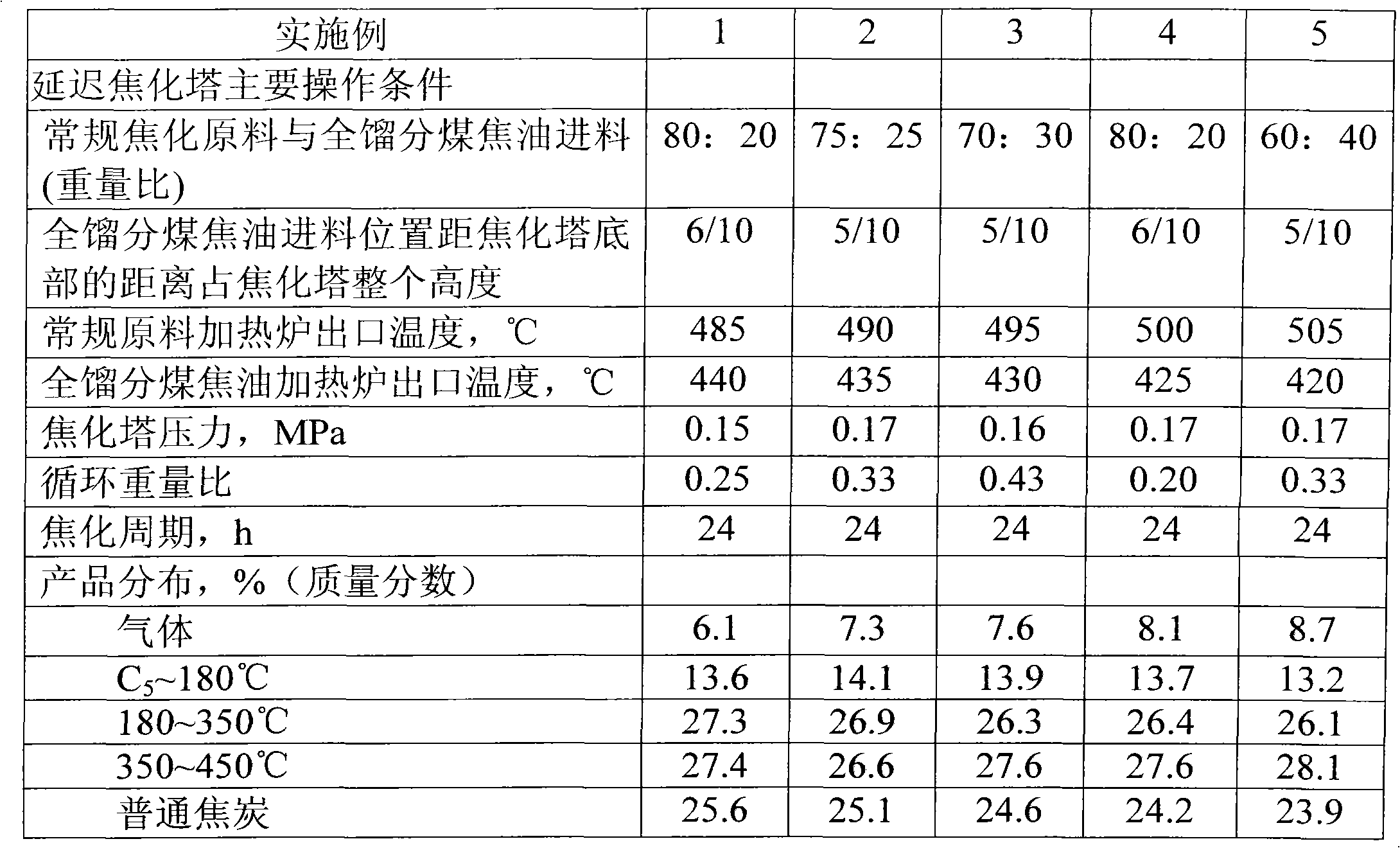

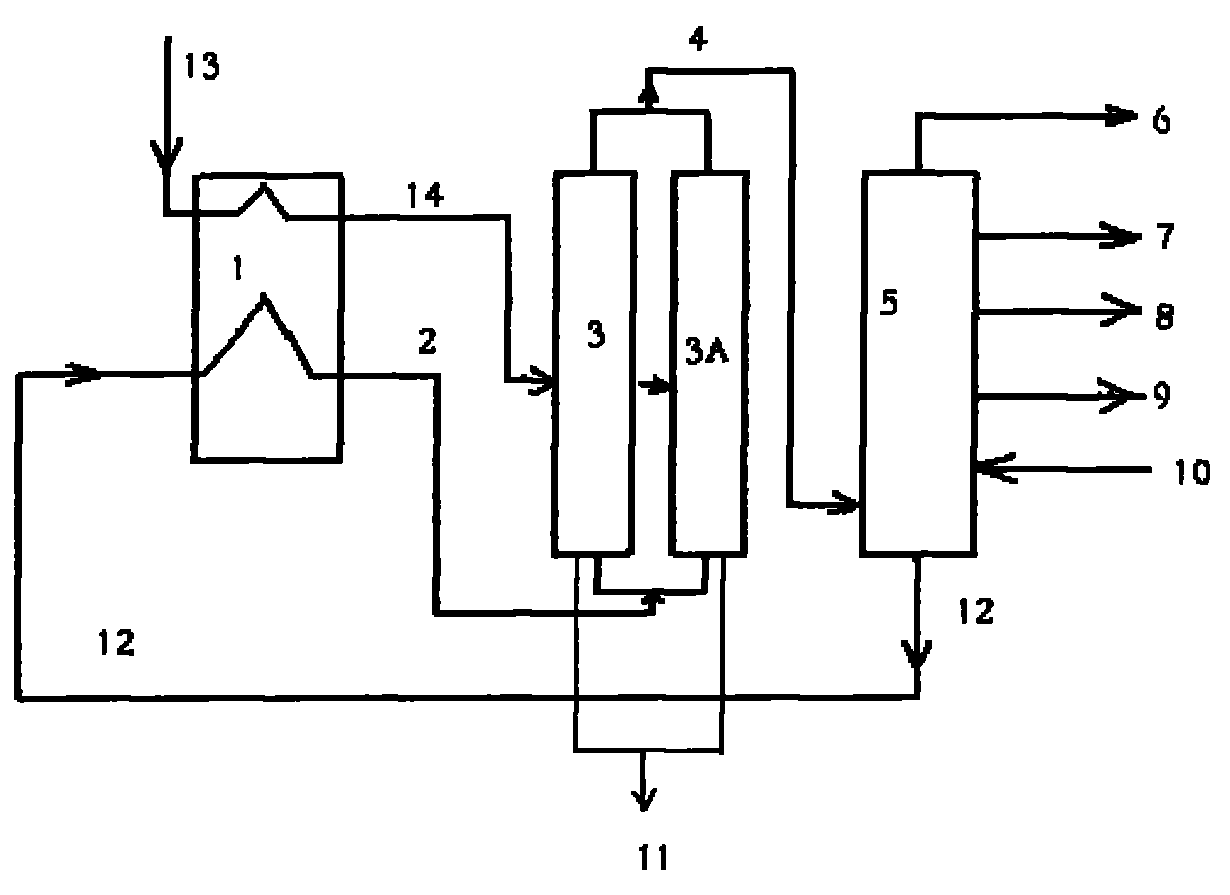

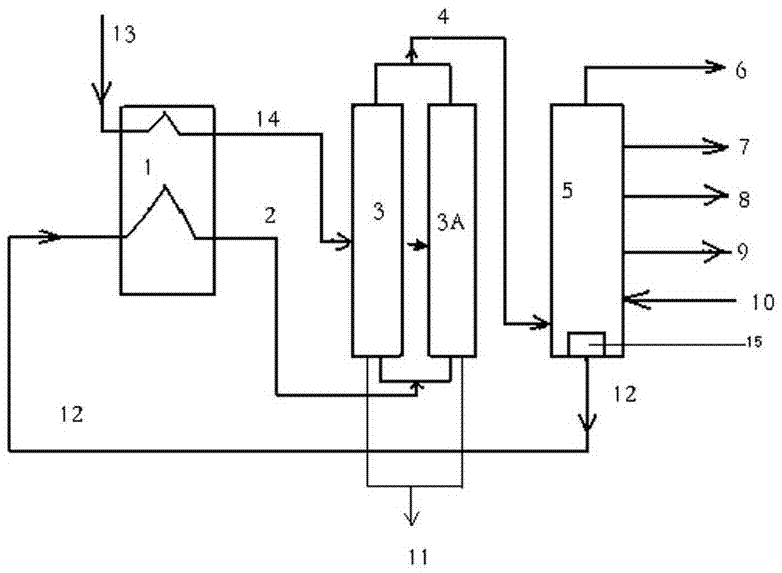

Method for producing needle coke raw material by using delayed coking process

ActiveCN102041013AExpand sourceThe method flow is simpleCoking carbonaceous materialsGeneration rateDesorption

The invention discloses a method for producing a needle coke raw material by using a delayed coking process. In the method, full-range coal tar is imported to the top and the middle and a high-temperature conventional coking raw material is imported to the bottom; the high-temperature oil gas generated by the conventional coking raw material via high-temperature cracking is mixed with the full-range coal tar with lower temperature at the top and the middle of a reactor so that the full-range coal tar can crack hydrocarbon molecules with high reaction activity at a proper high temperature to achieve the aim of desorption; for the full-range coal tar, under the condition of the delayed coking process, asphaltene and partial colloid are condensed to form coke which is deposited in a coking tower so as to remove the components going against the production of the needle coke; furthermore, by means of the injection of the low-temperature full-range coal tar, the cracking temperature of the conventional coking raw material is reduced, the high-temperature cracking time of the conventional raw material is shortened, the secondary reaction is decreased, the coke generation rate is reduced and the stable operation period of a single tower is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving microwave pyrolysis rate of low-rank coal

InactiveCN102517058ASpeed up the low temperature pyrolysis processShorten pyrolysis timeCoke ovensMicrowave pyrolysisPhysical chemistry

The invention relates to a method for improving microwave pyrolysis rate of low-rank coal. The method is characterized by comprising the following steps of: uniformly mixing semi-coke as a microwave absorbent with the low-rank coal according to the mixture ratio of 1 / 5, 2 / 5 or 3 / 5, then adding into a pyrolysis container, and then placing into a microwave reactor for performing microwave pyrolysis to get a solid product, wherein the heating final temperature is 650 DEG C-750 DEG C and the retention time of the final temperature is 20-40 minutes; and introducing nitrogen as protective gas during the pyrolysis process, wherein the semi-coke as the microwave absorbent is constituted by the solid product which is prepared from the low-rank coal under the condition that the pyrolysis final temperature is 650 DEG C-750 DEG C. The solid product (the semi-coke) which is obtained after performing the microwave pyrolysis on the low-rank coal can be recycled as the microwave absorbent, and the temperature increase rate of the coal in a microwave field can be also improved. The semi-coke as the microwave absorbent in the method provided by the invention is the solid product of the pyrolysis process, so that the problem that the product is separated from the microwave absorbent is avoided.

Owner:HENAN POLYTECHNIC UNIV

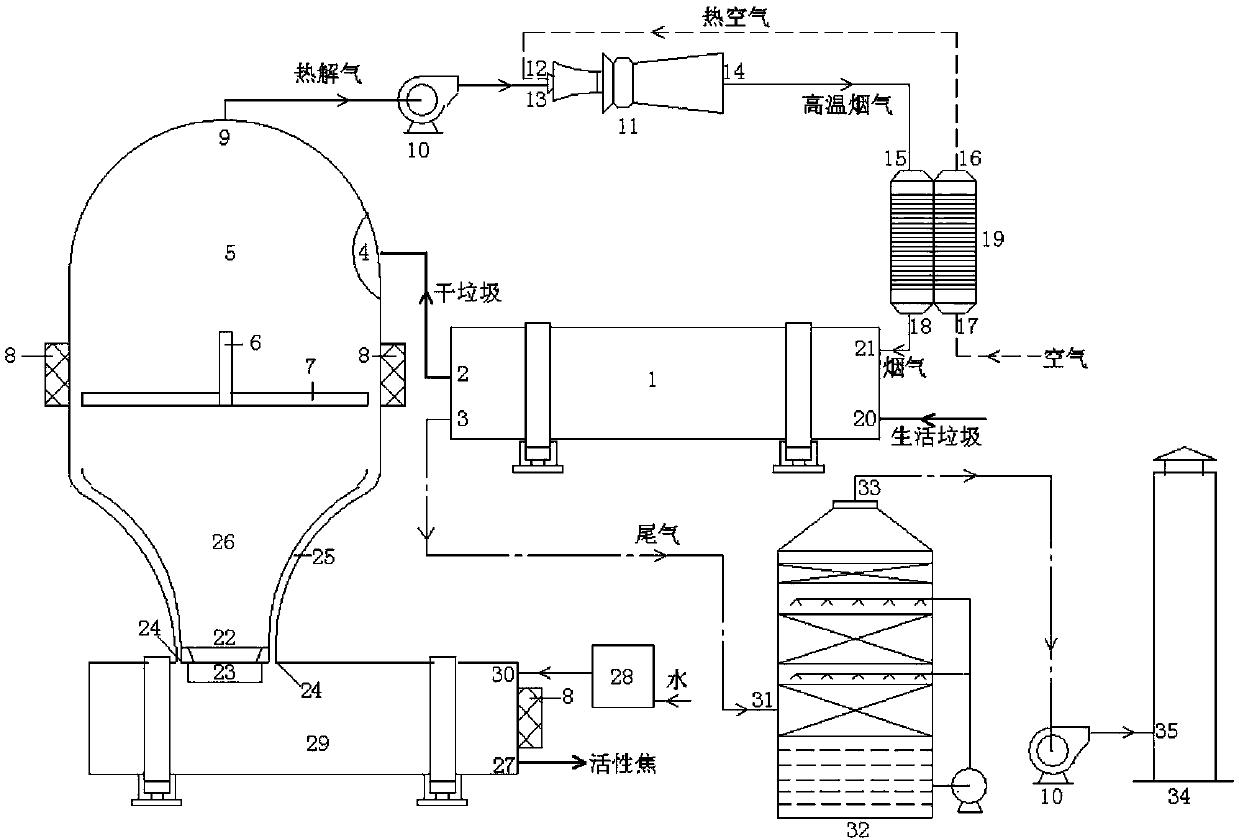

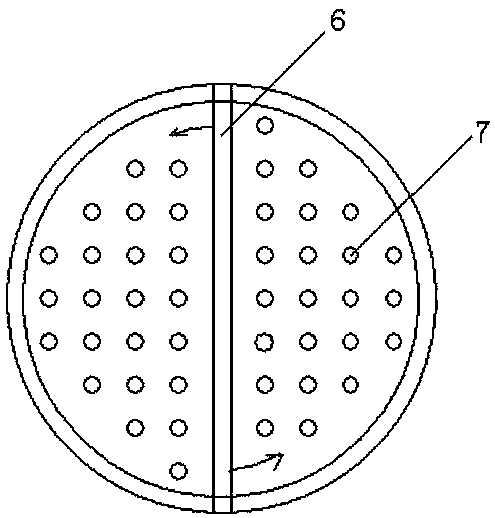

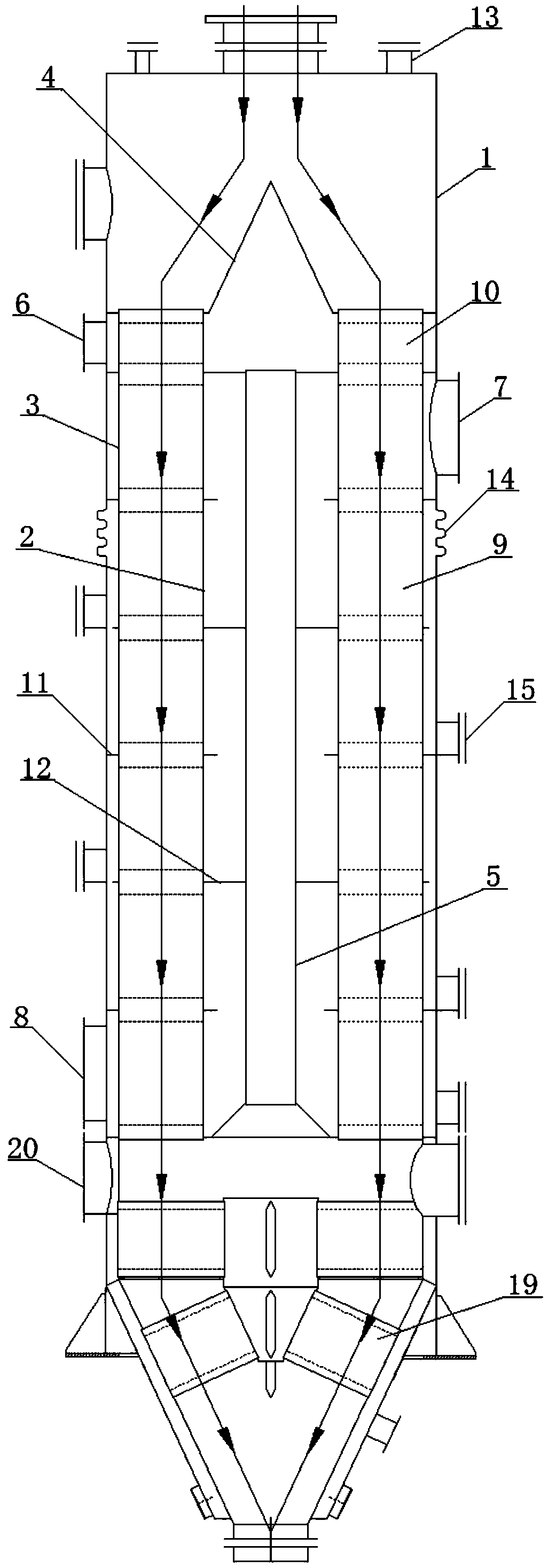

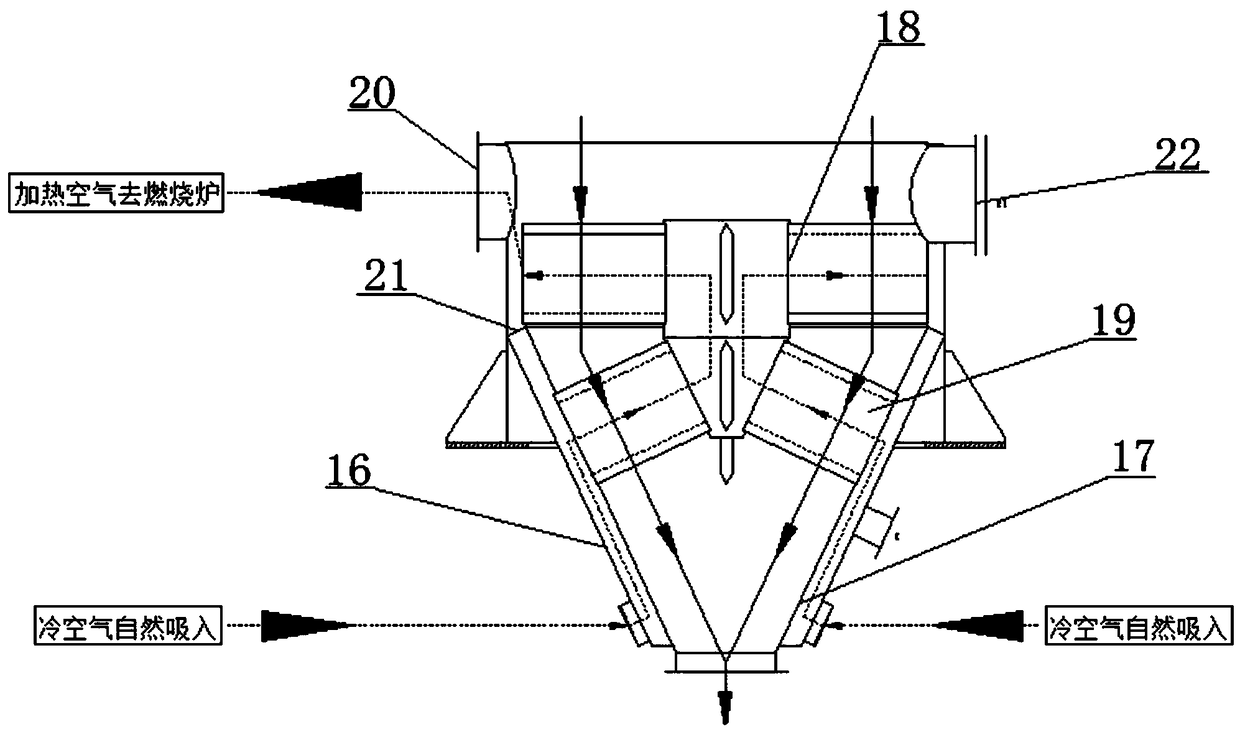

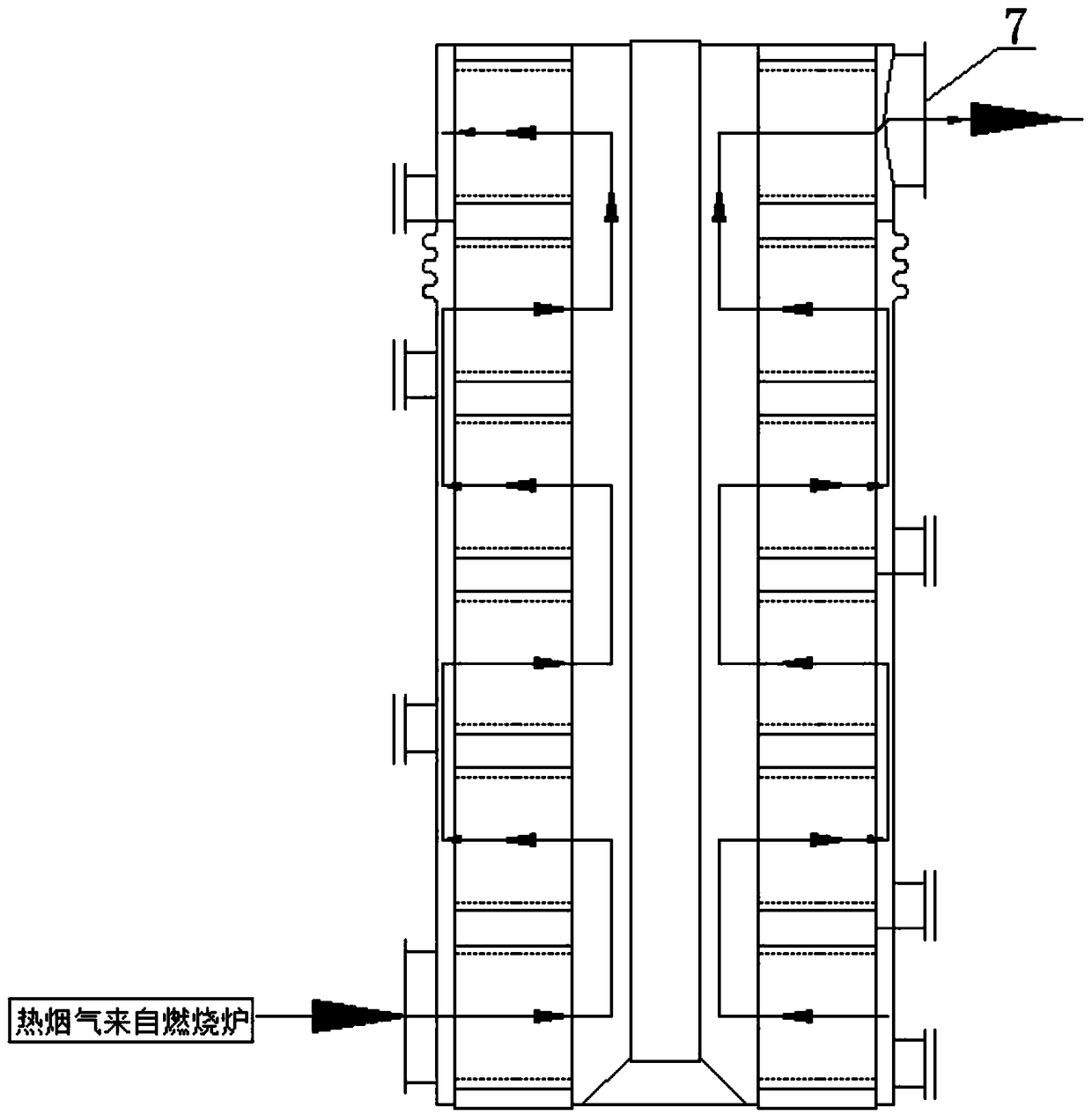

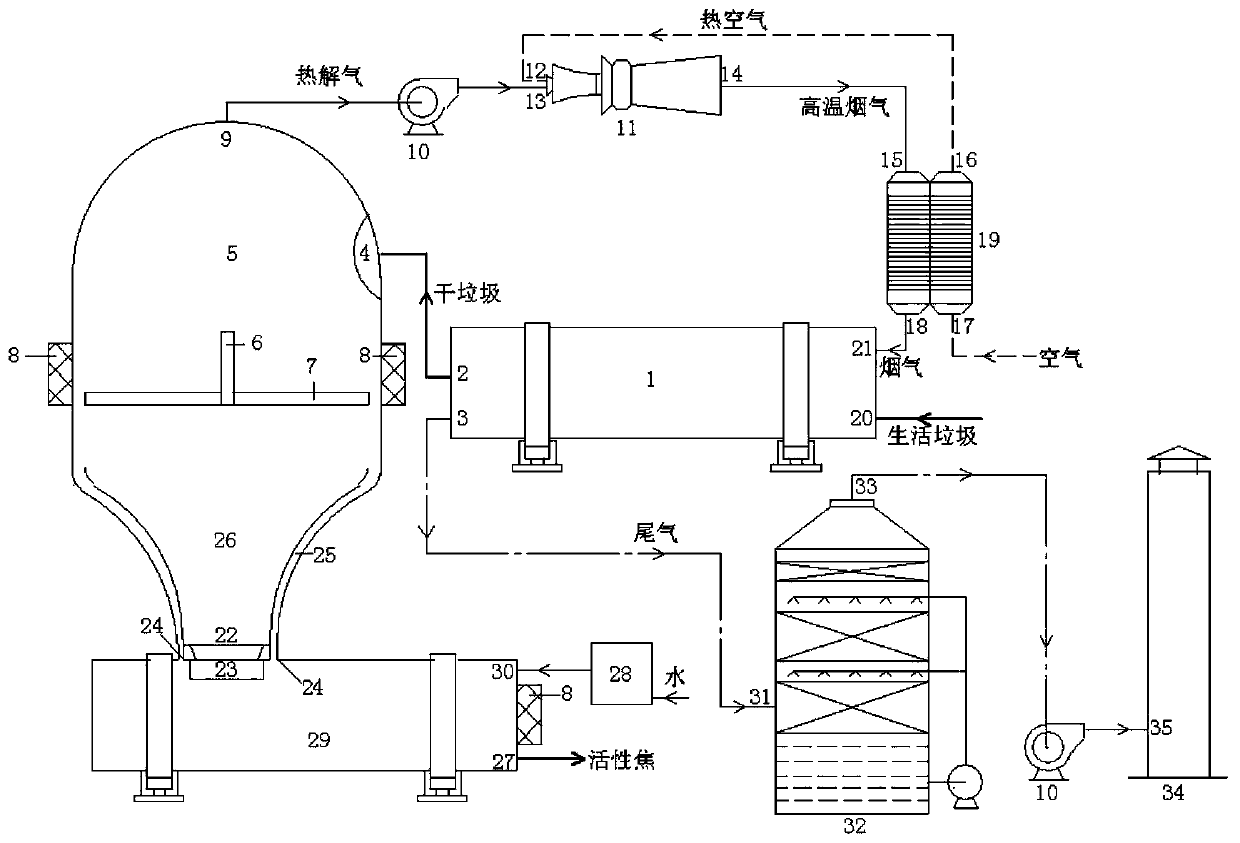

Device and method for preparing activated coke by pyrolysis of domestic waste

ActiveCN107934961ARealize integrated controlEfficient crushingCarbon compoundsLighting and heating apparatusAir preheaterMicrowave pyrolysis

The invention discloses a device and method for preparing activated coke by pyrolysis of domestic waste. The device mainly comprises a drying rotary kiln, a microwave pyrolysis furnace, a pyrolysis gas combustion chamber, an air preheater, a steam generator, a coke sample activation furnace and a flue gas purification tower; the drying rotary kiln is connected with the microwave pyrolysis furnace,and a flue gas outlet is connected with the flue gas purification tower, an induced draft fan and a chimney through a pipeline; the microwave pyrolysis furnace is connected with the induced draft fanand the pyrolysis gas combustion chamber through a pipeline, a flue gas outlet of the pyrolysis gas combustion chamber is connected with the air preheater, one way of the air preheater is connected with a hot-air inlet of the pyrolysis gas combustion chamber, and the other way is connected with the drying rotary kiln; and a storage chamber is connected with the coke sample activation furnace, a flue gas outlet of the coke sample activation furnace is connected with the microwave pyrolysis furnace through a gas bypass, and the coke sample activation furnace is connected with the steam generator. The device provided by the invention is adopted to pyrolyze the domestic waste, the efficiency is high, and emission is concentrated; and the device can further prepare high-quality activated cokeand complete large-scale treatment of the domestic waste.

Owner:HUAZHONG UNIV OF SCI & TECH

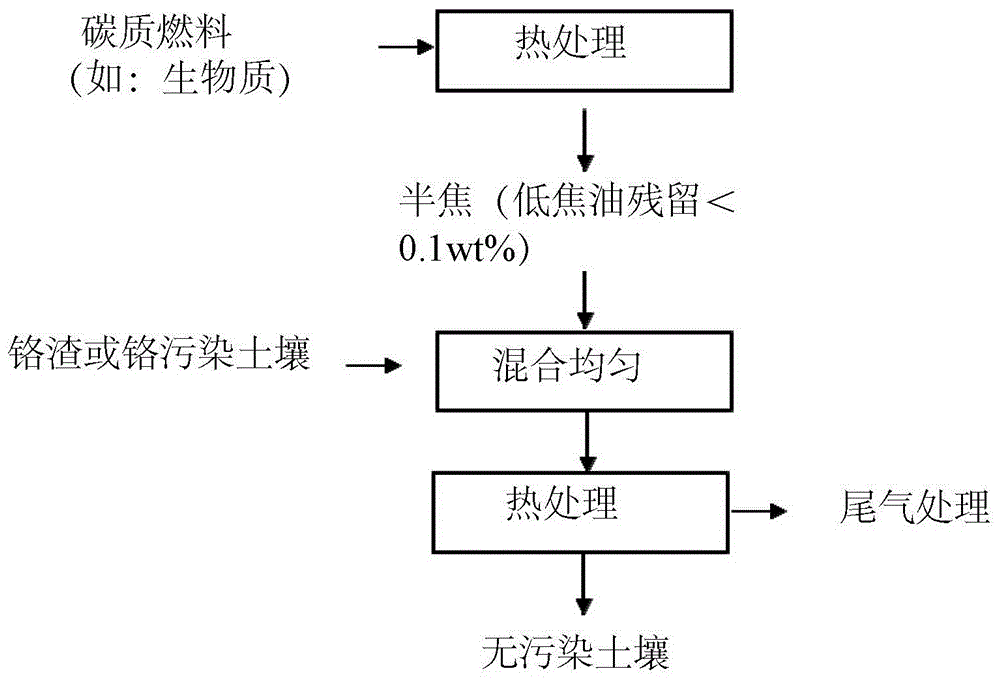

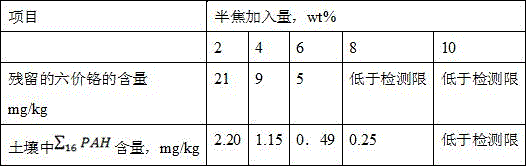

Remediation method for chromium slag or chromium contaminated soil

InactiveCN106391692ASpeed up the pyrolysis processImprove performanceContaminated soil reclamationSlagThermal treatment

The invention discloses a remediation method for chromium slag or chromium contaminated soil. The remediation method comprises the following steps: mixing the chromium slag or chromium contaminated soil with semi-coke; performing thermal treatment at the temperature of 400 to 1600 DEG C; and allowing pollutants in the chromium slag or chromium contaminated soil to have a reduction reaction at a high temperature to obtain non-contaminated soil, wherein the thermal treatment is performed under the protection of one or both of an inert gas and a reductive gas. According to the remediation method disclosed by the invention, the semi-coke is utilized for strengthened reduction of chromium in the chromium slag or chromium contaminated soil; the semi-coke can play a reduction effect on hexavalent chromium and can also improve soil, sequestrate carbon and treat wastes. The remediation method has the advantages of being high in chromium reduction efficiency, low in energy consumption, economical, feasible, environmentally friendly and the like, and has quite good application prospects.

Owner:BEIJING GEOENVIRON ENG & TECH

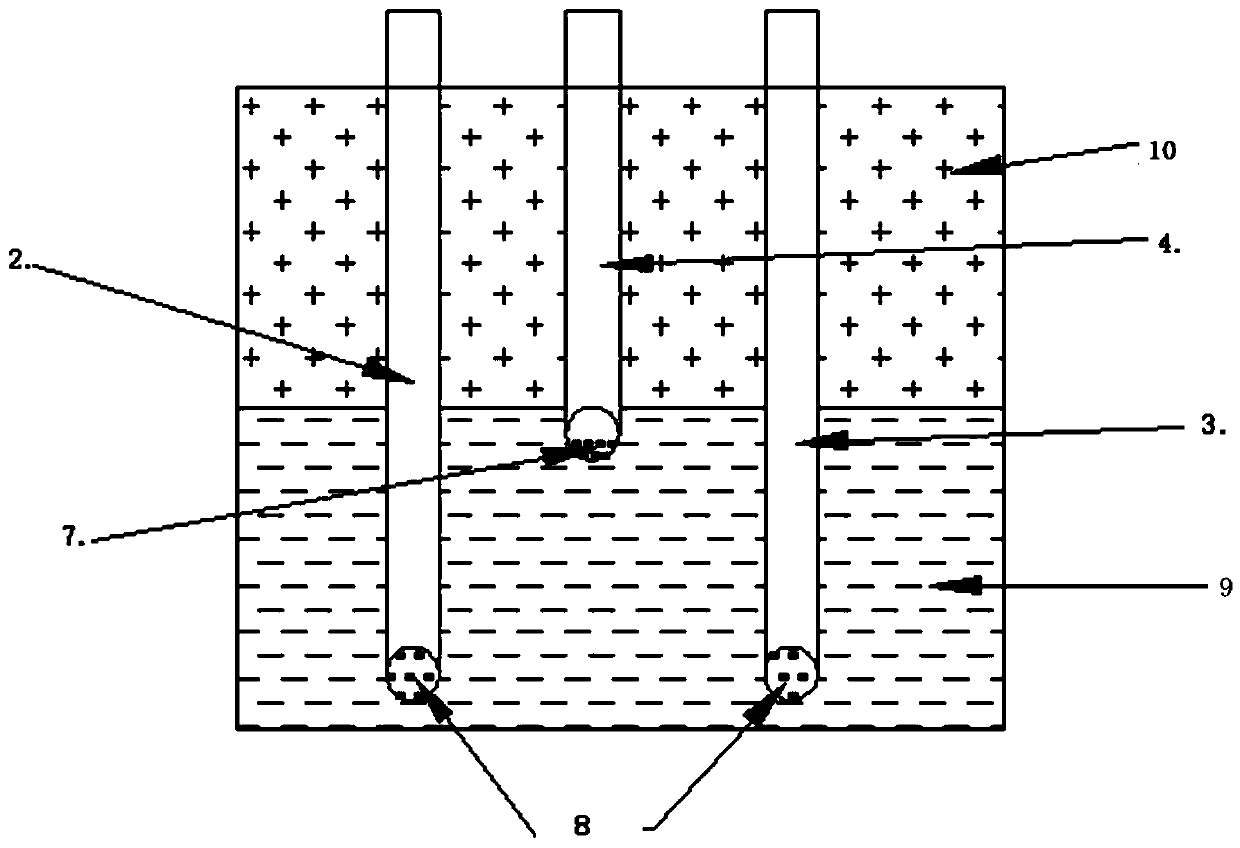

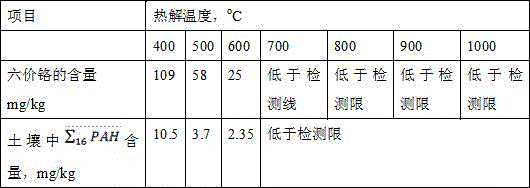

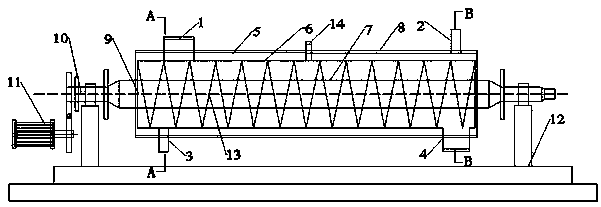

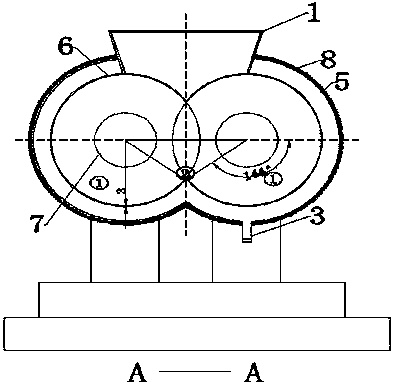

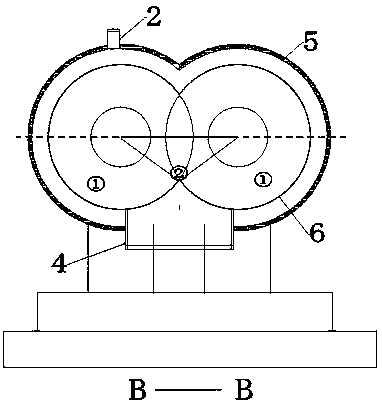

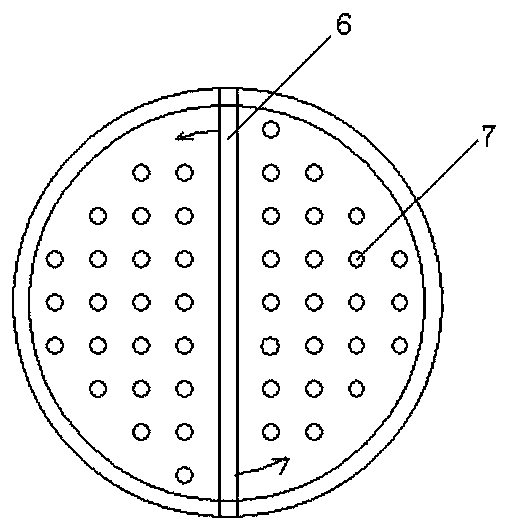

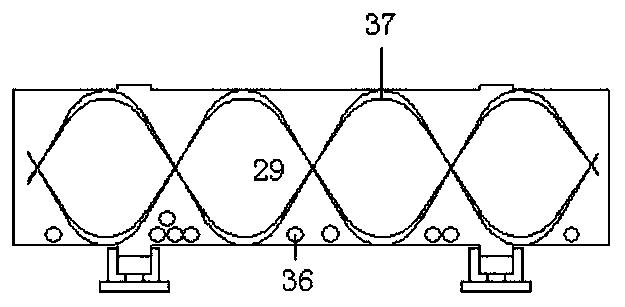

Grinding-disc pyrolysis reactor

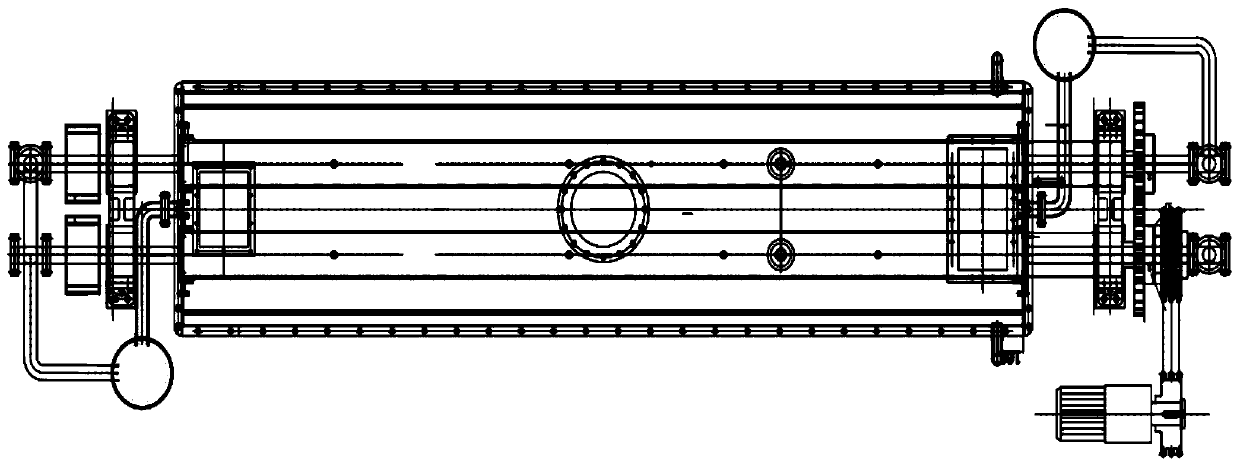

InactiveCN103242868AShorten pyrolysis timePyrolysis time guaranteeLiquid hydrocarbon mixture productionSpecial form destructive distillationEngineeringHeating furnace

The invention provides a grinding-disc pyrolysis reactor. A main body of the grinding-disc pyrolysis reactor consists of an upper furnace plate, a distributing plate, dust boards and scraping plates which are rotatable around a feeding pipe, and a lower furnace plate and a furnace wall which are fixed, wherein a the feeding pipe is arranged in the center of the furnace plate, and the distributing plate is arranged at the bottom of the furnace plate; a circle of dust boards and a pair or a plurality of pairs of scraping plates are arranged at the periphery of the distributing plate; a water seal or a sand seal is arranged between the upper furnace plate and the feeding pipe as well as the upper furnace plate and the furnace wall; the distributing plate is a mosaic grinded surface with a plurality of radial tooth grooves formed in the mosaic grinded surface, and through the rotation of the distributing plate, material distributing, turning and discharging functions can be achieved simultaneously; and the lower furnace plate is a flat thermal storage heating stove. The reactor is simple in structure, reliable in operation, convenient to maintain, large in productive capacity, wide in raw material adaptability, and especially suitable for pyrolysis of low metamorphic coal, oil shales, oil sand, biomasses, junked tires, plastic, garbage and the like.

Owner:柯妍

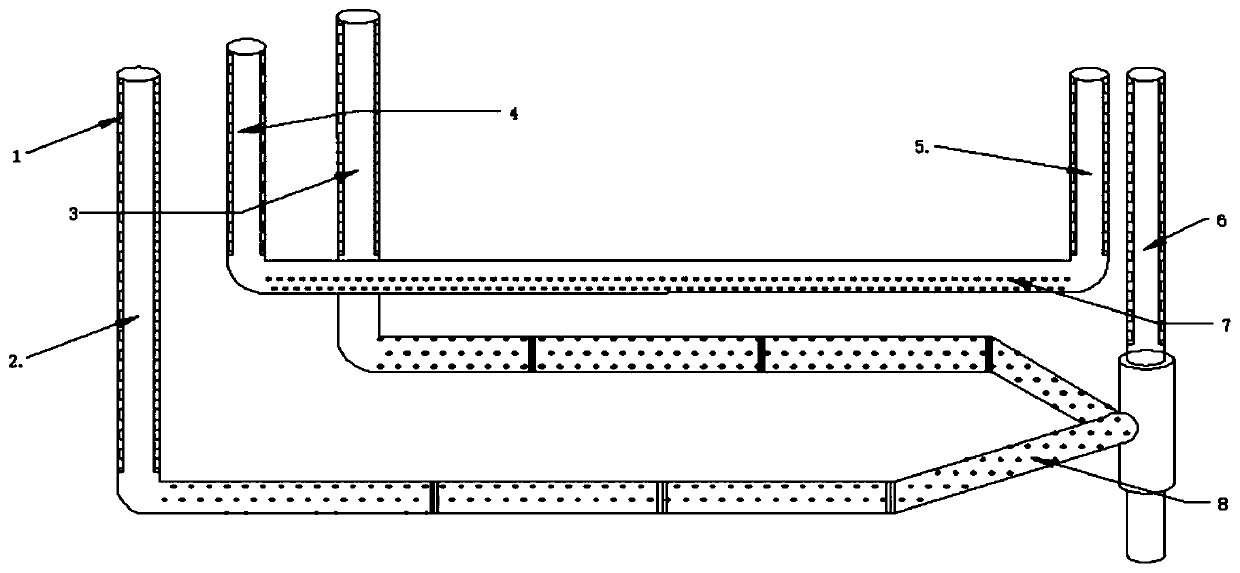

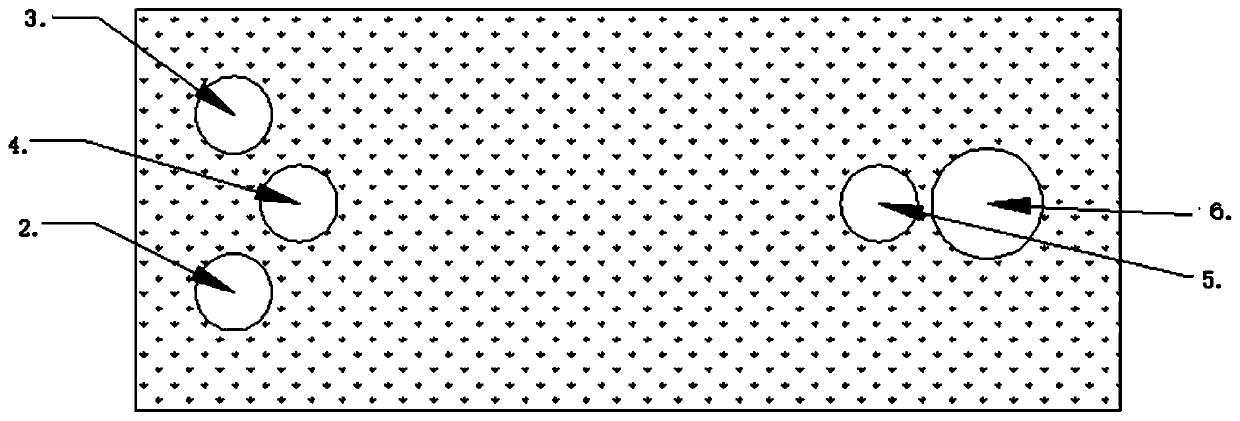

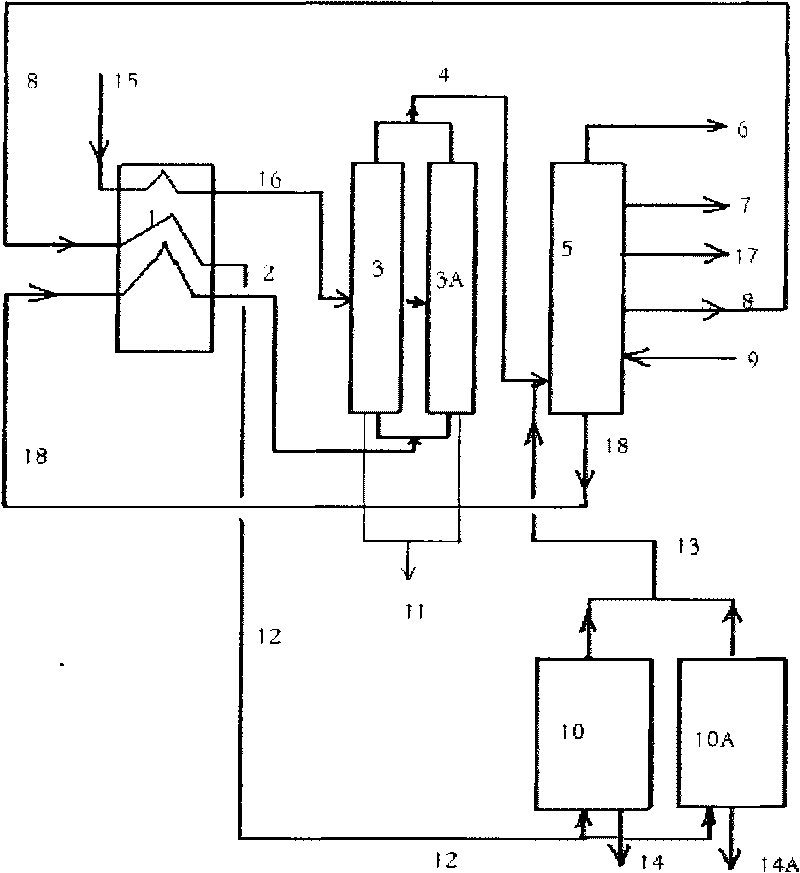

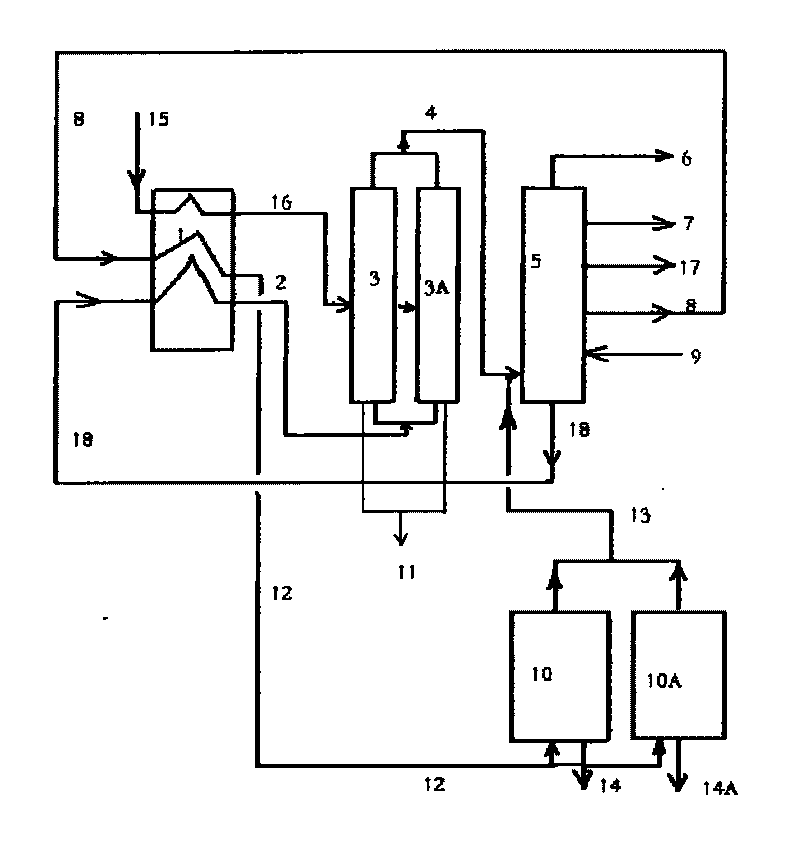

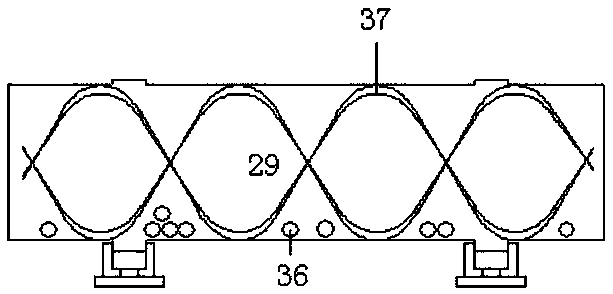

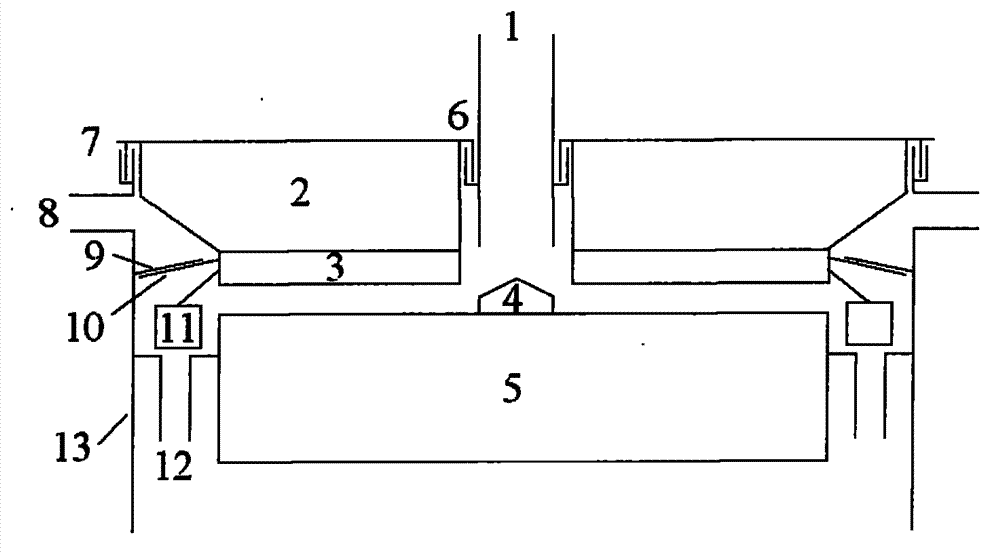

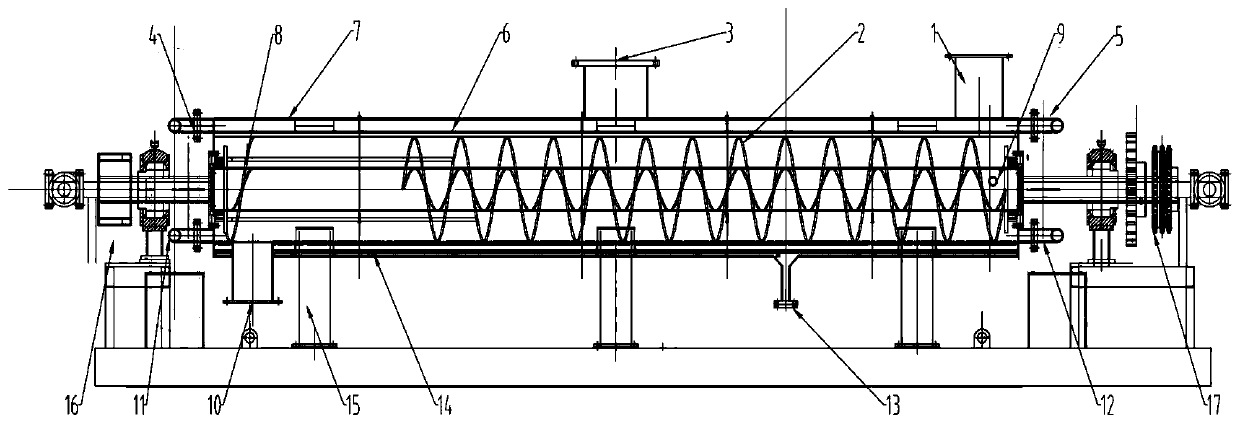

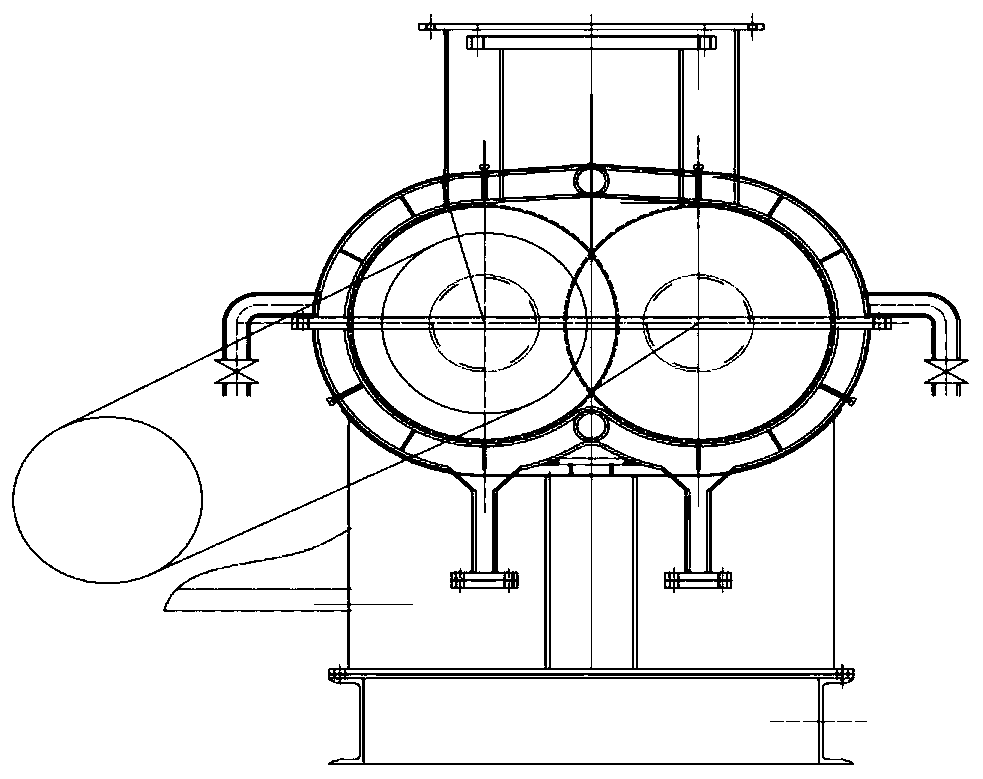

Efficient and energy-saving self-weight spiral progressive biomass pyrolysis system

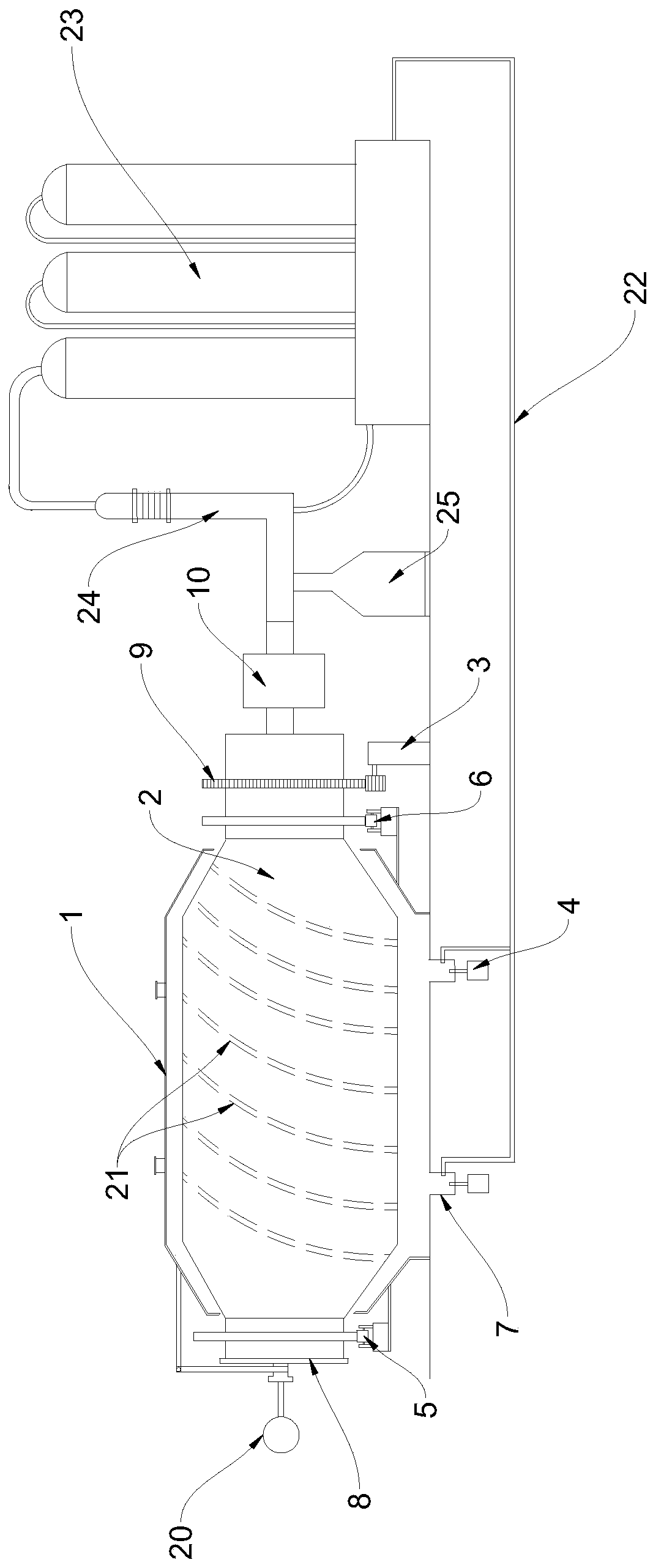

PendingCN109161389AIncrease the heat exchange areaShorten pyrolysis timeBiofuelsSpecial form destructive distillationBiomassProcess engineering

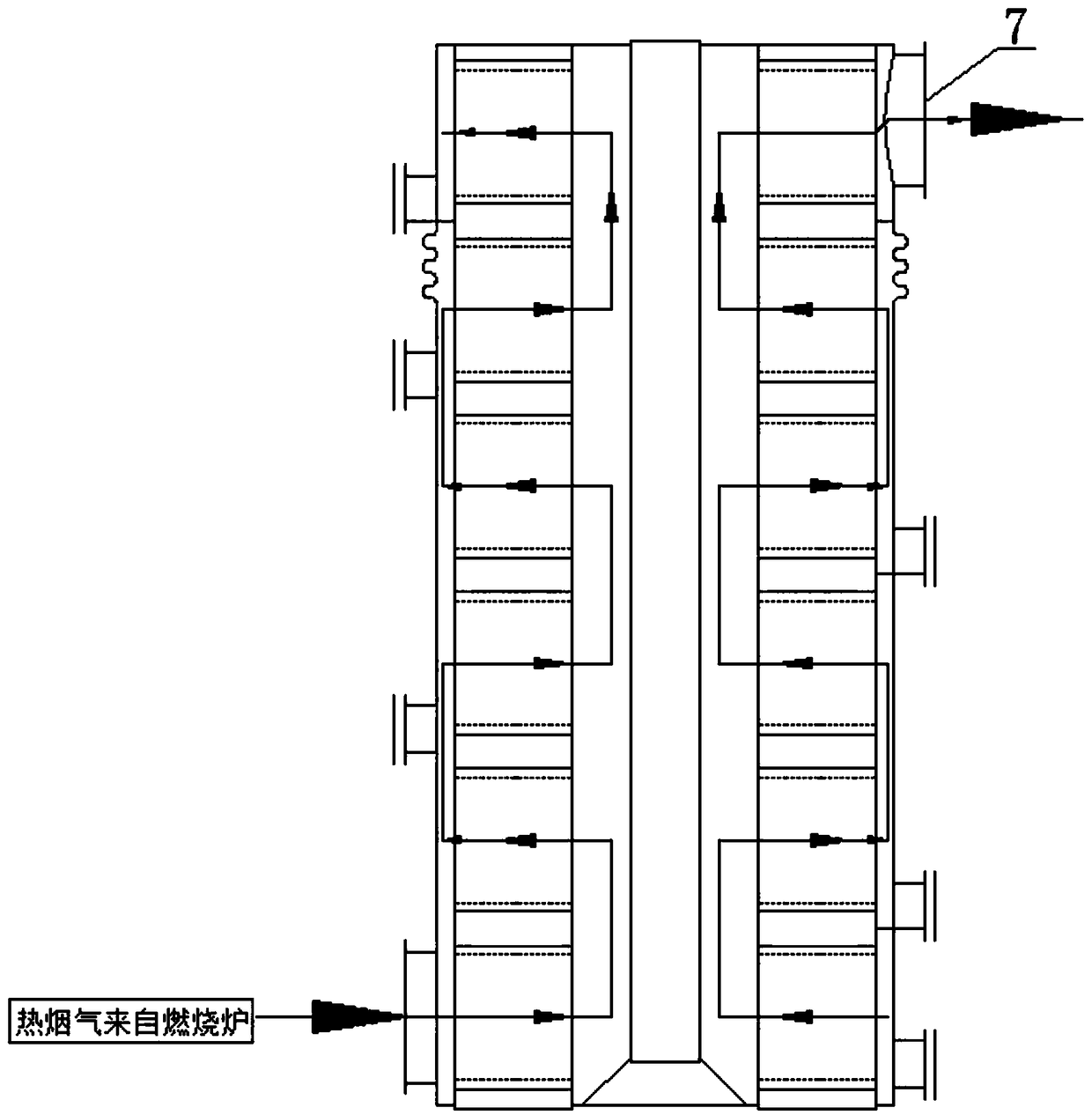

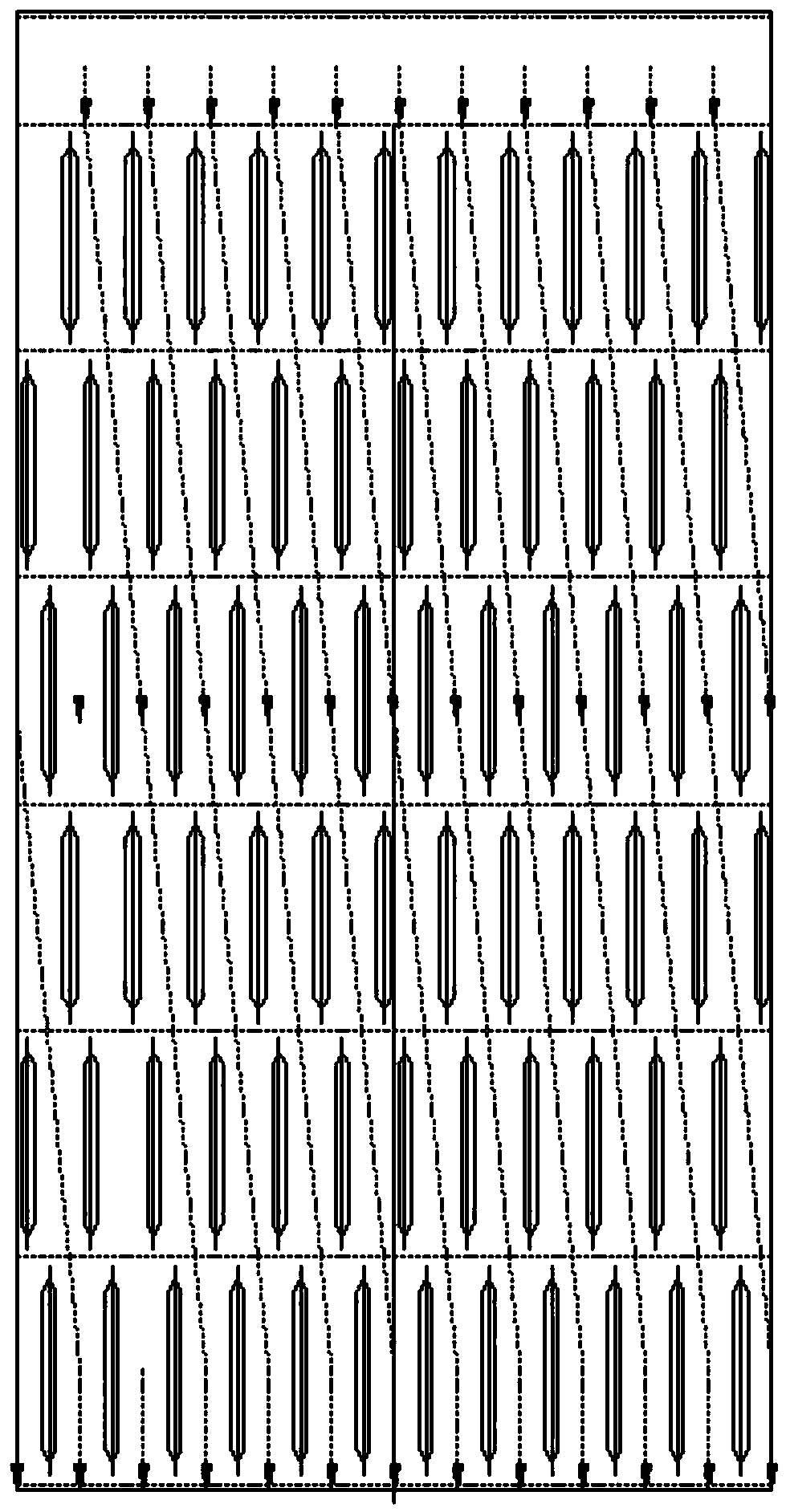

The invention discloses an efficient and energy-saving self-weight spiral progressive biomass pyrolysis system which comprises a pyrolysis furnace, a material distribution tank (23), an air cooler anda water cooling system, wherein an outlet of the material distribution tank (23) communicates with the material feeding hole of the pyrolysis furnace; a biomass charcoal outlet in the bottom of the pyrolysis furnace communicates with a material inlet in the upper part of the air cooler; a material outlet in the lower part of the air cooler communicates with the material feeding hole of the watercooling system; an inner cylinder (2) and an outer cylinder (3) are arranged in the middle inside the furnace body (1) of the pyrolysis furnace; a conical material distributor (4) is arranged at the top, corresponding to the material feeding hole of the furnace body (1), of the inner cylinder (2); a pyrolysis gas secondary pyrolysis tube (5) is arranged in the inner cylinder (2); the outlet of thepyrolysis gas secondary pyrolysis tube (5) communicates with a pyrolysis gas outlet (6); both a flue gas outlet (7) and a hot flue gas inlet (8) communicate with an inner cavity of the inner cylinder(2). Mutual actions of heat conduction are achieved, high heat utilization efficiency is achieved, and gradient utilization of energy is achieved.

Owner:HUBEI NORMAL UNIV +1

Method for producing needle-shaped coke raw material by delayed coking process

InactiveCN106867554AExpand sourceThe method flow is simpleCoking carbonaceous materialsWaxCavitation

The invention discloses a method for producing a needle-shaped coke raw material through treating FCC circulating oil and a conventional coked raw material by a delayed coking process. The method comprises the steps: low temperature FCC circulating oil is introduced to a medium-upper part of a delayed coking tower and makes contact with a high temperature oil gas phase produced from high temperature cracking of the conventional coked raw material introduced from the bottom of the delayed coking tower, a reaction is performed under delayed coking conditions, generated oil and gas enter a coking fractionating tower and are separated, and thus the needle-shaped coke raw material is obtained. An ultrasonic generator is mounted at the bottom of the coking fractionating tower, the ultrasonic wave cavitation principle is utilized, and the fractionation effect is improved, so the wax oil distilling-off rate is improved, and the high-quality high-yield needle-shaped coke raw material is obtained.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

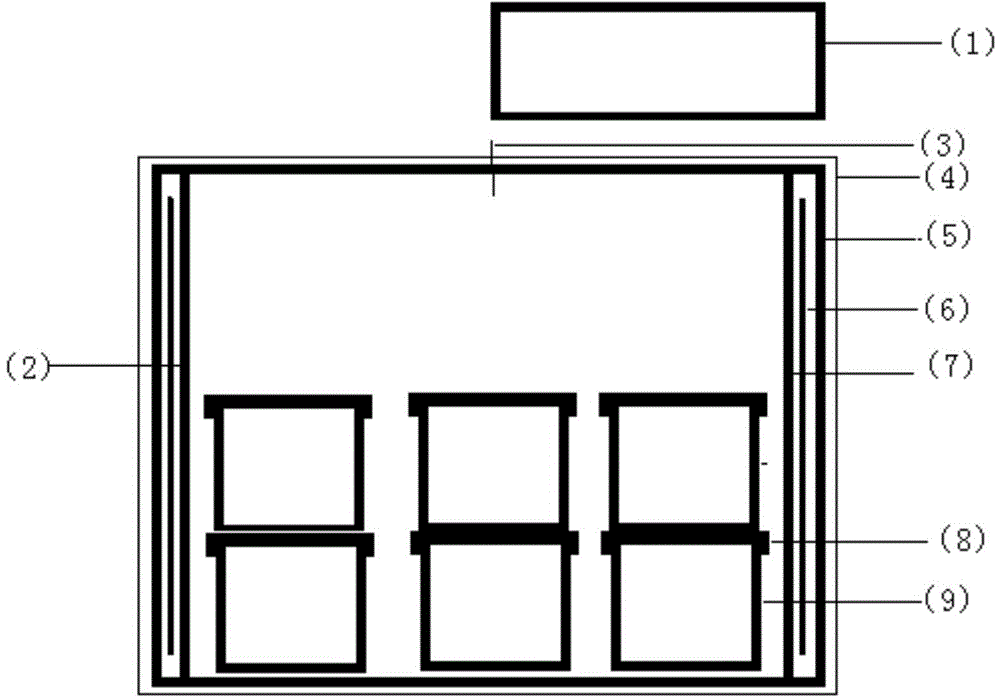

Closed charcoal preparation apparatus

InactiveCN104910932AImprove production efficiencyImprove productivityBiofuelsRetortsProduction rateRoom temperature

The invention relates to a charcoal preparation apparatus, and especially relates to a closed charcoal preparation apparatus. A technical scheme is characterized in that the apparatus comprises a temperature controller (1), a heater box (2) and a pyrolysis tank (9), and when charcoal is prepared, organic matters enter the pyrolysis tank (9), a lid (8) at the upper portion of the pyrolysis tank (9) is screwed up, the pyrolysis tank (9) is put in the heater box (2), and heating pyrolysis is carried out. The heater box is opened after the pyrolysis reaction, the pyrolysis tank (9) is cooled to room temperature, and then the prepared charcoal is taken out. The apparatus has the characteristics of ingenious conception, reasonable design, and realizes reduction of the pyrolysis temperature, shortening of the organic matter pyrolysis time and increase of the charcoal preparation efficiency by preparing charcoal through pyrolysis of organic substances in closed environment; and the apparatus can ensure anaerobic environment and improve the charcoal production rate through pyrolysis of the organic matters in a closed tank.

Owner:CHONGQING UNIV OF ARTS & SCI

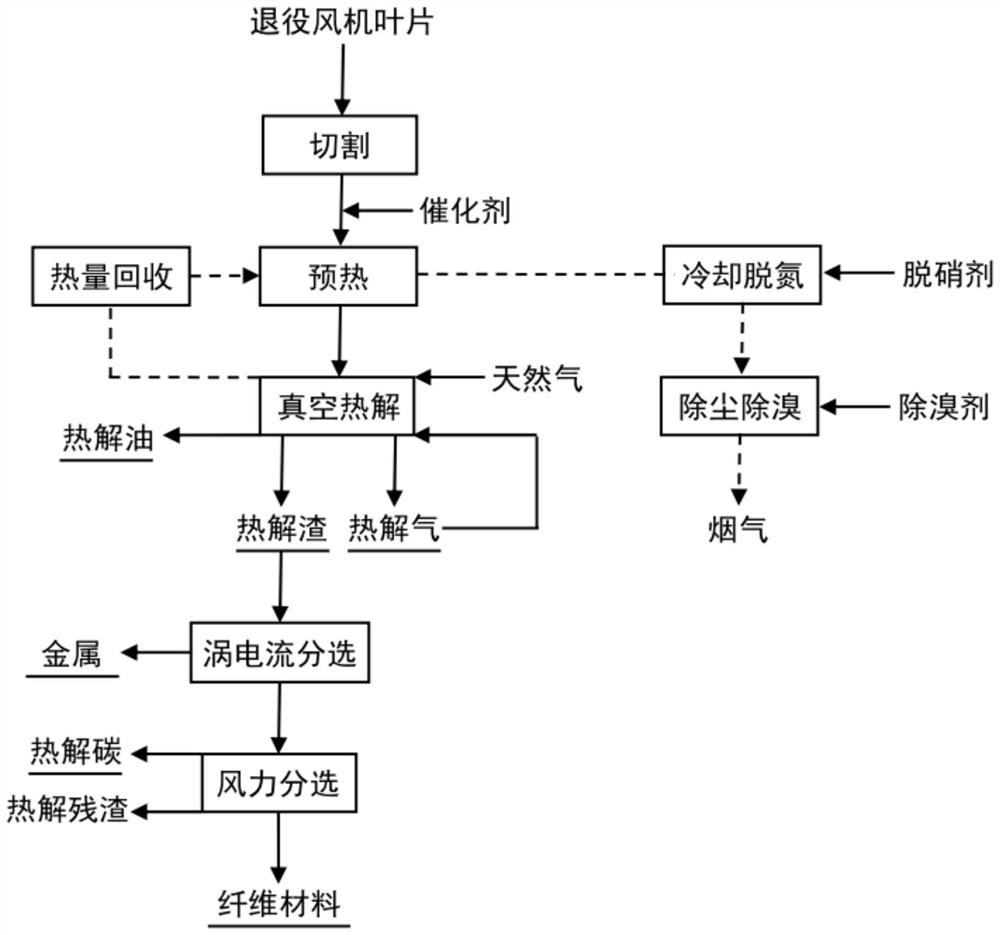

Vacuum pyrolysis treatment and recovery method for retired fan blades

ActiveCN114653729AAchieve dissociationAccurate temperature controlSolid waste disposalTransportation and packagingCatalytic pyrolysisFiber

The invention discloses a vacuum pyrolysis treatment and recovery method for retired fan blades, which comprises the following steps: (1) blade pretreatment: crushing the retired fan blades, adding a pyrolysis catalyst, and uniformly mixing; then, the combustion flue gas subjected to high-temperature treatment is introduced for preheating treatment; (2) vacuum pyrolysis: carrying out catalytic pyrolysis treatment on the pre-treated retired fan blade in a vacuum negative pressure state to obtain pyrolysis gas, pyrolysis oil and pyrolysis residues; (3) carrying out eddy current separation on the pyrolysis residues to obtain metal, and carrying out wind separation to obtain pyrolytic carbon, a fiber material and pyrolysis residues; (4) cooling and denitrifying the combustion flue gas generated in the step (1); and (5) removing dust and bromine from the cooled and denitrified combustion flue gas. According to the method, the retired fan blade can be efficiently treated, and resources such as fiber materials and metal in the retired fan blade can be recycled.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Method for accelerating microwave pyrolytic process of oily sludge by pyrolyzing residue thereof

InactiveCN101798163BSpeed up the pyrolysis processReduce energy consumptionSolid waste disposalSludge treatment by pyrolysisMicrowave pyrolysisNitrogen

The invention discloses a method for accelerating the microwave pyrolytic process of oily sludge by pyrolyzing residue thereof, which comprises the following steps: carrying out microwave pyrolysis on the oily sludge or sludge under the condition of nitrogenization, controlling the temperature to be 700-850 DEG C and performing microwave incineration for 5-15min to obtain solid microwave residue;mixing the microwave residue with the oily sludge or the sludge evenly, wherein the weight of the microwave residue is 0.5-5% of the oily sludge or the sludge; and then carrying out microwave pyrolysis on the oily sludge or the sludge under the condition of nitrogenization. The invention can accelerate the pyrolytic process of the oily sludge or the sludge, shorten the pyrolytic time, effectivelysave the energy consumption of the oily sludge or the sludge processing, and improve the processing efficiency; the residue after the microwave pyrolysis can be recycled; and the method of the invention has low cost, is economical and can be popularized and utilized.

Owner:SINOPEC PETROLEUM ENG DESIGN +1

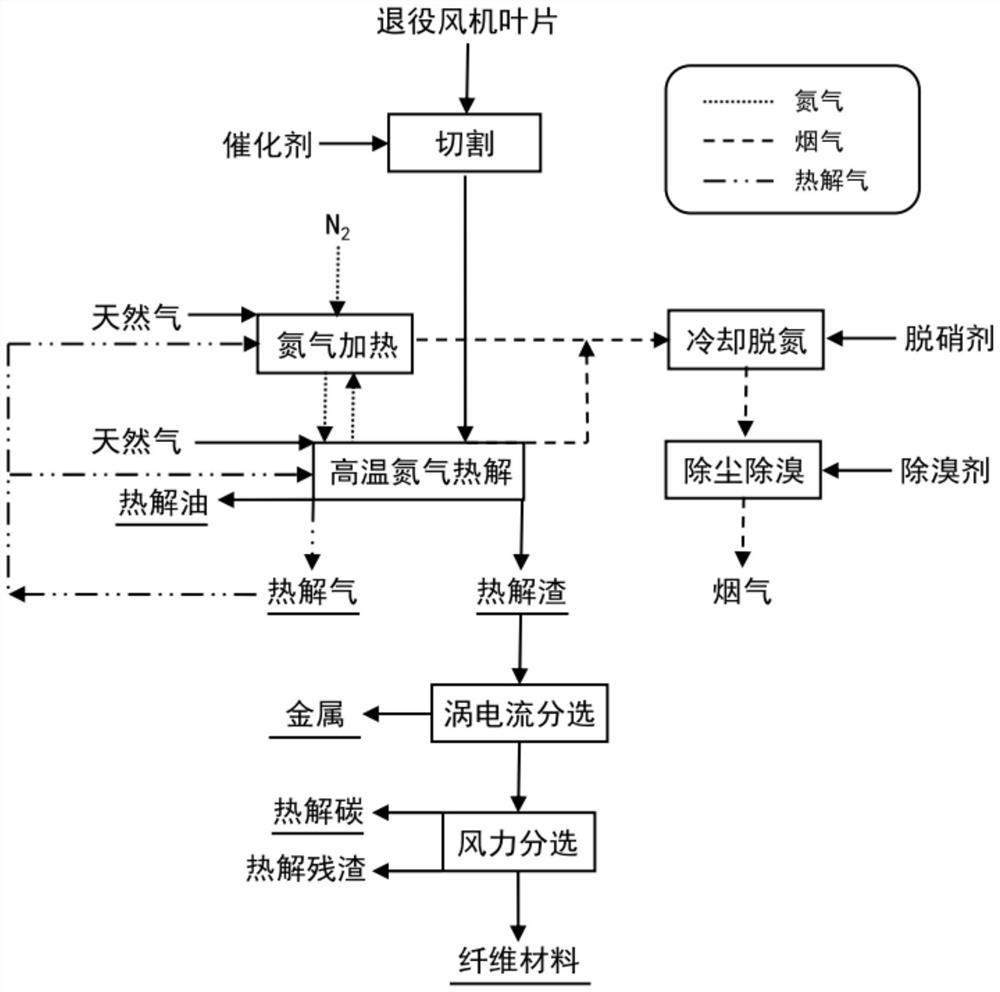

High-temperature nitrogen pyrolysis treatment and recovery method for retired fan blades

PendingCN114656985AAchieve clean lysisSuitable for large-scale industrial applicationsLighting and heating apparatusDispersed particle separationFiberCarbon fibers

The invention discloses a high-temperature nitrogen pyrolysis treatment and recovery method for retired fan blades, which comprises the following steps: (1) blade pretreatment: crushing the retired fan blades, adding a pyrolysis catalyst, and uniformly mixing; (2) nitrogen heating: heating nitrogen under a high-temperature condition to obtain high-temperature nitrogen; (3) performing high-temperature pyrolysis on the pre-treated retired fan blade in a high-temperature nitrogen atmosphere to obtain pyrolysis gas, pyrolysis oil and pyrolysis residues; (4) carrying out eddy current separation on the pyrolysis residues to obtain metal, and carrying out wind separation to obtain pyrolytic carbon, a fiber material and pyrolysis residues; (5) cooling and denitrifying the combustion flue gas generated in the steps (2) and (3); and (6) removing dust and bromine from the cooled and denitrified combustion flue gas. According to the method, the retired fan blade can be efficiently treated, and resources such as fiber materials and metal in the retired fan blade can be recycled.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Production method of needle coke

ActiveCN101724421BExpand sourceSimple processThermal non-catalytic crackingCoking carbonaceous materialsDecompositionSlurry

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

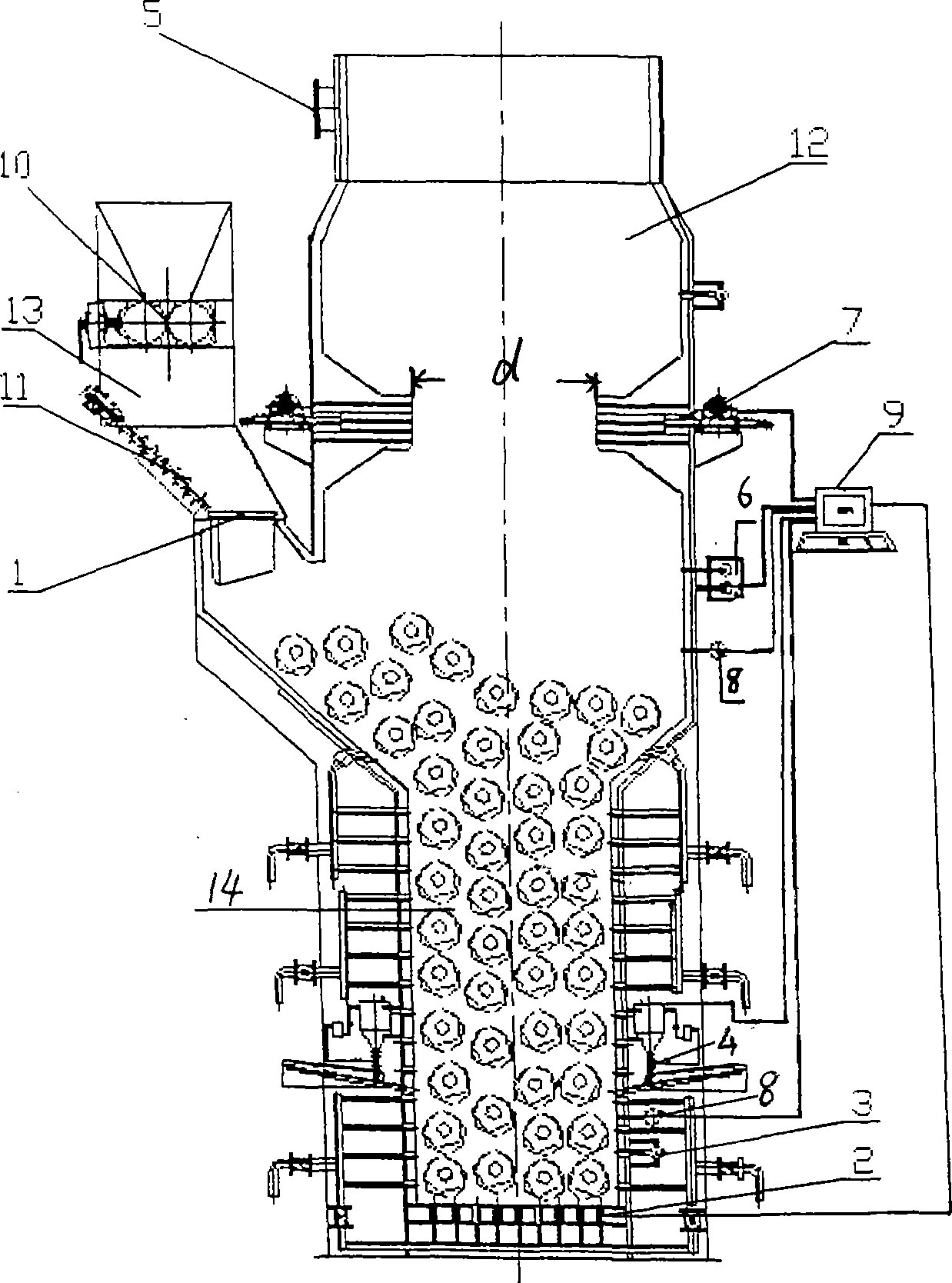

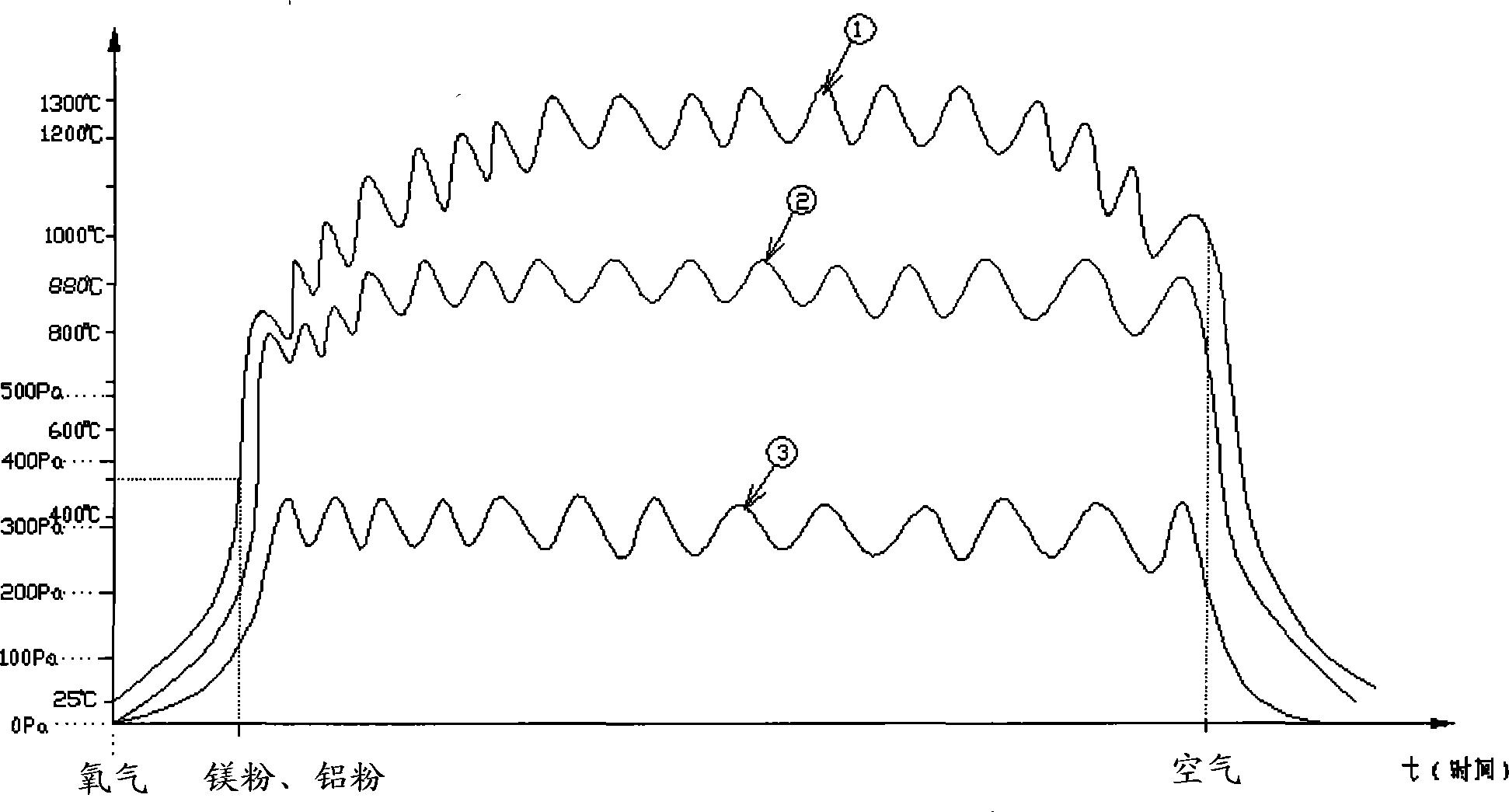

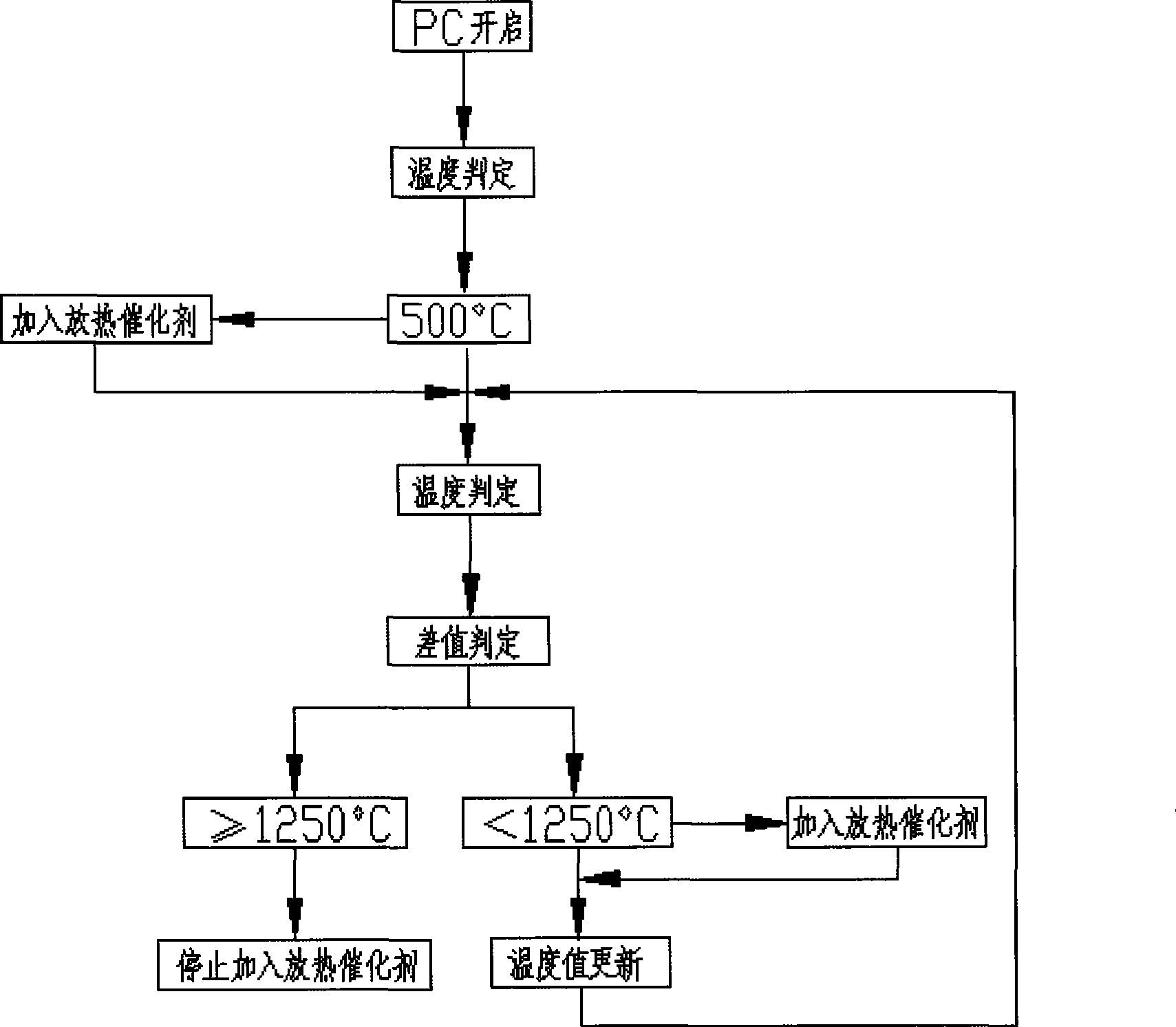

Exothermic catalytic combustion method for pyrolysis gasification submelting furnace under pure oxygen conditions

InactiveCN101520176AReduce lossEmission reductionCombustion using catalytic materialIncinerator apparatusInternal pressureCatalytic combustion

The invention provides an exothermic catalytic combustion method for a pyrolysis gasification submelting furnace under pure oxygen conditions, which is characterized in that pure oxygen is directly introduced into the pyrolysis gasification submelting furnace for pyrolysis after the ignition. During the pyrolysis, catalysts, namely magnesium powder, aluminum powder or a mixture of the magnesium powder and the aluminum powder is added from the furnace bottom, and the adding amount of the catalysts is between 0.1 and 1.0 kg for each ton of treated substance. During the pyrolysis gasification, the pressure in the furnace is adjusted by adjusting the opening degree of a rectification mechanism to ensure that the pressure inside the pyrolysis furnace is stable. The method has the advantages of low cost, energy conservation, and environmental protection.

Owner:SHANGHAI DISHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Pyrolyzer for treating combustible components in household garbage

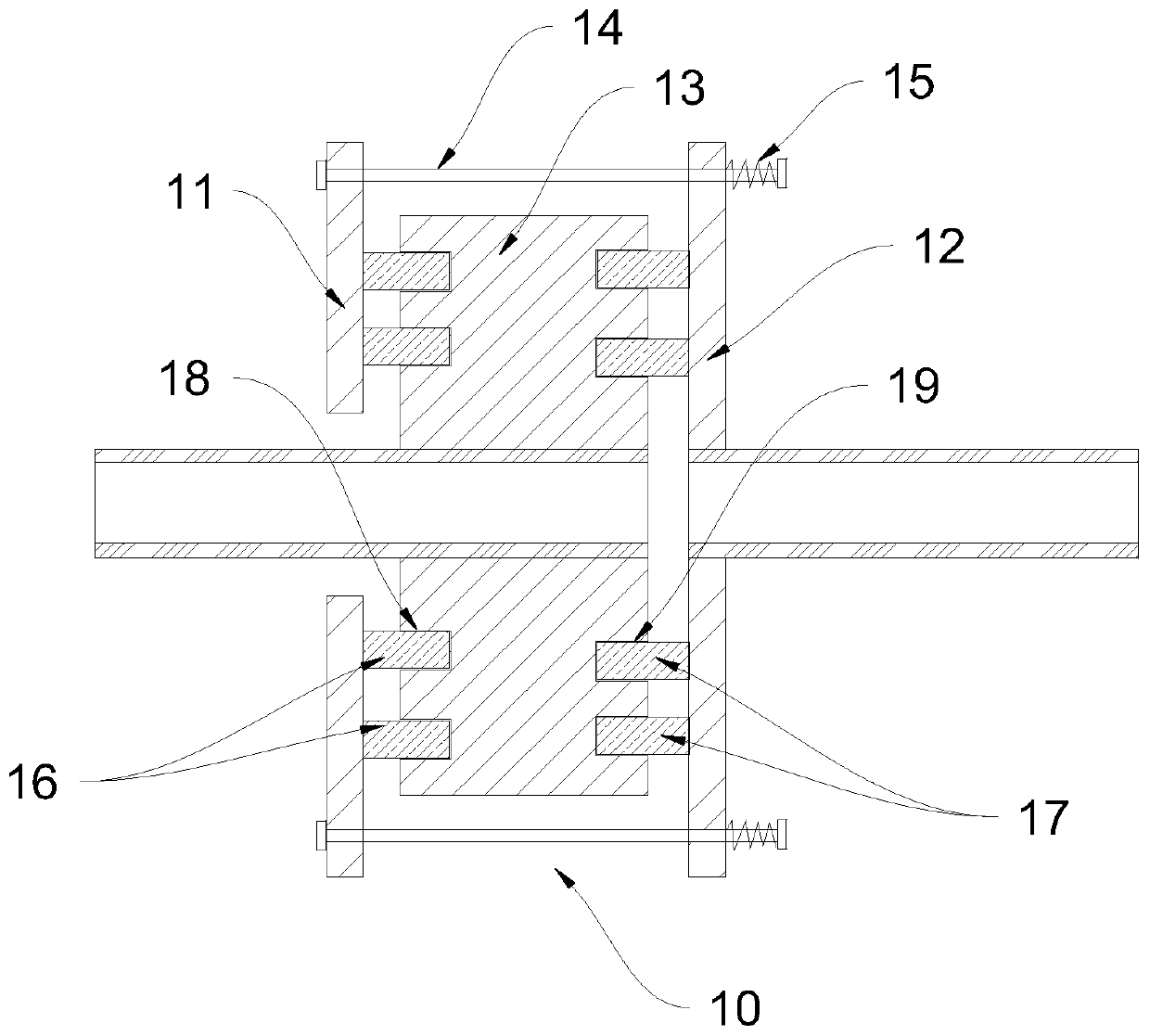

InactiveCN110922992AGuaranteed reliabilityGuaranteed pyrolysis uniformitySpecial form destructive distillationElectric machineryProcess engineering

The invention relates to a garbage pyrolyzer, which comprises an outer jacket, a furnace body, shaft-free screws, an inner heating pipe, a pyrolyzer heat preservation device, an end cover, a motor andthe like, wherein a pyrolysis chamber is arranged in the pyrolyzer, a material inlet and a pyrolysis gas outlet are formed in the upper portion of the pyrolysis chamber, a pyrolysis residue outlet and a heating medium gas inlet is formed in the lower end of the pyrolysis chamber, the two groups of the shaft-free screws play role in stirring and propelling in the pyrolyzer, and a gas discharge port is connected with a gasification device through a pipeline. According to the invention, the garbage pyrolyzer has the advantages of high reliability, short pyrolysis time, high efficiency, good effect, obvious decrement, low pollution, compact structure, convenient use and the like, and has wide market prospects in future garbage rear-end treatment.

Owner:深圳龙澄高科技环保股份有限公司

Self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device

ActiveCN109022001ARealize continuous productionIncrease the heat exchange areaBiofuelsSpecial form destructive distillationEngineeringDistributor

A self-weight spiral progressive type high-efficiency and energy-saving biomass pyrolysis furnace device comprises a pyrolysis furnace and an air cooler, a closed cavity is formed between the outer box body (16) and the inner box body (17) of the air cooler, a closed cylindrical shell (18) is arranged in the inner box body (17), a plurality of layers of air cooling flow deflectors (19) are arranged between the inner box body (17) and the cylindrical shell (18), an opening at one end of every air cooling flow deflector (19) is communicated with the inner chamber of the cylindrical shell (18), and an opening at the other end of the air cooling flow deflector (19) is communicated with the cavity between the outer box body (16) and the inner box body (17); and an inner cylinder (2) and an outer cylinder (3)are arranged in the inner part of the furnace body (1) of the pyrolysis furnace, a conical distributor (4) is arranged at a position, corresponding to the charging port of the furnace body (1), of the top of the inner cylinder (2), and a pyrolysis gas secondary pyrolysis tube (5) is arranged in the inner cylinder (2). The device has the advantages of heat transfer and interaction, high heat utilization efficiency, and realization of cascade utilization of energy.

Owner:HUBEI NORMAL UNIV

Device and method for preparing active coke by pyrolysis of domestic waste

ActiveCN107934961BRealize integrated controlEfficient crushingCarbon compoundsLighting and heating apparatusAir preheaterCombustion chamber

The invention discloses a device and method for preparing activated coke by pyrolysis of domestic waste. The device mainly comprises a drying rotary kiln, a microwave pyrolysis furnace, a pyrolysis gas combustion chamber, an air preheater, a steam generator, a coke sample activation furnace and a flue gas purification tower; the drying rotary kiln is connected with the microwave pyrolysis furnace,and a flue gas outlet is connected with the flue gas purification tower, an induced draft fan and a chimney through a pipeline; the microwave pyrolysis furnace is connected with the induced draft fanand the pyrolysis gas combustion chamber through a pipeline, a flue gas outlet of the pyrolysis gas combustion chamber is connected with the air preheater, one way of the air preheater is connected with a hot-air inlet of the pyrolysis gas combustion chamber, and the other way is connected with the drying rotary kiln; and a storage chamber is connected with the coke sample activation furnace, a flue gas outlet of the coke sample activation furnace is connected with the microwave pyrolysis furnace through a gas bypass, and the coke sample activation furnace is connected with the steam generator. The device provided by the invention is adopted to pyrolyze the domestic waste, the efficiency is high, and emission is concentrated; and the device can further prepare high-quality activated cokeand complete large-scale treatment of the domestic waste.

Owner:HUAZHONG UNIV OF SCI & TECH

Internal heating type pyrolysis device

PendingCN110669535AGuaranteed reliabilitySignificant reductionIndirect heating destructive distillationSpecial form destructive distillationThermodynamicsElectric machinery

The invention discloses a garbage internal heating type pyrolysis device. The garbage internal heating type pyrolysis device comprises an outer sleeve, a furnace body, a spiral internal heating pipe,a pyrolyzer heat preservation device, an end cover, a motor, a feeding / discharging opening, an impurity outlet device and the like; the outer sleeve of the pyrolysis device is a device for through-flow heating of hot fluid, and heat carried by hot fluid is used for heating materials through furnace body heat transfer; a central shell formed by the outer sleeve is an inner furnace body of the pyrolysis device and is a space for decomposing materials by absorbing heat; the spiral internal heating pipe is used for pushing to-be-pyrolyzed materials entering from the feeding opening to be pyrolyzed by the furnace body and discharged through the discharging opening through rotation a material inlet and a pyrolysis gas outlet are formed in the upper part of a pyrolysis chamber, a pyrolysis residue outlet and a heating medium gas inlet are formed in the lower end of the pyrolysis chamber, and a double-shaft screw is adopted to achieve stirring and propelling effect in the pyrolyzer, and can mutually clean garbage wound on shafts. The garbage internal heating type pyrolysis device has the advantages of being high in reliability, short in pyrolysis time, high in efficiency, good in effect,obvious in decrement, low in pollution, compact in structure, convenient to use and the like, and has wide market prospects in future garbage rear-end treatment.

Owner:深圳龙澄高科技环保股份有限公司

Delayed coking method for processing high-acid crude oil

The invention discloses a method for processing high-acid crude oil by a delayed crude oil process. In the method, low-temperature high-acid crude oil enters the upper part of a reactor; high-temperature low-acid coking raw material enters the bottom of the reactor; a high-temperature oil gas generated from the low-acid coking raw material through pyrolysis is mixed with the low-temperature high-acid crude oil on the upper part of the reactor; therefore, the high-acid crude oil is pyrolyzed and deacidified at an appropriate high temperature so as to fulfill the aim of deacidification; and simultaneously, the injection of the low-temperature high-acid crude oil reduces the cracking temperature of the low-acid coking raw material, shortens the pyrolysis time of a low-acid raw material, and reduces secondary reactions, thereby reducing the coke formation rate and prolonging the stable operating period of a single tower. The delayed coking method for processing the high-acid crude oil hasthe characteristics that the preheating temperature of the high-acid crude oil can avoid a strong corrosion phase of an acid, and can reduce or even avoid the corrosion of the acid on heating equipment even below a corrosion temperature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pyrolysis equipment for producing charcoal and byproducts

PendingCN110564435AEvenly heatedReduce usageBiofuelsIndirect heating destructive distillationCombustionCarbonization

Embodiments of the invention disclose pyrolysis equipment for producing charcoal and byproducts, belonging to the field of carbonization furnaces. The pyrolysis equipment comprises a decomposing furnace, a condenser and a sealed connector, at least one heat input port communicated with a combustion furnace is formed in the bottom of a shell of a decomposing furnace; a rotary furnace is arranged inthe decomposing furnace shell; a feeding port of the rotary furnace extends out of one end of the decomposing furnace shell and is in running fit with a first roller; a furnace cover in sealing fit with the feeding port of the rotary furnace is arranged at the feeding port; a gas outlet of the rotary furnace extends out of the other end of the decomposing furnace shell and is in running fit withthe second roller; and the driving motor is used for driving the rotary furnace to rotate around the axis of the rotary furnace. The rotary furnace is used for heating wood raw materials, and the spiral wings are arranged on the inner wall of the rotary furnace to stir the wood raw materials, so the wood raw materials are heated more uniformly, pyrolysis time is shortened, and conversion efficiency is improved; and generated waste gas is subjected to secondary combustion, so the use amount of a fuel can be reduced, and environmental pollution is avoided.

Owner:孙范哲

Coking method for processing highly acid crude oil

ActiveCN101280213BReduce corrosionCorrosion is reduced or even avoidedThermal non-catalytic crackingTowerHot Temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

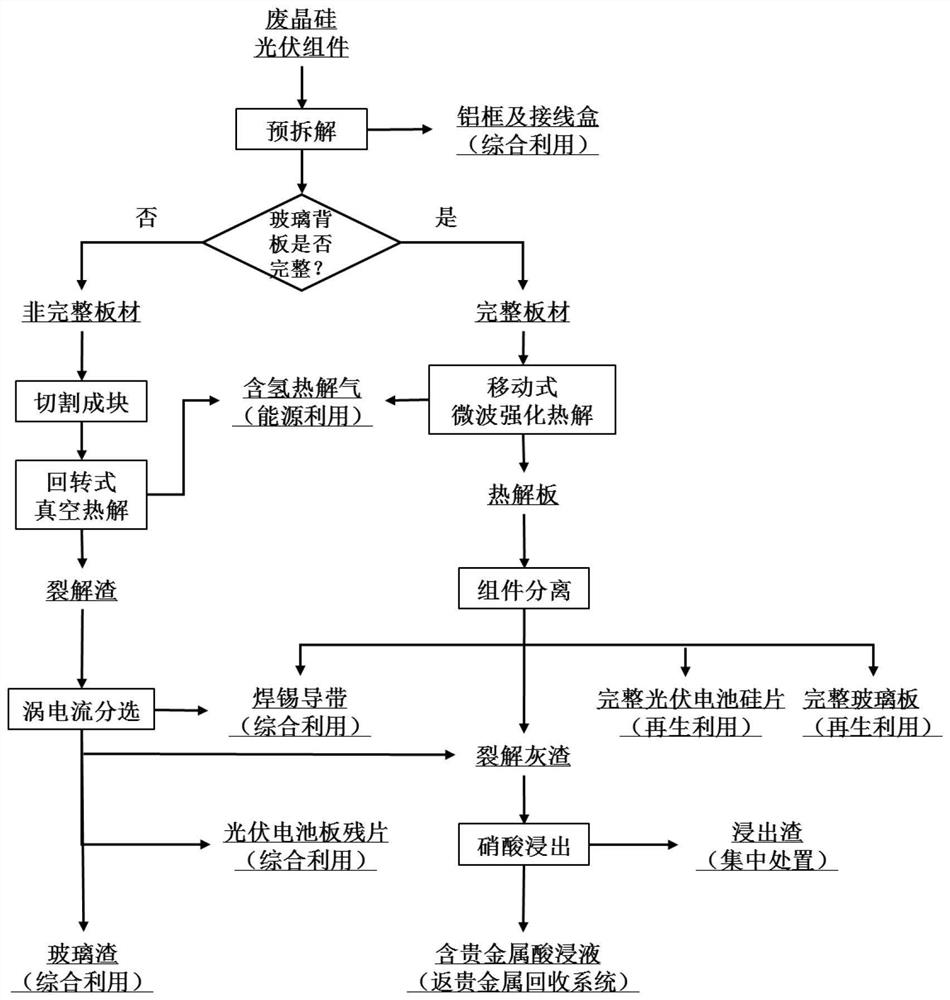

Method for comprehensively recovering all components of waste crystalline silicon photovoltaic module

PendingCN114833176AFast pyrolysisShorten pyrolysis timeSolid waste disposalTransportation and packagingSilicon chipCells panel

The invention discloses a method for comprehensively recovering all components of a waste crystalline silicon photovoltaic module. The method comprises the following steps: (1) pre-disassembling a collected waste crystalline silicon photovoltaic panel to obtain an incomplete panel and a complete panel; (2) cutting the incomplete plate into blocks, performing rotary vacuum pyrolysis to obtain first hydrogen-containing pyrolysis gas and pyrolysis residues, and sorting the pyrolysis residues to obtain glass residues, a first soldering tin conduction band, photovoltaic cell panel fragments and first pyrolysis ash residues; and (3) carrying out movable microwave enhanced pyrolysis on the complete plate to obtain second hydrogen-containing pyrolysis gas and a pyrolysis plate, carrying out component separation on the pyrolysis plate to obtain a complete photovoltaic cell silicon wafer, a complete glass plate, a second soldering tin conduction band and second pyrolysis ash, mixing the second pyrolysis ash with the first pyrolysis ash, and carrying out nitric acid leaching, and leaching residues and a precious metal-containing acid leaching solution are obtained. The method realizes all-component high-valued recovery of the waste crystalline silicon photovoltaic module, and has the characteristics of high comprehensive utilization rate of resources, short process flow, no flue gas pollution and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

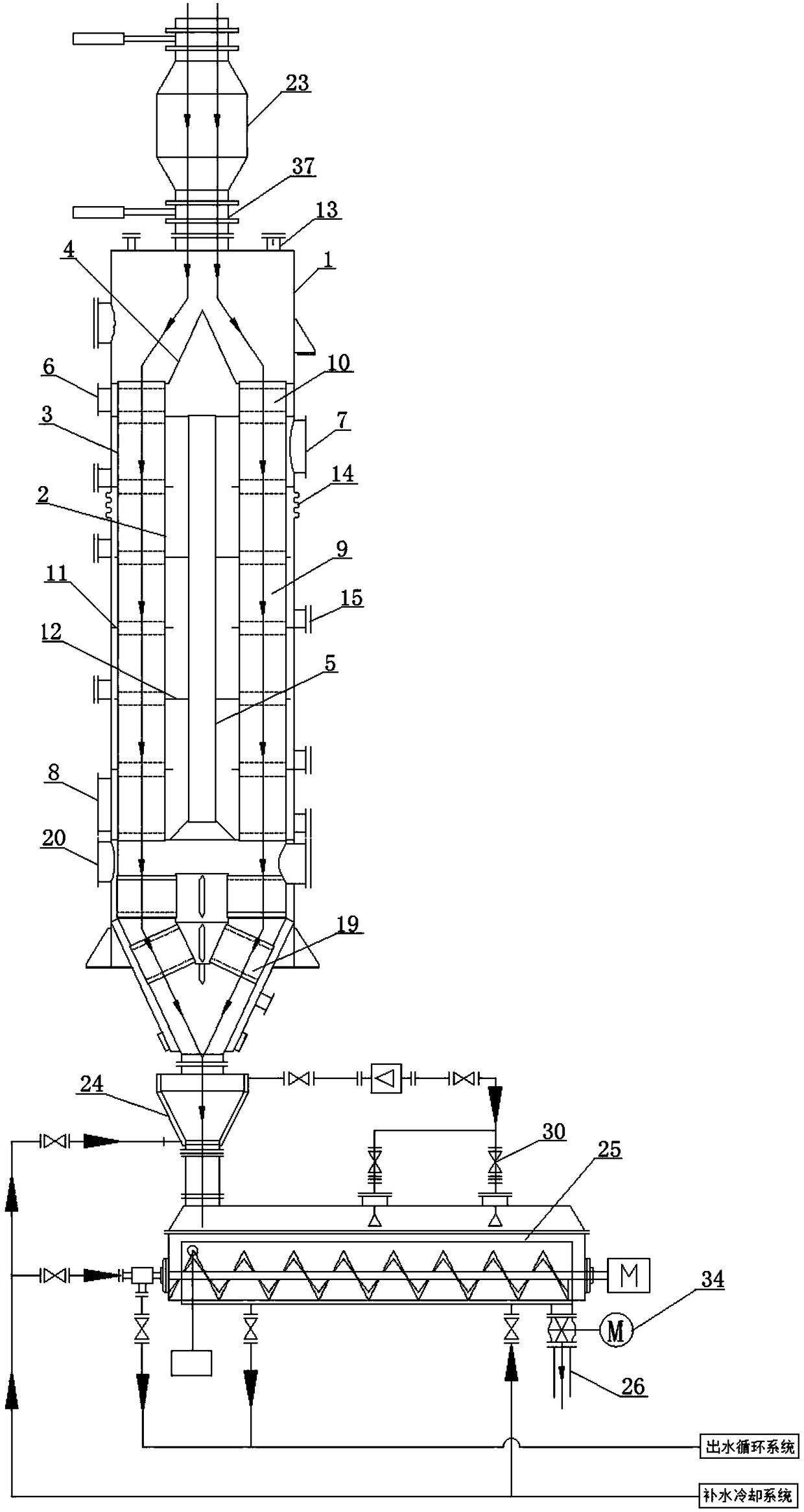

Integrated device and method for preparing oil product and synthetic gas from fine coal

InactiveCN104212495AAchieve near-isothermal solidsFast pyrolysisLiquid hydrocarbon mixture productionGasification with fuel pre-distillationSolid particleOxygen

The invention discloses an integrated device and method for preparing an oil product and synthetic gas from fine coal. The integrated device comprises an integrated reaction system, a cycle feeding-back system and a deep-separation purification system. The integrated reaction system comprises a gasification section and a fast pyrolysis section. The gasification section is an oxygen or air blast turbulent flow fluidized bed gasification furnace. Bed layer height and density are not kept by a low fluidization speed but by a high air-flow speed and a high solid cycle speed. The gasification section utilizes carbon obtained by the fast pyrolysis section. Synthetic gas produced by the gasification section and solid particles carried by the synthetic gas are used as heat sources of the fast pyrolysis section. The fast pyrolysis section is a cycle fluidized bed reactor. The cycle material in the fast pyrolysis section and gas and solid particles in the gasification section are mixed, and then temperatures of the two material flows are basically approximate to the heat-stage temperature so that just added coal does not contact with high-temperature gas and particles from the gasification furnace in the heat stage.

Owner:刘国海 +2

Energy-saving rosewood straightening process

InactiveCN111300566AGood flexibilityShorten pyrolysis timeWood compressionWood treatment detailsProcess engineeringAmmonia

The invention discloses an energy-saving rosewood straightening process, which comprises the following steps: a, soaking rosewood in a flitch form by using a hydrochloric acid solution with a concentration of 20-30% for 80-100 h to obtain a product A; b, soaking the product A with ammonia water until the wood acidity of the product A reaches 6.5-7 to obtain a product B; c, soaking the product B inflowing water for 2-4 days to obtain a product C; d, heating the product C in a steam box for 2-3 hours to obtain a product D; and e, straightening the product D to obtain a finished product, whereinin the step C, the product B is soaked in flowing water for 2-4 days to obtain a product C1, and the C1 product is air-dried to achieve the moisture content of the C1 product of 12-18% so as to obtain the product C. The process has the advantage of low energy consumption.

Owner:闵连根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com