Remediation method for chromium slag or chromium contaminated soil

A technology of chromium-contaminated soil and remediation method, applied in the restoration of contaminated soil, etc., can solve problems such as limitations, high equipment requirements, and unreasonable economics, and achieve the goals of widely popularizing and using, shortening pyrolysis time, and improving treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

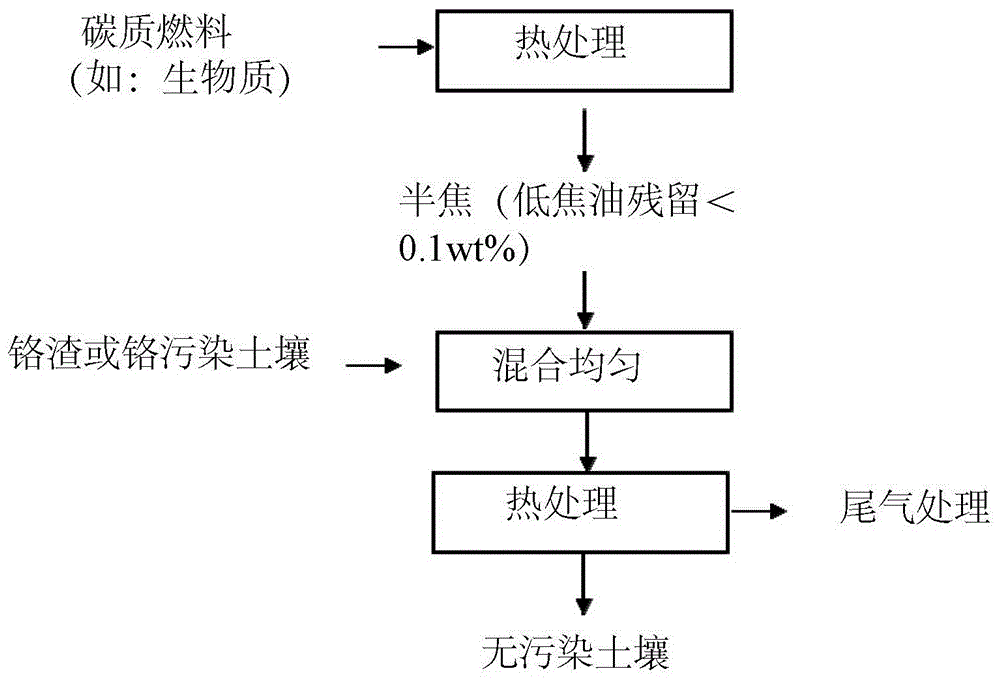

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Raw material (chromium slag polluted soil): the content of hexavalent chromium is 8750mg / kg.

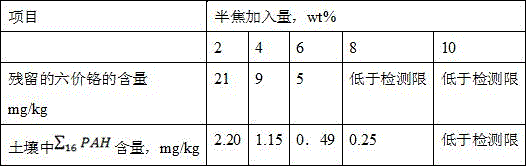

[0031] Mix corn stalk semi-coke with soil polluted by chromium slag evenly (semi-coke accounts for 2-10wt%, based on dry soil), and then put the mixture into a rotary kiln for pyrolysis under a nitrogen atmosphere. The pyrolysis temperature is 600 ° C, angle 2 degrees, rotating speed 2 rev / min, residence time 1 hour, the soil that pyrolysis is completed is cooled to room temperature. The content of hexavalent chromium and the content of participating PAH were analyzed by XANS and EPA method 8015M respectively. The detailed results are shown in Table 1.

[0032] Table 1 Residual hexavalent chromium and quantity

[0033]

[0034] Note: US EPA: 1) Naphthalene; 2) Acenaphthylene; )Acenaphthene; 4) Fluorene; 5) Phenanthrene; 6) Anthracene; anthracene benzo(a) anthracene; 10) Chrysene; 11) Benzo(b)fluoranthene benzo(b) fluoranthene; 12) Benzo(k)fluoranthene benzo(...

Embodiment 2

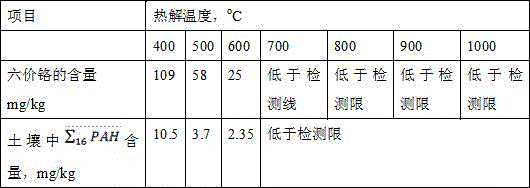

[0036] The experimental raw materials are the same as in Example 1, the addition of semi-coke is 4wt%, pyrolyzed in a fluidized bed under a nitrogen atmosphere, the pyrolysis temperature is 400-1000 ° C, the residence time is 10 minutes, and the pyrolyzed soil is cooled to room temperature. The content of hexavalent chromium and PAHs, the detailed results are shown in Table 2.

[0037] Table 2 Residual hexavalent chromium and quantity

[0038]

Embodiment 3

[0040] The soil obtained by pyrolysis at 700°C in Example 2 was cultivated at 25°C and humidity 100% (maintained with deionized water) without light for 3 months. After cultivating for three months, sieve the coke with a 5mm sieve. The coke obtained by sieving was washed three times with deionized water and air-dried. The change of C-O group was analyzed by XPS; the long-term oxidation stability of semi-coke was oxidized by hydrogen peroxide.

[0041] Hydrogen peroxide oxidation: 0.1g semi-coke is treated with 7ml 5% hydrogen peroxide at 80 degrees for two days.

[0042] The results showed that: C-O-Cr organometallic complexes could be detected, and the relative content of C-O, C=O and COOH decreased from 35.1% to 18.3%. It shows that the addition of semi-coke increases the oxidation resistance and helps to maintain the stability of the reduced chromium in the environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com