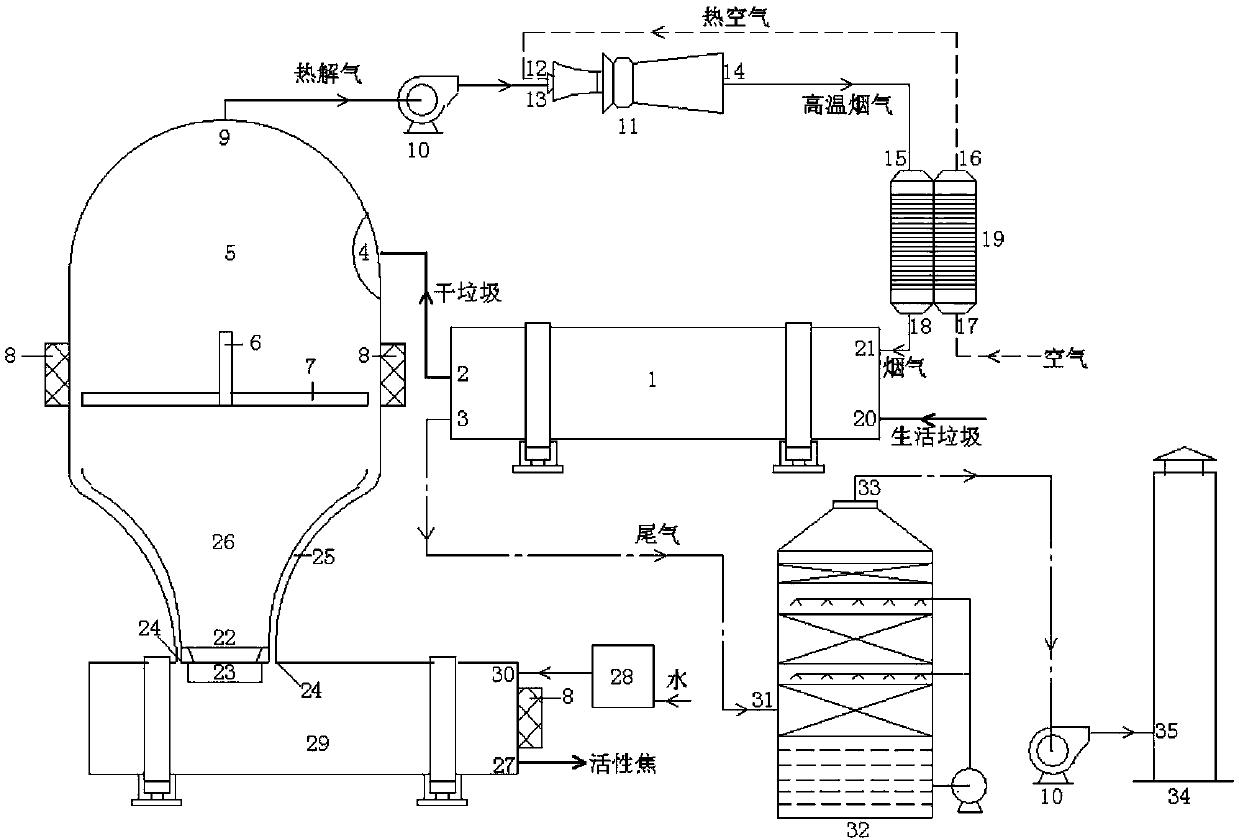

Device and method for preparing activated coke by pyrolysis of domestic waste

A domestic waste and activated coke technology, applied in lighting and heating equipment, chemical instruments and methods, coking ovens, etc., can solve the problems of continuous pyrolysis operation difficulties, high pyrolysis energy consumption, complex components, etc., and achieve Effects of shortening pyrolysis time, reducing pollution sources, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

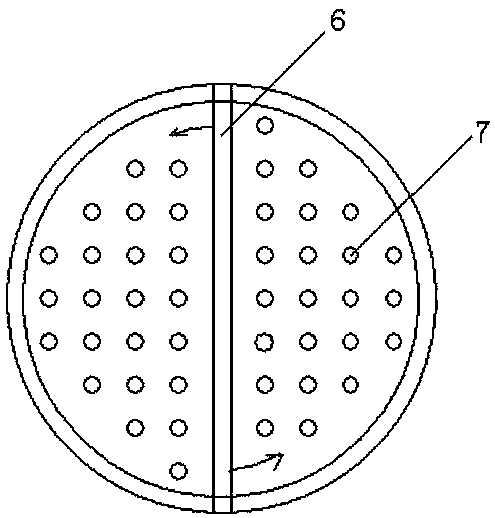

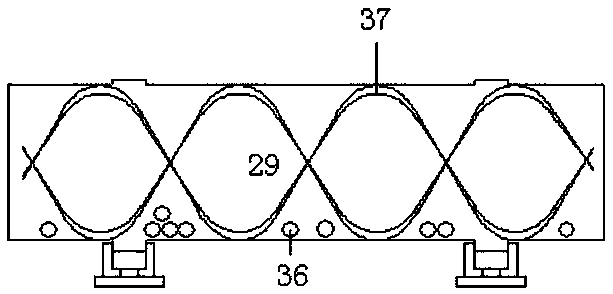

Embodiment 1

[0034] Domestic waste enters the drying rotary kiln. Under the action of flue gas and the rotation of the rotary kiln, the dried domestic waste gradually moves to the discharge port. The slope of the drying rotary kiln is set to 0.02, the speed is set to 5r / min, and the exhaust gas enters the The flue gas purification tower is discharged from the chimney by the induced draft fan after a series of treatments. Dry domestic waste enters the microwave pyrolysis furnace through the feed port. The microwave pyrolysis furnace is equipped with 2 microwave generators, and the power density of the microwave generators is 3×10 5 W / m 3 , Garbage is pyrolyzed under the action of microwave heating, and the temperature is controlled at 300°C. At the same time, under the crushing and disturbance of the stirring plate, the pyrolysis coke with small particle size enters the storage chamber through the sieve plate, and the rotating speed of the stirring plate is set at 5r / min. The pyrolysi...

Embodiment 2

[0036] Domestic waste enters the drying rotary kiln. Under the action of the flue gas and the rotation of the rotary kiln, the dried domestic waste gradually moves to the discharge port. The slope of the drying rotary kiln is set to 0.03, the speed is set to 8r / min, and the exhaust gas enters the The flue gas purification tower is discharged from the chimney by the induced draft fan after a series of treatments. Dry domestic waste enters the microwave pyrolysis furnace through the feed port. The microwave pyrolysis furnace is equipped with 2 microwave generators, and the power density of the microwave generators is 5×10 5 W / m 3 , Garbage is pyrolyzed under the action of microwave heating, and the temperature is controlled at 350°C. At the same time, under the crushing and disturbance of the stirring plate, the pyrolysis coke with small particle size enters the storage chamber through the sieve plate, and the rotating speed of the stirring plate is set at 7r / min. The pyro...

Embodiment 3

[0038] Domestic waste enters the drying rotary kiln. Under the action of the flue gas and the rotation of the rotary kiln, the dried domestic waste gradually moves to the discharge port. The slope of the drying rotary kiln is set to 0.03, the speed is set to 8r / min, and the exhaust gas enters the The flue gas purification tower is discharged from the chimney by the induced draft fan after a series of treatments. Dry domestic waste enters the microwave pyrolysis furnace through the feed port. The microwave pyrolysis furnace is equipped with 2 microwave generators, and the power density of the microwave generators is 5×10 5 W / m 3 , Garbage is pyrolyzed under the action of microwave heating, and the temperature is controlled at 350°C. At the same time, under the crushing and disturbance of the stirring plate, the pyrolysis coke with small particle size enters the storage chamber through the sieve plate, and the rotating speed of the stirring plate is set at 7r / min. The pyro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com