Patents

Literature

53results about How to "Avoid reloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

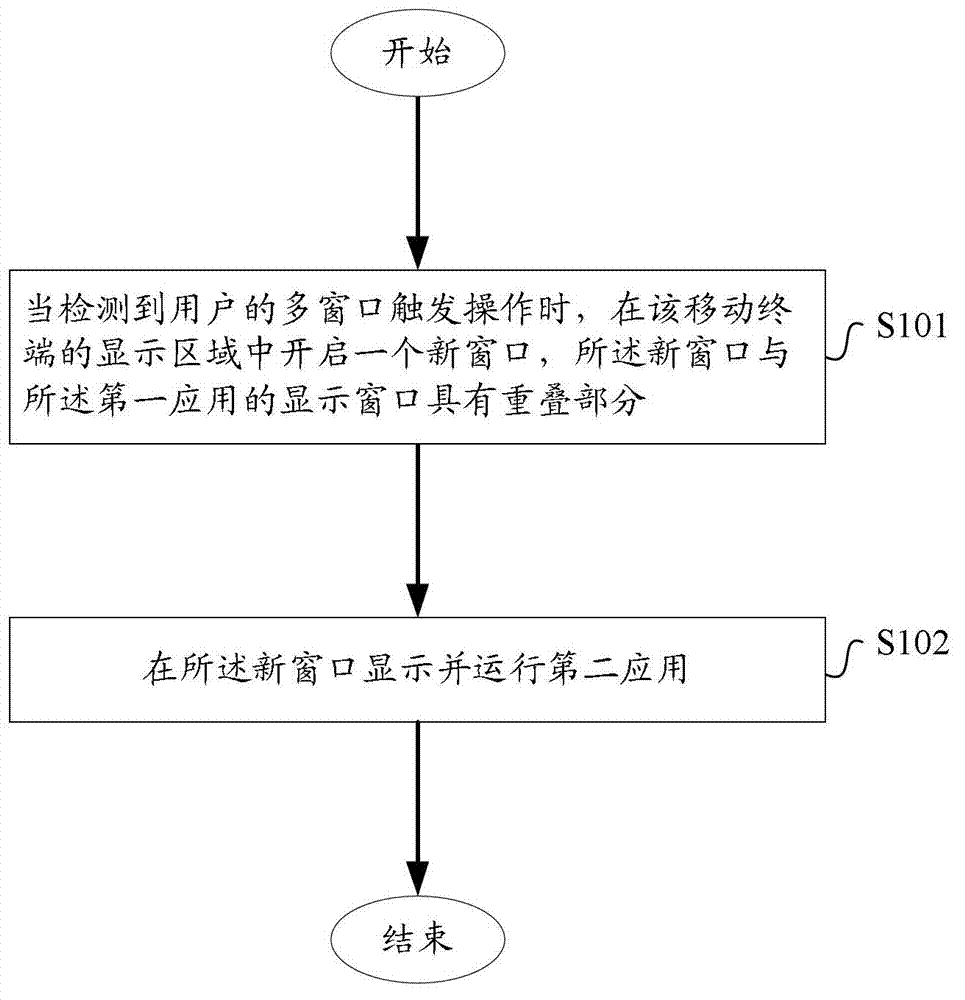

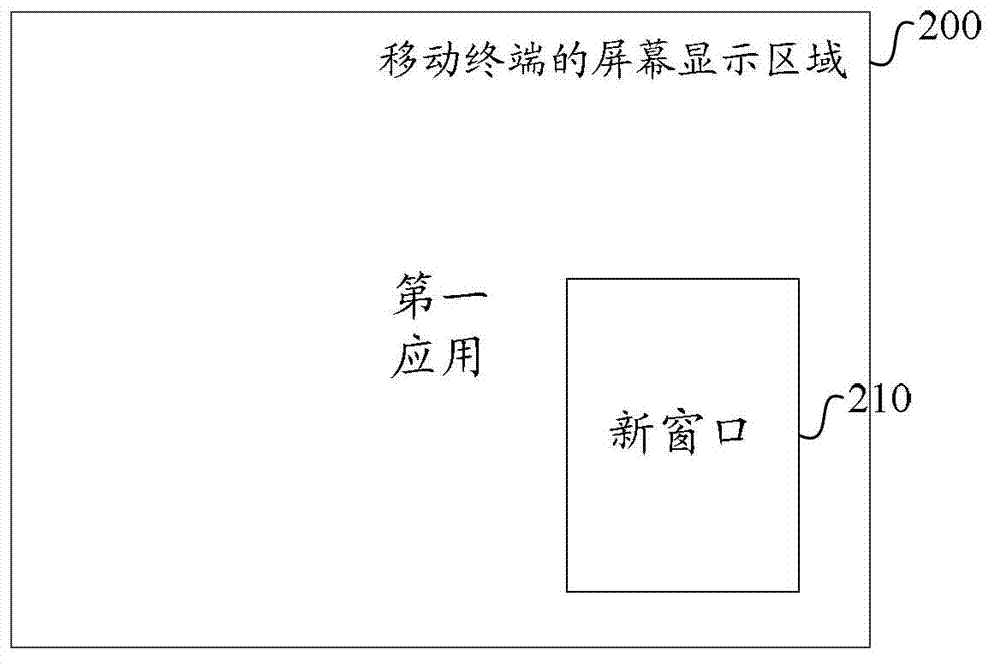

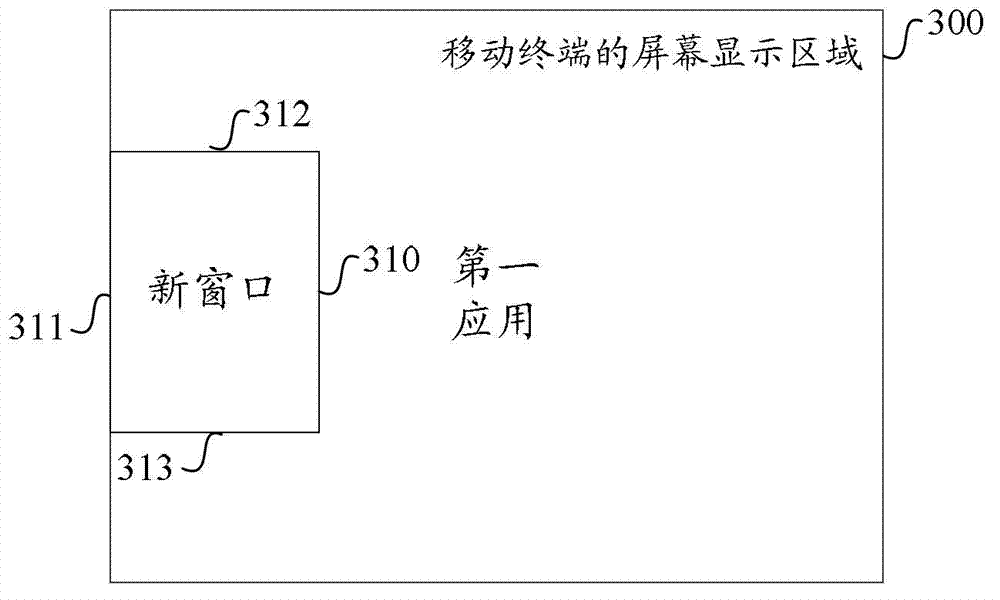

Method, device and equipment for displaying multiple application windows on mobile terminal

InactiveCN102968243AImprove information acquisition efficiency and ease of operationImprove user experienceInput/output processes for data processingMultiple applicationsComputer engineering

Owner:SHENZHEN YUNYINGGU TECH CO LTD

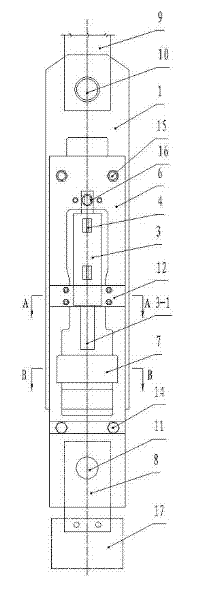

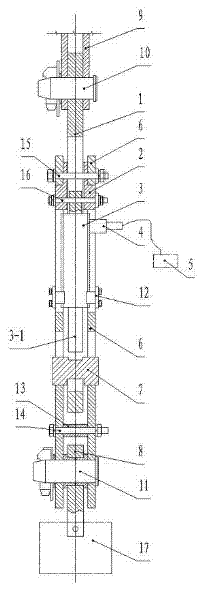

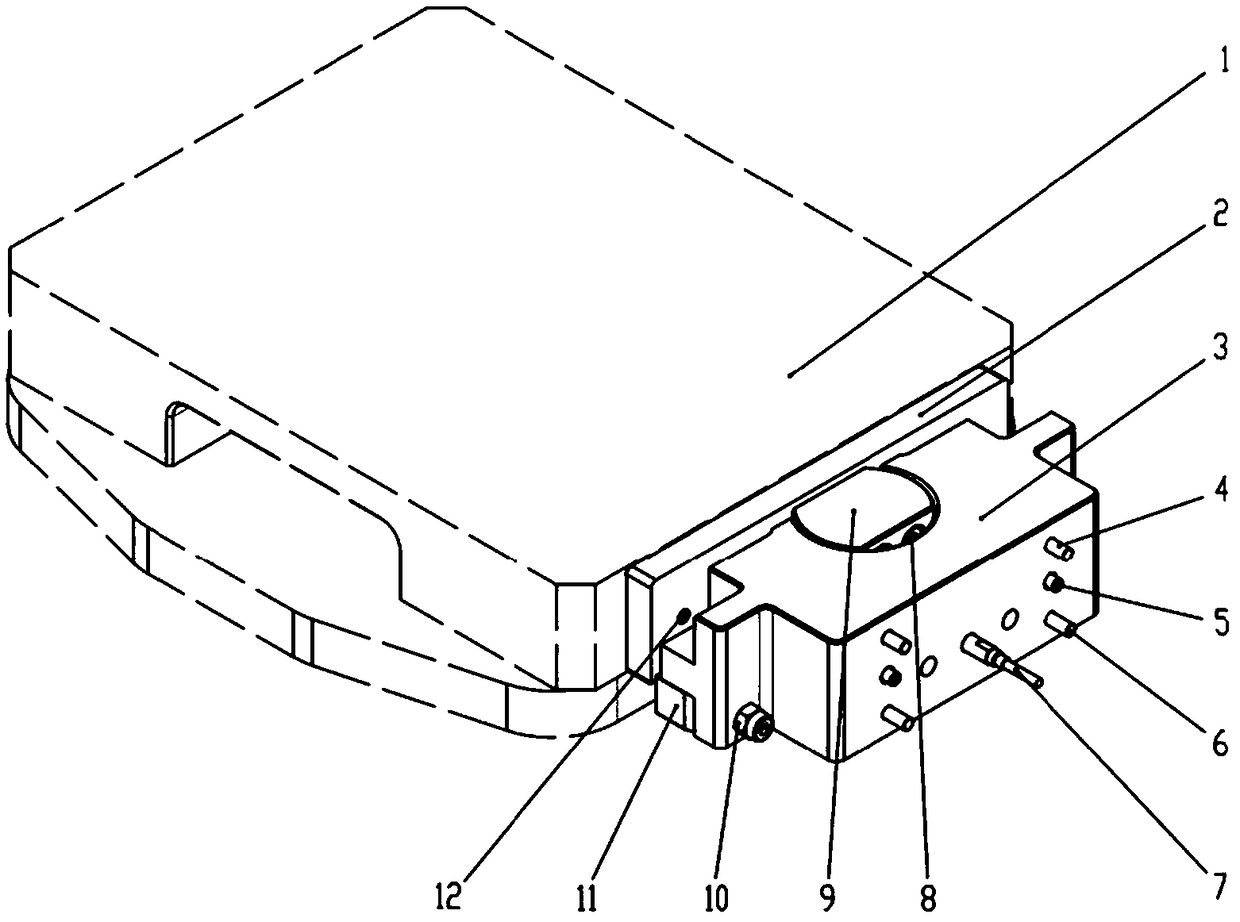

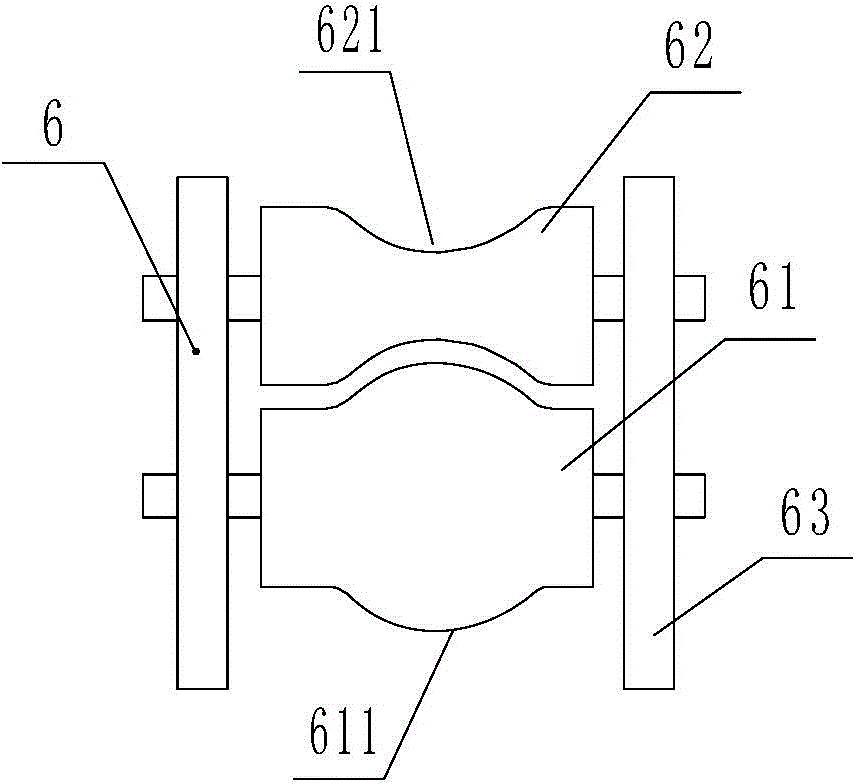

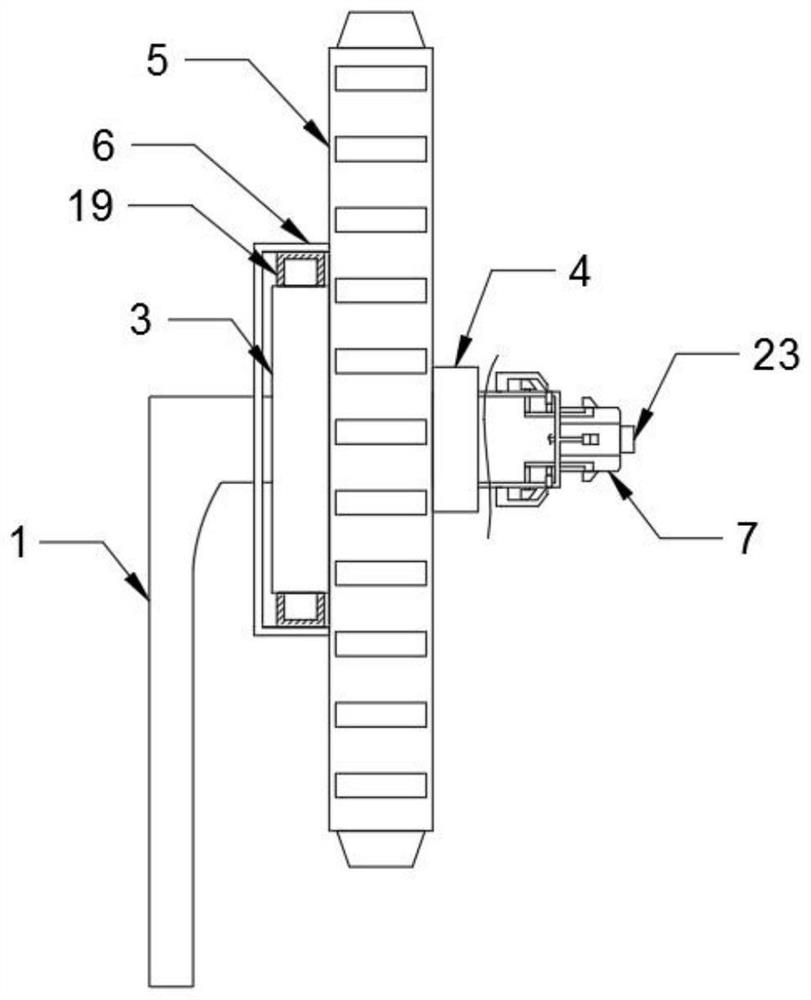

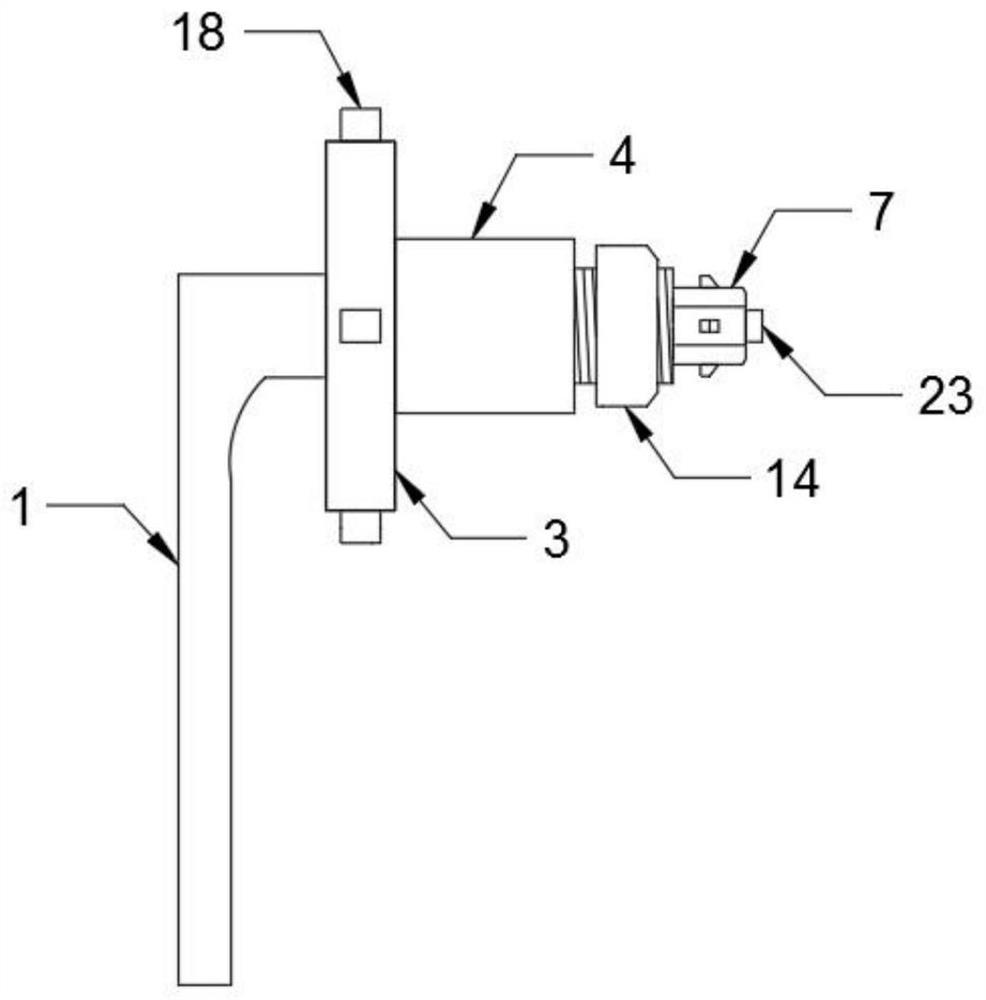

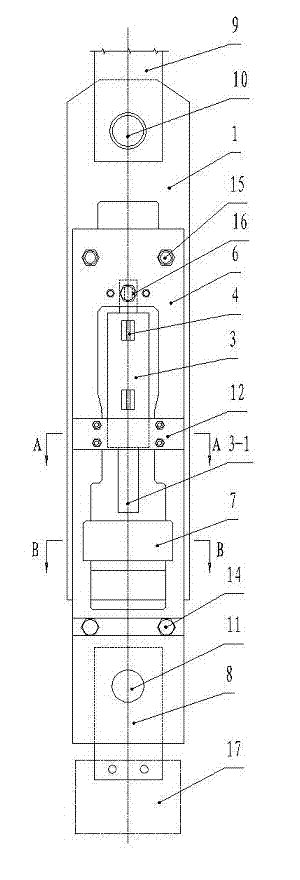

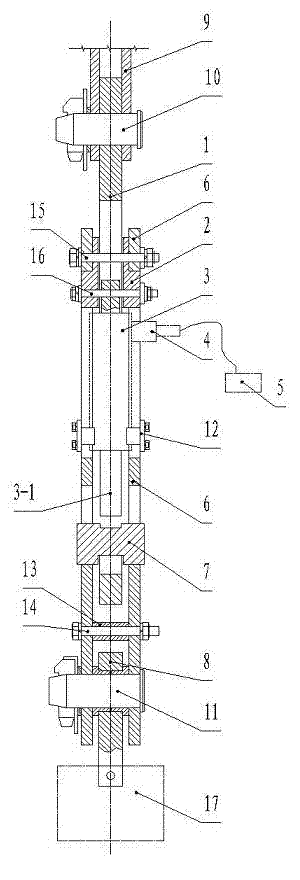

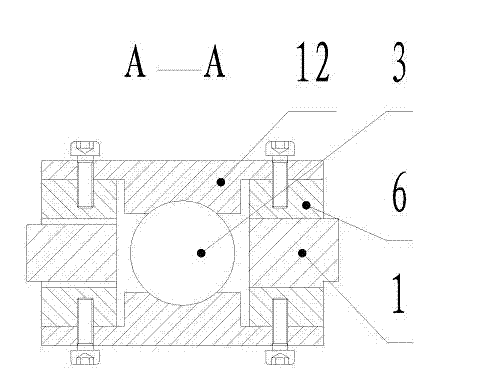

Sensing device for carrying out real-time monitoring on load bearing of single-rope winding hoisting system

InactiveCN102173359AGuaranteed automationJudging the jamming problemTension measurementElevatorsComputer moduleFuel tank

The invention discloses a sensing device for carrying out real-time monitoring on load bearing of a single-rope winding hoisting system, belonging to mining equipment.The device comprises a rack, an upper pull rod, a detection fuel tank, an upper bearing block, a lower bearing block, a pressure transmitter and a wireless transmitting module.The rack consists of two connected lateral plates, the upper bearing block is arranged at the upper ends of the two lateral plates, the lower ends of the lateral plates are connected with a lower connector which is connected with a container.The upper pullrod is neither connected with the lateral plates nor connected with the upper bearing block, the upper pull rod is connected with the upper connector, and the upper connector is connected with a hoisting steel wire rope. The detection fuel tank is connected with the upper bearing block, a piston rod is adjacent to the lower bearing block, the lower bearing block is plugged in long holes of the lateral plates in a sliding-fit manner, the pressure transmitter is arranged at the port of the detection fuel tank and connected with the wireless transmitting module. When loading is carried out on the container, the signals detected by the pressure transmitter are loaded weight signals; in the process of normal operation of the container, the signals detected by the pressure transmitter are loading signals from a steel wire rope terminal.

Owner:徐州泰荣煤矿设备有限公司 +1

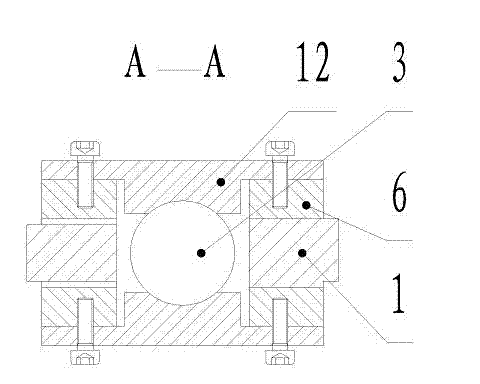

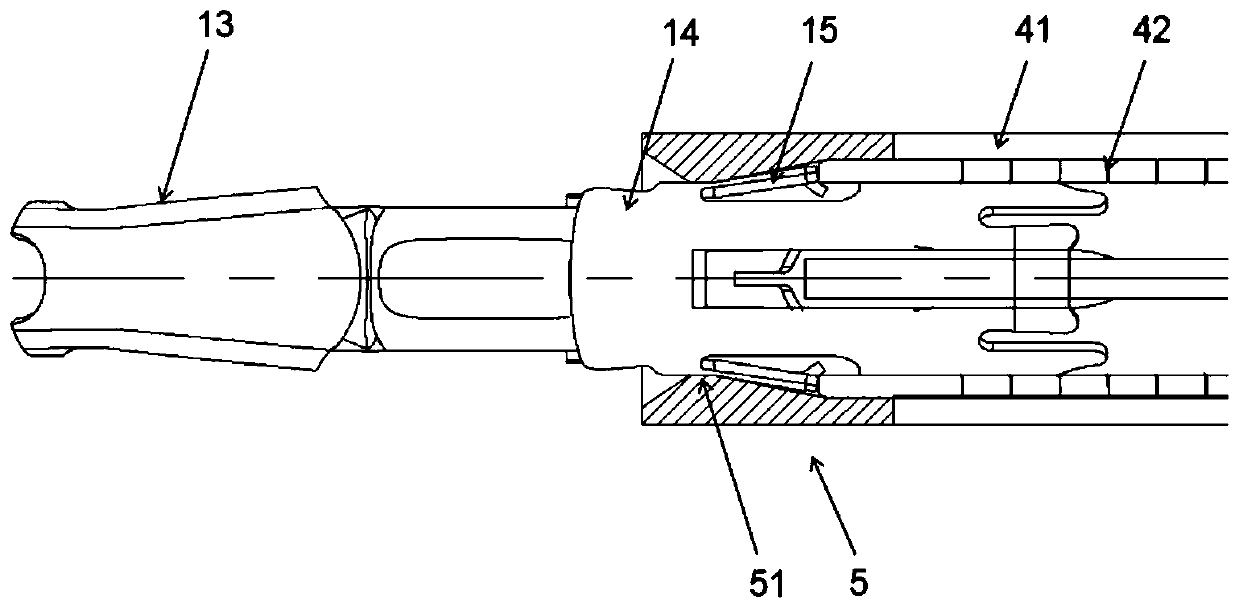

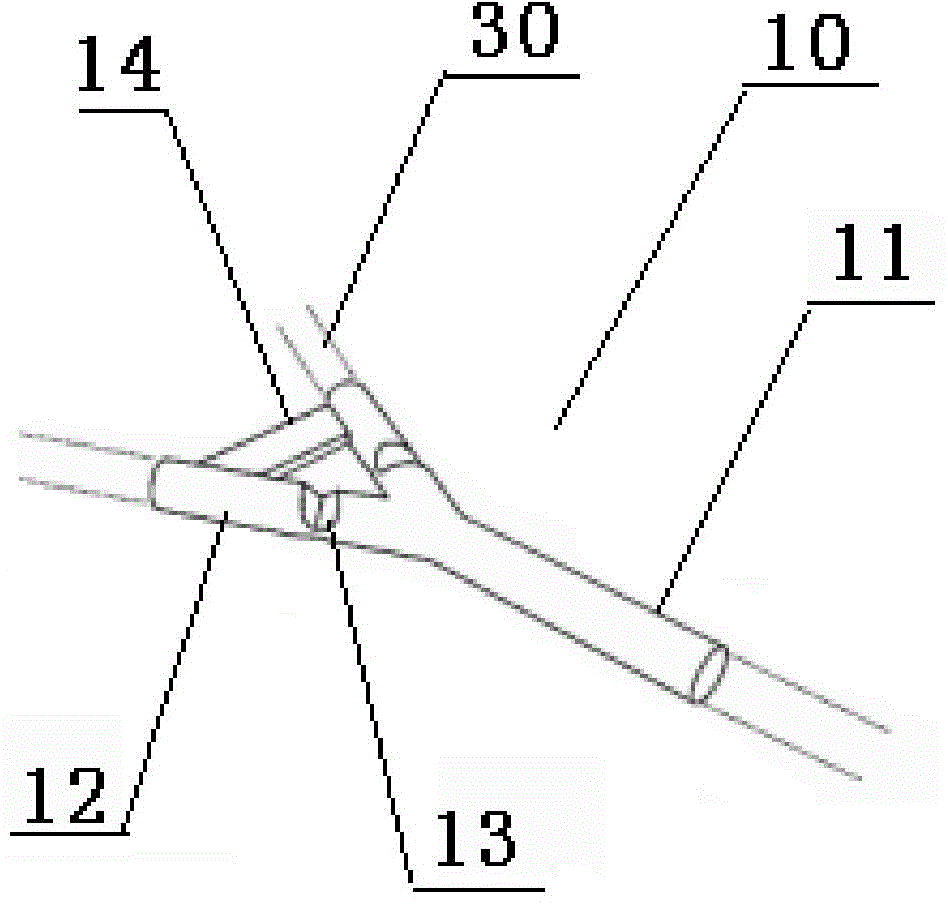

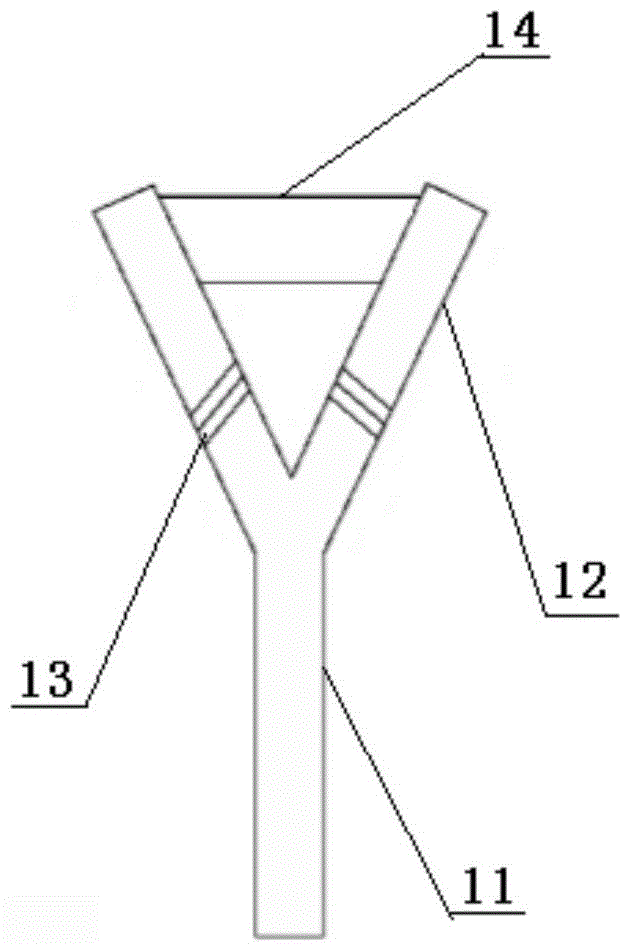

Medical hemostatic clip

PendingCN110613495AThe release process is stable and reliableSimple and reasonable structureWound clampsHemostaticsBiomedical engineering

A medical hemostatic clip includes at least the following structures: a clip component, a control line, a handle and a sheath pipe; the clip component is connected in series through the control line in the axial direction, and the control line is moved to control opening or closing of a clip located at the most far end; the handle is used to control the control line to move forward and backward; and the far end of the sheath pipe has a limiting component, the near end side of the limiting component has a limiting space facing the axial direction of the sheath pipe, and at least a part of the clip located at the most far end is releasably limited in the limiting space by the limiting component. The medical hemostatic clip has the technical effects of repeatable opening and closing, rotationand the like.

Owner:MICRO TECH (NANJING) CO LTD

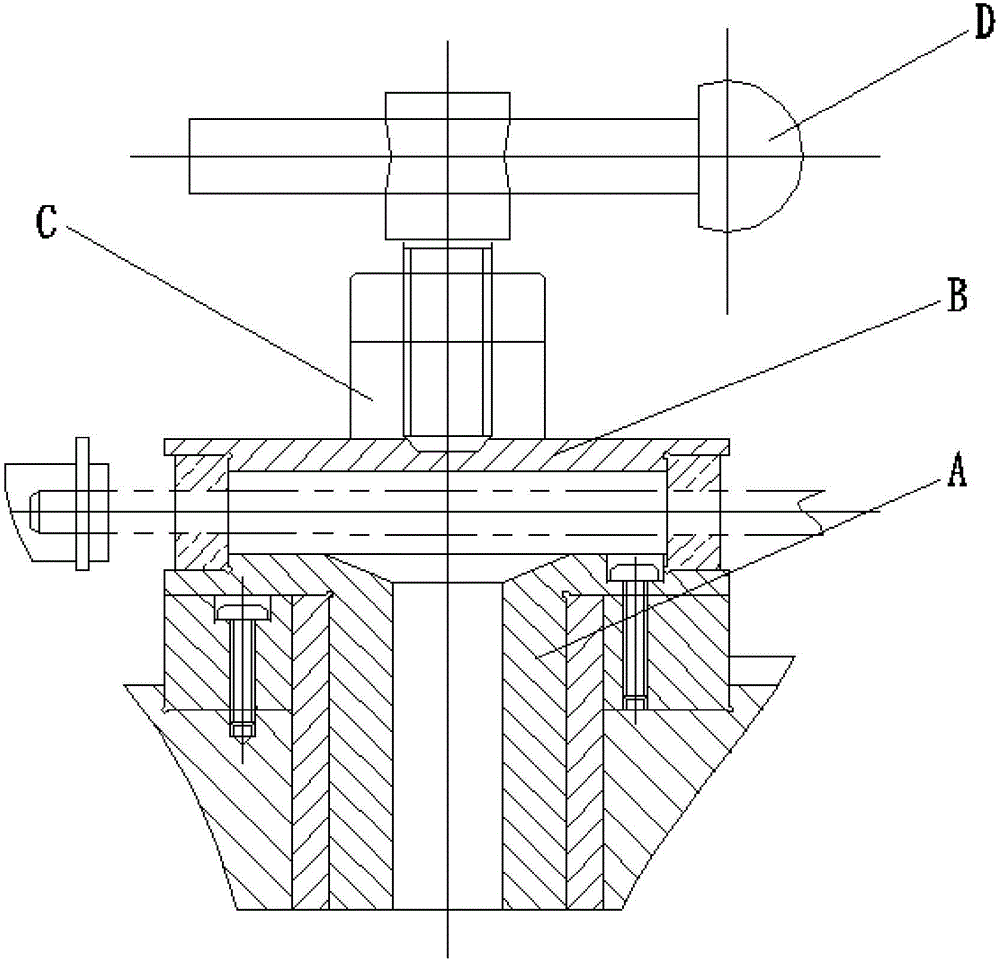

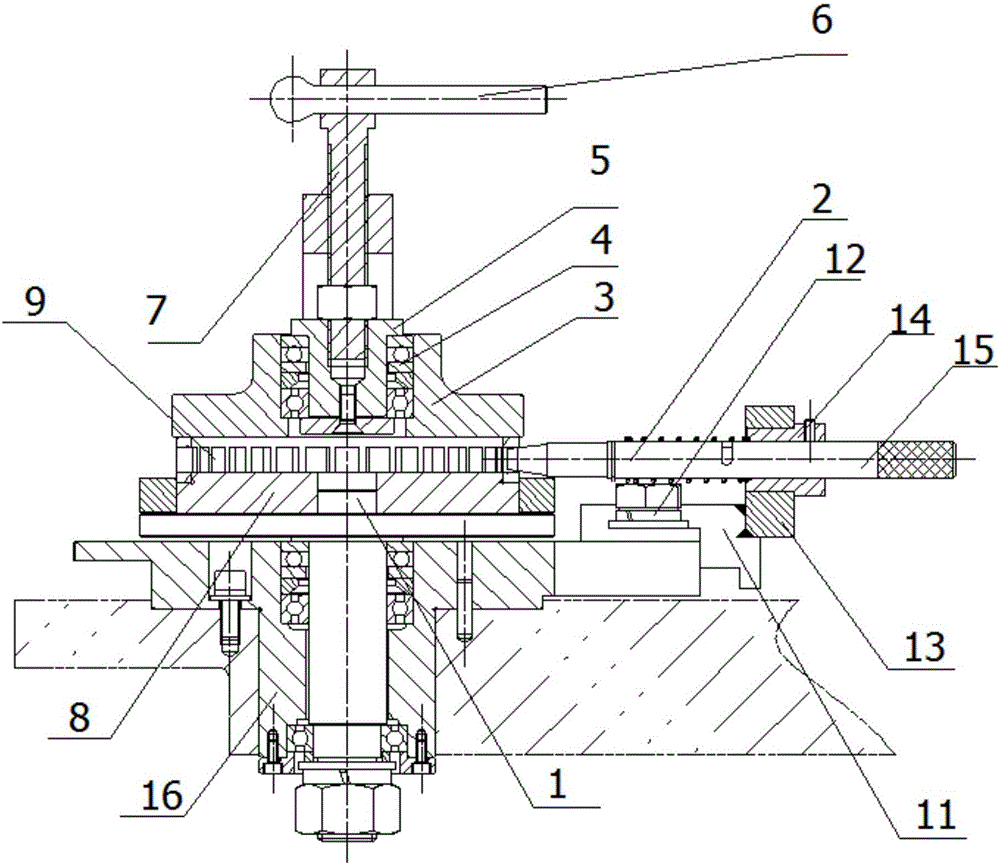

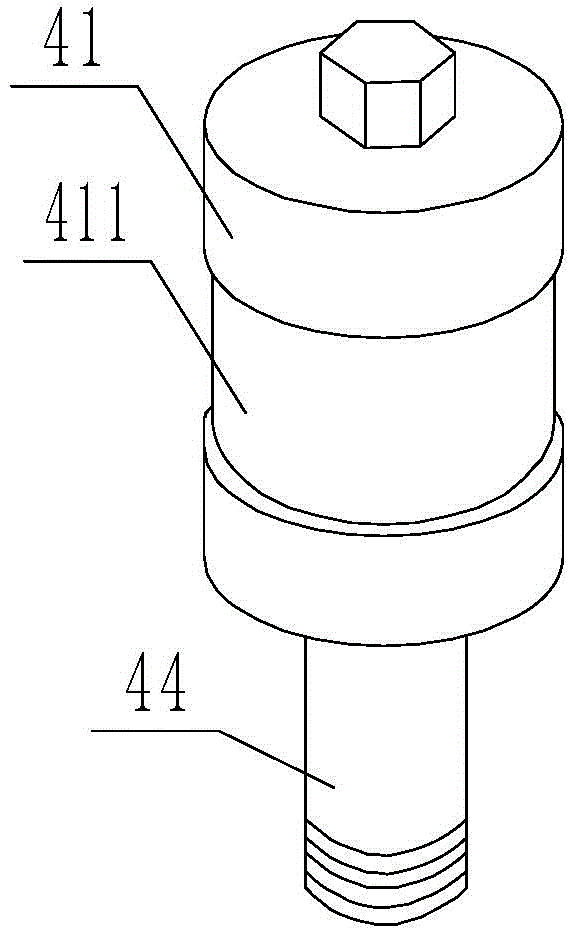

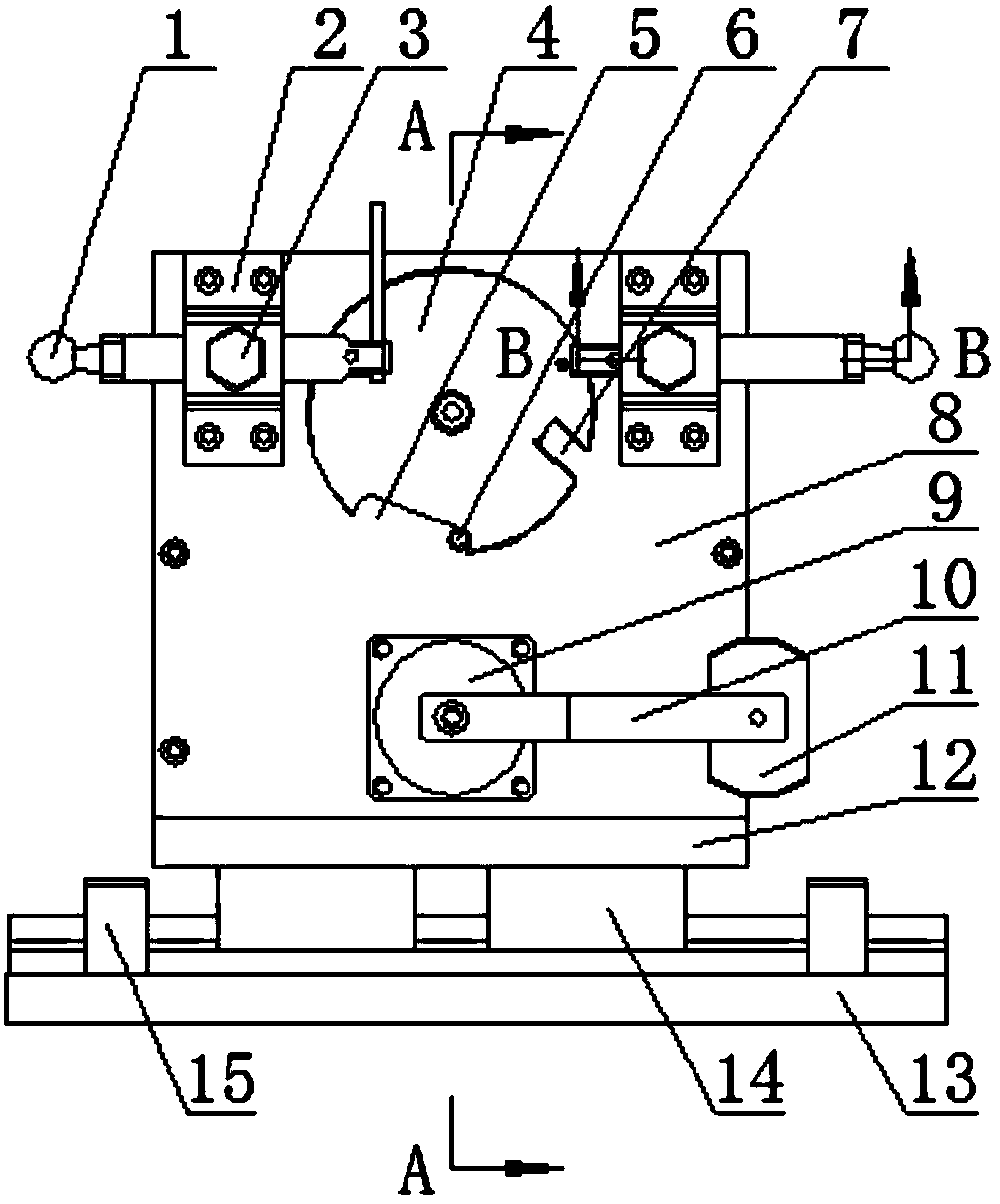

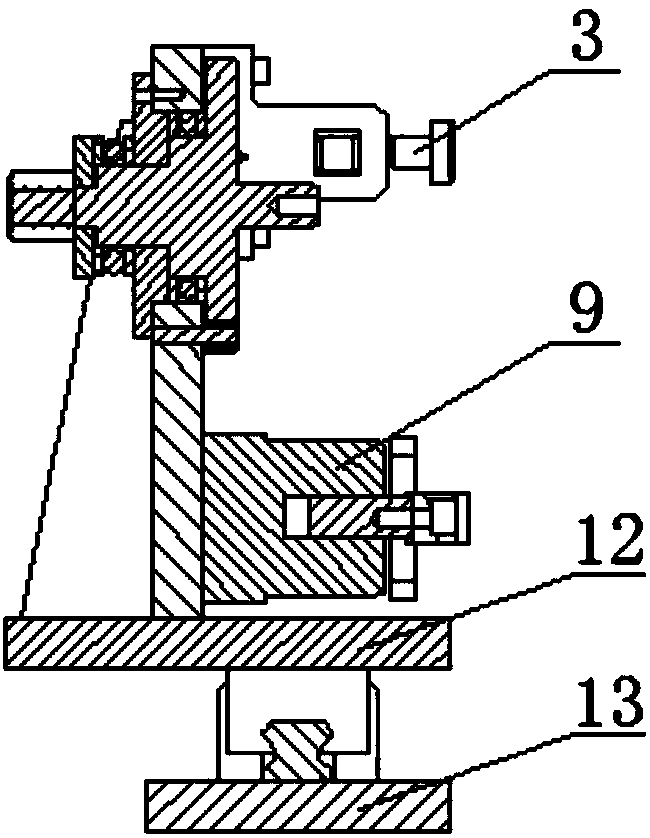

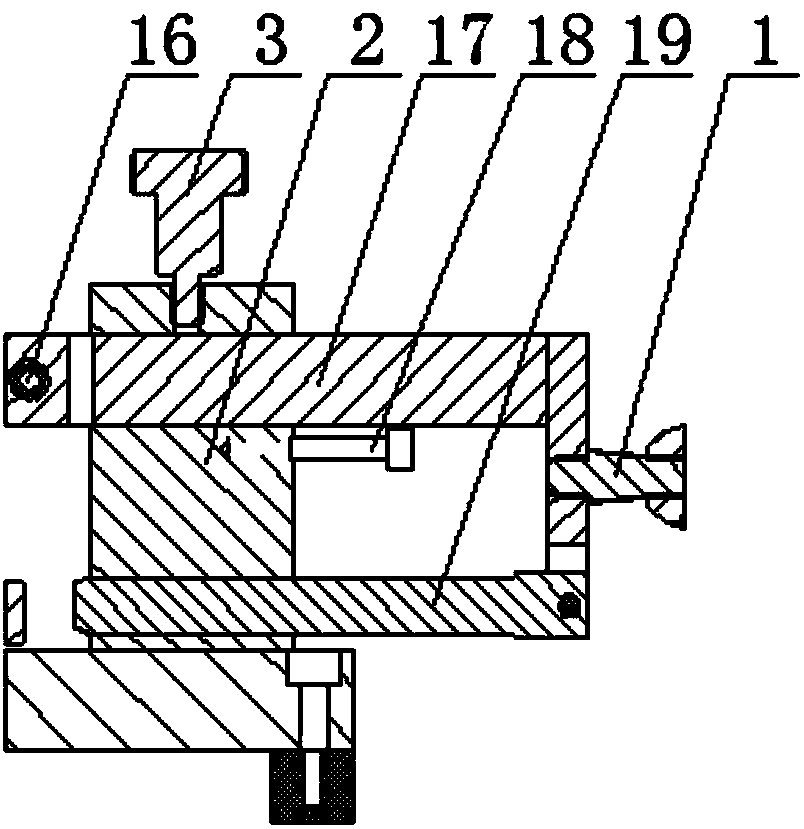

Tool for pocket hole of short cylindrical roller bearing retainer and pocket hole method thereof

The invention provides a tool for a pocket hole of a short cylindrical roller bearing retainer and a pocket hole method of the tool, relates to a tool for the pocket hole and the pocket hole method of the tool, and aims to solve the problem that due to the inconsistency between the axial position degree and the circumferential position degree of the pocket hole, the processing quality of the retainer is affected. According to the tool, a locating shaft is installed on a workbench in a rotatable mode, a locating rotating shaft is installed in a center hole formed in the locating shaft in a sleeved mode, and the retainer is installed on the locating shaft; a cover plate is installed on the retainer in a press mode, a stepped hole is formed in the middle of the cover plate, and a press block is installed in the stepped hole of the cover plate in a rotatable mode; and a press rod is vertically screwed into the press block, a screwing rod is horizontally arranged at the upper end of the press rod in a penetrating mode, and a locating pin is detachably inserted into the pocket hole of the retainer. The method comprises the steps that the tool for the pocket hole of the retainer is installed; the retainer is fixed; the position of the pocket hole to be broached is determined; the work of preparation before broaching is conducted; after a broaching machine is started, broaching of the pocket hole is accomplished; and broaching is conducted repeatedly until broaching of the pocket hole of the retainer is accomplished. The tool for the pocket hole and the pocket hole method of the tool are used for production of the bearing retainer.

Owner:AVIC HARBIN BEARING

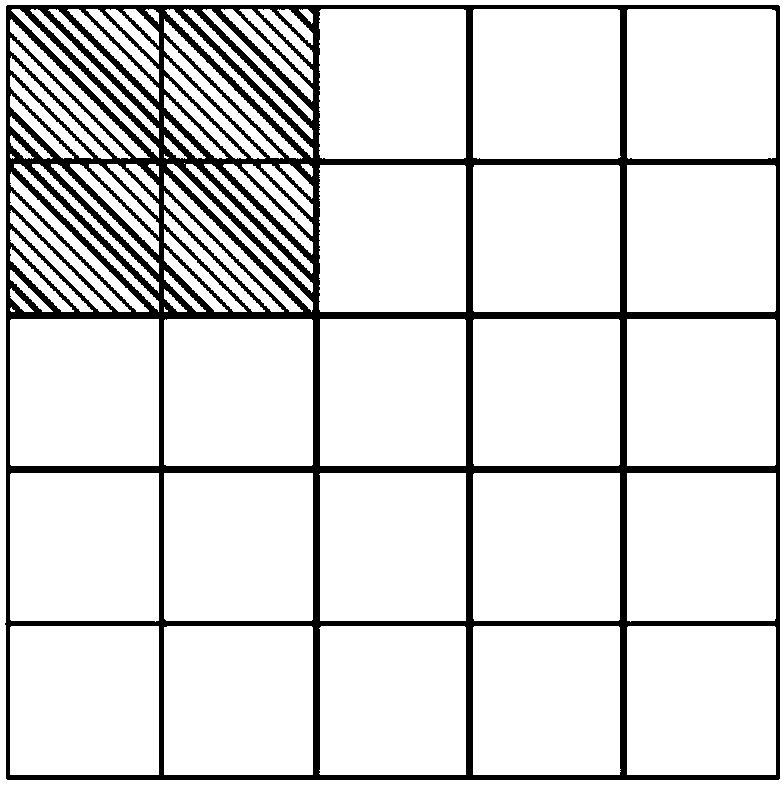

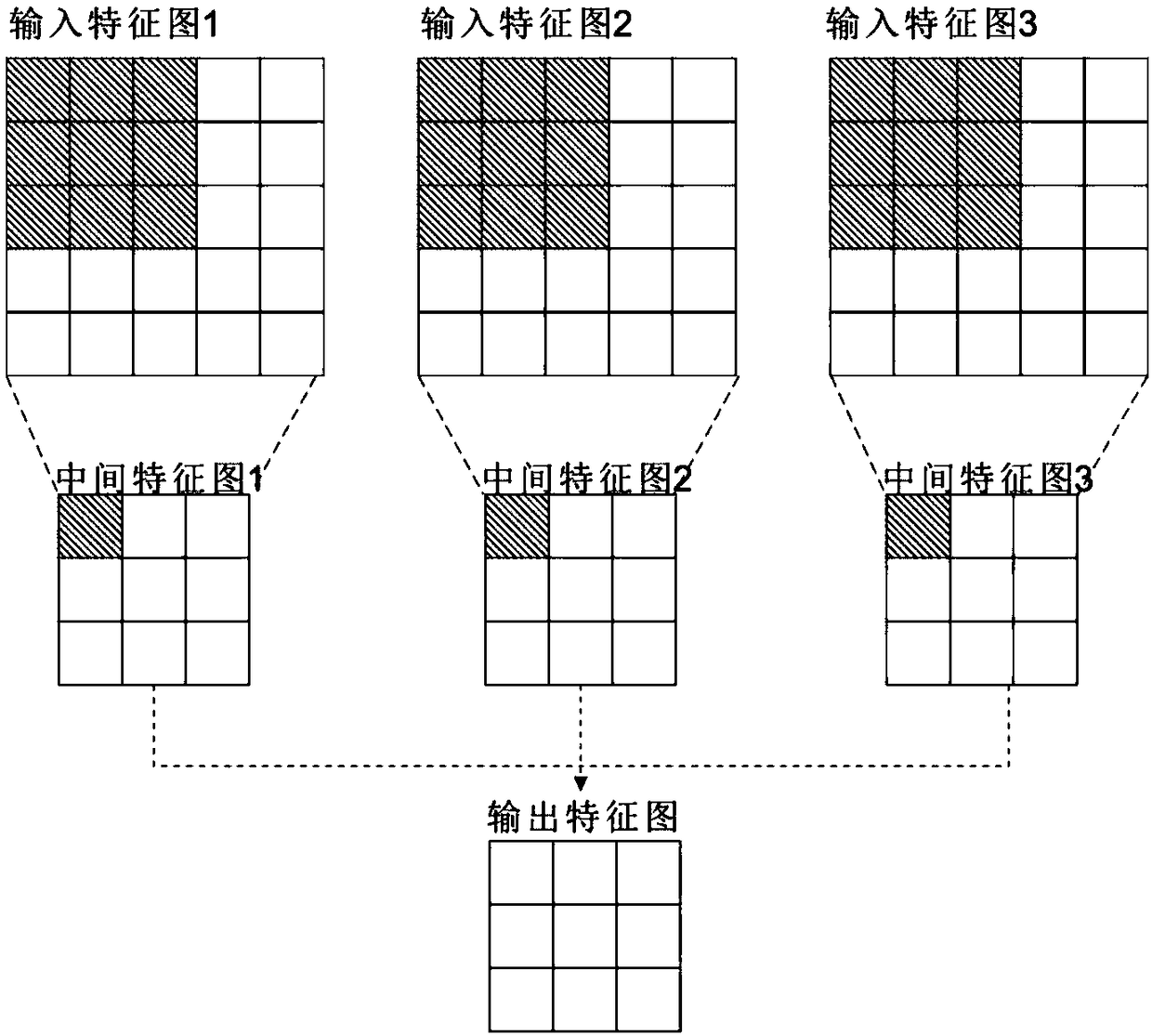

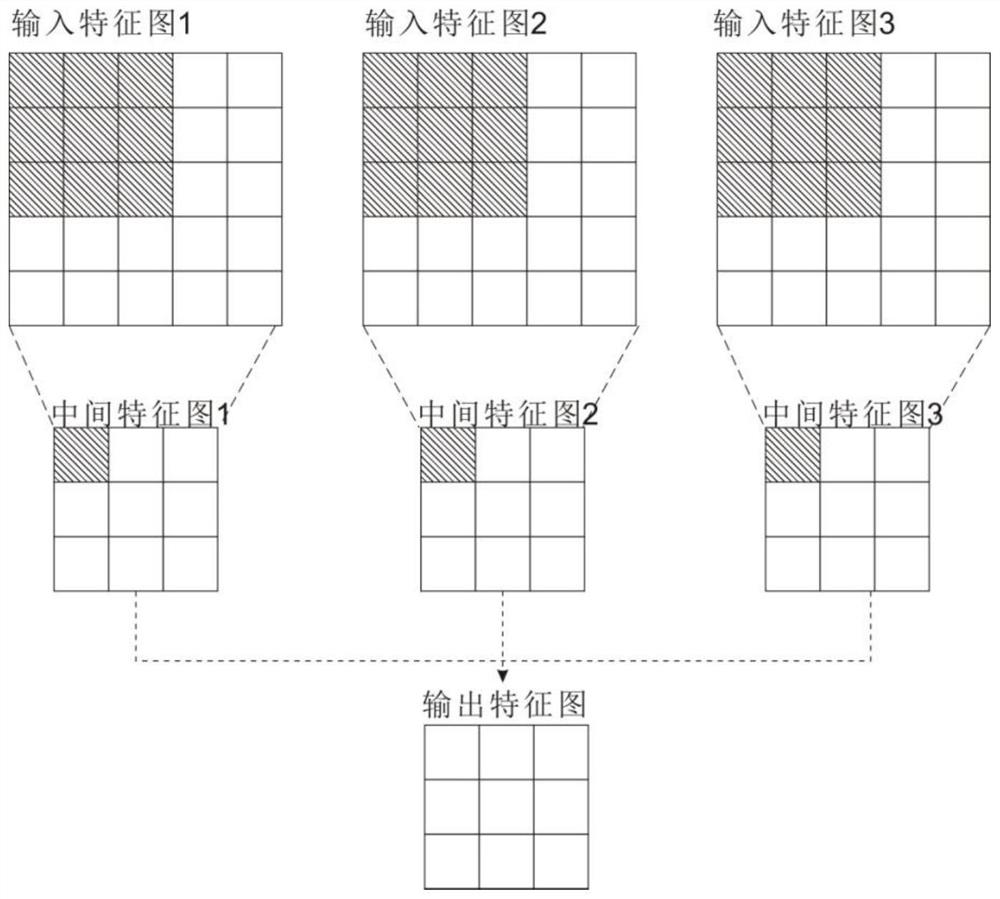

Programmable depth neural network processor

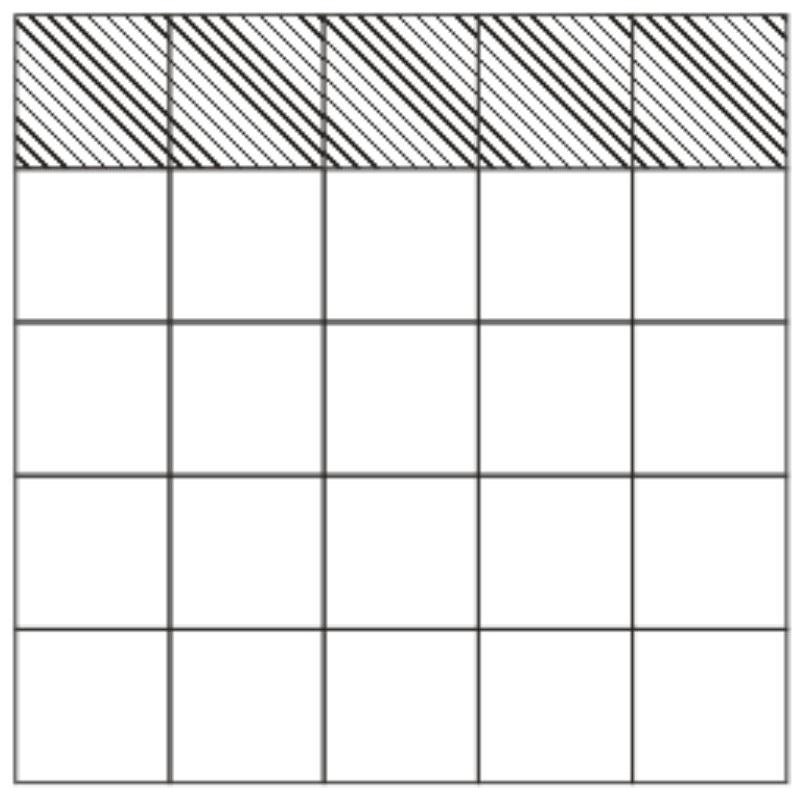

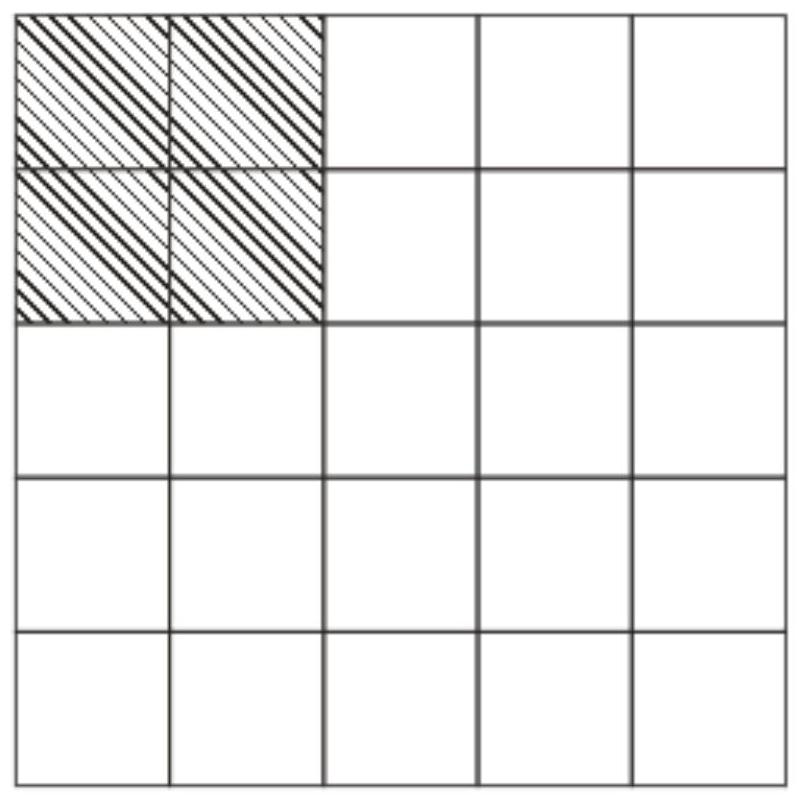

ActiveCN108520297AIncrease profitUtilization impactNeural architecturesPhysical realisationMultiplexingFilter cache

The invention discloses a programmable depth neural network processor, which comprises a program control unit, a filter cache area and a characteristic graph cache area, wherein the characteristic graph cache area is used for caching a plurality of characteristic graphs, and the filter cache area is used for caching weight data matched with the characteristic graph. The programmable depth neural network processor further comprises a layer processing engine, wherein the convolution unit part of the layer processing engine comprises a multiply accumulation unit, a convolution accumulation unit and a characteristic graph accumulation unit, which are arranged in order. The characteristic graph cache area and the filter cache area are connected with the input end of the layer processing engine,and a data shaping and multiplexing unit is further arranged between the characteristic graph buffer area and the input end of the layer processing engine. According to the invention, the multiplex control of the multiply accumulation unit, the characteristic graph data reading control and the characteristic graph accumulation control are carried out, and redundant data removal control is achieved, so that the programmable depth neural network processor with low power consumption and low cost is achieved.

Owner:周军

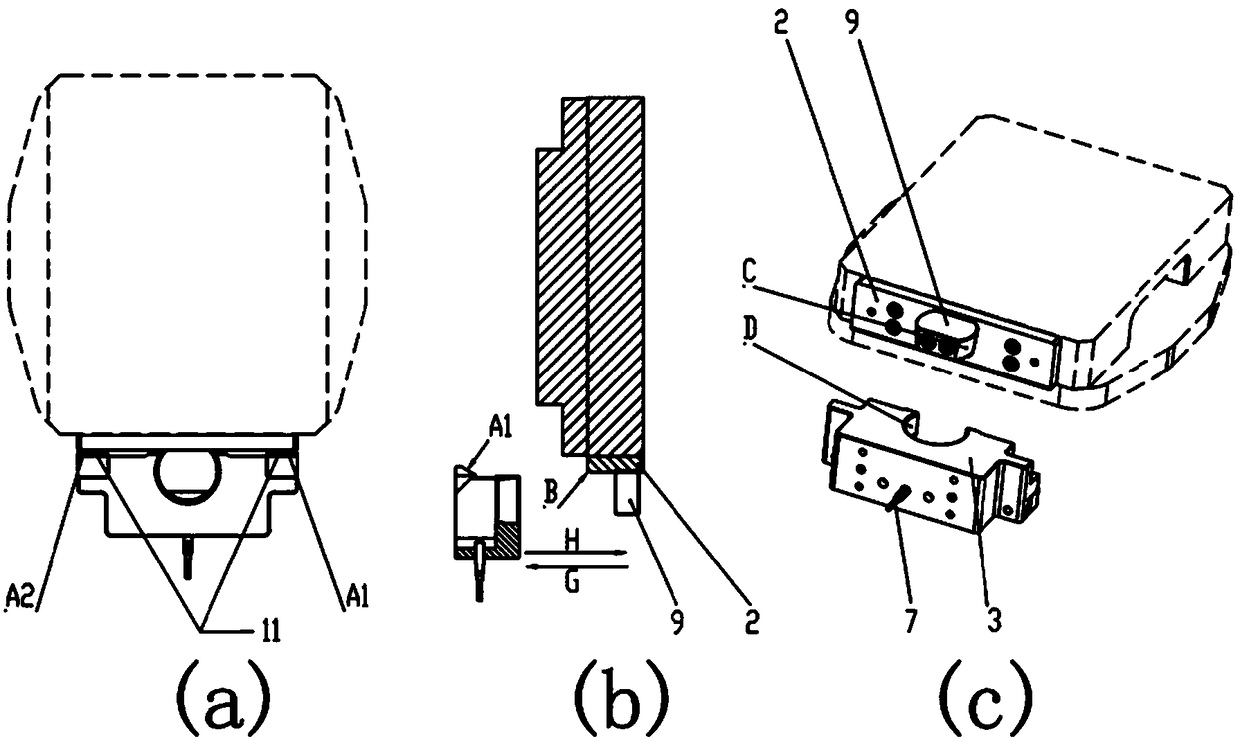

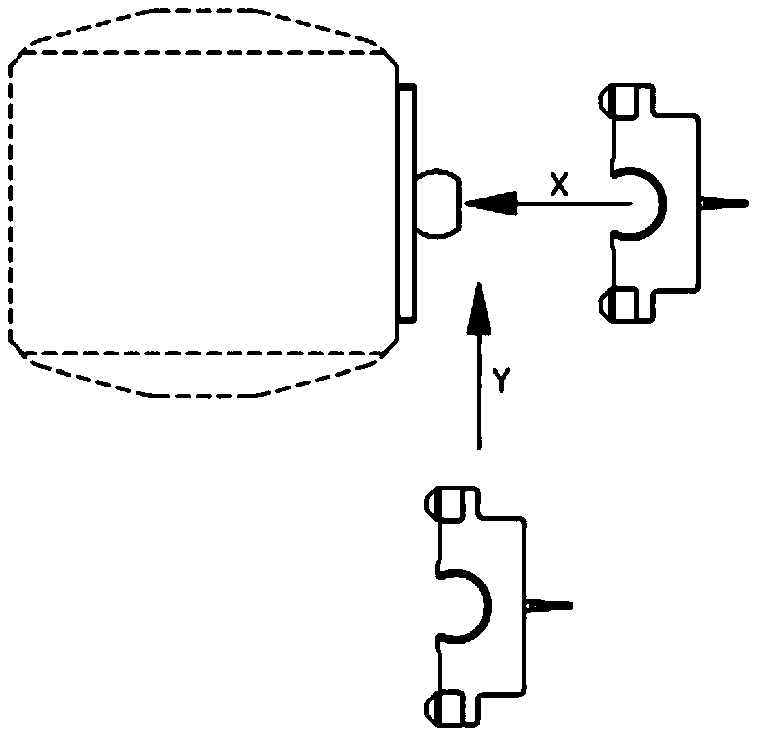

Grabbing mechanism without driving source and grabbing method

The invention provides a grabbing mechanism without a driving source and a grabbing method. A workpiece is locked by self-locking based on self gravity and friction force, and therefore energy consumption is avoided. The mechanism comprises a hooking claw grabbing block assembly and a hooking claw seat assembly; the hooking claw grabbing block assembly comprises a hooking claw grabbing block and amounting plate which is longitudinally arranged, and the hooking claw grabbing block is fixed on one side of the mounting plate; the side surface of the hooking claw grabbing block comprises an arc conical surface C used for being grabbed, an axis of the arc conical surface C is arranged in the longitudinal direction, and the conical bottom is downward; the hooking claw seat assembly comprises ahooking claw seat and two hooking claw positioning blocks; a hooking claw groove matched with the hooking claw grabbing block is formed in the upper surface of the hooking claw seat, and the hooking claw groove is provided with an arc conical surface D matched with the arc conical surface C; an opening is formed in one side surface of the hooking claw groove so as to enable the hooking claw grabbing block to enter the hooking claw groove when the hooking claw groove moves upwards; and the two hooking claw positioning blocks are mounted on the two sides of the hooking claw seat, and the hookingclaw positioning blocks position the mounting plate in a contact mode during grabbing.

Owner:西安精雕软件科技有限公司

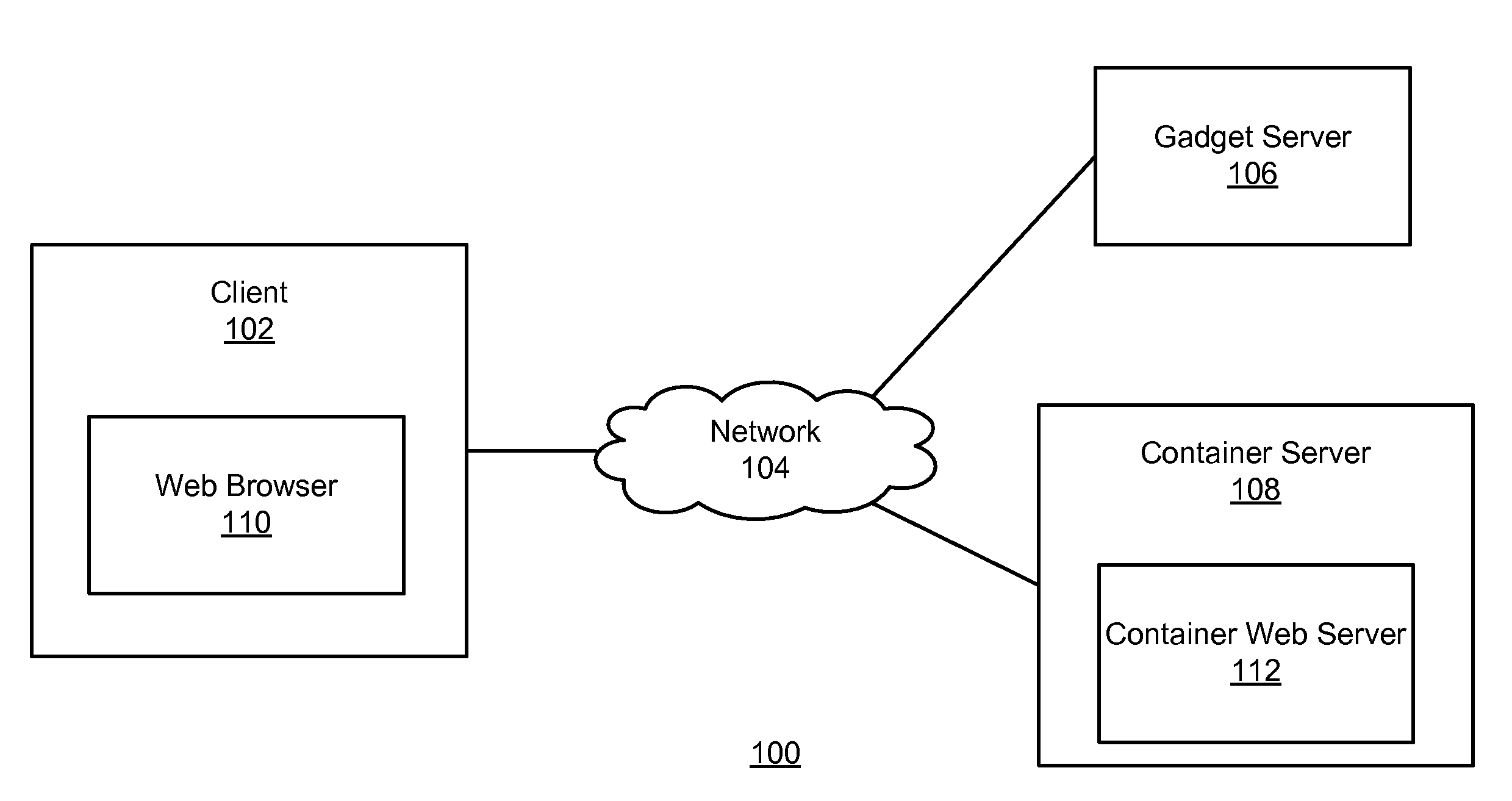

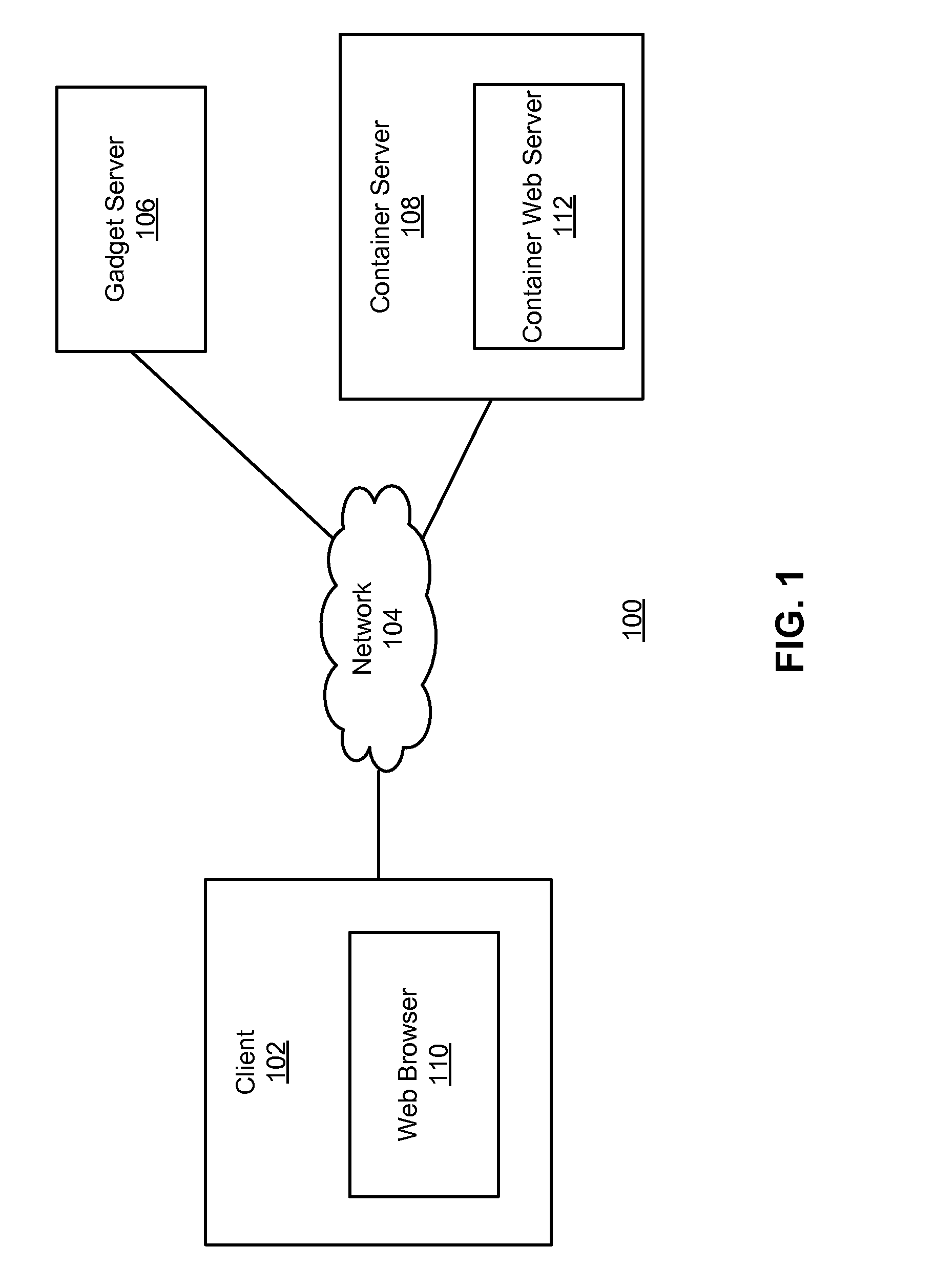

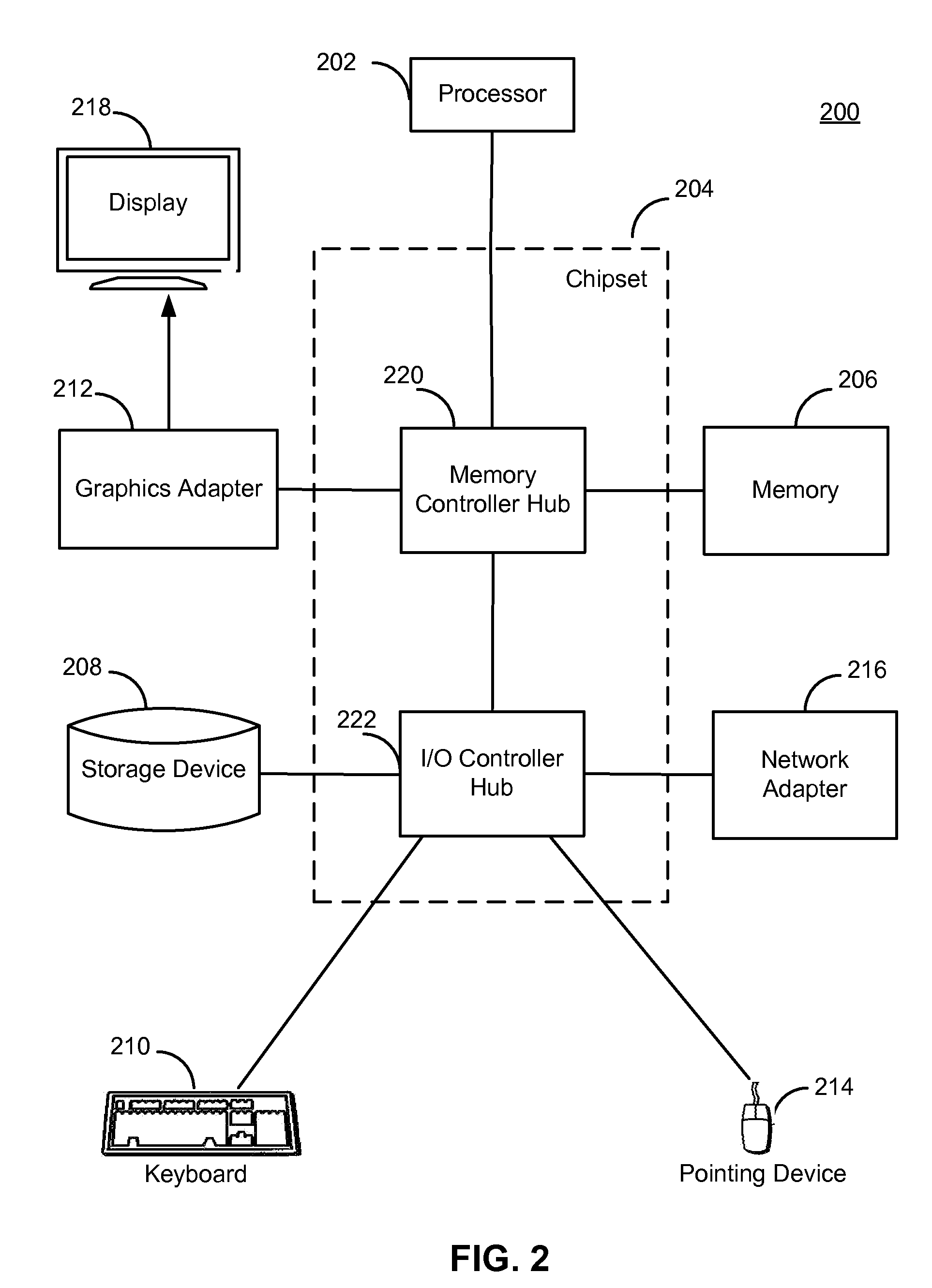

Gadget container verification

ActiveUS8266695B1Avoid reloadingMemory loss protectionDigital data processing detailsWeb browserWeb page

A system, method, and computer program product verifies web page containers of software gadgets. A request for a software gadget is received by a gadget server from a web browser at a client. The request includes a container web page parameter that identifies a web page. The gadget server determines whether the identified web page is an acceptable web page for containing the requested software gadget. If it is determined to be acceptable, the requested software gadget is prepared by inserting container verification code into the gadget. When the prepared software gadget is provided to the client, the container verification code executes and ensures that the requested software gadget is contained within the identified web page. The container verification code may include code for setting a container web page of the prepared software gadget to be the identified web page and for preventing unnecessary page reloads.

Owner:GOOGLE LLC

One-step molding process of roller bar stock on lathe

The invention discloses a one-step molding process of a roller bar stock on a lathe. The process comprises the following steps of: leveling a right end surface by adopting an end surface cutter; after the end surface is leveled to an appointed size, digging a hole on the right side of a roller; cutting off by using a cut-off tool, and meanwhile, synchronously profiling the left chamfer from the outer diameter of the right chamfer; and after finishing slotting by a slotting tool which is a flat cutter and a 5-degree chamfering cutter, assisting a clamping head to clamp and twist off a roller. By adopting the method, the turning processing of all surfaces of the roller can be finished in one-step clamping, the processed roller is molded at one time and can be directly sent to a grinding procedure after being subjected to heat treatment. The one-step molding process of a roller bar stock on a lathe can be used for realizing the one-step turning and molding of the processed roller, saves the material handling time, combines the procedures, saves the labor power, avoids secondary clamping of the processed roller, improves the processing precision, improves the processing efficiency and saves the total processing time. After the process is applied to lathes, an operator can simultaneously operate 3-4 lathes, thus a large quantity of labor power is saved.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

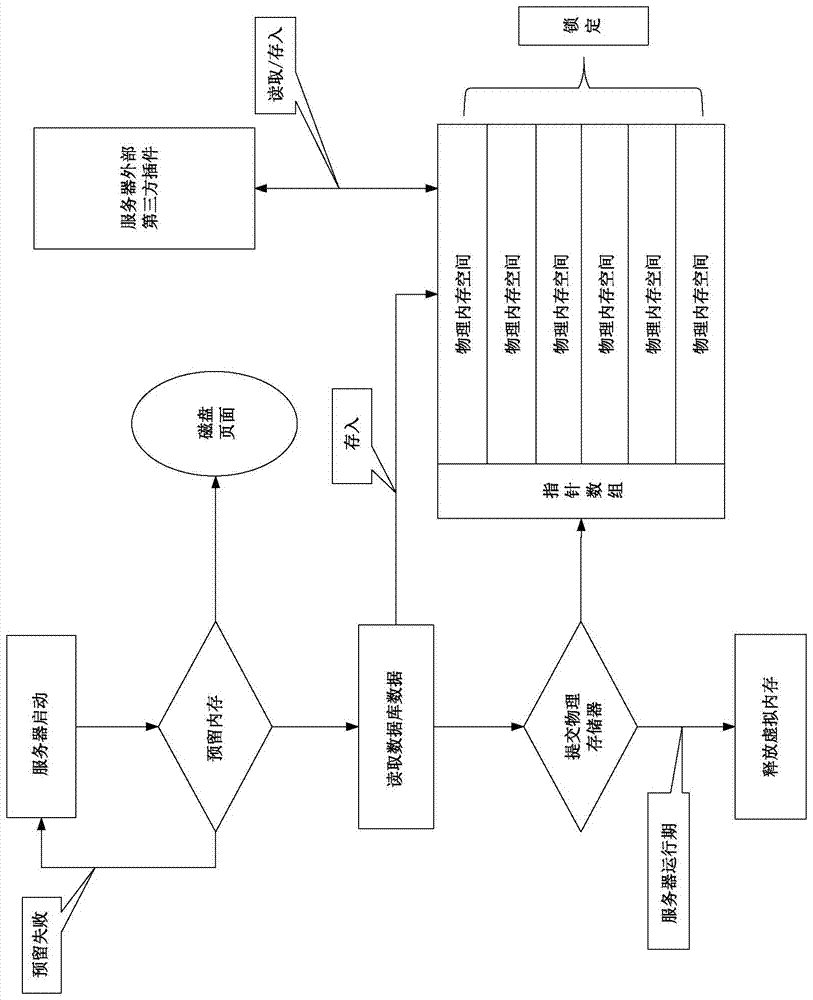

DSS-based efficient data system design method

ActiveCN107066281AMake full use of hardware resourcesEasy to useSoftware designSpecific program execution arrangementsVirtual memoryData access

The invention discloses a DSS-based efficient data system design method. A large virtual memory is opened up and a large amount of physical memories are submitted to a server for use; hardware resources of the server are fully utilized; by use of the virtual memory, the loading of a large data group becomes possible and the memory opening-up efficiency is remarkably improved; the data access is convenient and quick; by locking the physical memories, memory page exchange in a process space of the server during operation is prevented to the maximum extent, so that the performance loss of the server is greatly reduced; and by use of the virtual memory, one-time loading of the large data group is realized, so that the situation of reloading in an existing scheme is avoided, and especially the condition that the data loading situation in need of an I / O process causes crash on the server is avoided.

Owner:厦门市政智慧城市科技有限公司

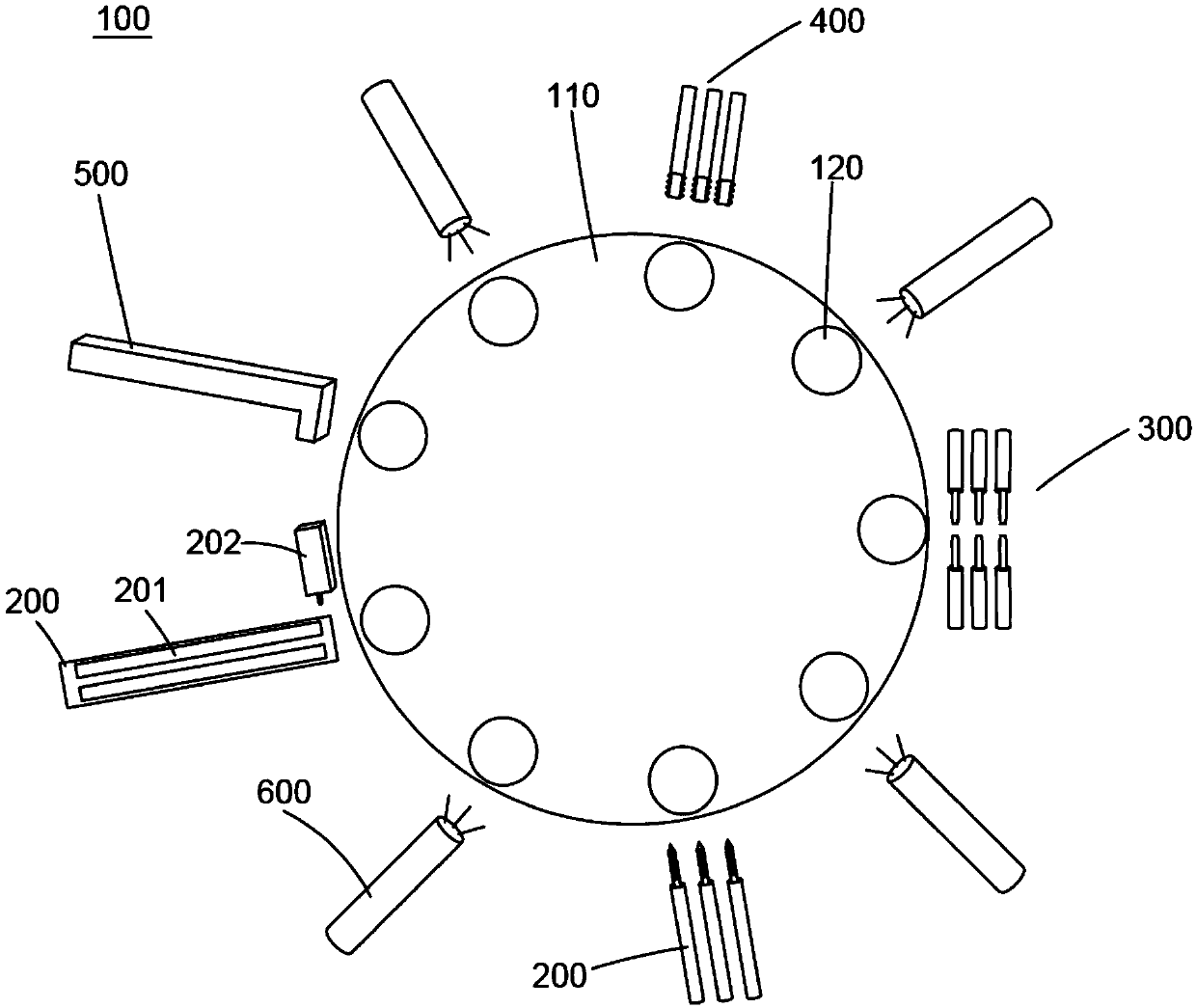

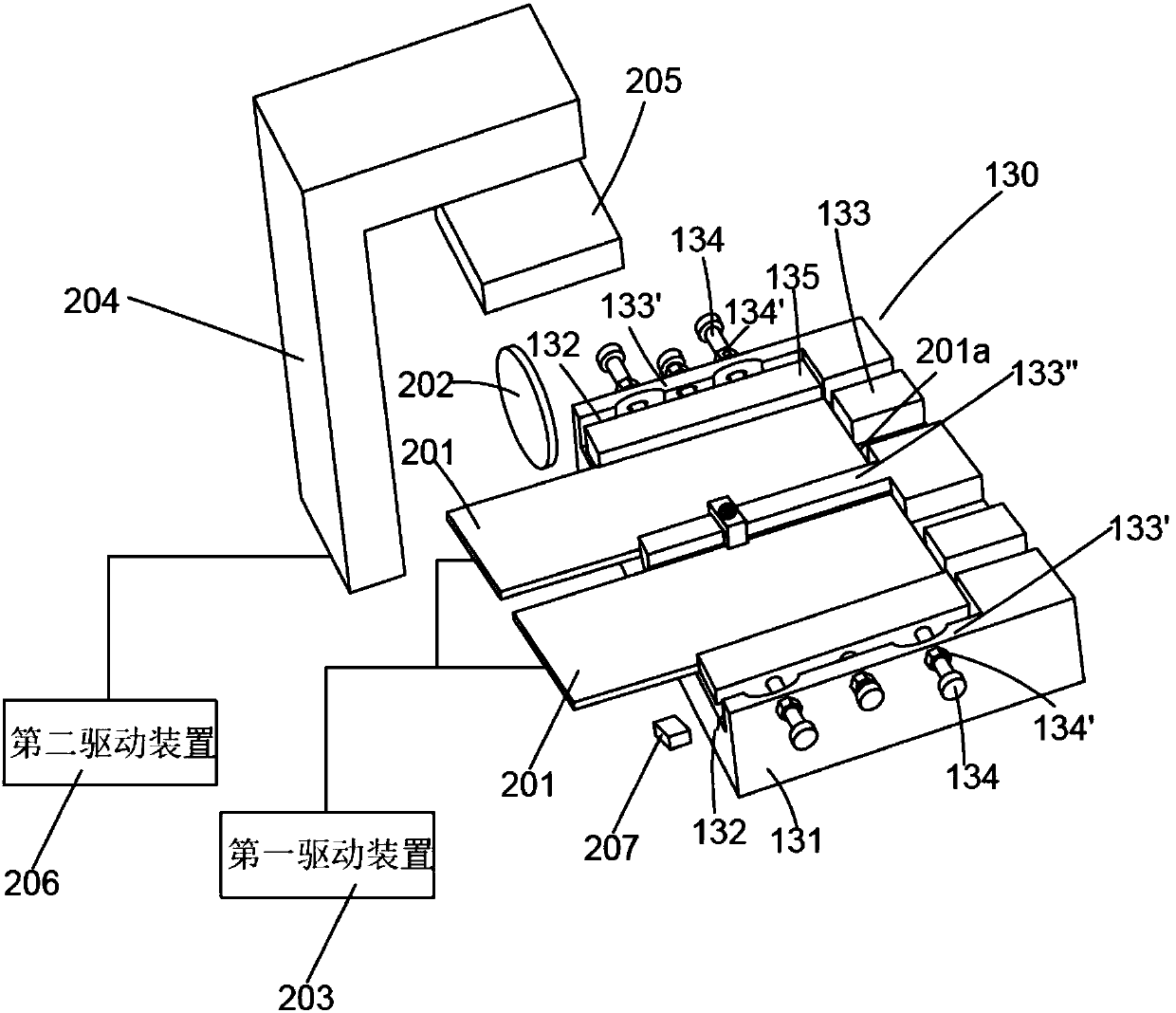

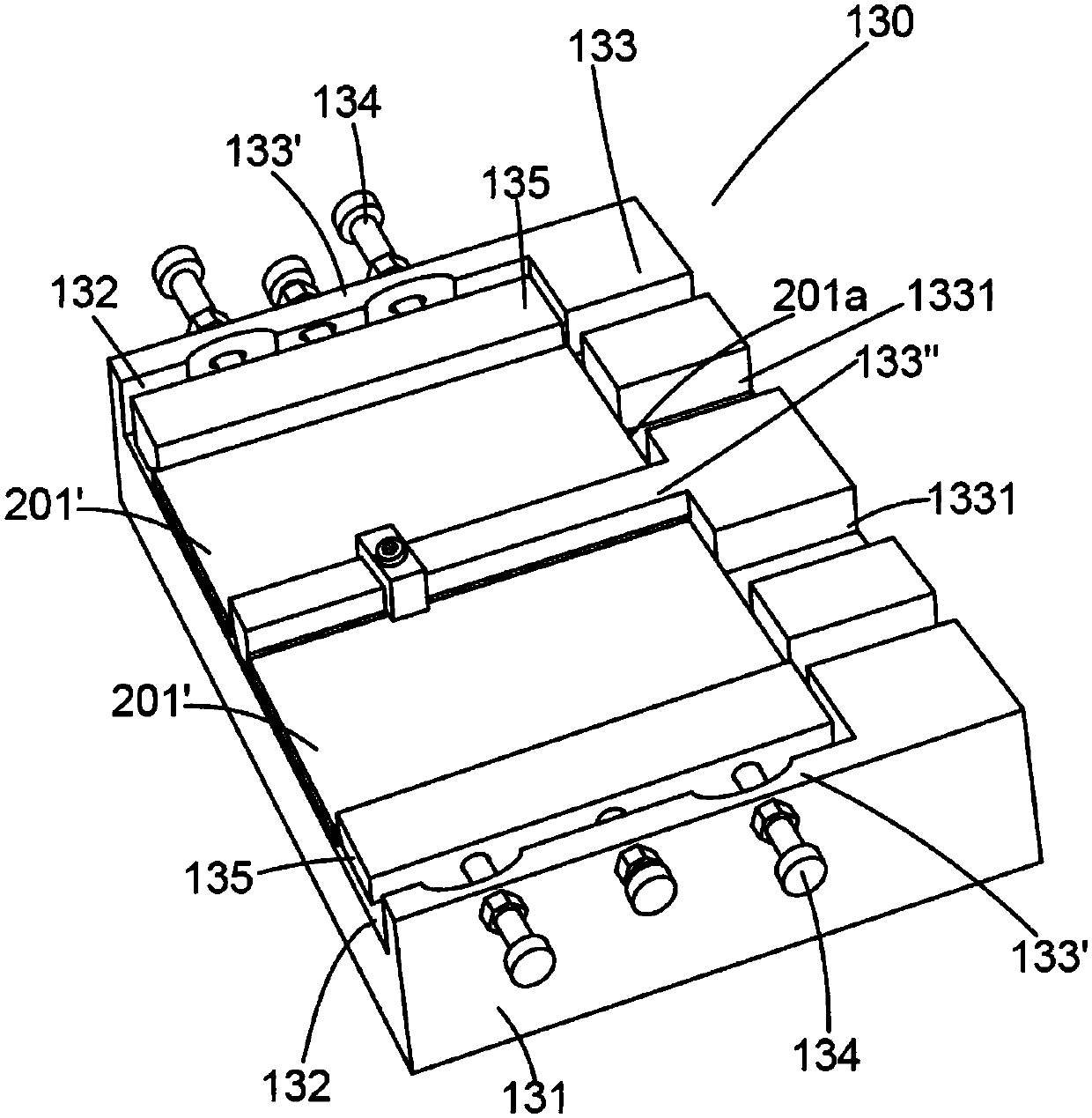

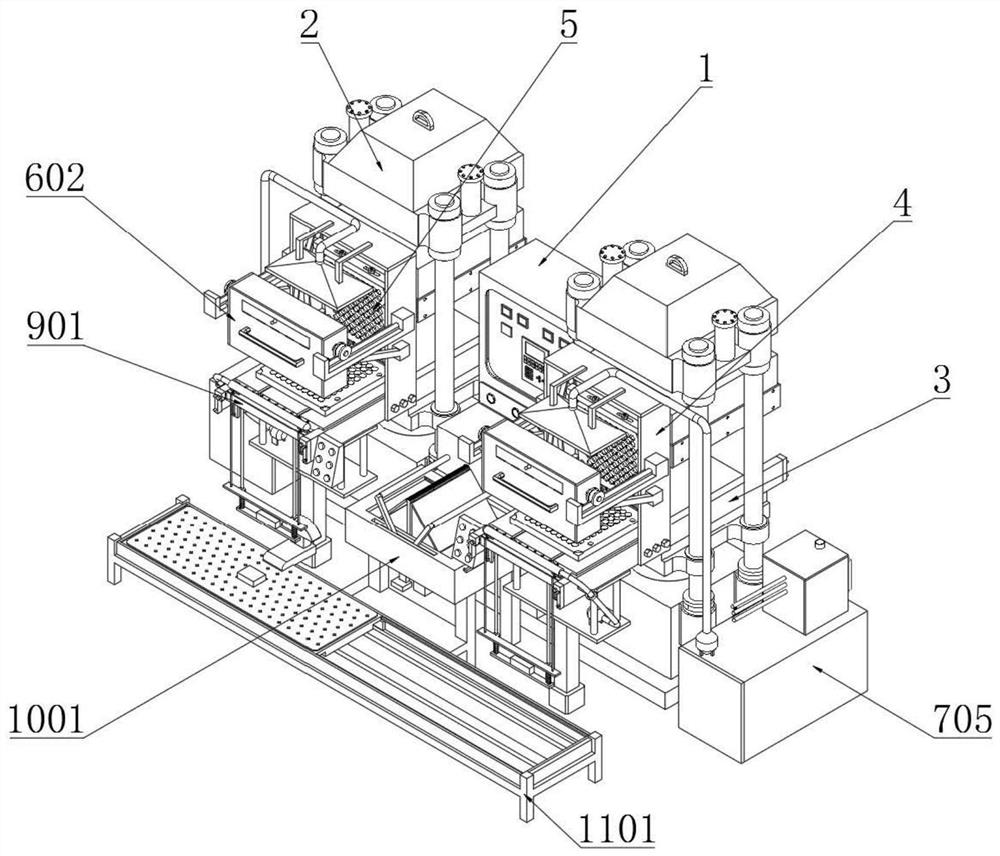

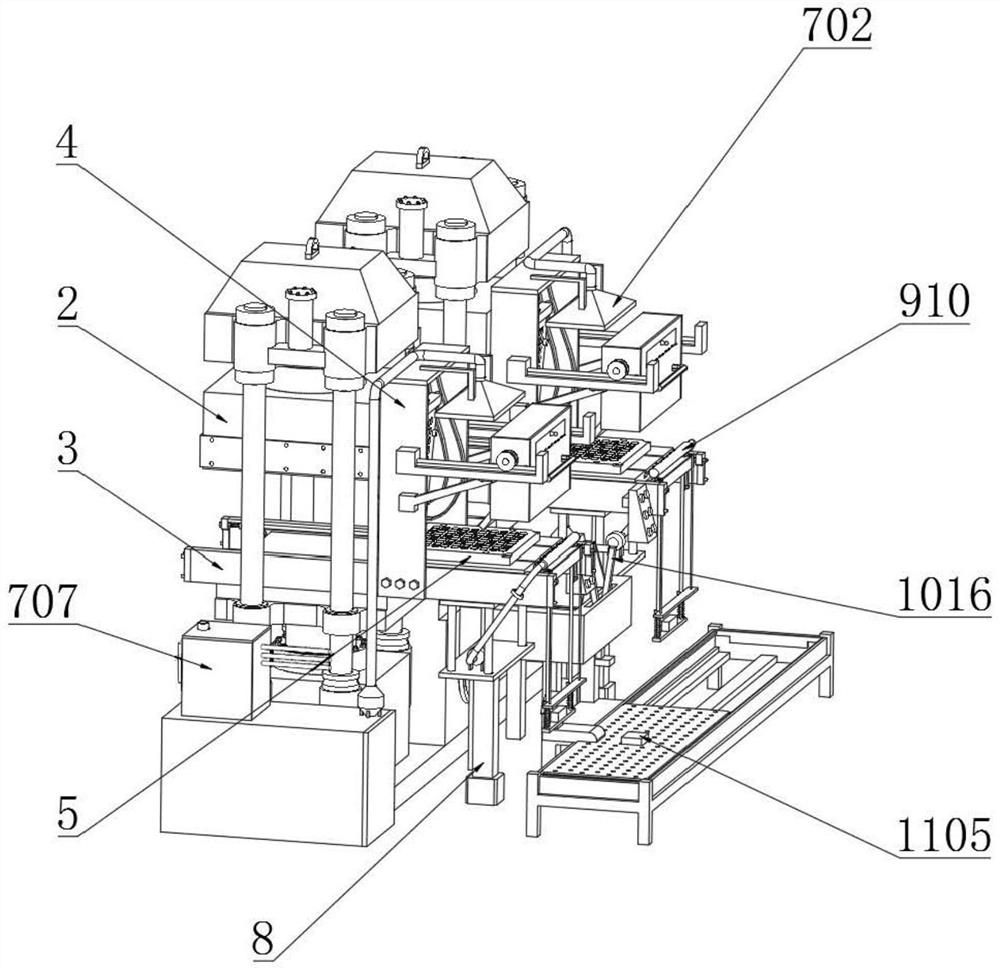

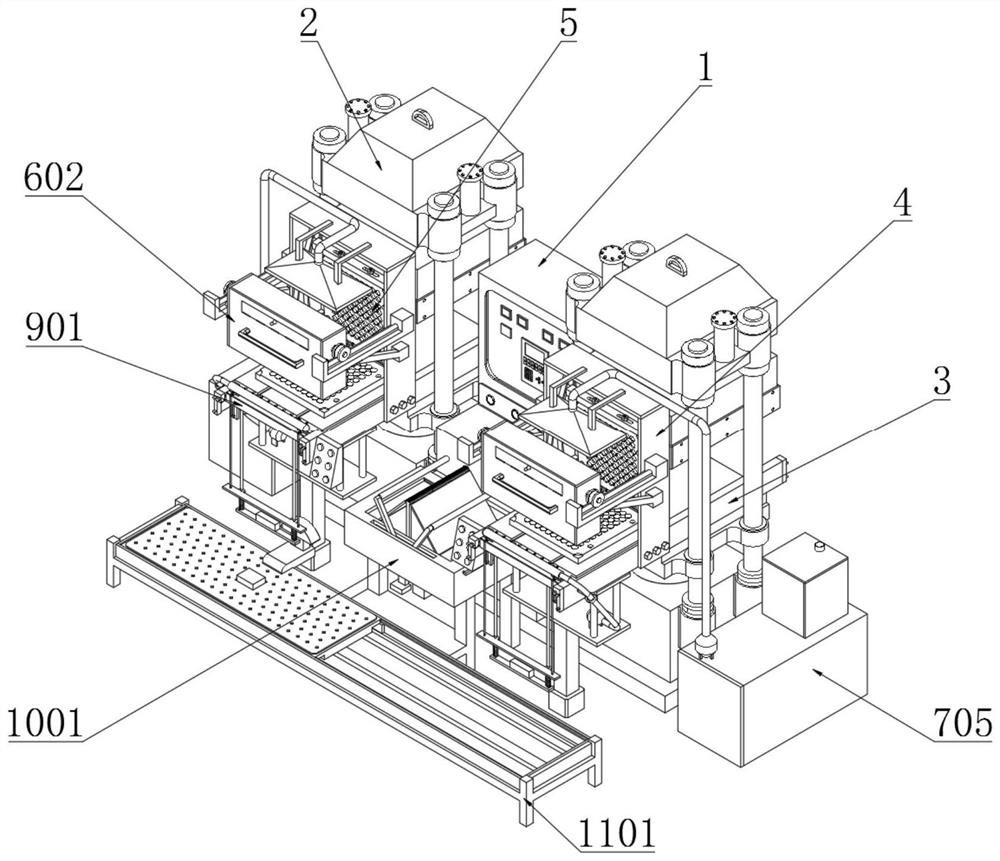

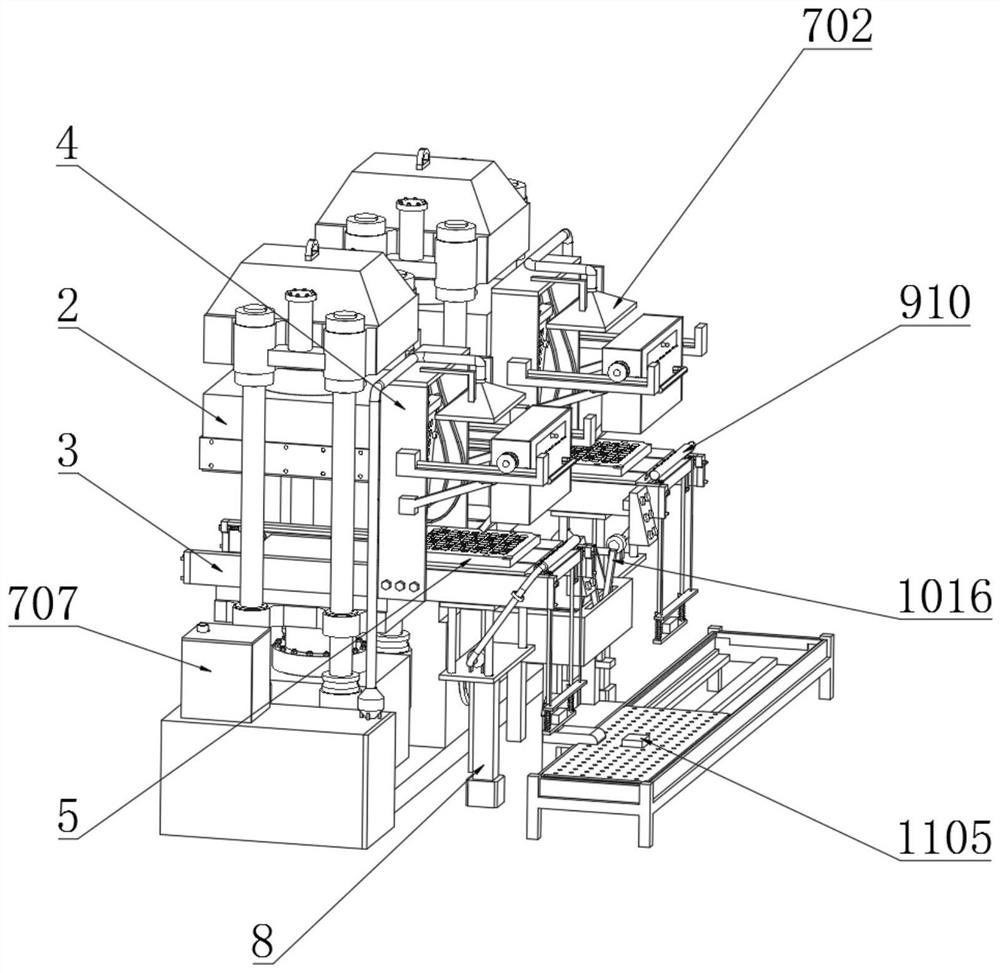

Full-automatic punching, tapping and chamfering machine

PendingCN107825139AImprove work efficiencyHigh degree of automationOther manufacturing equipments/toolsMetal working apparatusPunchingStructural engineering

The invention provides a full-automatic punching, tapping and chamfering machine which is applicable to punching, tapping and chamfering of an aluminum alloy part. The machine comprises a rotating worktable, an automatic feeding system, a double-side chamfering system and a discharging device, wherein a plurality of operation stations are arranged on the rotating worktable, and a loading componentis arranged at each operation station; a storing groove for storing the aluminum alloy part is formed in each loading component; the storing grooves are provided with opening parts; the automatic feeding system corresponds to one of the plurality of operation stations and comprises a first driving device, a second driving device, a pressing plate and a cutting device; the double-side chamfering system corresponds to at least one of the plurality of operation stations and comprises a driving device, an upper chamfering component and a lower end chamfering component; the upper end chamfering component and the lower end chamfering component are correspondingly arranged at two opposite sides of the rotating worktable; the discharging device corresponds to at least one of the plurality of operation stations and is used for discharging a finished part in each storing groove; the finished product is produced by punching, chamfering and tapping the aluminum alloy part.

Owner:FUJIAN SUNLIGHT SANYUAN ALUMINUM IND CO LTD

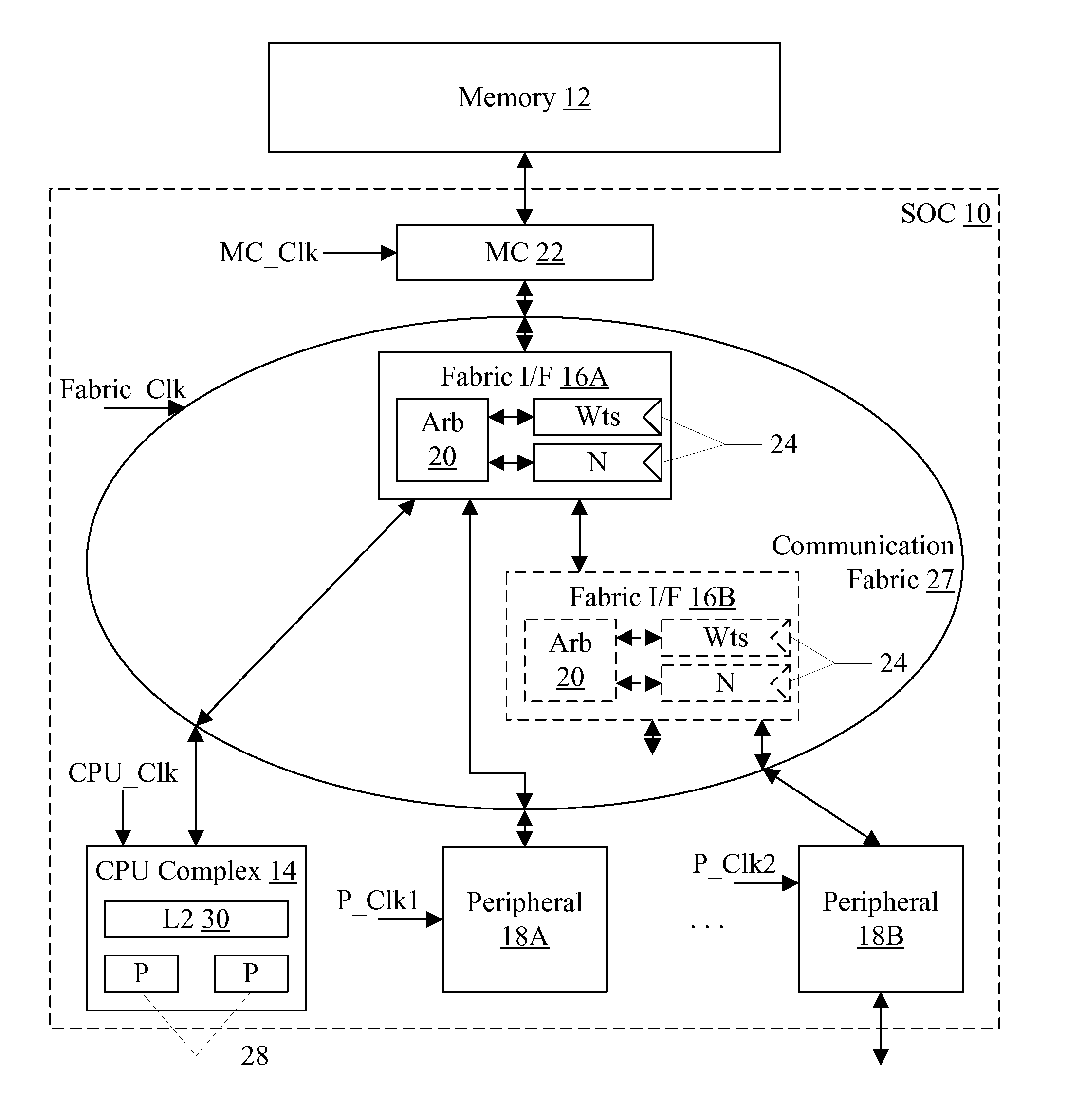

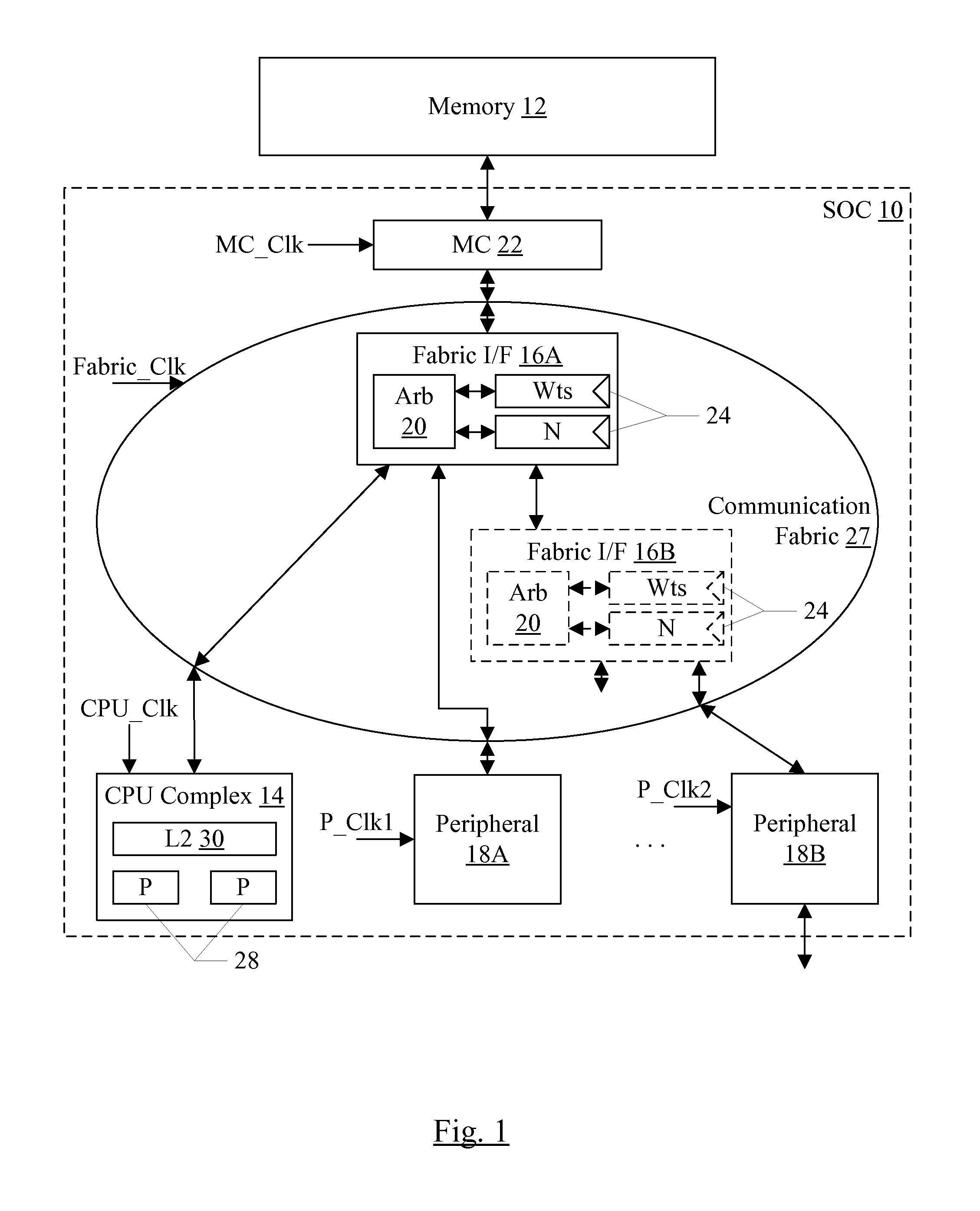

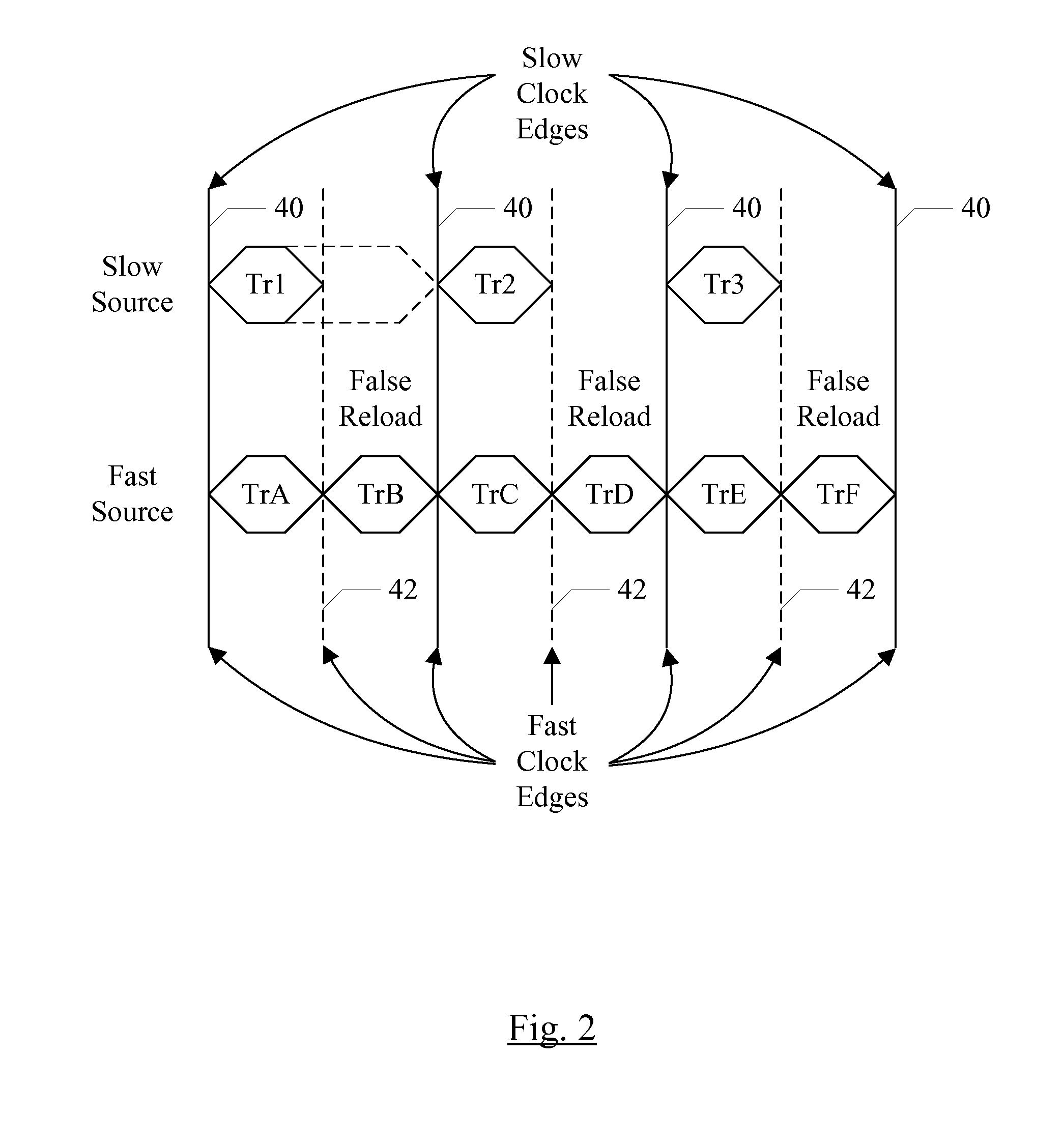

Round Robin Arbiter Handling Slow Transaction Sources and Preventing Block

ActiveUS20140310437A1Avoid weightReduce clock frequencyElectric digital data processingComputer scienceWeighted round robin

In an embodiment, an arbiter may implement a deficit-weighted round-robin scheme having a delayed weight-reload mechanism. The delay may be greater than or equal to a ratio of the fabric clock to a slower clock associated with one or more sources that have no transactions but that have unconsumed weights (or another measure of difference in transaction rate). If a transaction is provided from the one or more sources during the delay, the reload of the weights may be prevented. In some embodiments, the arbiter may be augmented to improve usage of the bandwidth on an interface in which some transactions may be limited for a period of time. The arbiter may implement a first pointer that performs round robin arbitration. If the first pointer is indicating a source whose transaction is temporarily blocked, a second pointer may search forward from the current position of the main pointer to locate a non-blocked transaction.

Owner:APPLE INC

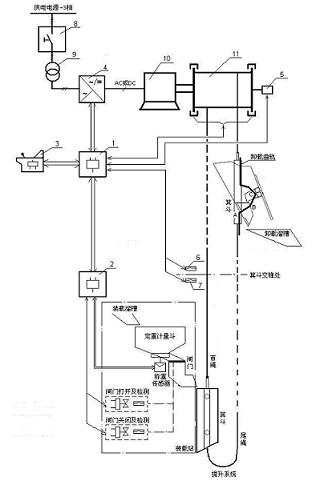

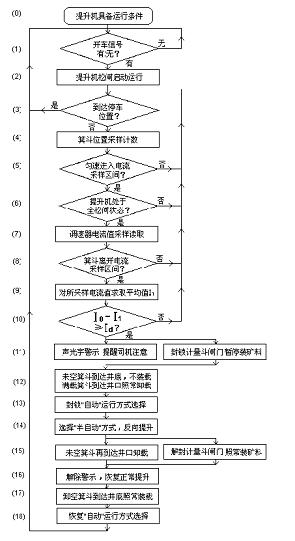

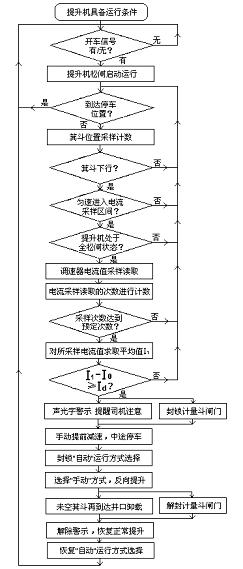

Lifting control device with skip emptying function

The invention belongs to mine lifting control technologies and provides a lifting control device with a skip emptying function. The lifting control device with the skip emptying function comprises an operating control system for automatically controlling a running process of a lifting system, a speed-adjusting system and a monitoring system, wherein the speed-adjusting system is used for supplying electricity to a motor and adjusting and controlling a running speed of an elevator, and the monitoring system is used for operating and monitoring a running process of the lifting control device. A fixed interval is arranged in a hardware mode or a combination mode of hardware and software; the elevator is in a full brake release state, and when a skip enters the set interval at a constant speed, sampling reading is continuously performed to current of a speed regulator in a circulating mode, and whether the skip is emptied is judged; and if the skip is not emptied, adopted corresponding measures are continuously taken to unload the skip which is not emptied. The lifting control device with the skip emptying function improves safe production capability of the lifting system, eliminates lifting intermittent time during the loading process of the skip, and improves production efficiency.

Owner:LUOYANG YUANCHUANG ELECTRIC

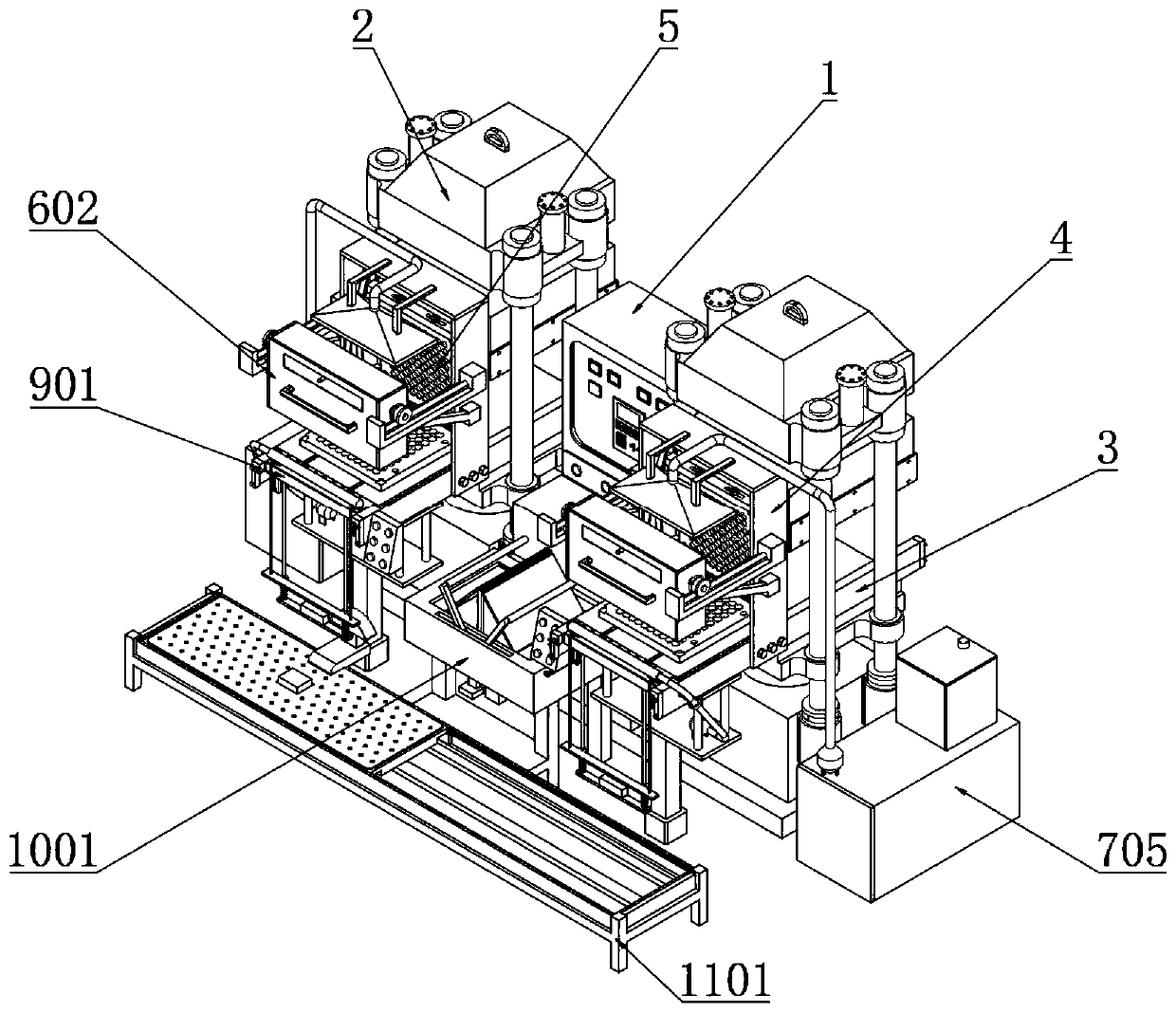

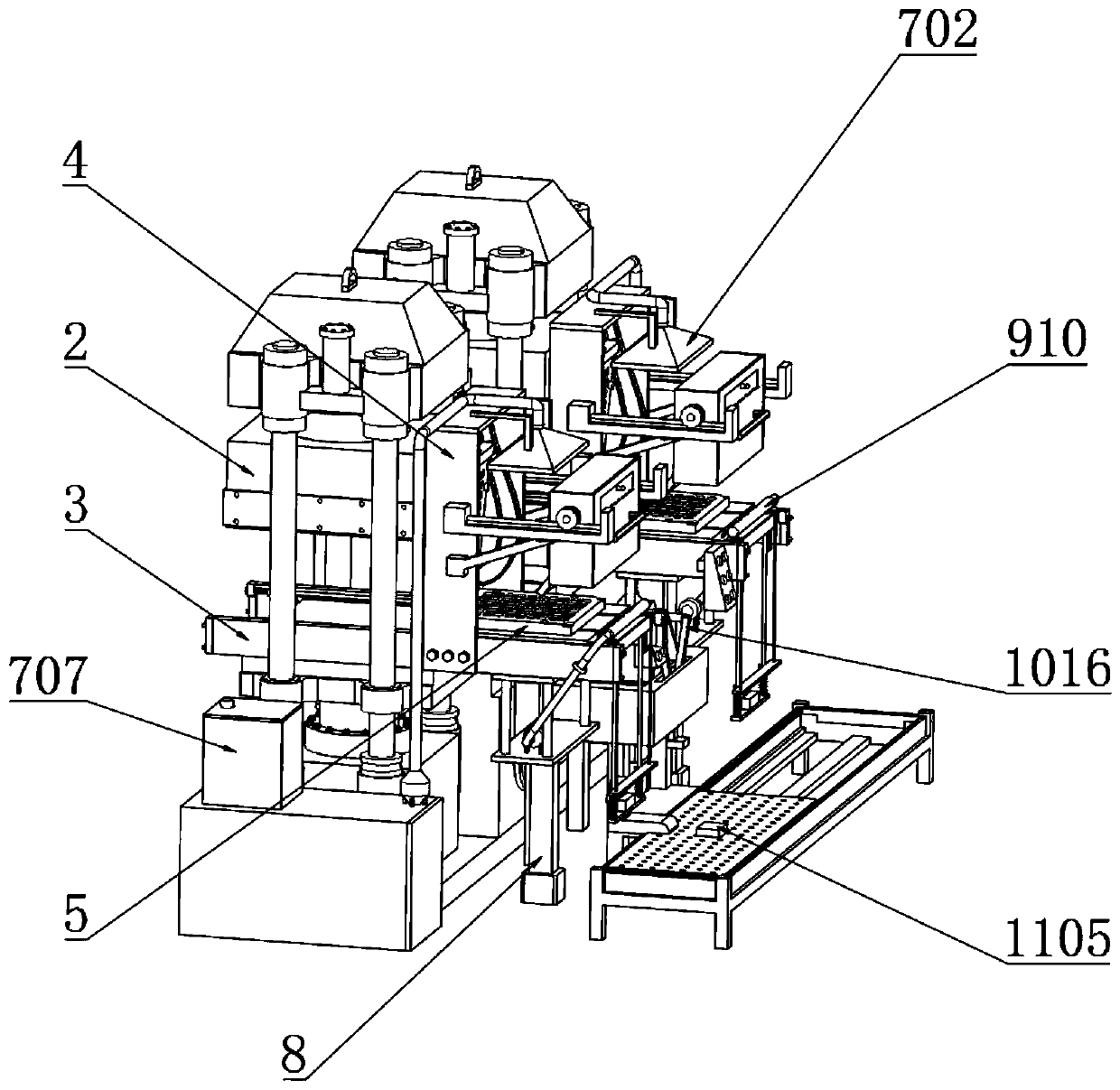

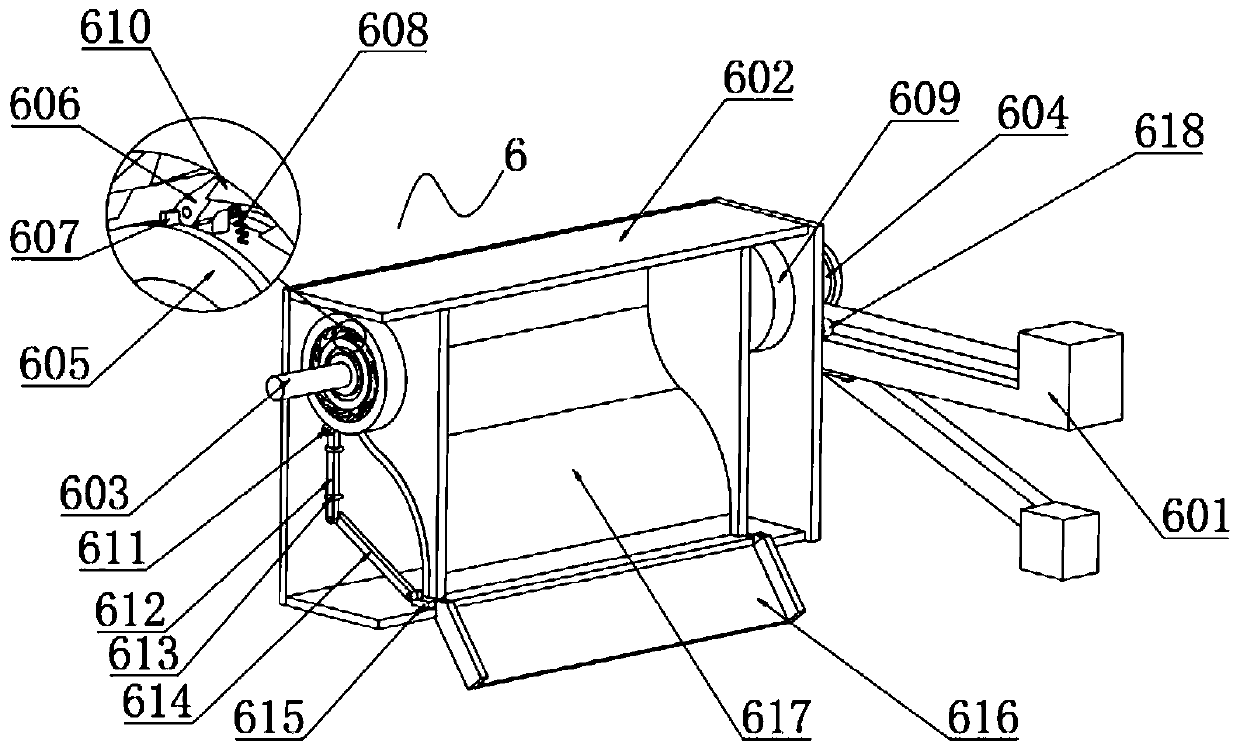

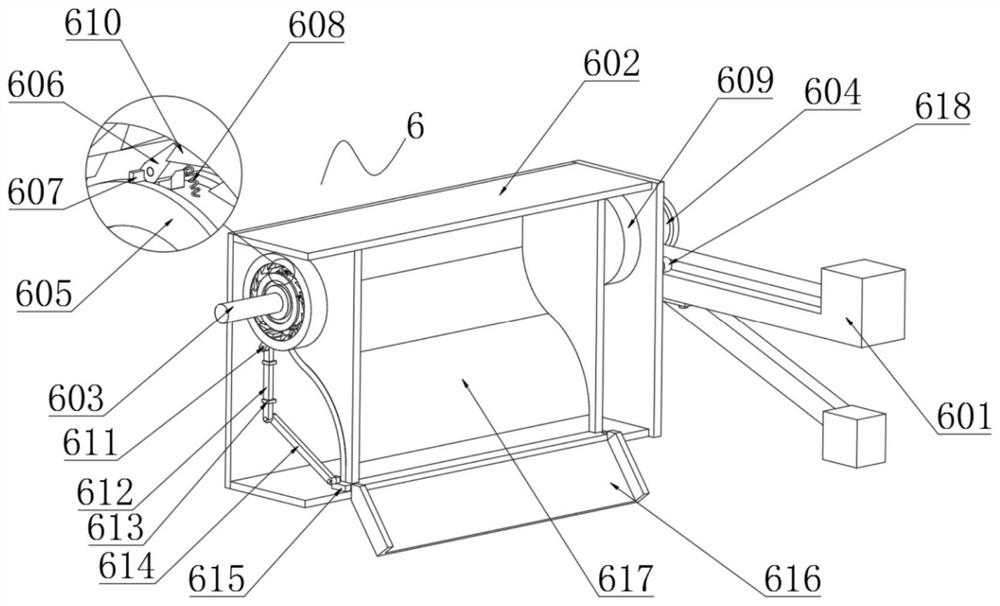

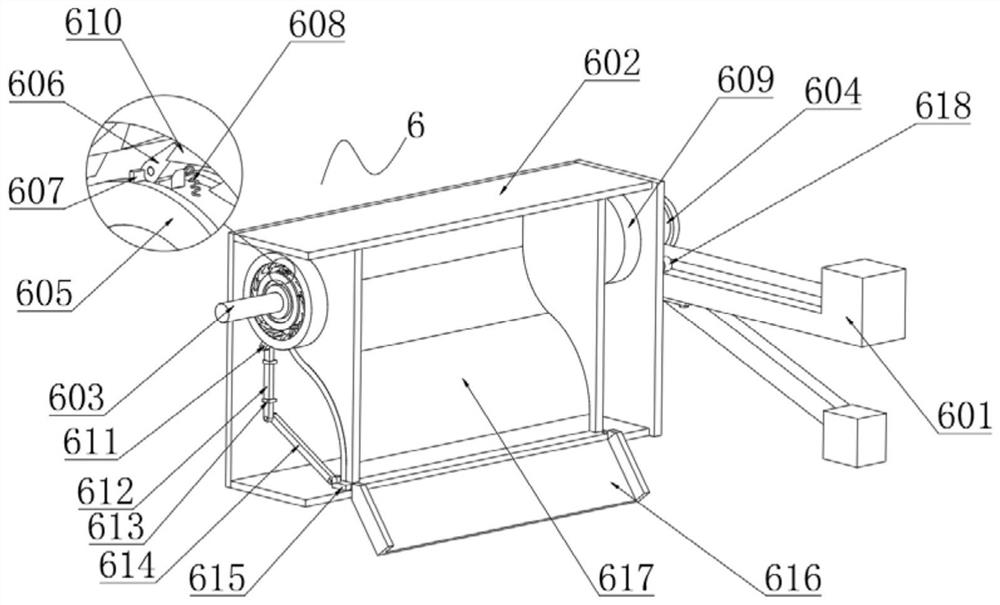

Double-station high-efficiency automatic rubber forming machine

ActiveCN111438862AScientific and reasonable structureEasy to useDirt cleaningRubber materialBraced frame

The invention discloses a double-station high-efficiency automatic rubber forming machine. Rubber forming machine main bodies are arranged at two sides of a control box of the rubber forming machine separately, and guide sliding frames are symmetrically arranged in the middle part of each rubber forming machine main body; and supporting frames are fixedly connected at the tops of the guide slidingframes, the inner sides of the guide sliding frames are slidably connected with forming molds, and the two sides of the supporting frames are fixedly connected with equidistant feeding mechanisms. According to the machine, by arranging a sliding rod, and swinging teeth, when the swinging teeth push forwards a feeding box, a driving rotating wheel is driven to rotate, and a strip-shaped rubber material in a discharging cavity is added to the forming molds through the discharging cavity by means of the driving rotating wheel, a transmission swinging rod and a pushing plate, so that the placement for adding the rubber material into the forming molds is simplified; and the rubber material in the discharging cavity can be uniformly added into the forming molds only by pushing the feeding box forwards, so that the labor intensity of operators is reduced, the working efficiency is improved, and the productivity is increased.

Owner:无锡市睿科机械部件有限公司

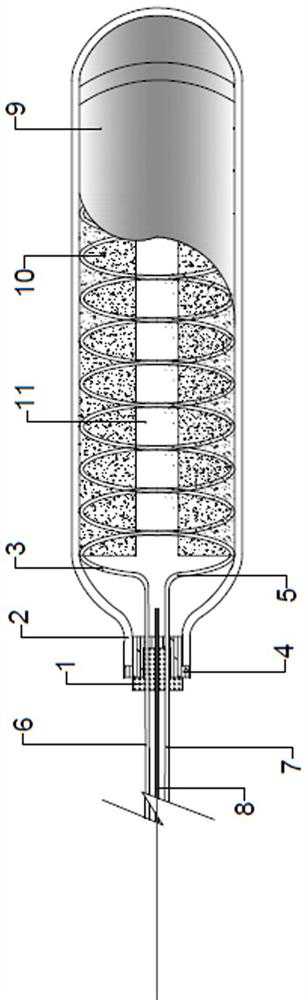

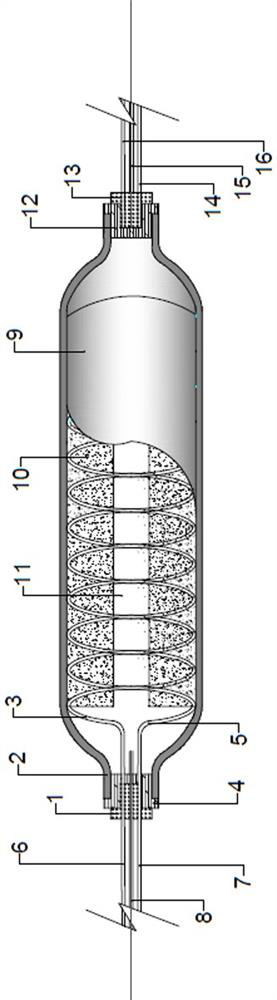

Solid hydrogen source device for hydrogen fuel

ActiveCN112066242ASimple structureEasy to processVessel mounting detailsReactant parameters controlHeat mass transferEngineering

The invention relates to a solid hydrogen source device for hydrogen fuel, and belongs to the technical field of hydrogen storage devices. Safety, portability and environmental adaptability of a solidhydrogen source to hydrogen utilization are achieved. According to the solution, a tank opening is formed in a hydrogen storage tank, a valve is mounted at the tank opening, a sealing ring is mountedbetween the valve and the tank opening, a heat exchange pipeline is of a double-spiral structure and is fixedly arranged on the inner wall of the hydrogen storage tank in a coiling manner, and a heatmass transfer inlet and a heat mass transfer outlet of the heat exchange pipeline respectively penetrate through the valve and extend to the outside of the hydrogen storage tank; a cavity is formed in the axis position in a tank body of the hydrogen storage tank, a hydrogen charging / discharging pipeline penetrates through the valve and communicates with the cavity, a plurality of material bins are arranged on the periphery of the cavity, the size of each material bin is not smaller than 4 / 5 of that of an inner cavity of the tank body of the hydrogen storage tank, a diaphragm is arranged on aside wall of each material bin, and the material bins are filled with solid hydrogen storage alloy powder. The device is simple in structure, safe, efficient, portable and suitable for various environments and has good reproducibility and stability.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Steel plate flattening device

InactiveCN105583256AAchieve flatnessGood rolling effectMetal-working feeding devicesPositioning devicesSheet steelEngineering

The invention provides a steel plate flattening device which comprises a base, a frame body, and a preliminary pressing roll device, a guide roll device, a roller device and a forming roll device that are sequentially arranged along the length direction of the base, wherein the preliminary pressing roll device comprises a lower preliminary pressing roll and a height-adjustable upper preliminary pressing roll correspondingly arranged above the lower preliminary pressing roll; the guide roll device comprises two height-adjustable guide rolls that are correspondingly arranged; and the distance between the two guide rolls can be adjusted; the roller device comprises an adjusting mechanism, a lower roller group fixedly mounted at the frame body, and an upper roller group above the lower roller group; the adjusting mechanism is arranged at the upper end of the frame body; the upper roller group is fixedly mounted on the adjusting mechanism; and the forming roll device comprises a lower forming roll and a height-adjustable upper forming roll correspondingly arranged above the lower forming roll. After an iron sheet is flattened twice, the flatness before processing is reached completely; and the iron sheet is limited by the guide rolls in a flattening process, so that no deviation occurs. After the flattening, preliminary forming processing is carried out by the upper forming roll and the lower forming roll, and the production efficiency is improved.

Owner:天津鑫旭成科技有限公司

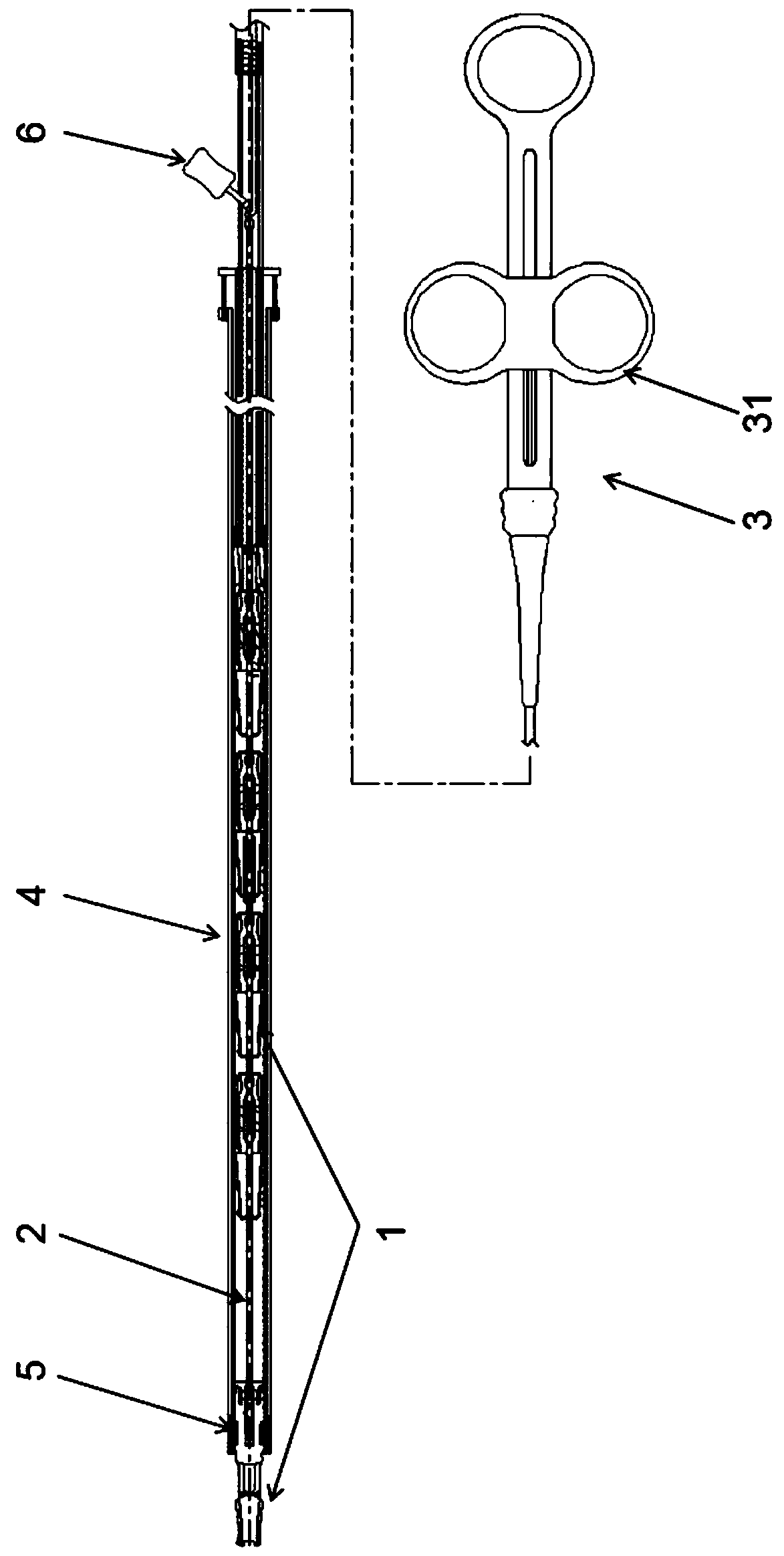

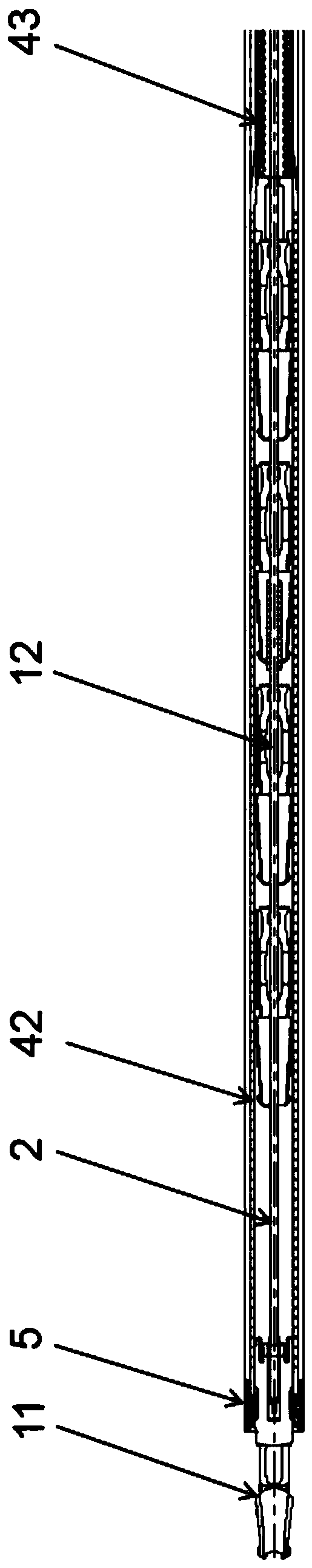

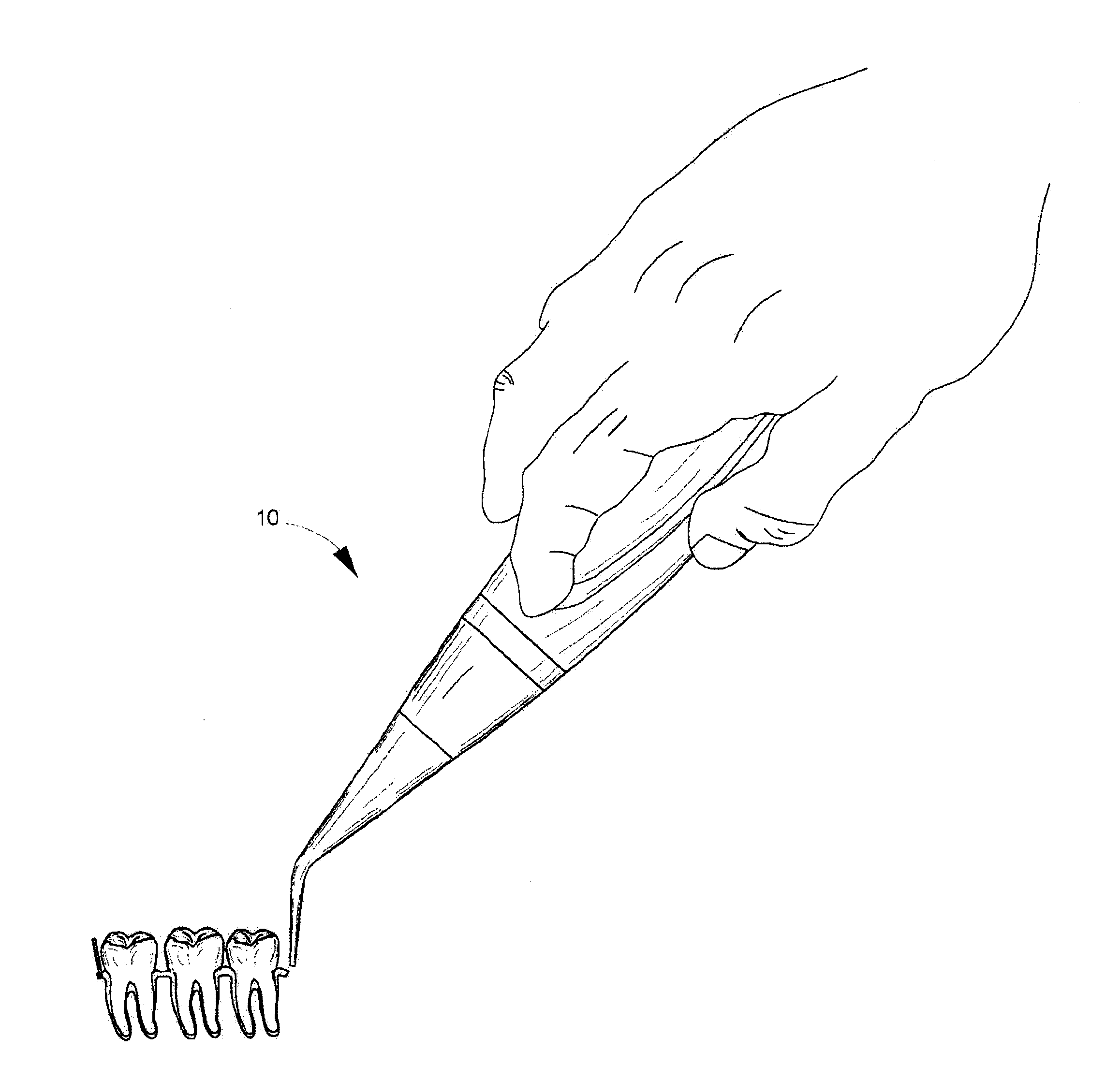

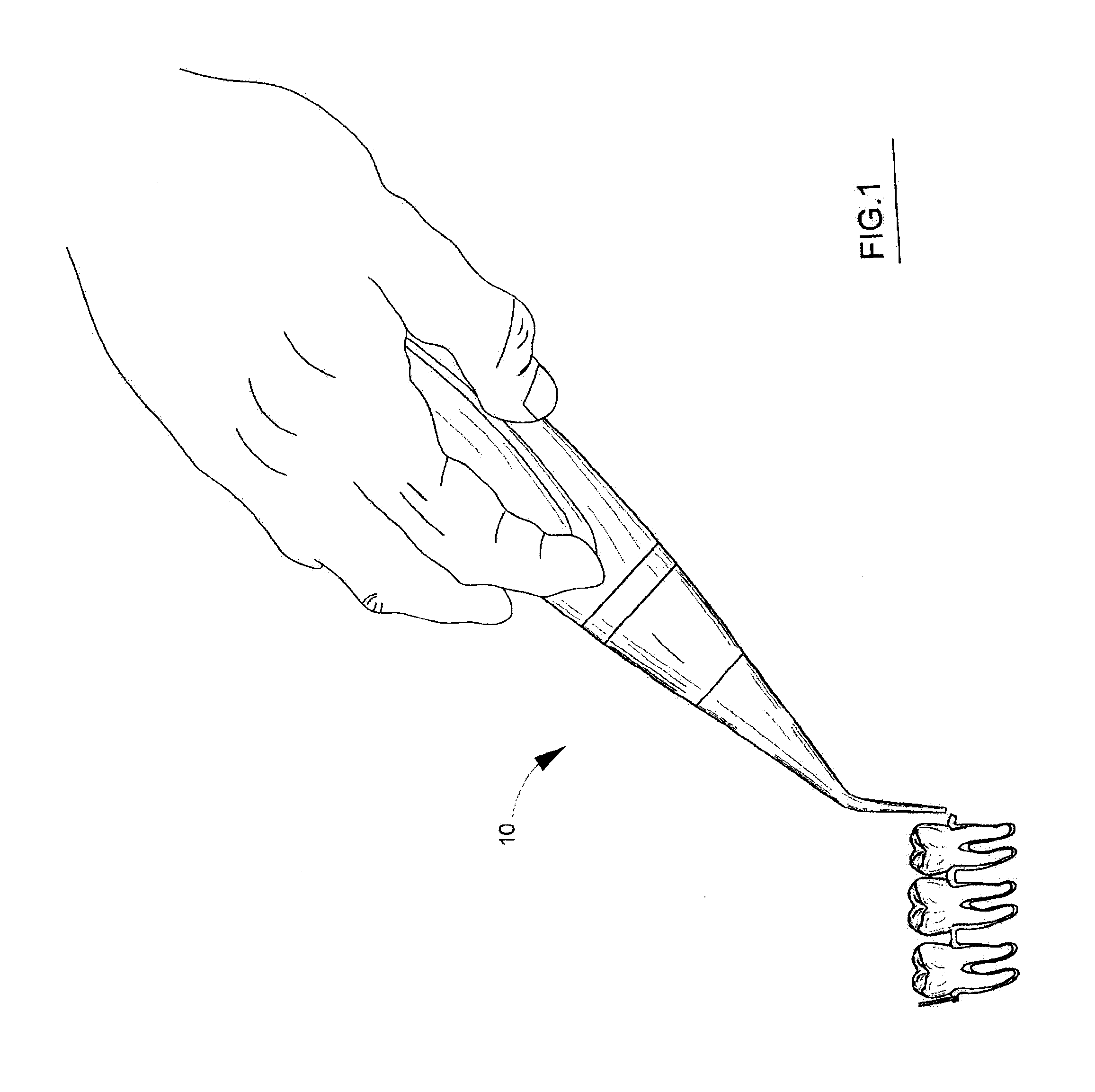

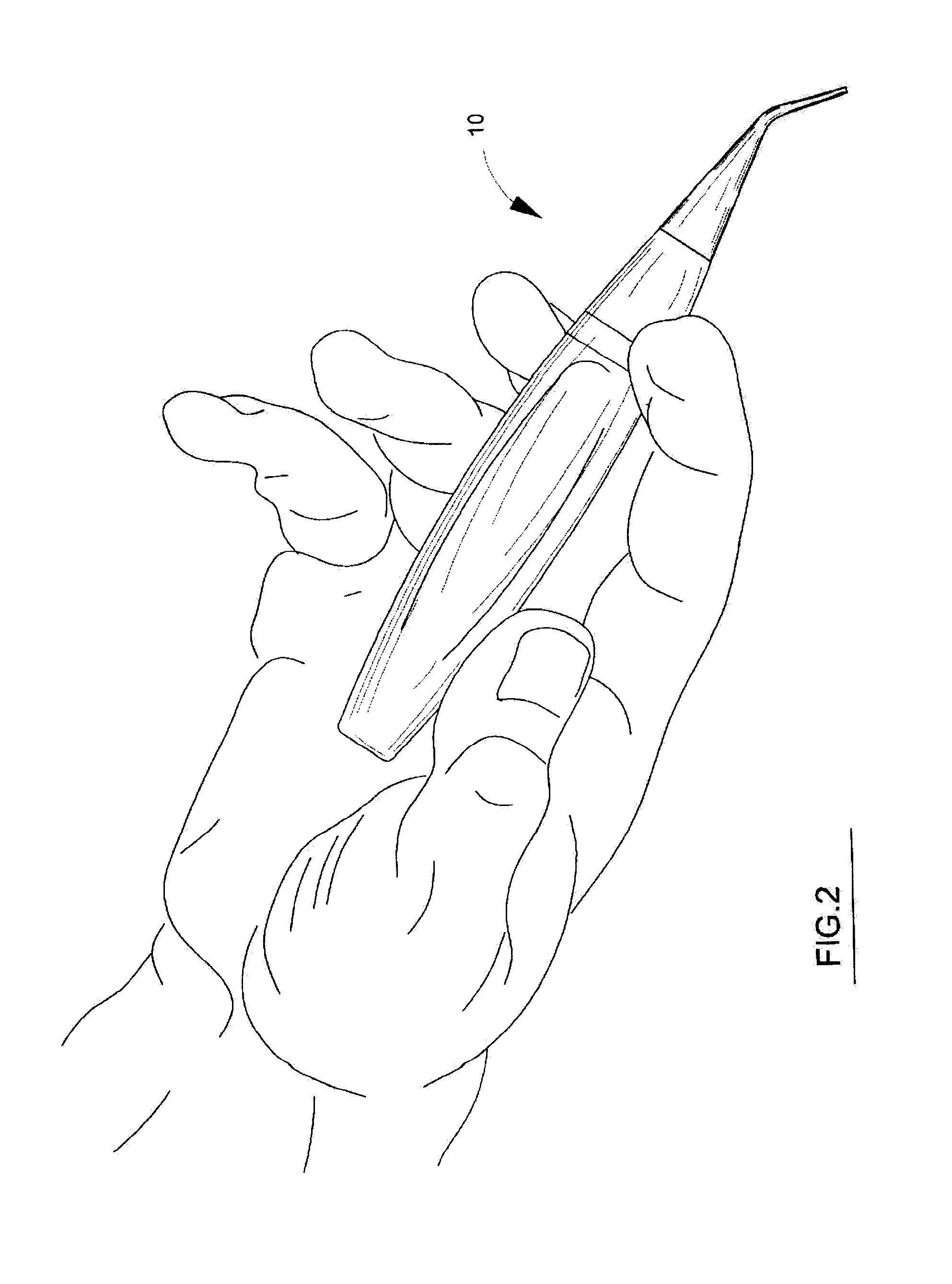

Regulated periodontal dispensing apparatus and multiple dose applicator with a semilunar valve.

ActiveUS20150017602A1Enhanced control of deliveryImprove mobilityTeeth fillingTeeth cappingHand heldHand held devices

The present invention is a hand-held device for dispensing multiple controlled dosage of powered material having a main body, a cavity in the main body constructed and arranged to be operatively associated with an actuator for dispensing a medicament, an actuator constructed and arranged for dispensing said medicament from said cavity through a delivery device, and a tip attached to said second end of said main body, wherein said tip is constructed and arranged at a fixed angle relative to said main body to facilitate periodontal delivery of a medicament.

Owner:PHARMA PHD II LLC

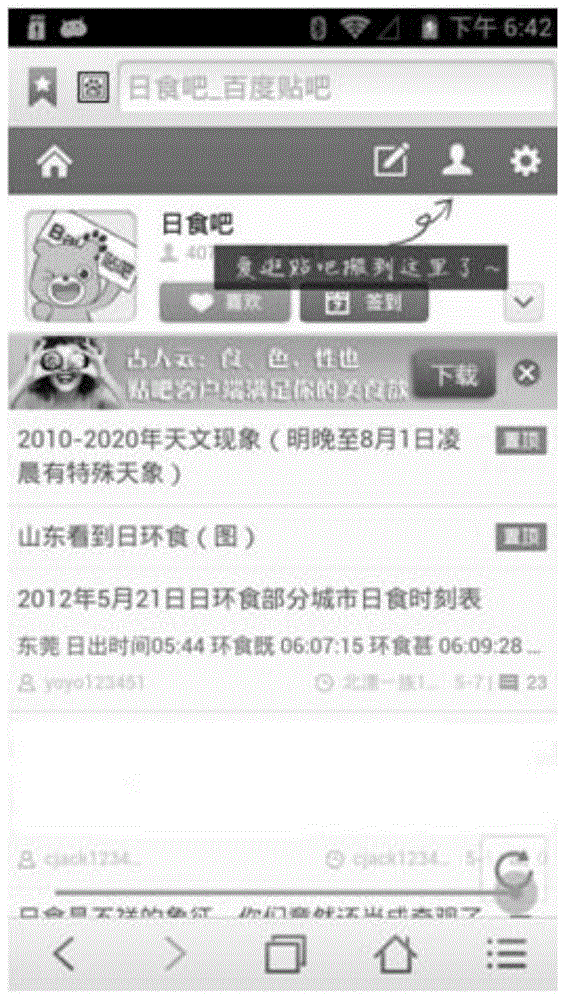

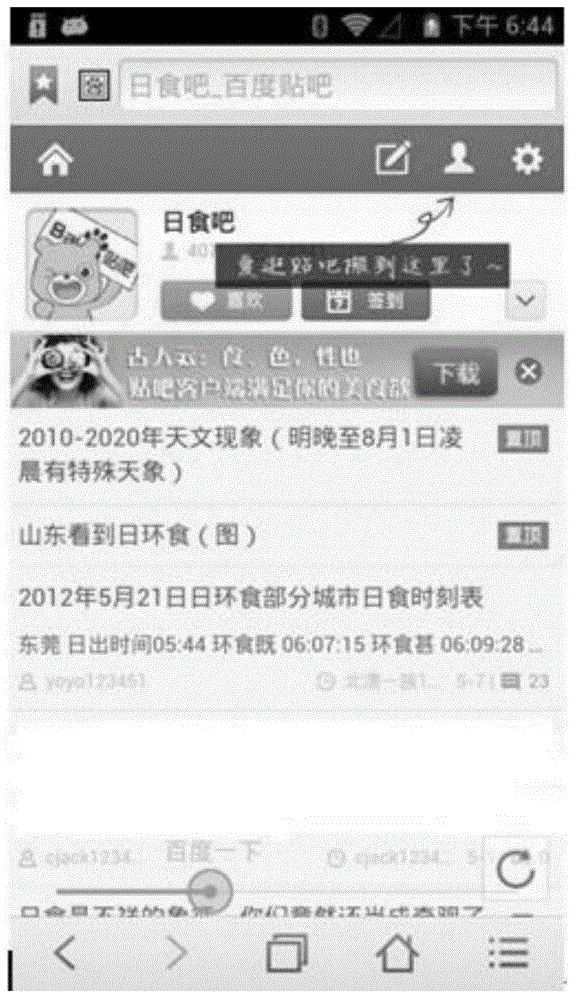

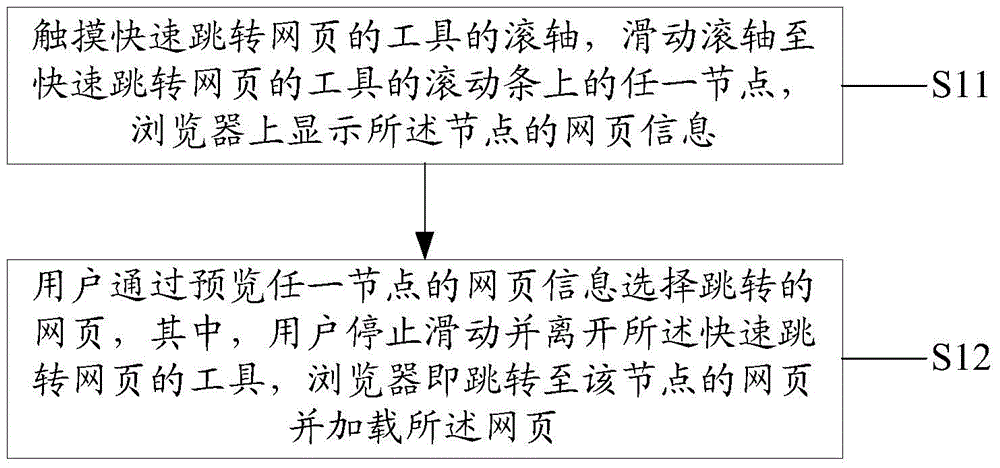

Browser webpage quick jumping method and usage method thereof

InactiveCN104424273AReduce stepsAvoid reloadingSpecial data processing applicationsInput/output processes for data processingTraffic capacityJumping function

The invention provides a browser webpage quick jumping method and usage method thereof. The method comprises the steps of: touching a roller of a webpage quick jumping tool, sliding the roller to any one node of a scroll bar of the webpage quick jumping tool, and displaying webpage information of the node on the browser; and previewing the webpage information of any one node to select a webpage to be jumped, wherein a user stops sliding and leave away from the webpage quick jumping tool, and the browser jumps to a webpage of the node and loads the webpage. The user can slide the roller to any one node and preview the webpage information of the node to decide whether to jump to the node; at the same time, the user is not required to repeatedly click forward / backward to arrive one browsing history, and the user can directly arrive the node by sliding the roller to any one node, so that operation steps of the user is reduced. In addition, when terminal internal storage is relatively low, a page cache will be recovered; and through a direct jumping function, the useless webpage is not reloaded, and the network traffic is saved.

Owner:LEADCORE TECH

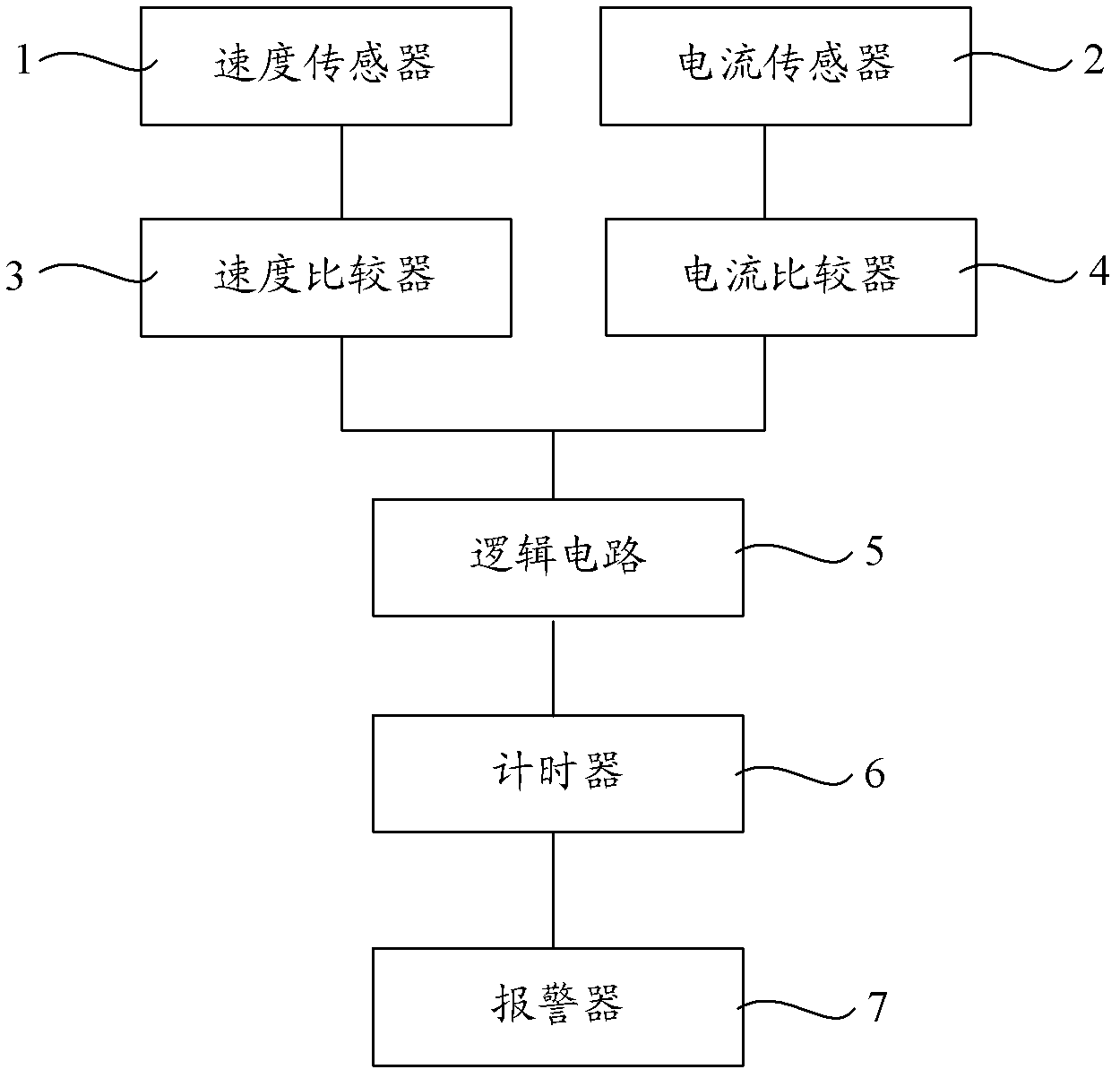

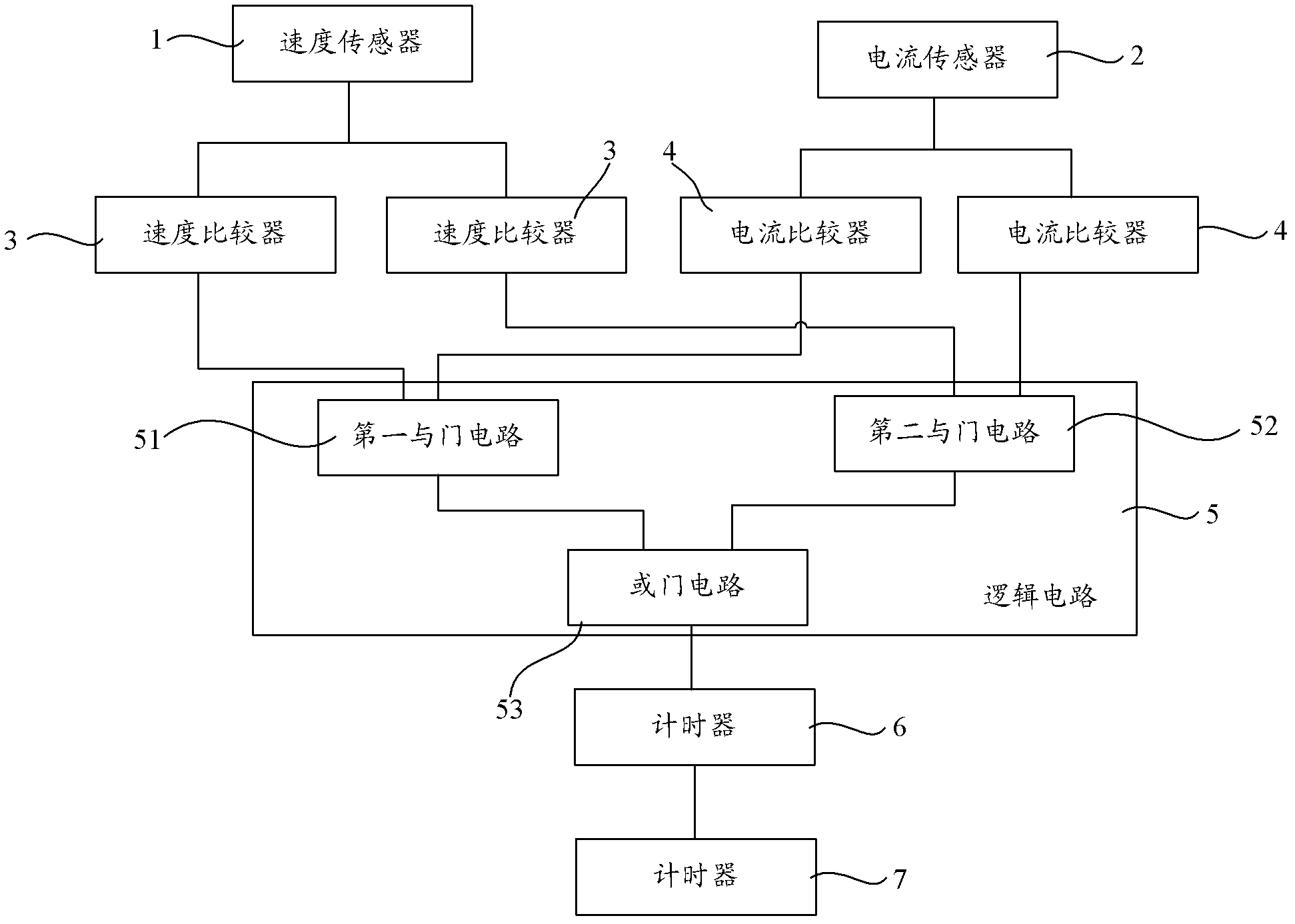

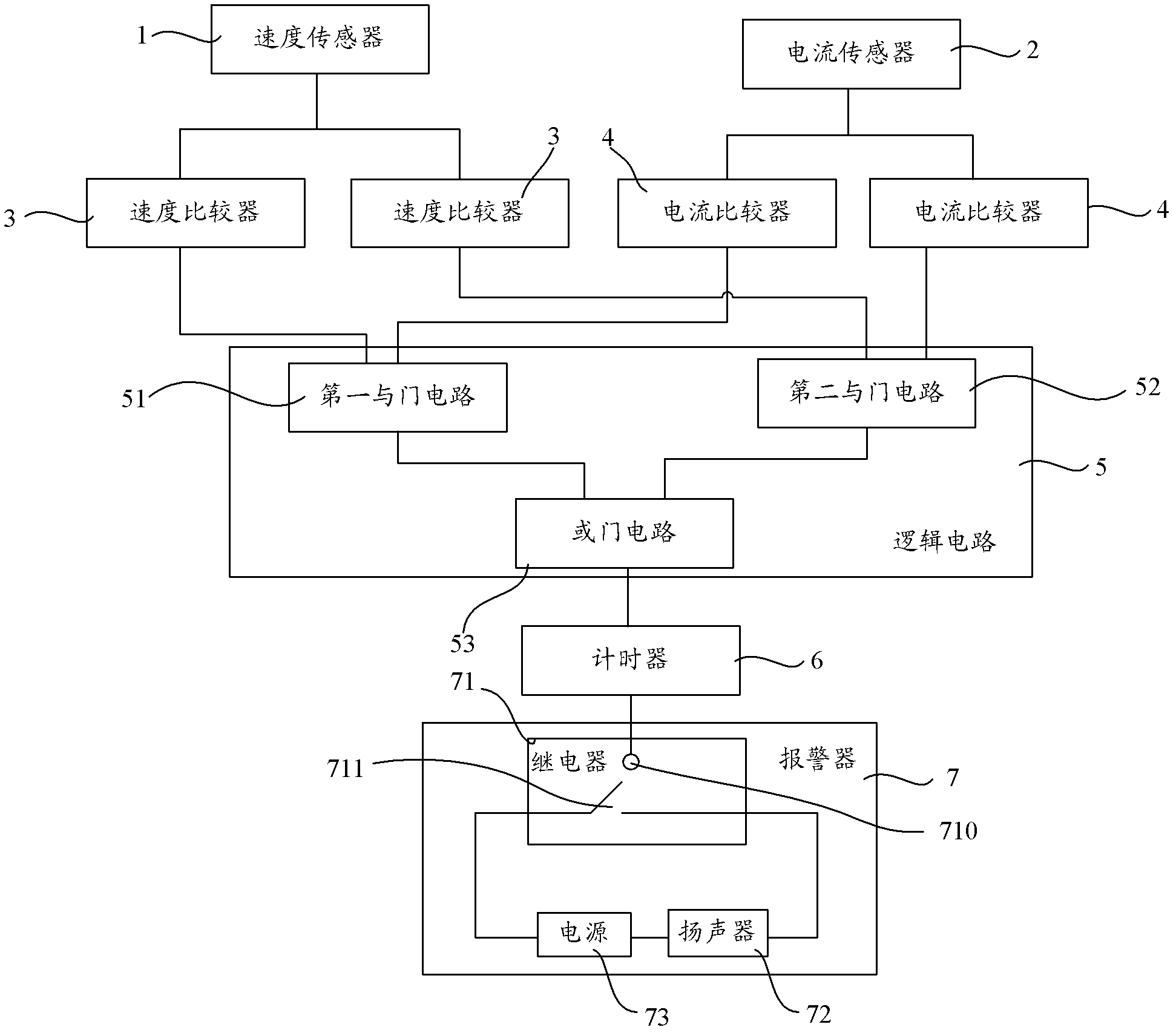

Winch alarm device for mining

ActiveCN103101851AIncrease productivityAvoid safety accidentsWinding mechanismsPower flowElectric machinery

The invention provides a winch alarm device for mining. A measuring device comprises a velocity sensor, a current sensor, a velocity comparator, a current comparator, a logic circuit, a timer and an alarm, wherein the velocity sensor is connected with a rotating shaft of a motor in a winch, the current sensor is arranged in an excitation circuit of the motor in the winch, the velocity comparator is connected with the velocity sensor, the current comparator is connected with the current sensor, the velocity comparator and the current comparator are respectively connected with the logic circuit, the timer is connected with the logic circuit, and the alarm is connected with the timer. According to the winch alarm device for the mining, when a condition of heavy load unloading of the winch occurs, an alarm signal is generated to remind a worker operating the winch of taking corresponding measures, so that production efficiency is improved. Meanwhile, safety accidents are prevented from occurring, and guarantee is provided for safety production operation.

Owner:HUAINAN MINING IND GRP

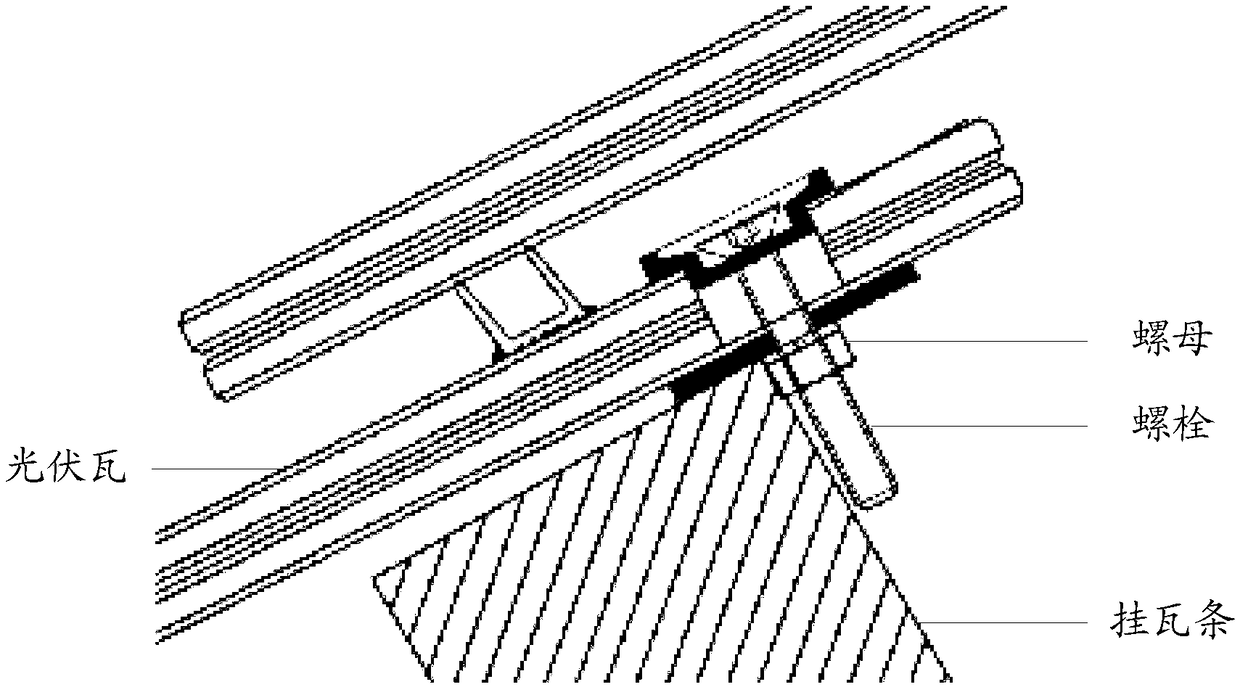

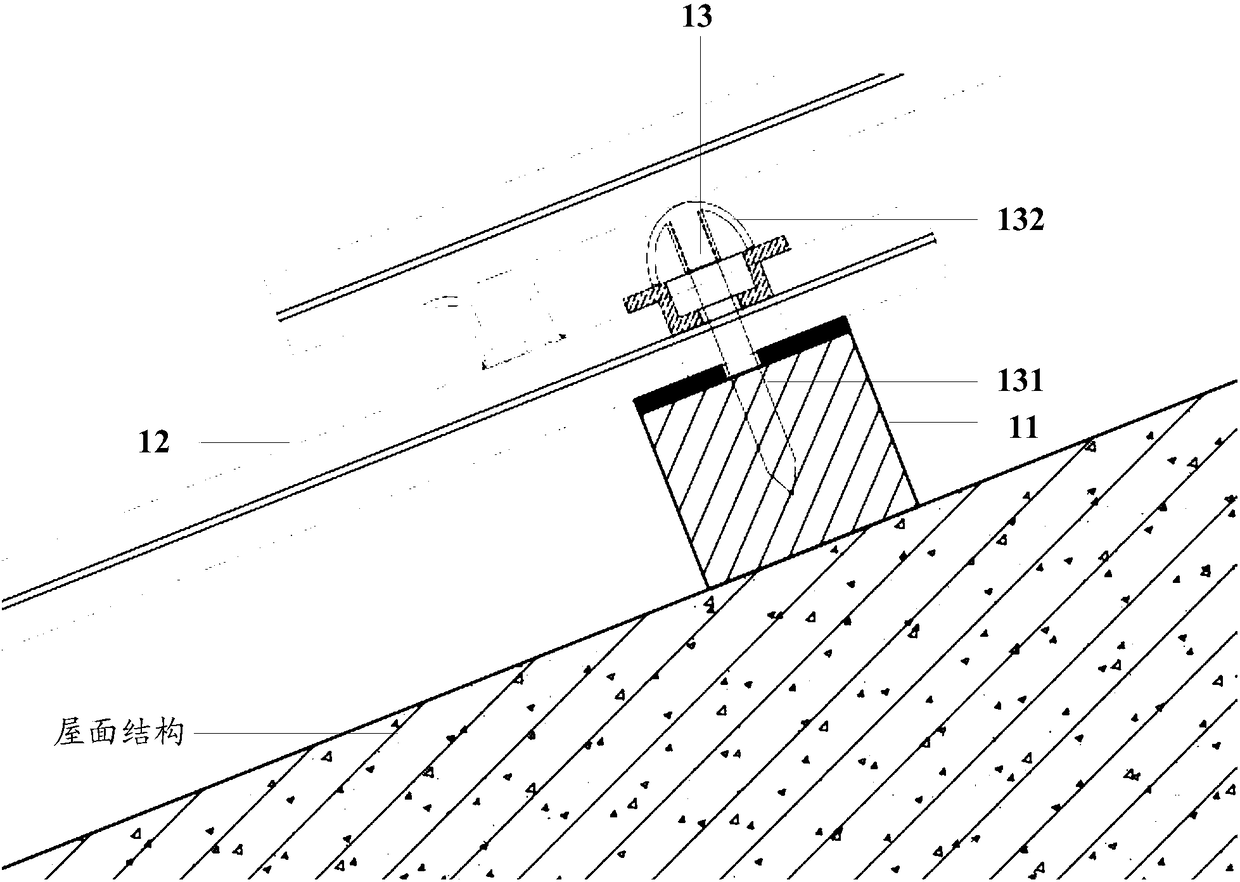

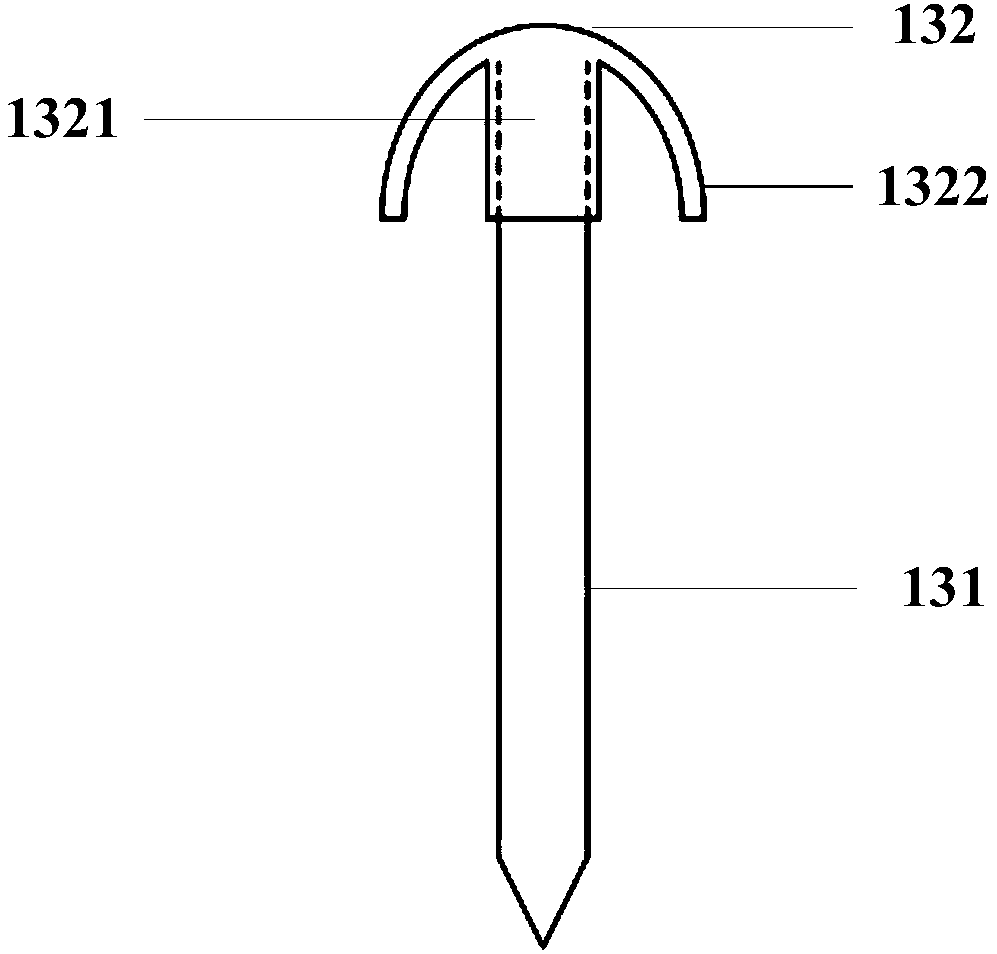

Photovoltaic tile connecting system

PendingCN108590051AGuaranteed firmnessEasy to replacePhotovoltaic supportsRoof covering using slabs/sheetsMarine engineeringNatural state

The invention relates to the technical field of photovoltaic power generation, and discloses a photovoltaic tile connecting system. The photovoltaic tile connecting system comprises a tile hanging strip and a photovoltaic tile and further comprises an elastic connecting piece; the elastic connecting piece comprises a nail body and an elastic nail cap arranged at one end of the nail body; a mounting hole is formed in the photovoltaic tile; the end, away from the elastic nail cap, of the nail body penetrates through the mounting hole of the photovoltaic tile to be fixedly connected with the tilehanging strip; when the elastic nail cap is in a natural state, the elastic nail cap is used for limiting the photovoltaic tile to the position between the elastic nail cap and the tile hanging strip; and when the elastic nail cap is in a clenched state, the elastic nail cap can penetrate through the mounting hole. In the photovoltaic tile connecting system, the nail body of the elastic connecting piece is fixedly connected with the tile hanging strip, and thus the wind resistance of the photovoltaic tile is improved; and in addition, the elastic connecting piece is provided with the elasticnail cap which can be clenched, when the photovoltaic tile needs to be replaced, the elastic connecting piece does not need to be dismounted an remounted, replacing of the photovoltaic tile can be finished only by clenching the elastic nail cap, and the replacing efficiency of the photovoltaic tile is improved.

Owner:汉瓦技术有限公司

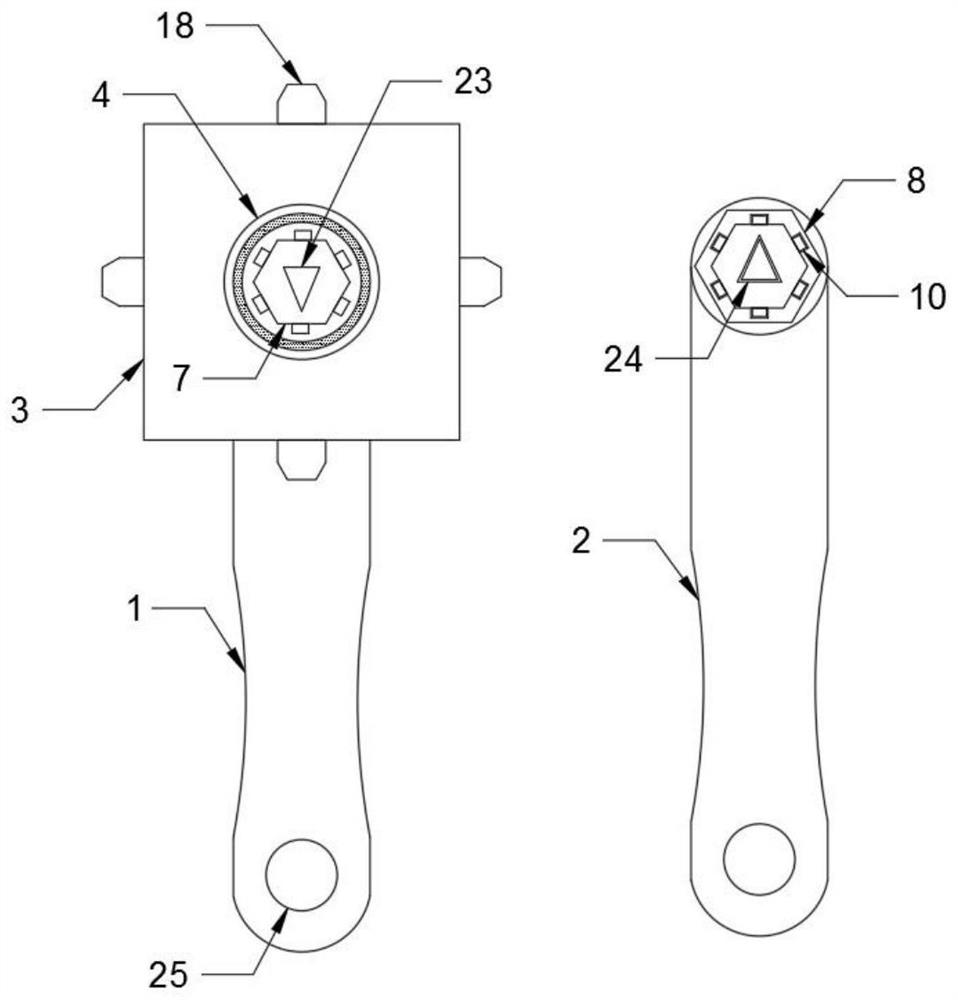

Bicycle crank convenient to replace

InactiveCN113060236AThe process is convenient and fastEasy to disassembleVehicle cranksGear wheelCrank

,The invention discloses a bicycle crank convenient to replace. The bicycle crank comprises a first crank body and a second crank body, a connecting block is fixedly arranged on one side of the upper end of the first crank body, a connecting rod is fixedly arranged in the middle of the side, away from the first crank body, of the connecting block, a gear movably sleeves the middle of the surface of the connecting rod a fixing frame is fixedly arranged on the side, close to the first crank, of the gear, an inserting block is fixedly arranged at the end, away from the connecting block, of the connecting rod, an inserting groove is fixedly formed in the middle of the surface of the upper end of the second crank, a first clamping mechanism is arranged in the inserting block, the first clamping mechanism comprises first clamping blocks, a first clamping groove, a transmission rod, a telescopic rod, an extrusion block and a moving block, and the plurality of first clamping blocks are uniformly and fixedly arranged on the periphery of the outer side surface of the insertion block. The bicycle crank is good in use effect, the first crank and the second crank can be conveniently disassembled and assembled, and meanwhile the first crank and the gear can be conveniently disassembled and assembled.

Owner:天津市双鑫隆自行车配件有限公司

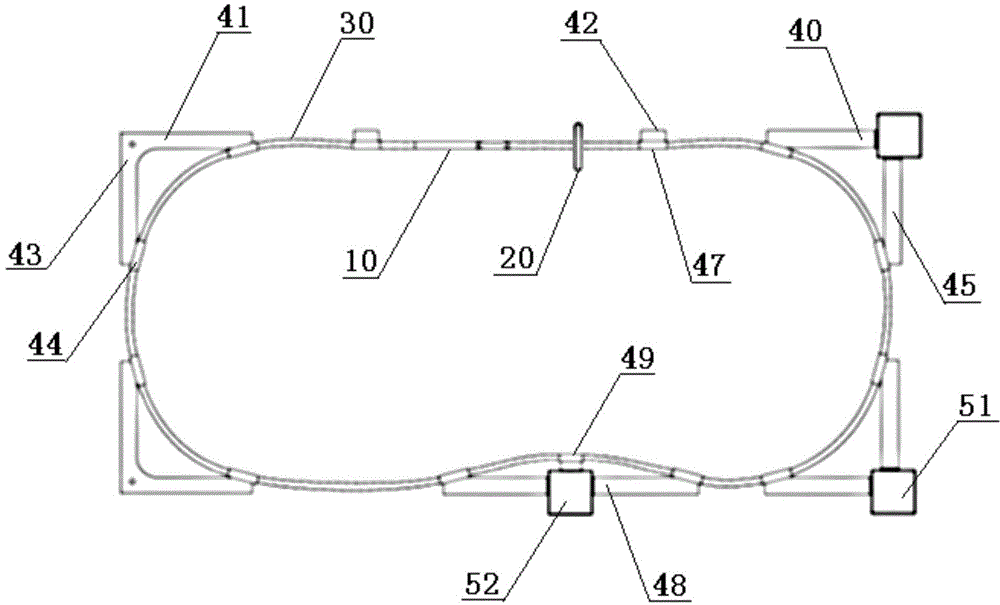

Diverter used for outdoor training and safety protection device comprising diverter

The invention provides a safety protection device used for outdoor training. The safety protection device comprises a safety rope, a sliding lock, a support and a diverter, wherein the sliding lock glidingly sheathes the safety rope, the support is used for supporting and fixing the safety rope so as to form a climbing route, and the diverter is arranged at the crotch of the climbing route; a main channel of the diverter is connected with a main safety rope, and two branch channels are respectively connected with two branch safety ropes. According to the safety protection device provided by the invention, fixation, installation and steering of the safety rope can be realized under the condition that a few pillars are used and even no pillar is used, and meanwhile, the sliding lock can smoothly pass through the diverter and the support so as to help the sliding lock to freely slide and turn on the safety rope, therefore safety equipment is effectively prevented from being disassembled and reassembled, the condition requirement on a field for the outdoor training is reduced, the cost input is reduced, the safety performance of the safety protection device is improved, and the activity experience of a participant is greatly enhanced.

Owner:北京乐仕堡科技发展有限公司

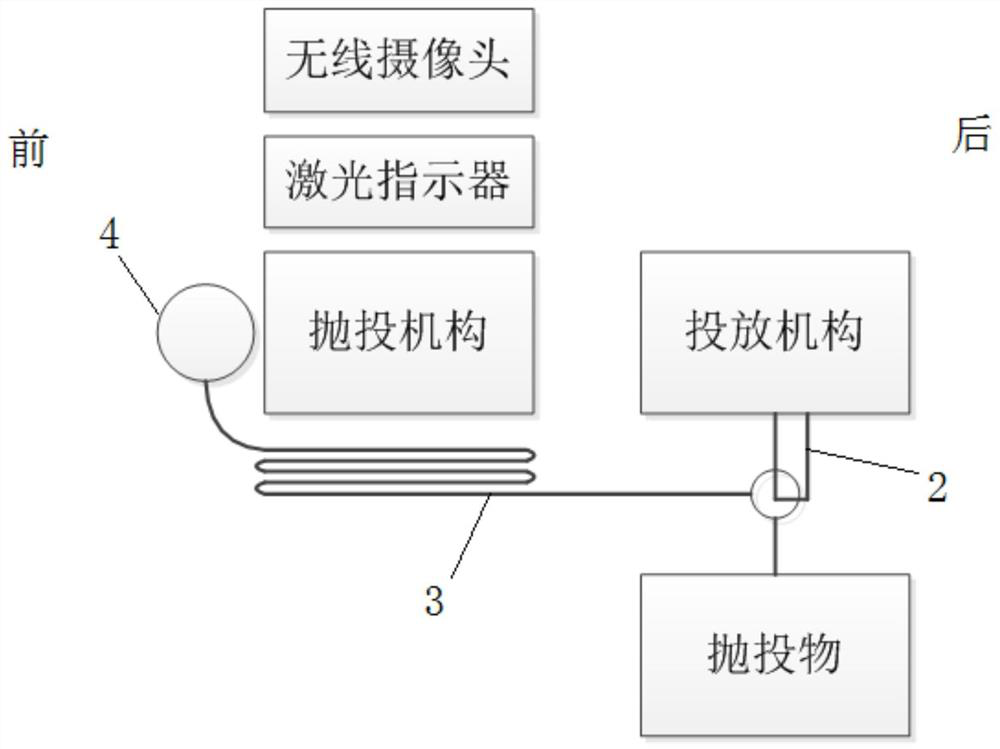

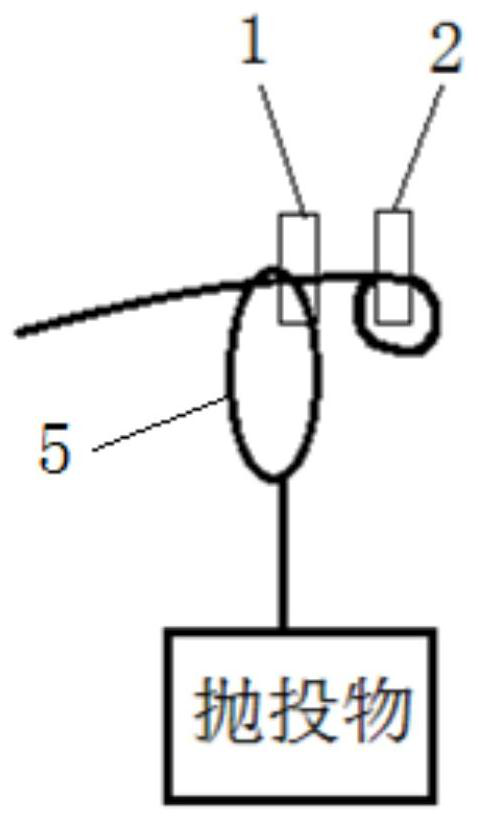

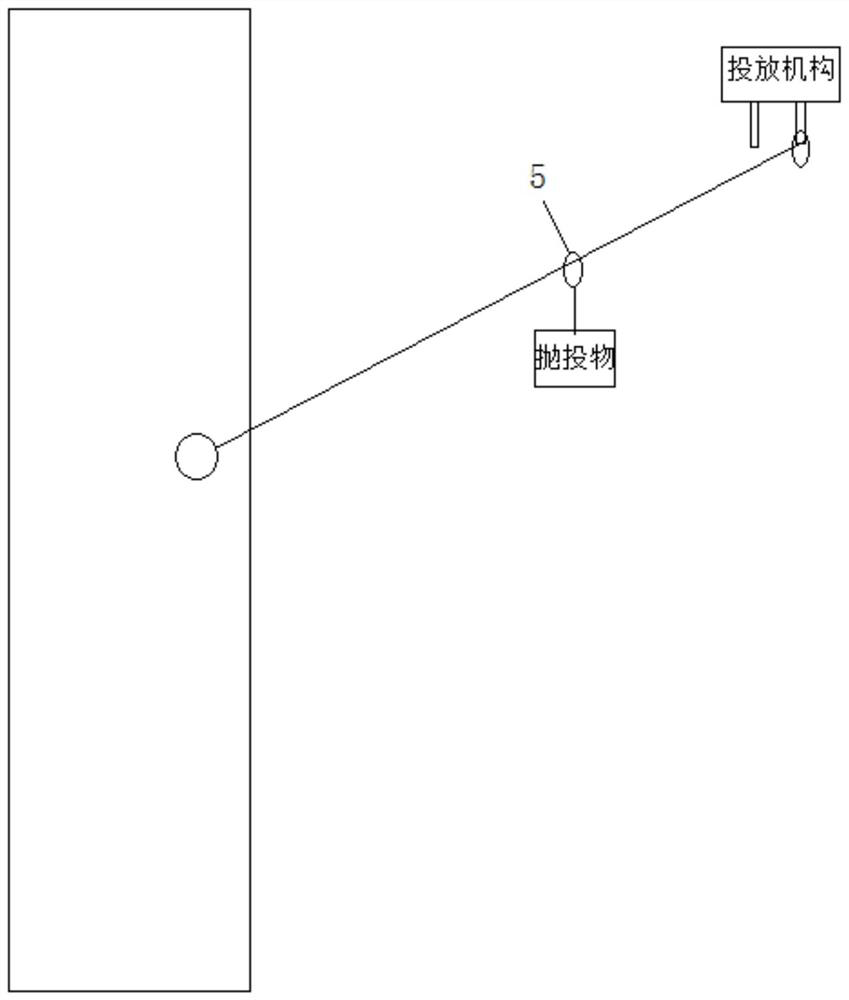

Lateral throwing device of unmanned aerial vehicle and operation method thereof

PendingCN111703576ARealize lateral throwing material equipmentImprove adaptabilityFreight handlingLaunching weaponsEmergency rescueClassical mechanics

The invention relates to a lateral throwing device of an unmanned aerial vehicle. The front end of a traction rope is connected with a guide head with a weight increasing function, the rear end of thetraction rope is connected with a thrown object, and a throwing mechanism is connected with the traction rope through a throwing rope lock catch; a wireless camera acquires image information in frontof a transverse direction and transmits the image information to the far end where an unmanned aerial vehicle operator is located; a laser pointer emits a reference point forwards in a transverse direction, and the wireless camera acquires the relative position between the reference point and a target projection part; and the throwing mechanism transversely throws the guide head to the target projection part and unlocks the throwing rope lock catch after the traction rope is controlled by a person at the target projection part. The traction rope connected with the thrown object is laterally launched, the traction rope is received and controlled by a person at the target projection position to transfer the thrown object, and then the unmanned aerial vehicle laterally throws goods and materials. The adaptability of the unmanned aerial vehicle in various emergency rescue scenes is improved, and the unmanned aerial vehicle can be applied to the fields of emergency rescue, police officers,aloft work and the like.

Owner:SHANGHAI FIRE RES INST OF MEM

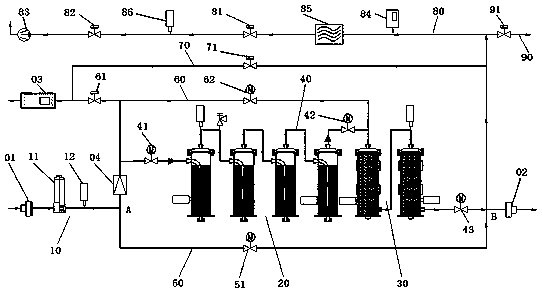

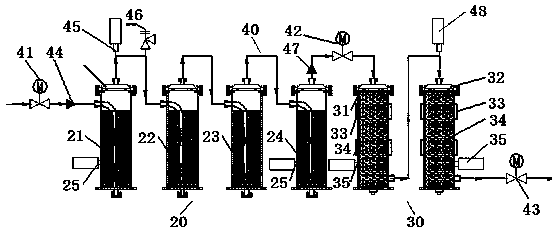

Sulfur hexafluoride gas purification system

ActiveCN111186819AHigh reuse rateAvoid Recycling EquipmentDispersed particle separationSulfur and halogen compoundsGas insulationSulfur fluoride

The present invention relates to a sulfur hexafluoride gas purification system, which comprises: an alkaline washing unit filled with an alkaline medium and used for removing acidic components of a gas when sulfur hexafluoride gas is introduced; a drying unit filled with a drying medium and used for removing moisture of the gas when the sulfur hexafluoride gas is introduced, wherein the alkali washing unit is connected with the drying unit in series, the front end of the drying unit is communicated with the rear end of the alkali washing unit, the inlet of the alkali washing unit is connectedwith a gas inlet pipeline used for being connected with gas insulation electrical equipment, and the outlet of the drying unit is connected with a gas outlet pipeline used for being connected with gasextraction equipment. According to the invention, the alkaline medium in the alkaline washing unit can be subjected to an acid-alkali neutralization reaction with the acidic component in sulfur hexafluoride gas, and the drying unit is located at the downstream of the alkaline washing unit and can absorb the moisture contained in the sulfur hexafluoride gas due to neutralization reaction and / or the sulfur hexafluoride gas, so that the sulfur hexafluoride gas is purified by the alkaline washing unit and the drying unit to obtain dry and pure sulfur hexafluoride gas.

Owner:HENAN PINGGAO ELECTRIC +2

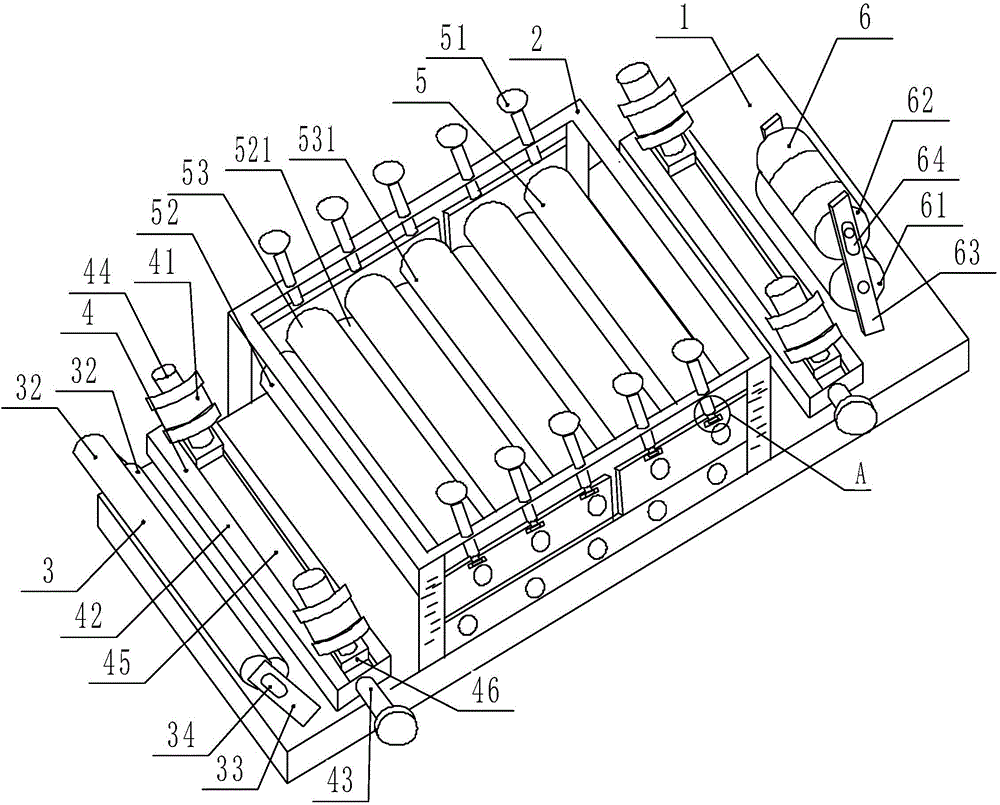

Compressor cylinder body fixing equipment

InactiveCN109968068AIncrease profitReduce manufacturing costWork clamping meansPositioning apparatusEngineeringCylinder block

The invention relates to compressor cylinder body fixing equipment. The equipment comprises a bottom plate, linear guide rails, a workbench, a vertical plate, a rotating disk, an end face pressing plate, a 90-degree rotating air cylinder and a side positioning mechanism. The compressor cylinder body fixing equipment is ingenious in design, reasonable in structure, convenient to use, high in practicability and low in cost, the equipment can be used after being installed on a common bench drill, two inclined holes on the left side wall and the right side wall of the compressor cylinder body canbe machined through once clamping, so that the clamping and machining speed is increased, the processing precision is improved, the production cost is reduced, and the market competitiveness of enterprises is improved.

Owner:TIANJIN JINLAI PRECISION MACHINERY

Anti-blocking rubber forming device

InactiveCN111673970AScientific and reasonable structureEasy to useDispersed particle filtrationTransportation and packagingForeign matterActivated carbon filtration

The invention discloses an anti-blocking rubber forming device which comprises a rubber forming machine control box, an equidistant feeding mechanism, a tail gas treatment mechanism, a mold clearing mechanism, a finished product collecting mechanism and a quick moving mechanism. The side wall of a deodorizing box in the tail gas treatment mechanism is fixedly connected with multiple electric clearing push rods, and the number of the electric clearing push rods is equal to that of activated carbon filtering screens. An output rod of each electric clearing push rod is fixedly connected with a brush plate, and the lower ends of the brush plates are fixedly connected with brush wires. An inlet pressure sensor and an outlet pressure sensor are arranged at the positions, on the lower sides and the upper sides of the activated carbon filtering screens, of the side wall of the deodorizing box correspondingly. A foreign matter collecting box is arranged on the side wall of the side, opposite tothe electric clearing push rods, of the deodorizing box, and the outer wall of the foreign matter collecting box is fixedly connected with multiple matched electric push rods; and an output rod of each matched electric push rod is fixedly connected with an opening and closing plate, each opening and closing plate is located above the corresponding activated carbon filtering screen, and the opening and closing plates can be inlaid on the side walls of the deodorizing box.

Owner:刘理仁

Sensing device for carrying out real-time monitoring on load bearing of single-rope winding hoisting system

InactiveCN102173359BGuaranteed automationJudging the jamming problemTension measurementElevatorsFuel tankComputer module

The invention discloses a sensing device for carrying out real-time monitoring on load bearing of a single-rope winding hoisting system, belonging to mining equipment.The device comprises a rack, an upper pull rod, a detection fuel tank, an upper bearing block, a lower bearing block, a pressure transmitter and a wireless transmitting module.The rack consists of two connected lateral plates, the upper bearing block is arranged at the upper ends of the two lateral plates, the lower ends of the lateral plates are connected with a lower connector which is connected with a container.The upper pull rod is neither connected with the lateral plates nor connected with the upper bearing block, the upper pull rod is connected with the upper connector, and the upper connector is connected with a hoisting steel wire rope. The detection fuel tank is connected with the upper bearing block, a piston rod is adjacent to the lower bearing block, the lower bearing block is plugged in long holes of the lateral plates in a sliding-fit manner, the pressure transmitter is arranged at the port of the detection fuel tank and connected with the wireless transmitting module. When loading is carried out on the container, the signals detected by the pressure transmitter are loaded weight signals; in the process of normal operation of the container, the signals detected by the pressure transmitter are loading signals from a steel wire rope terminal.

Owner:徐州泰荣煤矿设备有限公司 +1

Programmable Deep Neural Network Processor

ActiveCN108520297BIncrease profitUtilization impactNeural architecturesPhysical realisationComputer hardwareMultiplexing

The invention discloses a programmable deep neural network processor, which includes a program control unit, a filter buffer area, and a feature map buffer area. The feature map buffer area is used to cache multiple feature maps. The filter buffer area is used for It also includes a layer processing engine, and the convolution unit part of the layer processing engine includes a multiplication and accumulation unit, a convolution accumulation unit and a feature map accumulation unit arranged in sequence, and the feature map cache The area and the filter buffer area are connected to the input end of the layer processing engine, and a data shaping and multiplexing unit is also arranged between the feature map buffer area and the input end of the layer processing engine. The present invention realizes a low-power, low-cost programmable deep neural network processor through the multiplexing control of the multiply-accumulate unit, the feature map data reading control, the feature map accumulation control, and the redundant data elimination control.

Owner:周军

One-step molding process of roller bar lathe

The invention discloses a one-step molding process of a roller bar stock DDF3 on a lathe. The process comprises the following steps of: leveling a right end surface by adopting an end surface cutter; after the end surface is leveled to an appointed size, digging a hole on the right side of a roller; cutting off by using a cut-off tool, and meanwhile, synchronously profiling the left chamfer from the outer diameter of the right chamfer; and after finishing slotting by a slotting tool which is a flat cutter and a 5-degree chamfering cutter, assisting a clamping head to clamp and twist off a roller. By adopting the method, the turning processing of all surfaces of the roller can be finished in one-step clamping, the processed roller is molded at one time and can be directly sent to a grinding procedure after being subjected to heat treatment. The one-step molding process of a roller bar stock DDF3 on a lathe can be used for realizing the one-step turning and molding of the processed roller, saves the material handling time, combines the procedures, saves the labor power, avoids secondary clamping of the processed roller, improves the processing precision, improves the processing efficiency and saves the total processing time. After the process is applied to lathes, an operator can simultaneously operate 3-4 lathes, thus a large quantity of labor power is saved.

Owner:WAFANGDIAN BEARING GRP CO LTD +1

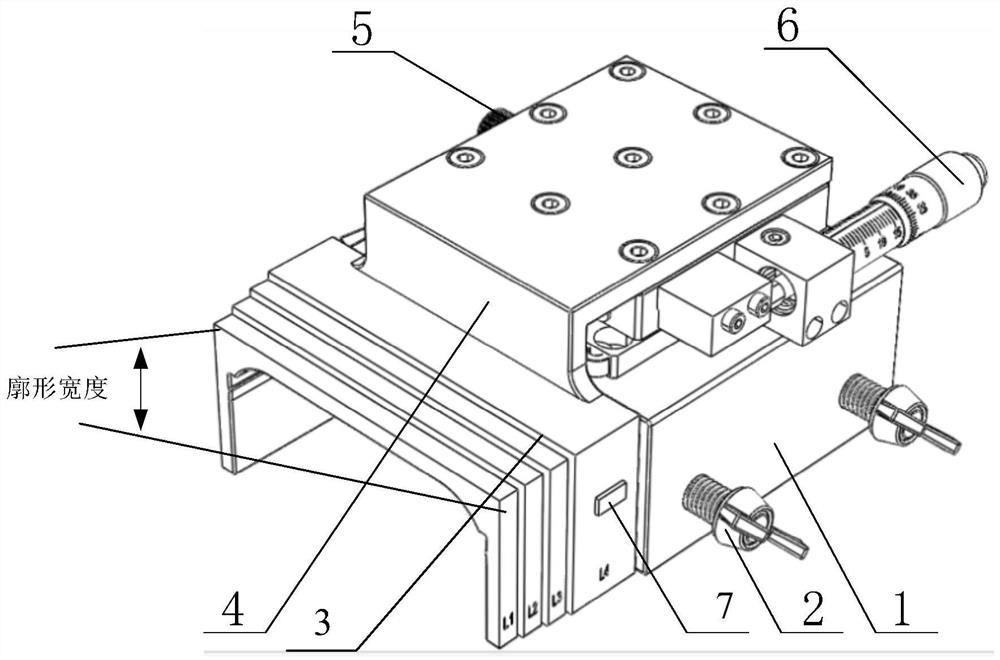

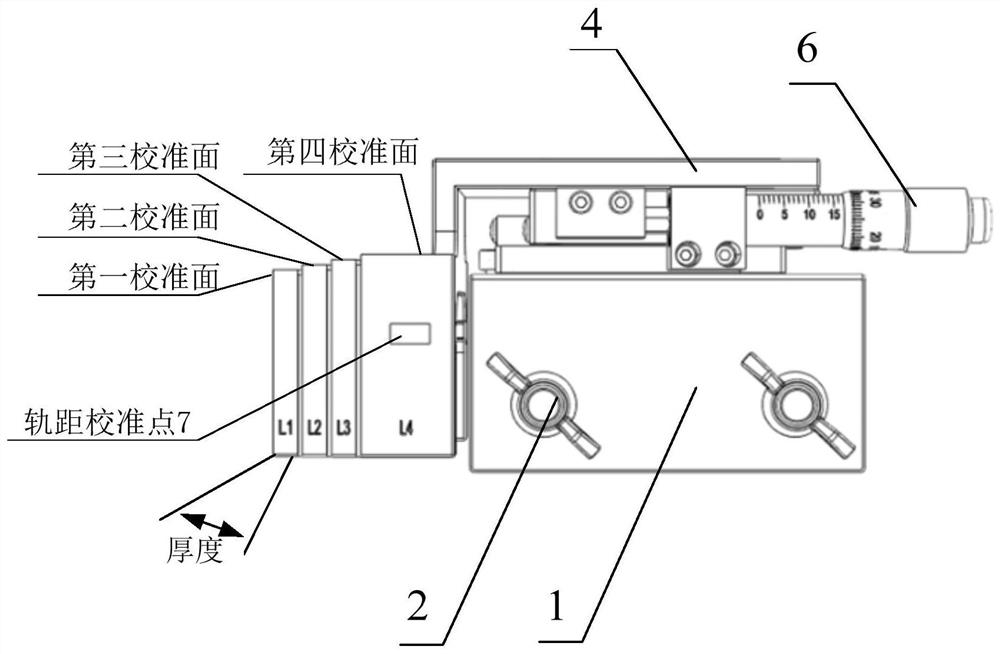

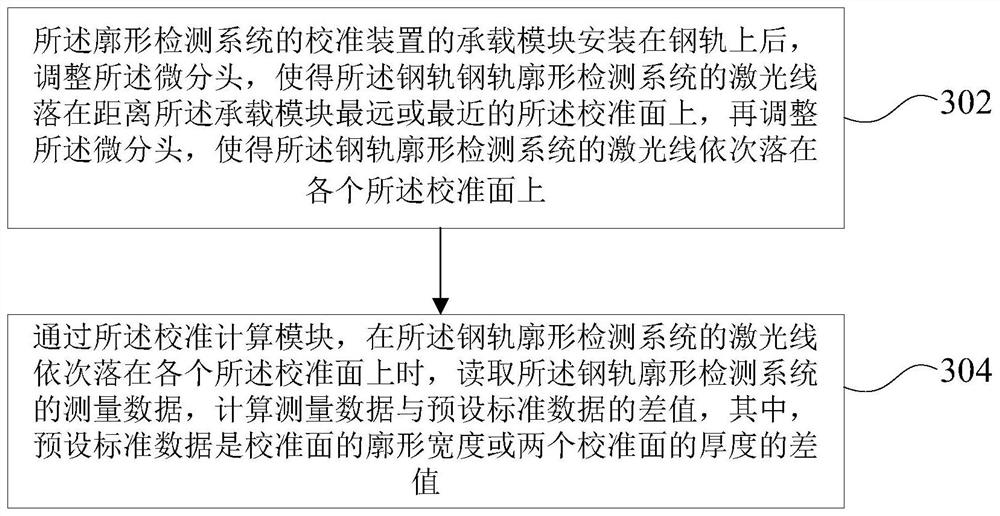

Calibration device of profile detection system and working method thereof

The embodiment of the invention provides a calibration device of a profile detection system and a working method thereof, and the device comprises a bearing module which is installed on a steel rail;a fixed module of a fine movement platform, fixed on the bearing module, and the sliding module of the fine movement platform being connected with the calibration module; a calibration module, comprising at least three calibration surfaces which are parallel to one another and are arranged at equal intervals, the parallel directions of the calibration surfaces being perpendicular to the extendingdirection of the steel rail, the planes of the calibration surfaces being parallel to the top surface of the steel rail, and the thicknesses of the calibration surfaces being sequentially decreased progressively in an equal-difference mode in the direction away from the bearing module; a micrometer head, fixed on the fixed module of the fine moving platform, and a screw rod of the micrometer headbeing connected with the sliding module; a calibration calculation module, correspondingly acquiring measurement data of the steel rail profile detection system and calculating a difference value between the measurement data and preset standard data when laser rays of the steel rail profile detection system sequentially fall on each calibration surface. According to the scheme, the steel rail profile detection system can be calibrated under the installation state of the steel rail profile detection system.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

A double-station automatic rubber molding machine

ActiveCN111438862BScientific and reasonable structureEasy to useDirt cleaningRubber materialBraced frame

The invention discloses a double-station high-efficiency automatic rubber forming machine. Rubber forming machine main bodies are arranged at two sides of a control box of the rubber forming machine separately, and guide sliding frames are symmetrically arranged in the middle part of each rubber forming machine main body; and supporting frames are fixedly connected at the tops of the guide slidingframes, the inner sides of the guide sliding frames are slidably connected with forming molds, and the two sides of the supporting frames are fixedly connected with equidistant feeding mechanisms. According to the machine, by arranging a sliding rod, and swinging teeth, when the swinging teeth push forwards a feeding box, a driving rotating wheel is driven to rotate, and a strip-shaped rubber material in a discharging cavity is added to the forming molds through the discharging cavity by means of the driving rotating wheel, a transmission swinging rod and a pushing plate, so that the placement for adding the rubber material into the forming molds is simplified; and the rubber material in the discharging cavity can be uniformly added into the forming molds only by pushing the feeding box forwards, so that the labor intensity of operators is reduced, the working efficiency is improved, and the productivity is increased.

Owner:无锡市睿科机械部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com