Sensing device for carrying out real-time monitoring on load bearing of single-rope winding hoisting system

A lifting system and real-time monitoring technology, which is applied in elevators, transportation and packaging, tension measurement, etc., can solve problems such as cans stuck, and achieve the effects of preventing secondary loading, ensuring automation, and preventing skips from loosening ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

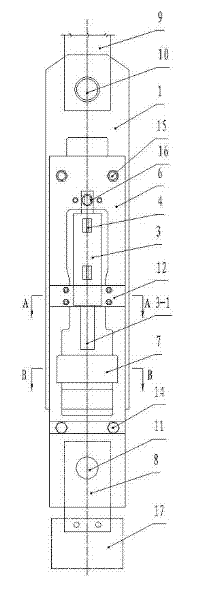

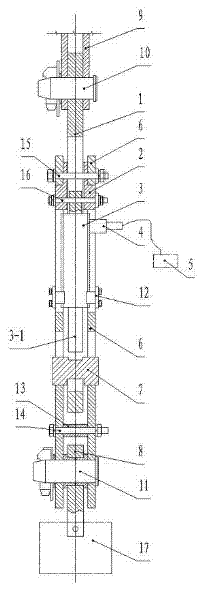

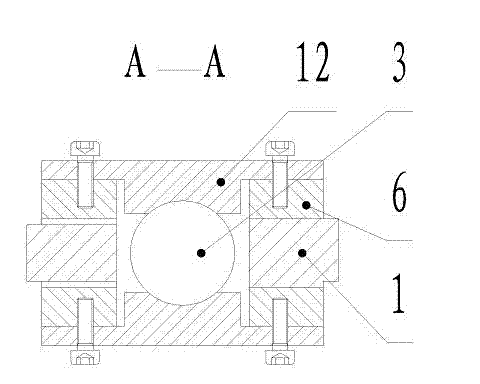

[0018] Such as figure 1 , figure 2 Shown: a real-time monitoring and sensing device for a single-rope winding hoisting system, characterized in that the device includes: a frame, an upper pull rod 1, a detection cylinder 3, an upper load-bearing block 2, a lower load-bearing block 7, and a pressure transmitter 4 and a wireless transmitting module 5; the frame is formed by connecting two side plates 6 with the same structure, and the side plates 6 are strip-shaped plates; the upper load-bearing block 2 is clamped on the two sides The upper end of the plate 6 is fixed by the bolt and nut assembly II15; the lower end of the side plate 6 is connected to the lower connector 8 through the lower connecting pin 11; the lower connector 8 is connected to the container 17; the upper pull rod 1 is connected to the side The plates 6 are similar in structure. The upper tie rod 1 is located between the two side plates 6. The upper tie rod 1 is not connected to the side plates 6 and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com