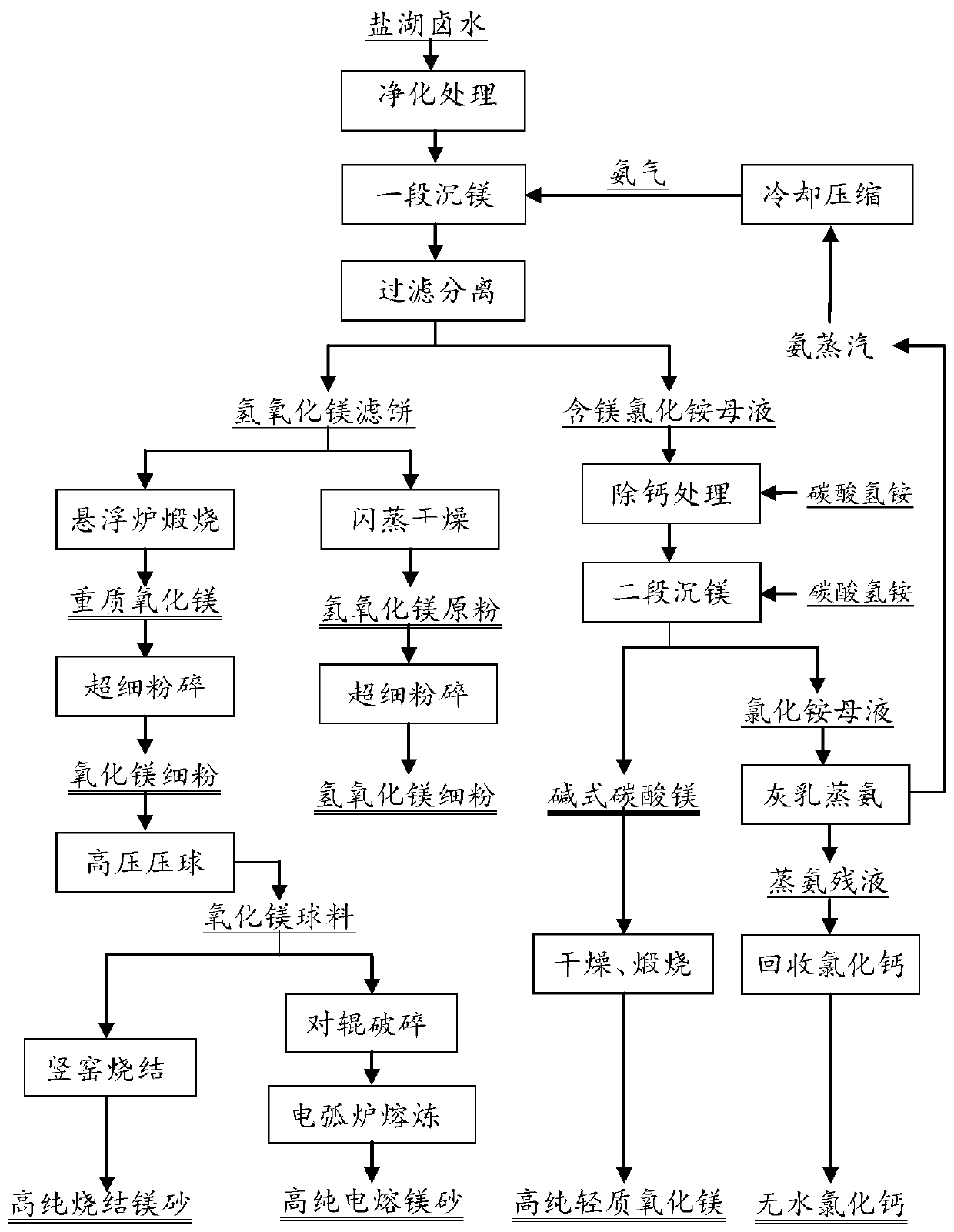

Method for producing high-purity magnesium hydroxide, high-purity magnesium oxide and high-purity magnesia series magnesium products by using salt lake brine

A technology of magnesium hydroxide and salt lake brine, applied in the direction of magnesium hydroxide, magnesium oxide, calcium/strontium/barium halides, etc., can solve problems such as low production efficiency, shrinking output, fine magnesium hydroxide particles, etc., and achieve resource improvement The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

[0047] 1. Preparation of raw brine

[0048] The source of brine can be the old brine discharged during the production process of salt lake potash fertilizer (potassium chloride), or the brine obtained after the old brine is evaporated, concentrated, and crystallized in the salt field by adding water and dissolving the bischofite The preparation of brine by dissolving has obtained a national invention patent. The patent name is: a method for continuously dissolving bischofite in salt lakes to prepare a high-concentration magnesium chloride solution, patent number: ZL 201410068315.X). Before the brine enters the production reaction system, it needs to be filtered and purified to remove the sediment and other insoluble suspended matter impurities in the brine. Typical brine components are: MgCl 2 30%~35%, NaCl0.30%~0.60%, KCl0.25%~0.50%, CaCl 2 0.01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com