Large wind power generation blade recovery treatment method and treatment system

A technology for wind power generation blades and recycling, which is applied in plastic recycling, grain processing, mechanical material recycling, etc. It can solve the problems of limited secondary utilization, material waste, and low material utilization rate, and achieve low cost, cost reduction, and environmental protection. friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

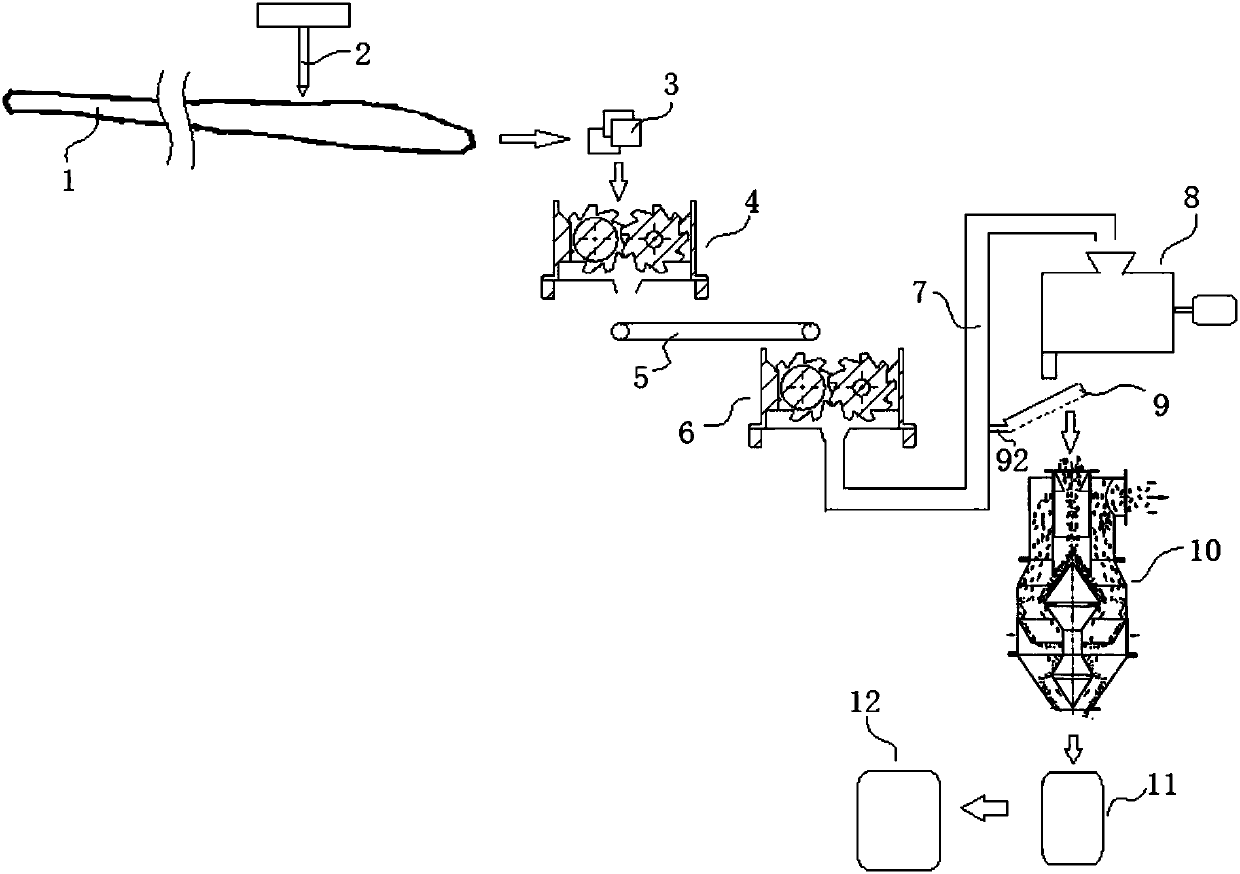

[0052] A method for recycling large-scale wind power blades, used for recycling large-sized damaged blades, comprising the following steps:

[0053] (1) dividing the large-sized damaged blade to be recovered into small-sized blade blocks with a width of no more than 1 m;

[0054] (2) Shred the blade block into a powder with a maximum size of no more than 1250 mesh;

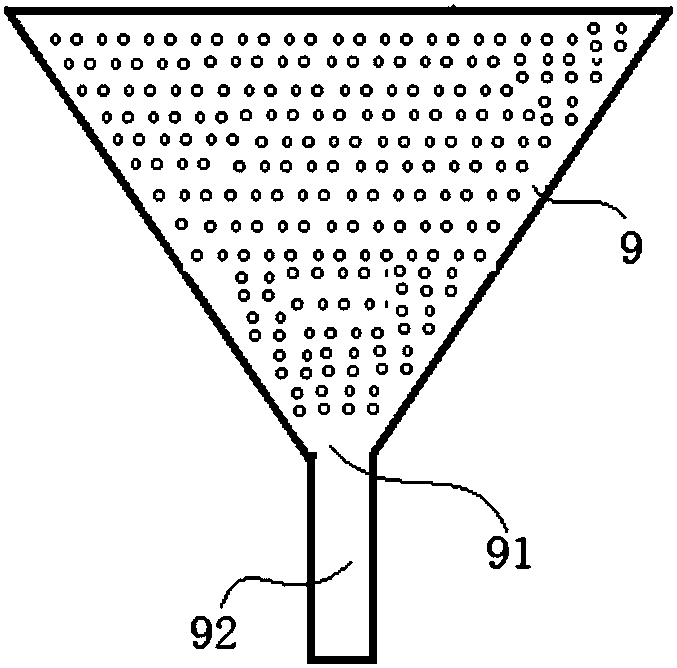

[0055] (3) Separating the powder according to the material type, separating the resin glass fiber powder and light material powder with a density less than the density of the resin glass fiber powder;

[0056] (4) activate the resin glass fiber powder with an activator, and obtain the activated resin glass fiber powder after drying;

[0057](5) Stir and mix the activated resin glass fiber powder, resin, short glass fiber, initiator, mold release agent and filler evenly under low shear force to obtain a lumpy mixture used to produce conformable material products, realizing large Recycling of dimensionally damaged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com