A double-station automatic rubber molding machine

A rubber molding machine, double-station technology, applied in cleaning methods and utensils, chemical instruments and methods, and smoke removal, etc., can solve the problems of increasing the labor intensity of operators, reducing productivity, and inefficiency, and achieving reduced labor intensity, The effect of increasing productivity and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

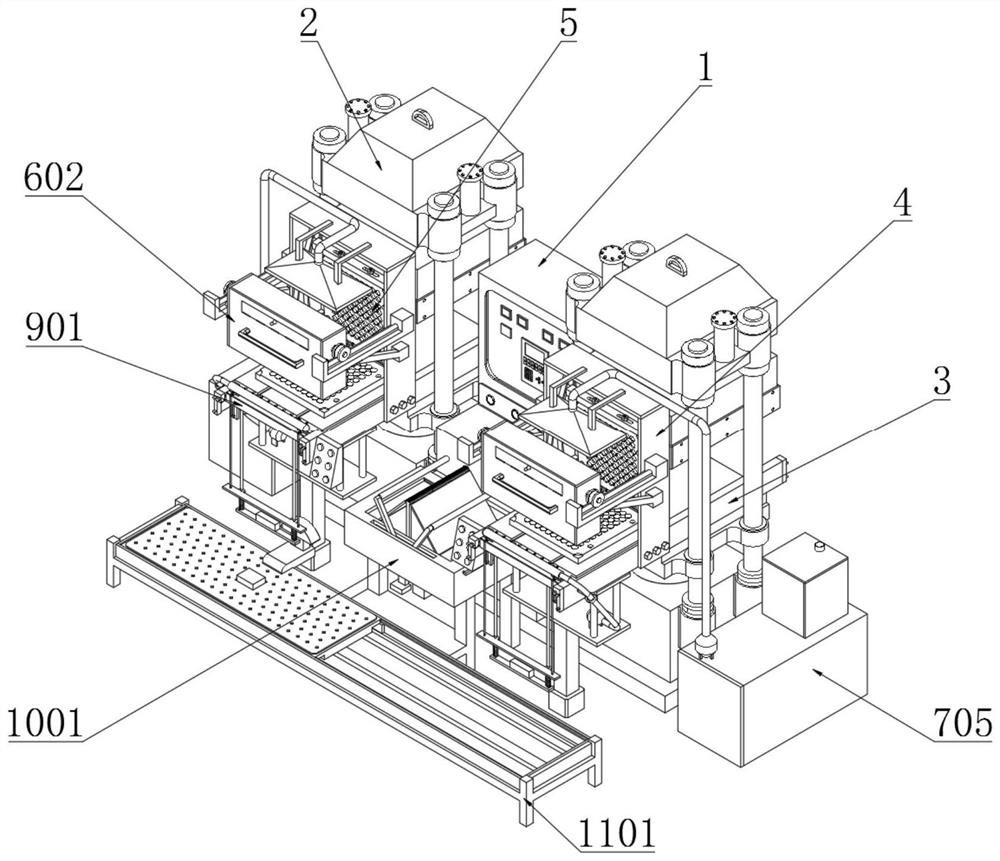

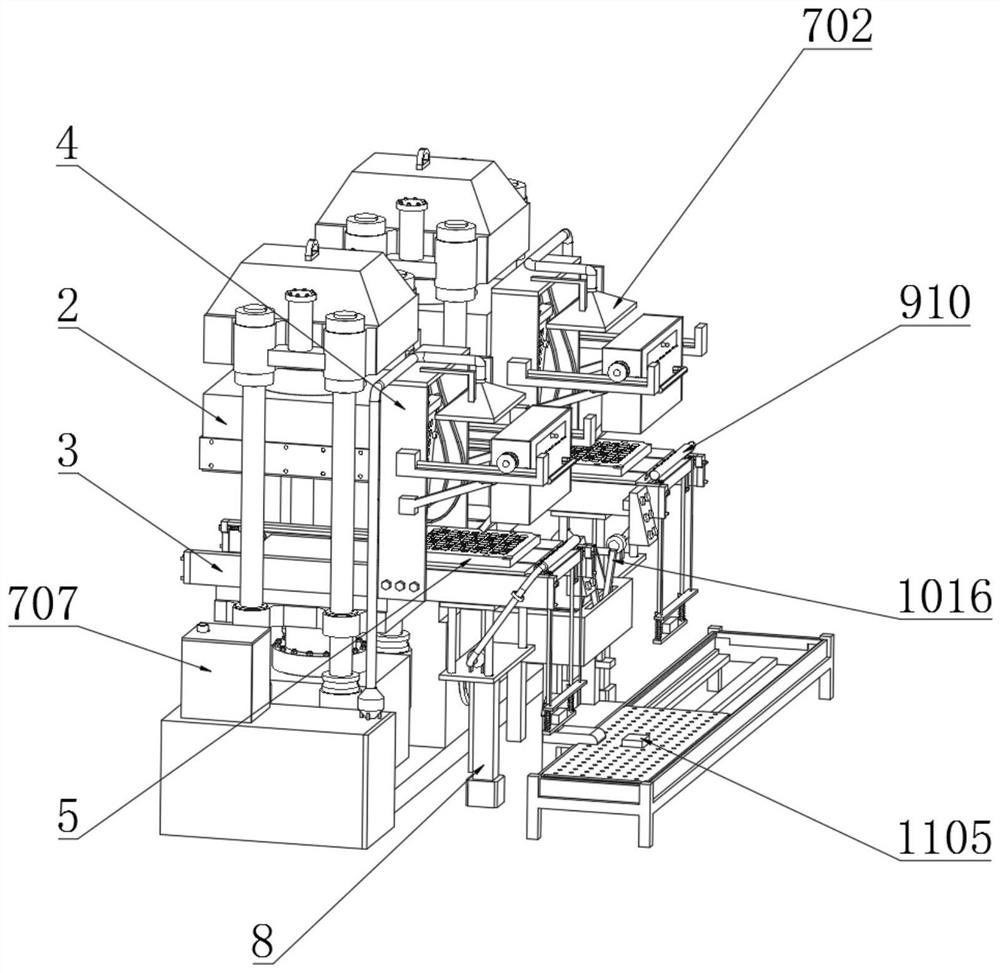

[0055] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a double-station automatic rubber molding machine, including a rubber molding machine control box 1, a rubber molding machine main body 2 is arranged on both sides of the rubber molding machine control box 1, and a rubber molding machine main body 2 The middle part is symmetrically provided with a guide sliding frame 3, the top of the guide sliding frame 3 is fixedly connected with a support frame 4, the inner side of the guide slide frame 3 is slidably connected with a forming mold 5, and the two support frames 4 are fixedly connected with equidistant upper Material mechanism 6;

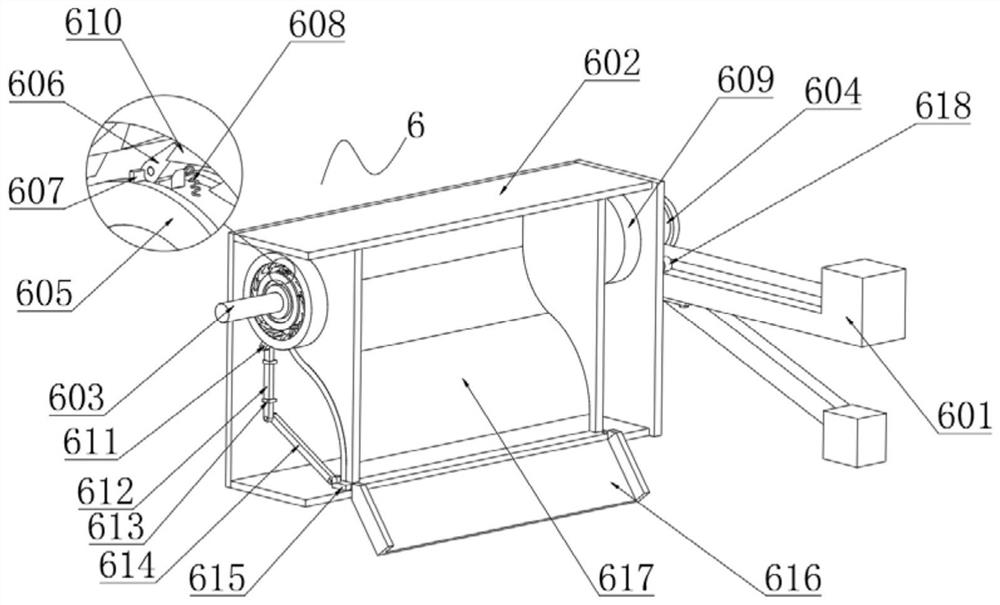

[0056] The equidistant feeding mechanism 6 includes a support sliding frame 601, a feeding box 602, a sliding bar 603, a friction roller 604, an inner drive wheel 605, a swing tooth 606, a limiting flat bar 607, a reset arc spring 608, a driving rotary Wheel 609, inner driving gear 610, swing lever 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com