Sulfur hexafluoride gas purification system

A technology of sulfur hexafluoride gas and purification system, applied in inorganic chemistry, sulfur compounds, sulfur and halogen compounds, etc., can solve the problems affecting the service life of the recovery device, corrosion of the recovery device, equipment accidents, etc., to improve the reuse rate , reduce the purification process, improve the efficiency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

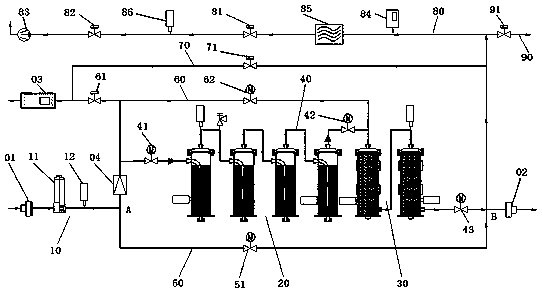

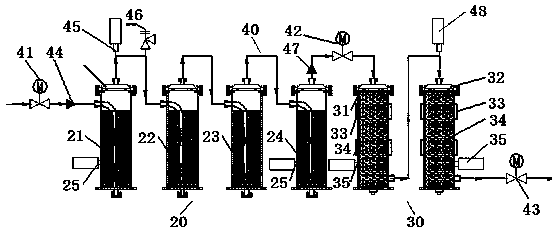

[0050] Embodiment 1 of the sulfur hexafluoride gas purification system in the present invention: the sulfur hexafluoride gas purification system in the present invention can purify the sulfur hexafluoride gas containing impurities to obtain dry, pure and reusable Sulfur hexafluoride gas. When in use, the sulfur hexafluoride gas purification system is arranged between the gas-insulated electrical equipment filled with sulfur hexafluoride gas and the air extraction equipment. The air extraction equipment is equipped with an air pump, which can purify and recycle the electrical equipment. The sulfur hexafluoride gas is pumped into the purification system, and the sulfur hexafluoride gas is pumped into the extraction equipment after being purified by the purification system.

[0051] Such as figure 1 and figure 2 As shown, the sulfur hexafluoride gas purification system is provided with an air intake pipeline at the head end, and the air intake joint 01 is located at the front ...

Embodiment 2

[0080] Embodiment 2 of the sulfur hexafluoride gas purification system in the present invention: the difference from the above-mentioned embodiments is that the sulfur hexafluoride gas purification system in this embodiment is provided with an air intake pipeline, an alkali The washing unit, drying unit and gas outlet pipeline are no longer provided with branch pipelines, so that sulfur hexafluoride gas can only pass through the alkali cleaning unit and drying unit in sequence during purification, and cannot pass through the alkali cleaning unit and drying unit.

Embodiment 3

[0081] Embodiment 3 of the sulfur hexafluoride gas purification system in the present invention: the difference from the above embodiments is that the sulfur hexafluoride gas purification system in this embodiment is provided with branch pipelines, and the branch pipelines are only for six Sulfur fluoride gas passes over the non-alkaline cleaning line of the alkaline cleaning unit. In other embodiments, the branch pipeline may only be a purification-free pipeline for the sulfur hexafluoride gas to pass through the alkali cleaning unit and the drying unit at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com