Silica brick for glass furnace

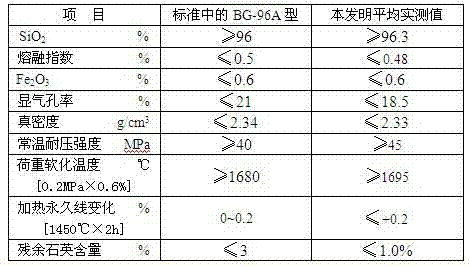

A glass kiln and silica brick technology, applied in the field of refractory materials, can solve the problems of unmentioned product rate, service life and impurity content, high residual quartz content, cumbersome production process, etc., and achieves good high temperature performance and high SiO2 content. , the effect of low apparent porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

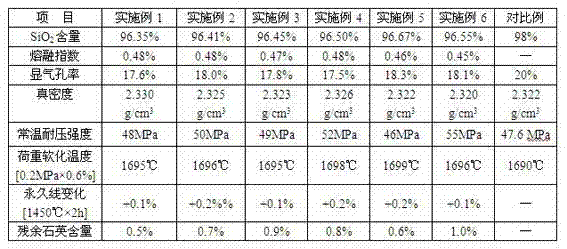

Embodiment 1

[0032] Silica bricks for glass kilns, the weight percentage of the components contained is: 30% of silica with a particle size of 3~1.0mm, 20% of silica with a particle size of 1.0~0.5mm, 50% of silica with a particle size of less than 0.5mm, and The total weight of the above components is 5% of additives and 2% of composite additives, of which SiO in silica 2 The content is not less than 99%, Al 2 o 3 Content not higher than 0.25% and Fe 2 o 3 The content is not higher than 0.45%; the additive is SiO 2 Waste silica material with a content of not less than 96%; the compound additive is a mixture of milk of lime, iron scale and calcium lignosulfonate.

Embodiment 2

[0034] Silica bricks for glass kilns, the weight percentage of the components contained is: 45% of silica with a particle size of 3~1.0mm, 5% of silica with a particle size of 1.0~0.5mm, 50% of silica with a particle size of less than 0.5mm, and The total weight of the above components is 15% of additives and 10% of composite additives, of which SiO in silica 2 The content is not less than 99%, Al 2 o 3 Content not higher than 0.25% and Fe 2 o3 The content is not higher than 0.45%; the additive is SiO 2 Waste silica bricks with a content of not less than 96%; the composite additive is a mixture of 75% milk of lime, 15% iron scale and 10% calcium lignosulfonate.

Embodiment 3

[0036] Silica bricks for glass kilns, the weight percentage of the components contained is: 45% of silica with a particle size of 3~1.0mm, 25% of silica with a particle size of 1.0~0.5mm, 30% of silica with a particle size of less than 0.5mm, and The total weight of the above components is 10% of additives and 8% of composite additives, of which SiO in silica 2 The content is not less than 99%, Al 2 o 3 Content not higher than 0.25% and Fe 2 o 3 The content is not higher than 0.45%; the additive is SiO 2 The content is not less than 96% waste silica material, waste quartz tube with a particle size of 3~0.5mm; the composite additive is a mixture of 90% lime milk, 3% iron scale and 7% calcium lignosulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com