Process for producing silicon-based carbon composite material for lithium ion battery cathode

A silicon-based composite material, lithium-ion battery technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of small theoretical processing capacity of graphite, high production cost of nano-silicon and thin-film silicon, material pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

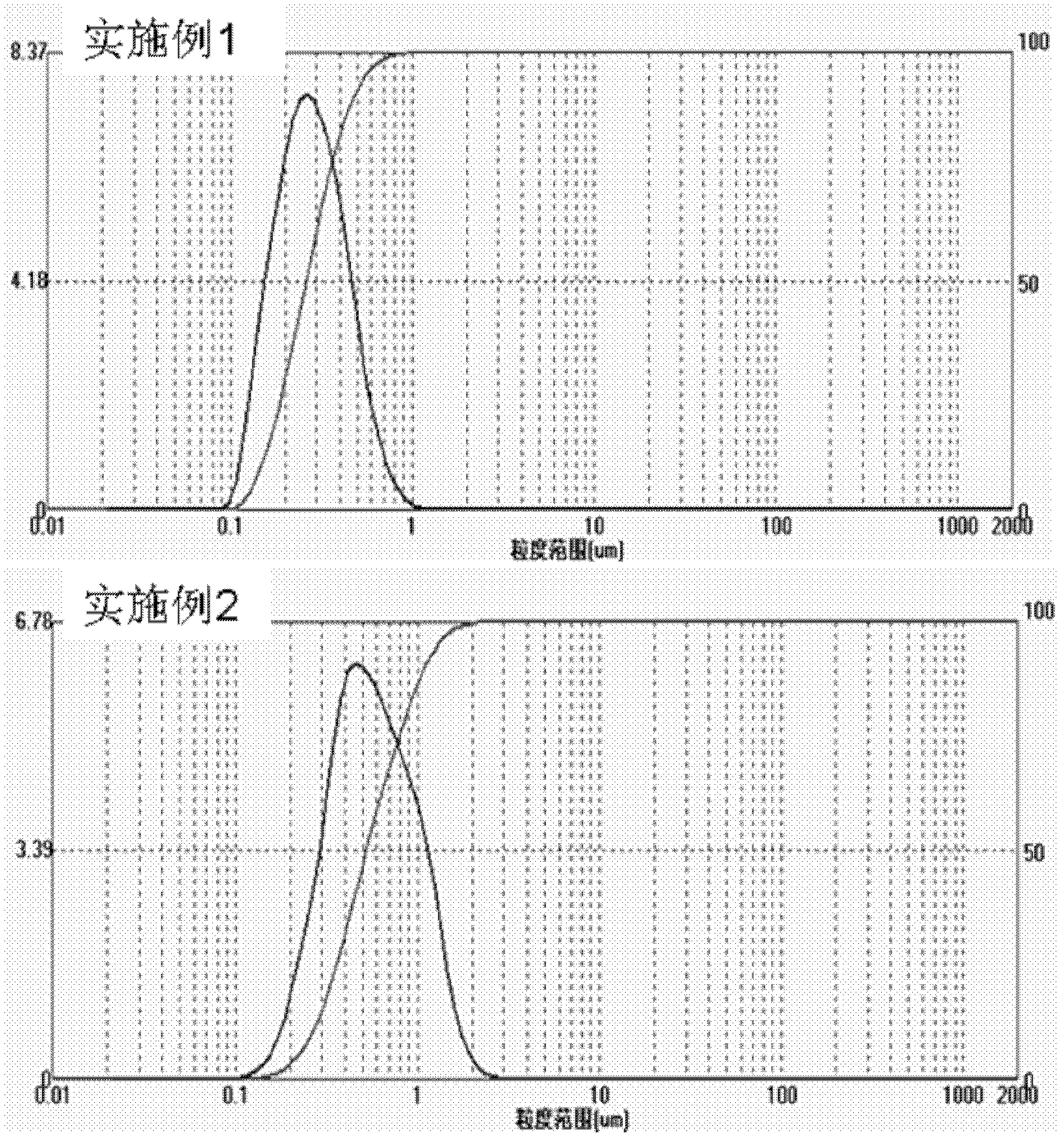

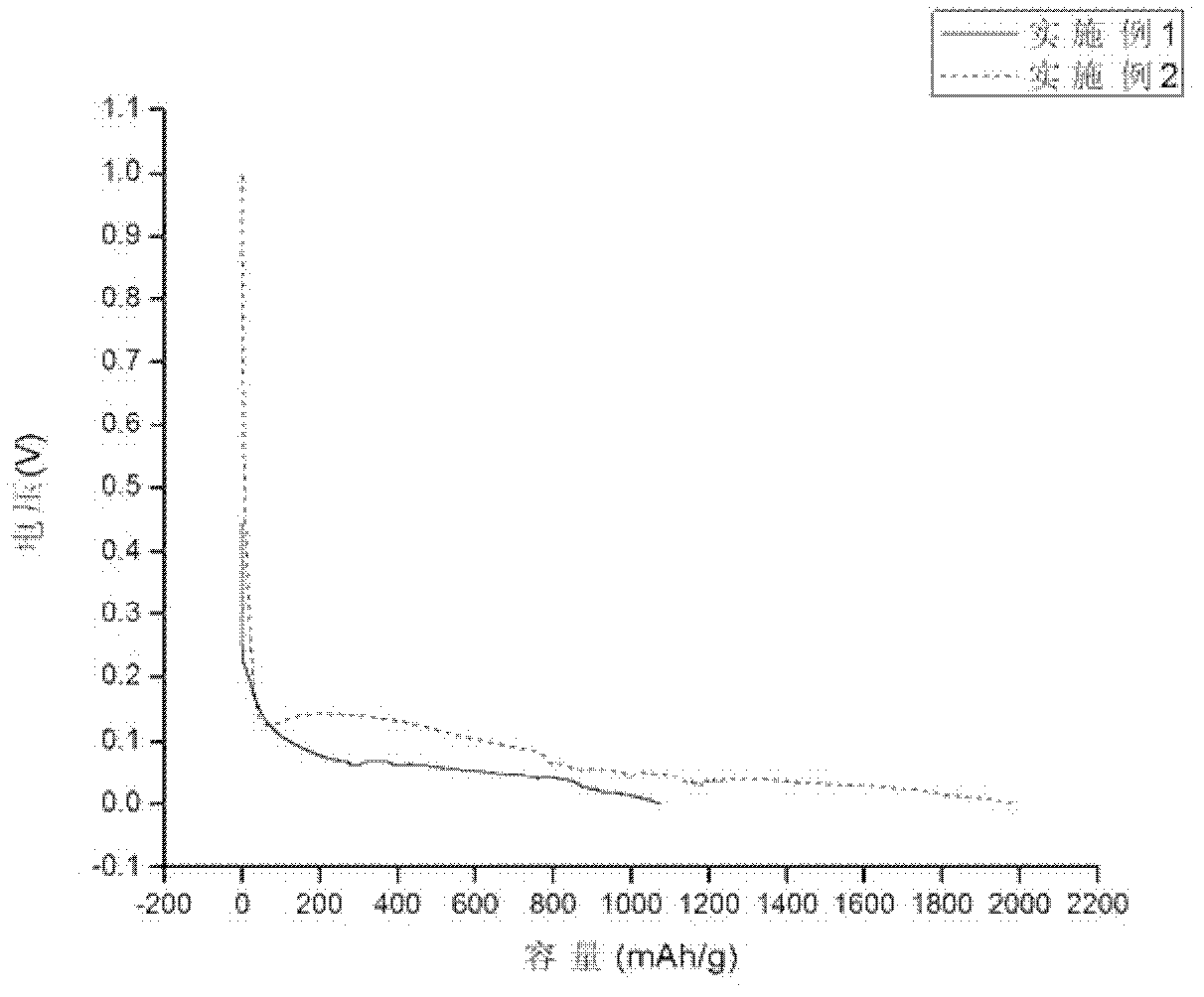

[0015] A kind of preparation method of lithium-ion battery negative pole silicon-based composite material, take Si powder as main material, take graphite powder as auxiliary material, the particle size of Si powder and graphite powder is all less than 20 μ m, Si powder and graphite powder are 95 by mass ratio: 5 After mixing, put it into a steel ball mill jar, vacuumize the steel ball mill jar and replace it with argon gas for three times, then fill it with argon as a protective gas, put the ball mill jar filled with protective gas in a planetary ball mill, and grind The diameter of the ball is 15-5mm, and the ball is milled at a speed of 500 rpm for 80 hours to obtain a powder with a particle size of less than 20 μm, which is the silicon-based composite material for the negative electrode of the lithium-ion battery. The particle size distribution is as follows: figure 1 shown.

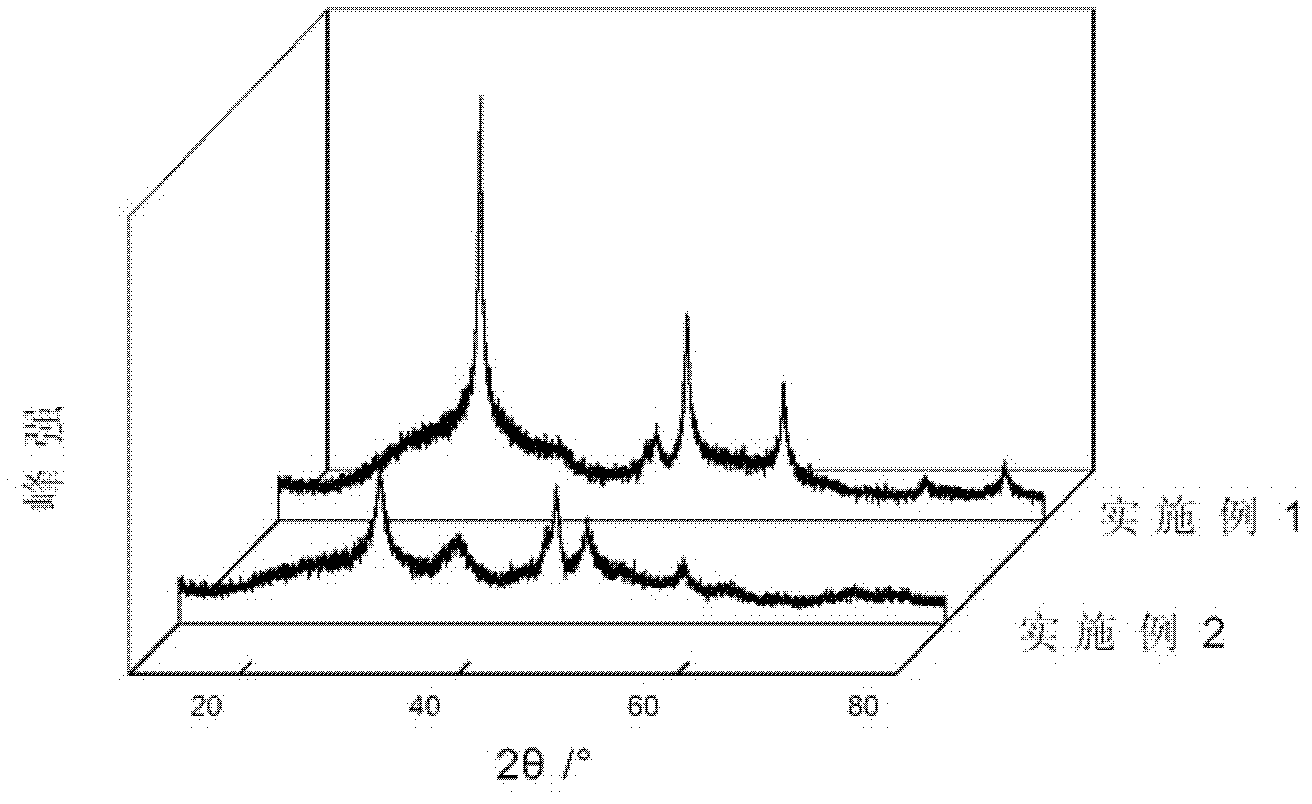

[0016] figure 2 It is the X-ray diffraction figure of embodiment 1. It can be seen from the fig...

Embodiment 2

[0018] A kind of preparation method of lithium-ion battery negative electrode silicon-based composite material, take Si powder as main material, take flocculent carbon black as auxiliary material, the particle size of Si powder and flocculent carbon black is all less than 20 μ m, Si powder and flocculent carbon black Mixed according to the mass ratio of 95:5 and put into the steel ball milling jar, vacuumize the steel ball milling jar and replace it with argon gas for three times, then fill it with argon as a protective gas, and place the ball milling jar filled with protective gas In the planetary ball mill, the diameter of the ball is 15-5mm, and the ball is milled at a speed of 500 rpm for 80 hours, and the powder with a particle size of less than 20 μm is the silicon-based composite material for the negative electrode of the lithium-ion battery. The particle size distribution is as follows: figure 1 shown.

[0019] figure 2 It is the X-ray diffraction figure of embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com