High-capacity composite anode material, preparation method, and lithium ion battery containing high-capacity composite anode material

A negative electrode material and negative electrode technology, applied in the field of new energy materials, can solve the problems of low expansion, poor utilization and high capacity of silicon-based materials, high first effect, etc., to achieve small volume expansion, improved contact and conductivity , reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

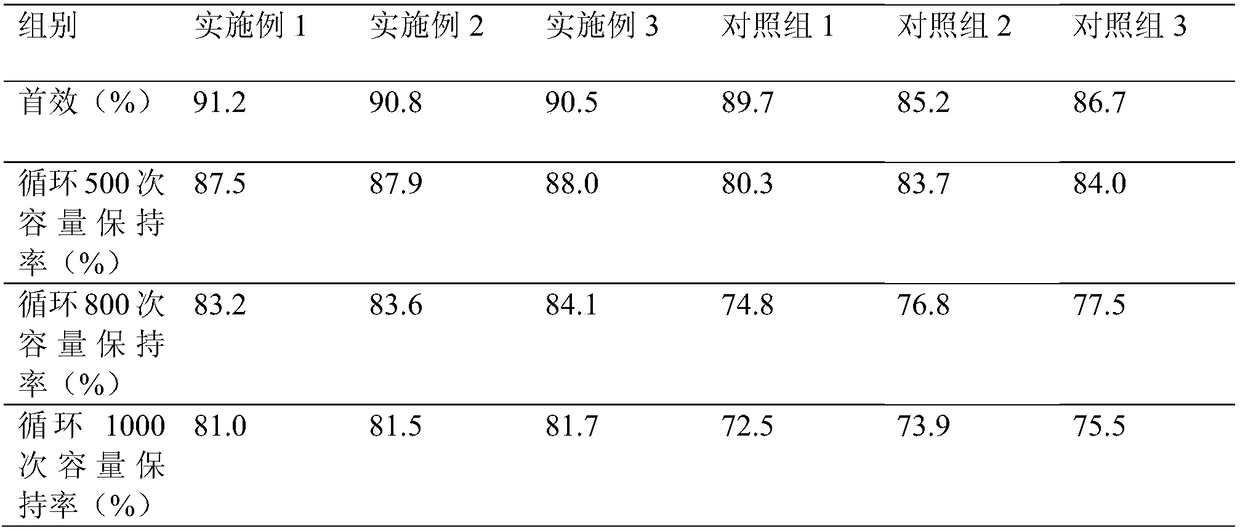

Examples

Embodiment 1

[0075](1) Using a gaseous organic carbon source, by chemical vapor deposition, mixing with nano-silicon (median particle size 20nm) and silicon oxide (median particle size 30nm), and then ball milling at a speed of 300r / min 12h, and then mechanical fusion at a speed of 1000r / min for 30min to obtain a carbonized precursor;

[0076] (2) Under the protection of an inert gas, first raise the temperature to 100° C. for 8 hours, and then raise the temperature to 900° C. for 24 hours to obtain a composite negative electrode material.

Embodiment 2

[0078] (1) Using a liquid organic carbon source, mix the organic carbon source, nano-silicon (with a median particle size of 100nm) and silicon oxide (with a median particle size of 1000nm), and then ball mill at a speed of 2000r / min for 0.5h, Then mechanically fuse at a speed of 3000r / min for 10 minutes to obtain a carbonized precursor;

[0079] (2) Under the protection of an inert gas, first raise the temperature to 200° C. for 2 hours, and then raise the temperature to 1000° C. for 12 hours to obtain a composite negative electrode material.

Embodiment 3

[0081] (1) Using a solid organic carbon source, mix the organic carbon source, nano-silicon (with a median particle size of 200nm) and silicon oxide (with a median particle size of 150nm), then ball mill at a speed of 800r / min for 9h, and then Mechanical fusion at a speed of 600r / min for 300min to obtain a carbonized precursor;

[0082] (2) Under the protection of an inert gas, first raise the temperature to 300° C. for 1.5 hours, and then raise the temperature to 850° C. for 22 hours to obtain a composite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com