Patents

Literature

65 results about "Heat mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat transfer is the transfer of energy due to temperature difference whereas mass transfer is the transfer of energy due to concentration difference.

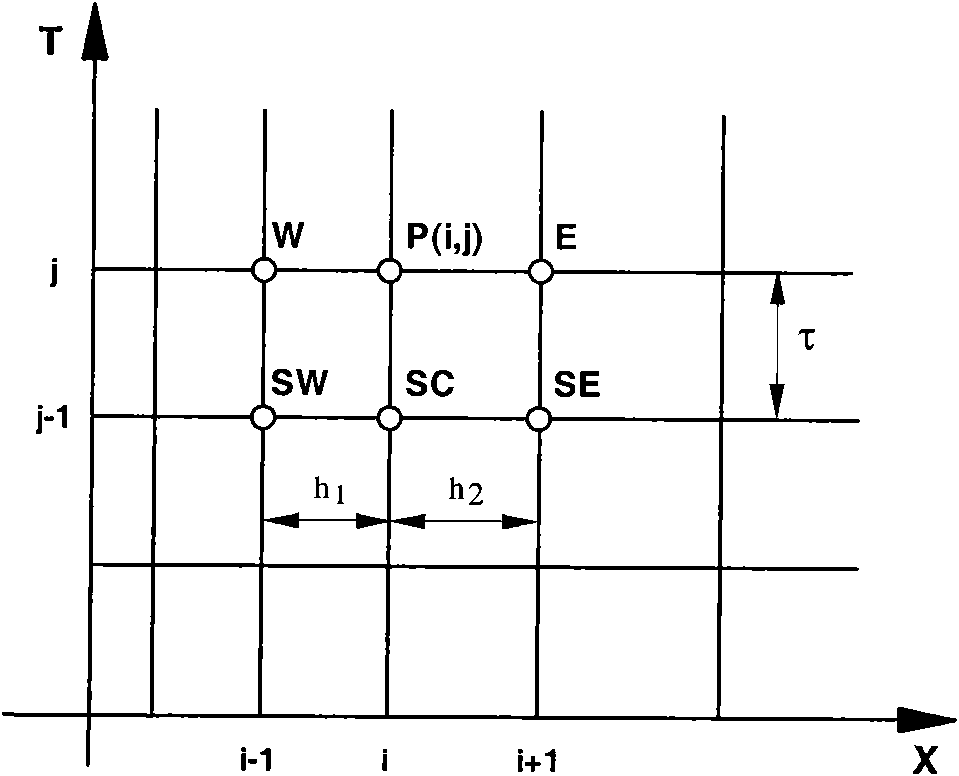

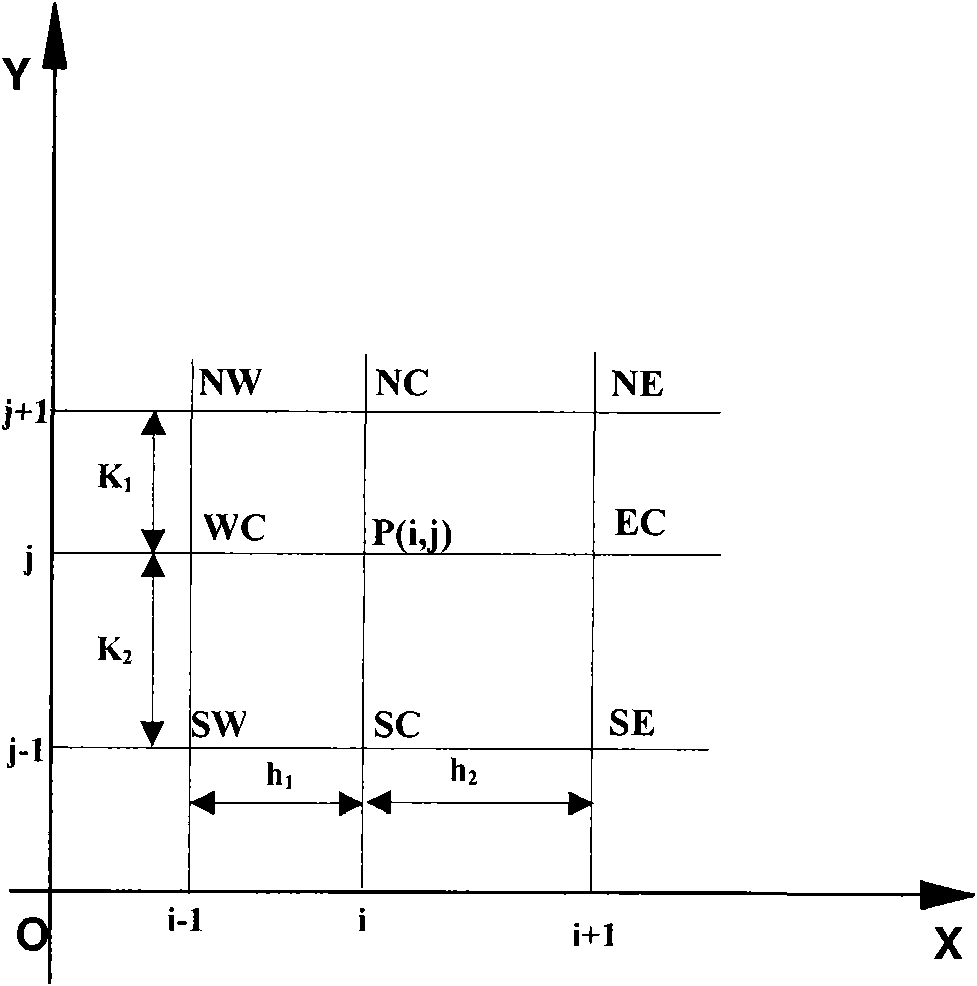

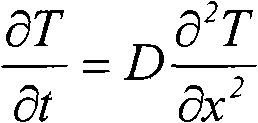

High-precision difference method for simulating transport diffusion problem

InactiveCN101615219AImprove simulation accuracySimulation results are accurateSpecial data processing applicationsDiffusionHeat mass transfer

The invention relates to a numerical simulation method in the engineering field such as environment, water conservancy and the like and discloses a high-precision difference method with strong universality for series typical model equations suitable for solving problems of flow and heat-mass transfer of various fluids, in particular the problem of transport diffusion. Aiming at the defects that conventional limited difference format of the prior water environment simulation only has low one-order or two-order precision, while the prior multi-step differential equal-high precision method generally relates to a lot of grid points, has over complex construction mode and is most based on quite regular even rectangular meshes, and the like, the invention provides a high-precision difference method under an uneven mesh. The method adopts an indeterminate coefficient method to determine an influence coefficient between a point to be solved and an adjacent point in a difference equation so that the difference format reaches maximum-order precision under the mesh structure. Because the difference format is constructed by adopting an uneven grid system, the density of the mesh distance can be flexibly adjusted according to the size of the variation gradient of physical quantity to be solved, and the simulation precision and efficiency are effectively improved.

Owner:BEIJING NORMAL UNIVERSITY

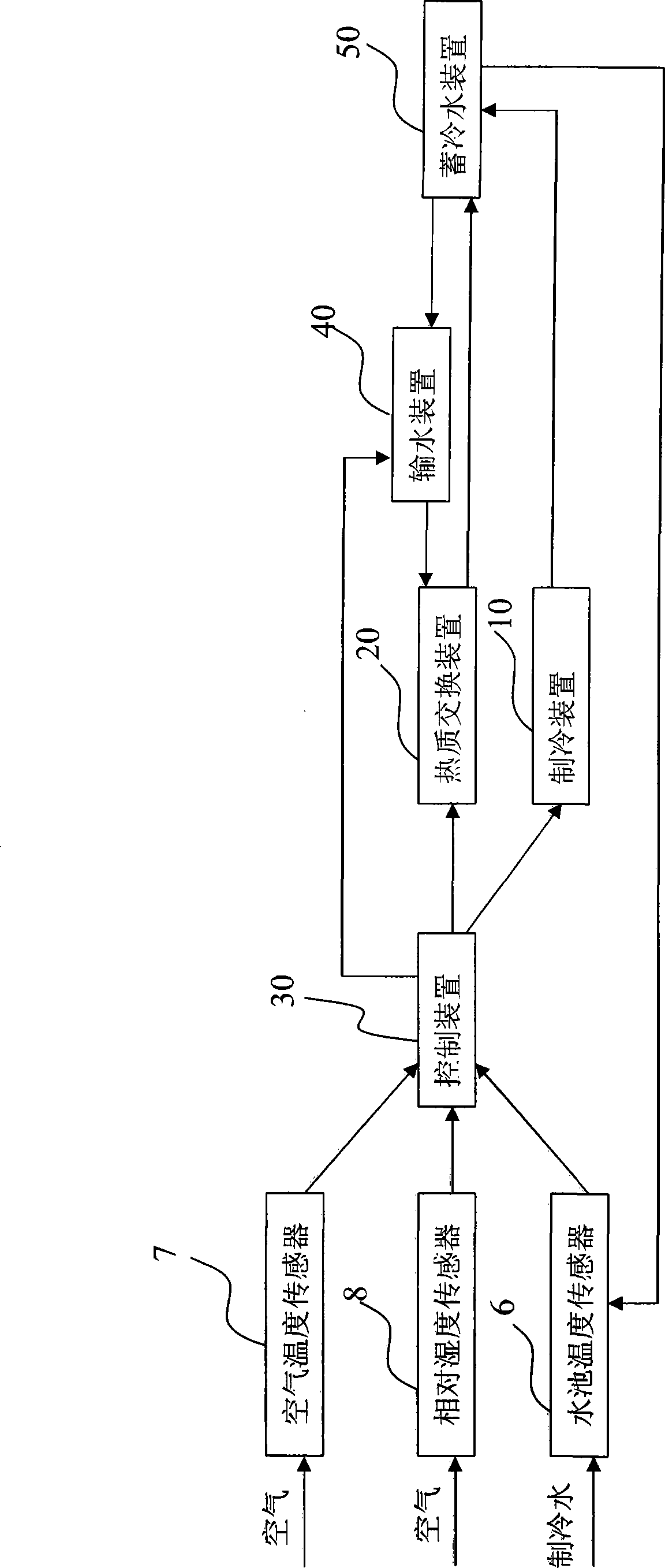

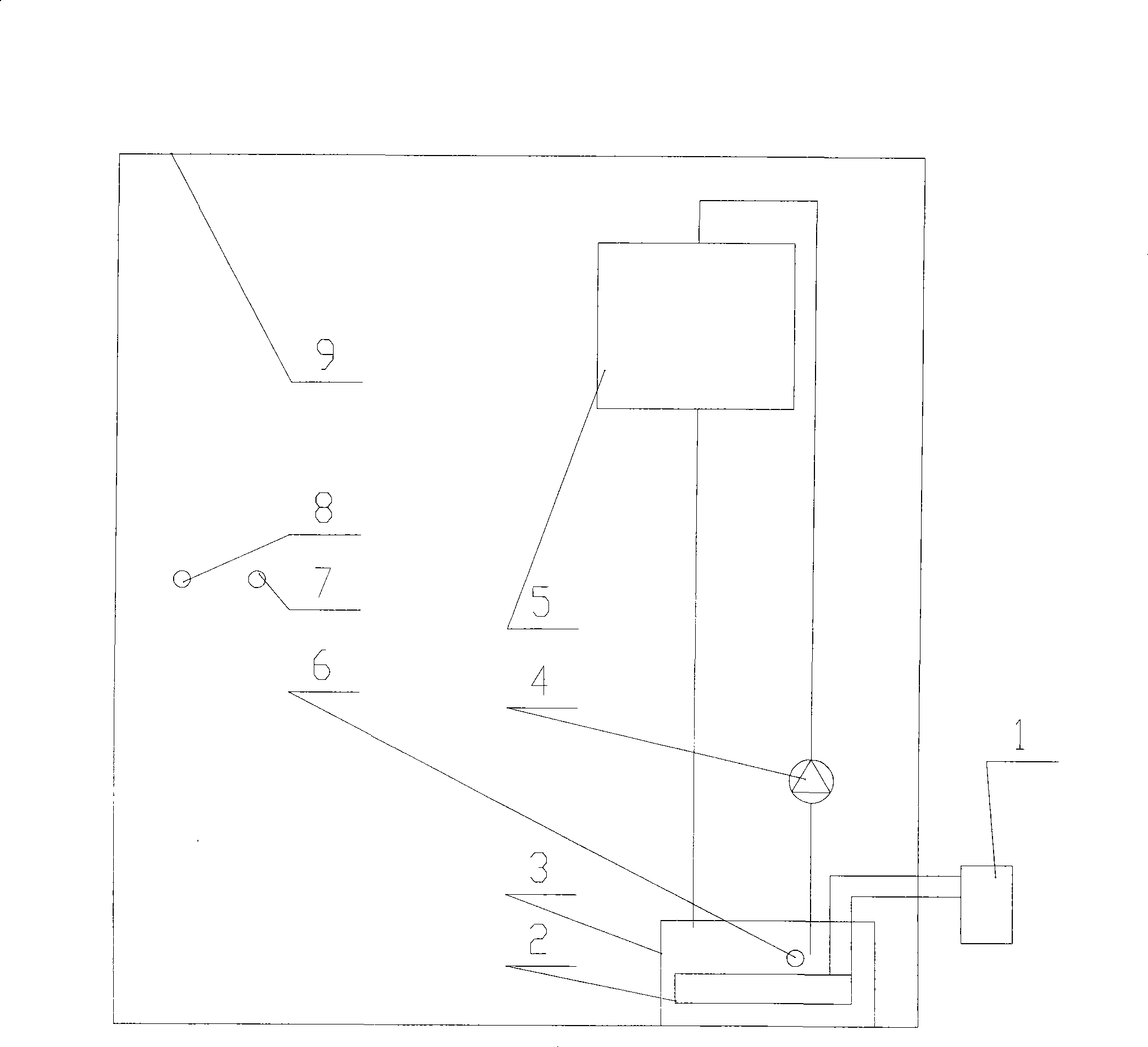

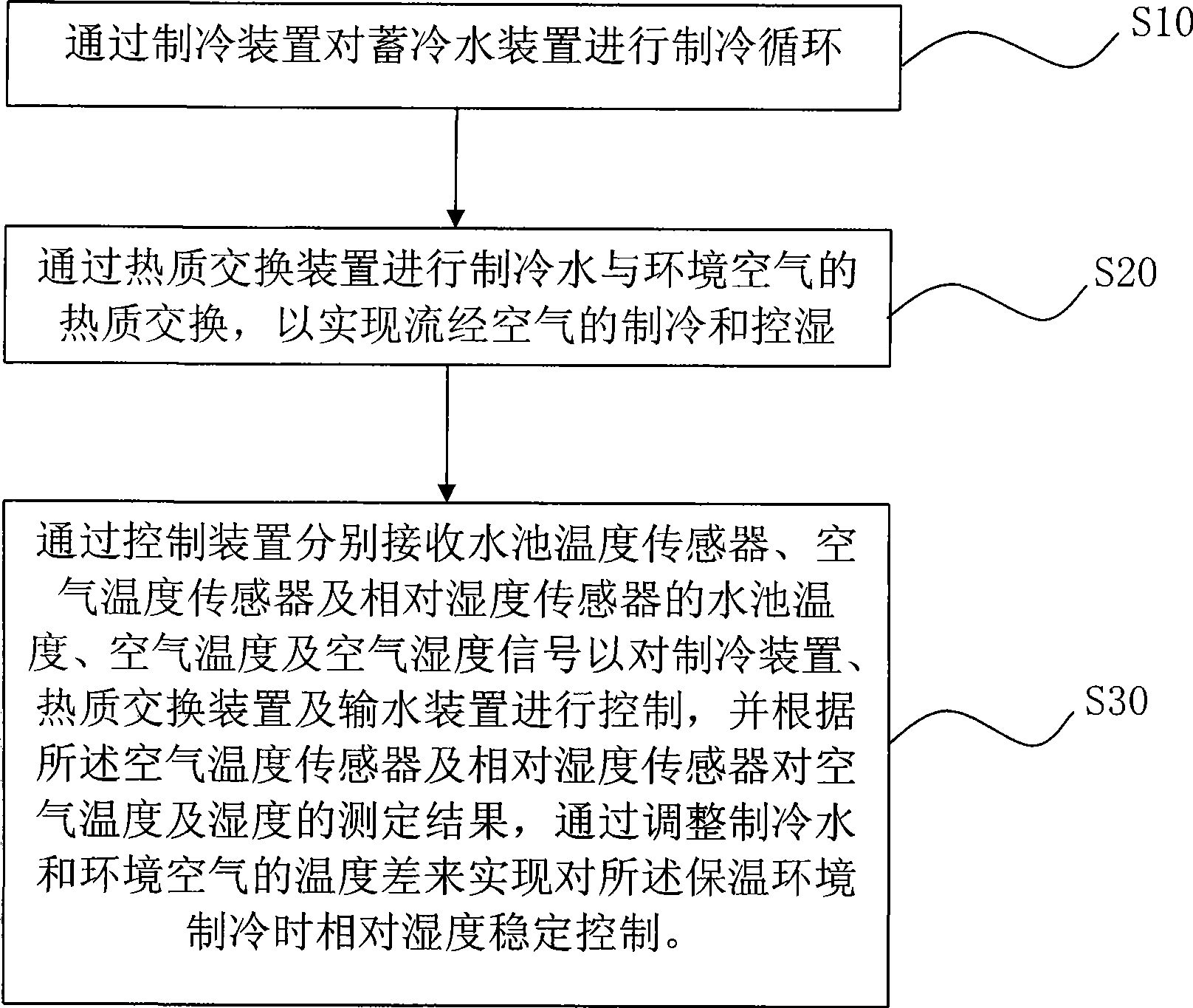

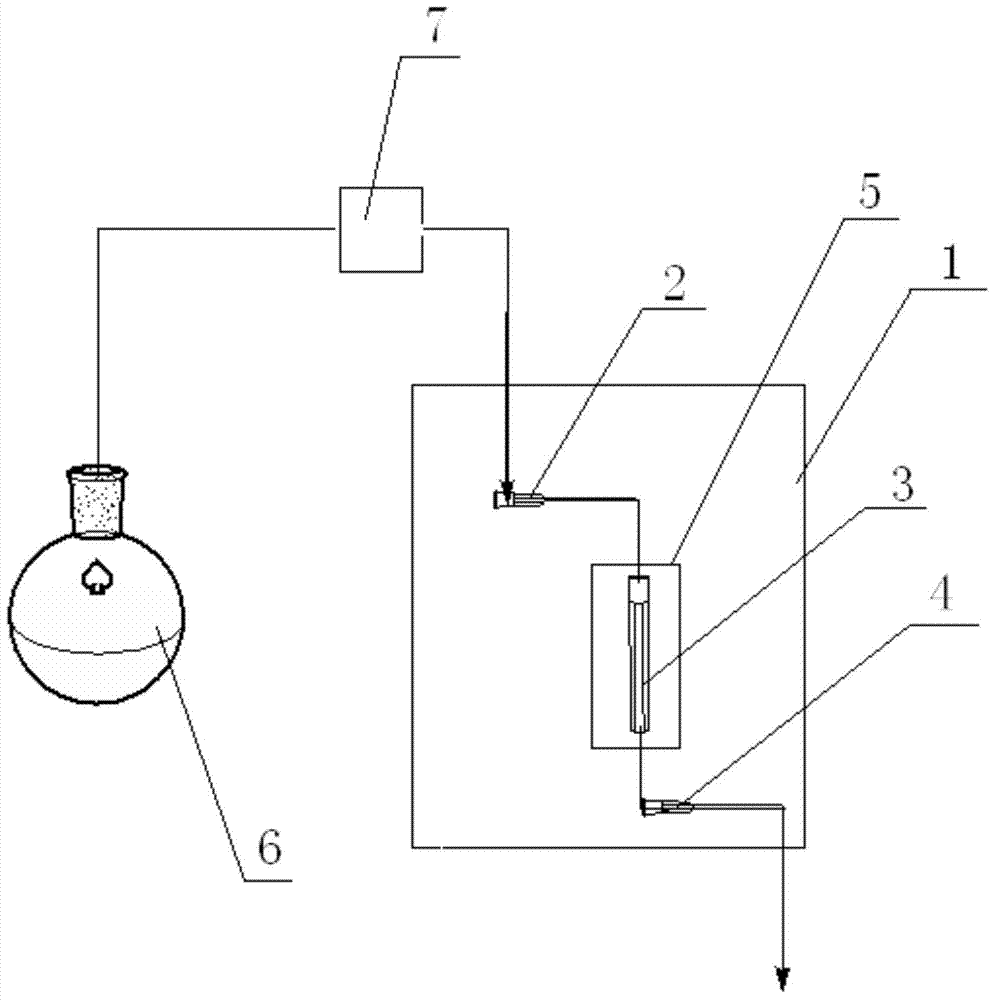

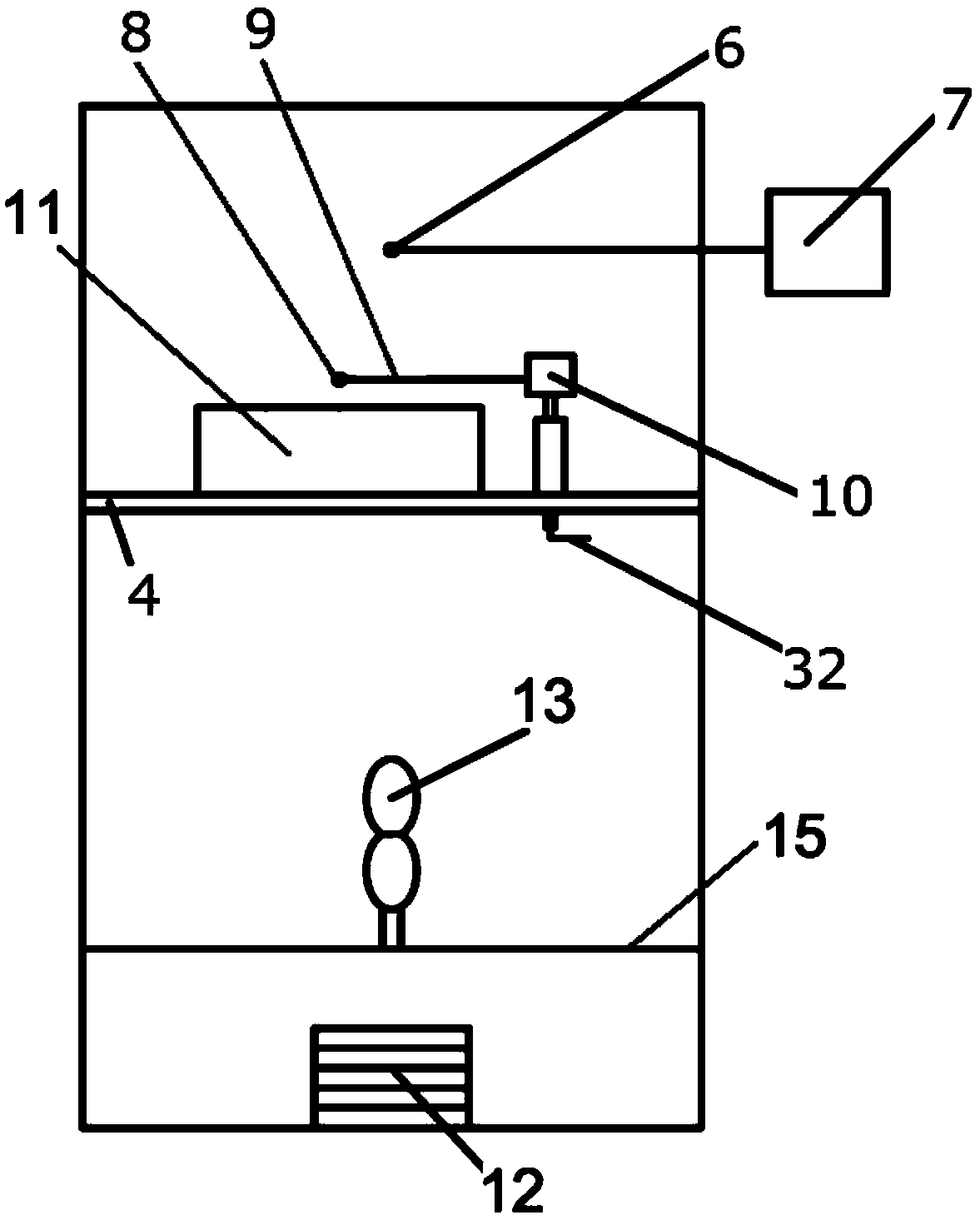

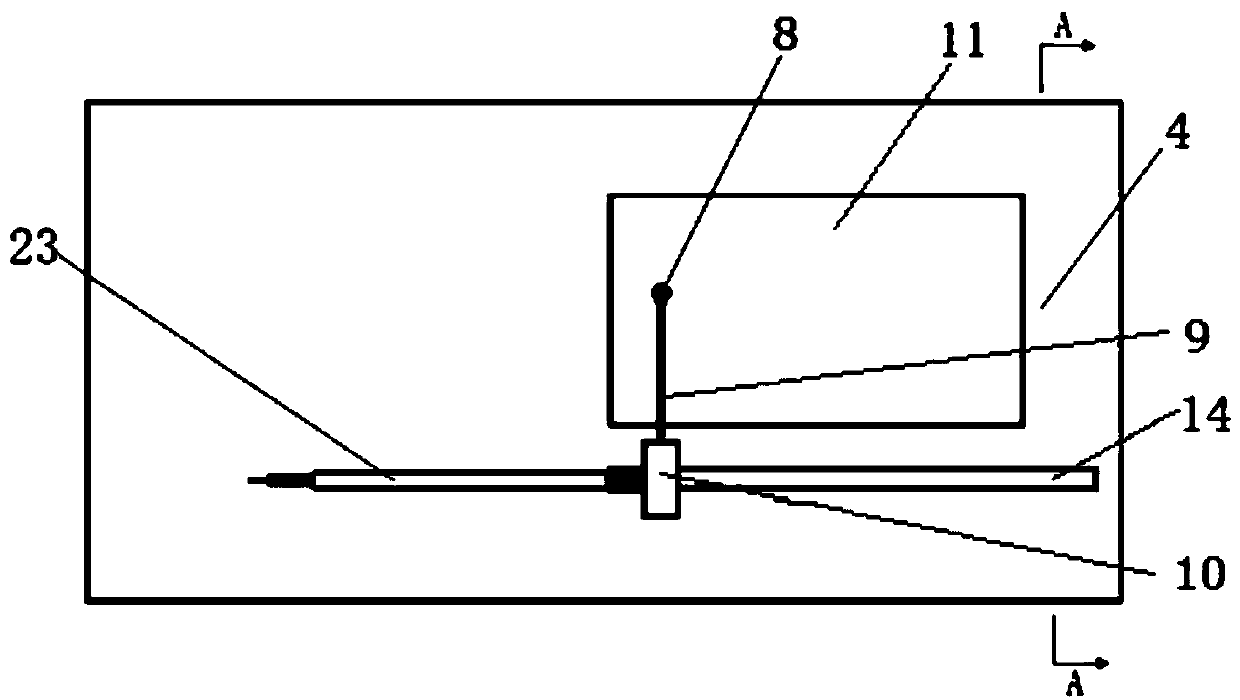

Refrigerating device and its relative moisture control method during refrigeration

InactiveCN101476759AIncrease humidityConducive to adjusting peak and valley electricity price differenceMechanical apparatusSpace heating and ventilation safety systemsHeat mass transferEngineering

The invention relates to refrigeration equipment and a method of the refrigeration equipment for controlling relative humidity during refrigeration. The equipment comprises a refrigeration device, a control device, a heat-mass transfer device, a cold water storage device, a water delivering device, a water pool temperature sensor, an air temperature sensor and a relative humidity sensor, wherein the heat-mass transfer device, the cold water storage device, the water delivering device, the water pool temperature sensor, the air temperature sensor and the relative humidity sensor are arranged in a heat-preservation environment; the water pool temperature sensor is arranged in the cold water storage device; one end of the heat-mass transfer device is connected with the cold water storage device through the water delivering device and other end of the heat-mass transfer device is connected with the cold water storage device directly; and the water pool temperature sensor, the air temperature sensor and the relative humidity sensor are connected with the control device respectively, and the control device is connected with the refrigeration device, the heat-mass transfer device and the water delivering device respectively and realizes the stable control over the relative humidity of the heat-preservation environment during refrigeration by adjusting the temperature difference between refrigerating cold water and the air in the environment according to the results of the detection of air temperature and humidity of the air temperature sensor and the relative humidity sensor.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

Colorless thermal mass transfer compositions and articles

ActiveUS20080118638A1High glossIncrease brightnessDecorative surface effectsSynthetic resin layered productsAcrylic resinHeat mass transfer

Retroreflective sheeting articles comprising a colorless thermal mass transferred image, methods of thermal mass transfer printing substrate such as polymeric films with a colorless thermal mass transferable composition, and thermal mass transfer ribbon articles comprising a colorless thermal mass transferable composition are described. The thermal mass transfer composition comprises a homogeneous unreactive thermoplastic composition comprising at least one acrylic resin and less than 3 wt-% of components that are opaque at ambient temperature.

Owner:3M INNOVATIVE PROPERTIES CO

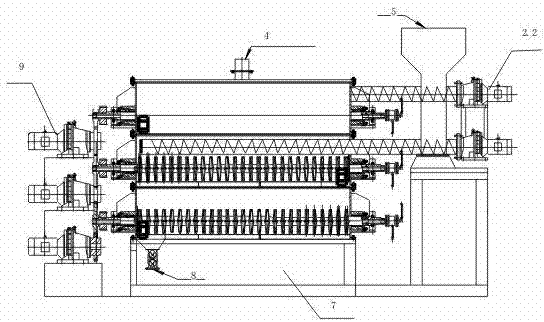

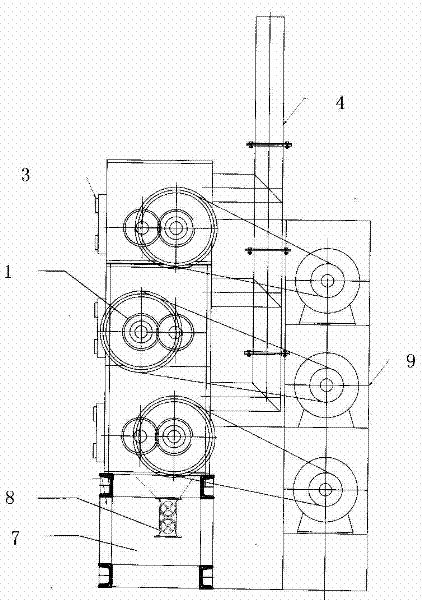

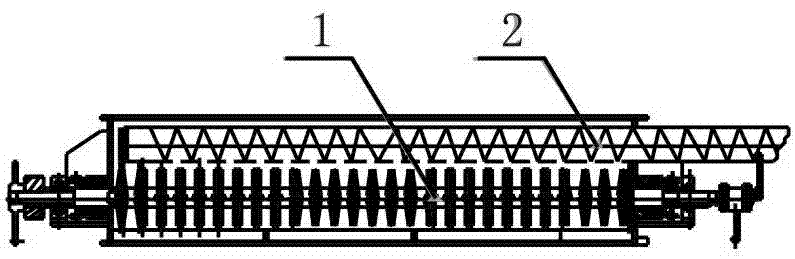

Hot-shaft mixing drying process and device

InactiveCN102364276AWell mixedEnhance heat and mass transferDrying machines with non-progressive movementsDrying solid materialsHeat mass transferMechanical engineering

The invention relates to a conduction heating drying technical field, and discloses a hot-shaft mixing drying process and a device. The device consists of a bottom of a single drying unit layer or multiple superimposed drying unit layers and a drying material box (7), wherein each drying unit layer is structurally formed by arranging two hollow blade shafts (1) with a group of fan-shaped blades which are arranged in pairs inside a rectangular shell (3) and a feeding system; the feeding system is arranged above the two parallel hollow blade shafts (1); and the feeding system comprises a helical feeding system for drying wet powder materials and paste materials or a carriage feeding system for drying liquid materials. Previously-paved dry materials inside the drying layers are adequately mixed with the newly-fed wet material to dry, so the heat exchanging area can be improved, the drying efficiency can be improved, the heat transfer of the wet material can be improved, and the drying speed of the material can be improved; and the situation that the the shaft is easily wound by the fed wet material can be avoided, so the power of the dry-shaft device can be greatly reduced.

Owner:许建庄

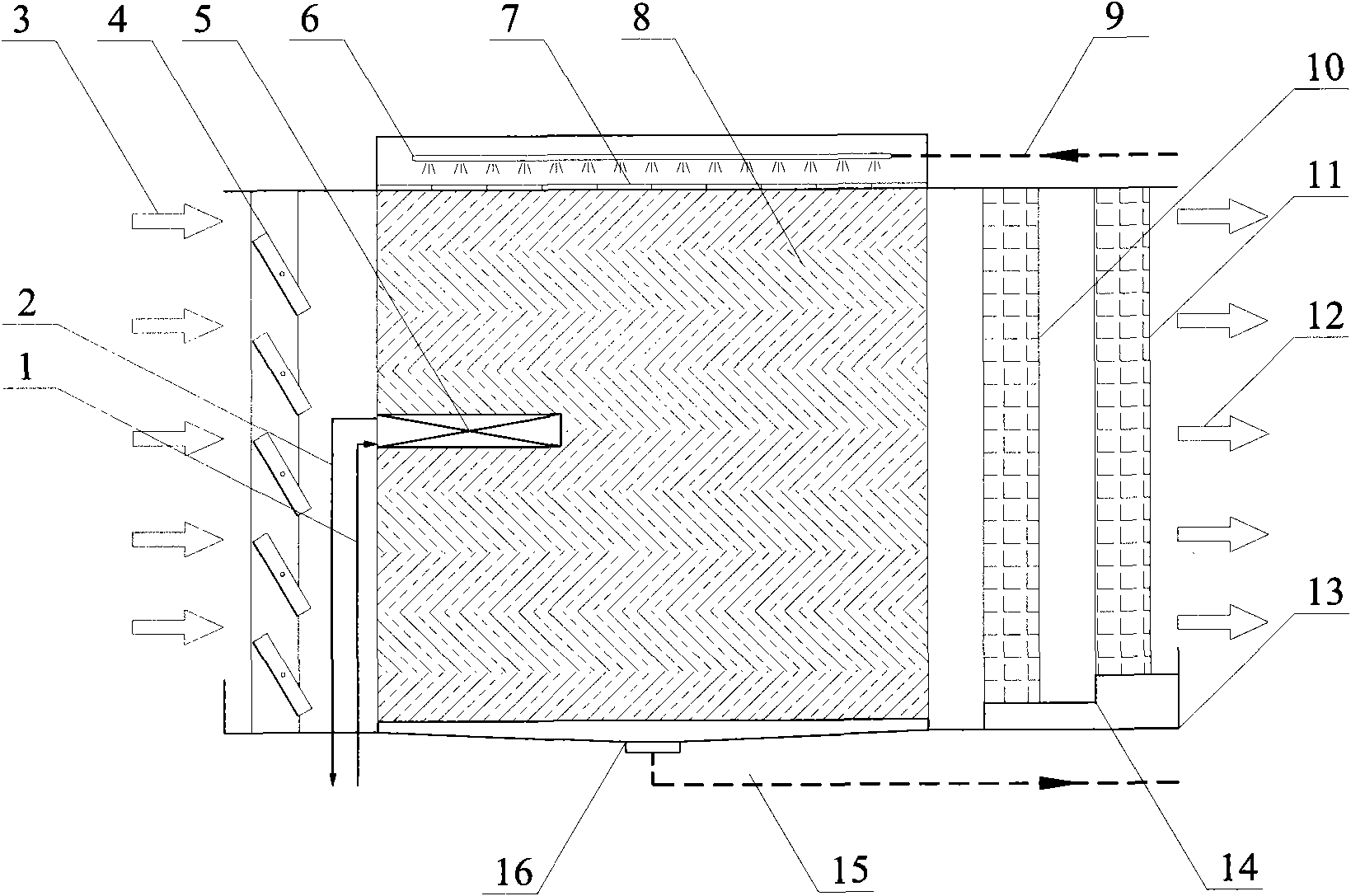

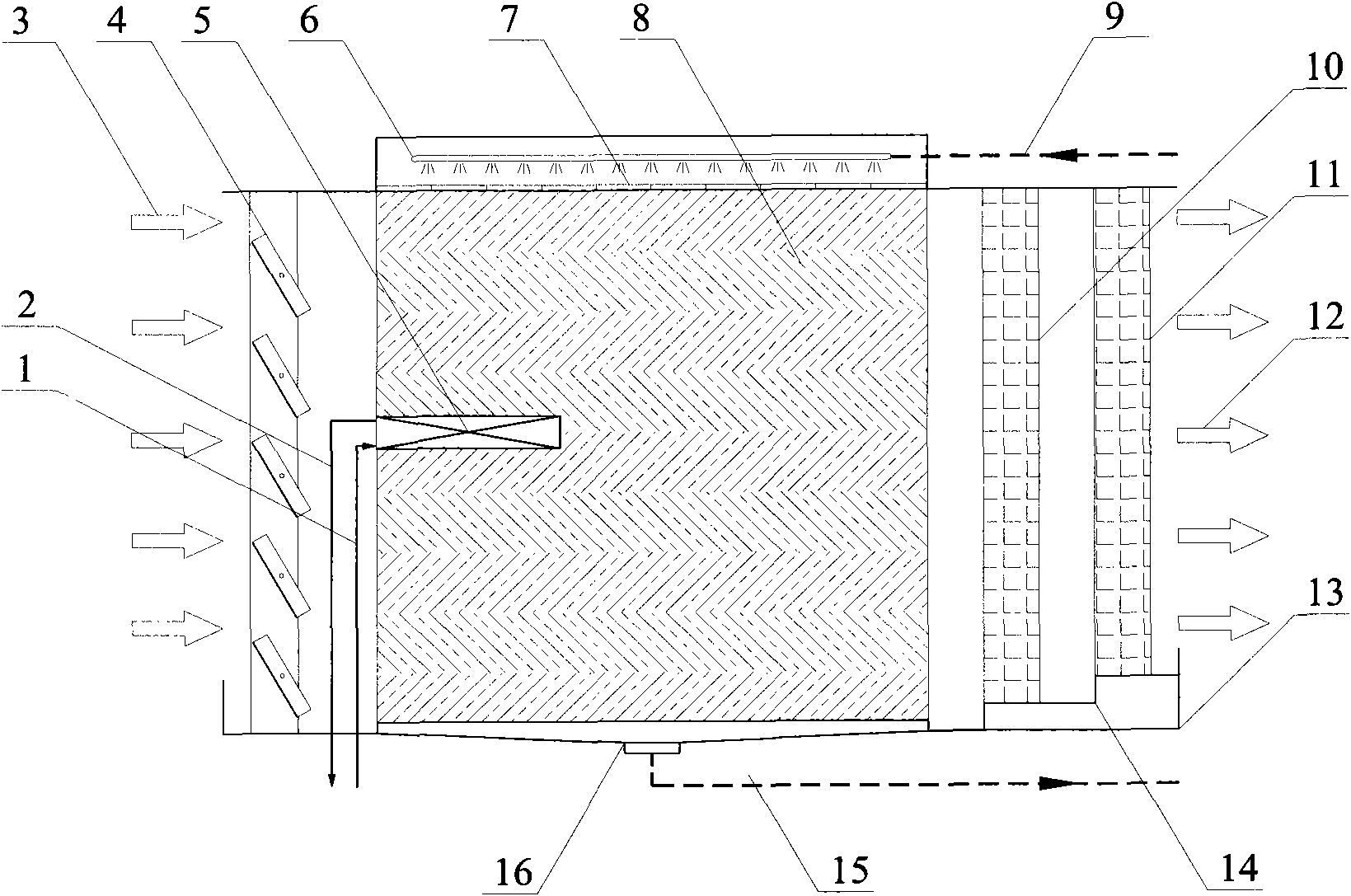

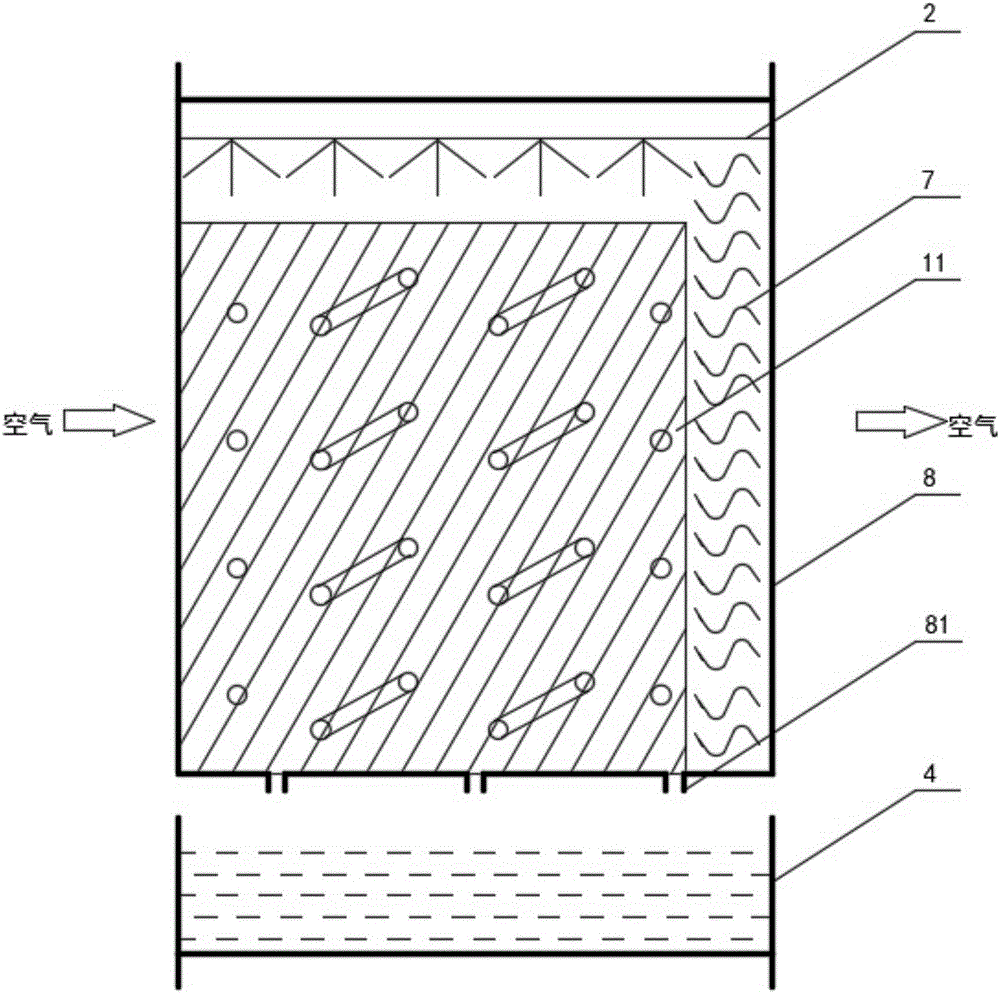

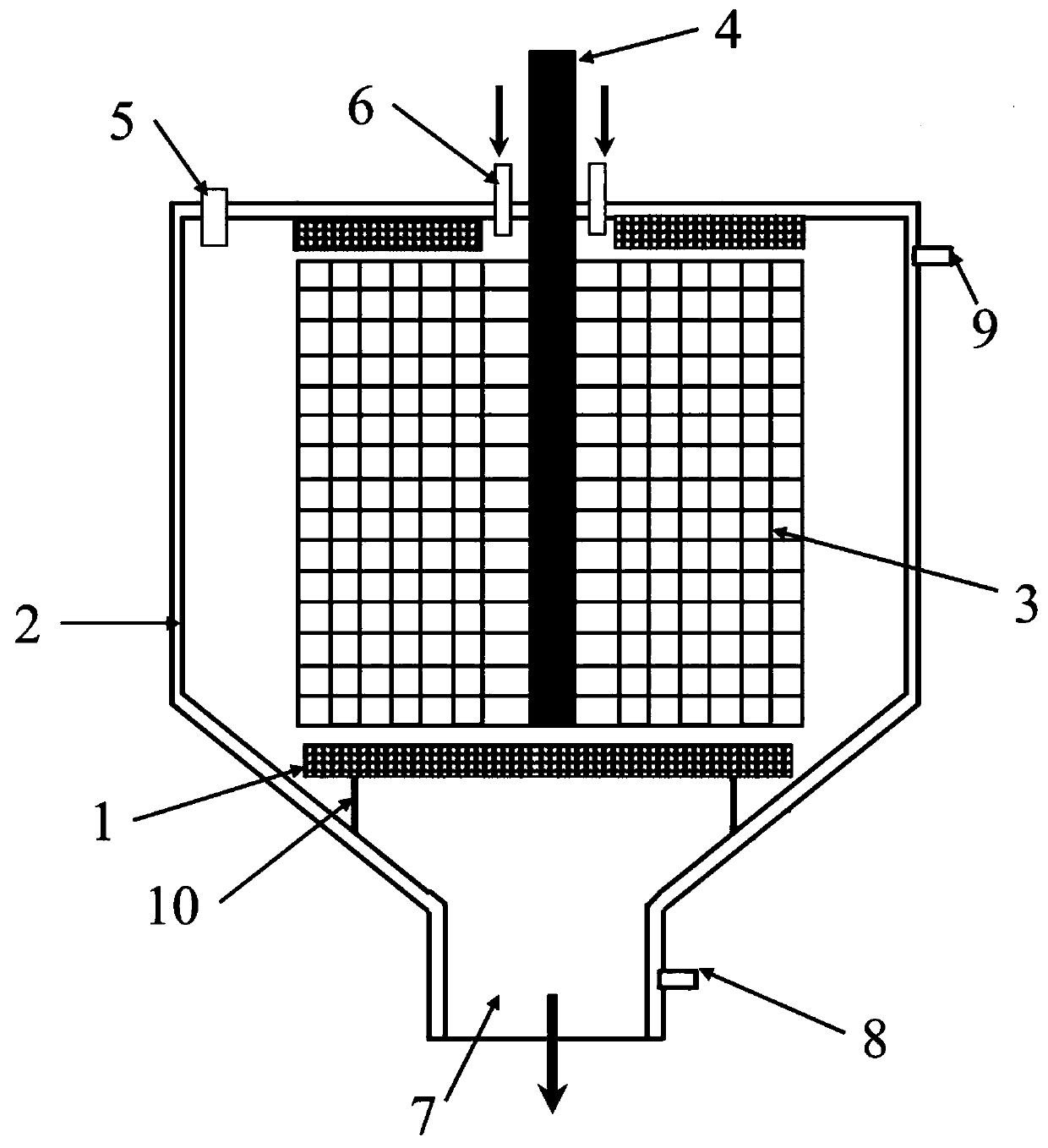

Cross-flow type air handling device

InactiveCN101881491AAvoid spillingAvoid blind spotsLighting and heating apparatusSpace heating and ventilation detailsViscous liquidHeat mass transfer

The invention relates to a cross-flow type air handling device, comprising a viscous-liquid shutter, a packing layer, liquid distributors, defoaming layers and a liquid collecting disc, wherein the front of the packing layer is provided with the viscous-liquid shutter; the rear of the packing layer is provided with a primary-effect defoaming layer and a final-effect defoaming layer; a primary liquid distributor is arranged above the packing layer and is connected with a solution inlet pipe; a final liquid distributor is arranged below the primary liquid distributor; the middle part of the packing layer is provided with a cooling / heating coil; a water inlet and a water inlet pipe of the cooling / heating coil are connected, and a water outlet and a water outlet pipe thereof are connected; the bottom parts of the packing layer, the primary-effect defoaming layer and the final-effect defoaming layer are arranged on the liquid collecting disc; and the bottom part of the liquid collecting disc is provided with a solution backflow port which is connected with a solution distributing pipe. The cross-flow type air handling device utilizes a form of local inner cooling, two-stage solution distribution and two-stage defoaming to effectively improve heat and mass transferring efficiency of a cross-flow dehumidifying and regenerating device, not only has simple structure and convenient manufacture, but also effectively avoids the problems of air with liquid, solution splashing and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Multi-flow evaporative condenser

ActiveCN111521032AReduced heat and mass exchange rateReduce exchange rateSteam/vapor condensersStationary conduit assembliesCondenser (heat transfer)Heat mass transfer

The invention discloses a multi-flow evaporative condenser, and belongs to the technical field of condensing equipment. A wet air outlet is added according to the increase of air humidity, so that nearly-saturated wet air can be directly blown away by a fan while rising in a shell; the resistance encountered during upward flowing of the wet air can be reduced compared with the original way that the wet air continually rises across a heat exchange tube bundle; and the pump power consumption of the fan is reduced. In addition, more dry air can be enabled to enter the shell in order to improve the mass and heat transfer efficiency between the air and cooling water. In the condenser, a horizontal tube bundle is adopted instead of a traditional coil in order to realize arrangement of the tube spacing according to the principle of optimal thicknesses of liquid films outside tubes, ensure the formation of thin and uniform liquid films outside the tubes, improve the evaporative heat transfer rate, avoid the occurrence of scaling, and improve the compactness of a heat exchanger so as to reduce the size of equipment. In the multi-flow evaporative condenser, multiple flows are adopted insteadof the traditional single flow, so that timely separation of condensate in the tubes is facilitated so as to strengthen condensation heat transfer in the tubes.

Owner:SHANDONG JIANZHU UNIV

Microwave calcium carbide furnace reactor and method for preparing calcium carbide by using same

ActiveCN107986279AReduce partial pressureReduce energy costsChemical industryCalcium carbideHigh energyWater circulation

The invention discloses a microwave calcium carbide furnace reactor. The microwave calcium carbide furnace reactor comprises a microwave reaction furnace body, wherein the microwave reaction furnace body comprises a microwave energy gathering cavity, a shell and an insulating layer positioned between the shell and the energy gathering cavity; a reaction chamber for materials is formed in the microwave energy gathering cavity; a material insulating reaction system is arranged inside the reaction chamber; an air exhausting system and a temperature monitoring system are arranged on the energy gathering cavity; the microwave calcium carbide furnace reactor further comprises a microwave energy generating system for conducting microwave into the energy gathering cavity, namely the reaction chamber; a water circulating cooling system is further connected to the microwave energy generating system and the microwave energy gathering cavity. The invention further provides a method for preparing calcium carbide by using the calcium carbide furnace reactor. Through use of microwave heating, the heat and mass transfer process between the reaction materials can be intensified, so that the formation temperature of the calcium carbide is greatly reduced, and the calcium carbide is synthesized at a relatively low temperature of 1600-1900 DEG C; the reaction speed is high, the energy utilizationrate is high, operation is convenient, dust pollution is free, and the problems of high investment, high pollution and high energy consumption of an arc calcium carbide furnace are solved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

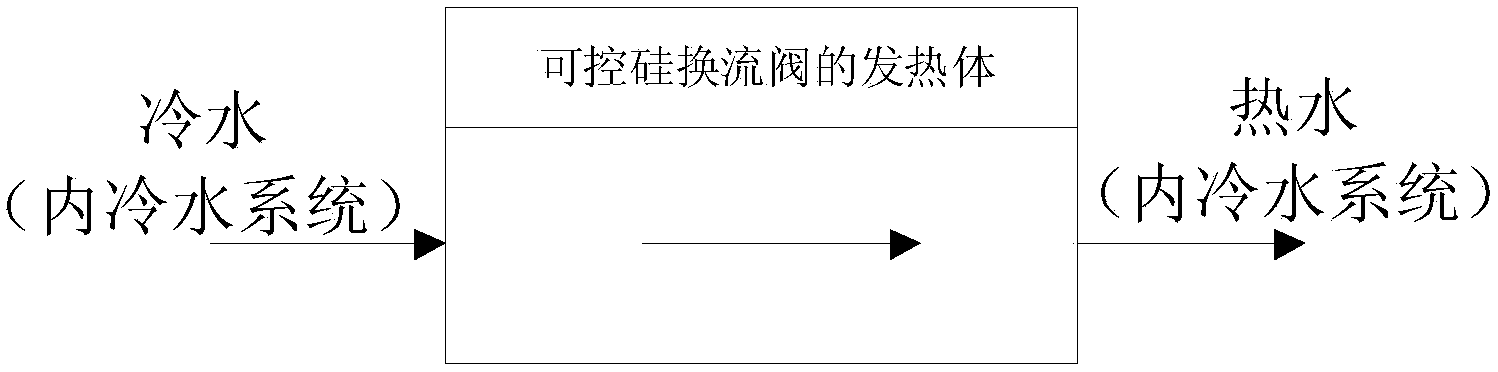

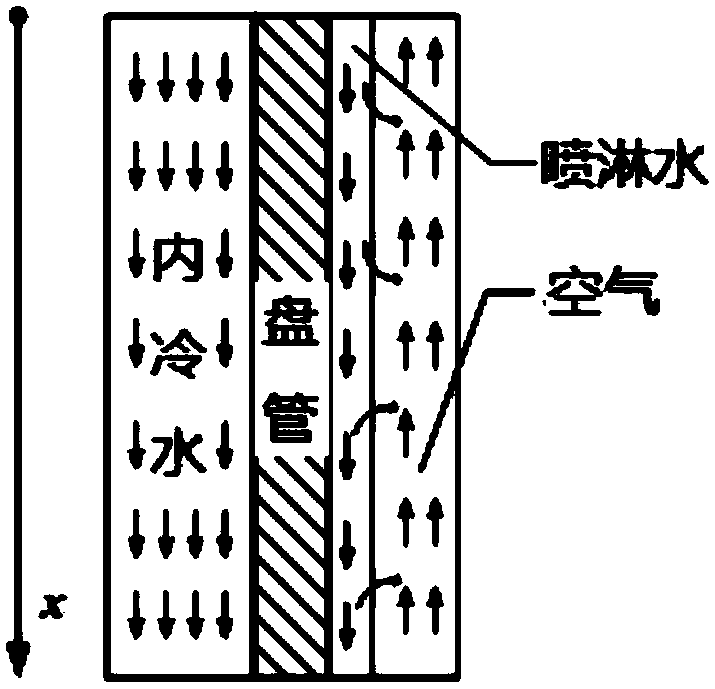

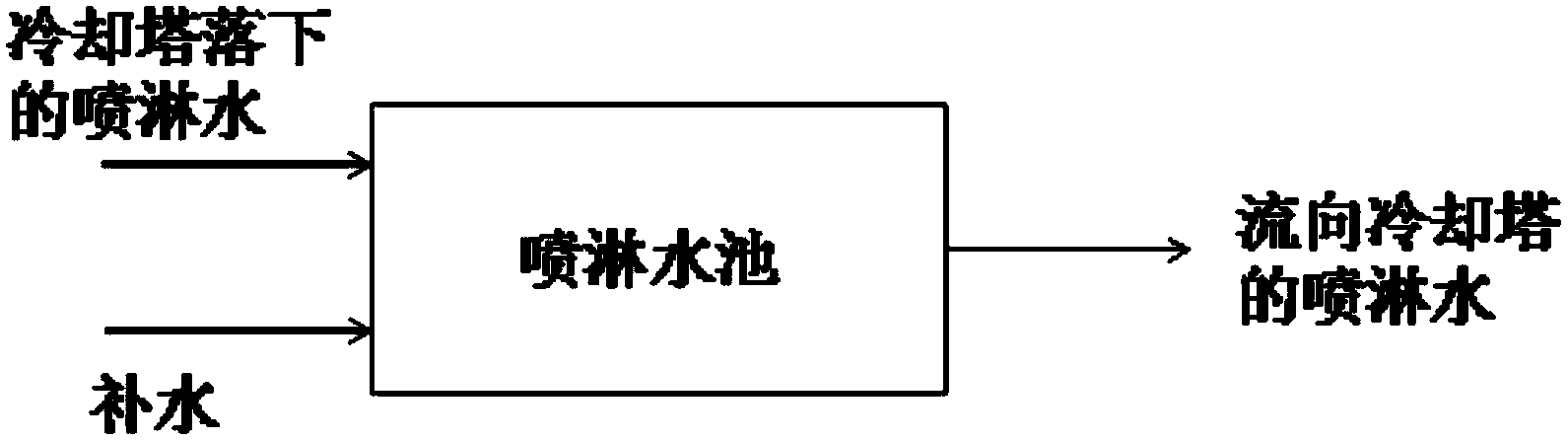

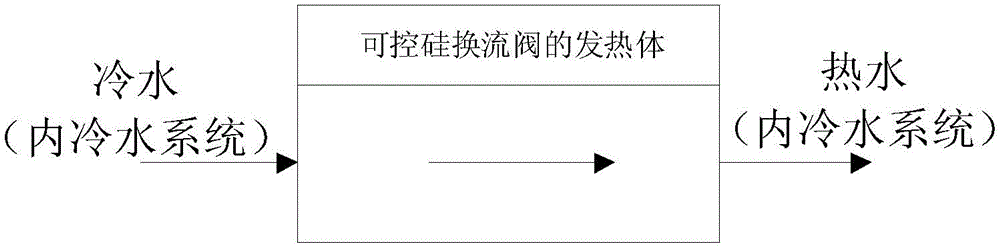

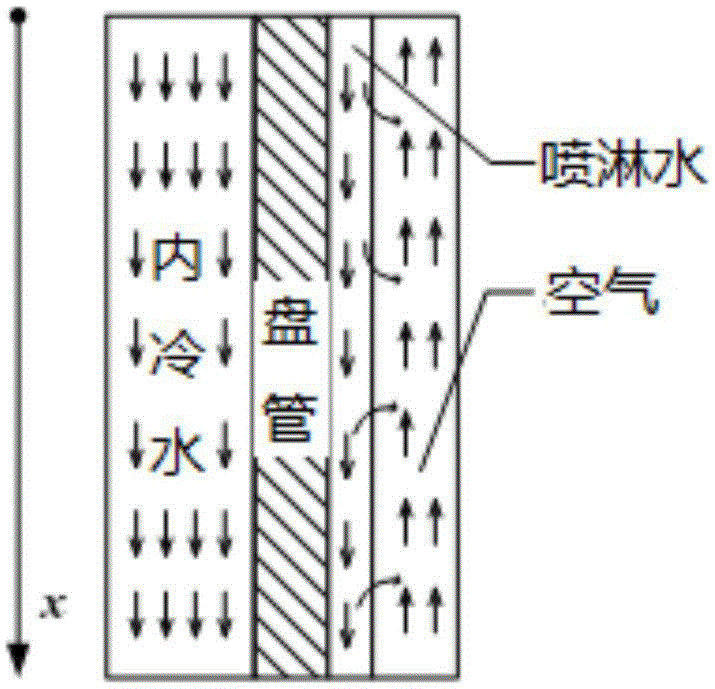

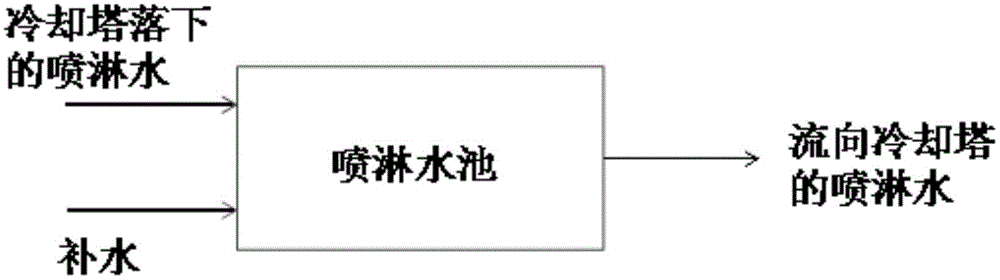

Online monitoring and assessment method for heat exchange efficiency of water-cooling system of converter valve

ActiveCN104239724ASafe and stable operationSpecial data processing applicationsHeat mass transferEngineering

The invention relates to an online monitoring and assessment method for heat exchange efficiency of a water-cooling system of a converter valve. The online monitoring and assessment method comprises the following steps: (1) building a thermotechnical model of a valve-cooling system of the converter valve; (2) analyzing the heat exchange performance of the converter valve under different operation conditions through the built model; (3) analyzing all heat and mass transfer coefficients by selecting a classical heat exchange coefficient relation, heat-mass transfer analogy and the falling film theory; (4) analyzing the influences of all the heat and mass transfer coefficients on the heat exchange performance of the converter valve. Compared with the prior art, the online monitoring and assessment method disclosed by the invention has the advantages that the converter valve can reliably and stably run, and the like.

Owner:STATE GRID CORP OF CHINA +1

Method for producing citrate by using microchannel reactor

ActiveCN103497104ASimple processImprove operational safetyOrganic compound preparationCarboxylic acid esters preparationAlcoholHeat mass transfer

The invention provides a method for producing citrate by using a microchannel reactor. The method comprises the following steps: dissolving citric acid in alcohol to obtain citric acid alcohol liquor; heating a catalyst column to a constant temperature; introducing the citric acid alcohol liquor to the microchannel reactor (1), wherein the citric acid alcohol liquor passes through the catalyst column at a constant flow rate; and collecting a catalyst column effluent to obtain the citrate. The method is simple in process, can continuously produce citrate, has high operating safety and high selectivity, and is small in reaction volume and short in time. The catalyst can be repeatedly used, and the equipment is hardly corroded. Meanwhile, as no water carrying agents are used, the esterification rate is over 96% by means of such characteristics of the microchannel reactor as efficient heat mass transfer capacity and easiness in direct amplification. The product has high quality and the energy consumption is low, so that the method is an environment-friendly and efficient method for synthesizing citrate.

Owner:NANJING UNIV OF TECH

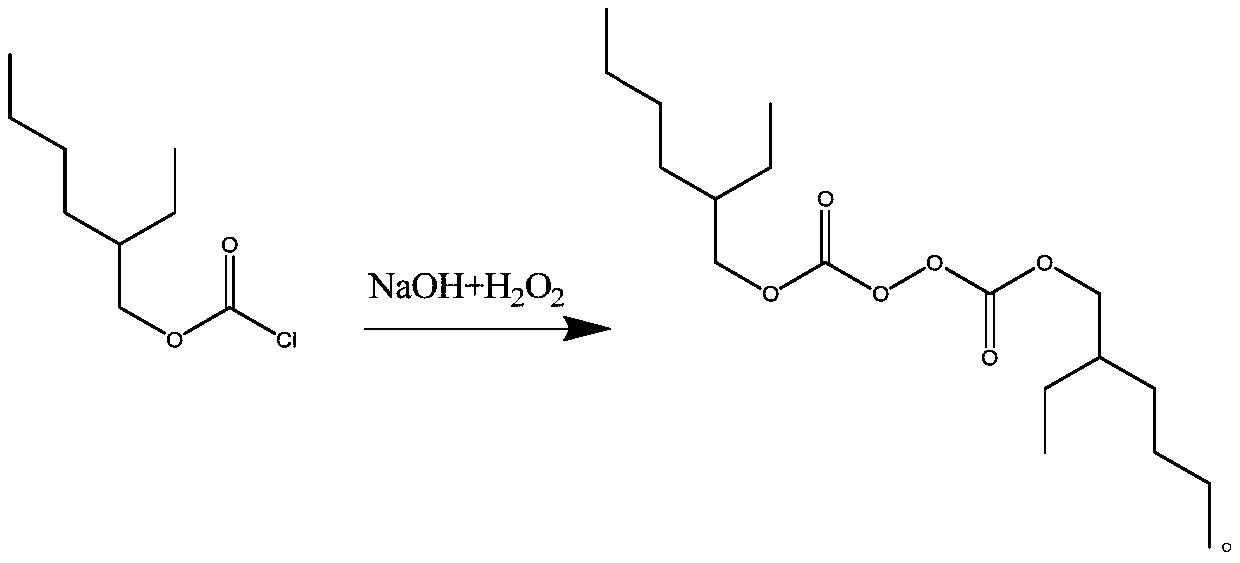

Synthesis method of bis(2-ethylhexyl)peroxydicarbonate

ActiveCN110256320AImprove conversion rateHigh selectivityOrganic compound preparationChemical/physical/physico-chemical microreactorsSynthesis methodsHeat mass transfer

The invention belongs to the technical field of chemical engineering, and specifically relates to a synthesis method of bis(2-ethylhexyl)peroxydicarbonate. According to the method, hydrogen peroxide and sodium hydroxide are mixed in a first micro-channel continuous flow reactor; then the mixture is mixed with chlorinated esters in a second micro-channel continuous flow reactor to carry out reactions; the temperature of the first micro-channel continuous flow reactor is 15 to 30 DEG C; the second micro-channel continuous flow reactor is formed by connecting 3 to 10 micro-channel mixer substrates; and the temperature of the second micro-channel continuous flow reactor is controlled in a range of 30 to 40 DEG C. The heat-mass transfer efficiency of the synthesis method is high; the temperature is controlled in different sections; the product decomposition caused by uncontrolled temperature, increased side reactions, and the like is prevented; and at the same time, the energy consumption and danger coefficient are reduced. The reaction conversion rate of the synthesis method is 99.2% or more, and the selectivity is 98.5% or more.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

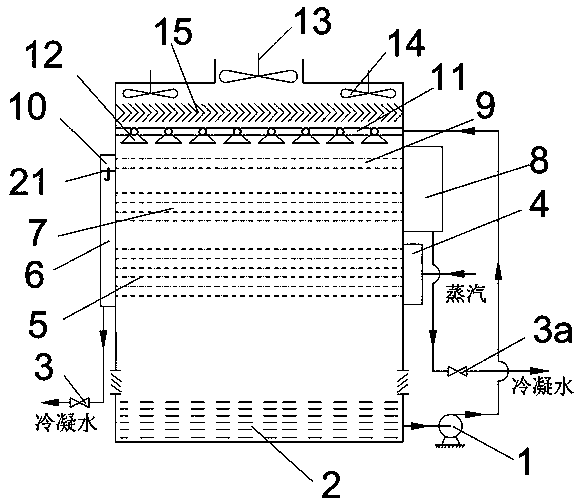

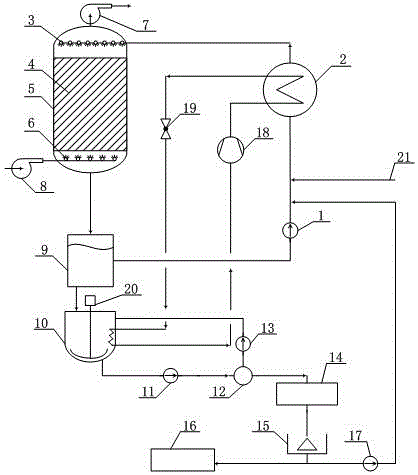

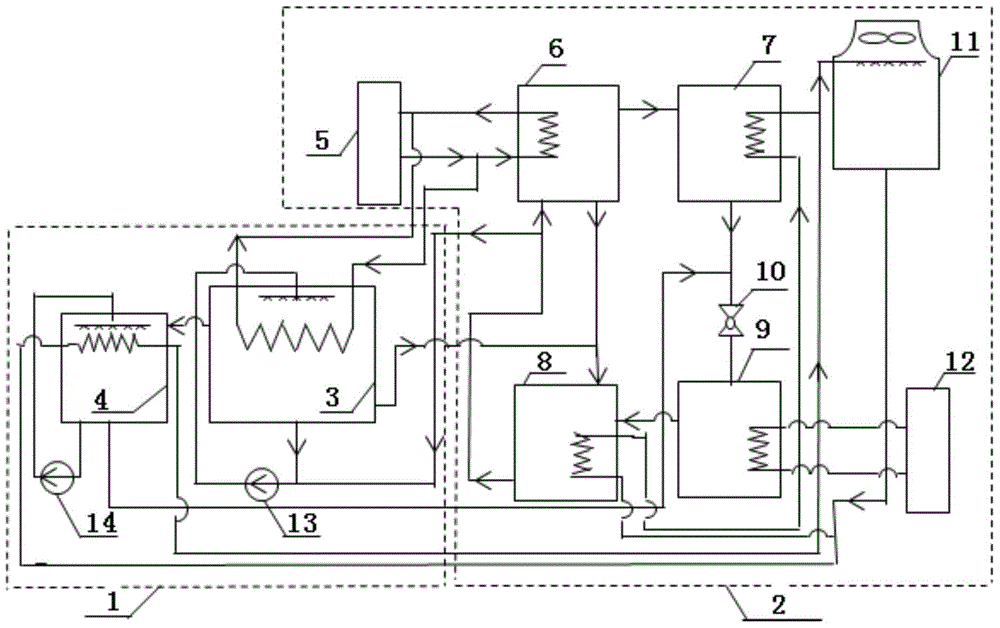

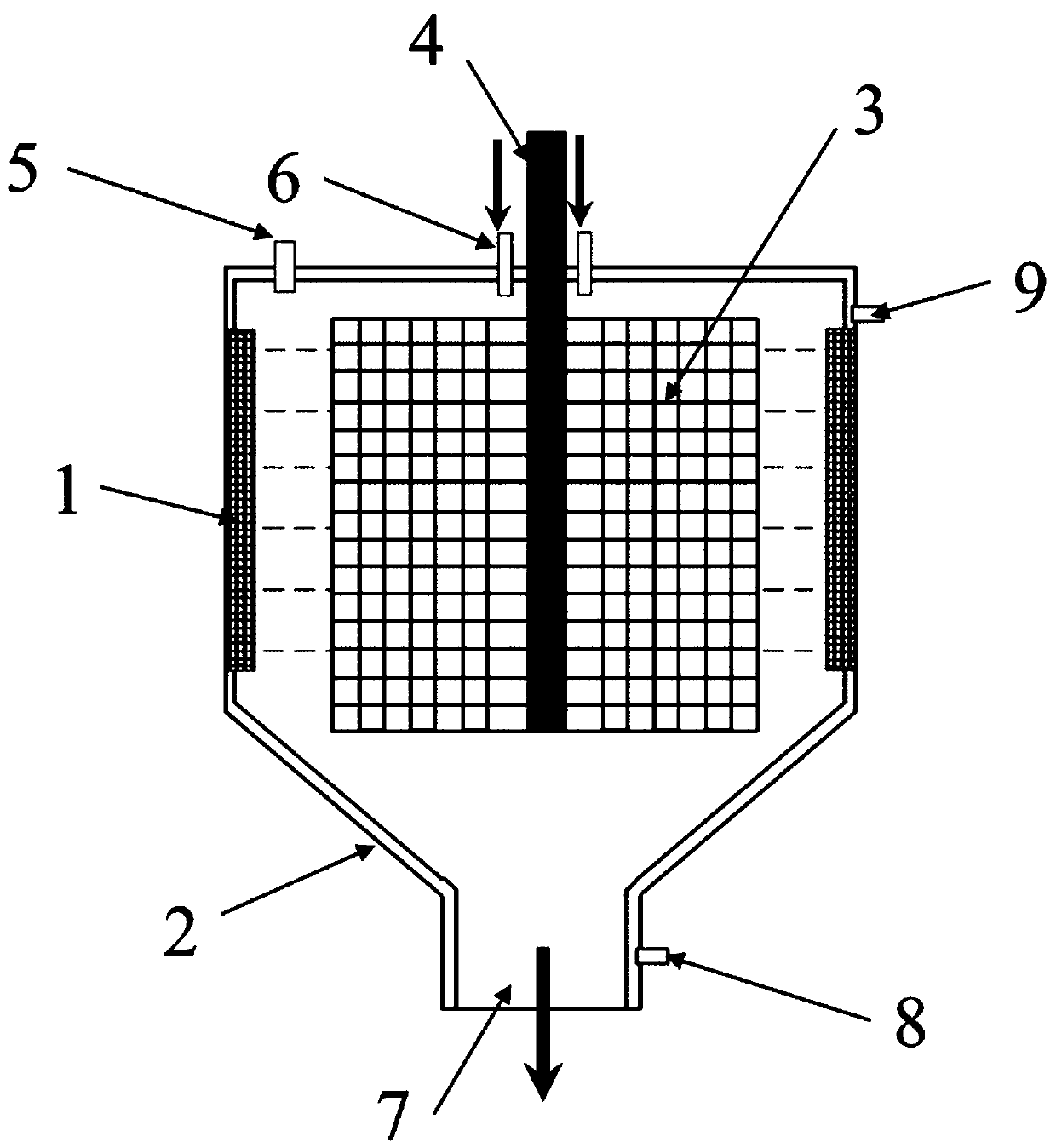

Heat-mass co-transfer evaporation and crystallization system and working method thereof

ActiveCN106693414AAchieve evaporative crystallizationAchieve transferEvaporationSolution crystallizationSolubilityEvaporation

The invention discloses a heat-mass co-transfer evaporation and crystallization system and a working method thereof, and belongs to the field of solution evaporation and crystallization. The heat-mass co-transfer evaporation and crystallization system mainly comprises an air blower, a draught fan, a heat-mass transfer tank, a heater, a crystallization tank, a maturing tank, a compressor, an expansion valve, and the like. The heat-mass co-transfer evaporation and crystallization system is characterized in that air and a solution are in direct contact to transfer heat and mass in the heat-mass transfer tank, and thus the solution is evaporated and crystallized; due to additional arrangement of the maturing tank in the system, the solution can be further crystallized; a low-melting point working medium is evaporated after absorbing heat in the maturing tank, is subjected to compression heating by using the compressor, and is further added into the heater to heat the solution to be evaporated, so that internal energy transfer of the system is achieved. The heat-mass co-transfer evaporation and crystallization system adopts a heat-mass co-transfer method, evaporation and crystallization of the solution can be achieved at normal temperature, the heating temperature is low, the noble metal consumption amount is small, and a remarkable energy conservation effect can be achieved. The system is applicable to evaporation and crystallization processes of solutions of which the solubility is improved along with increase of temperature.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

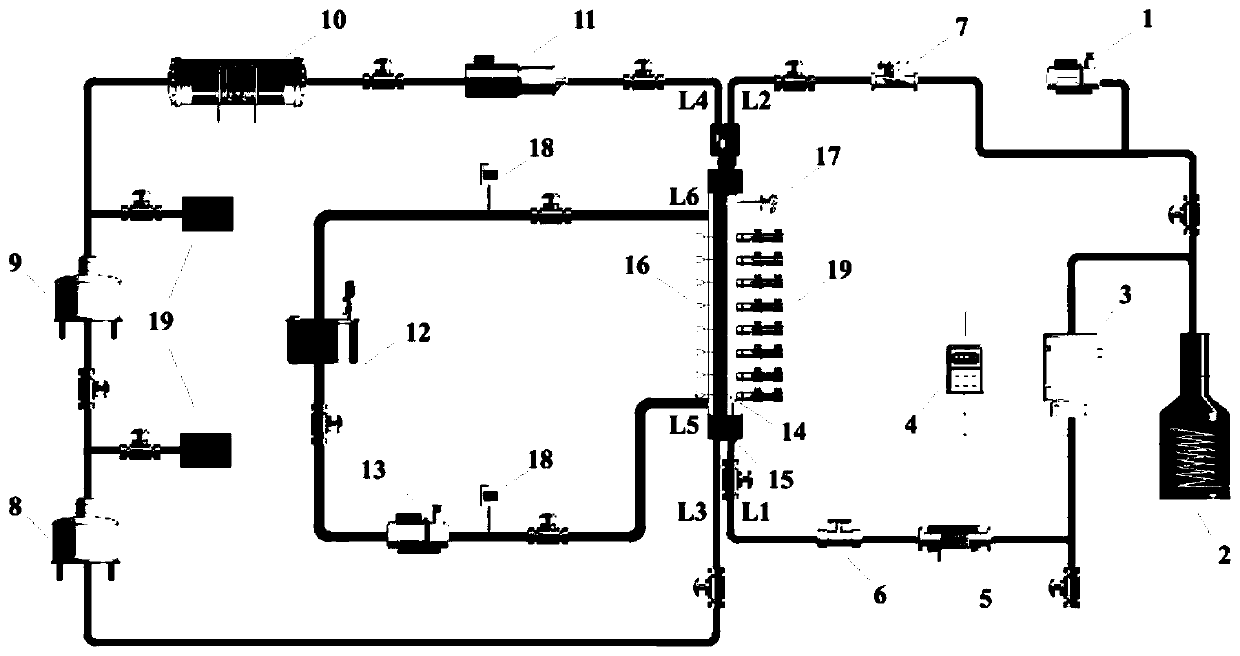

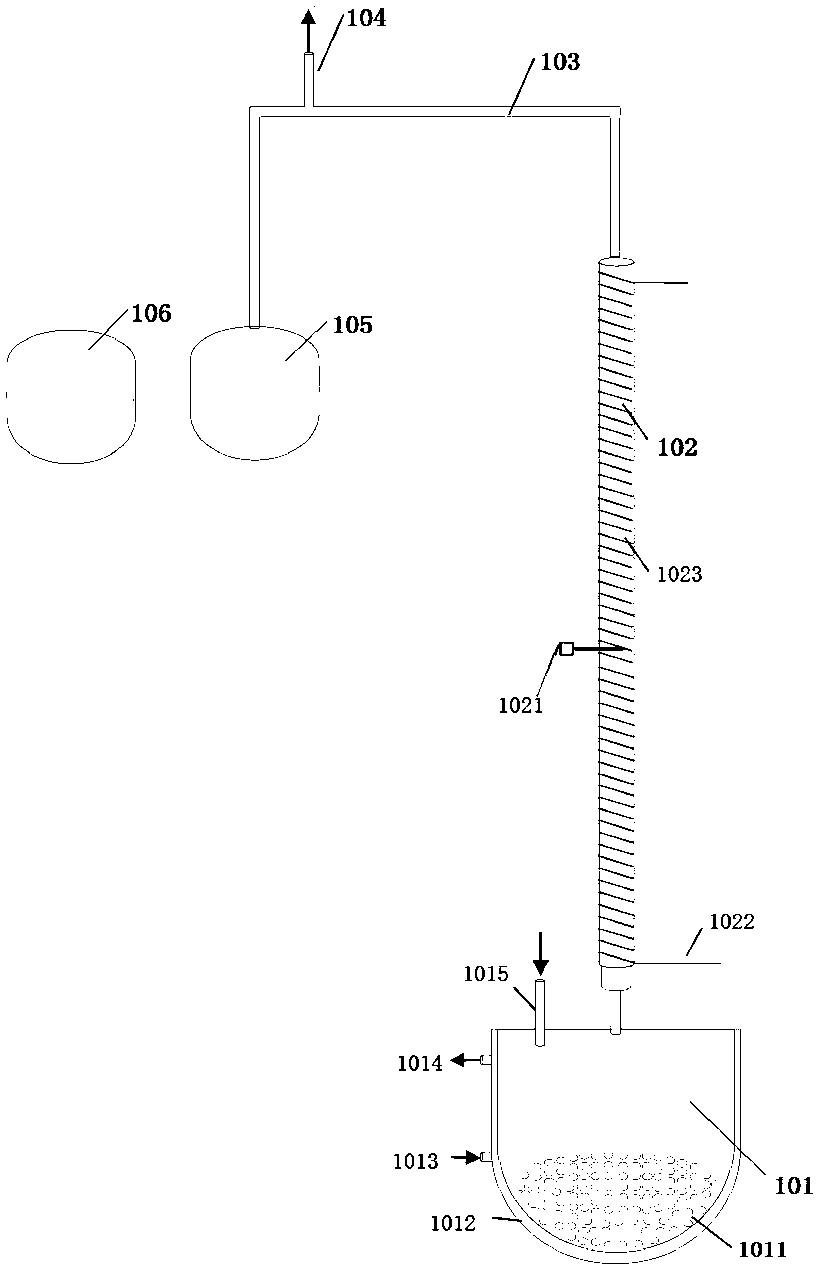

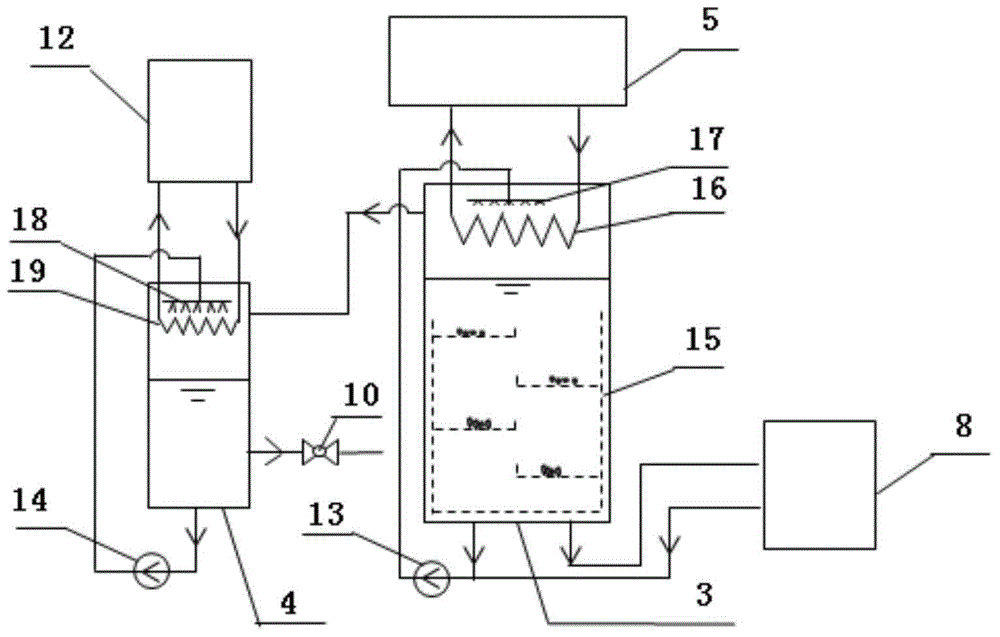

Self-pressurization type lithium bromide bubbling absorption device and control method thereof

ActiveCN111520933AStable vacuumEasy dischargeEnergy efficient heating/coolingClimate change adaptationHeat mass transferLithium bromide

The invention discloses a self-pressurization type lithium bromide bubbling absorption device and a control method thereof. Bubbling under negative pressure is implemented by utilizing a pressurization technology. In a vapor system, water vapor is pressurized through a variable-frequency booster pump so that the water vapor can successfully bubble in a lithium bromide solution in the vacuum state.A micro-pressure one-way balance valve is used for pressure balancing, wherein the micro-pressure one-way balance valve is arranged at an inlet of a gas exhaust pipe, the vapor which is not absorbedyet is quickly exhausted to balance system internal pressure, and then it can be guaranteed that an absorber has the stable vacuum state inside. With the self-pressurization type lithium bromide bubbling absorption device and the control method thereof, the lithium bromide solution bubbling and absorption process in the vacuum state is implemented, an effective path and effective measures are provided for heat and mass transfer performance of a lithium bromide absorption type cooling or heat pump and improvement on an internal absorption effect of a lithium bromide absorption type cooling or heat pump unit, and the device and the control method thereof have significance in improvement on the performance of and the miniaturization optimal design of an absorption type cooling or heat pump system.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

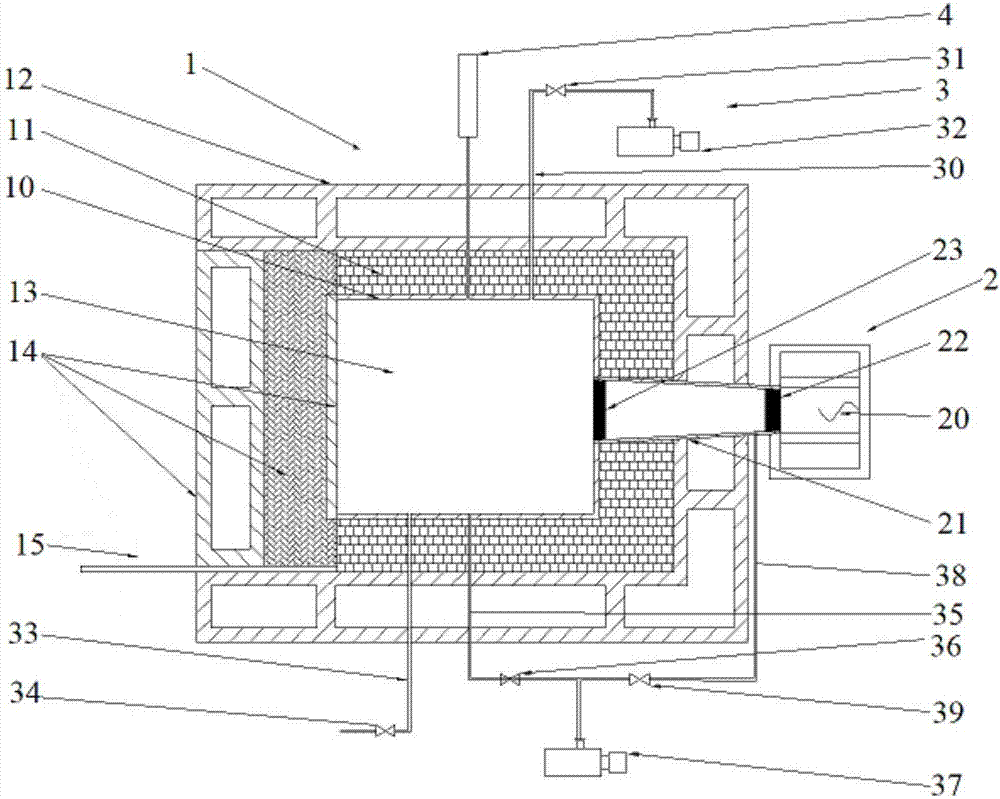

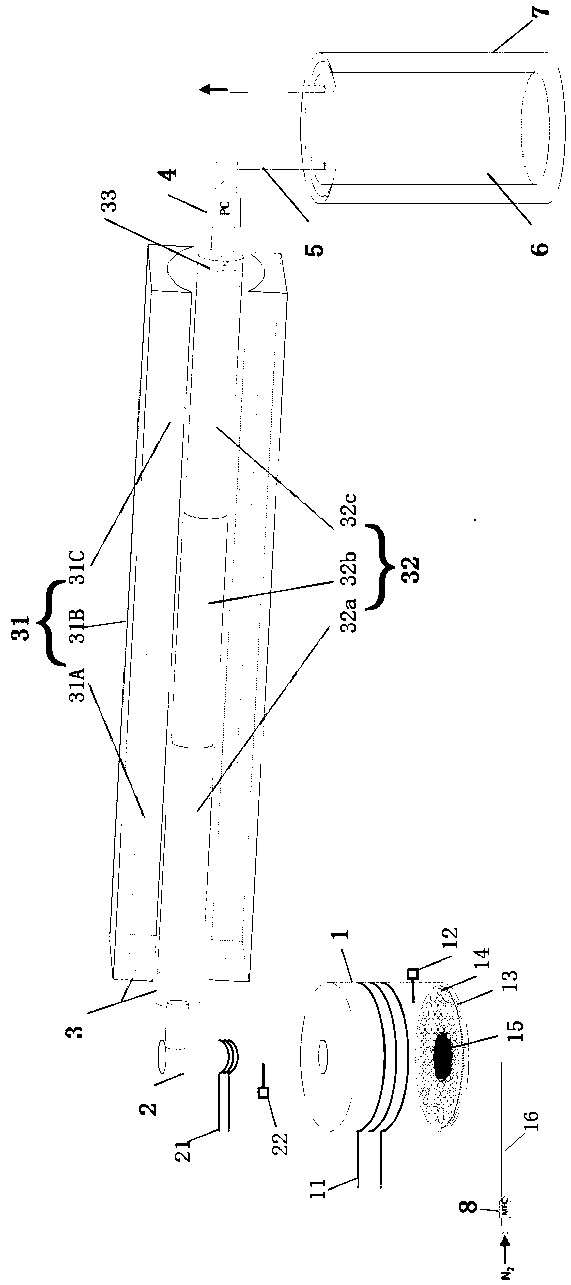

Sublimation purification device for ultra-high purity metallocene source and ultra-high purity metallocene source extraction method thereof

PendingCN108299516AEasy transferHigh puritySublimationMetallocenesTemperature controlHeat mass transfer

The invention discloses a sublimation purification device for an ultra-high purity metallocene source. The sublimation purification device includes a reactor, a buffer tube, a gradient sublimation tube and a front fraction collection tank. The invention also discloses a method for using the sublimation purification device for the ultra-high purity metallocene source to extract the ultra-high purity metallocene source. According to the sublimation purification device and the method, by adding inert particles of different particle sizes, the heat mass transfer is further strengthened by magneticstirring, materials are dispersed, agglomeration and inclusion are reduced, uniform heat transfer between materials is accelerated, and the effect of accelerating sublimation is achieved. The addition of high-purity nitrogen can reduce the partial pressure of the metallocene surface, and at the same time, the action of air flow accelerates the sublimation and improves the purification rate. The segmental temperature control of the vacuum distillation of the metallocene source is achieved by a lateral gradient sublimation method, so that the purification rate and the purity of the material areimproved, the product yield is improved, and the high purity metallocene source with the mass fraction greater than or equal to 99.99995% can be obtained.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

Equipment for promoting heat and water transfer on surface of wood

InactiveCN108800874AGet rid of dependenceIncrease heatDrying using combination processesDrying solid materials without heatHeat mass transferThin layer

The invention discloses equipment for promoting heat and water transfer on the surface of wood. The equipment comprises an ultrasonic treatment device for ultrasonically treating the surface of wood placed in a drying room. The ultrasonic treatment device treats the surface of the wood in the wood drying process ultrasonically. In the wood drying process, ultrasonic waves can promote the transfereffect of heat and water on the surface of the wood and eliminate a heat mass transfer thin layer on the surface of the wood to further accelerate the water on the surface of the water to move towarda drying medium, so that heat is promoted to be quickly transferred to the surface of the wood. The equipment plays a huge role of reducing the drying energy consumption and shortening the drying period. The equipment and method provided by the invention can achieve a continuous drying process of the wood and an energy-saving drying process of the wood.

Owner:BEIJING FORESTRY UNIVERSITY

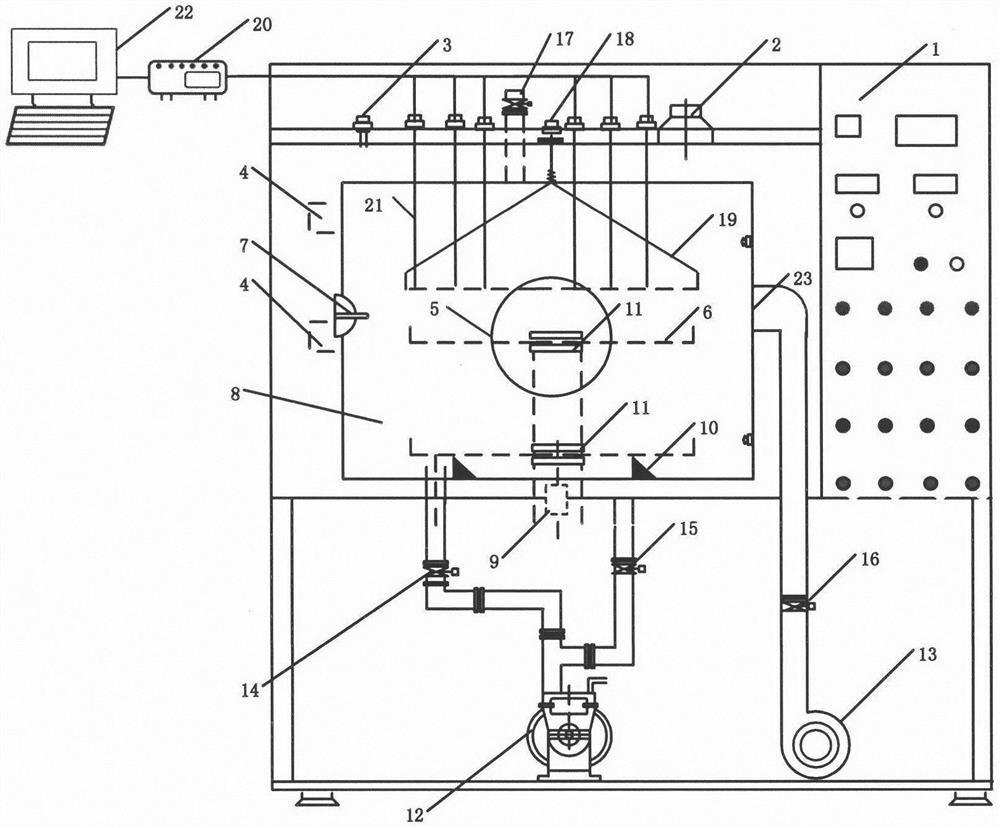

Drying method of clothes treatment equipment and clothes treatment equipment

ActiveCN111058259AImprove drying uniformityConducive to loadTextiles and paperLaundry driersHeat mass transferProcess engineering

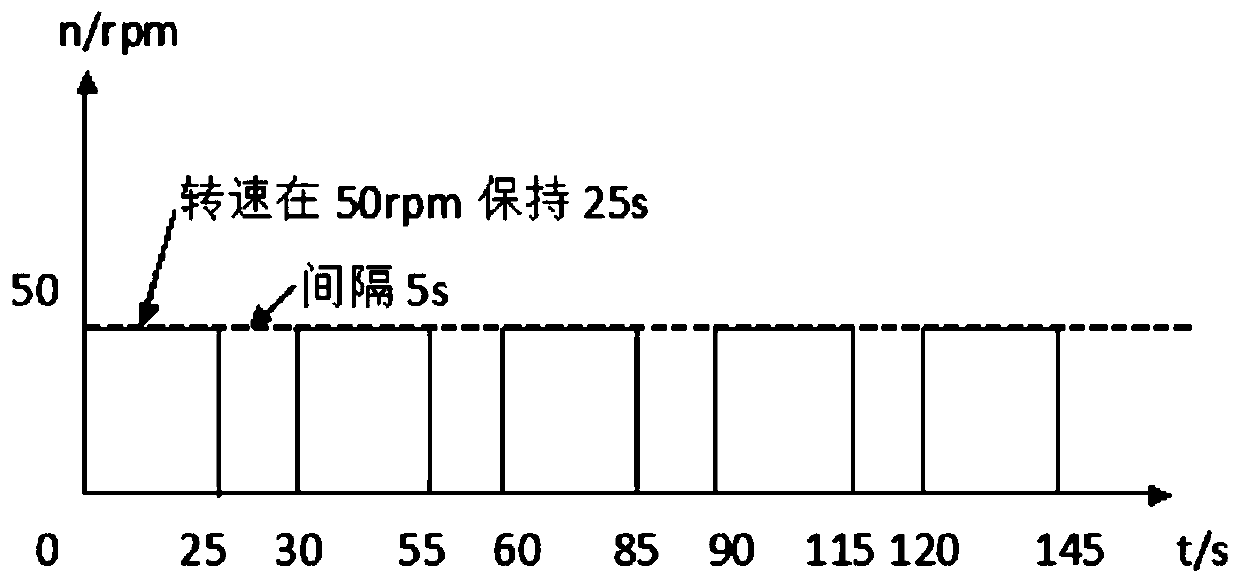

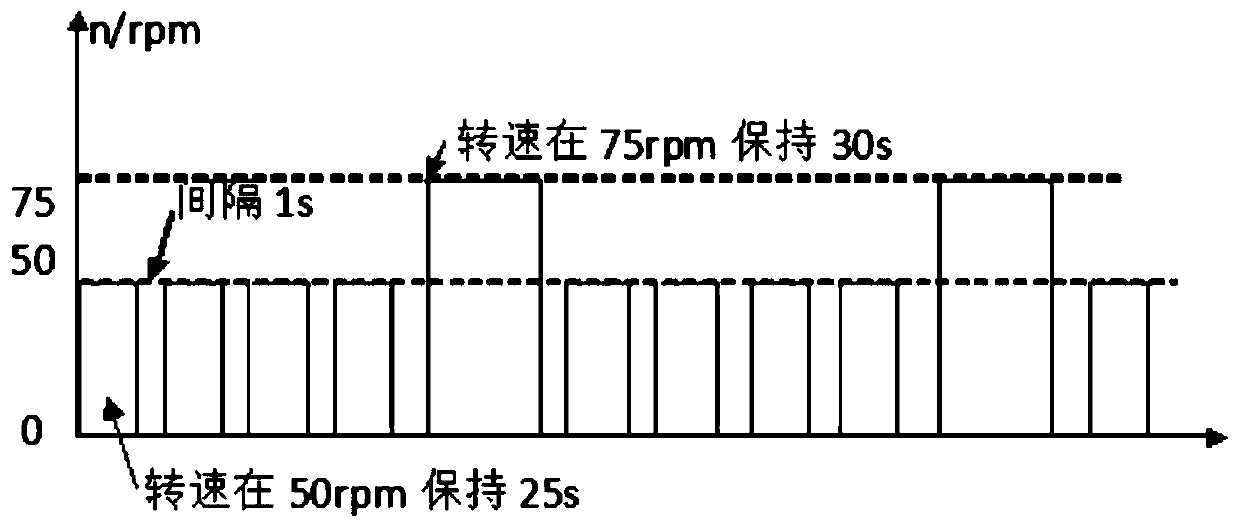

The invention belongs to the field of clothes treatment equipment, and particularly discloses a drying method of clothes treatment equipment. The clothes treatment equipment comprises a rotatable drying cylinder. The method comprises a preheating stage S0, a low-speed drying stage S1, a high-speed drying stage S2 and an alternate stage S3. In the preheating stage, the drying cylinder is preheated,so that the temperature in the drying cylinder reaches a preset temperature. In the low-speed drying stage, when the temperature in the drying cylinder reaches the preset temperature, the drying cylinder is controlled to perform uniform-speed drying at a first rotating speed for a first preset time. In the high-speed drying stage, after the first preset time, the drying cylinder is controlled toperform uniform-speed drying at a second rotating speed for a second preset time, wherein the second rotating speed is higher than the first rotating speed. In the alternate stage, after the second preset time, the low-speed drying stage and the high-speed drying stage are controlled to be alternately performed until preset drying termination conditions are met. By controlling the rotating speed and the rotation-stop ratio of the drying cylinder in the drying process, the relationship between a load movement track and load heat mass transfer is improved, so that the clothes drying uniformity is greatly improved.

Owner:GREE ELECTRIC APPLIANCES INC

Vibration type multifunctional combined drying device capable of automatically controlling temperature and humidity

PendingCN113623973AAchieve vibrationAchieve rotationDrying solid materials with heatFood processingEngineeringVacuum drying

The invention relates to a fruit and vegetable material drying device, in particular to a vibration type multifunctional combined drying device capable of automatically controlling temperature and humidity. The device is composed of a control device, an infrared thermometer, a weighing sensor, a weighing frame, an optical fiber thermometer, a computer, a hot air heating device, a microwave magnetron, a drying cavity, a material tray, a vibration device, a rotating device, a vacuum pump, an observation window, a drying cavity door, an electromagnetic valve, an illuminating lamp and the like. In the drying process, movement of the materials is regulated and controlled through the vibration device and rotating equipment, hot air drying can be coupled with microwave drying under the non-vacuum condition, the heat and mass transfer directions of the materials can be consistent, hot spots of the materials are avoided, and the purpose of uniform and rapid drying is achieved. Through an automatic temperature and humidity control device, the internal temperature of the materials is monitored in real time, overheating damage of the materials is avoided, meanwhile, the real-time water content of the materials is tracked, and the drying end point is judged. According to the device, the flexibility of equipment is remarkably improved, materials are vibrated and rotated under the conditions of microwave vacuum drying and microwave coupling hot air, the purpose of efficient and uniform drying is achieved, the quality of dried products is effectively improved, energy consumption is remarkably reduced, and the production cost is reduced.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

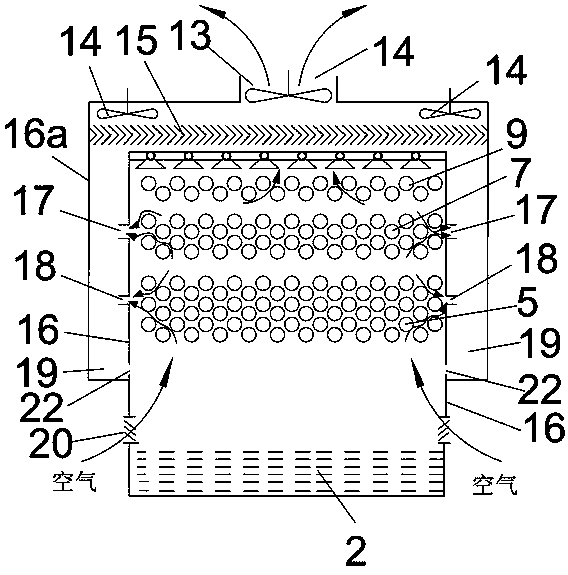

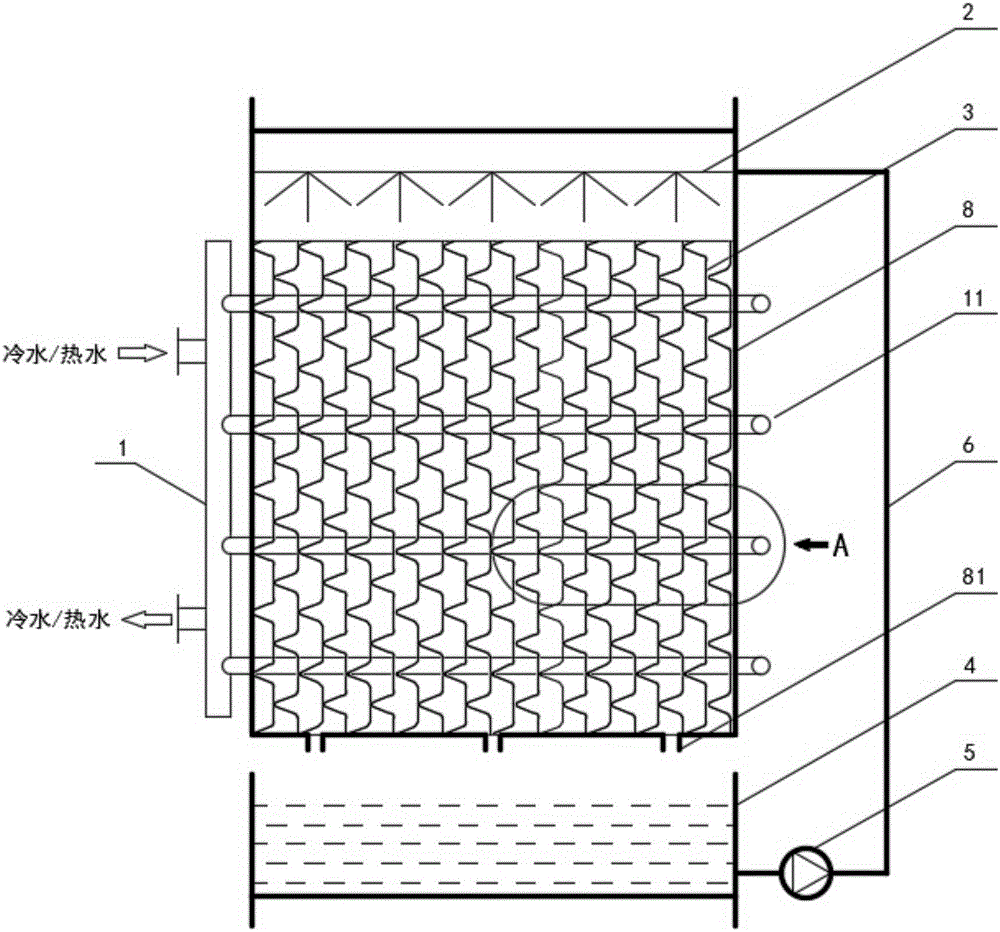

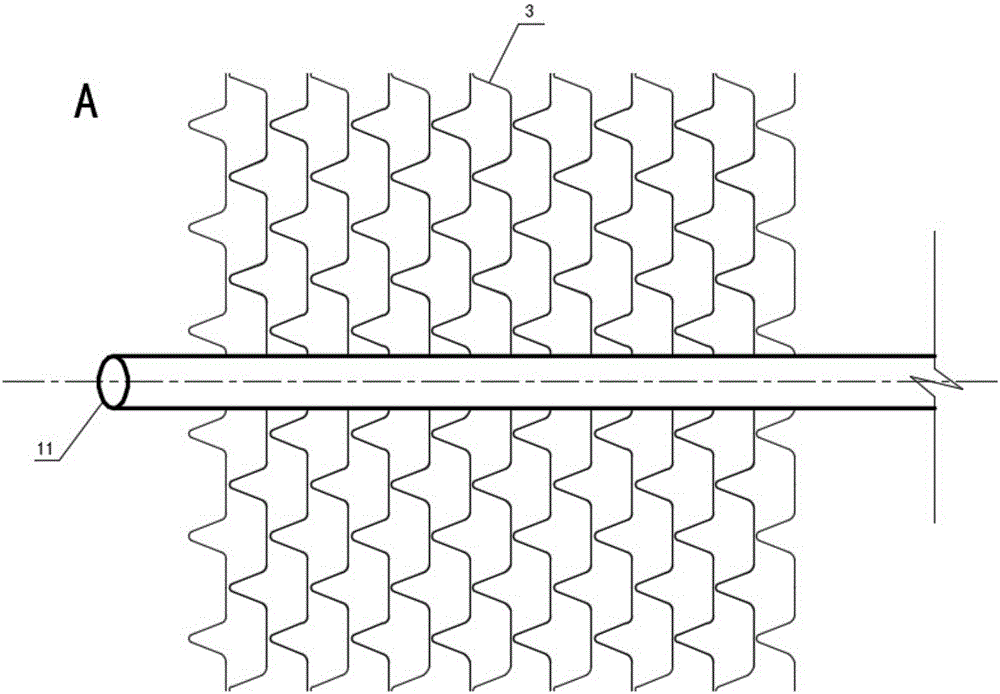

Gas-liquid whole-heat exchange device with built-in cold and heat source based on metal fiberfill

ActiveCN105890147AIncrease contact areaExtension of timeSpace heating and ventilation detailsTrickle coolersMetal fiberHeat mass transfer

The invention discloses a gas-liquid whole-heat exchange device with a built-in cold and heat source based on a metal fiberfill. The gas-liquid whole-heat exchange device comprises a heat exchange coil, a sprayer, a metal fiberfill, a solution tank, a solution pump, a solution circulating pipeline and a tank body, wherein the solution tank is located under the tank body; the sprayer is arranged above the metal fiberfill; the solution tank is communicated with the sprayer through the solution circulating pipeline; the solution pump is arranged on the solution circulating pipeline; the heat exchange coil and the metal fiberfill are arranged in the tank body; the metal fiberfill is formed by overlapping and assembling the inclined ripple metal fiber mats at two angles; the surfaces of the metal fiber mats are preferably treated through hydrophilic nano coating; the heat exchange coil comprises a metal heat exchange tube which penetrates through the metal fiber mats along the overlapped direction of the metal fiber mats; a solution flowing channel and an air-guide channel are formed between the two adjacent metal fiber mats. According to the device, can effectively increase the contact area between the solution and air can be effectively increased, the contact time of the solution and air can be effectively prolonged, the heat mass transfer coefficient can be increased and the device can be served as a dehumidifying or regenerating unit of a solution humidity-adjusting air-conditioning system.

Owner:BEIJING KANGFU TECH

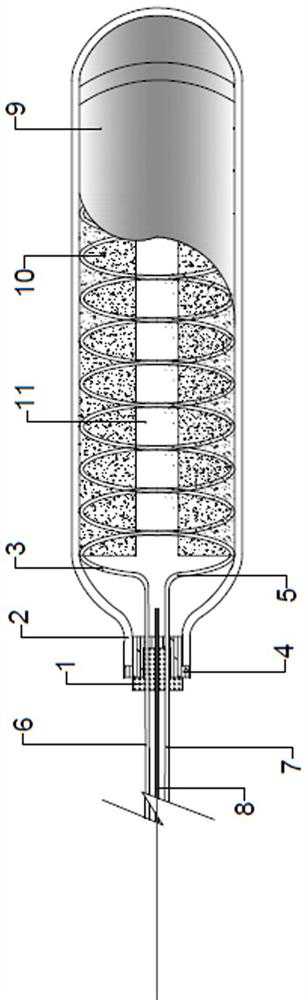

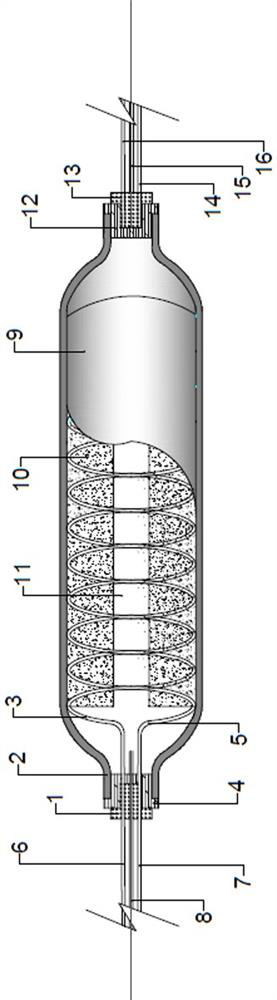

Solid hydrogen source device for hydrogen fuel

ActiveCN112066242ASimple structureEasy to processVessel mounting detailsReactant parameters controlHeat mass transferEngineering

The invention relates to a solid hydrogen source device for hydrogen fuel, and belongs to the technical field of hydrogen storage devices. Safety, portability and environmental adaptability of a solidhydrogen source to hydrogen utilization are achieved. According to the solution, a tank opening is formed in a hydrogen storage tank, a valve is mounted at the tank opening, a sealing ring is mountedbetween the valve and the tank opening, a heat exchange pipeline is of a double-spiral structure and is fixedly arranged on the inner wall of the hydrogen storage tank in a coiling manner, and a heatmass transfer inlet and a heat mass transfer outlet of the heat exchange pipeline respectively penetrate through the valve and extend to the outside of the hydrogen storage tank; a cavity is formed in the axis position in a tank body of the hydrogen storage tank, a hydrogen charging / discharging pipeline penetrates through the valve and communicates with the cavity, a plurality of material bins are arranged on the periphery of the cavity, the size of each material bin is not smaller than 4 / 5 of that of an inner cavity of the tank body of the hydrogen storage tank, a diaphragm is arranged on aside wall of each material bin, and the material bins are filled with solid hydrogen storage alloy powder. The device is simple in structure, safe, efficient, portable and suitable for various environments and has good reproducibility and stability.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

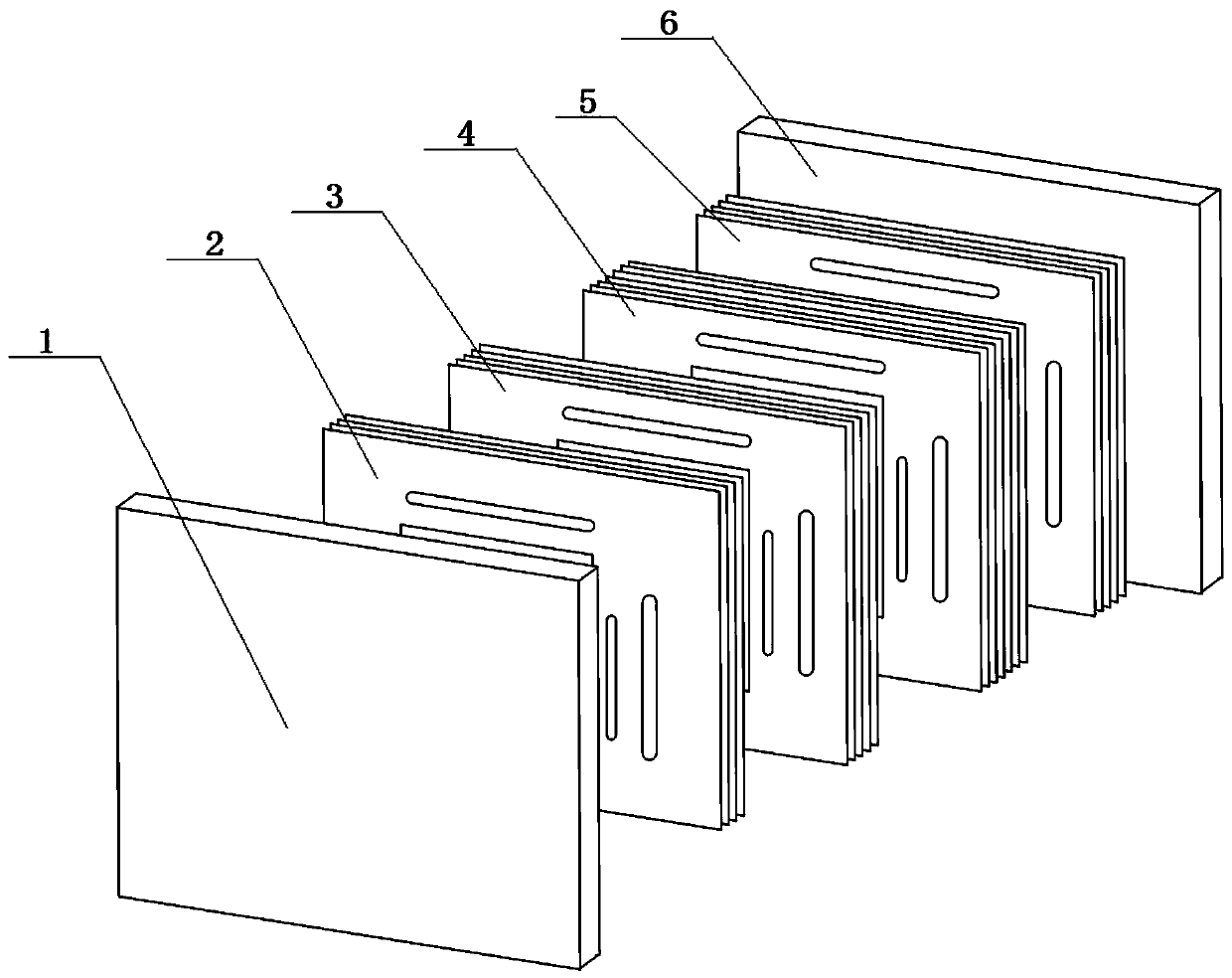

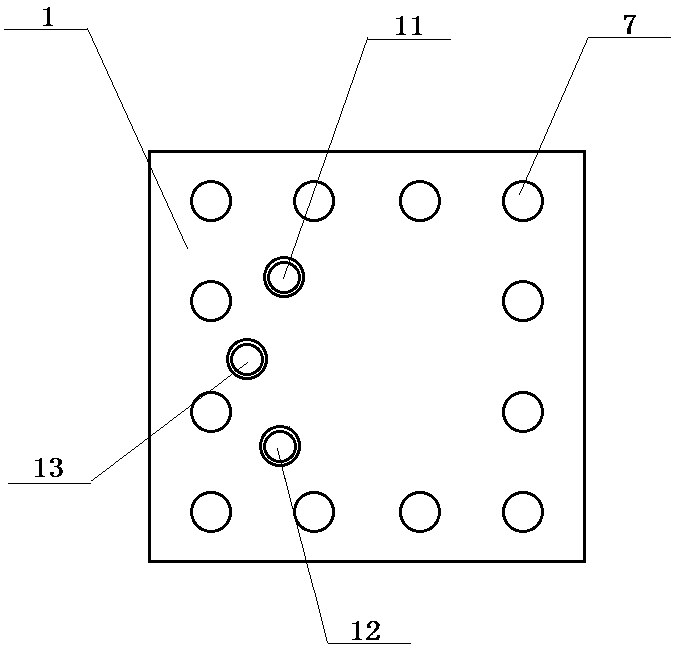

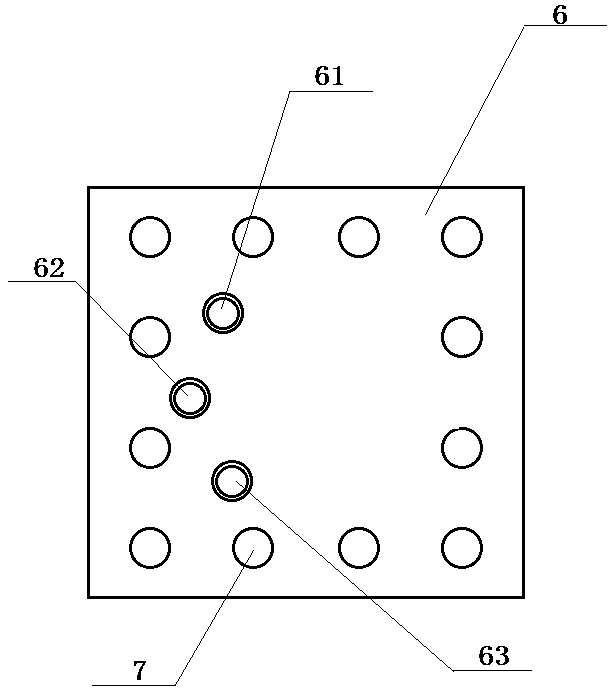

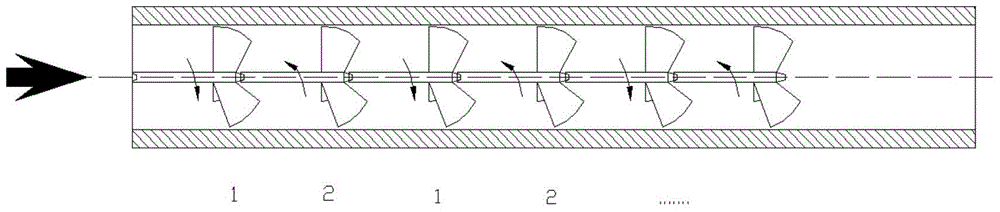

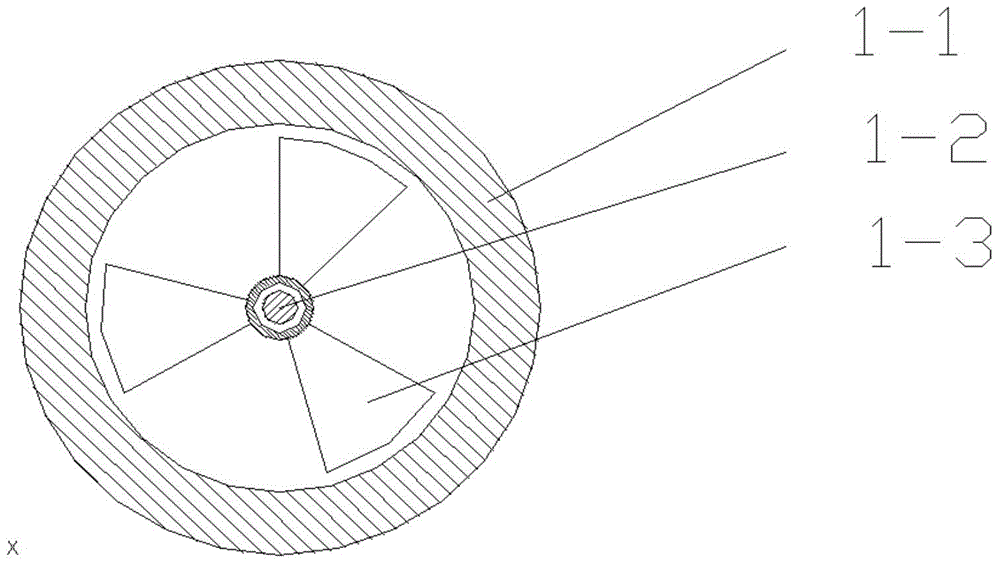

Method for preparing palladium membrane module and application of palladium membrane module to reactor used for preparing hydrogen from methanol

PendingCN110420644AImprove heat transfer effectUniform temperatureHydrogenHydrogen/synthetic gas productionCombustion chamberHydrogen

The invention discloses a method for preparing a palladium membrane module and application of the palladium membrane module to a reactor used for preparing hydrogen from methanol. The method for preparing the palladium membrane module is to plate two sides of a structural support body with a layer of a palladium alloy membrane and a layer of a methanol-to-hydrogen catalyst membrane respectively byusing an electroless plating manner. The reactor used for preparing hydrogen from methanol comprises a cover plate I, a heat exchanger I, a reforming combustion chamber, a heat exchanger II, an evaporator and a cover plate II, wherein the heat exchanger I, the reforming combustion chamber, the heat exchanger II and the evaporator are sequentially overlapped and are then placed between the cover plate I and the cover plate II; the reforming combustion chamber is composed of a plurality of partition plates and a plurality of reforming combustion plates, and the partition plates and the reforming combustion plates are arranged repeatedly and alternately; and the evaporator is composed of a plurality of partition plates and a plurality of evaporation plates, and the partition plates and the evaporation plate are arranged repeatedly and alternately. The reactor of the invention has good heat mass transfer effect, uniform catalyst temperature at each position, small heat loss and high hydrogen yield.

Owner:广西氢朝能源科技有限公司

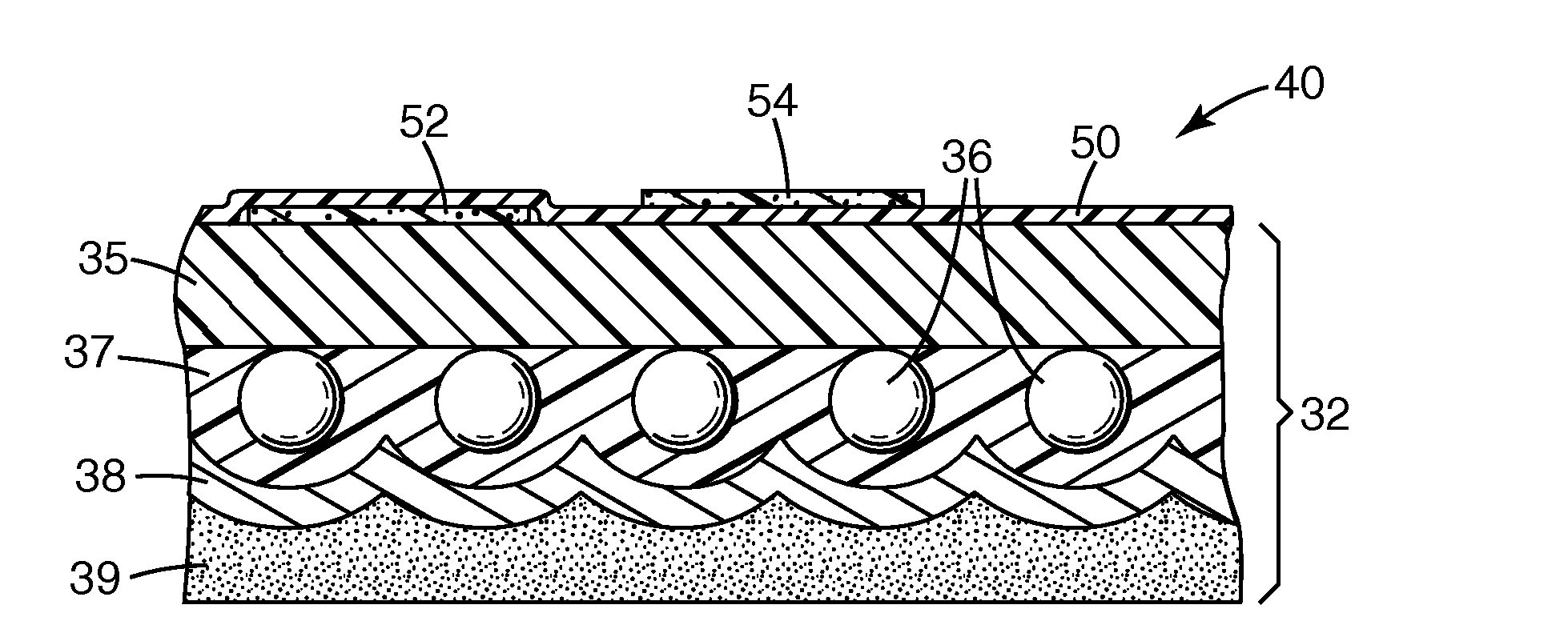

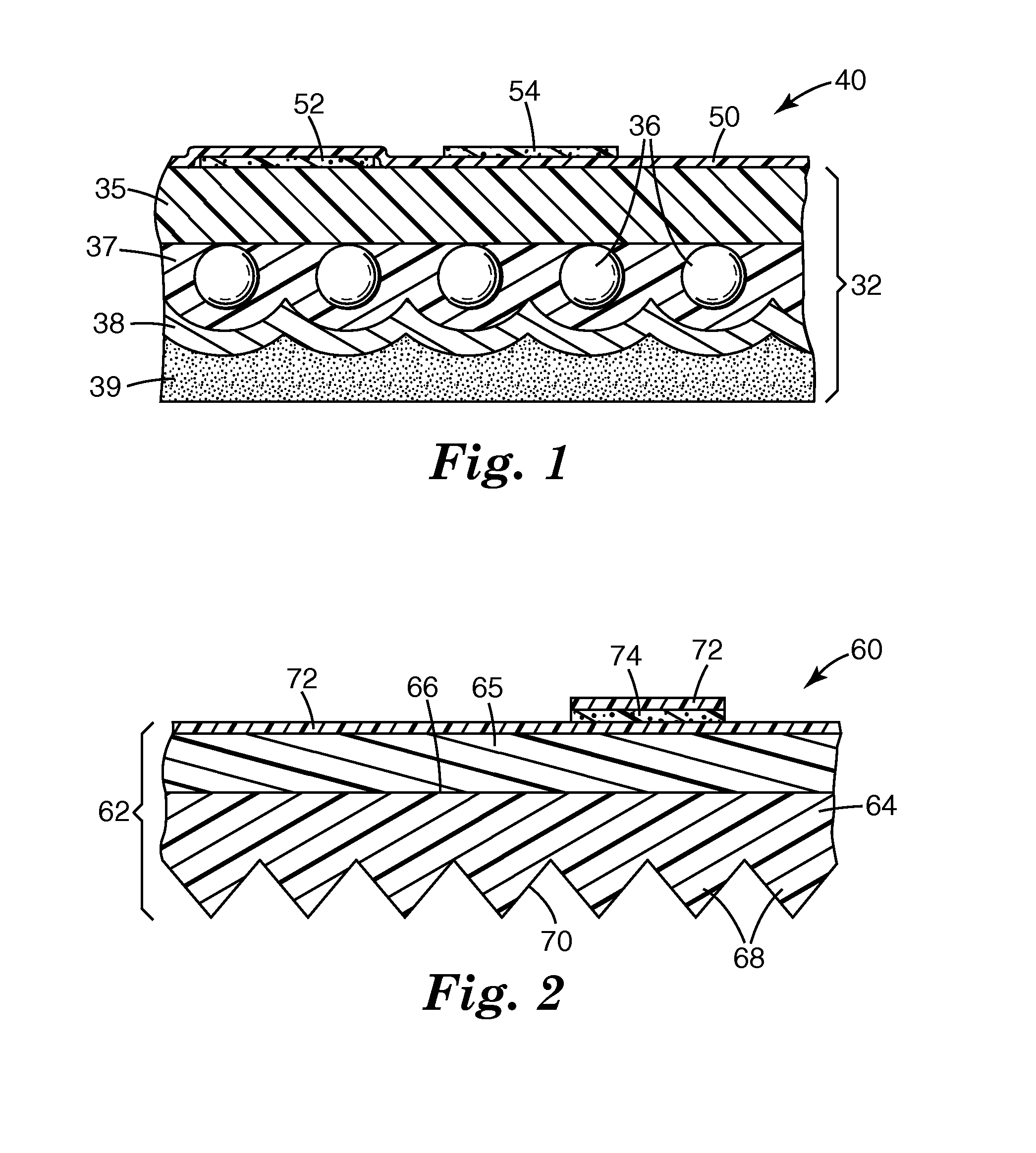

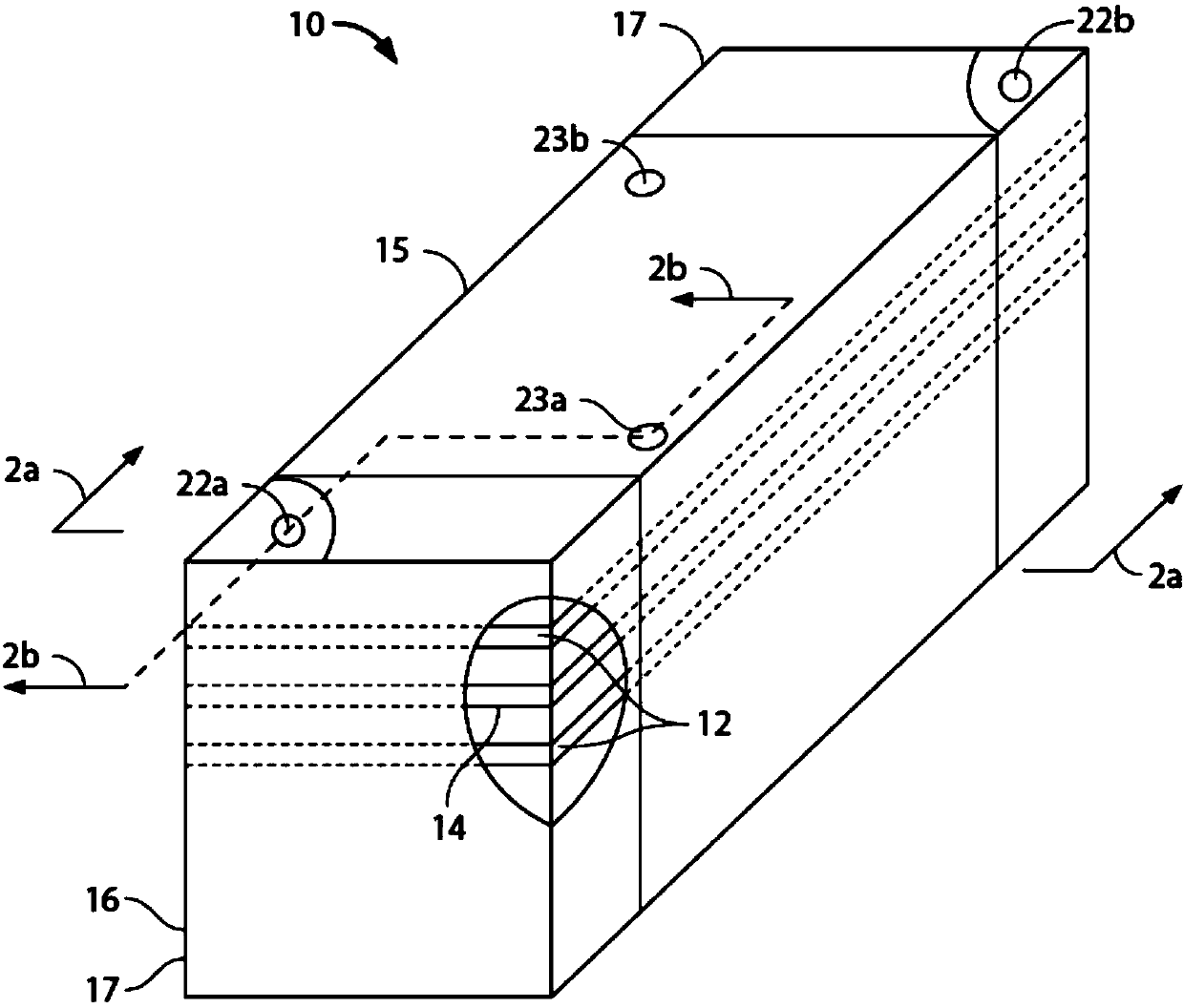

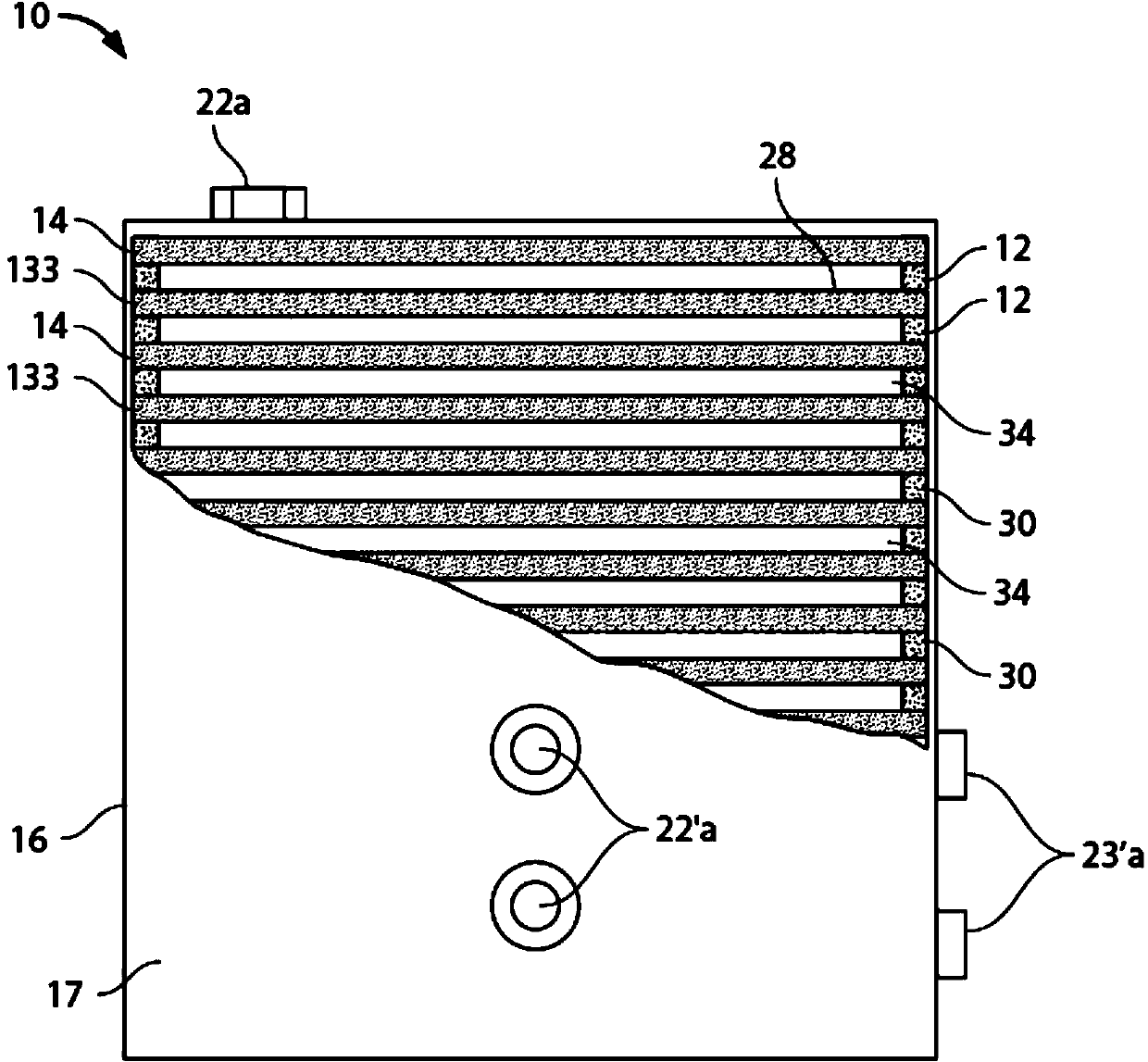

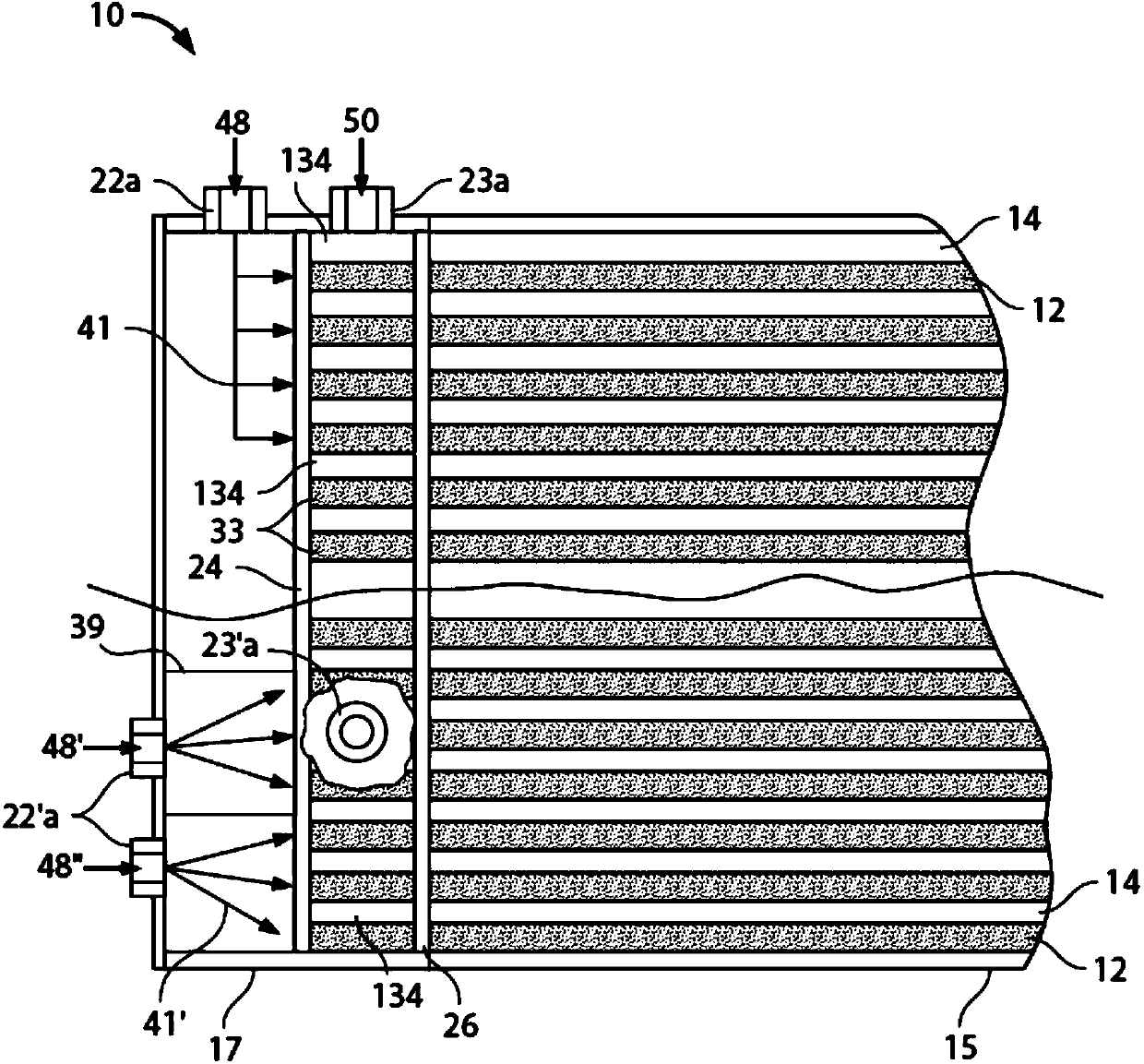

Plate and frame and spiral wound membrane modules for heat and mass transfer

InactiveCN103874537AReduce maintenanceReduce/or customizeMembranesDistillationHeat mass transferDistillation

The invention relates to membrane modules and applications therefor. In particular, the invention relates to the construction of membrane modules for use in forward osmosis, heat exchange, and distillation processes.

Owner:OASYS WATER

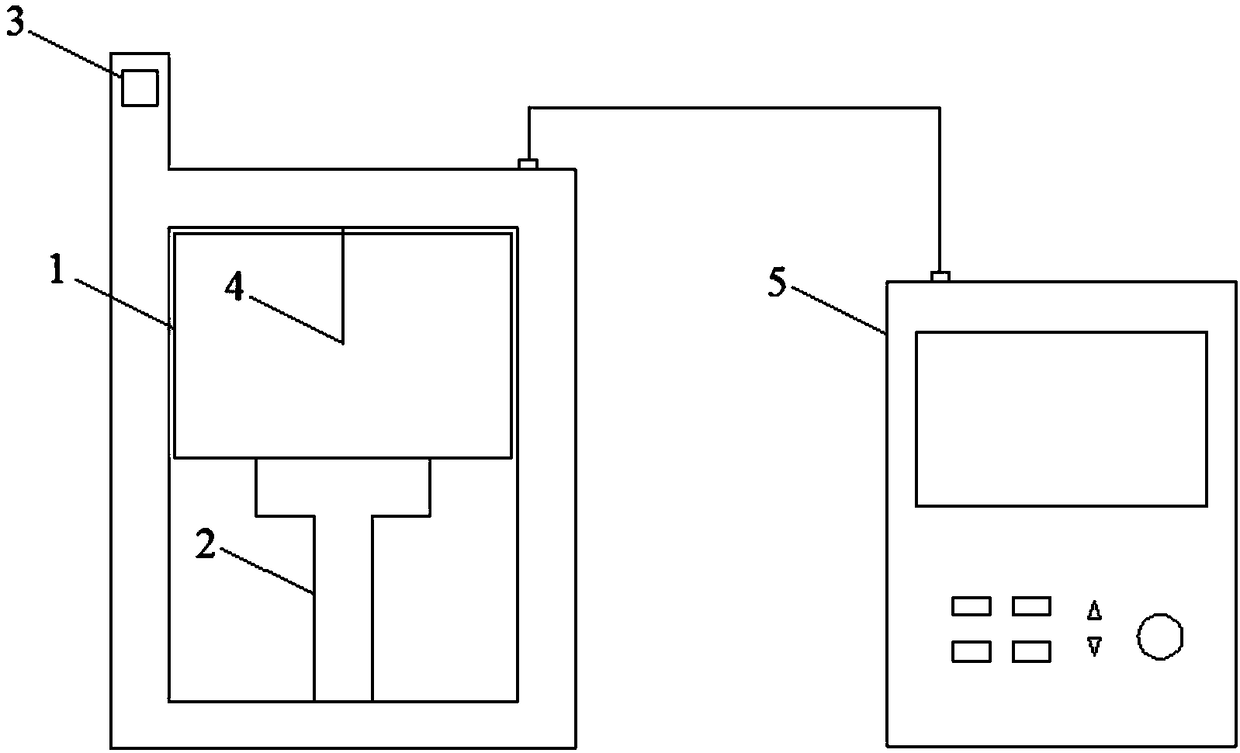

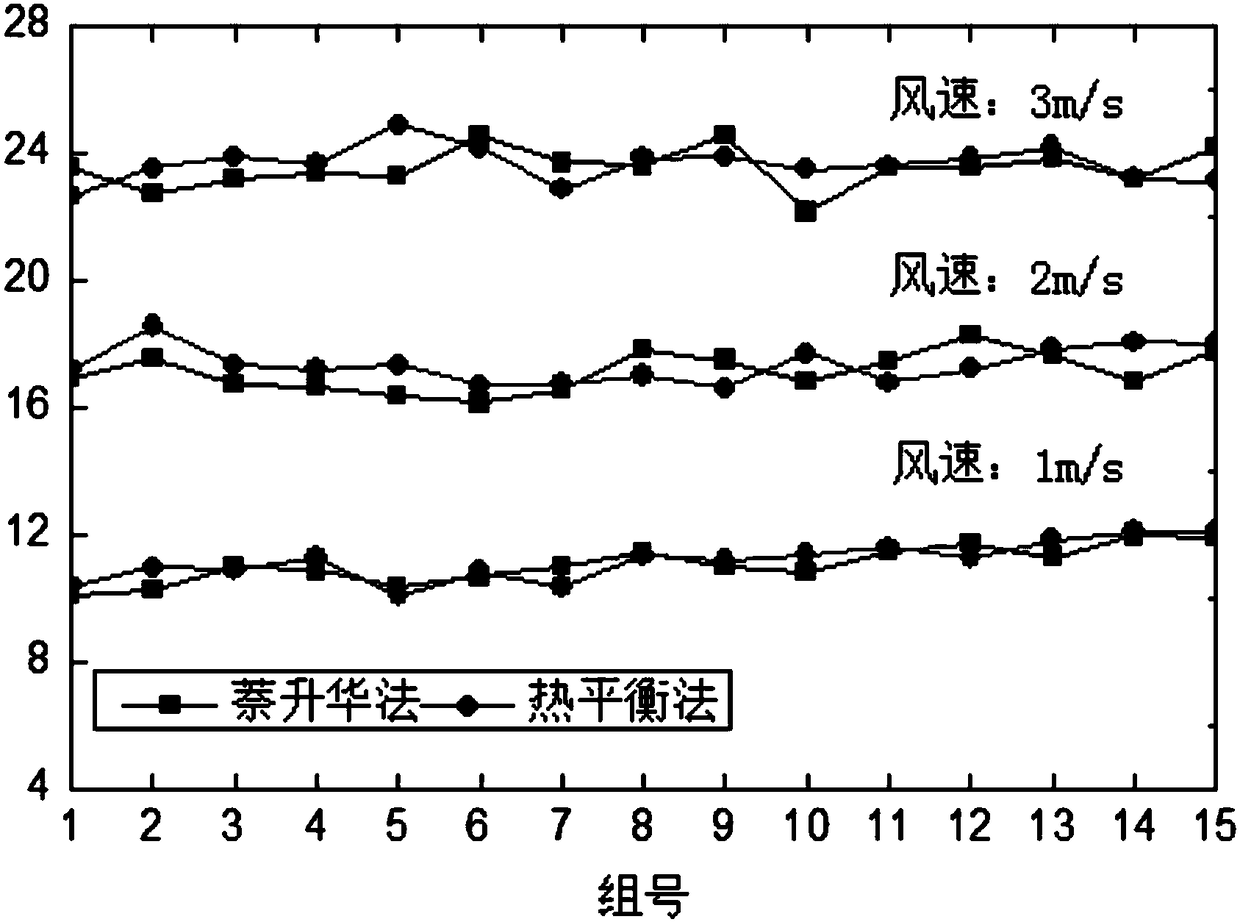

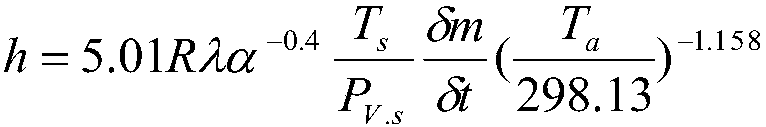

Method of measuring convection heat transfer coefficient of outer surface of building

InactiveCN108445042ASimple methodImprove accuracyMaterial thermal conductivityMaterial heat developmentHeat mass transferEngineering

A method of measuring convection heat transfer coefficient of the outer surface of a building belongs to the technical field of coefficient measurement and is based on naphthalene sublimation and heat-mass transfer analogy experiment; a corresponding measuring apparatus is also provided; mass transfer coefficient of naphthalene under certain conditions can be obtained by measuring sublimation rateof naphthalene; convection heat transfer coefficient under these conditions is acquired via heat transfer and mass transfer analogy. The method is simple to perform and has good results accuracy.

Owner:BEIJING UNIV OF TECH

Steam-liquid-solid three-phase energy accumulator

ActiveCN104406326AReduce volumeAvoid the dangers of crystallizationMechanical apparatusEnergy efficient heating/coolingDissolutionEngineering

The invention provides a steam-liquid-solid three-phase energy accumulator, and belongs to the technical field of energy accumulation. The steam-liquid-solid three-phase energy accumulator uses an absorption type refrigeration work medium as an energy accumulation medium, a three-phase energy accumulation tank and a liquid stage refrigerant accumulation tank are organically combined for forming the steam-liquid-solid three-phase energy accumulator, the two accumulation tanks respectively adopt the upper part heat exchange and lower part liquid storage integration and liquid self circulation spraying design, an upper part heat exchanger of the three-phase energy accumulator adopts a surface porous pipe heat exchanger for reinforcing the heat mass transfer process, the solution crystallization and crystal dissolution are accelerated through the arrangement of a crystal distributor at the lower part of the three-phase energy accumulation tank, and four layers of filter screen devices are arranged and are ranged in a staggered way in different layers. The steam-liquid-solid three-phase energy accumulator has the advantages that the danger caused by crystallization in the existing solution absorption type energy accumulation is avoided, meanwhile, the energy accumulation density is obviously improved through being compared with that of a three-phase energy accumulation mode, the energy accumulation density can be improved by more than 50 percent through the 50-percent crystallization rate, in other words, the 50-percent crystallization rate is realized, the size of the energy accumulator is reduced by more than a half, the regulation and the control are simple, the steam-liquid-solid three-phase energy accumulator is combined with a traditional absorption type refrigeration air conditioner system for forming an absorption type refrigeration air conditioner system with the three-phase energy accumulator.

Owner:BEIJING UNIV OF TECH

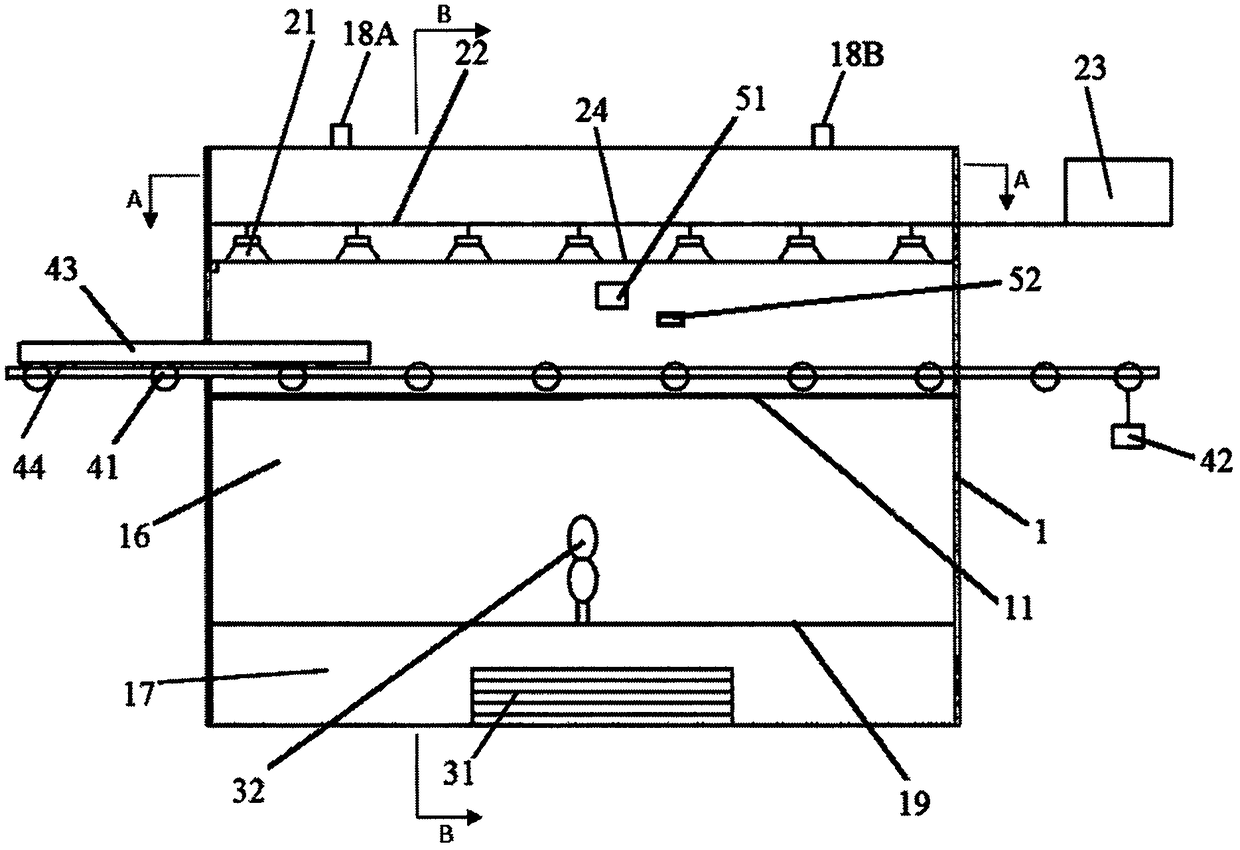

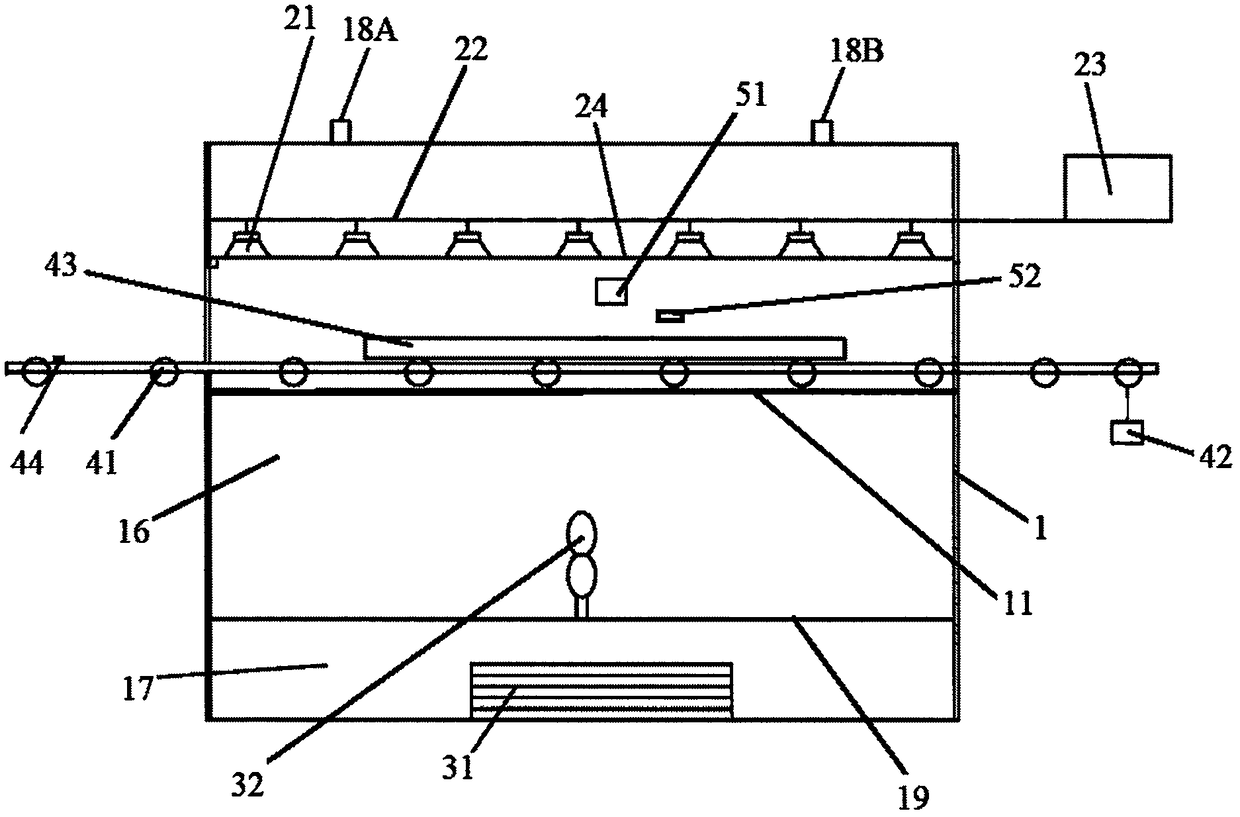

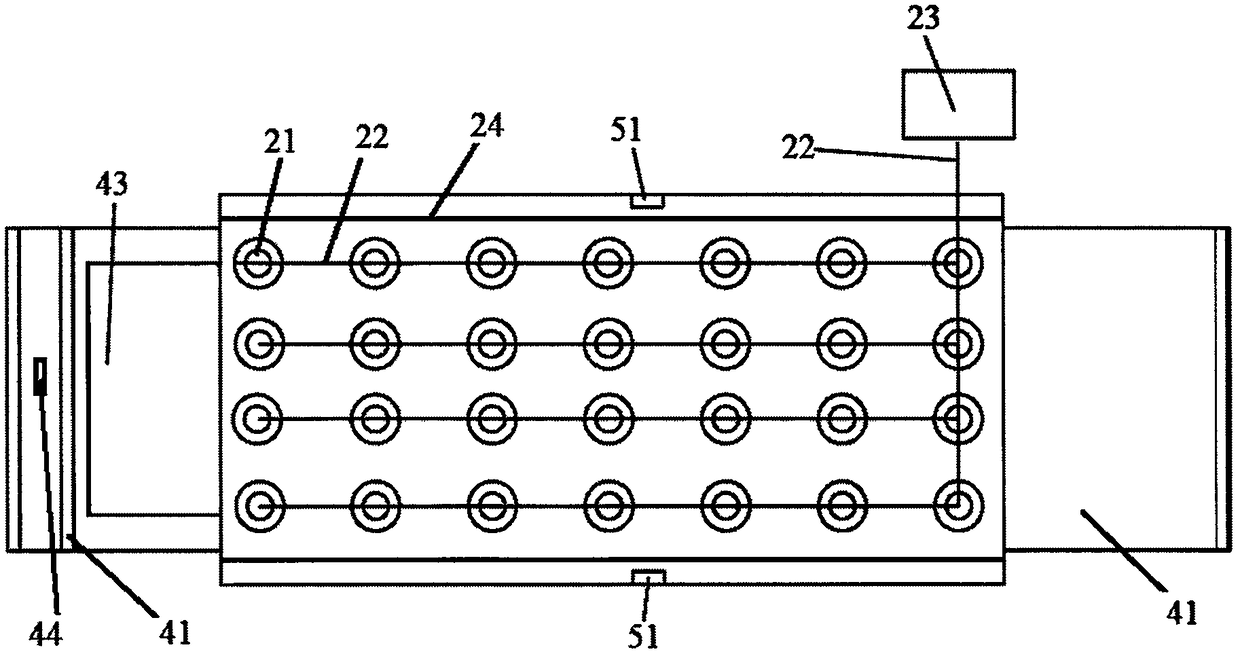

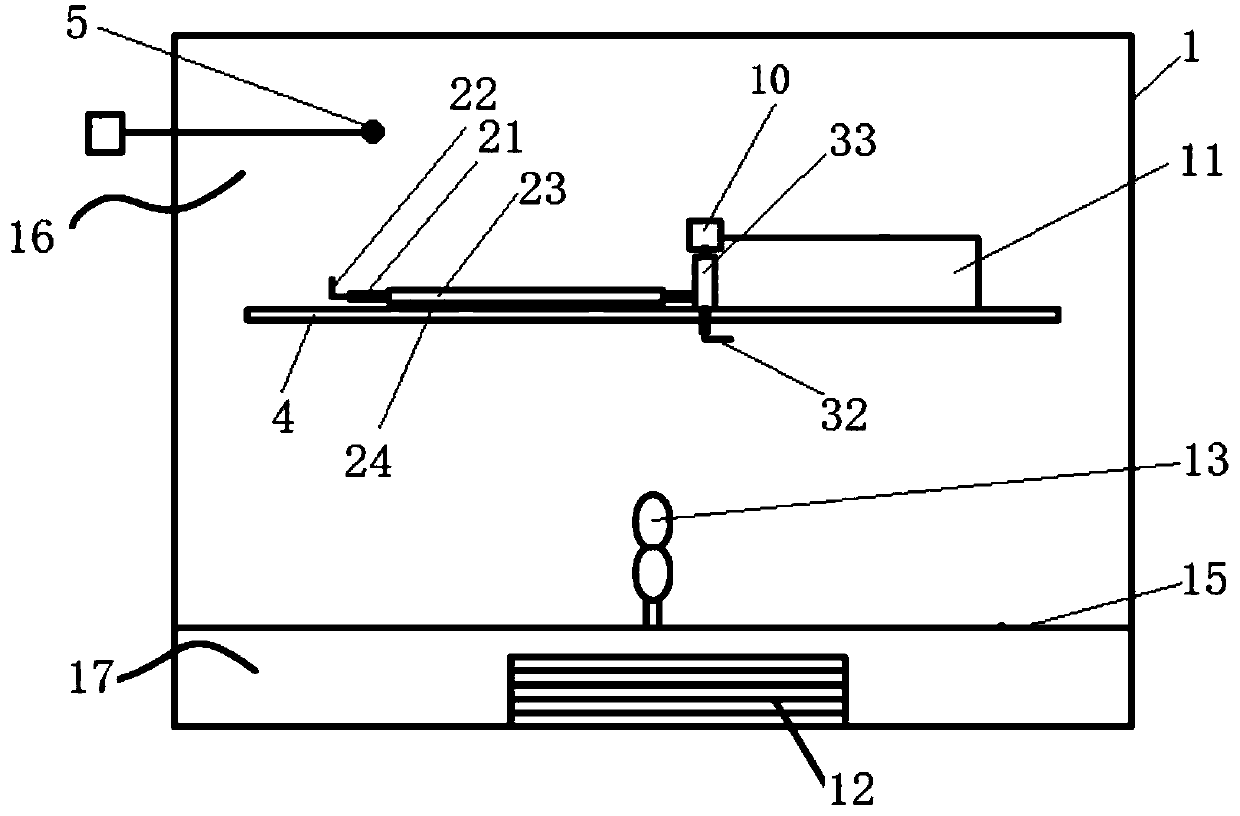

Equipment for measuring thickness of heat and mass transfer thin layer on wood surface in drying process

ActiveCN109682339AImprove drying qualityHigh measurement accuracyDrying gas arrangementsDrying chambers/containersMeasurement deviceHeat mass transfer

The invention discloses equipment for measuring the thickness of a heat and mass transfer thin layer on the wood surface in the drying process. The equipment comprises a wood drying chamber, a first feeding device, a second feeding device and a measuring device, wherein the first feeding device, the second feeding device and the measuring device are arranged in the drying chamber, and the drying chamber is internally and horizontally provided with a bracket used for placing to-be-dried wood; the first feeding device is perpendicular to the second feeding device, the second feeding device is fixed at the front end of the first feeding device, and the first feeding device pushes the second feeding device to move horizontally in the longitudinal direction or horizontal direction of the dryingchamber. The equipment for measuring the thickness of the heat and mass transfer thin layer on the wood surface in the drying process has the advantages that the collected data volume is large, measured results are accurate, the precision is high, the heat and mass transfer thin layer in the drying process of wood is improved, data support is provided for the wood drying quality, and good theoretical guidance is provided for strengthening heat and moisture transfer on the wood surface and increasing the wood drying rate.

Owner:BEIJING FORESTRY UNIVERSITY

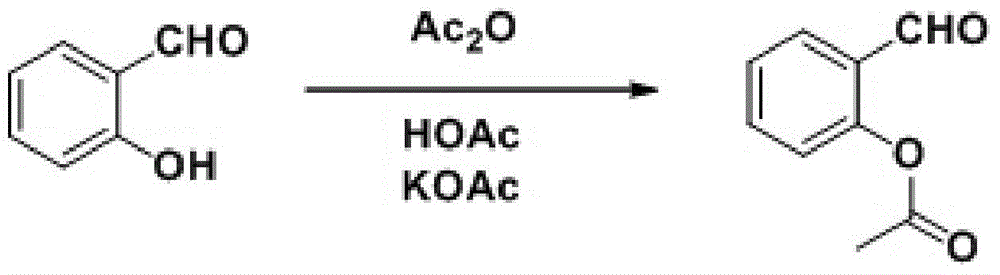

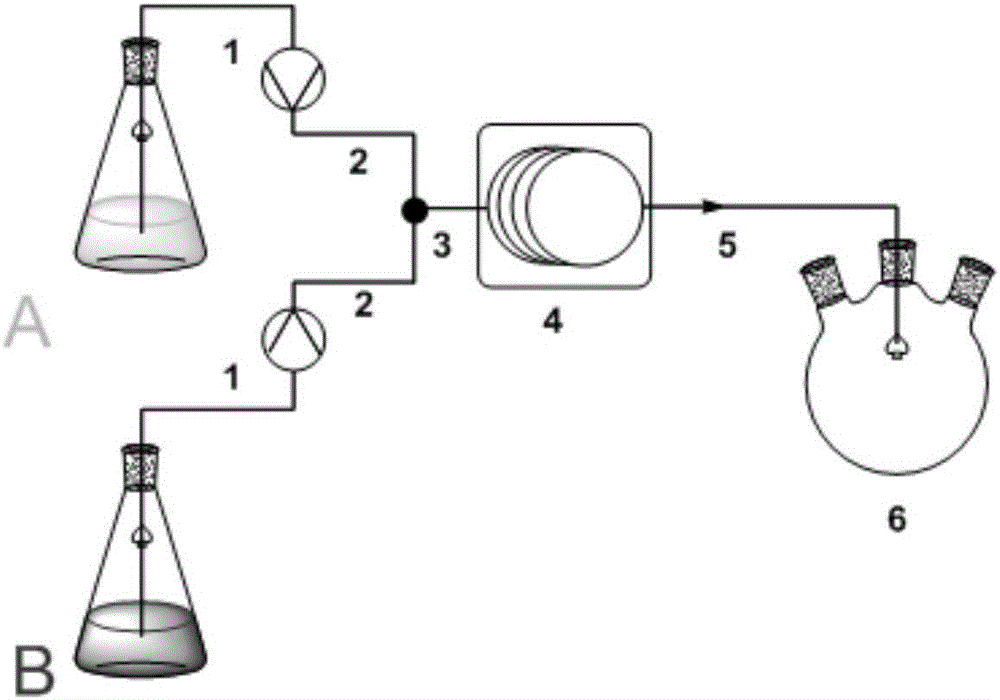

Method for producing coumarin intermediate through microreactor in pilot-plant-scale manner

InactiveCN104649900ASimple processImprove operational safetyOrganic compound preparationCarboxylic acid esters preparationAcetic anhydride2-hydroxybenzaldehyde

The invention discloses a method for producing coumarin intermediate through microreactor in a pilot-plant-scale manner. The method comprises the following steps: preparing potassium acetate, acetic anhydride and acetic acid into homogenous solution, pumping salicylaldehyde into a microreaction device, and reacting to obtain the coumarin intermediate. Compared with the prior art, the method is simple in technology, can conduct continuous production, has higher operation safety and high selectivity, the reaction is small, the time is short, the catalyst can be repeatedly utilized, and the corrosion to equipment is small; in addition, by utilizing the high-efficiency heat mass transfer capability and easily direct amplification of the micro-channel reactor, the conversion rate is up to more than 99%, the coumarin intermediate is good in quality, low in energy consumption, and thus the method is a green, environment-friendly and high-efficiency method for synthesizing the courmarin intermediate.

Owner:NANJING UNIV OF TECH

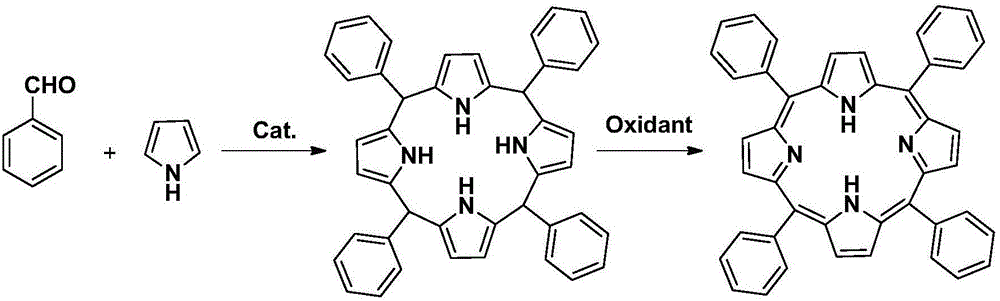

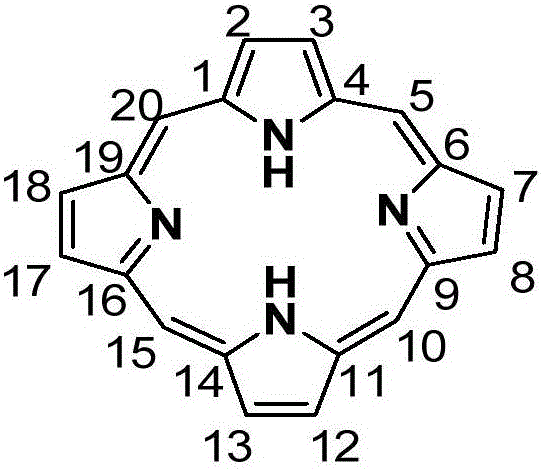

Method for preparing tetraphenylporphyrin through micro reaction device

The invention discloses a method for preparing tetraphenylporphyrin through a micro reaction device.The method includes the following steps that 1, benzaldehyde, pyrrole, absolute ethyl alcohol and anhydrous dichloromethane are mixed uniformly to obtain a homogeneous solution A, boron trifluoride diethyl etherate and anhydrous dichloromethane are mixed to obtain a homogeneous solution B; 2, the homogeneous solutions are simultaneously pumped into the micro reaction device; 3, effluent liquid is collected to serve as a crude porphyrinogen product; 4, an oxidizing agent is added into the effluent liquid obtained in the step 3 and stirred to react in nitrogen atmosphere to obtain tetraphenylporphyrin.The method is simple in technology, allows continuous production, short in reaction time, higher in reaction selectivity than conventional reactions and high in operation safety.Meanwhile, the conversion rate is obviously increased to be 50% means of the efficient heat mass transfer capacity and the characteristic of easy direction amplification of the microchannel reactor compared with conventional conditions, and selectivity different from that of conventional reactions can be embodied.

Owner:NANJING UNIV OF TECH

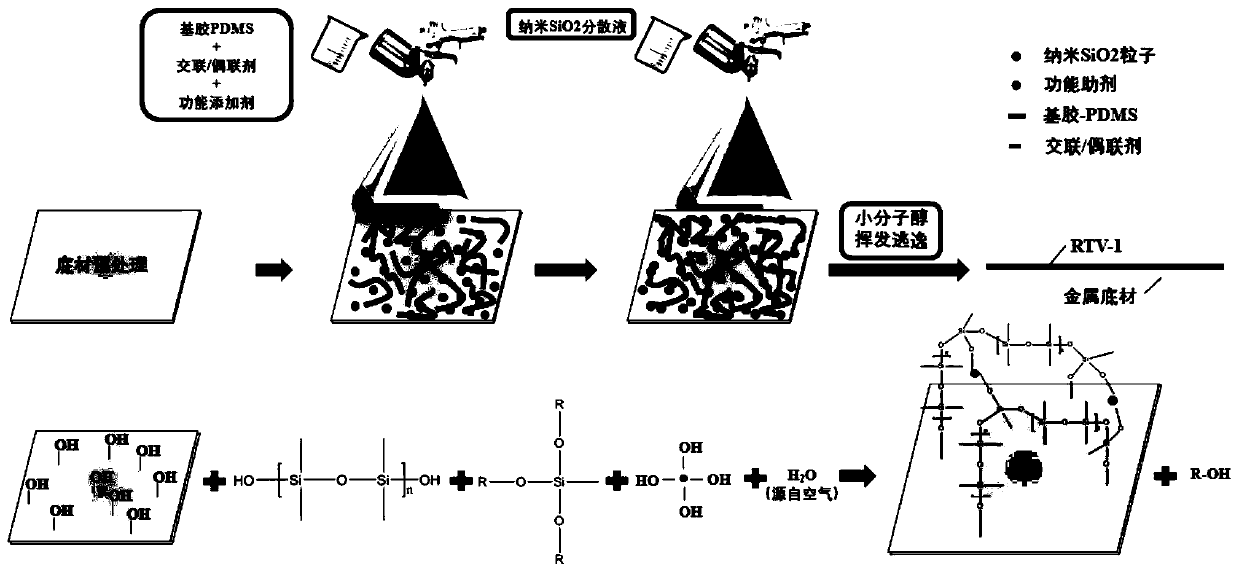

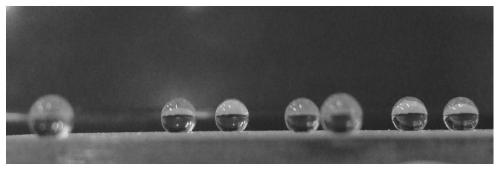

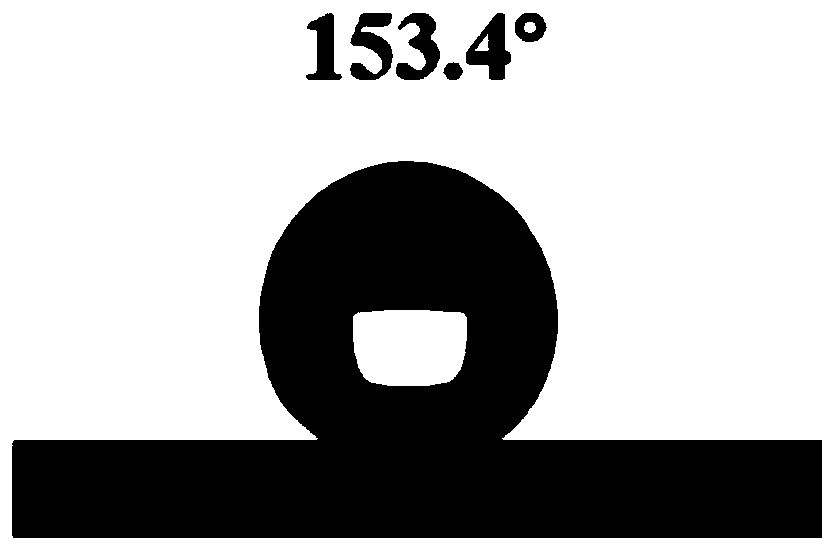

Preparing method of super-hydrophobic coatings of condensing and heat exchange pipe and condensing heat exchange pipe

PendingCN111068997AImprove adhesionExpand industrial applicationsPretreated surfacesCoatingsMicro nanoPtru catalyst

The invention discloses a preparing method of super-hydrophobic coatings of a condensing heat exchange pipe. The method includes the steps of preprocessing the metal surface of the heat exchange pipe,processing the surface of the heat exchange pipe through a first coating material to form the first coating, and forming the second coating on the surface of the first coating through a second coating material, wherein the first coating material is prepared by dispersing a base material in a dispersing medium, the base material comprises, by weight, 100 parts of an organic silicon rubber base, 10-50 parts of a crosslinking agent or coupling agent, 5-30 parts of nano-silica particles, 0.1-0.5 part of a catalyst and 2-10 parts of a performance additive, and the second coating material is nano-silica particle water dispersion liquid with the solid content of 1-20%. By means of the method, the super-hydrophobic performance is realized on the surface of the metal heat exchange pipe, meanwhilethe stability of the micro-nanostructure constructed by the nano-silica particles or other functional particles of the structure is ensured, the stable super-hydrophobic phenomenon is maintained on the surface of the heat exchange pipe, and the heat matter transferring efficiency in the vapor condensing process is improved.

Owner:江苏中圣压力容器装备制造有限公司

Device for heat and mass transfer and reaction of high-viscosity materials

PendingCN110860262AShort stayReduce cokingEvaporator accessoriesChemical/physical/physico-chemical processesMagnetic tension forceHeat mass transfer

The invention discloses a device for heat and mass transfer and a reaction of high-viscosity materials, belonging to the field of material heat exchange equipment and reactors. The mass transfer device for the high-viscosity materials comprises magnetic force generators which can generate a magnetic force field for heating, a jacket shell which is used for containing materials and installing the magnetic force generators, a dispersing assembly which is used for transferring the materials, and a hollow shaft which is used for driving the dispersing assembly to rotate, wherein the magnetic forcegenerators are located inside or outside the shell, and the magnetic force generators are oppositely installed in an up-down direction or a left-right direction. The device of the invention has the beneficial effects of high heating power, high heat transfer efficiency, shortened material retention time, uniform heating, safe operation performance and great reduction in material coking.

Owner:FUZHOU UNIV

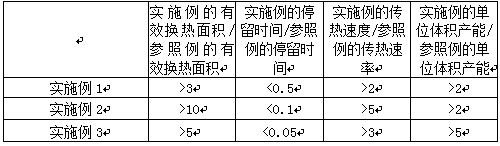

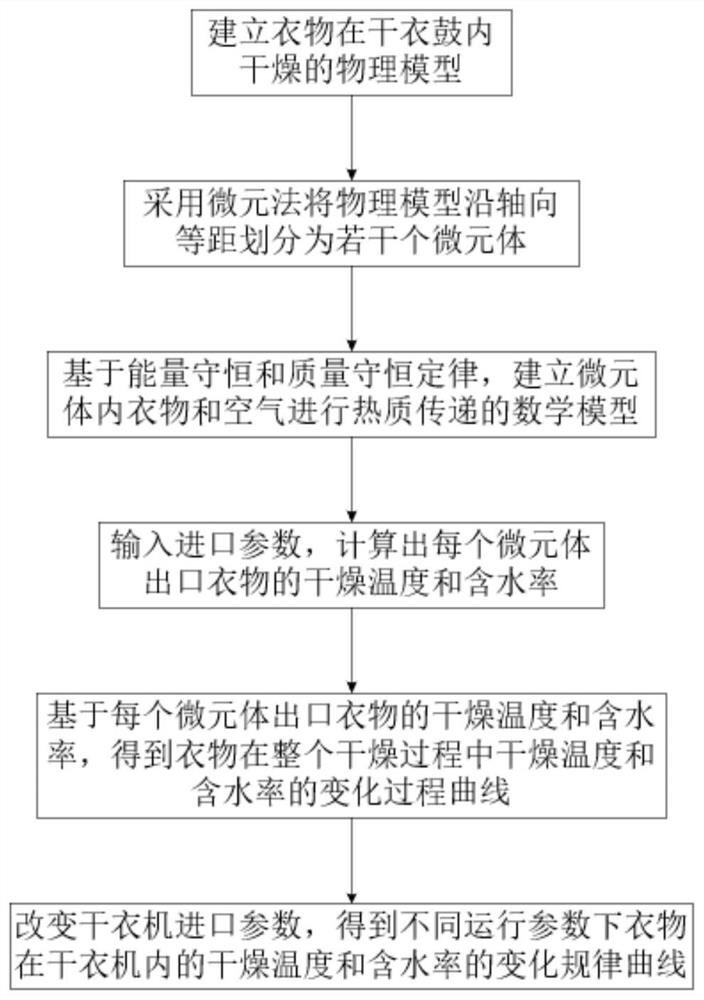

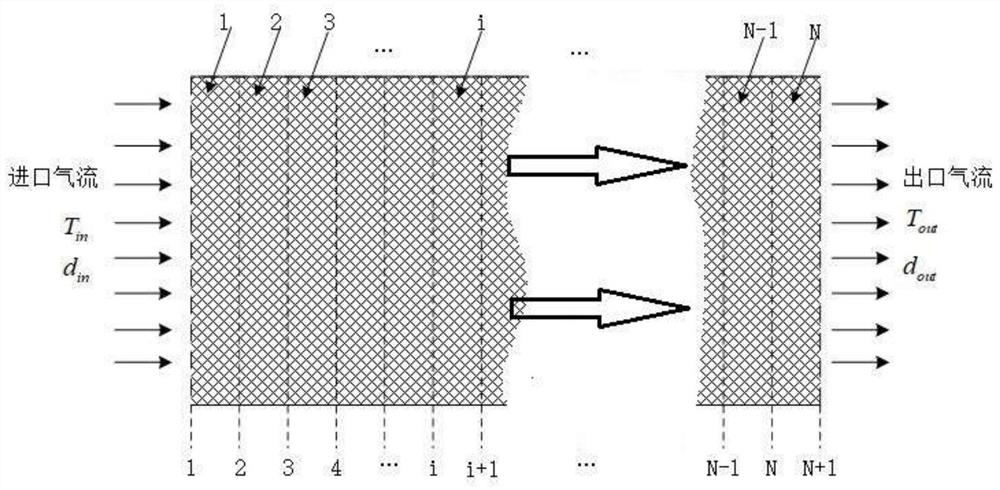

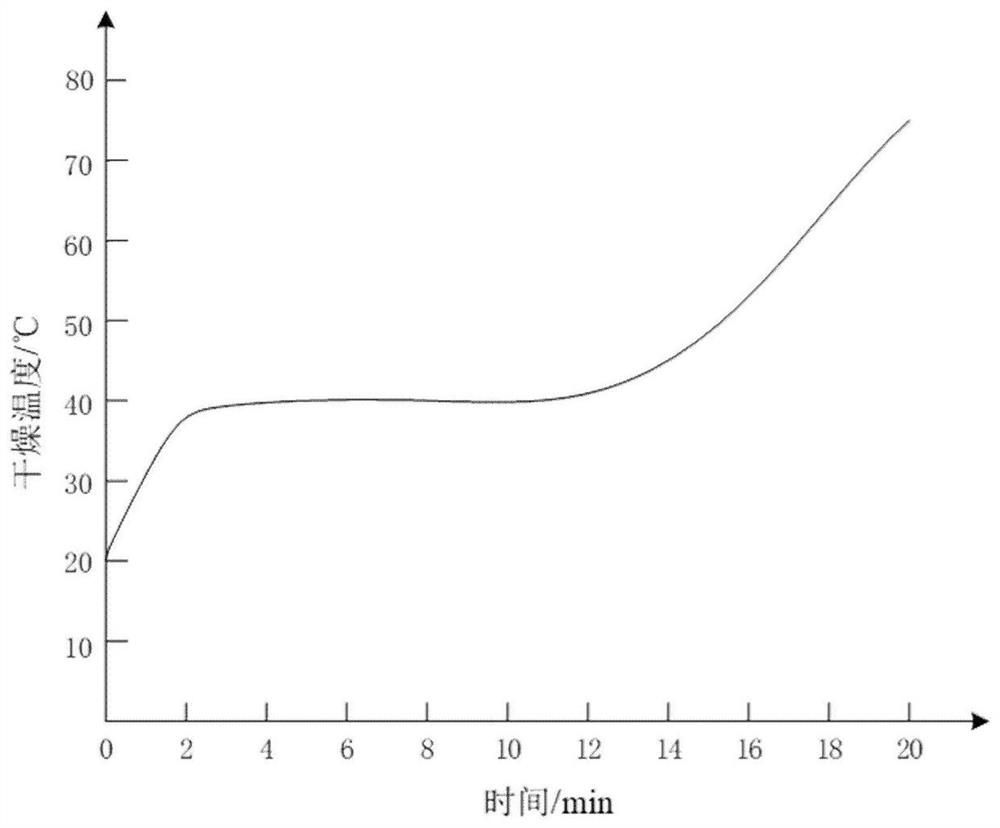

Numerical simulation method for predicting heat and mass transfer rule of clothes in clothes dryer

PendingCN113609660AGuaranteed drying qualityWill not be affected by drying parametersDesign optimisation/simulationSpecial data processing applicationsThermodynamicsHeat mass transfer

The invention discloses a numerical simulation method for predicting a heat and mass transfer rule of clothes in a clothes dryer. The method comprises the following steps: constructing a physical model of the clothes and the clothes dryer by adopting three-dimensional modeling software; uniformly dividing the physical model into a plurality of equidistant infinitesimal bodies along the axial direction; establishing a mathematical model of heat and mass transfer of the clothes and air in the clothes dryer for each infinitesimal body; based on the law of conservation of mass and the law of conservation of energy, establishing an equation set of heat and mass transfer of clothes in the infinitesimal body; inputting inlet parameters of the clothes dryer, and calculating the drying temperature and the moisture content of the clothes at the outlet of each infinitesimal body; and on the basis of the drying temperature and the moisture content of the clothes at the outlet of each infinitesimal body, obtaining a change curve of the drying temperature and the moisture content of the clothes in the whole drying process in the clothes dryer. Therefore, the operation condition can be changed, a change rule curve of the drying temperature and the moisture content of the clothes in the clothes dryer under different operation parameters is obtained, the method can be used for predicting the drying quality of the clothes, and proper operation parameters are provided for operation of the clothes dryer.

Owner:JIANGSU UNIV OF SCI & TECH

On-line monitoring and evaluation method of heat exchange efficiency for water cooling system of diverter valve

ActiveCN104239724BSafe and stable operationSpecial data processing applicationsHeat mass transferEngineering

Owner:STATE GRID CORP OF CHINA +1

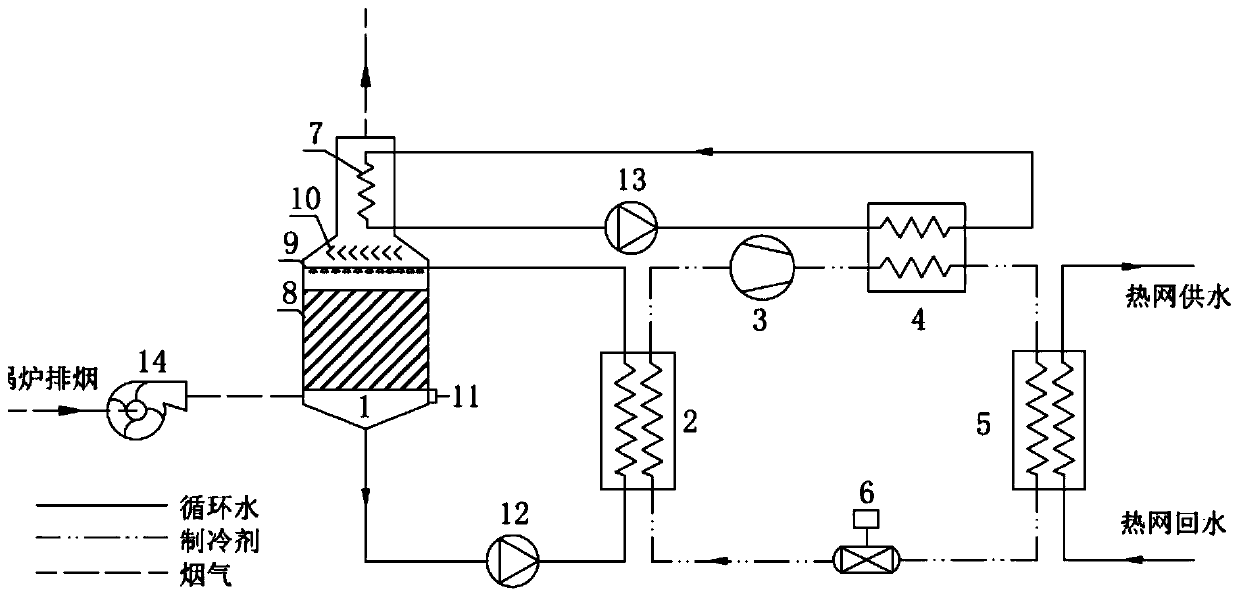

Smoke gas waste heat full heat recycling and upgrading heat source tower heat pump

InactiveCN111023134ANo regeneration problemsLarge transfer areaMechanical apparatusHeat pumpsWater vaporSmoke plume

The invention discloses a smoke gas waste heat full heat recycling and upgrading heat source tower heat pump. The smoke gas waste heat full heat recycling and upgrading heat source tower heat pump comprises a smoke gas loop, a circulating water loop and a refrigerant loop. The giant temperature difference between low-temperature circulating water and exhaust smoke gas and water steam partial pressure difference are used for achieving capturing of a large amount of sensible heat and latent heat contained in smoke gas, through refrigerant steam compression circulation, upgrading of captured low-level waste heat can be achieved, and the heat is directly supplied to a heat network. Low-temperature circulating water is used for replacing a solution to serve as heat source tower circular workingmedia, the regeneration problem after solution humidity absorbing can be thoroughly solved, and a system is more simple and efficient. A direct contact type heat source tower is adopted as a low-temperature circulating water and smoke gas heat exchange device, the heat transfer and mass transfer coefficient is high, the heat mass transfer area is large, the heat mass transfer potential differenceis large, the main heat transfer and mass transfer capacity is high, the corrosion problem of a dividing wall type heat exchanger in the wall heat use can be thoroughly solved, heat of a compressor exhaust overheat segment is used for reheating smoke gas after total heat recycling, the phenomenon that final exhaust smoke is in the saturation state can be avoided, and the wet smoke plume phenomenon can be avoided.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com