Patents

Literature

137results about How to "Stable vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

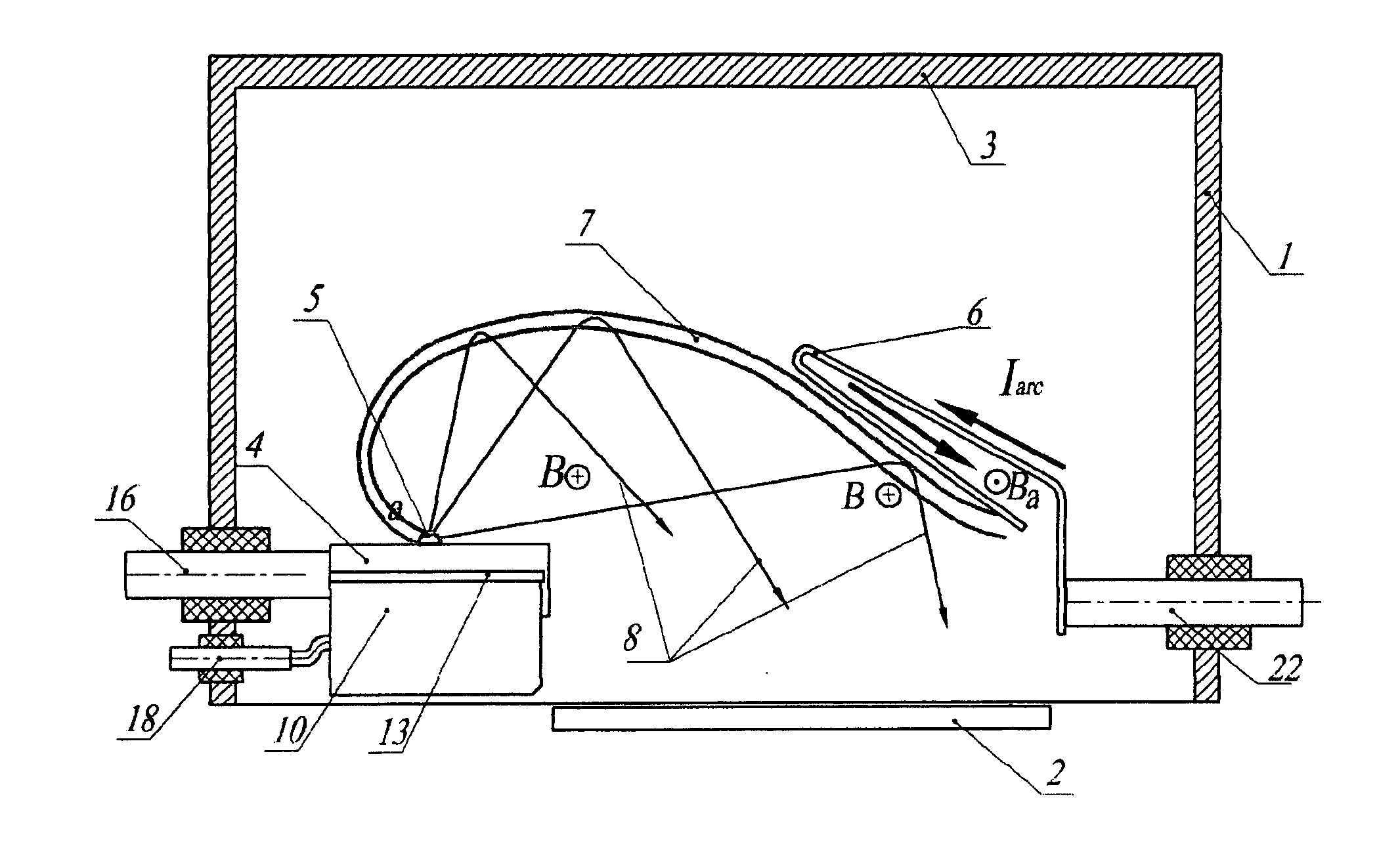

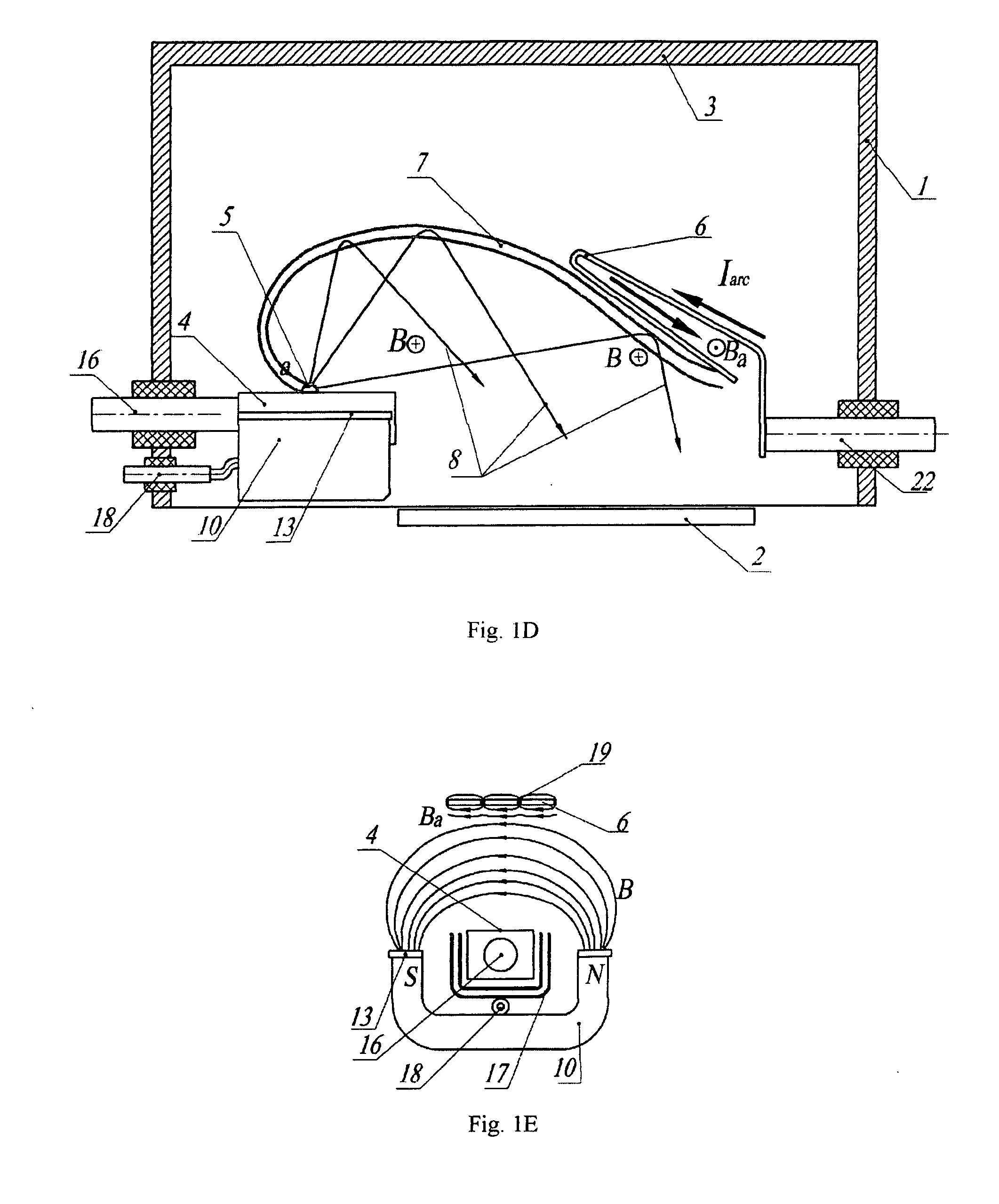

Cathode-arc source of metal/carbon plasma with filtration

InactiveUS20070034501A1Improve transportation efficiencyIncrease the number ofCellsElectric discharge tubesStationary conditionsCurrent sheet

The a cathode-arc source of metal plasma with filtration, used, in particular, for deposition of DLC, utilizes the effect of fast ions reflection from the Hall stratum in a transversal arched magnetic field to filtrate vacuum arc plasma arc from contaminating macroparticles and vapor. Various embodiments for producing maximal plasma flux at the source outlet, in particular, a pulse source with more the one cathode units for deposition of coating inside pipes / cavities, for deposition of coating in a stationary / quasi-stationary condition are offered. The cathode is made of a consumable material and is exposed to poles of magnets on both ends of cathode for creating a transversal magnetic field of an arched configuration in a discharge gap between the cathode and the anode. The anode geometry adequate to the mechanism of the arc current passage through a transversal magnetic field is offered. To avoid longitudinal and transverse short circuits of the current layer, an installation of non-conducting surfaces at ends or sectioned shields under a floating potential at the cathode sides is provided. The method of creating the Hall stratum in said transversal magnetic field of arched configuration is offered.

Owner:BENDER EFIM

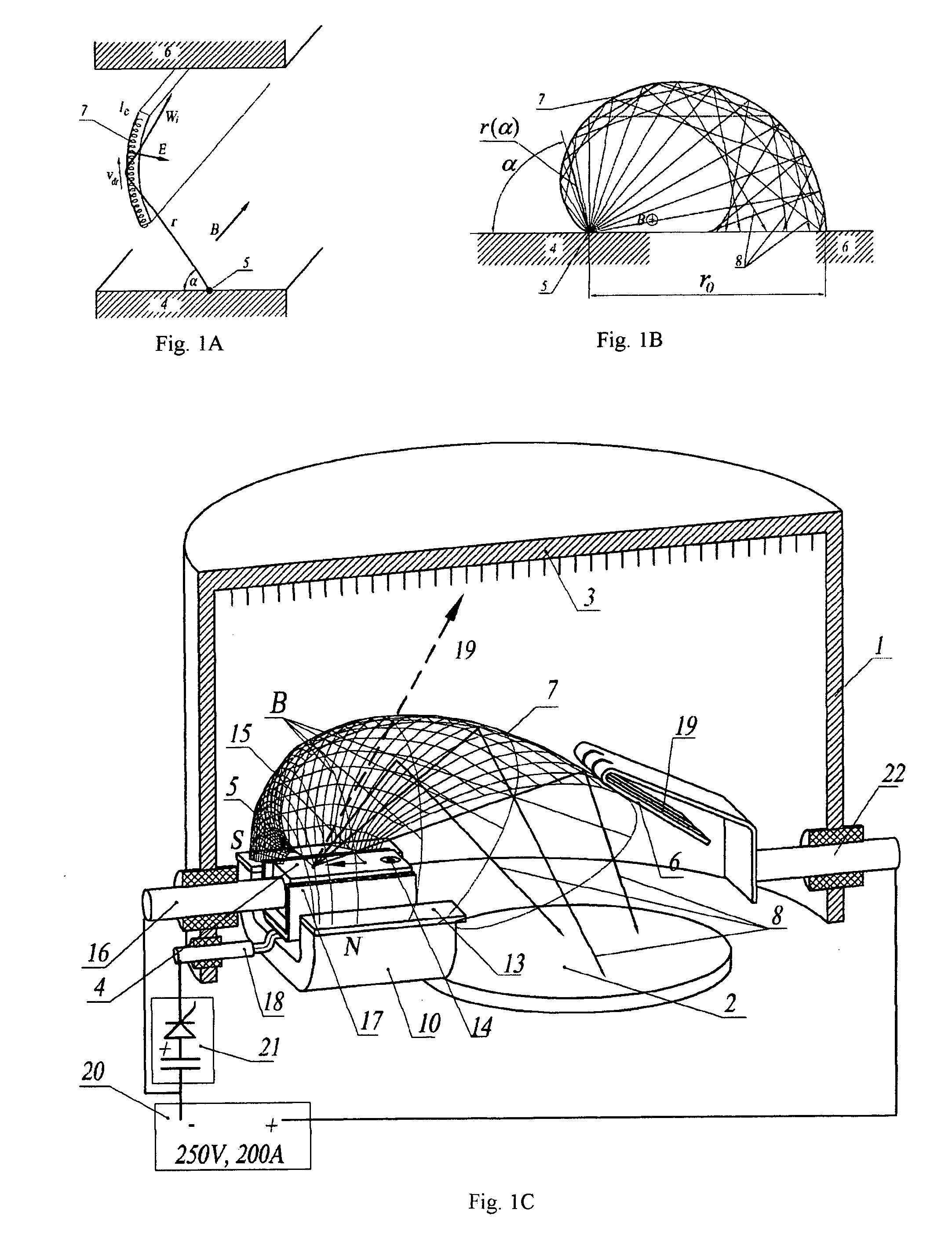

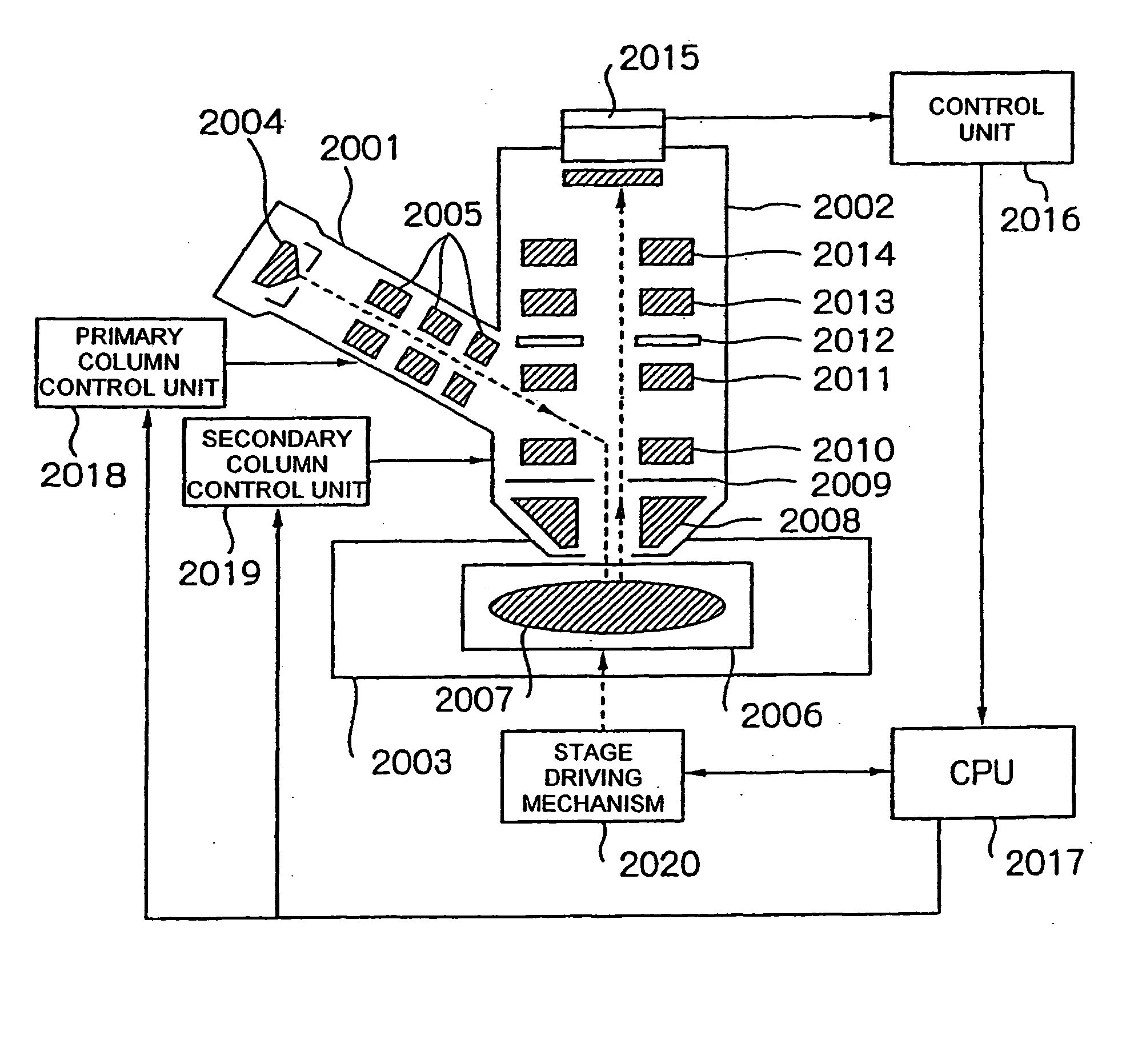

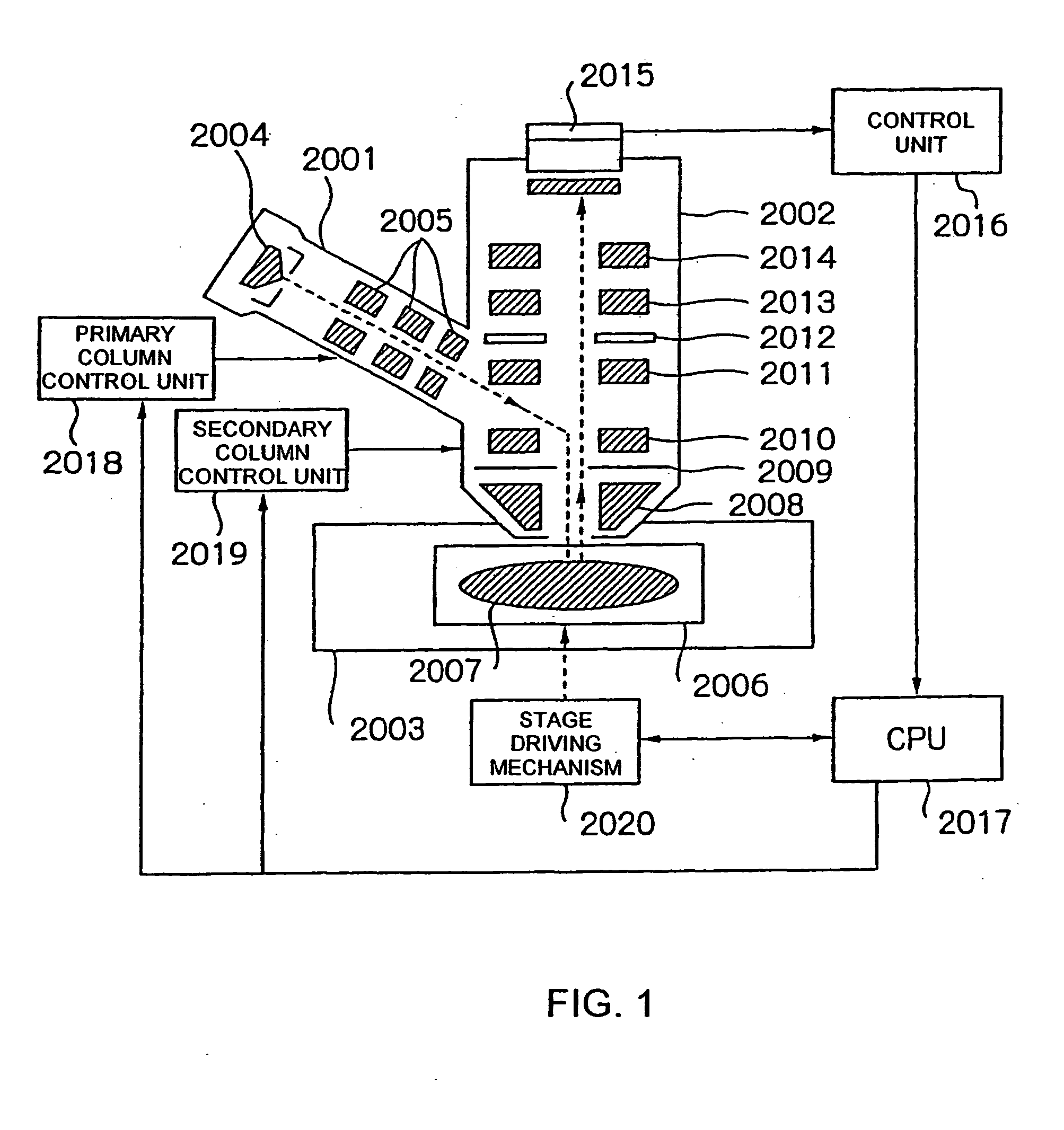

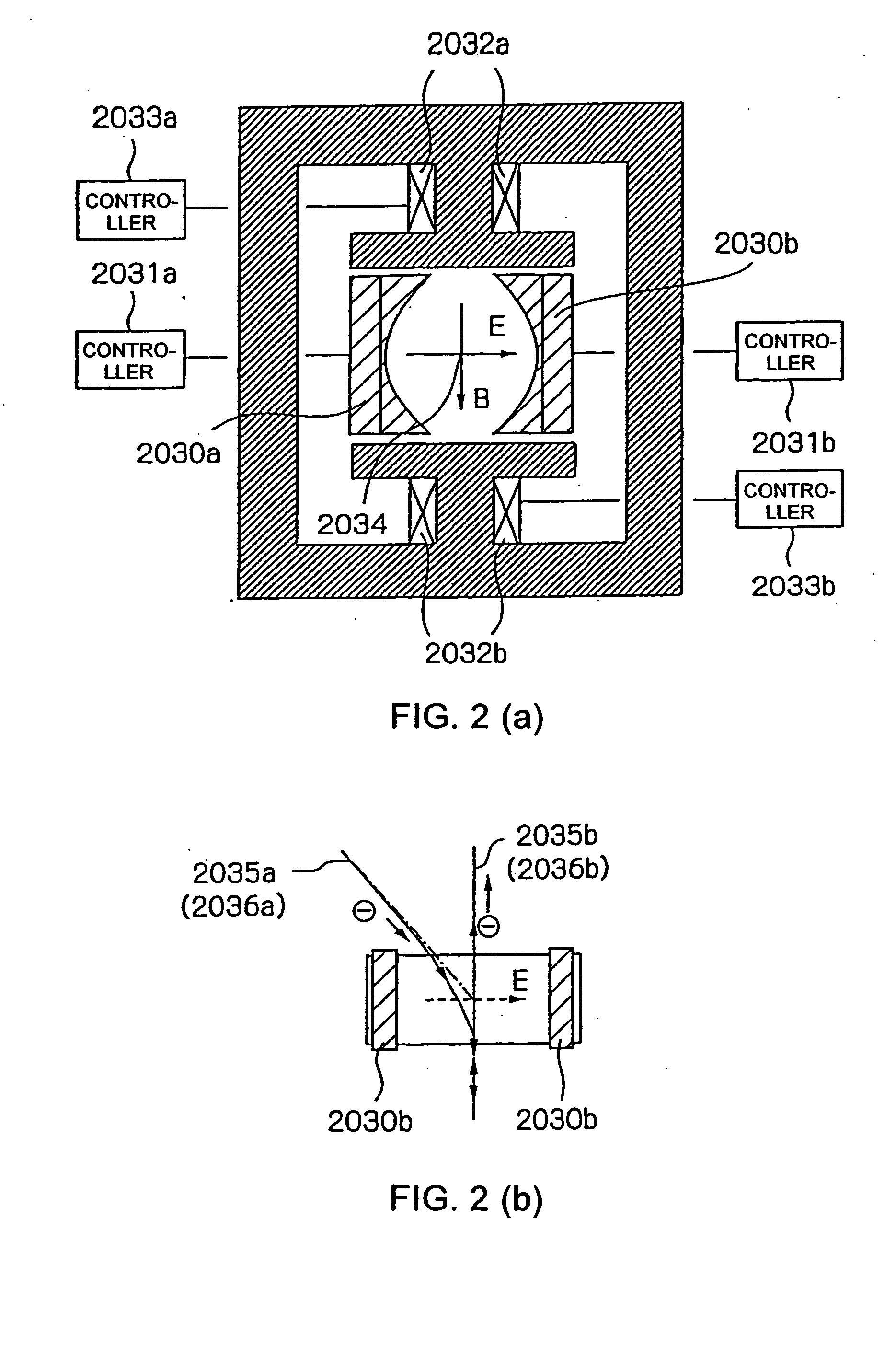

Sheet beam-type inspection apparatus

InactiveUS20050092921A1Minimize impactStable processingMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingBeam source

An electron beam apparatus such as a sheet beam based testing apparatus has an electron-optical system for irradiating an object under testing with a primary electron beam from an electron beam source, and projecting an image of a secondary electron beam emitted by the irradiation of the primary electron beam, and a detector for detecting the secondary electron beam image projected by the electron-optical system. Specifically, the electron beam apparatus comprises beam generating means 2004 for irradiating an electron beam having a particular width, a primary electron-optical system 2001 for leading the beam to reach the surface of a substrate 2006 under testing, a secondary electron-optical system 2002 for trapping secondary electrons generated from the substrate 2006 and introducing them into an image processing system 2015, a stage 2003 for transportably holding the substrate 2006 with a continuous degree of freedom equal to at least one, a testing chamber for the substrate 2006, a substrate transport mechanism for transporting the substrate 2006 into and out of the testing chamber, an image processing analyzer 2015 for detecting defects on the substrate 2006, a vibration isolating mechanism for the testing chamber, a vacuum system for holding the testing chamber at a vacuum, and a control system 2017 for displaying or storing positions of defects on the substrate 2006.

Owner:EBARA CORP

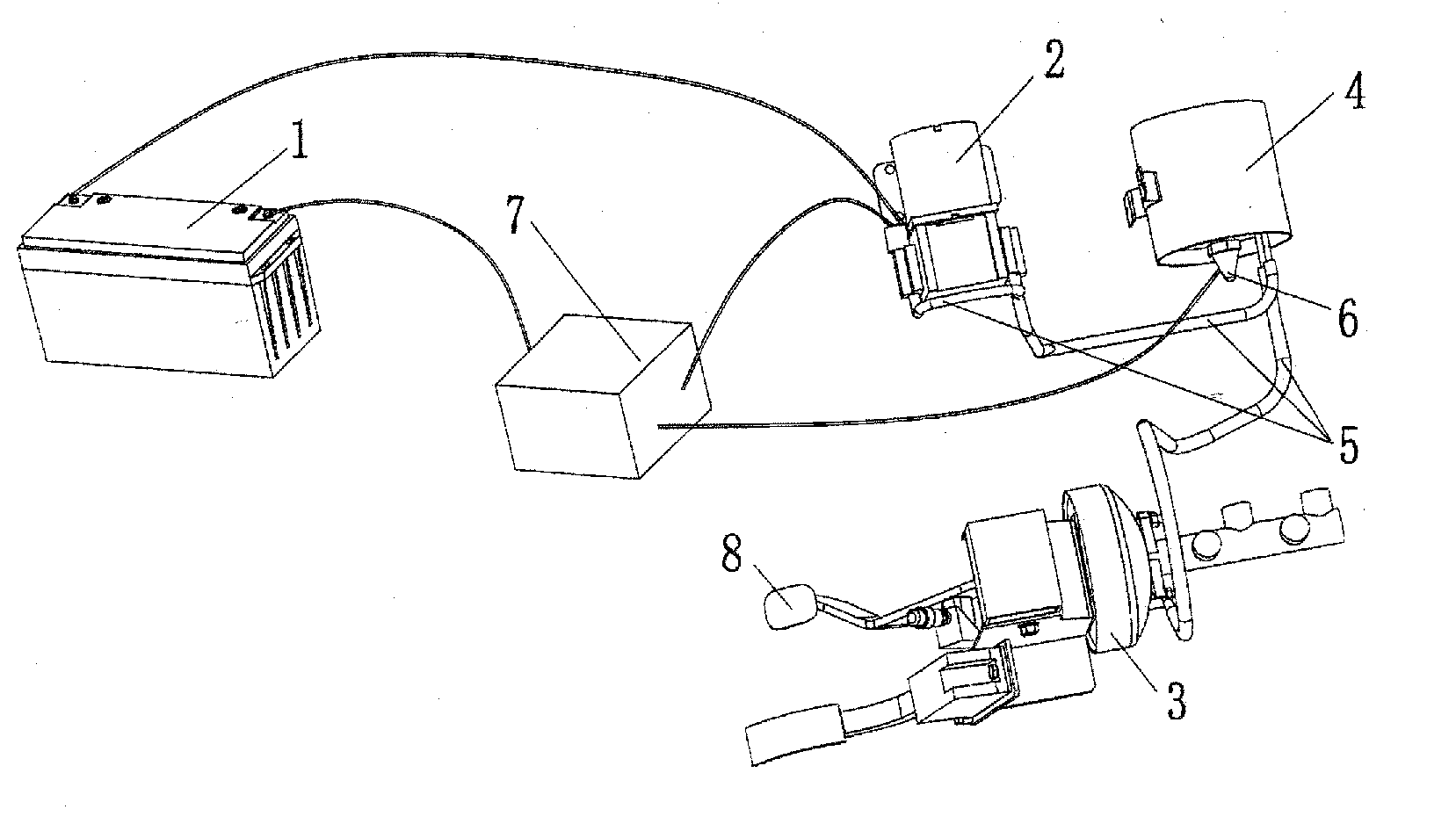

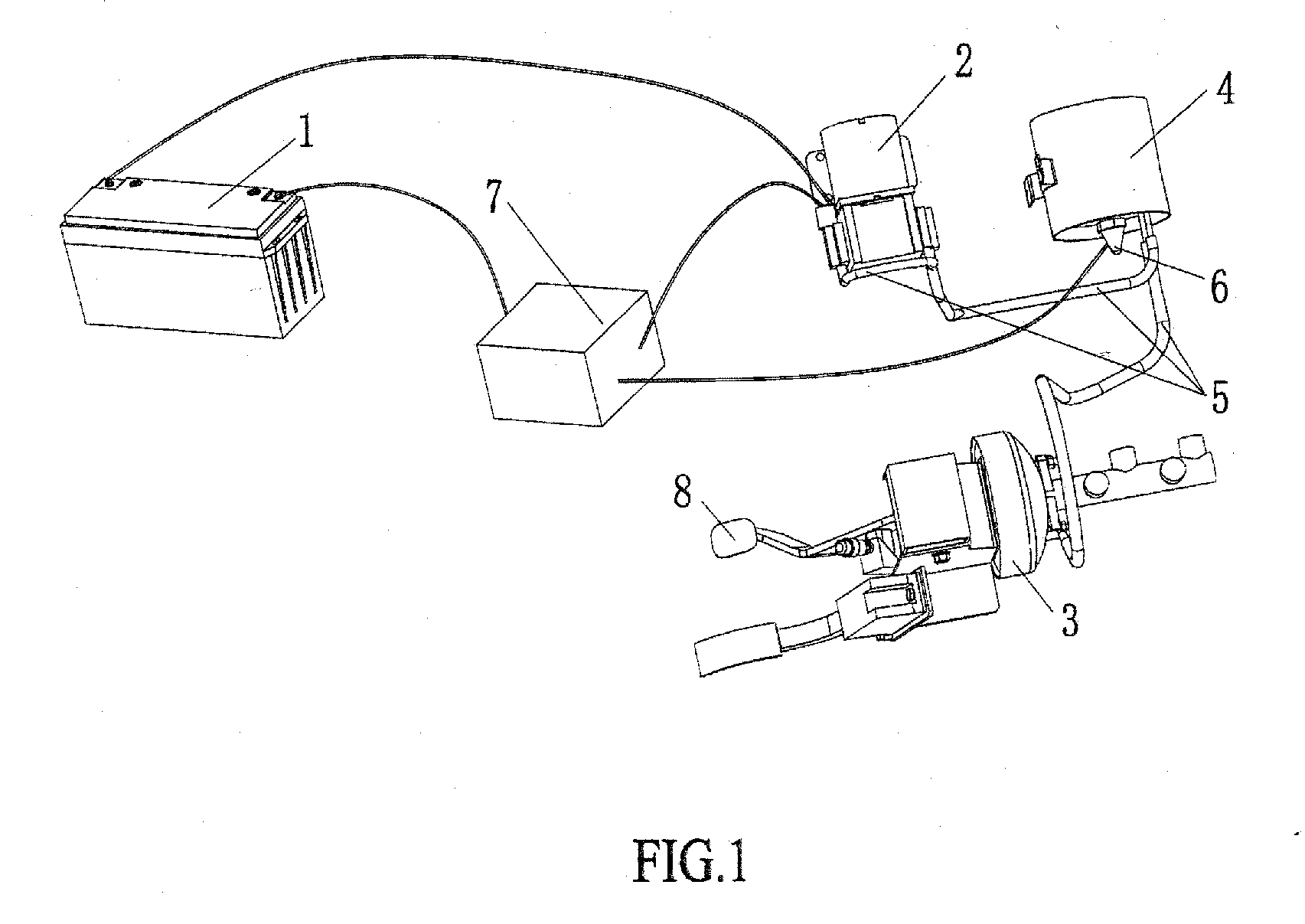

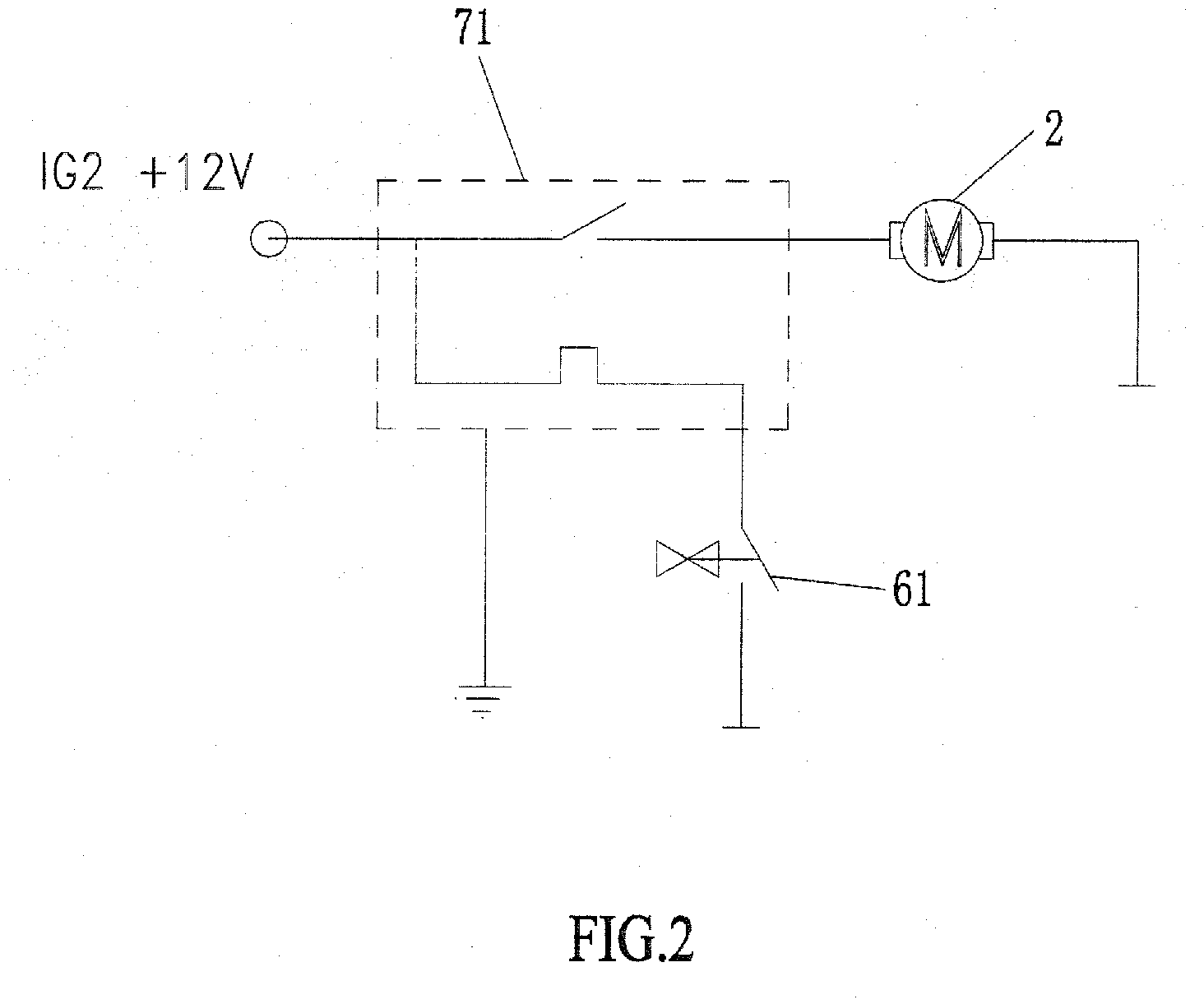

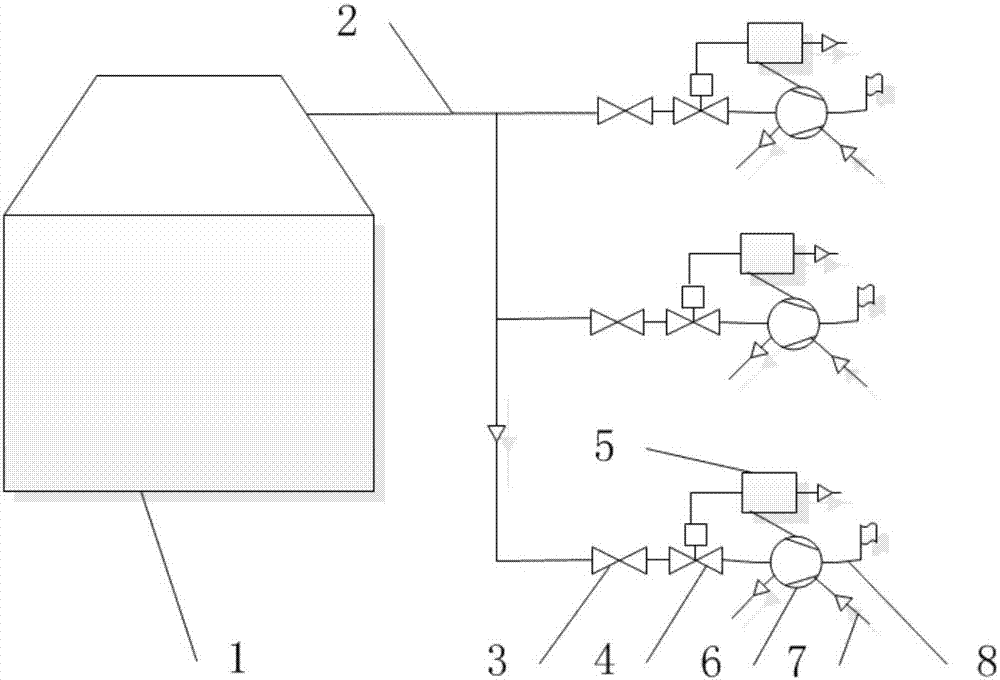

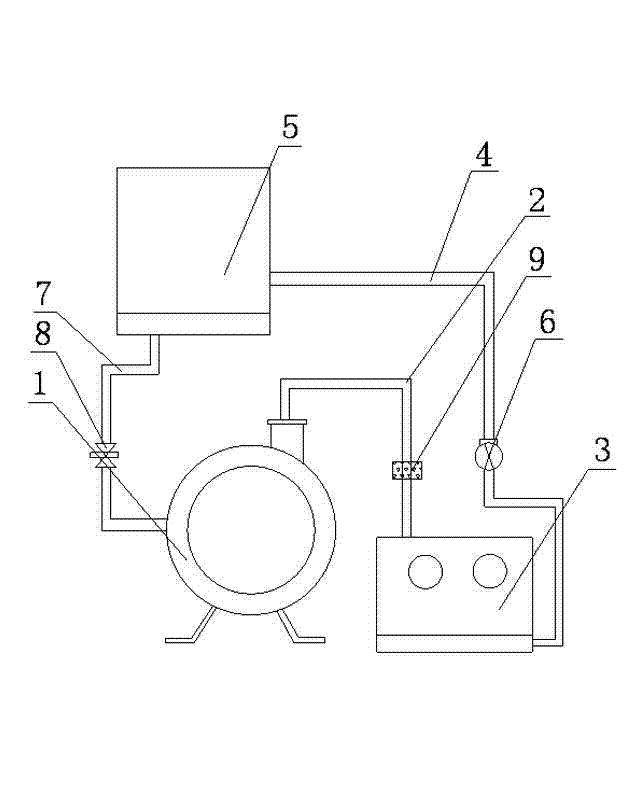

Brake auxiliary system of electric car

InactiveUS20110089754A1Extend brake lifeLow failure rateBraking action transmissionPump/compressor arrangementsElectric carsEngineering

The invention discloses a brake auxiliary system having a vacuum container, which comprises an auxiliary power supply, a vacuum pump, a vacuum booster and a vacuum container, wherein the vacuum container and the vacuum booster are both connected with the vacuum pump which supplied power by the auxiliary power supply, a pressure detector and a delay control switch are disposed on the vacuum container, keeping the vacuum degree in the vacuum container within a certain range. The vacuum container of the present invention makes the vacuum pump enable to work intermittently, avoiding frequent start of the vacuum pump when brake and also extending the life of the brake. Because of the pressure detector and the delay control switch, the vacuum inside the vacuum container is kept stable, and the efficiency of vacuum booster is ensured. The invention has low cost, simple and reliable structure, it is green and energy-saving, and it can reduce the energy consumption of the electric car auxiliary power supply and increase the driving miles.

Owner:FENG SEN +2

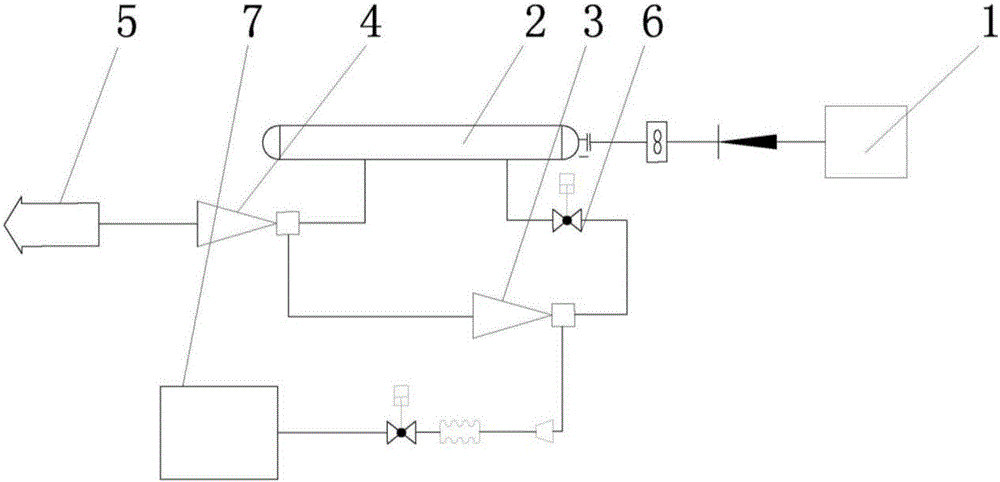

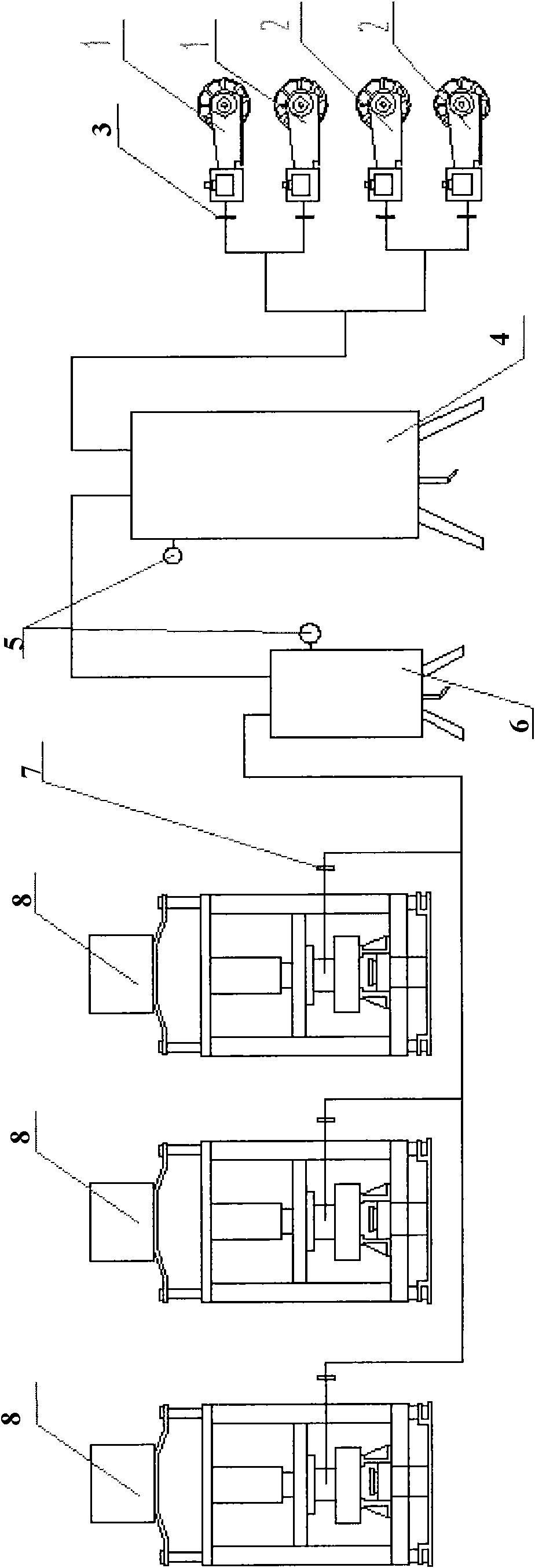

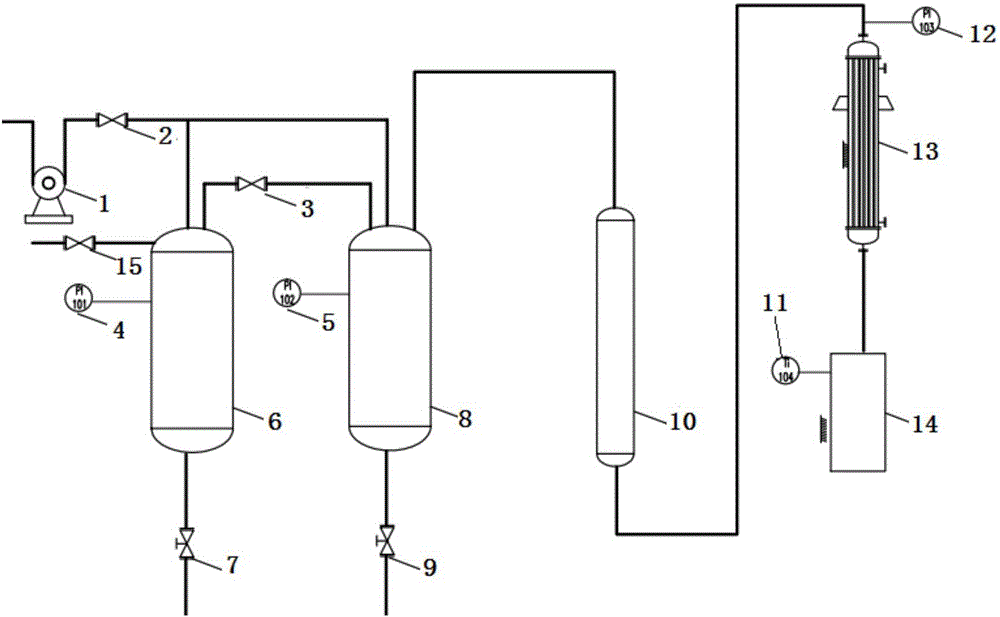

Vacuumizing system and method for vacuum cabin of ramjet engine

ActiveCN106368990AImprove test capabilitiesIncrease air flowGas-turbine engine testingJet pumpsRamjetWorking range

The invention belongs to the technical field of ramjet engine tests, and in particular relates to a vacuumizing system and a vacuumizing method for a vacuum cabin of a ramjet engine. The system comprises a vapor source, a vapor distributer, a first-stage ejection device, a second-stage ejection device, a muffling tower and a switch valve, wherein the first-stage ejection device and the second-stage ejection device are connected in series; a vapor inlet of the first-stage ejection device communicates with the vapor distributor through the switch valve; a vapor inlet of the second-stage ejection device communicates with the vapor distributor; a vapor outlet of the second-stage ejection device communicates with the external environment through the muffling tower; a vacuumizing inlet of the first-stage ejection device communicates with the vacuum cabin to be vacuumized; and the vapor distributor is connected with the vapor source. The system and the method, provided by the invention, have the advantages of large working range and high vacuumizing ability.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

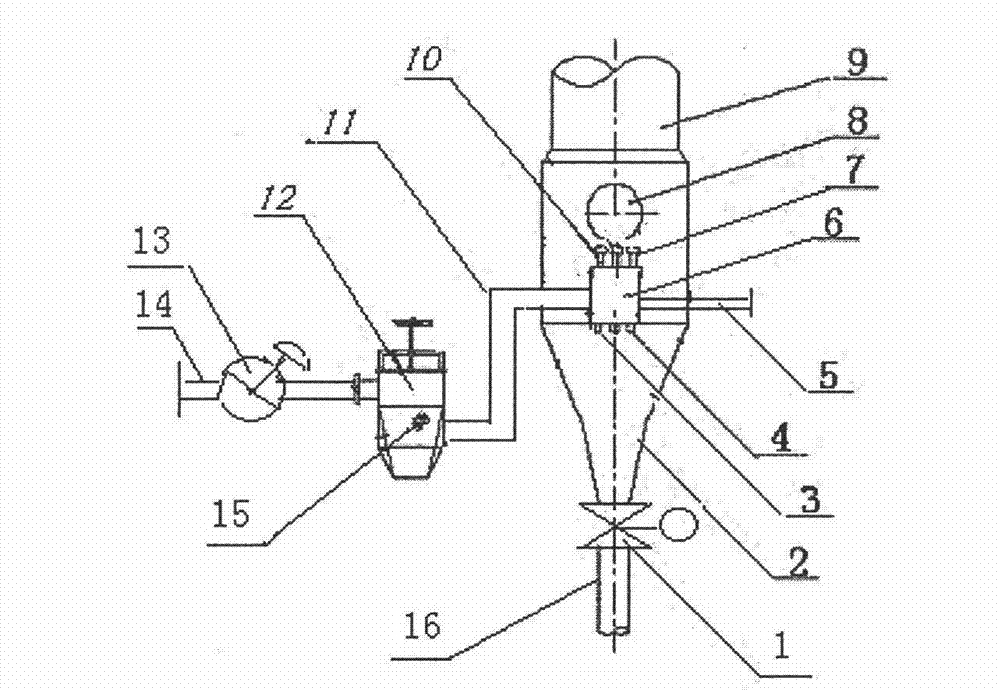

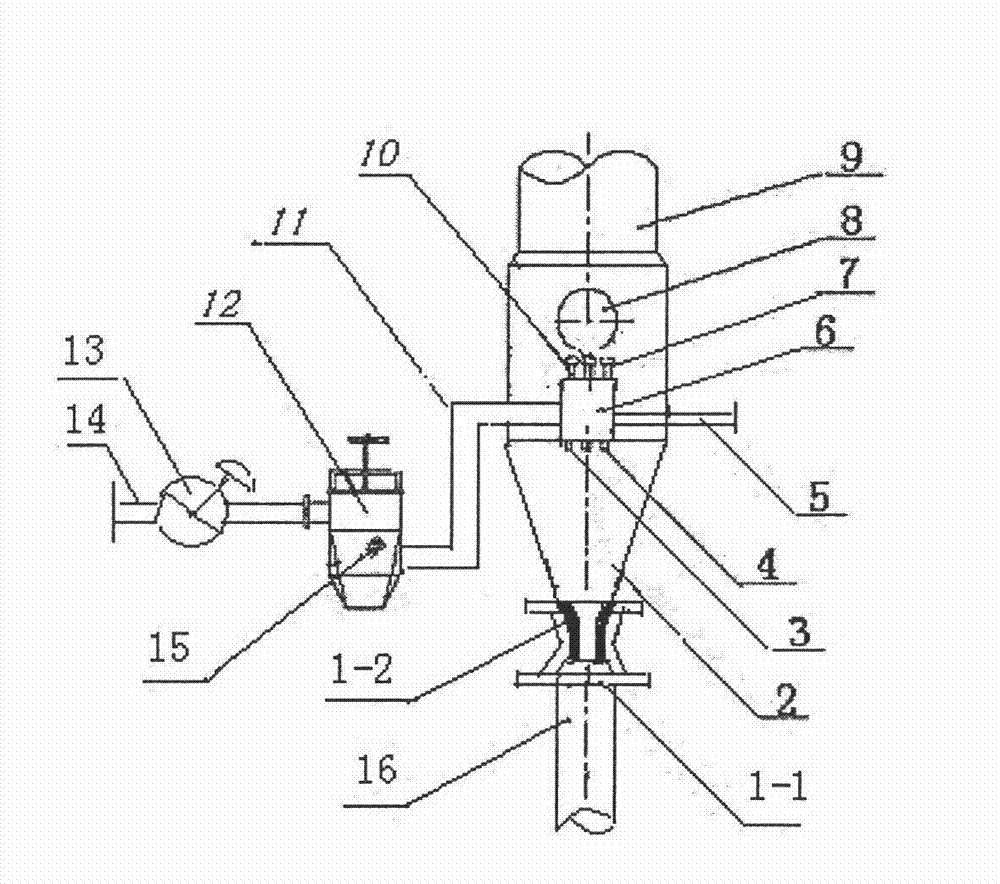

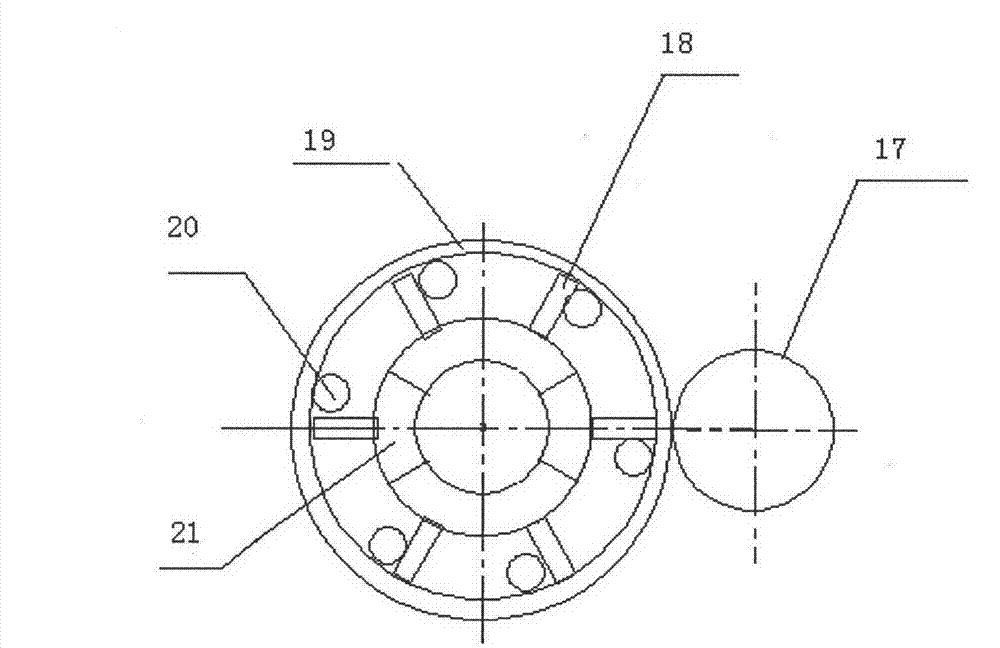

Full automatic control water jet condenser with characteristics of concentric diameter changing throat part, temperature control, constant water pressure and adjustable nozzles

InactiveCN103074453AGood effectStable high vacuumSugar juice boiling/evaporationAutomatic controlSpray nozzle

The present invention discloses a full automatic control water jet condenser with characteristics of a concentric diameter changing throat part, temperature control, constant water pressure and adjustable nozzles, wherein the full automatic control water jet condenser is used in sugar refineries. The full automatic control water jet condenser is characterized in that part of spray nozzles and jet nozzles arranged in a water chamber are nozzles provided with a pneumatic opening and closing control device, a throat part of the condenser is provided with a concentric diameter changing throat part device, and the pneumatic opening and closing controlled nozzles and the concentric diameter changing throat part device can jointly act and perform adjustment control according to a water temperature and a water supply amount of water entering the condenser water chamber. According to the present invention, a pressure transmitter for detecting a vacuum degree of a container (a sugar boiling tank or an evaporation tank), a temperature transmitter for detecting a temperature of a material (a syrup and a sugar paste) inside the container, and a pressure transmitter for detecting water pressure inside the water chamber jointly adjust and control an opening degree of an automatic control water inlet valve, such that the condenser can achieve a high vacuum degree under a normal production condition, and can achieve a preset vacuum degree and a preset material temperature during production condition changing, wherein the existing wet type water jet condensers used in sugar refineries at home and abroad do not have the advantages of the condenser of the present invention.

Owner:NANNING MAST SUGAR MACHINE EQUIP MFG CO LTD

Gypsum type rapid precision casting method for nonferrous metal

The invention relates to a gypsum type rapid precision casting method for nonferrous metal. The gypsum type rapid precision casting method is characterized by including the steps that a rapid prototype part of a to-be-cast part, a runner rapid prototype part, a riser rapid prototype part and an air channel rapid prototype part are manufactured through a 3D printer and placed in prepared gypsum slurry, and air pipe joint inserts are sleeved with the air channel rapid prototype part; a dried gypsum mold is heated, the rapid prototype part of the part, the runner rapid prototype part, the riser rapid prototype part and the air channel rapid prototype part are burnt out, and then a part cavity, a runner, an air channel and a riser are formed in a gypsum casting mold; the gypsum casting mold is placed in a casting box, the periphery of the gypsum casting mold is filled with dry sand, and a sprue cup is placed in an opening in the upper end of the runner; the gypsum casting mold is fixed through a pressing beam and a rubber pressing block for vibration and compaction, and then the part cavity, the runner, the air channel and the riser are vacuumized; and nonferrous metal casting liquid is poured which vibration is carried out, vibration is stopped after pouring is finished, the gypsum casting mold is taken out, and a needed casting is obtained. The casting quality of the nonferrous metal part can be improved, and the beneficial effects of being easy and convenient to operate and the like are achieved.

Owner:苏州森斯杰网络科技有限公司

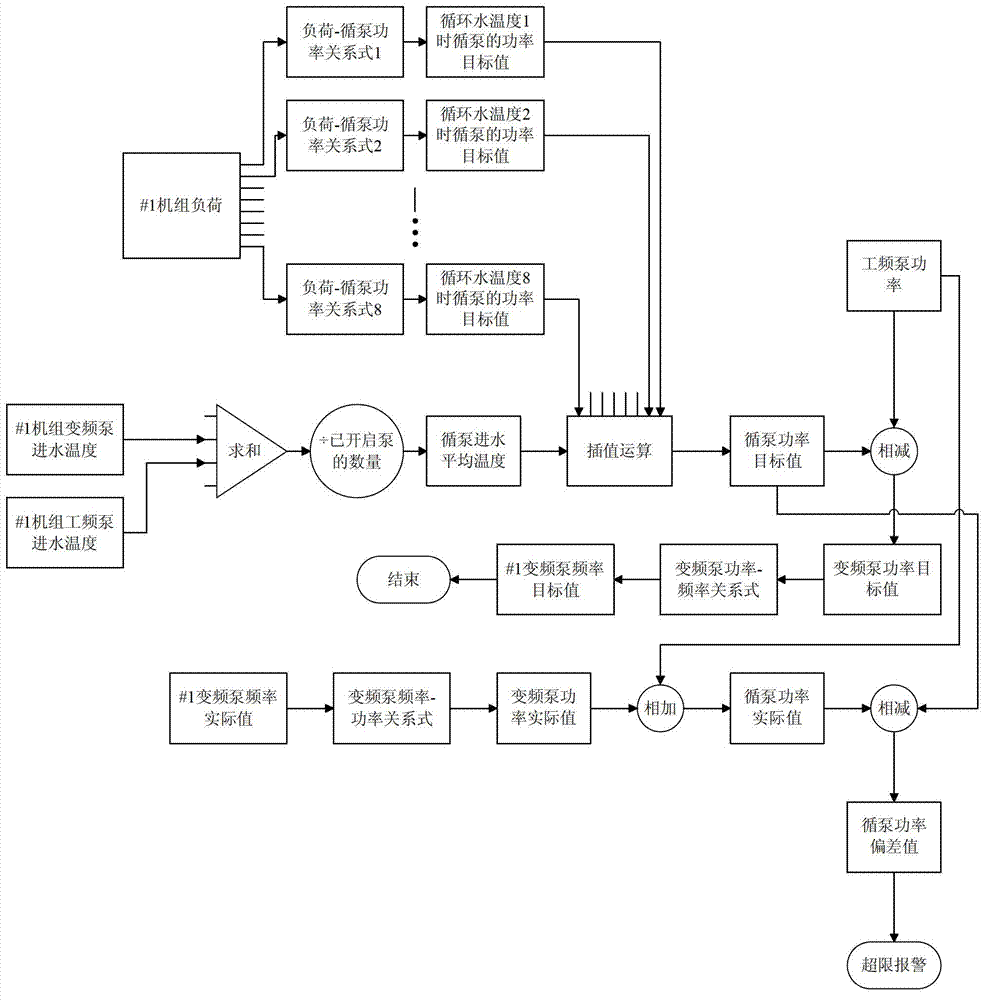

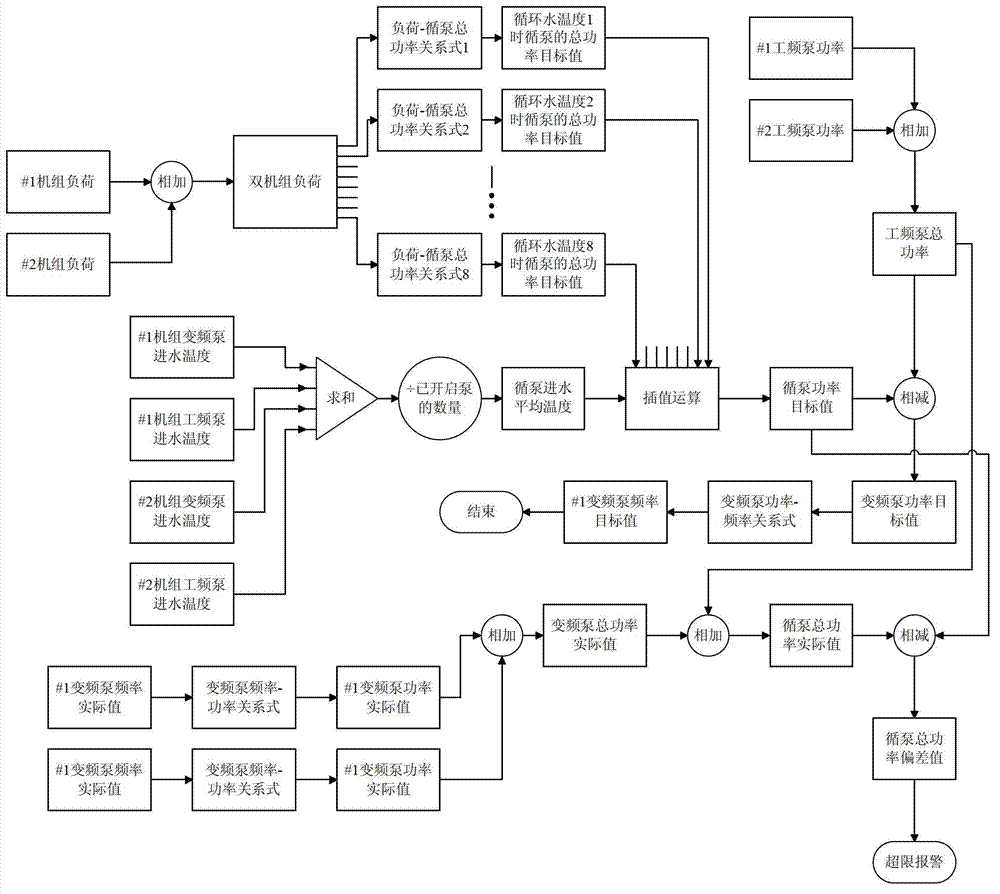

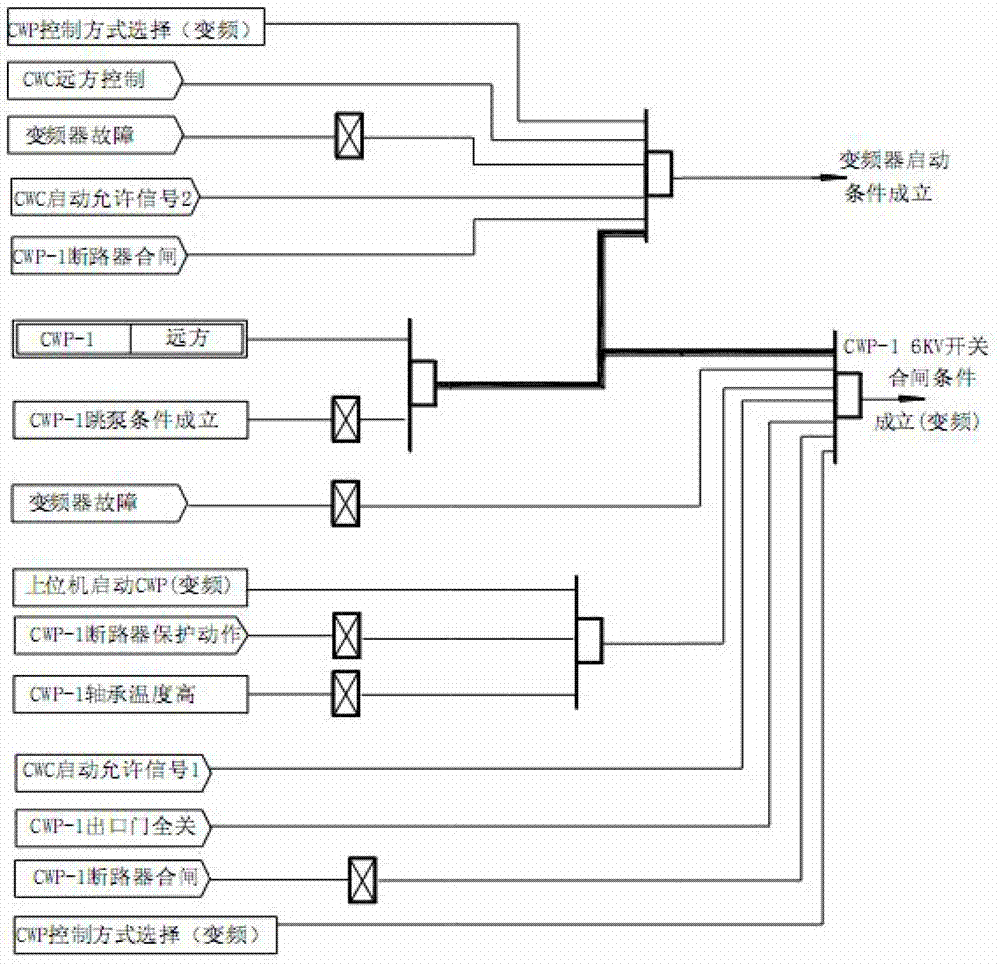

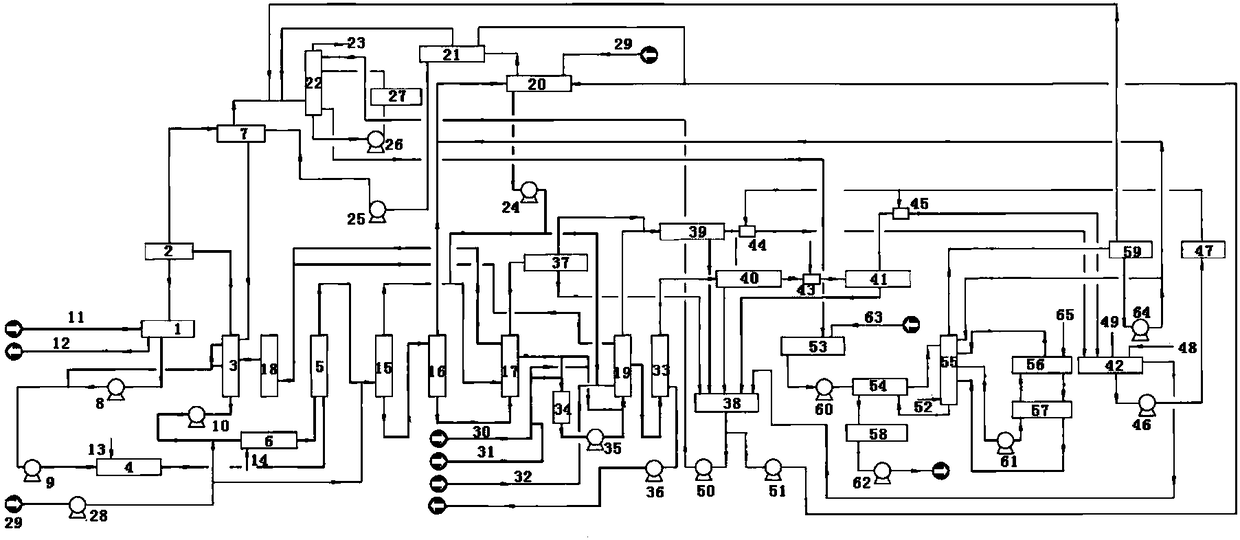

Frequency conversion control method of circulating water pumps of two steam turbine generator sets

InactiveCN103195522ARealize frequency conversion automatic controlStable vacuumEnergy industrySteam engine plantsAutomatic controlFrequency conversion

The invention provides a frequency conversion control method of circulating water pumps of two steam turbine generator sets. The frequency conversion control method includes that variable frequency pumps are introduced into the frequency conversion control method, and an original mode of 'two steam turbine generator sets with four power frequency pumps' is changed into a mode of 'two steam turbine generator sets with two variable frequency pumps and two power frequency pumps'; and the power frequency pumps are automatically started or closed and the frequencies of the variable frequency pumps are regulated according to load demands of the steam turbine generator sets, so that vacuum degree of condensers of the steam turbine generator sets is stable, and automatic control of variable frequency of the steam turbine generator sets is realized. A variable frequency speed adjustment technology is a modern advanced speed adjustment technology which can not only provide stable and high efficient speed adjustment quality to meet usage requirements of users, but also save a large quantity of energy when the variable frequency speed adjustment technology is applied to loads, such as fans, pumps and the like which have square torque characteristics, and maximum energy-saving rate can reach 30%-70%.

Owner:上海吴泾第二发电有限责任公司

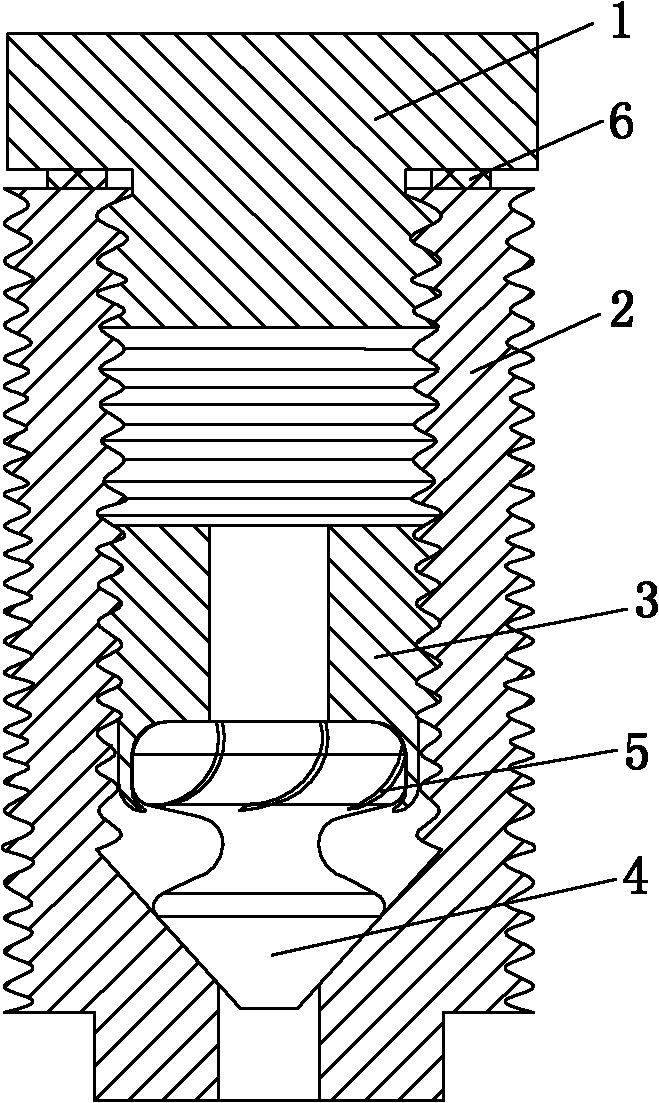

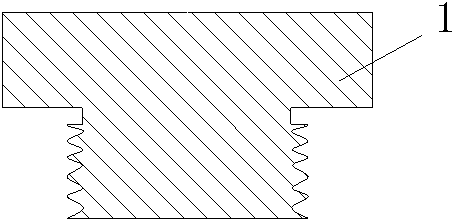

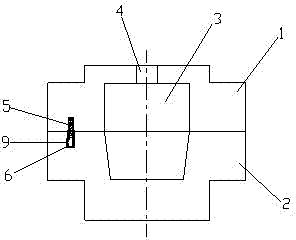

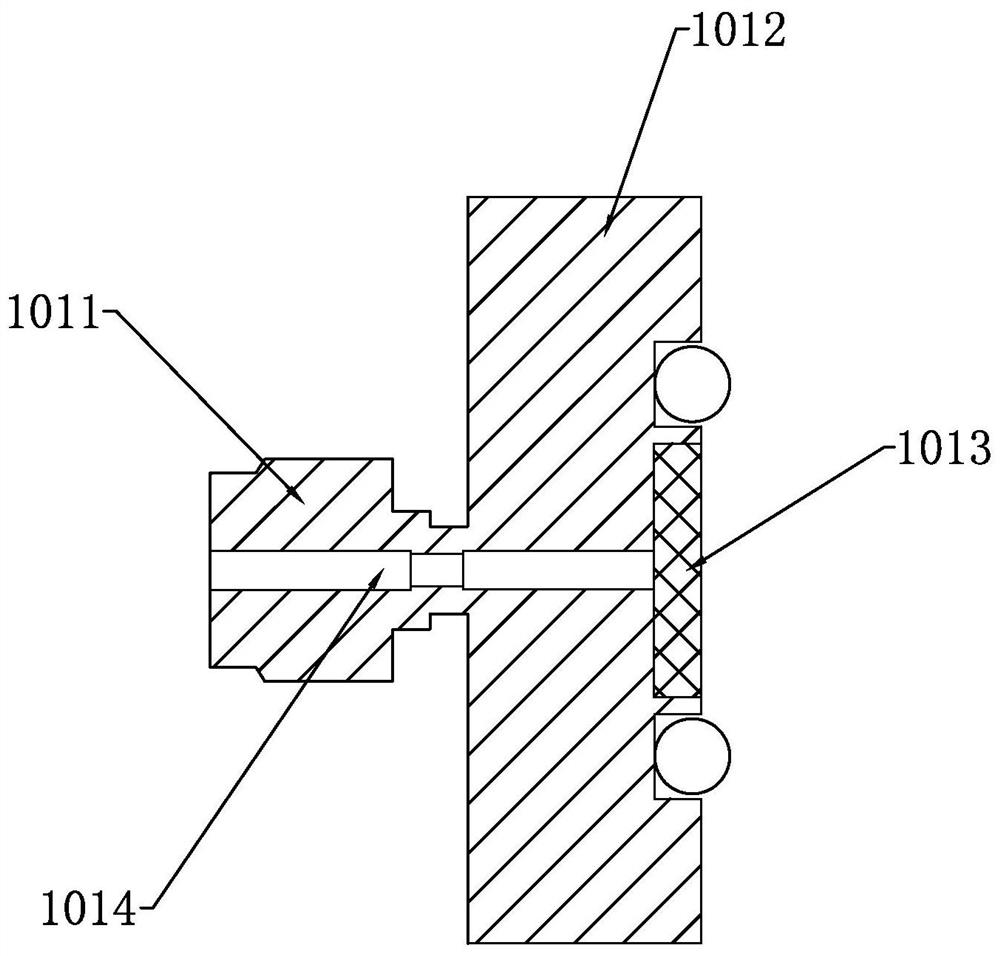

Double-seal internally-closed thimble vacuum valve

The invention discloses a double-seal internally-closed thimble vacuum valve, belonging to the technical field of vacuum heat pipes. The vacuum valve comprises a nut (1), a shell (2) with an internal screw thread and an external screw thread, a thimble (3) with an external screw thread hexagon, a thimble plug (4) and a red copper gasket (6) padded below the nut (1), wherein the thimble plug (4) is arranged on the bottom end in the shell (2) and is provided with an aspirating hole (5); the thimble (3) is connected with the thimble plug (4) by frapping a pipe socket close to the lower end of the thimble, and thus, the tip of the thimble plug (4) can be in arbitrary orientation and does not deviate due to screw thread space when the thimble (3) is screwed down. The invention has the beneficial effect of small structure and can stably keep vacuum degree for a long term in different vacuum cavity medium environments.

Owner:胡国强

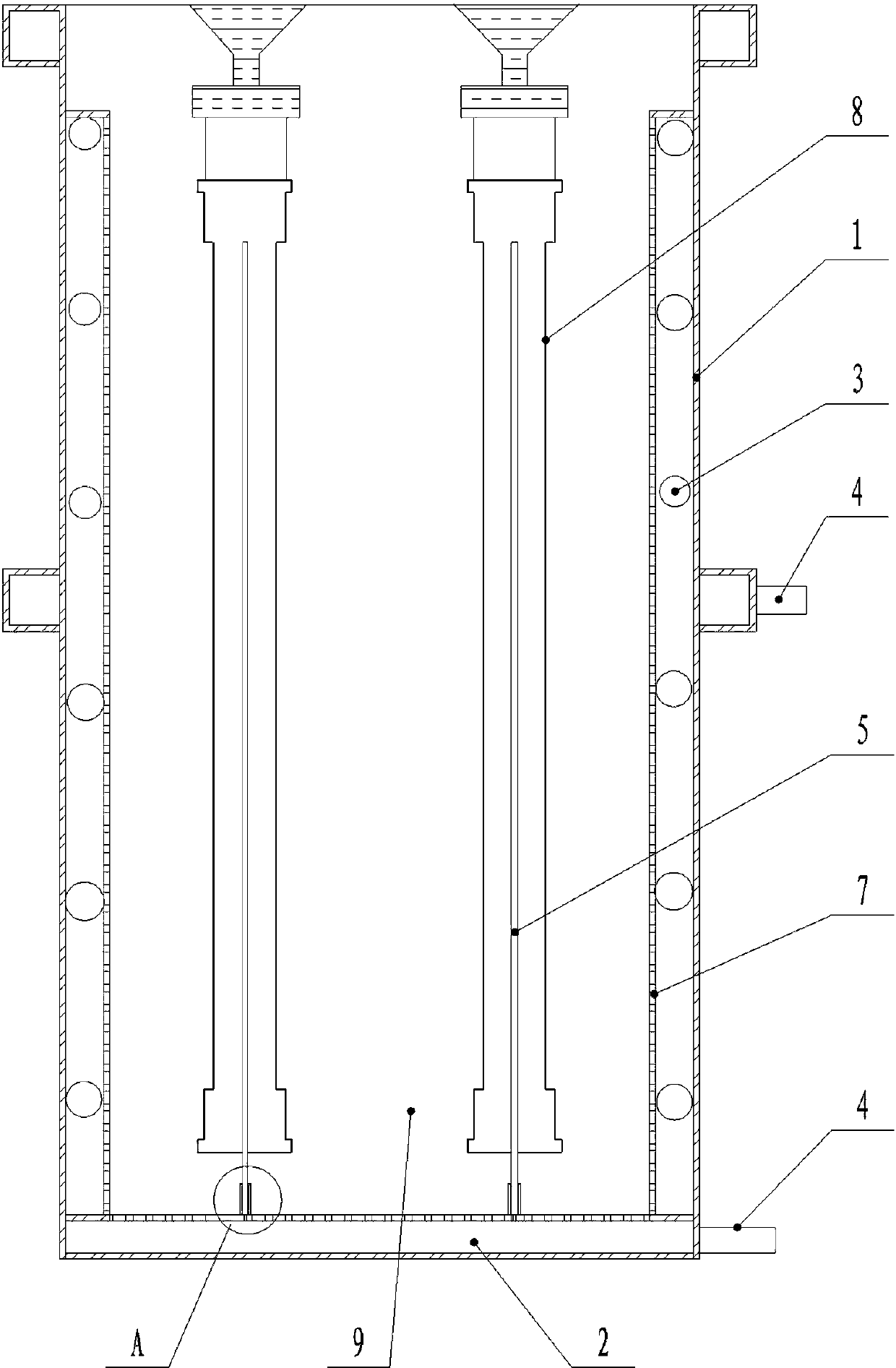

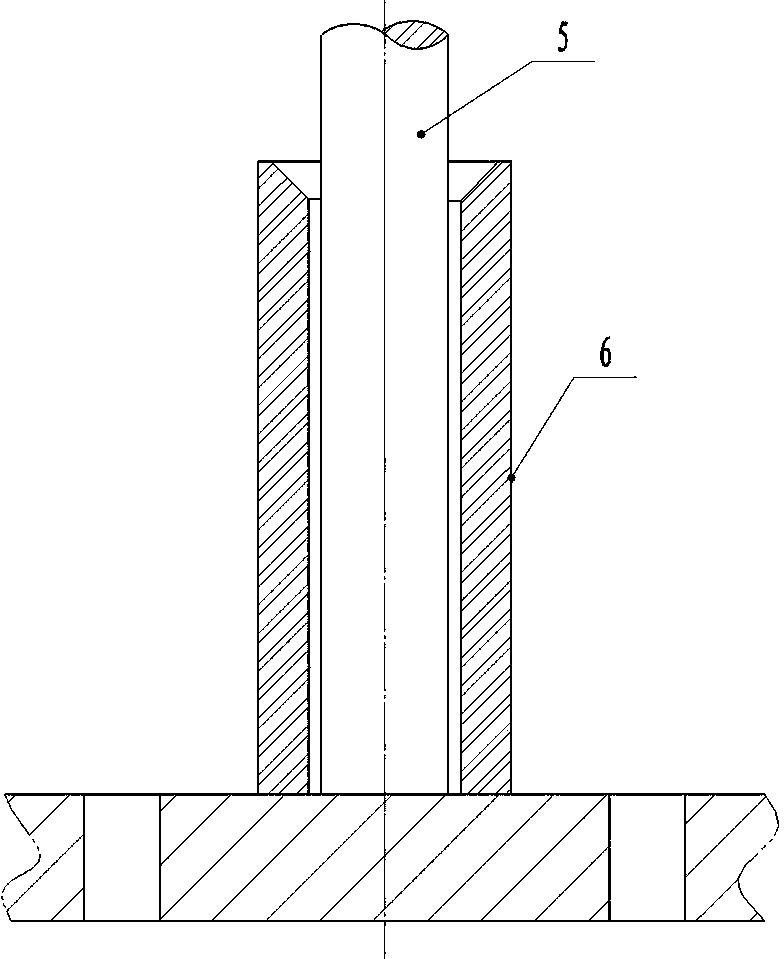

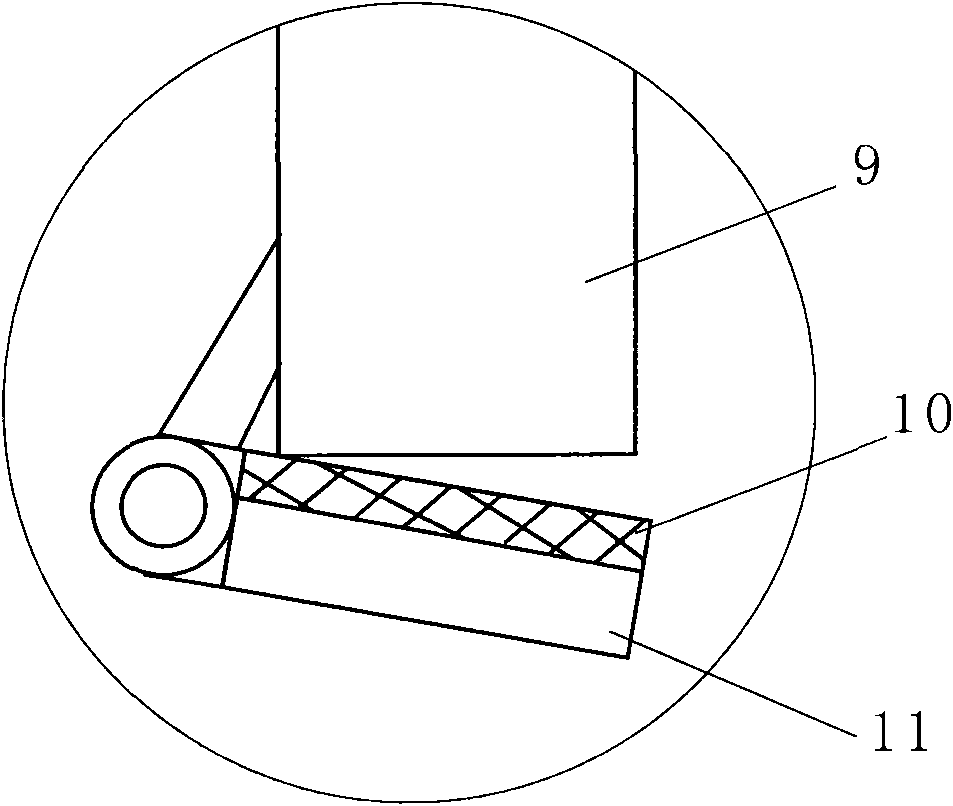

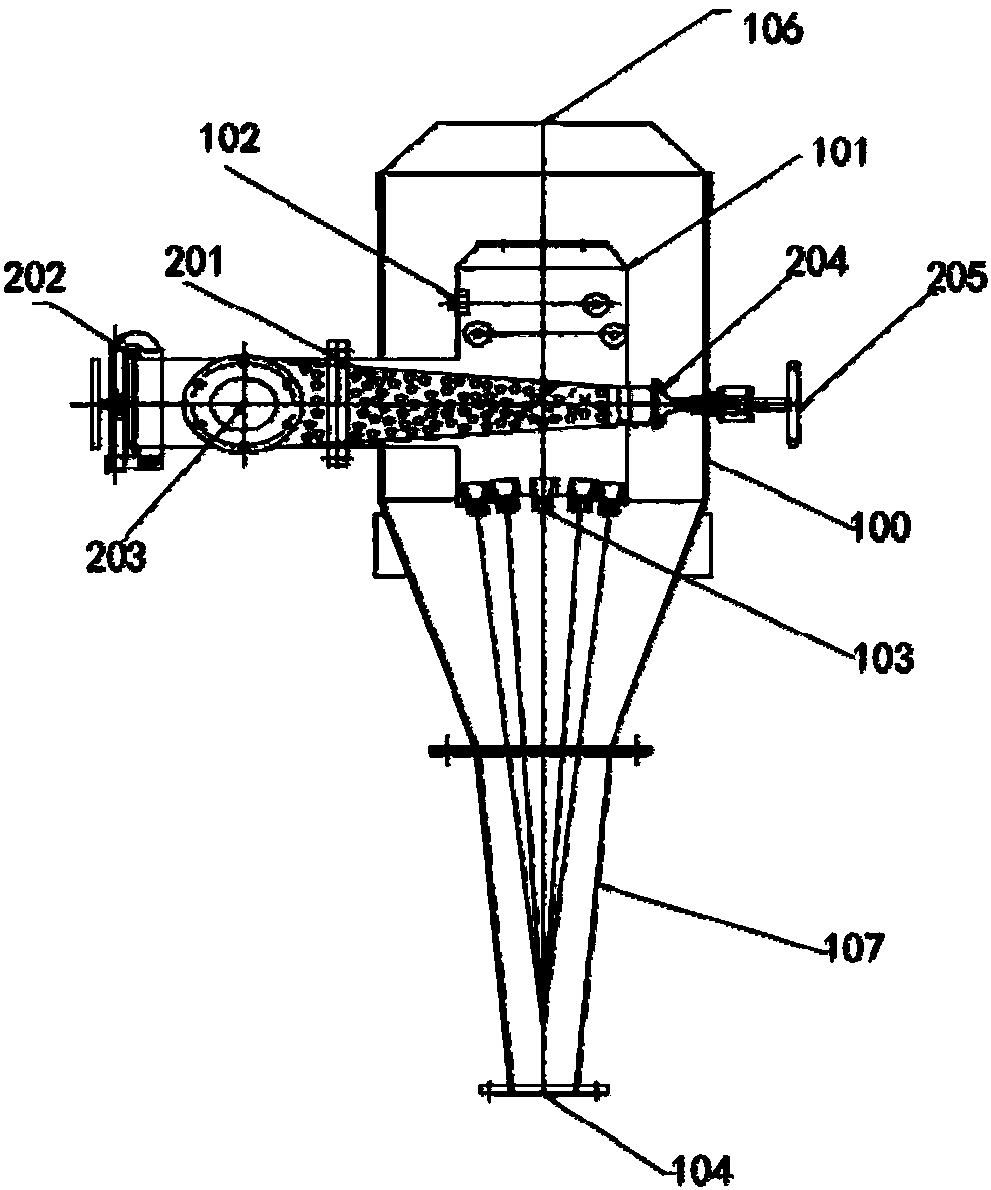

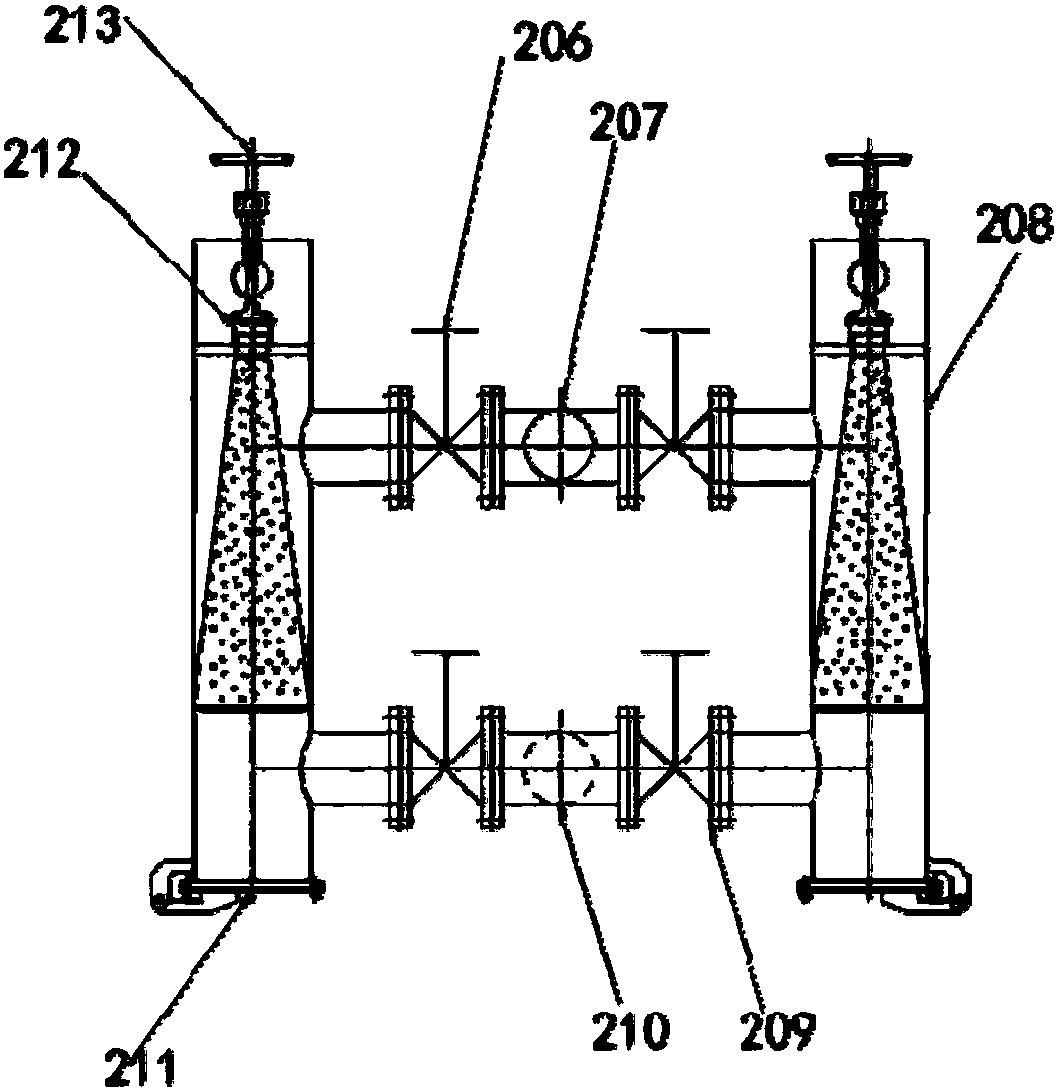

Lost foam casting process for double-bell-and-spigot grey cast iron thin wall pipe fittings and sand box for process

InactiveCN103418747AUniform strengthUniform stiffnessFoundry mouldsFoundry coresPipe fittingWater cooling

The invention relates to the lost foam casting field, in particular to a lost foam casting process for double-bell-and-spigot grey cast iron thin wall pipe fittings and a sand box for the process. The sand box for the process achieves the application of the lost foam casting process in the field of grey cast iron thin wall pipe fitting production. The process includes the steps of bead particle pre-foaming, mold building and molding, white mold drying and bonding, coating, drying, packaging, negative-pressure pouring, going out of a box and polishing. The mold building and molding procedure includes the steps of mold closing-filling of EPS bead particles-inflating of steam, curing of the EPS bead particles and white mold molding-filling of cooling water for cooling-die opening and white mold taking. The packaging procedure includes the steps of pouring bottom sand in the sand box to be compact in a vibration mode, scrapping flat, inserting a vertical core bar in the bottom sand, enabling the vertical core bar to be perpendicular to a bottom plate of the sand box, using the vertical core bar as the central axis to place the dried pipe fitting white mold on the bottom sand, filling dry sand in the sand box to be compact in a vibration mode, covering a polyethylene film on the sand box to wait for being poured. The lost foam casting process is reasonable in improvement, suitable for processing high-precision and high-quality grey cast iron thin wall pipe fittings and double-bell-and-spigot grey cast iron thin wall pipe fittings with lengths of above 1.5 meters.

Owner:阳城县华王通用离心铸管厂 +1

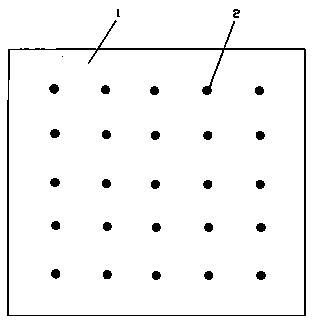

Support-provided film for vacuum glass and manufacturing method

InactiveCN105502900ASimple preparation procedureIncrease productivityGlass reforming apparatusGlass productionEngineering

The invention discloses a support-provided film for vacuum glass. The film is characterized by comprising a film substrate and a set of supports, wherein the supports are protrusion structures arranged in arrays and are fixed to the film substrate through a bonding material. The film can be directly laid on the surface of a lower glass body, the purpose of placing and positioning the intermediate supports of the vacuum glass is well achieved, the vacuum glass manufacturing process is simplified, the production cost is lowered, and the production efficiency of a factory is improved; besides, the film manufacturing method is easy and convenient to implement, facilitates industrial production, provides a technical guarantee for achieving automatic production of the vacuum glass and creates conditions for keeping the stability and durability of the vacuum degree of the vacuum glass.

Owner:TAICANG YAOHUA GLASS

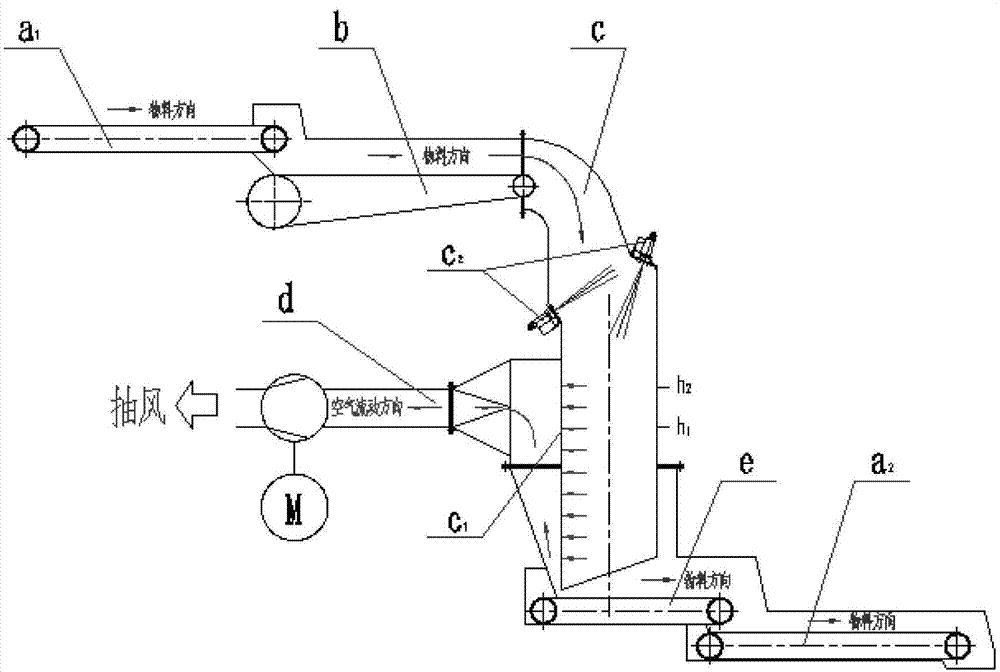

Method for controlling height of material layer of bin of two-sided jet-type charging machine

InactiveCN104489919AStable vacuumImproving the effect of double-sided jet feedingCigarette manufactureEngineeringConveyor belt

The invention discloses a method for controlling the height of a material layer of a bin of a two-sided jet-type charging machine. The method comprises the following steps: respectively placing a metering type belt weigher at each of a feeding position and a discharging position of the two-sided jet-type charging machine, weighing a fed material and a discharged material to calculate a weight accumulation error of the two belt weighers at the same moment to calculate the value of the weight of a material accumulated in a charging bin at the moment, then calculating the value of the volume of the material according to a volume weight of the material, finally dividing a sectional area of the bin to obtain an accumulation height h of the current material; and comparing the h with required height intervals h1 and h2, and controlling the conveyor belt speed of a variable frequency speed control discharging conveying machine by adopting an incremental PID algorithm. The control method can be used for ensuring that the accumulation height of the material in the bin is basically constant.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

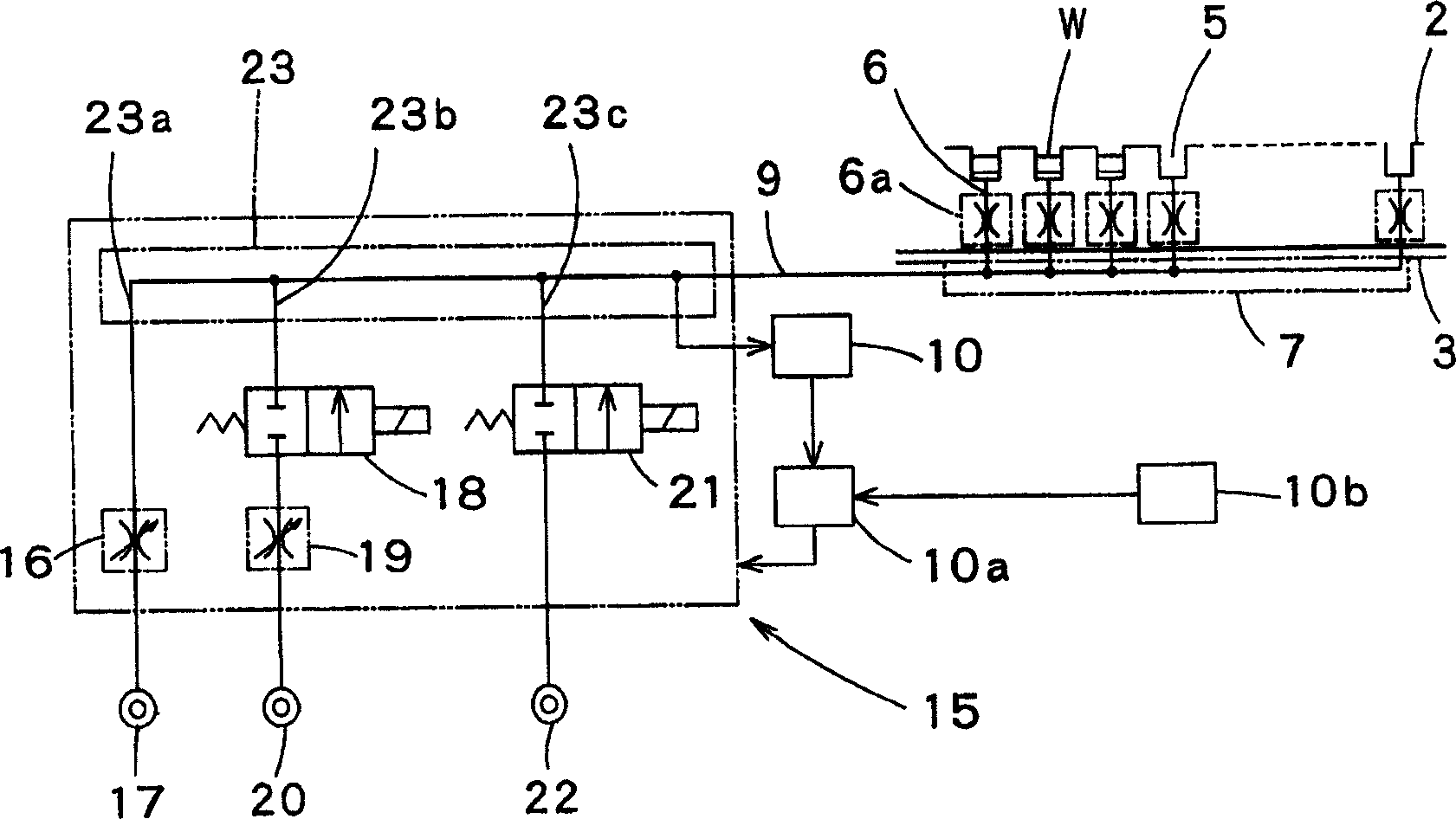

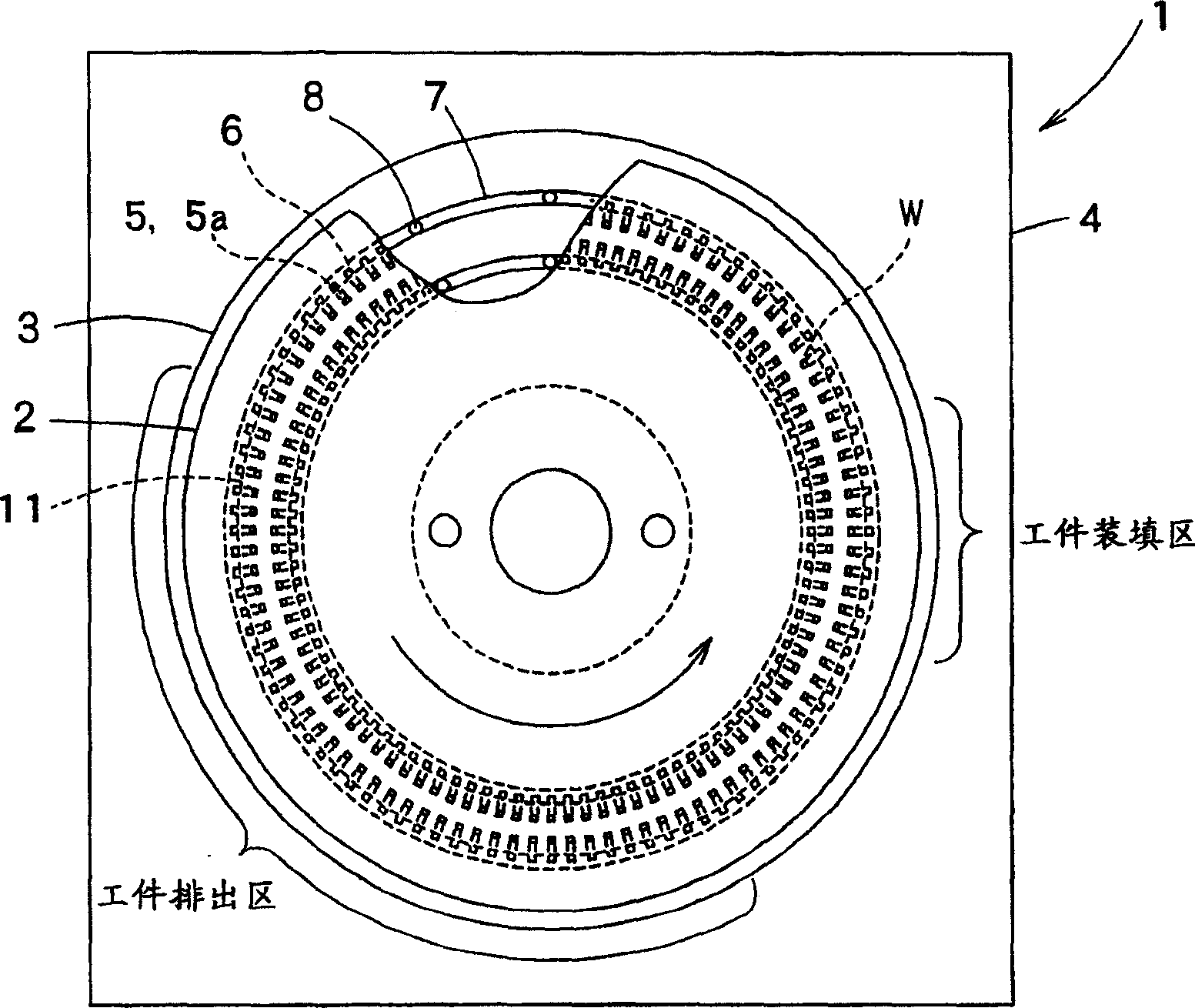

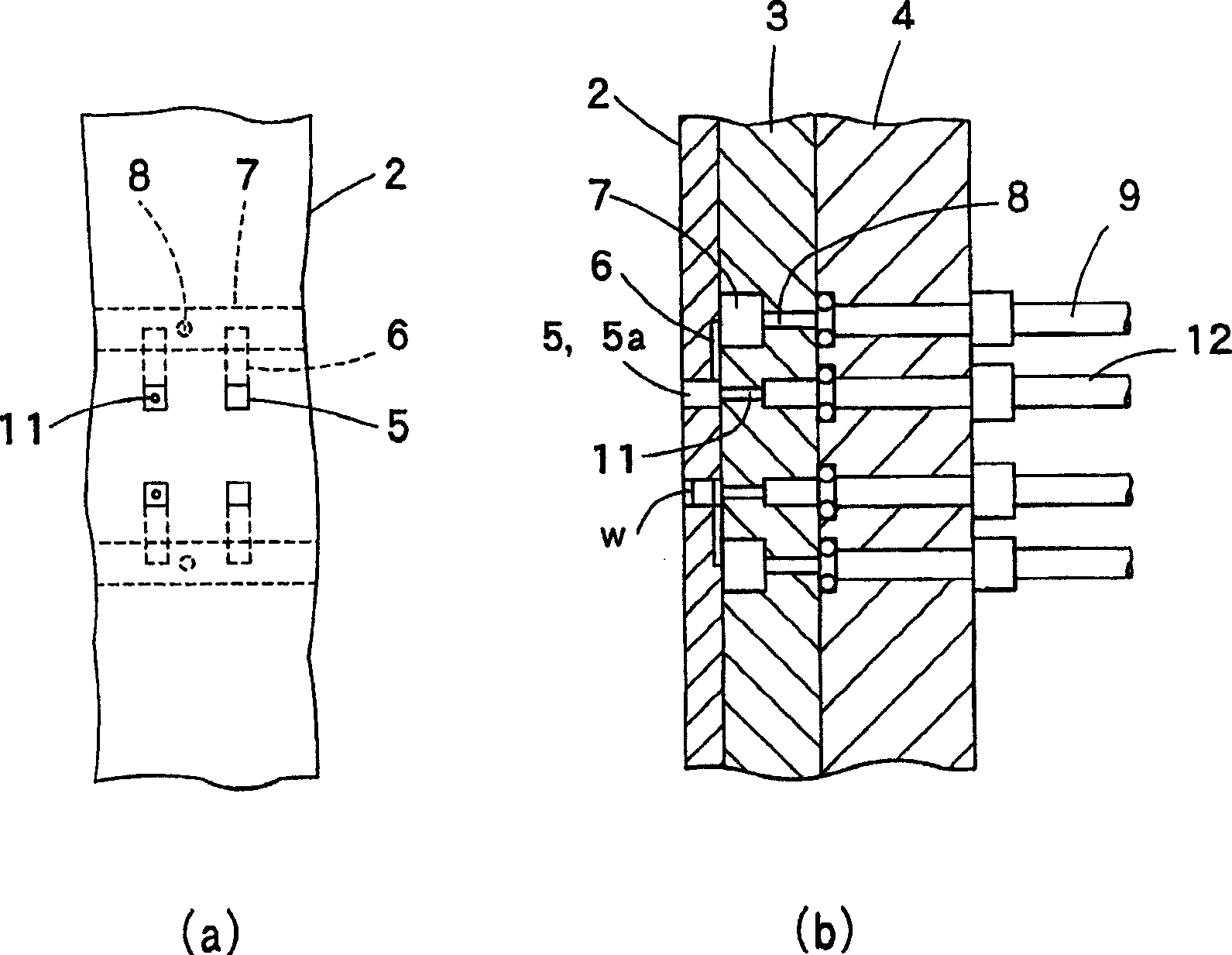

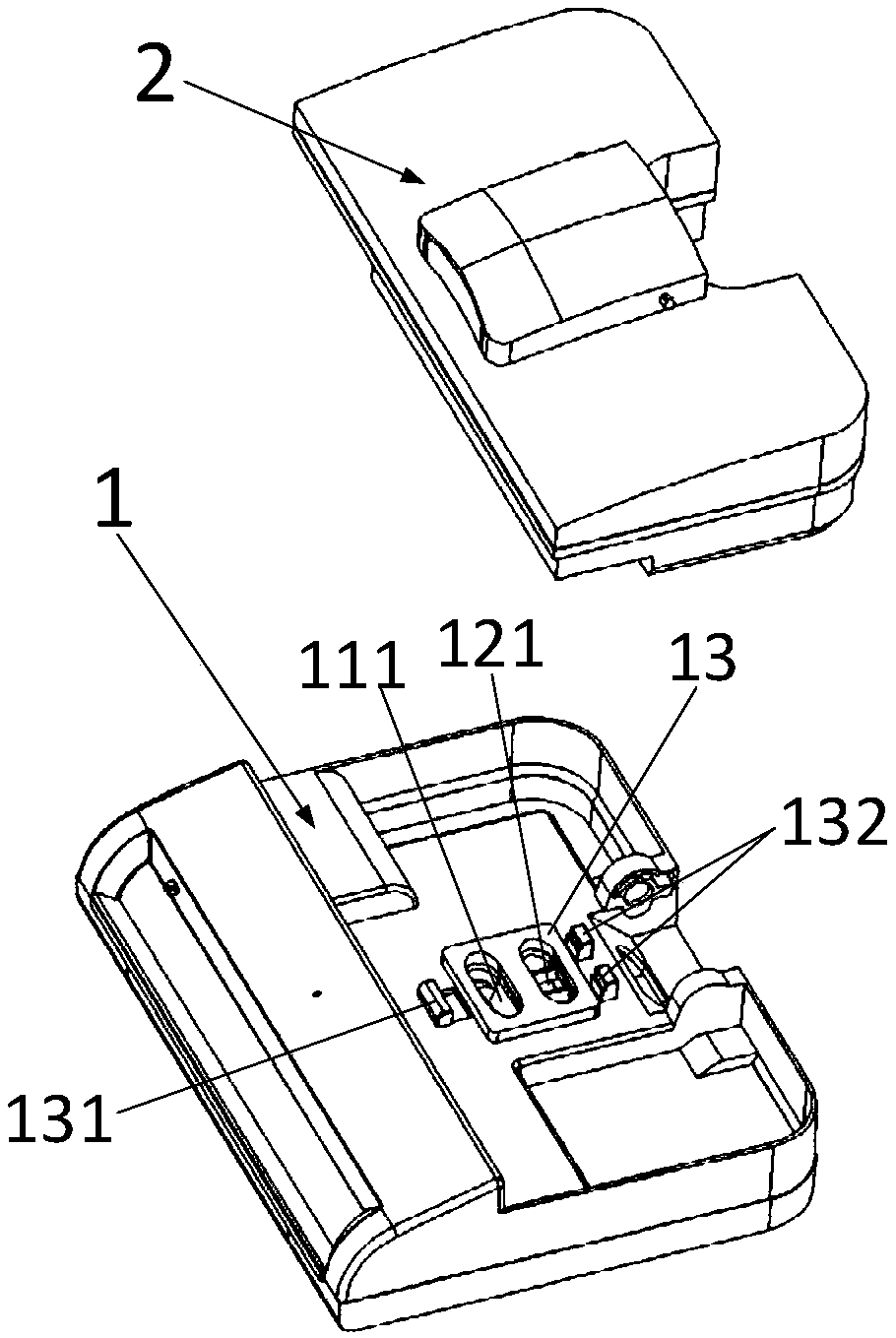

Vacuum attraction system

ActiveCN1725948AStable vacuumStable deliveryThin material handlingElectrical componentsAtmospheric airPulp and paper industry

The subject of the invention is to provide a vacuum suction system capable of stably charging a workpiece into a workpiece storing hole of a workpiece carrying table and discharging the workpiece. This system is provided with the workpiece carrying table 2 having the workpiece storing hole 5 and a table base 3 having a vacuum suction groove 7 communicated with the workpiece storing hole 5 of the workpiece carrying table 2. The workpiece storing hole 5 and the vacuum suction groove 7 are communicated with a vacuum generation source 17 via a vacuum pipe 9. A negative pressure sensor 10 is connected to the vacuum pipe 9. Based on a signal from the negative pressure sensor 10, compressed air from a compressed air generation source 20 is delivered to the vacuum pipe 9, or the inside of the vacuum pipe 9 is opened to the atmosphere to regulate a degree of vacuum in the vacuum pipe 9.

Owner:TOKYO WELD CO LTD

Urea production system and method for absorbing melamine tail gas

PendingCN108299243AReduce water contentReduce loadUrea derivatives preparationProductsDesorptionEvaporation

The invention relates to a urea production system and method for absorbing melamine tail gas, and belongs to the field of urea production. The urea production system comprises a urea synthesis section, a recycle recovery section, an evaporation section, an evaporation condensate recovery section and a desorption and hydrolysis section; the urea synthesis section comprises a liquid ammonia buffer groove, an ammonia condenser, a first adsorption tower, a liquid ammonia preheater, a urea synthesis tower, a carbomate preheater and an inert gas refining purifier; the recycle recovery section comprises a predistillation tower, a second separation tower, a flash evaporator, a first absorption external cooler, a first section evaporator, a two-circulation first condenser, a two-circulation secondcondenser and a tail absorption tower; the predistillation tower is adopted to reduce the water volume entering into the synthesis tower, the flash evaporator is added, the urea is concentrated, a waterpower ejector is used to vacuumize and recycle ammonia and carbon dioxide in the tail gas, the ratio of H2O and CO2 is reduced, and the conversion rate of the CO2 is improved; the system load is reduced; and under the condition of not additionally supplementing the carbon dioxide, and the tail gas from a triamine device by condensation and absorption is taken as a raw material of urea production.

Owner:山东鸿运工程设计有限公司 +1

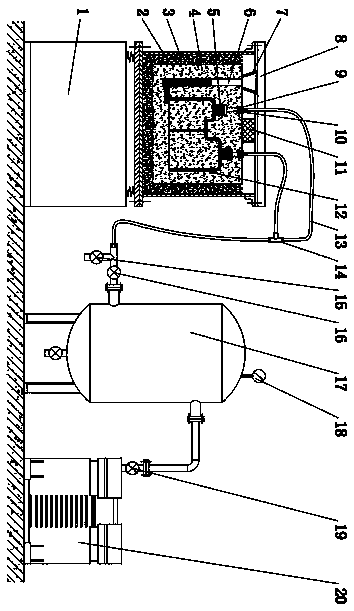

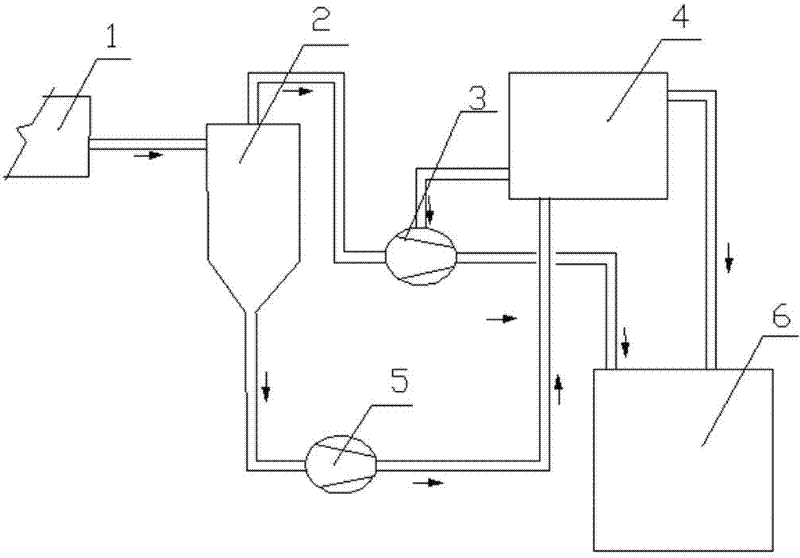

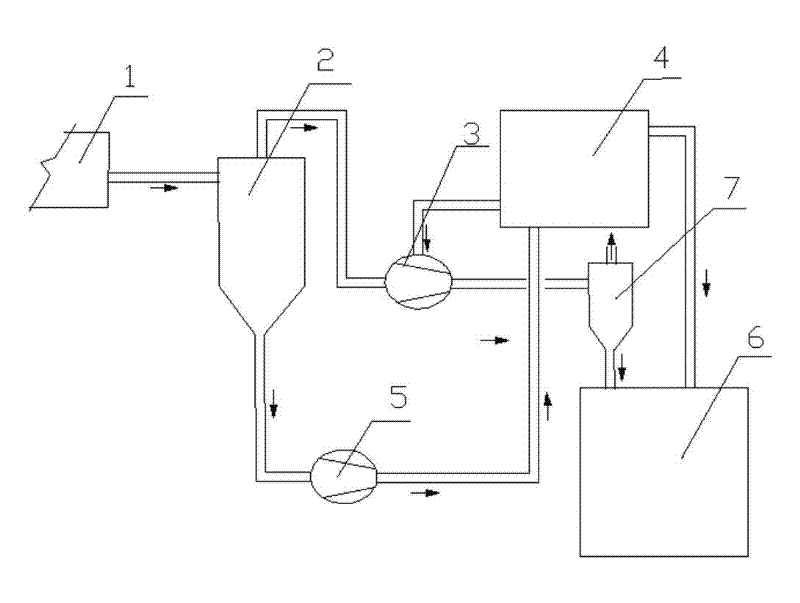

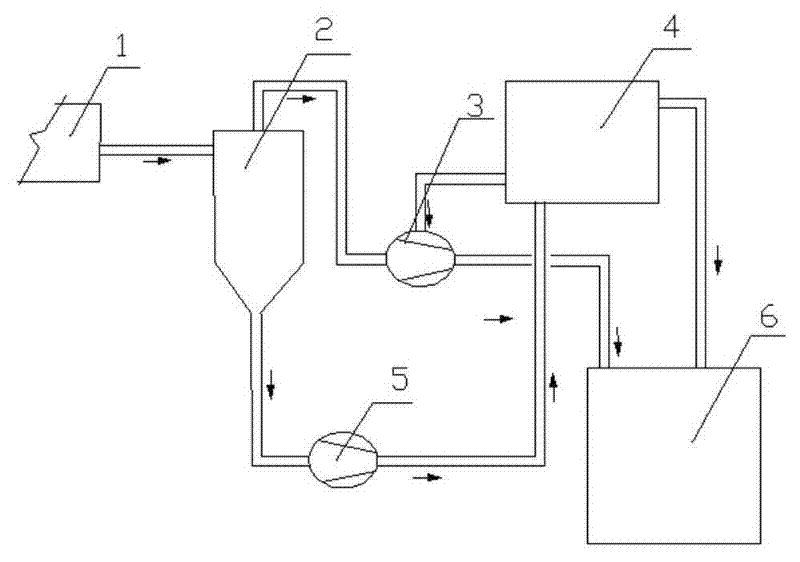

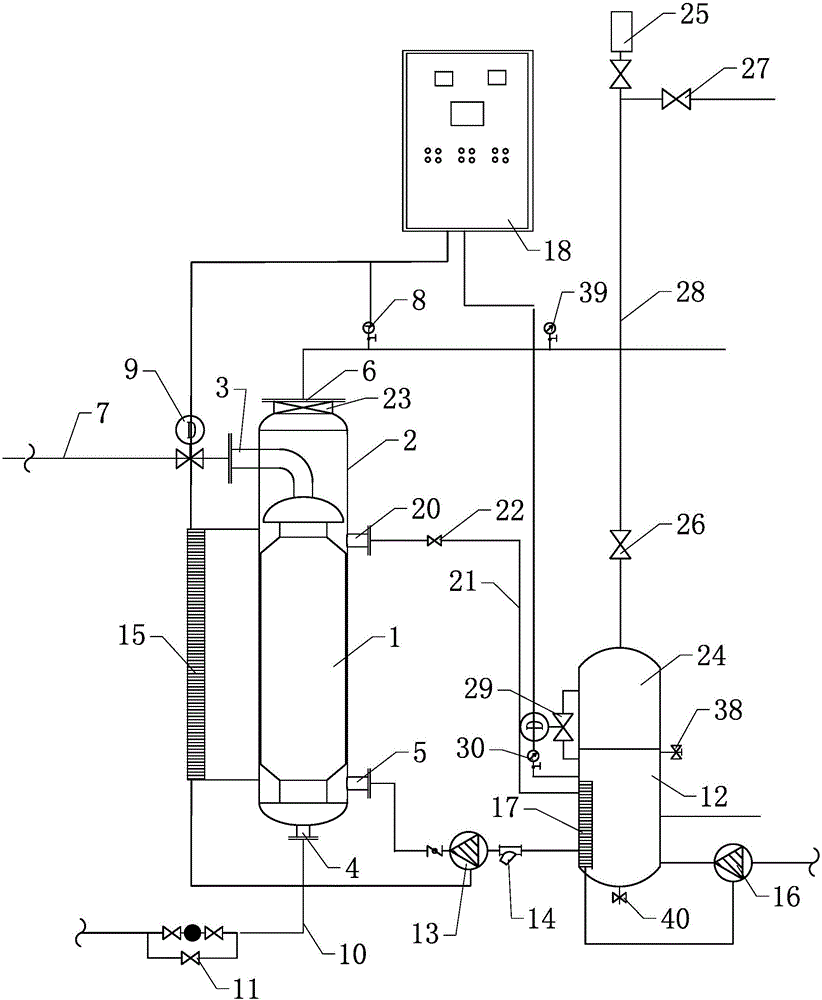

Wet-pressing molding centralized drainage vacuum system

InactiveCN101628445AGuaranteed vacuumImprove molding efficiencyCeramic shaping apparatusInductances/transformers/magnets manufacturePulp and paper industryRoughcast

The invention discloses a wet-pressing molding centralized vacuum drainage system, comprising double-vacuum pump groups, a vacuum tank, a moisture separator and a valve. The technical points of the system are as follows: the outlet ends of two groups of double-vacuum pumps arranged in parallel are communicated by a three-way valve, a negative pressure vacuum tank and the moisture separator in turn, and the outlet ends on the top part of the moisture separator is communicated with the inlet ends of at least two hydraulic press moulds arranged in parallel by an anti-corrosion pipeline and the valve; the vacuum degree in the system is maintained in a constant range; and the end part of a water drain pipe at the bottom part of the moisture separator is also provided with a flip-style drainage door with a rubber gasket. The vacuum drainage system reduces the work noise, power consumption and floor area of the pumps; the reciprocating vacuum pump groups are connected with a large vacuum tank through the three-way valve to keep the vacuum degree of the whole system stable, thereby improving the molding efficiency in pressing slugs; meanwhile, all pipelines adopt PC plastic pipes and the mode of embedding pipes underground, thereby reducing the amount of the maintenance of the pipelines.

Owner:沈阳矿山机械有限公司

Waste water recycling device for paper making vacuum system and water saving method

InactiveCN102249359AEvenly loadedStable vacuumWater/sewage treatment by degassingWaste water treatment from plant processingWater savingAtmospheric air

The invention discloses a waste water recycling device for a paper making vacuum system and a water saving method. The device consists of a gas-water separator, a vacuum pump, a filtrate pump, a header box, a white water pool and pipelines, wherein the air outlet of the gas-water separator is connected with the inlet of the vacuum pump; the liquid draining outlet of the vacuum pump is connected with the white water pool; the pumping port of the gas-water separator is connected with the inlet of the filtrate pump; the outlet of the filtrate pump is connected with the header box; the lower part of the header box is provided with a liquid outlet; the liquid outlet is connected with the working liquid inlet of the vacuum pump; the upper part of the header box is provided with an overflow port; and the overflow port is connected with the white water pool. In the working process, the mixture of gas and white water of a vacuum dehydrating element is collected into the gas-water separator, the separated gas enters the vacuum pump from the air outlet of the gas-water separator and is emitted into the atmosphere through the vacuum pump, the white water enters the filtrate pump form the pumping port of the gas-water separator and is conveyed into the header box through the filtrate pump, and a part of white water of the header box enters the vacuum pump and is taken as a working liquid instead of clear water.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

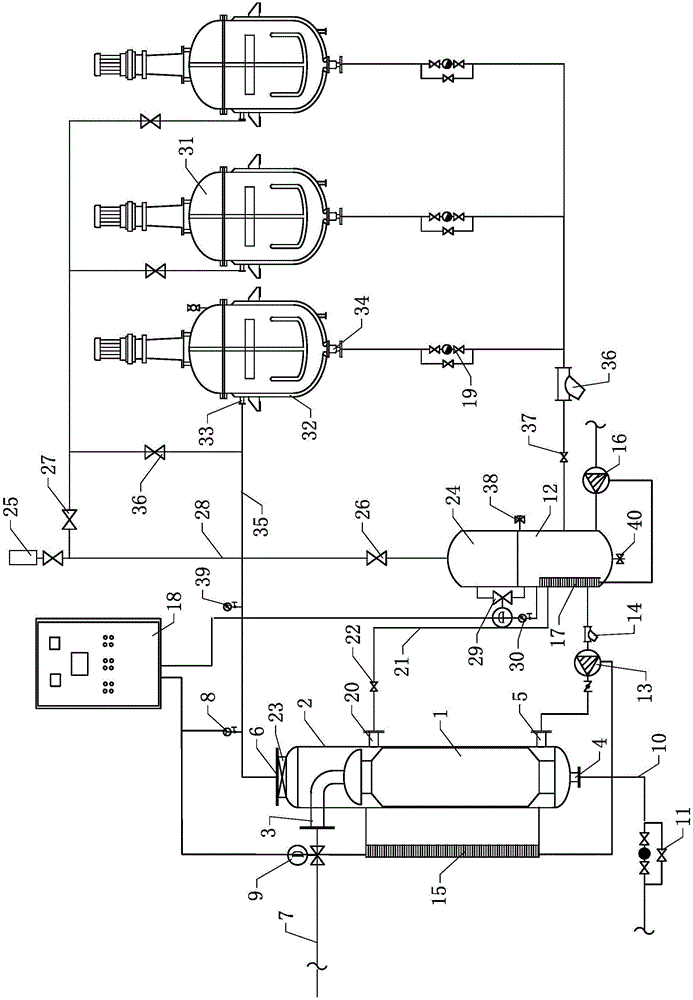

Efficient temperature control system and temperature control method thereof

ActiveCN105892521AMeet heating requirementsImprove heat utilizationTemperature control using electric meansTemperature controlEngineering

The invention discloses an efficient temperature control system. The efficient temperature control system includes a low pressure steam generation apparatus and at least one reaction vessel, wherein a clamping sleeve is arranged in the reaction vessel; the clamping sleeve is provided with a low pressure steam inlet and a condensate liquid outlet; the low pressure steam inlet utilizes a low pressure steam conveying pipe to communicate with a low pressure steam outlet of the low pressure steam generation apparatus; and the low pressure steam generated from the low pressure steam generation apparatus enters the clamping sleeve to perform temperature control heating on the reaction vessel. The invention also provides a temperature control method for implementing the efficient temperature control system. The efficient temperature control system and the temperature control method thereof can save the industrial steam, are high in the heat energy utilization rate, can accurately control the temperature of the steam, and also can guarantee that the heating steam is in the low pressure state so that the safety is guaranteed.

Owner:HIMILE MECHANICAL MFG

Self-pressurization type lithium bromide bubbling absorption device and control method thereof

ActiveCN111520933AStable vacuumEasy dischargeEnergy efficient heating/coolingClimate change adaptationHeat mass transferLithium bromide

The invention discloses a self-pressurization type lithium bromide bubbling absorption device and a control method thereof. Bubbling under negative pressure is implemented by utilizing a pressurization technology. In a vapor system, water vapor is pressurized through a variable-frequency booster pump so that the water vapor can successfully bubble in a lithium bromide solution in the vacuum state.A micro-pressure one-way balance valve is used for pressure balancing, wherein the micro-pressure one-way balance valve is arranged at an inlet of a gas exhaust pipe, the vapor which is not absorbedyet is quickly exhausted to balance system internal pressure, and then it can be guaranteed that an absorber has the stable vacuum state inside. With the self-pressurization type lithium bromide bubbling absorption device and the control method thereof, the lithium bromide solution bubbling and absorption process in the vacuum state is implemented, an effective path and effective measures are provided for heat and mass transfer performance of a lithium bromide absorption type cooling or heat pump and improvement on an internal absorption effect of a lithium bromide absorption type cooling or heat pump unit, and the device and the control method thereof have significance in improvement on the performance of and the miniaturization optimal design of an absorption type cooling or heat pump system.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

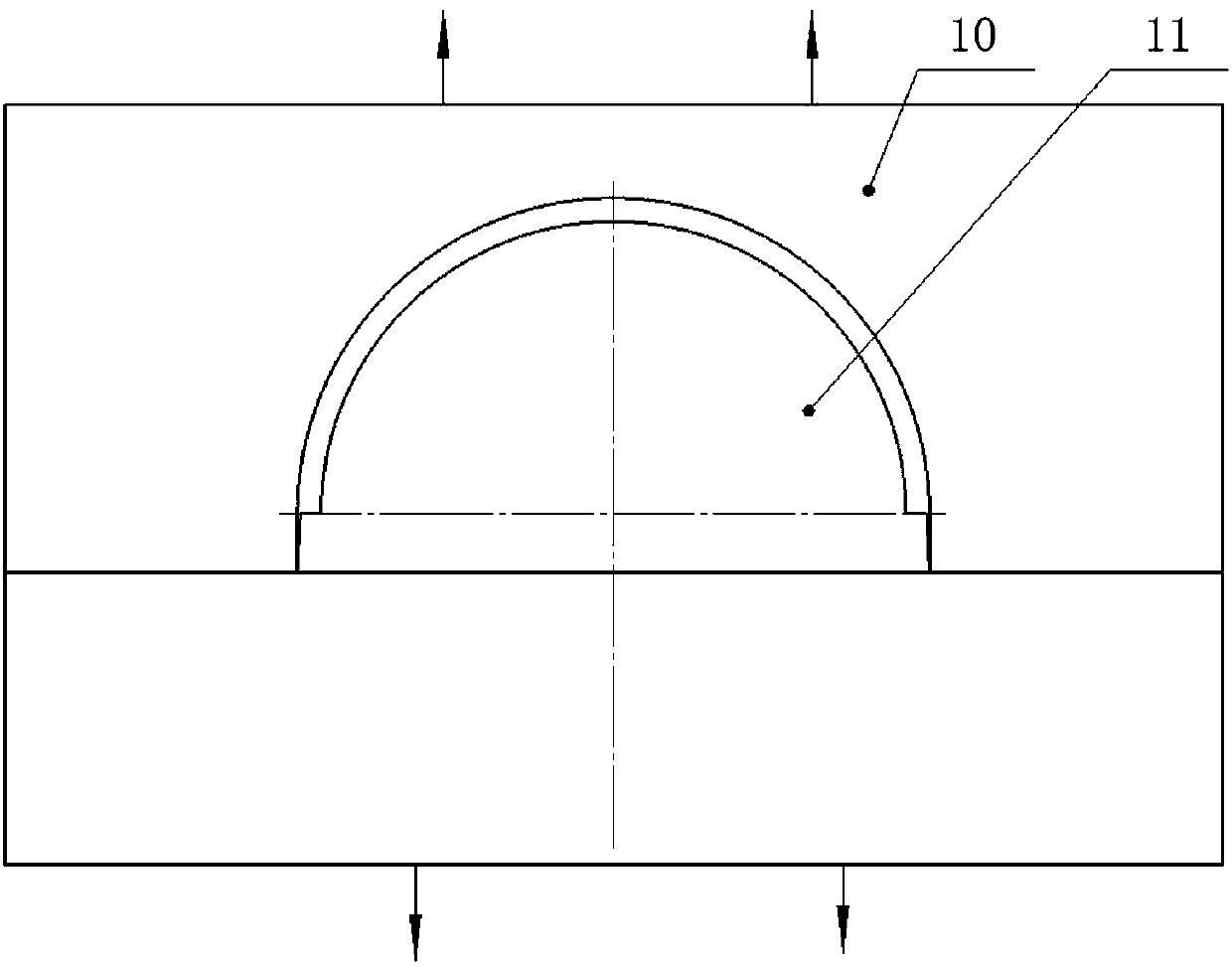

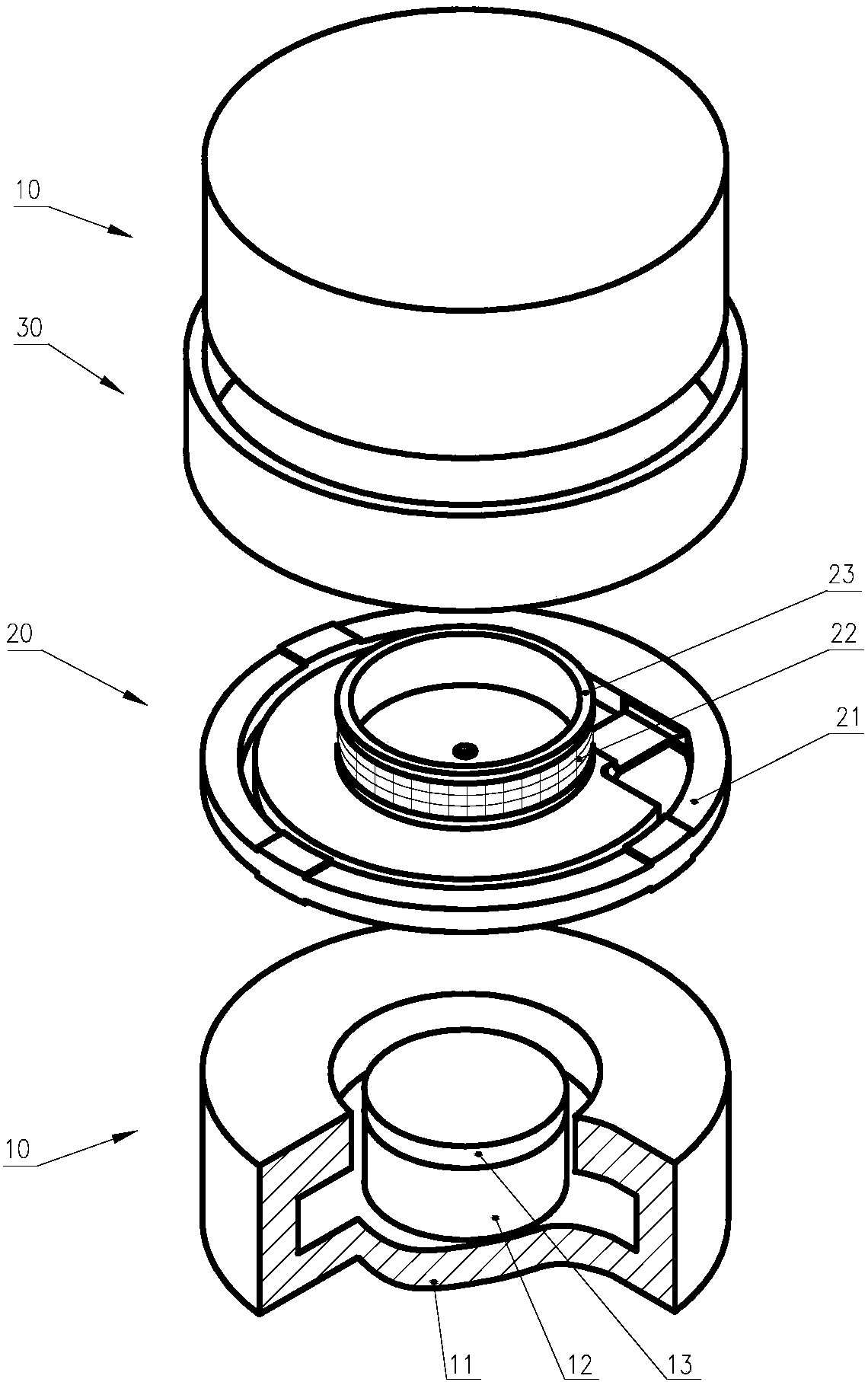

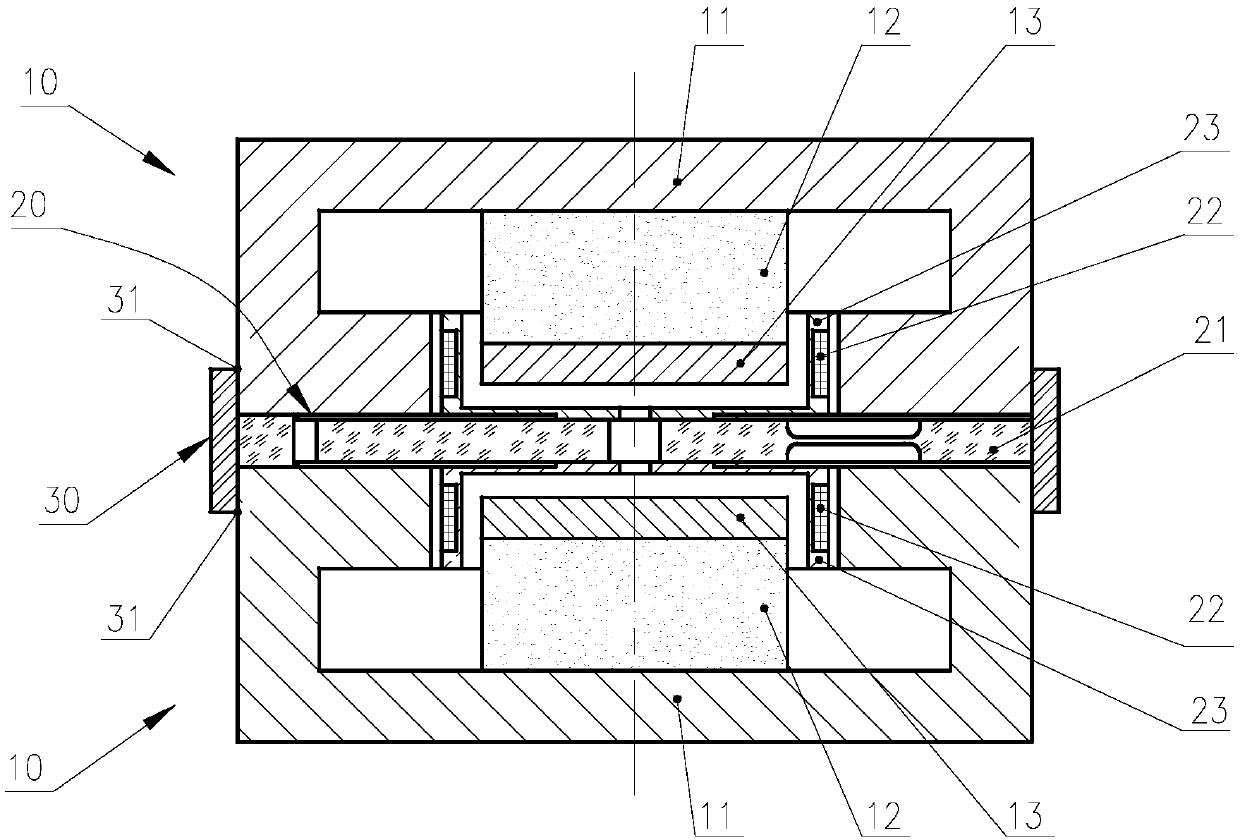

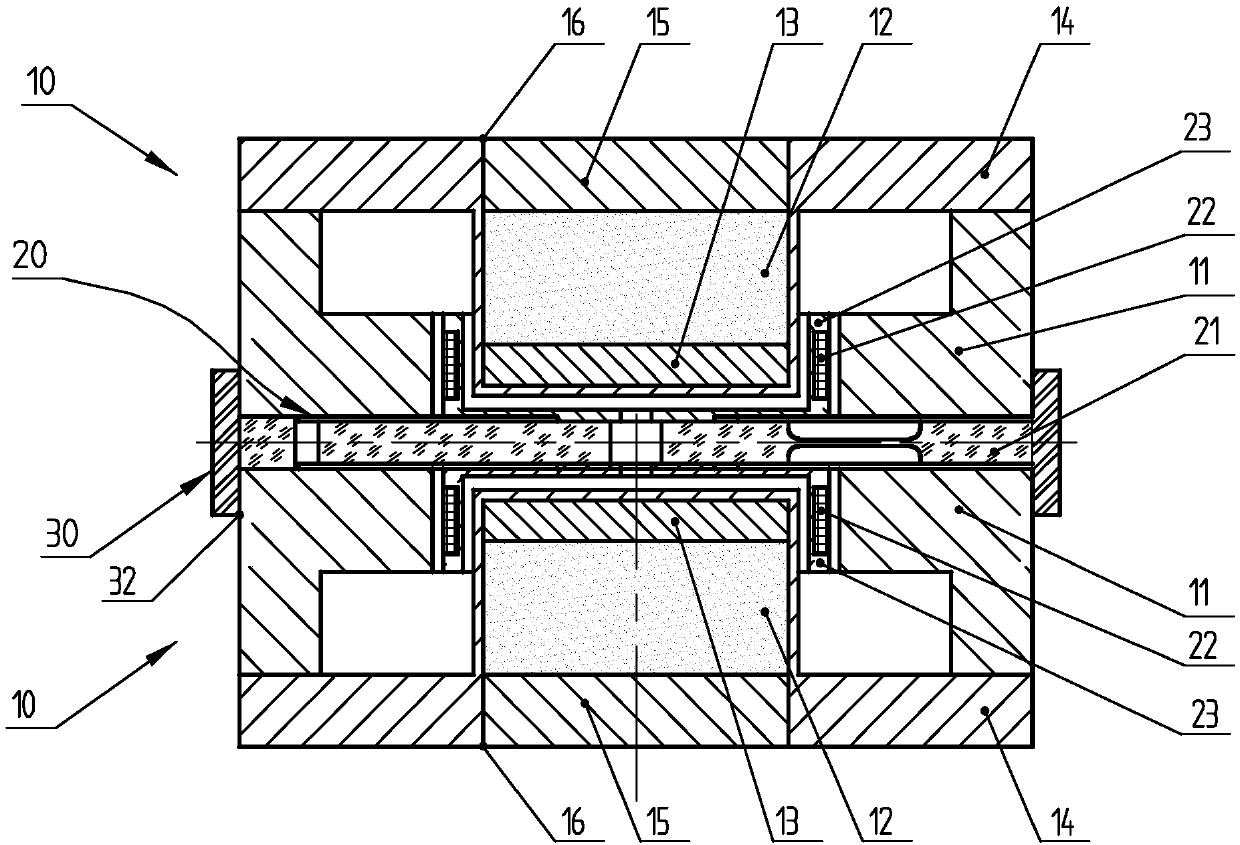

Vacuum retaining structure for high-resolution quartz flexible accelerometer

ActiveCN107703329AInhibit outgassing rateStable vacuumAcceleration measurement using interia forcesImage resolutionMagnet

The invention relates to a vacuum retaining structure for a high-resolution quartz flexible accelerometer. The vacuum retaining structure comprises upper and lower magnetic ring components, a pendulumcomponent and a connecting ring, wherein the pendulum component is composed of a quartz pendulum, a torquer coil and a coil skeleton; each of the upper and lower magnetic ring components is composedof a magnetic ring, a cylindrical permanent magnet, a magnetic cover and a magnetic base; the bottom of the magnetic ring is coaxially installed on the magnetic cover, a groove raised upward and opened downward is coaxially formed in the center of the magnetic cover, the cylindrical permanent magnet and the magnetic base are coaxially arranged inside the groove in sequence from top to bottom, andthe magnetic base is sealed with the magnetic cover together in a laser sealing manner to form a closed cavity; the magnetic ring components are used in pair, installed in a coaxial mirror image manner and welded together through the connecting ring in a laser sealing manner, and the pendulum component is fixedly installed therebetween. By improving the magnetic ring component structures based onthe existing quartz flexible accelerometer structure and increasing the laser welding seal design, the degree of vacuum inside the accelerometer is retained, and the resolution stability of the accelerometer over time is retained.

Owner:TIANJIN NAVIGATION INSTR RES INST

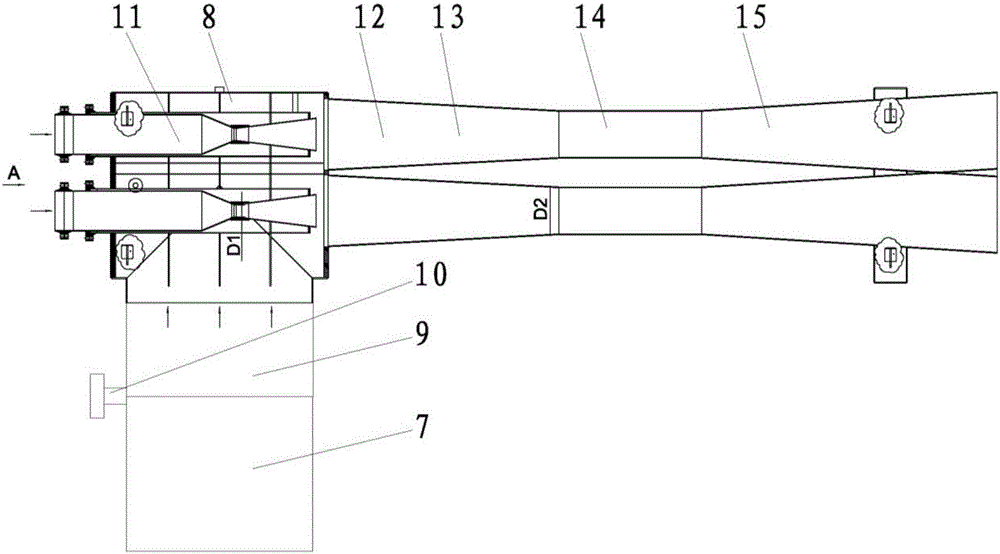

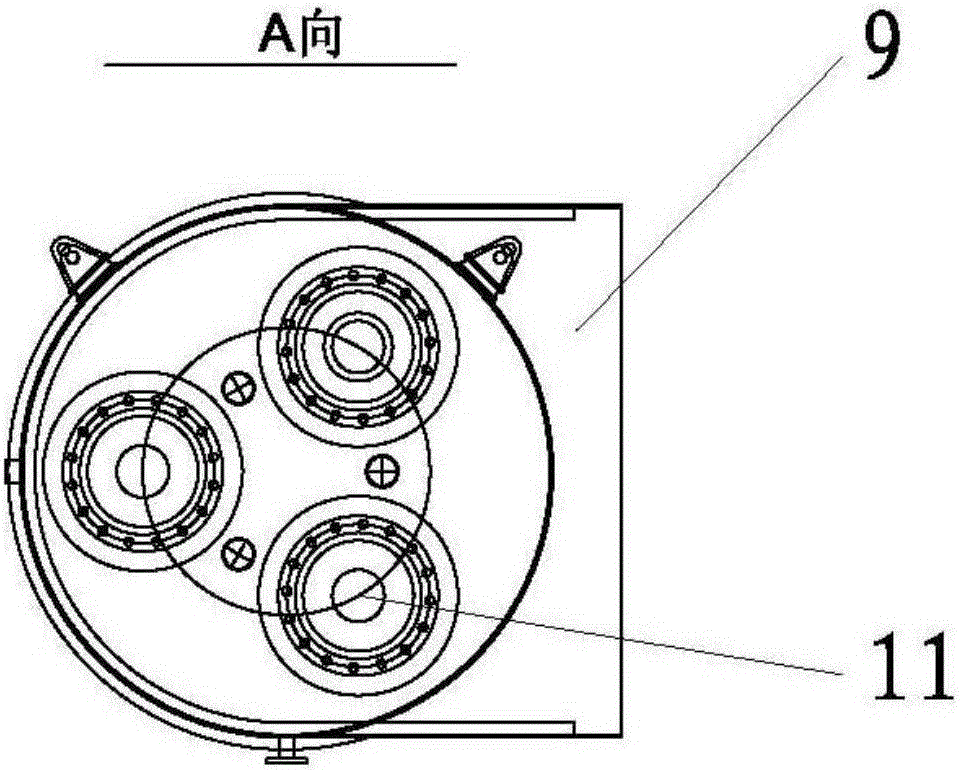

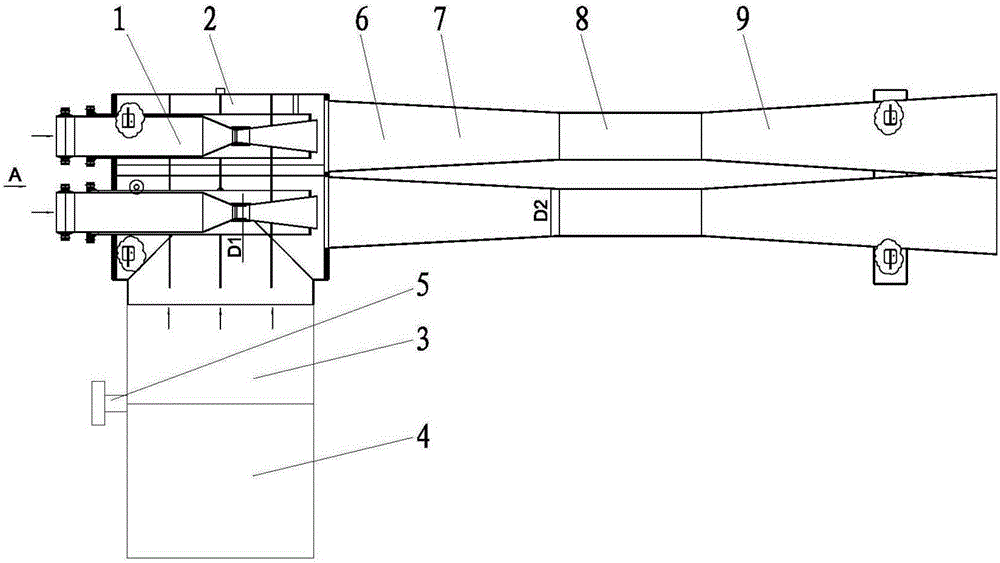

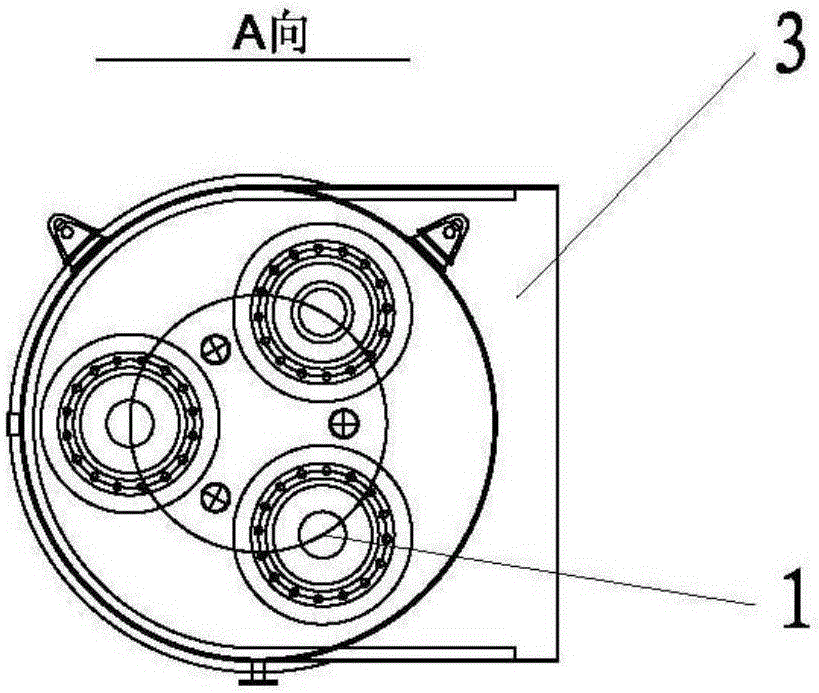

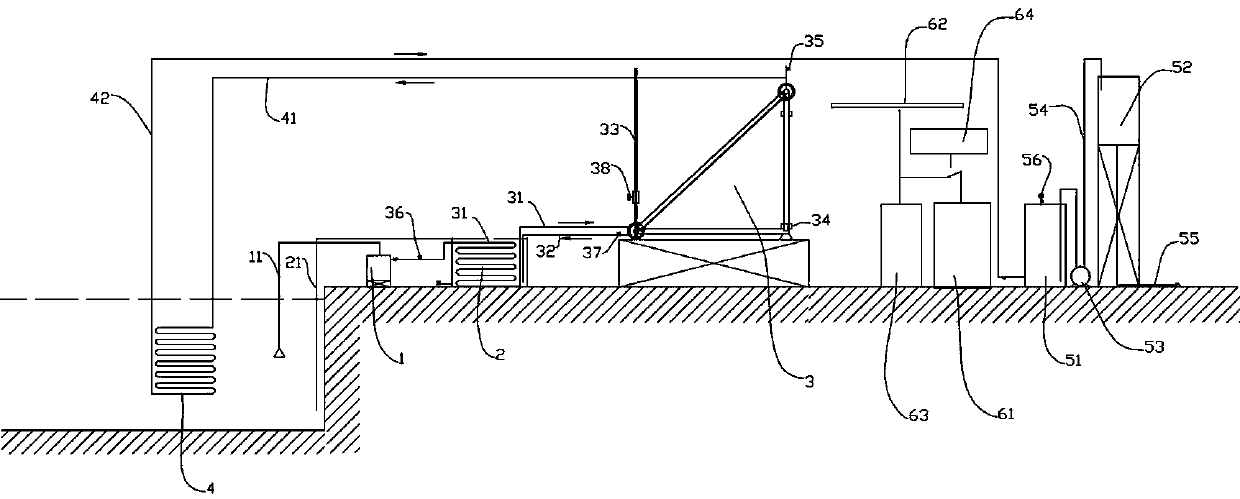

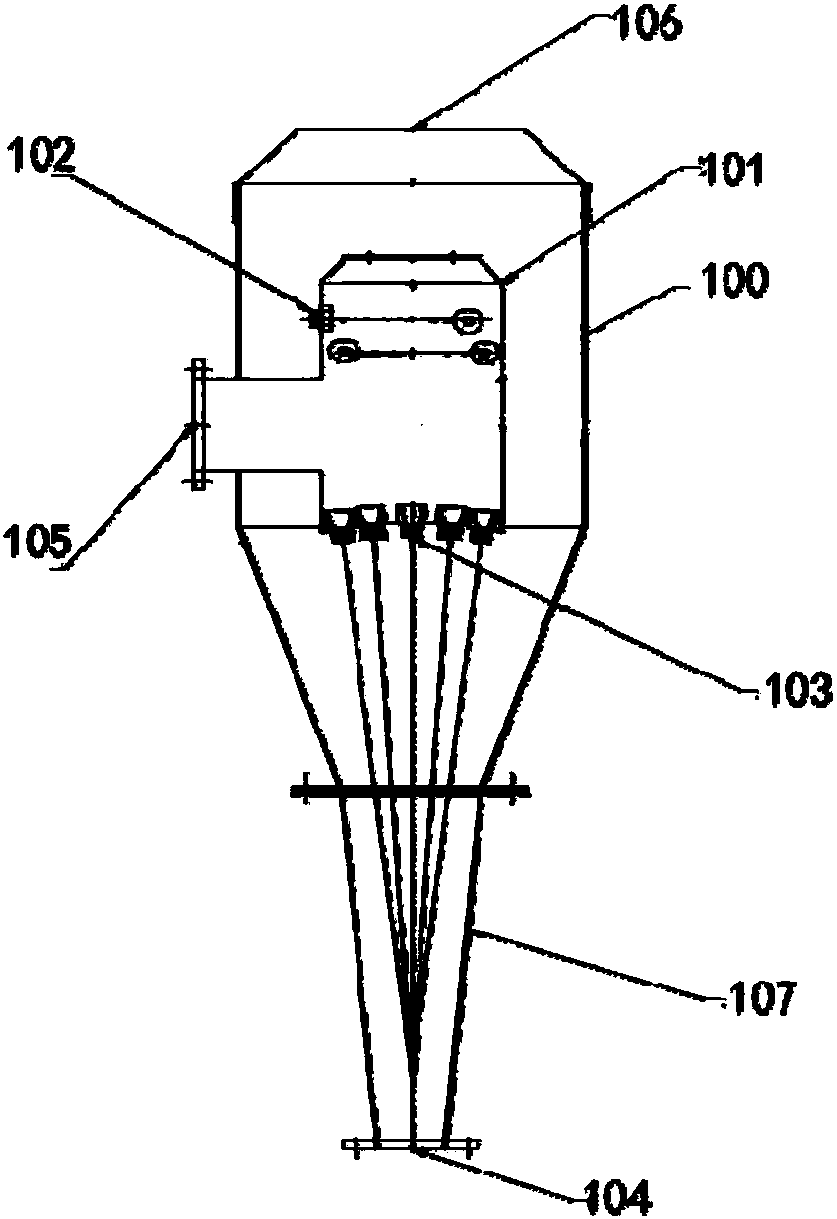

Apparatus for injecting tail gas and inflow hot air in vacuum cabin of ramjet

The invention belongs to the technical field of ramjet test, and specifically relates to an apparatus for injecting the tail gas and inflow hot air in a vacuum cabin of a ramjet. The apparatus comprises a receiving chamber, a vacuum pipeline, a vacuum butterfly valve, an injection nozzle and a throttle pipeline, wherein the injection nozzle is of a De-Laval nozzle structure and is inserted in the receiving chamber, the inlet of the injection nozzle is exposed outside the receiving chamber for receiving external high-temperature steam, the outlet of the injection nozzle is positioned in the receiving chamber and communicates with the inlet of the throttle pipeline, and the vacuum pipeline is installed on the side surface of the receiving chamber and connected with the vacuum cabin of the ramjet through the vacuum butterfly valve. The apparatus can satisfy long-time test and stably retain pressure in the vacuum cabin.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

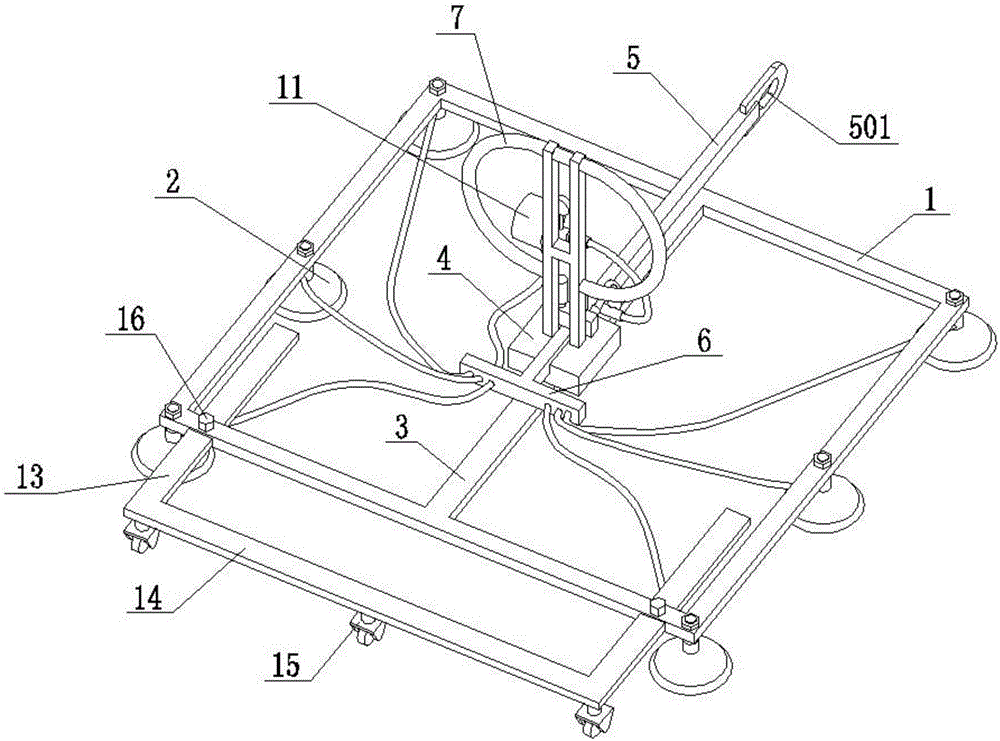

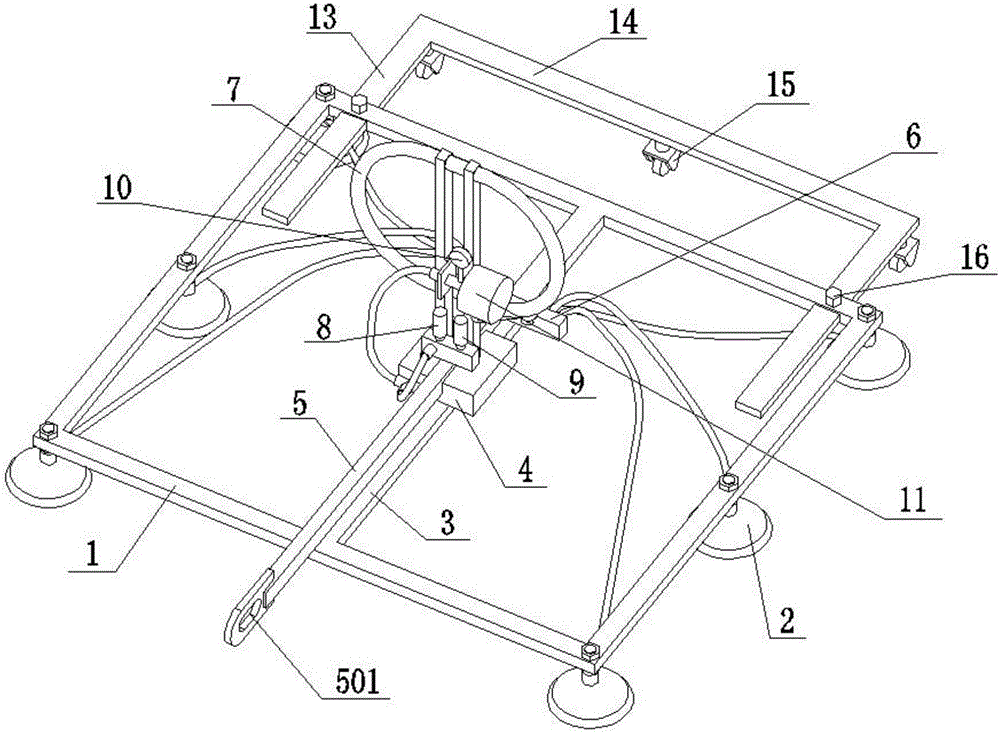

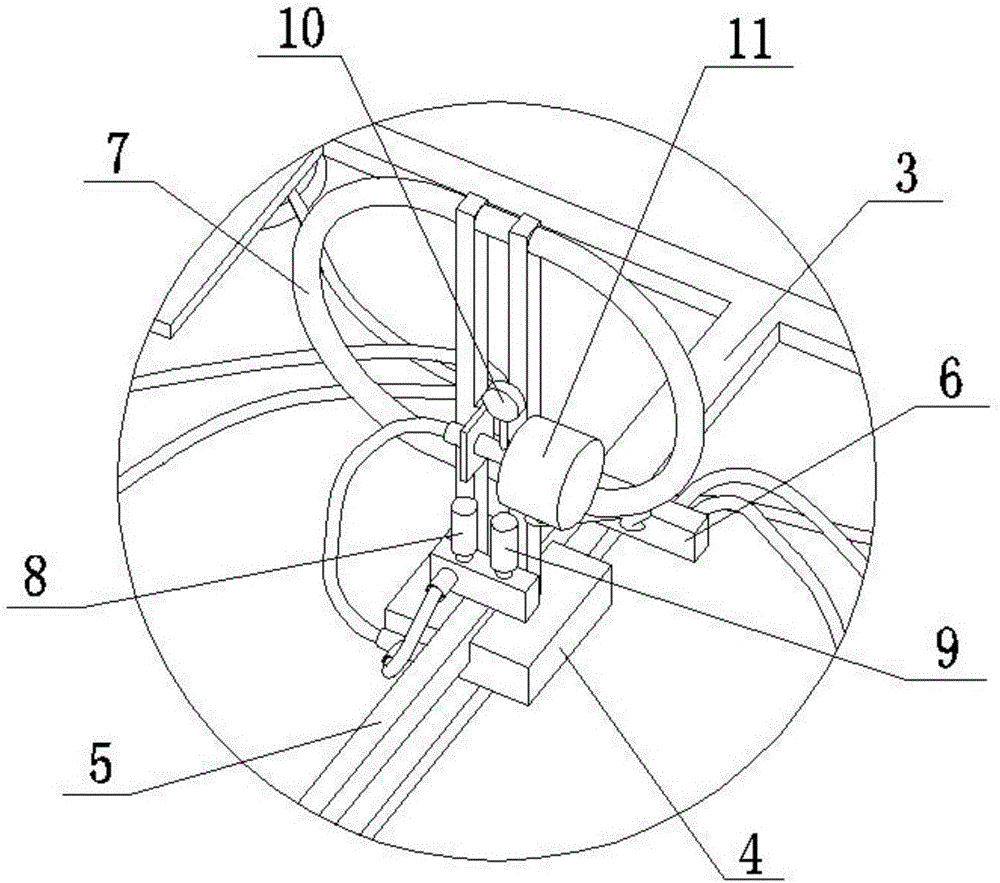

Installation device for passenger car windscreen

The invention discloses an installation device for a passenger car windscreen. The installation device comprises a suction cup frame, a plurality of suction cups are installed at the bottom of the suction cup frame, and the middle of the suction cup frame is provided with a supporting beam; a connection block is welded to the supporting beam, one side of the connection block is provided with a gas distributor, the other side of the connection block is provided with a lifting beam parallel to the suction cup frame, and the top end of the lifting beam is provided with a lifting lug; a gas outlet of the gas distributor is connected with the suction cups through gas pipes, and a gas inlet of the gas distributor is connected with a gas source drying tank and a gas-pressure meter through gas pipes in sequence; and the gas-pressure meter is connected with a vacuum pump and a gas blowing pump through gas pipes. According to the installation device for the passenger car windscreen, the multiple suction cups are arranged on the two opposite edges of the suction cup frame so that the passenger car windscreen can be adsorbed, the connection block is arranged on the supporting beam in the middle of the suction cup frame to be connected with the lifting beam, and the lifting beam is hung on lifting equipment through the lifting lug at the top end of the lifting beam; and the lifting equipment drives the passenger car windscreen to do vertical movement, horizontal movement and turnover movement so that the passenger car windscreen can be carried to the installation position to be installed, and convenience and quickness are achieved.

Owner:ANHUI ANKAI AUTOMOBILE

Titanium-aluminum-silicon alloy coating material and preparation method thereof

InactiveCN103898358AHigh calorific valueUniform compositionVacuum evaporation coatingSputtering coatingSilicon alloyRoom temperature

The invention relates to a titanium-aluminum-silicon alloy coating material and a preparation method thereof. The titanium-aluminum-silicon alloy coating material comprises, on the basis of atomic percent, 5 to 91% of titanium, 5 to 45% of aluminum and 1 to 60% of silicon. The invention further comprises the hot-pressing sintering preparation method for the titanium-aluminum-silicon alloy coating material. The method comprises the following steps: filling a sintering die with Ti3Al alloy powder, AlSi powder, titanium powder, aluminum powder and silicon powder, putting the sintering die into a vacuum hot pressing furnace and carrying out heating to a temperature of 600 to 700 DEG C when a vacuum degree is less than 1 Pa, wherein a heating rate is maintained to be 2 to 10 DEG C / min and the pressure of the pressure head of the hot pressing furnace is maintained to be 5 to 10 MPa; and continuing heating to 800 to 1400 DEG C, allowing the pressure of the pressure head of the hot pressing furnace to rise to 15 to 20 MPa, maintaining the temperature and the pressure for 30 to 120 min, then carrying out cooling and pressure relief and finally carrying out natural cooling to room temperature. The titanium-aluminum-silicon alloy coating material provided by the invention has the advantages of uniform alloy components, high compactness, short process flow, low production cost and stable quality.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Vacuum pumping running maintaining system of newly-built power plant condenser and running method of vacuum pumping running maintaining system

InactiveCN106907939AOvercome energy consumptionOvercome resourcesSteam/vapor condensersVacuum pumpingPower station

The invention discloses a vacuum pumping running maintaining system of a newly-built power plant condenser and a running method of the vacuum pumping running maintaining system. The running maintaining system comprises a plurality of vacuum pump subsystems which are arranged in parallel and communicate with the air outlet end of the power plant condenser through an air inlet pipeline. An air inlet hand valve, an air inlet rapid closing pneumatic valve and a dry type screw vacuum pump, all of which are connected through a pipeline are arranged in each vacuum pump subsystem, wherein the controlled end of the dry type screw vacuum pump and the controlled end of the air inlet rapid closing pneumatic valve are connected with a control device, and the air outlet end of the screw vacuum pump is connected with an air outlet pipeline. According to the vacuum pumping running maintaining system, the character that the dry type screw vacuum pumps can run in a speed adjusting manner is utilized, in the initial stage of running of the vacuum pumping running maintaining system of the power plant condenser, unit vacuum can be rapidly established with the high pumping speed, and meanwhile when a unit runs normally, the vacuum of the unit is maintained with low power and energy consumption, and the problems that a condenser vacuum pumping running maintaining system in a traditional power plant is high in energy consumption and large in occupied area, and equipment resources are wasted are solved.

Owner:河北建投能源科学技术研究院有限公司

Vacuum desalination system and process

ActiveCN104030515ASave energyReduce usageGeneral water supply conservationSeawater treatmentDesalinationEvaporation

The invention provides a vacuum desalination system and process. The system comprises a water pumping and preheating device, a vacuum distillation device, a fresh water storage device, and a system control device which is electrically connected with the vacuum distillation device and the fresh water storage device, wherein the water pumping and preheating device, the vacuum distillation device, the fresh water storage device and the system control device are sequentially connected. The water pumping and preheating device comprises a seawater filter and a seawater preheating pool. The vacuum distillation device comprises a seawater heater and a steam condenser. The fresh water storage device comprises a closed vacuum fresh water tank and a vacuum pump communicated with the vacuum fresh water tank. According to the vacuum desalination system and process, the seawater to be desalted is preheated through waste heat of the concentrated seawater generated after evaporation is conducted through the seawater heater, fresh water steam is condensed through temperature difference between the seawater and the steam, the waste heat generated by the system and energy of the nature are fully utilized, and thus the system has the functions of energy conservation and environment protection; the vacuum pump is arranged on the system to provide the functions of vacuum degree and water pumping for the system, and one pump is used for multiple purposes; through the desalination process based on the vacuum desalination system, fresh water production is higher than that of products and processes of the same heat collecting temperature.

Owner:LONGNAN ZHIFU PLASTIC PROD CO LTD

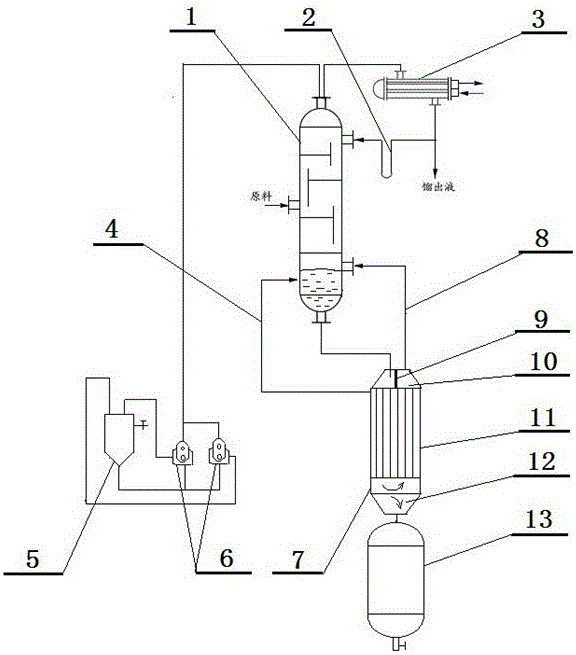

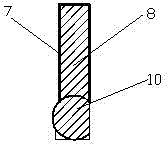

Turpentine rectification tower vacuum system

PendingCN106699502AStable vacuumGood for volatilizationDistillation purification/separationVacuum distillation separationReboilerTurpentine

The invention discloses a turpentine rectification tower vacuum system which comprises a rectification tower (1), a condenser (3), water ring vacuum pumps (6) and a reboiler (7), wherein a discharge port on the top of the rectification tower (1) is connected with the condenser (3); the bottom of the rectification tower is connected with a feed port on the top of the reboiler (7); the bottom of the reboiler (7) is connected with a waste liquid storage tank (13); the water ring vacuum pumps (6) are connected with the top of the rectification tower (1); and the water ring vacuum pumps (6) are also connected with an oil-water separator (5). The two water ring vacuum pumps constitute the vacuum system, so that the vacuum degree of the rectification tower is stabler, the effective components can be volatilized more conveniently, and the substance and energy exchanges between the gas phase and liquid phase of the turpentine can be kept stable. The circulation of the circulating water can utilized to take a small amount of the turpentine component out of the vacuum system, thereby enhancing the purity and yield of the alpha-pinene and beta-pinene products, and reducing the environmental pollution.

Owner:GUANGXI FORESTRY RES INST

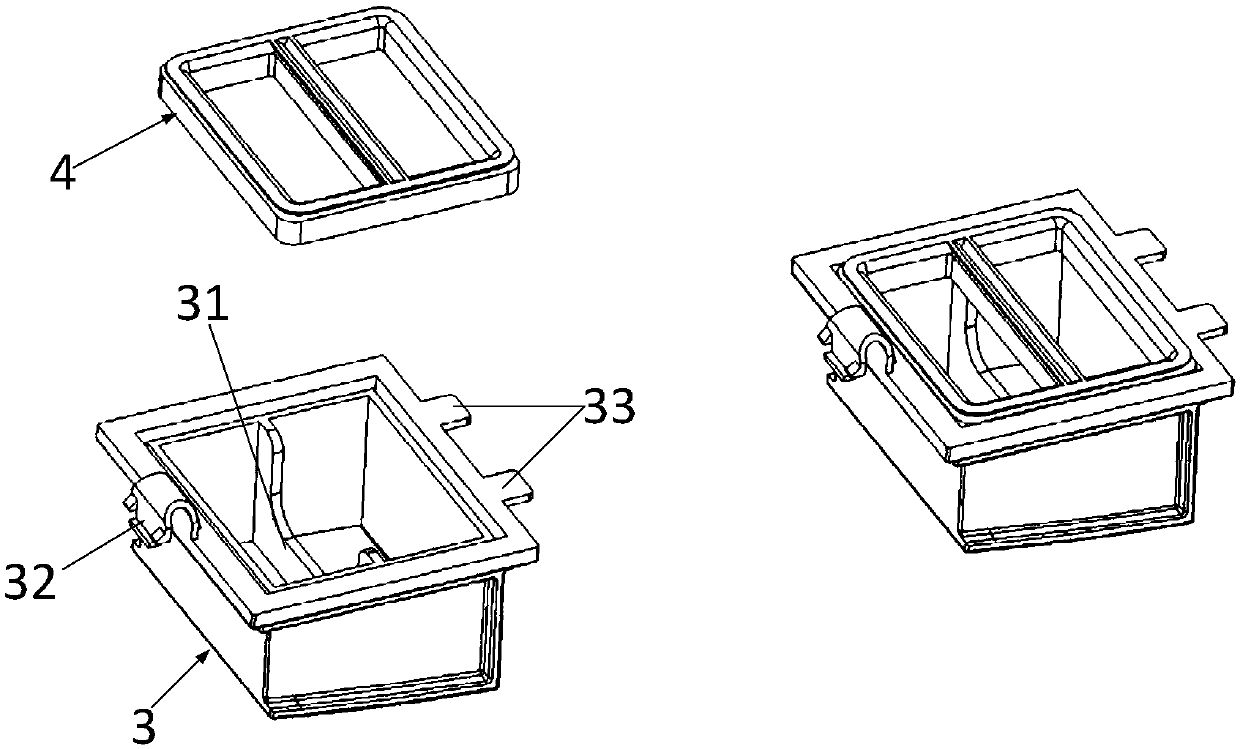

Injection mold facilitating vacuum-pumping

InactiveCN103481461AReasonable structural designGood sealing conditionVacuum pumpingInjection product

The invention discloses an injection mold facilitating vacuum-pumping. The injection mold comprises an upper mold and a lower mold, wherein an injection mold cavity is formed when the upper mold and the lower mold are matched; a feeding hole is formed in the top of the upper mold; a sealing ring structure is arranged between the upper mold and the lower mold and arranged on the periphery of the injection mold cavity; the sealing ring structure comprises a sealing ring and a sealing ring groove which are in clearance fit; the sealing ring is arranged on the lower surface of the upper mold; and the sealing ring groove is formed in the upper surface of the lower mold. The disclosed injection mold facilitating vacuum-pumping is reasonable in structural design; and the sealing ring structure added between the upper mold and the lower mold can effectively improve the sealing condition during vacuum-pumping operation of the mold, so that better and more stable vacuum degree can be obtained by the injection mold cavity faster, and the finished product quality of a plastic injection product is improved.

Owner:SUZHOU YIQUN MOLD

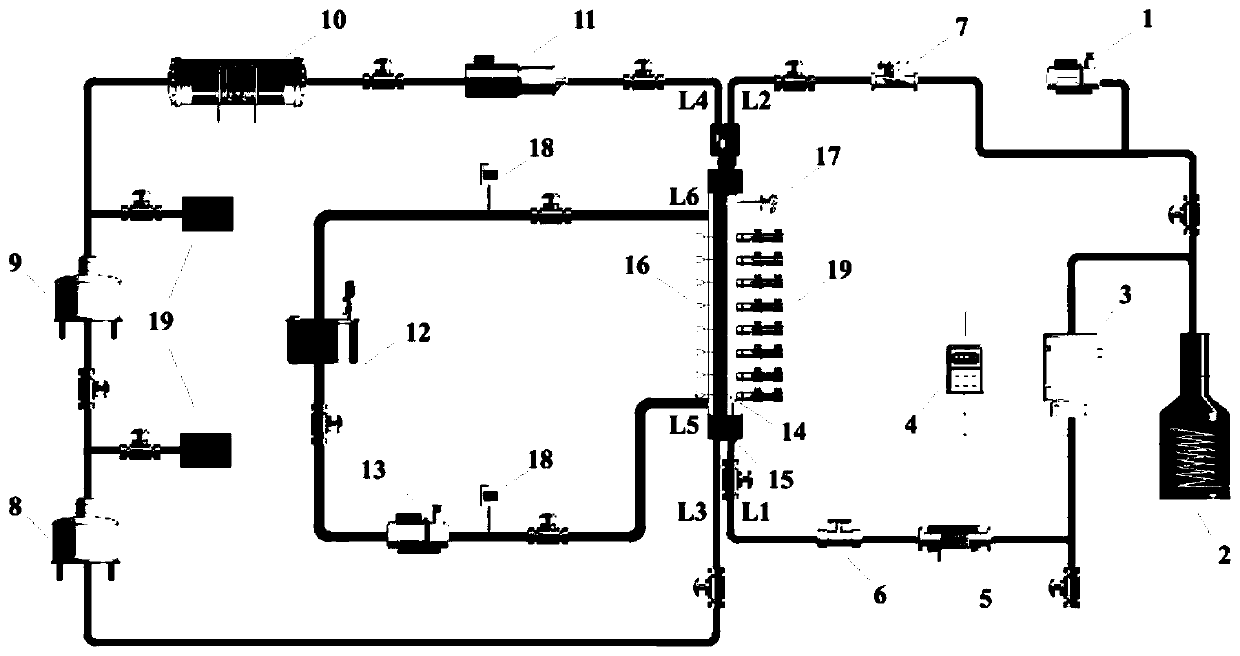

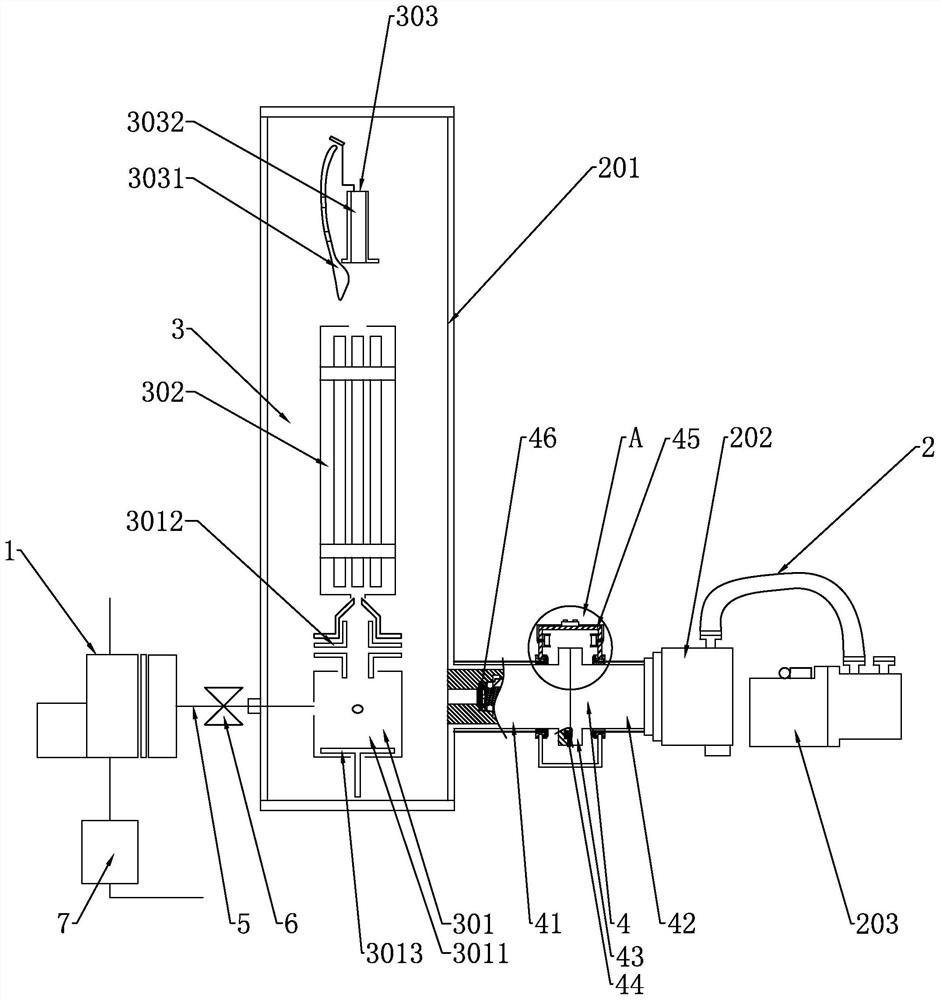

Traditional Chinese medicine extract dynamic boiling point-saturated vapor pressure tester

PendingCN107436273AAvoid detection errorsStable vacuumInvestigating phase/state changeBuffer tankBoiling point

The present invention discloses a traditional Chinese medicine extract dynamic boiling point-saturated vapor pressure tester including a vacuum pump, the vacuum pump is respectively connected with a 1# vacuum buffer tank and a 2# vacuum buffer tank through pipelines, the 1# vacuum buffer tank and the 2# vacuum buffer tank are connected by a pipeline, the 2# vacuum buffer tank is in turn connected with a drying tower, a condenser and a heating boiler through pipelines. The traditional Chinese medicine extract dynamic boiling point-saturated vapor pressure tester is based on a dynamic boiling point-saturated vapor pressure correlation theory, and can realize the detection of different boiling points and corresponding saturated vapor pressures of a traditional Chinese medicine extract under different concentration conditions.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

Water-cooled efficient vacuum condenser system

PendingCN107699640AWith spray condensationFunctionalSugar juice boiling/evaporationPipe waterWater filter

The invention discloses a water-cooled efficient vacuum condenser system. The system comprises a vapor generating tank, a pipeline, a water filtering device, a vacuum condensation device, a hot watercollection tank, a circulating water tank and a water suction pump in connection through the pipeline. The water filtering device is designed in a single-filter or double-filter form to meet differentoperating requirements; by combination of a plurality of atomizing nozzles and spraying nozzles, the nozzles are detachable, so that convenience in demounting and maintenance is achieved; the atomizing nozzles are in a form of bi-tangential rotary spraying and vertical-transverse mixed contact, a large whirling mist range is realized, and condensation efficiency is improved to achieve water saving and energy saving by taking advantages of water atomization contact area increase and rapid vacuumizing resulted from jet concentration. By adoption of the water-cooled efficient vacuum condenser system, the vacuum degree can be effectively raised, water consumption is reduced, and short time and stability in vacuumizing are realized; simple equipment structure, simplicity and convenience in operation and maintenance and low production cost are realized; the cooling water cyclic utilization rate is high; equipment investment and maintenance cost is low due to availability for mounting basedon an original foundation.

Owner:广西盈维机械科技有限公司

Mass spectrometer for food detection and use method thereof

ActiveCN113030232AImprove accuracyGuaranteed vacuumMaterial analysis by electric/magnetic meansPipe fittingMass analyzer

The invention relates to a mass spectrometer for food detection, which comprises a sample introduction device, a vacuum generation device and a mass spectrometer body. The mass spectrometer body comprises an ion source device, a quadrupole device and a detector device. The vacuum generation device comprises a vacuum cavity, a molecular pump and a backing pump. The molecular pump is connected with the vacuum cavity through a connecting pipe fitting. A driving device is connected to the sample introduction device in a driving mode, and the sample introduction device comprises a membrane supporting piece and a sample introduction support. The connecting pipe fitting comprises a first air pipe, a second air pipe and connecting flanges. The connecting flanges comprise a first flange and a second flange, and a sealing assembly is arranged between the first flange and the second flange. A vacuum degree stabilizing device is arranged on the connecting pipe fitting. The vacuum degree stabilizing device comprises an air pipe damage alarm assembly and a vacuum degree keeping assembly. Compared with the prior art, the mass spectrometer has the advantages that a liquid sample can be directly input into the mass spectrometer body for detection, a complicated treatment process is not needed, and the working efficiency and the practicability of the mass spectrometer are improved.

Owner:丽水蓝城农科检测技术有限公司

Modified water-ring vacuum pump water supply device

InactiveCN103089665ANot easy to scaleSimple structurePump componentsRadial flow pumpsPulp and paper industryVacuum pump

The invention relates to a modified water-ring vacuum pump water supply device which comprises a water-ring vacuum pump body and an inlet pipeline. The modified water-ring vacuum pump water supply device is characterized in that the water-ring vacuum pump body is connected with a vapor-water separator through the inlet pipeline, the vapor-water separator is connected with a cooling tank through a return water pipe, a water pump is disposed on the return water pipe, the cooling tank is connected with the water-ring vacuum pump body through a cooling water inlet pipe, an inflow control device is disposed on the cooling water inlet pipe, and a filtering device is disposed on the inlet pipeline. The modified water-ring vacuum pump water supply device has the advantages that the modified water-ring vacuum pump water supply device is simple in structure and convenient to use, the vacuum pump scales less easily, water supply is stable, and vacuity is stabilized.

Owner:NANTONG LONGYING VACUUM PUMP

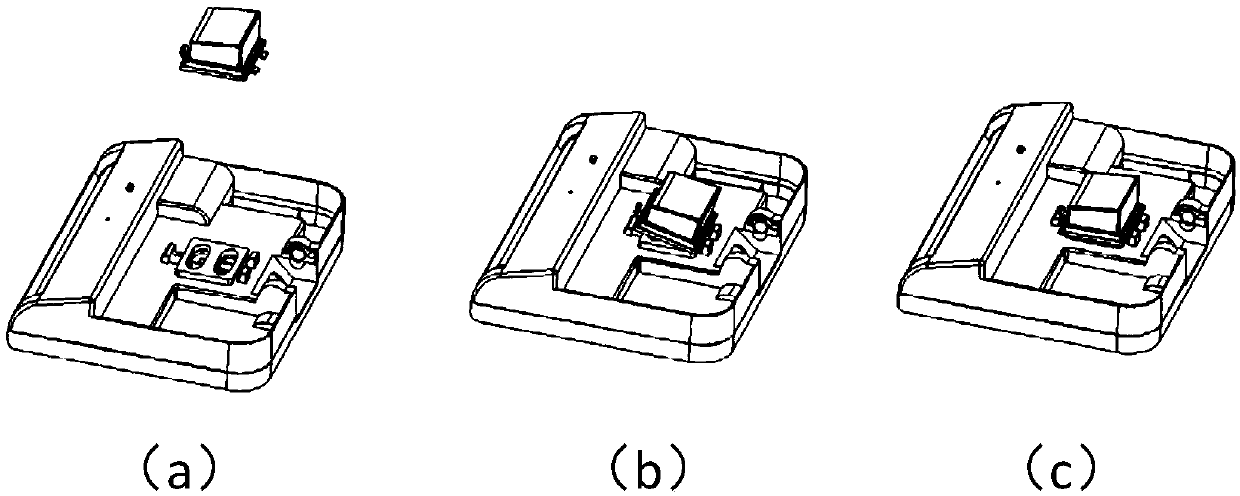

Brush head and dust collector

The invention relates to the field of dust collectors, and in particular provides a brush head. The brush head comprises a shell, a water tank and a connector, wherein an air suction channel is arranged in the shell, and the air suction channel comprises a first flow channel and a second flow channel not communicating with each other; the water tank is detachably connected to the shell, a third flow channel is arranged in the water tank, when the water tank is connected with the shell, one end of the third flow channel communicates with the other end of the first flow channel, and the other end of the third flow channel communicates with the other rend of the second flow channel; and the connector can be detachably connected with the shell, when the water tank is not connected with the shell, the connector is connected on the shell so that the other end of the first flow channel communicates with the other end of the second flow channel through the connector. The brush head has the dryand wet integrated function, meanwhile, the rapid switchover of the dry type function and the wet type function can be realized, the brush head does not need to be replaced, so that the user experience is improved, and the cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com